Method for capping nickel and stainless steel continuous casting tail billet

A continuous casting slab and stainless steel technology, which is applied in the capping field of nickel stainless steel continuous casting tail billet, can solve the problems of long shrinkage cavity of tail billet and affecting the yield of cast billet

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

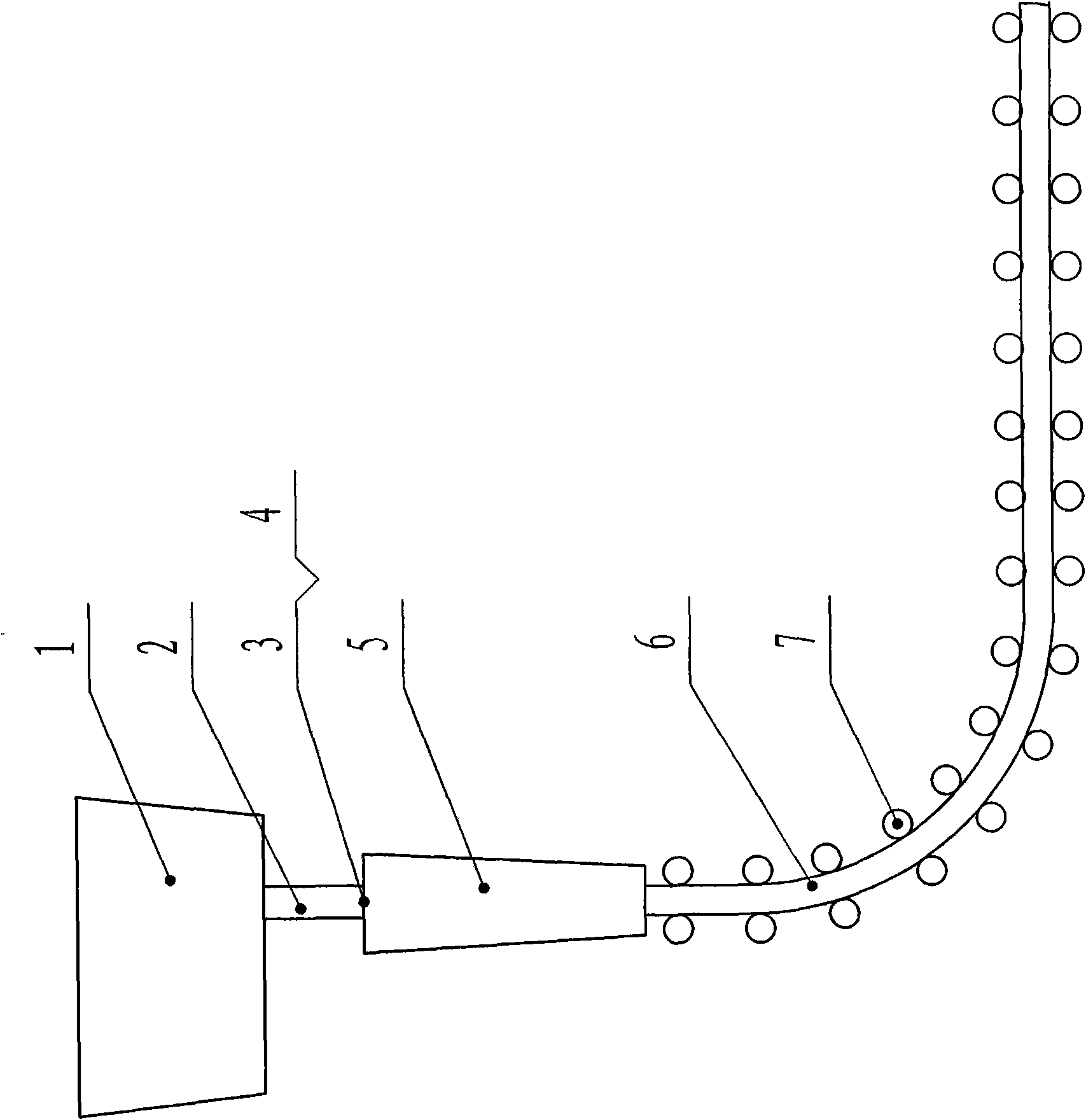

[0032] This embodiment is implemented on a straight-arc continuous casting machine with soft reduction function. see figure 1 . The nominal capacity of the tundish 1 is 24 tons, the specification thickness of the continuous casting slab 6 is 200mm, the width is 1535mm, and the length of the crystallizer 5 is 900mm. The target pulling speed is 1.15m / min.

[0033] The embodiment of the capping method of the nickel stainless steel continuous casting tail blank is the following steps in sequence:

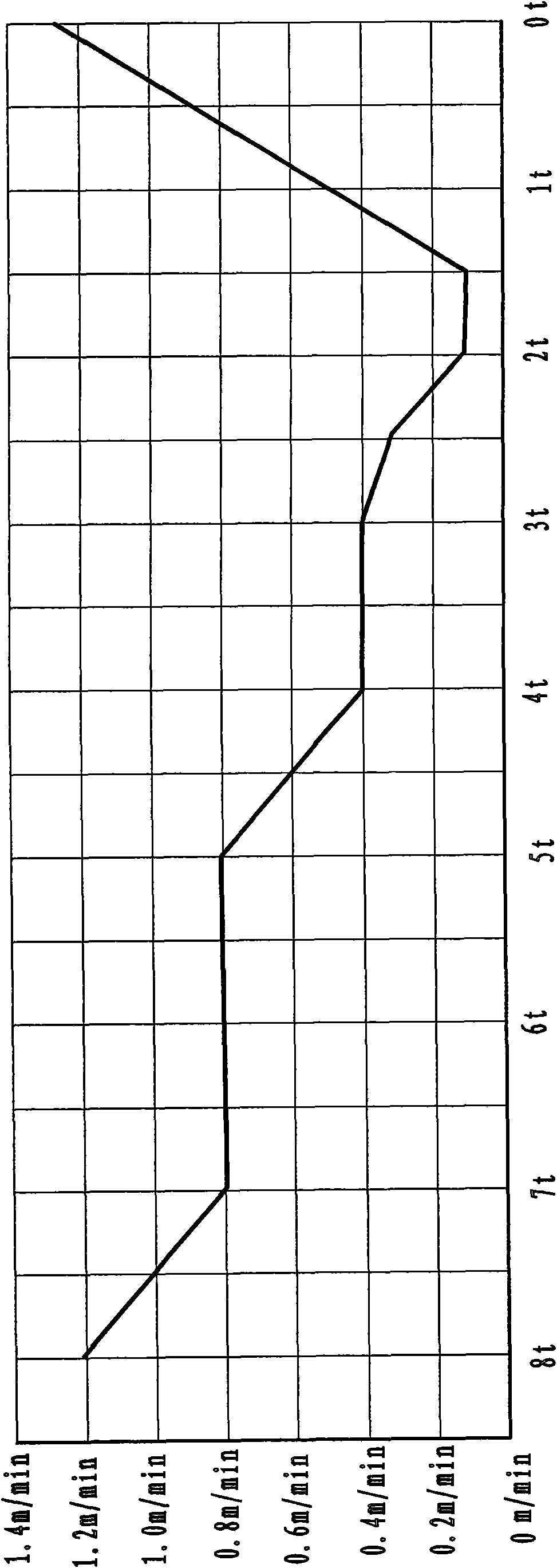

[0034] When there are still 8 tons of molten steel in I tundish 1, according to figure 2 The relationship curve between the amount of molten steel in the tundish 1 and the casting speed of the continuous casting slab, the casting speed of the continuous casting slab 6 starts to slow down from 1.15m / min, and when there are 7.5 tons of molten steel in the tundish 1, the casting speed drops to 1.0m / min, when there are 7 tons of molten steel in the tundish 1, the pulling speed drops t...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com