Continuous casting machine sector section centering measurement method

A continuous casting machine segment and measurement method technology, which is applied in the direction of mechanical gap measurement, mechanical measuring device, measuring device, etc., can solve the problems of easy deformation of the detection model, high production cost, and decreased detection accuracy, so as to facilitate large-scale organization Production, save production cost and transportation cost, improve the effect of measurement accuracy

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

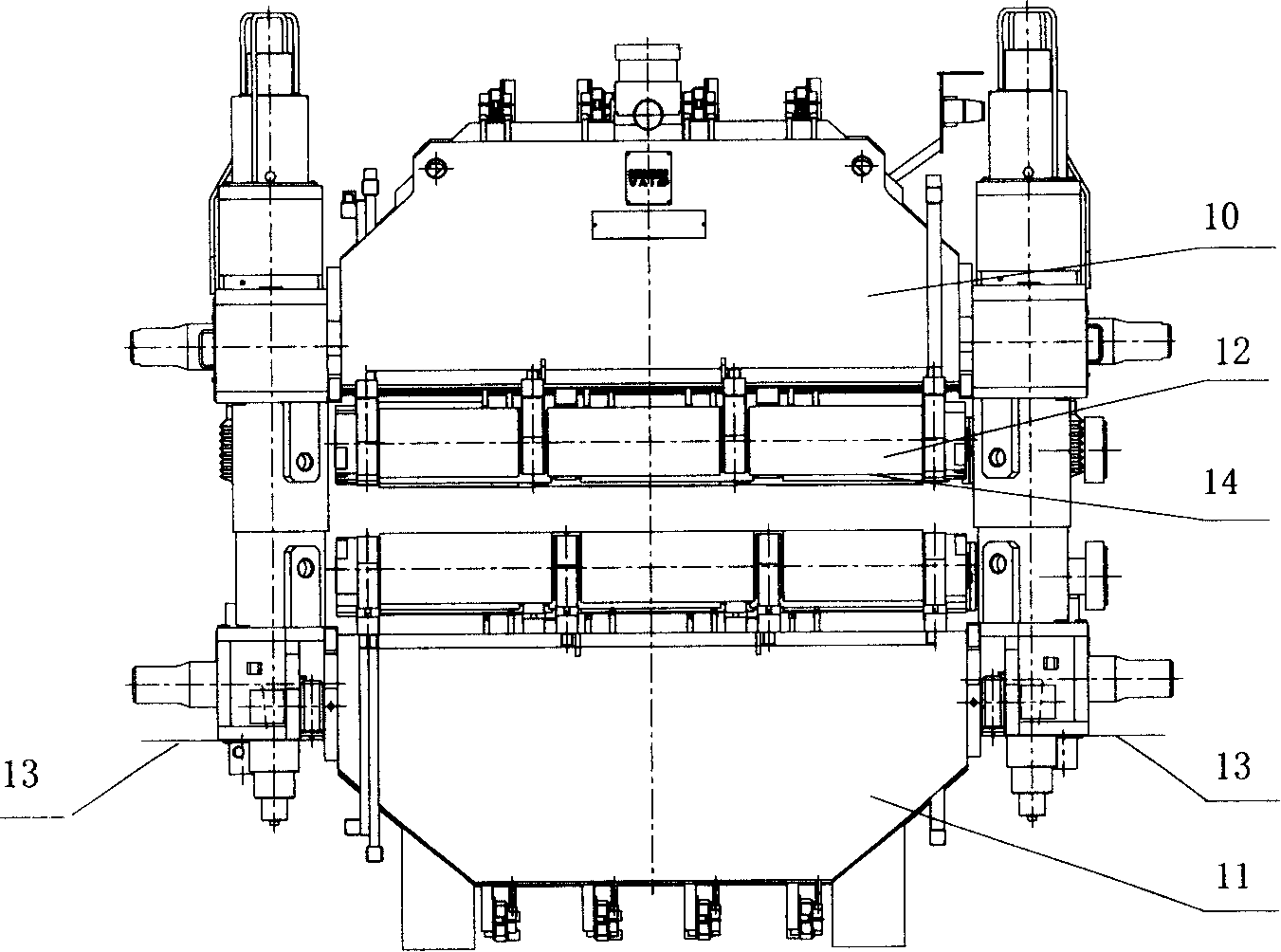

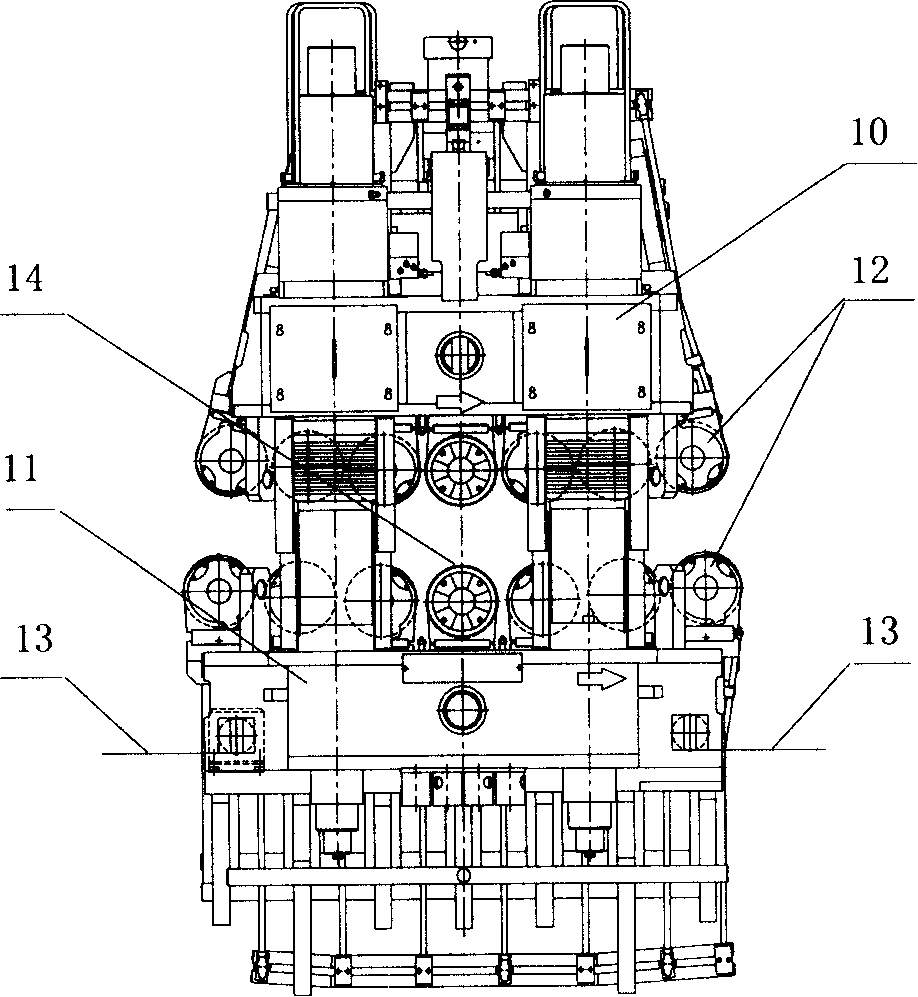

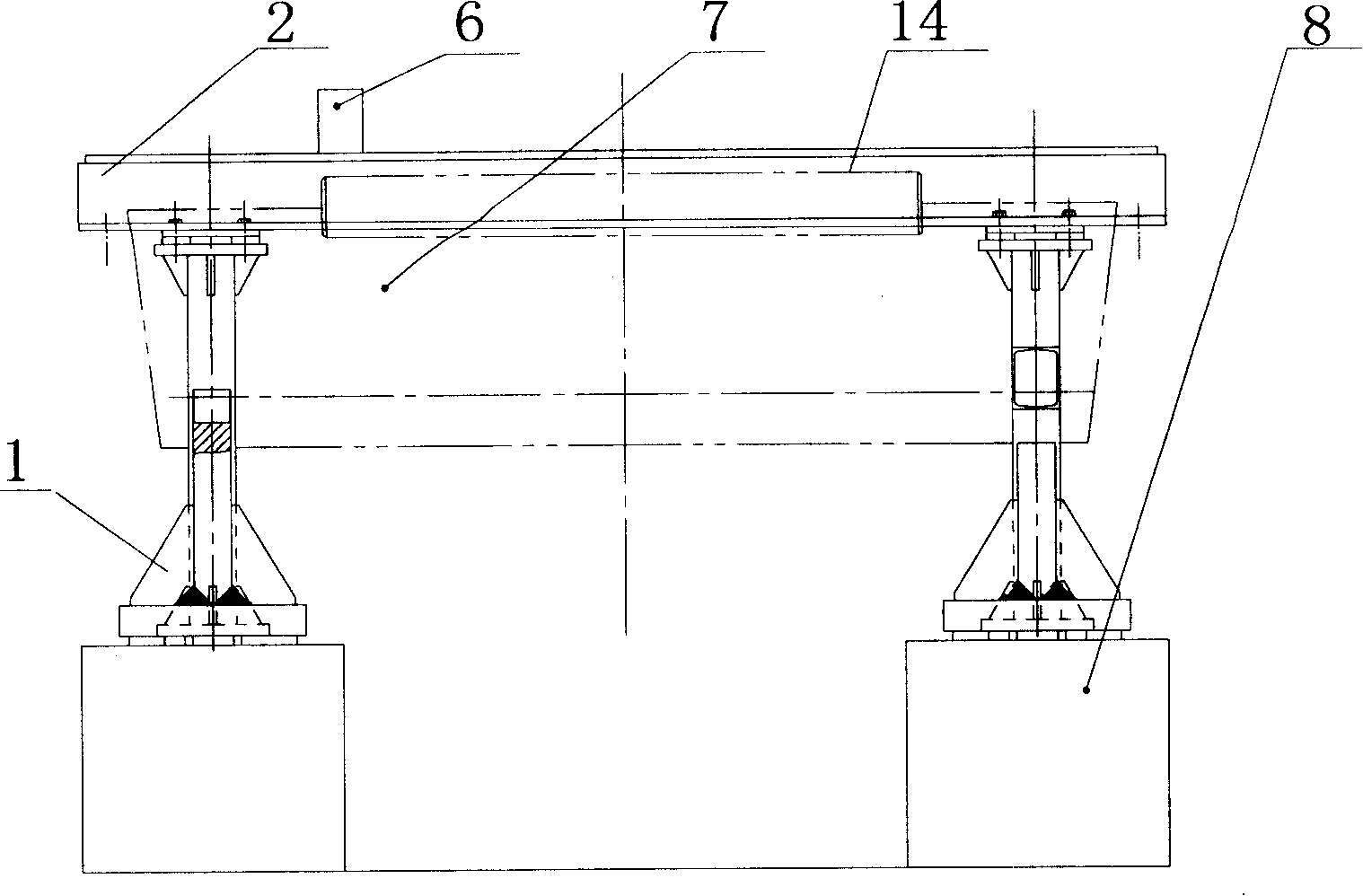

[0026] As mentioned above, the centering measurement of the continuous casting machine sector refers to the detection of the distance between the reference plane and the roll surface, but since the reference plane and the roll surface are not on the same axis, and the sector is a large component, it is difficult to measure directly. The basic idea of the present invention is to convert the measuring standard to the straightedge, then move the straightedge to the position of each roller surface, measure the distance between each roller surface and the straightedge, and then obtain the distance between each roller surface and the measuring standard. Whether the distance meets the requirements.

[0027] The following parts need to be processed in advance by adopting the method for measuring the centering of the segment of the continuous casting machine of the present invention.

[0028] According to different specifications of the measured workpiece (inner or outer arc frame), ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com