Continuous casting bloom soft press technology based on tail end electromagnetic stirring

A terminal electromagnetic stirring and blooming technology, which is applied in the field of metal casting, can solve the problems that the effect has not been reported, and achieve the effects of convenient and effective control, increased service life, and uniform concentration of molten steel

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

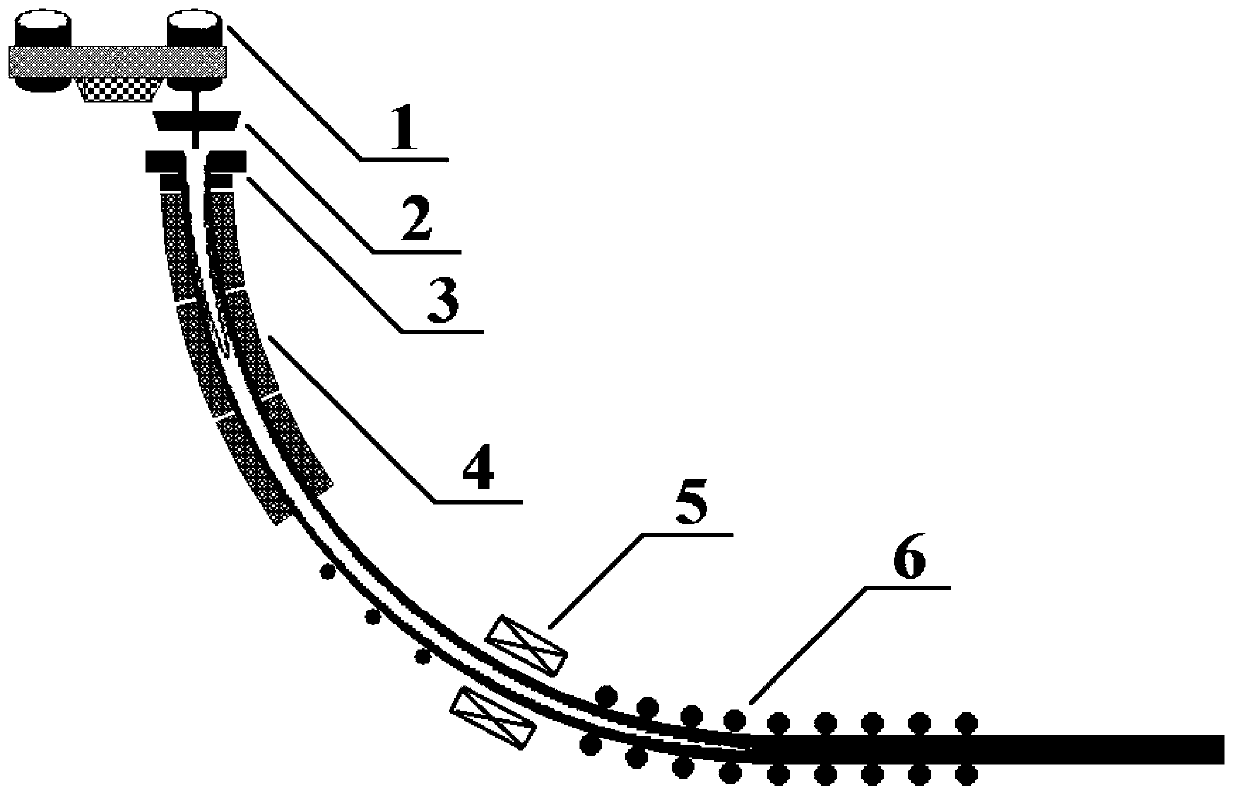

Image

Examples

Embodiment 1

[0017] The 425mm×320mm continuous casting bloom bearing steel in a steel plant is under the condition of no end electromagnetic stirring and light reduction, and the center segregation and porosity are quite serious when the casting speed is 0.65m / min. The bearing steel in this steel plant is continuously cast and lightly reduced when the casting speed is 0.65m / min, the total reduction is 17mm, and the reduction range is fs0.30-0.80. The liquid phase between the columnar crystals is not completely solidified, and the light reduction process At the same time as the straightening process, the slab cracked along the columnar grains, forming serious intermediate cracks, and the central shrinkage cavity was also clearly visible, and the internal quality was quite poor. In order to increase the equiaxed crystal ratio and suppress the occurrence of internal cracks, the terminal electromagnetic stirring device was installed in the air-cooled area 14.1m away from the meniscus. When the...

Embodiment 2

[0019] When the 350mm×470mm continuous casting bloom bearing steel of a steel plant is lightly reduced under the condition of casting speed 0.50m / min, due to the small total reduction of 9mm and no end electromagnetic stirring, the middle crack and central shrinkage cavity are very serious , seriously affecting the yield of rolled products. Under the condition of ensuring output and constant pulling speed, in order to suppress the occurrence of intermediate cracks and reduce the size of the central shrinkage cavity, the steel plant installed an end electromagnetic stirrer in the air-cooled area 14.5m away from the meniscus, and at the same time greatly Increased the total depression when lightly depressing. When the superheat of molten steel in the tundish is 20-30C, the casting speed is 0.50m / min, the terminal electromagnetic stirring current is 550A, the frequency is 6Hz, the total reduction is 20-22mm, and the reduction range fs=0.39-1.0, divide into three pouring times Mo...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com