Technology for producing 38CrMoAl steel by converter-LF (low frequency)-RH (rockwell hardness)-continuous casting

A -LF-RH-, converter technology, applied in the field of 38CrMoAl production

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

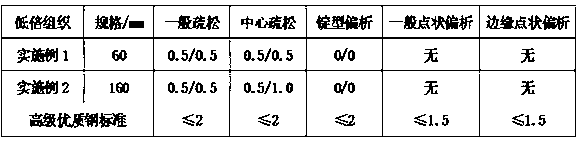

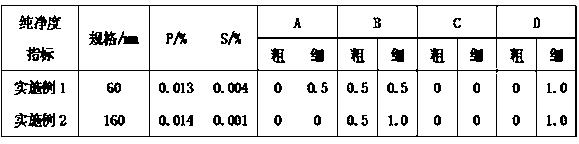

Embodiment 1

[0031] 200mm×200mm cross-section continuous casting billet has been continuously poured up to 8 furnaces, and the pouring has been smooth without nodules. The specific process is as follows:

[0032] 1) The converter uses 92t of high-quality molten iron as the main raw material. The molten iron is treated with slag removal, and is matched with 6t of pig iron to form the main raw material for steelmaking. During the blowing process, the amount of lime, dolomite, ore, etc. should be adjusted as appropriate, and the oxidation slag should be poured out by shaking the furnace in the mid-stage of blowing, and the secondary slag will be formed; the steel tapping control C≥0.08%, to prevent peroxidation tapping;

[0033] 2) Ferromanganese and ferrochrome are added in the tapping process of the converter for alloying, and calcium carbide 200kg / furnace and Al cake 120kg / furnace are added, and the slag material is added in combination of 600kg / furnace lime and 600kg / furnace pre-melted ref...

Embodiment 2

[0040] φ380mm cross-section continuous casting round billet has more than 9 continuous casting furnaces, and the casting is smooth without nodules. The specific main process methods are as follows:

[0041] 1) Ferromanganese and ferrochromium are added to alloy during the tapping process of the converter, calcium carbide 2.0~3.0kg / t steel and Al cake 3kg / t steel are added, slag materials are 5.0~6.0kg / t steel lime and 6.0~7.0kg / t Combined addition of steel pre-melted refining slag;

[0042] 2) Randomly analyze the slag from one of the furnaces during the refining process. The binary basicity R2 of the slag in the early stage of refining is 10.95, and its chemical composition wt% is: CaO 60.88%, SiO 2 5.56%, MgO 3.29%, Al 2 o 3 30.25%, TiO 2 0.35%, S 1.31%, the rest is TFe(Mn); the binary alkalinity R2 of the final refining slag is 33.70, and its chemical composition wt% is: CaO 54.93%, SiO 2 1.63%, MgO 1.45%, Al 2 o 3 40.50%, TiO 2 0.08%, S 0.95%, the rest is TFe(...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com