Patents

Literature

Hiro is an intelligent assistant for R&D personnel, combined with Patent DNA, to facilitate innovative research.

53results about How to "Production is stable and smooth" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

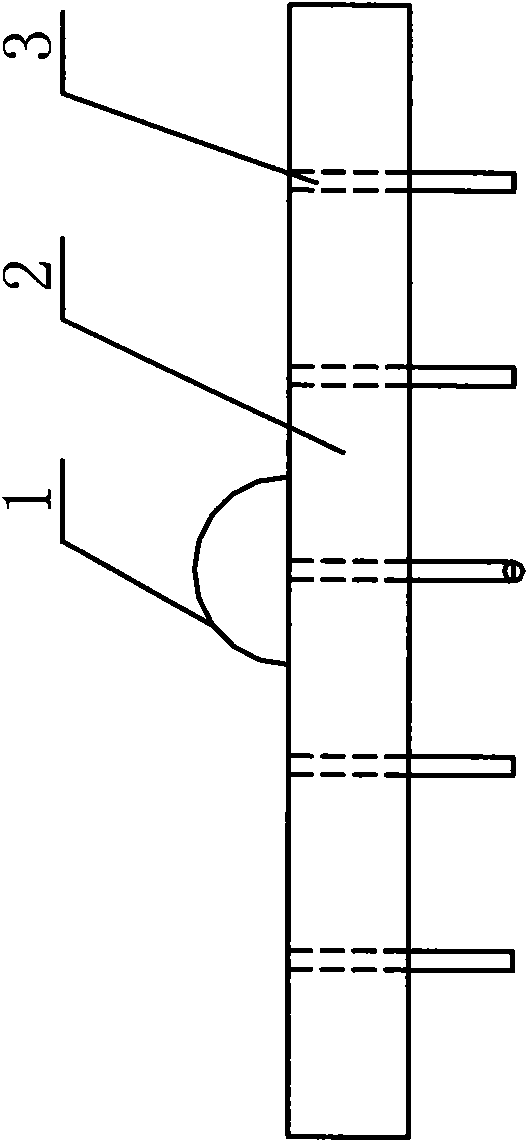

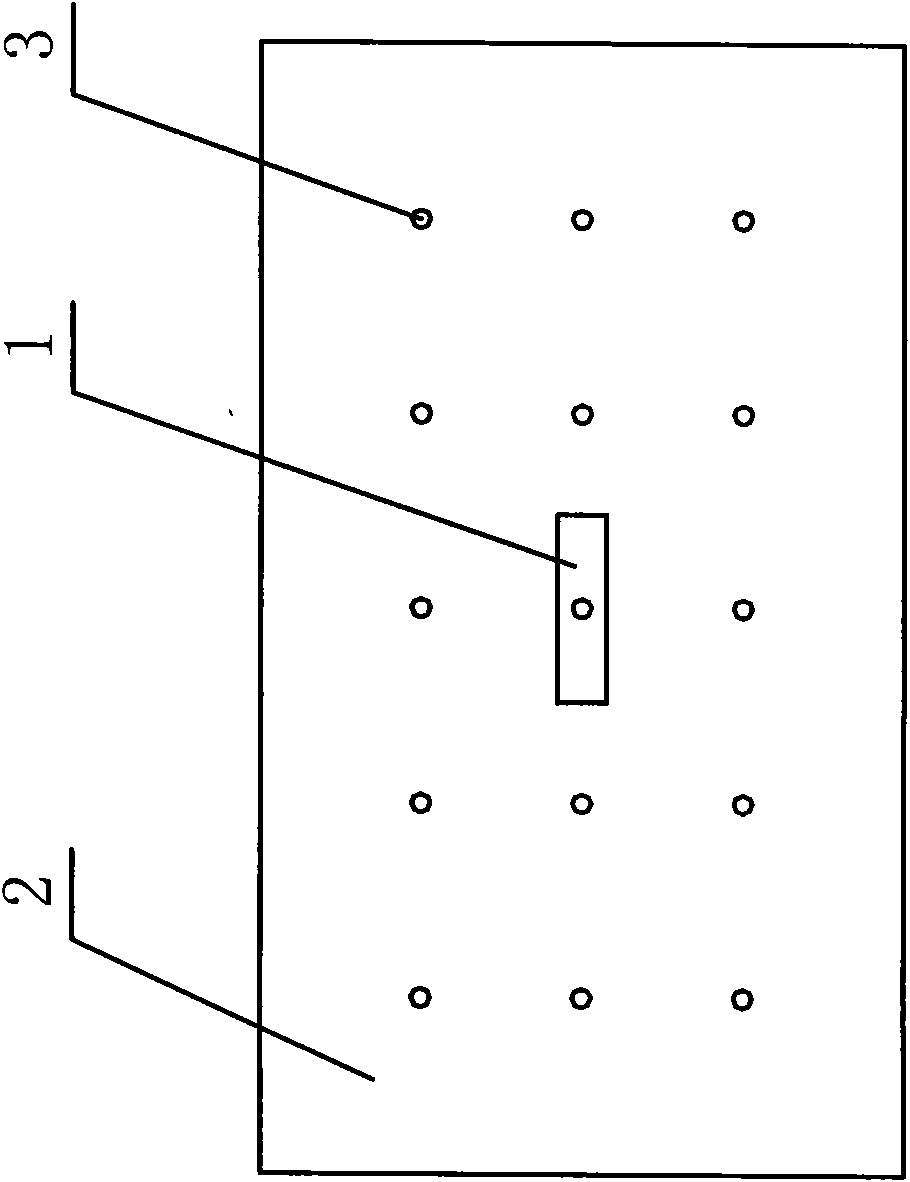

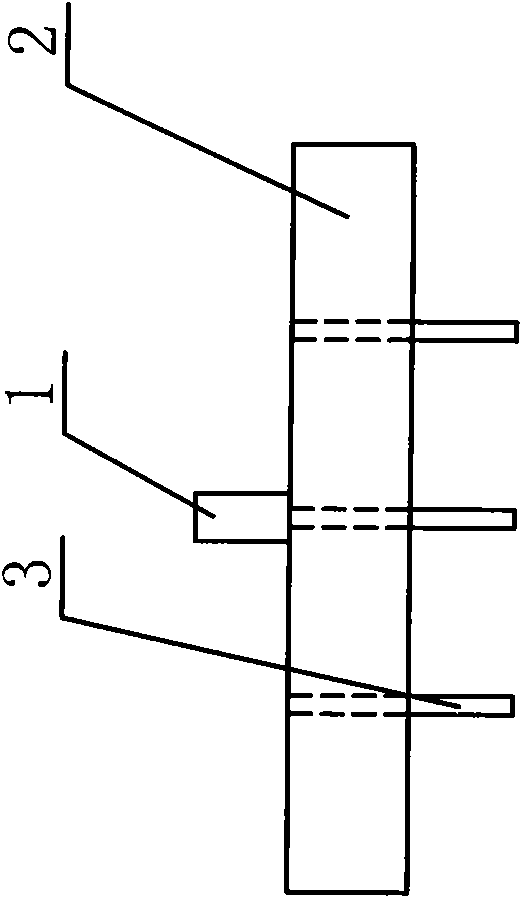

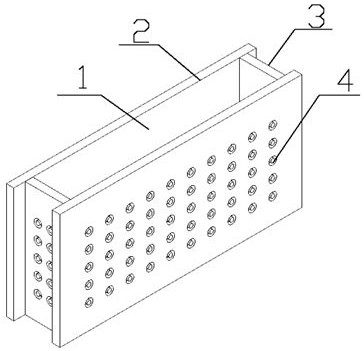

Device and method for measuring thickness of covering slag and liquid level fluctuation of molten steel

InactiveCN101612648AFluctuation of liquid level is smallReduce slab inclusionsMechanical thickness measurementsCasting parameters measurement/indication devicesBattenWood plank

The invention relates to a device and a method for measuring the thickness of covering slag and the liquid level fluctuation of molten steel. The device consists of a handle, a density board and a probe, wherein the handle is arranged in the middle part of the upper surface of the density board, and the probe is fixed on the lower surface of the density board; the handle is made of materials which are difficult to combust and melt such as iron sheets, battens and the like; the density board is made of heat-insulating materials such as wood boards and the like; and the probe is made of iron wires. The device and the method have the advantages that the device and the method can accurately measure the thicknesses of a molten slag layer at various positions on a liquid level of a crystallizer, the average value of the thicknesses and the liquid level fluctuation to achieve the aims of accurately controlling a melting structure of the covering slag and reducing the liquid level fluctuation, thereby reducing the inclusion of casting blanks, improving the quality of the casting blanks, and ensuring the steady operation of the production.

Owner:ANGANG STEEL CO LTD

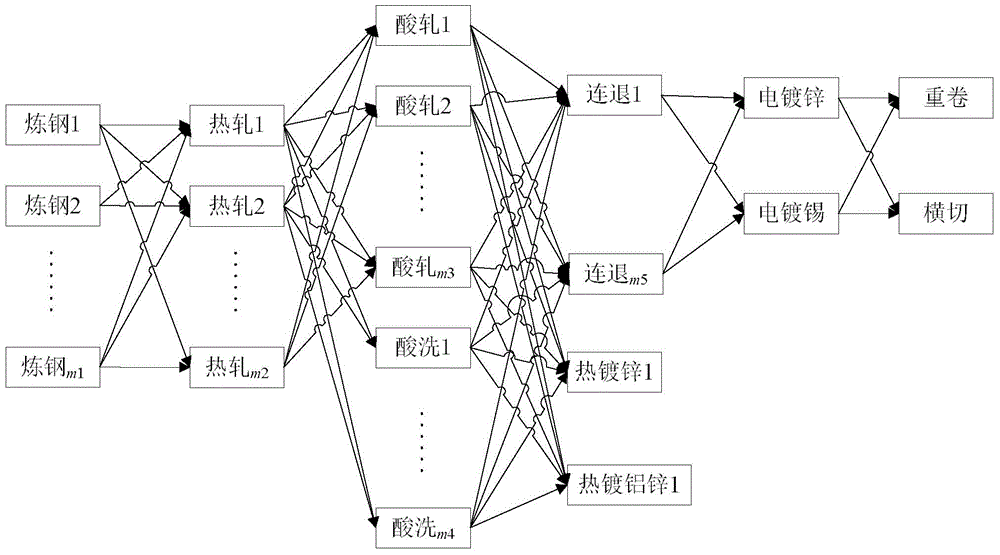

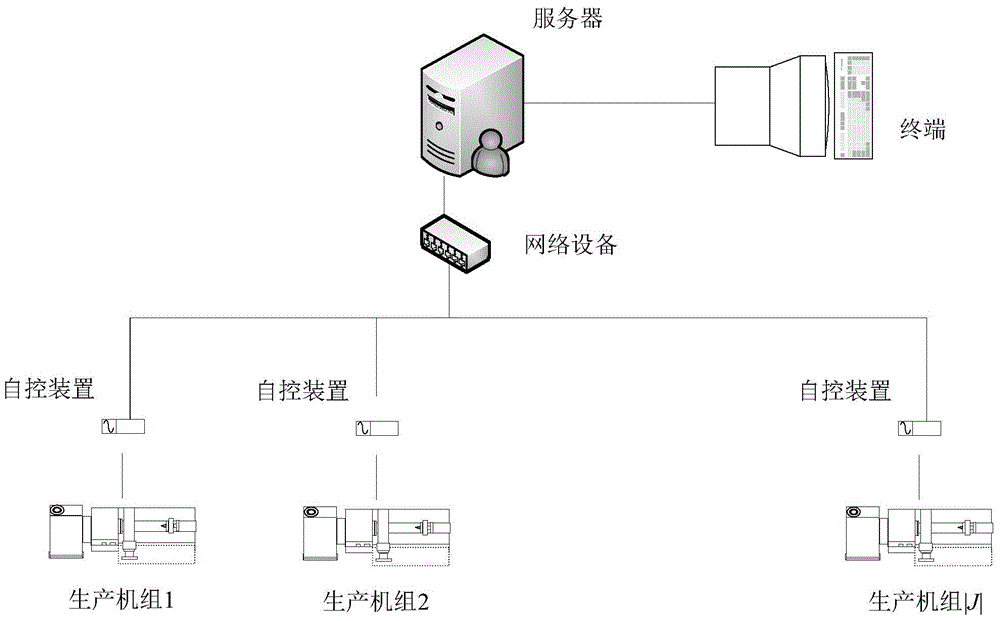

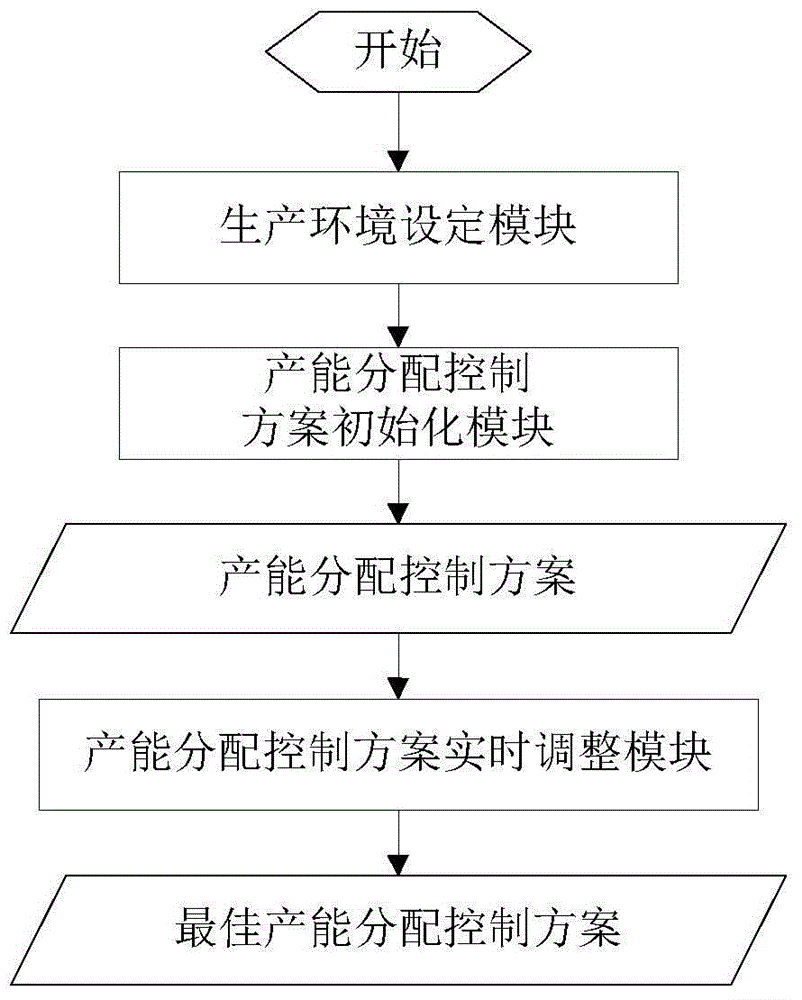

Complete flow unit productivity allocation control method for metallurgical enterprise

ActiveCN104635683AMeet needsSmooth demandTotal factory controlProgramme total factory controlDistribution controlComputer science

The invention provides a complete flow unit productivity allocation control method for a metallurgical enterprise. The complete flow unit productivity allocation control method comprises the steps that a complete flow unit productivity allocation control model of the metallurgical enterprise is established according to the production state of each unit and the contractual processing route of the metallurgical enterprise; the productivity allocation situation of each unit is determined, including the contract selection situation and the contract processing sequence of each unit, and the stability estimation index value of the complete flow unit productivity allocation control scheme of the metallurgical enterprise is calculated; the productivity distribution control is carried out according to the complete flow unit productivity allocation control scheme of the metallurgical enterprise and the corresponding production contract , and the complete flow unit productivity allocation control scheme of the metallurgical enterprise is adjusted in real time; the complete flow unit optimal productivity allocation control scheme of the metallurgical enterprise is issued to the complete flow unit for productivity distribution control. According to the complete flow unit productivity allocation control method for the metallurgical enterprise, the productivity allocation scheme is established by coordinating the units, so that the requirements of production equipment are met to the greatest extent, the production of each unit can be carried out stably, the production process is more reasonable, and the production switching is reduced.

Owner:NORTHEASTERN UNIV

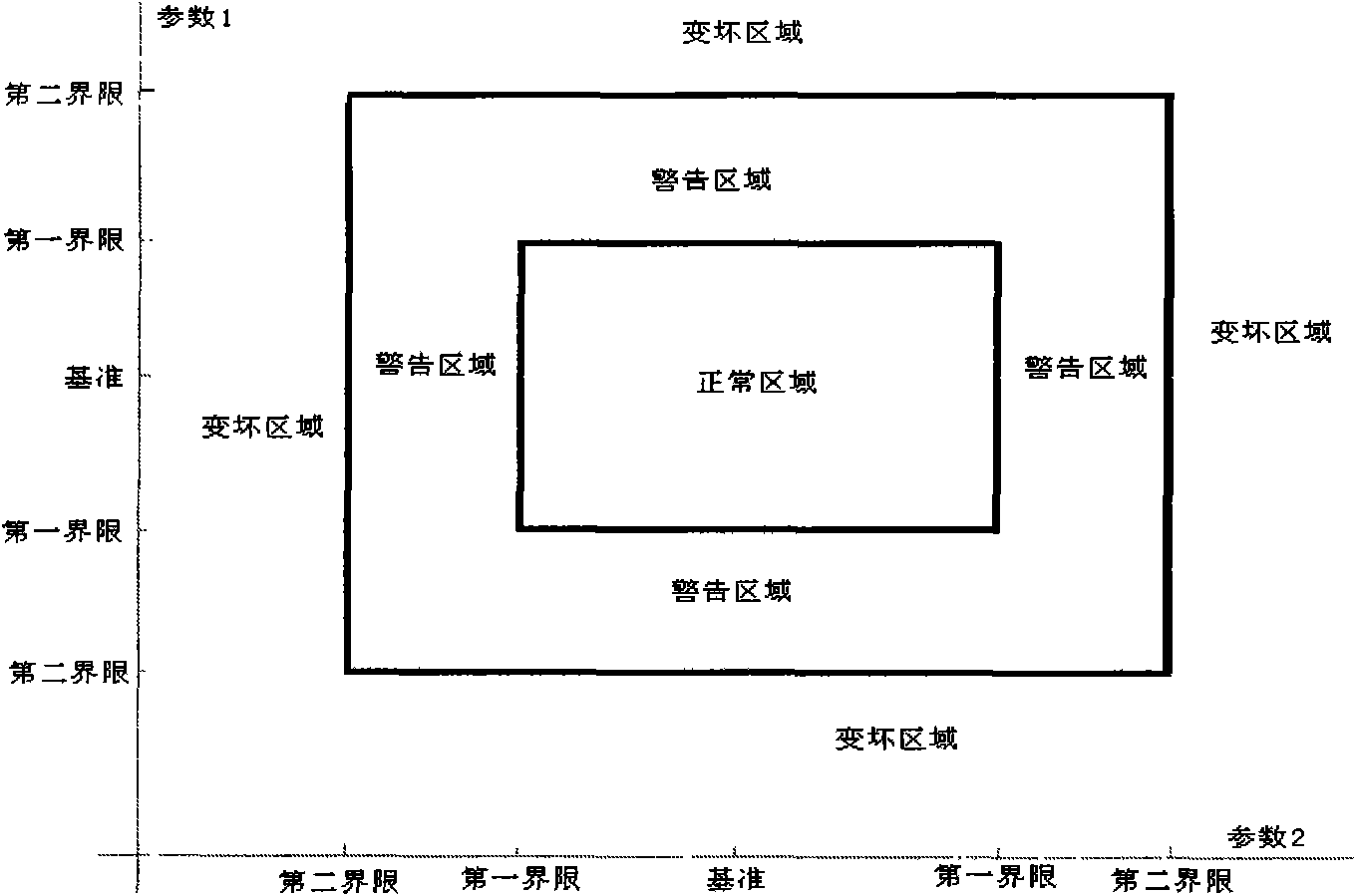

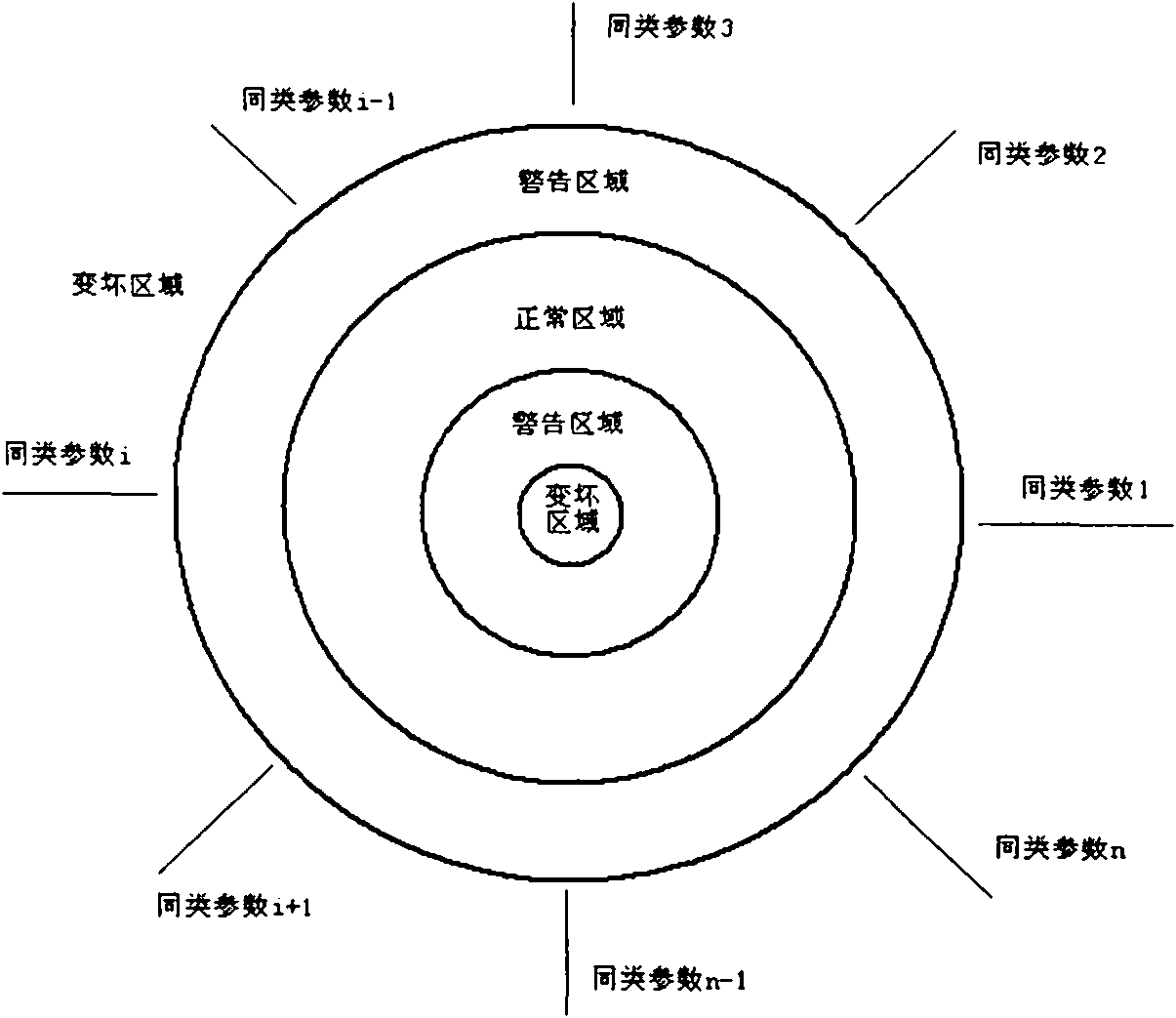

Method for evaluating conditions of blast furnace

ActiveCN101881955AThe method is simple and reliableLow costTotal factory controlProgramme total factory controlSingle useComputer science

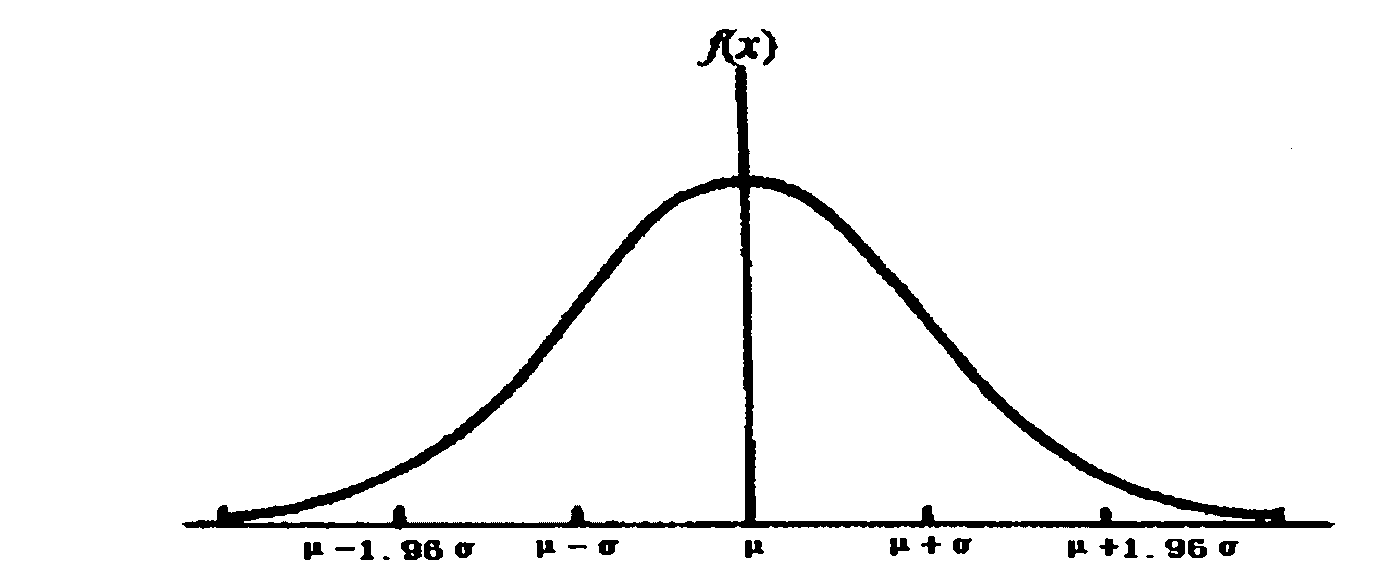

The invention discloses a method for evaluating conditions of a blast furnace. The method can represent each main aspect of the working condition of the blast furnace in certain period, and two different types of relevant production parameters or the historical data of multiple relevant same-type parameters are adopted as a reference for evaluation. By taking the average value of the historical data of each parameter as the reference, a first boundary and a second boundary are determined according to the distribution of the historical data. The area in the first boundary is the NORMAL area, the area between the first boundary and the second boundary is the WARNING area, and the area outside the second boundary is the DETERIORATING area. The working condition of the aspect is described by the largest ratio of the data quantity of the data to be evaluated and falling into each area to the total data quantity to be evaluated. The overall working condition of the blast furnace is described by the weighted average. The invention solves the problems of difficult continuous running, single use range, unavailable popularization and the like of the traditional evaluating method, caused by artificial factors of specialists influence and the like, and has the advantages of simplicity, reliability, low cost and good effect.

Owner:ANGANG STEEL CO LTD

Method for effectively roasting and leaching vanadium slag

InactiveCN103031445ALight in massReduce the amount of liquid phaseProcess efficiency improvementPregnant leach solutionSlag

The invention discloses a method for effectively roasting and leaching vanadium slag. The method comprises the following steps of: preparing a catalyst into vanadium slag powder of which the particle size is not more than 0.1mm and uniformly mixing to obtain a mixture; roasting the mixture under a strong oxidizing atmosphere to obtain vanadium-containing clinker; and treating the vanadium-containing clinker by leaching liquid, and performing suction filtration for many times so as to obtain leaching residues and vanadium solution, wherein the leaching agent is dissolved with water to obtain the leaching liquid. By the method, in a single vanadium slag system, two conversion steps in the vanadium slag roasting process are carried out separately, so that the amount of generated low-melting-point substances is reduced, the liquid phase quantity is reduced, and the production process can be stably and successfully carried out; and moreover, the operation process is simple and feasible, and the conventional production is hardly transformed a lot, and a new agent is not needed to be replaced.

Owner:PANGANG GRP PANZHIHUA STEEL & VANADIUM

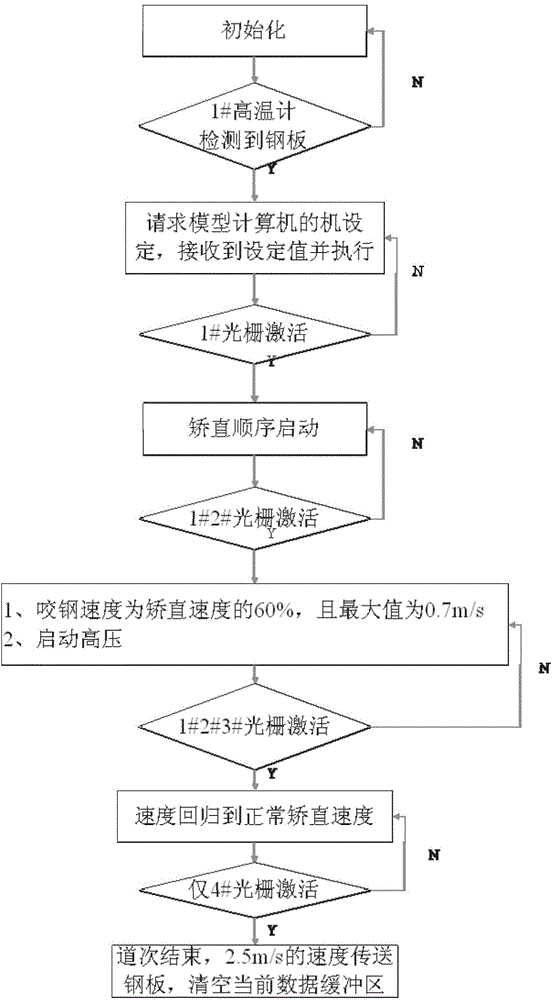

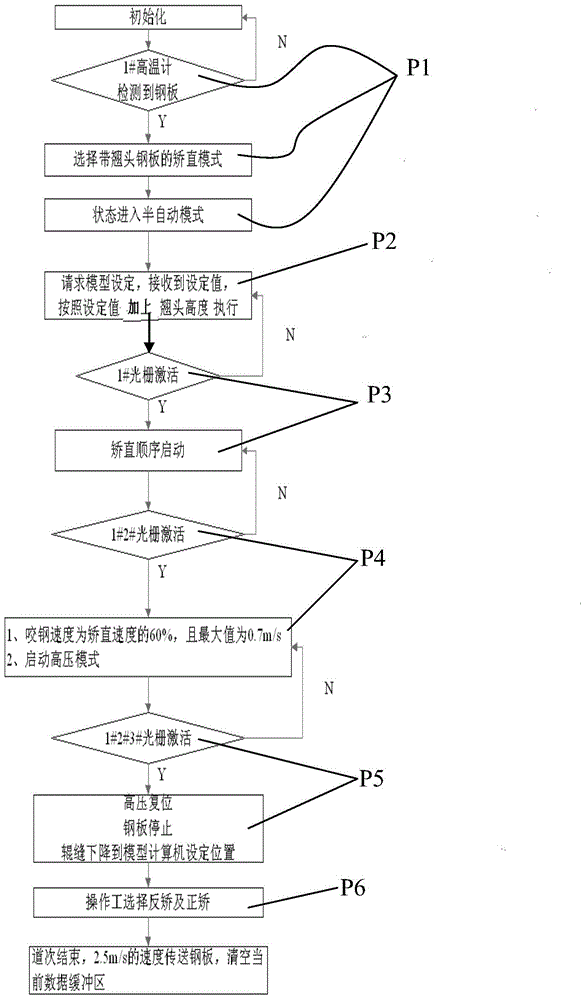

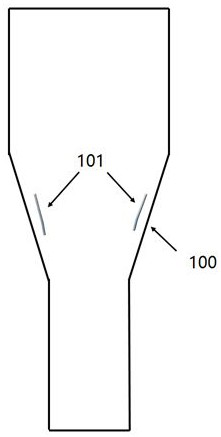

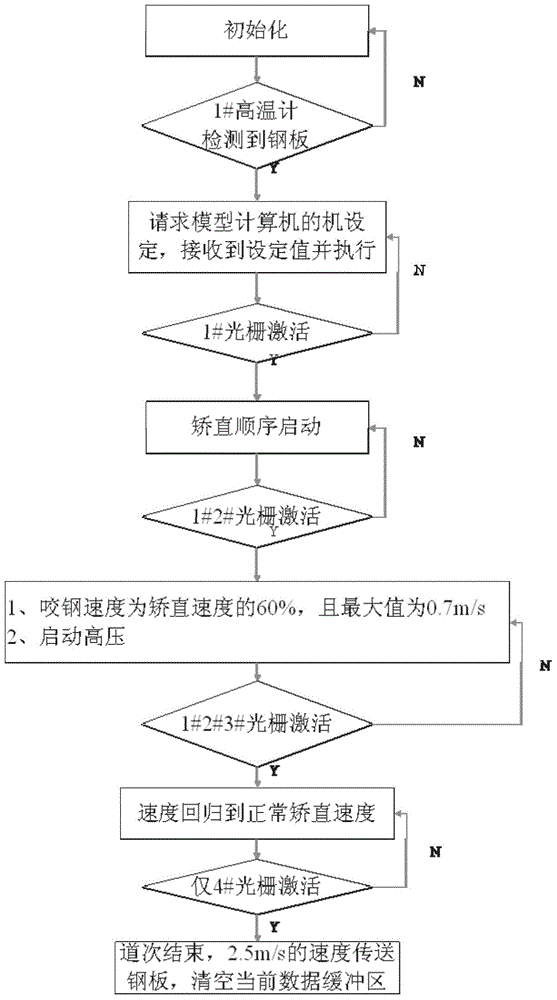

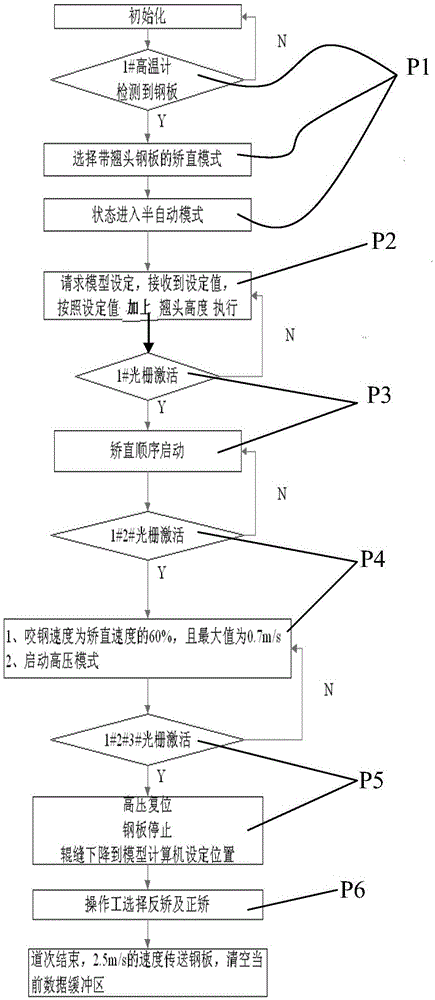

Straightening method of head turning steel plate

ActiveCN104438458AProtection subjectHigh degree of automationMetal working apparatusGratingSheet steel

The invention discloses a straightening method of a head turning steel plate. The method comprises the following steps: when a high temperature meter detects that the steel plate is discharged from a finish mill, a turning head steel plate straightening mode is selected, the reverse correction is synchronously selected, and the state enters a semi-automatic mode; a set value of a model computer is requested, and the operation is performed by adding a head turning height according to the set value after receiving the set value; when a first grating is activated, the straightening sequence is started; when first and second gratings are activated, a position tracking and high pressure mode is started, and the steel is bitten with a speed of not higher than 0.7 m / s; when first, second and third gratings are activated, the steel plate enters a straightening machine, a steel plate stop button is pressed down to stop the steel plate, the high-pressure return is performed, and a roller gap is descended to the set position of the model computer; and when the position of the roller gap arrives at the set value of the model computer, the reverse correction is selected, and the forward straightening is performed to finish the straightening sequence. The method can set the roller gap according to the height of the steel plate turning head to guarantee normal steel biting and straightening effects.

Owner:BAOSHAN IRON & STEEL CO LTD

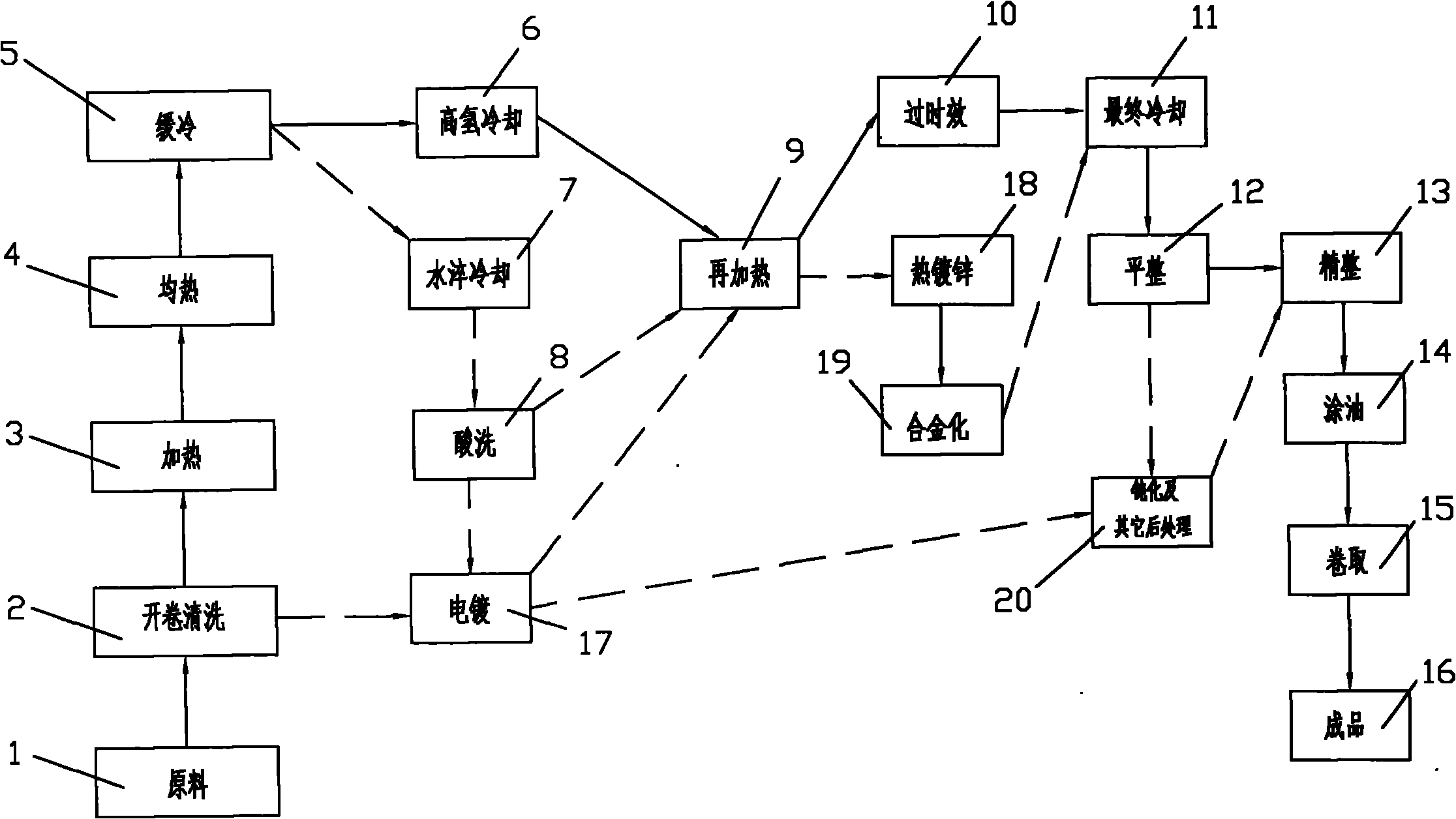

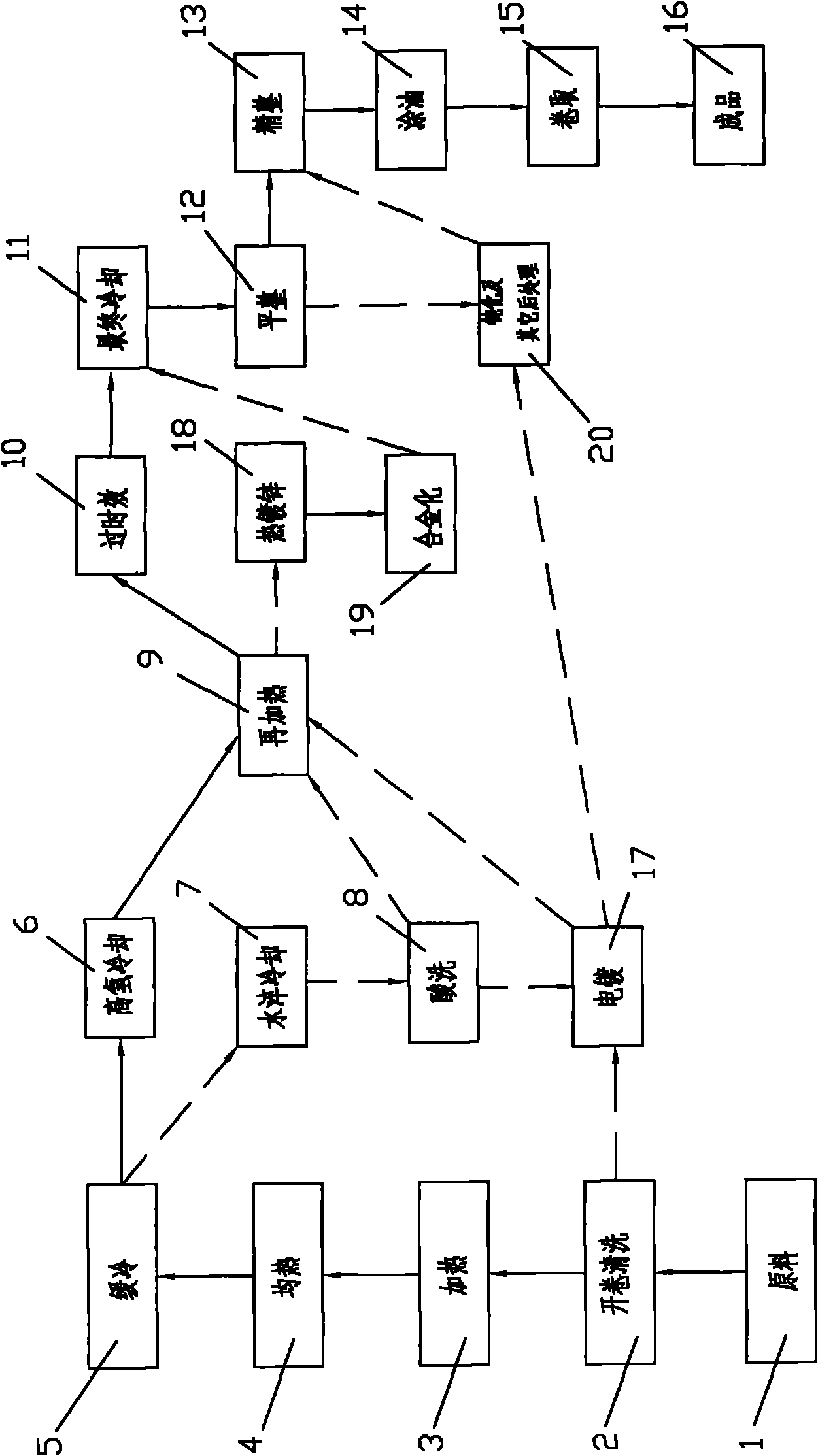

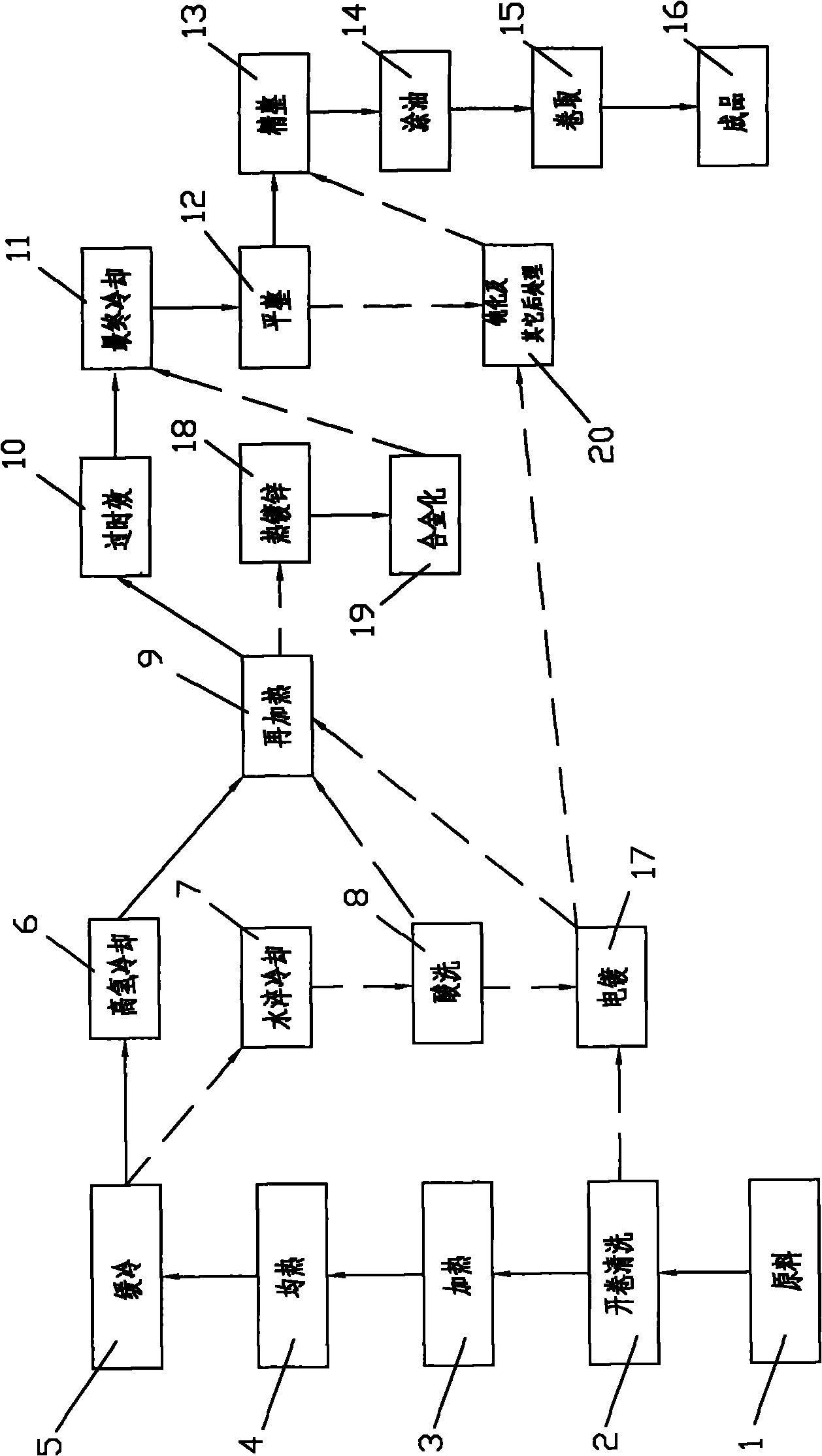

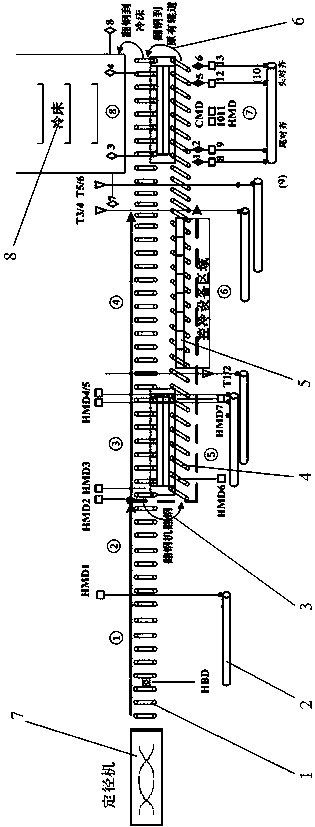

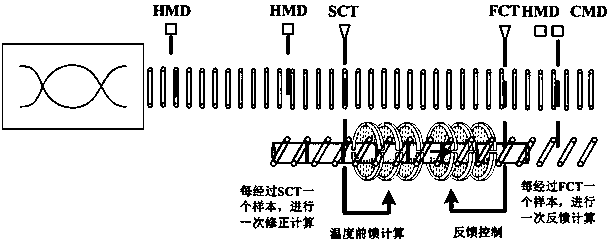

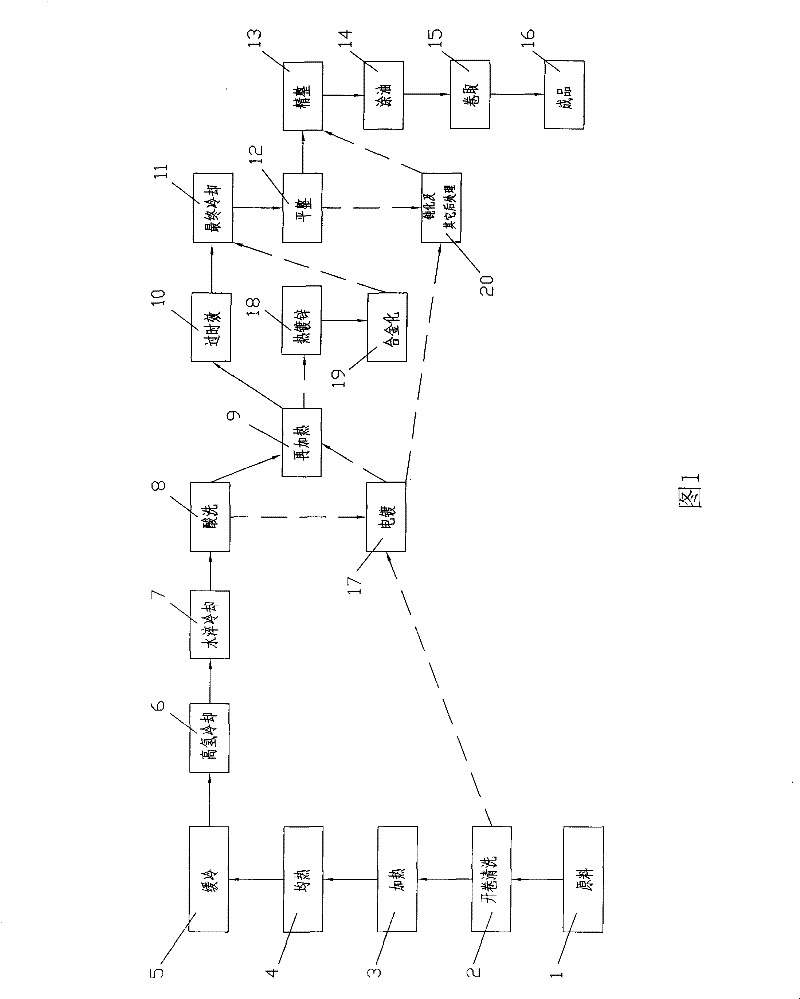

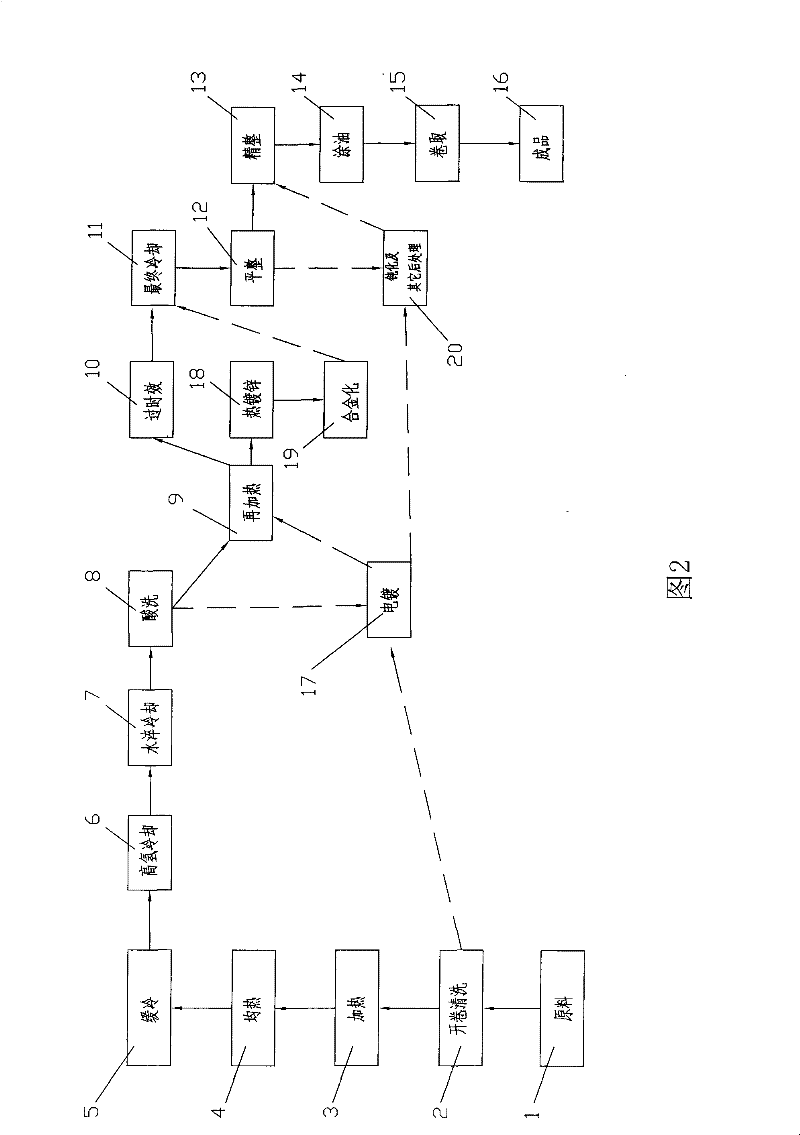

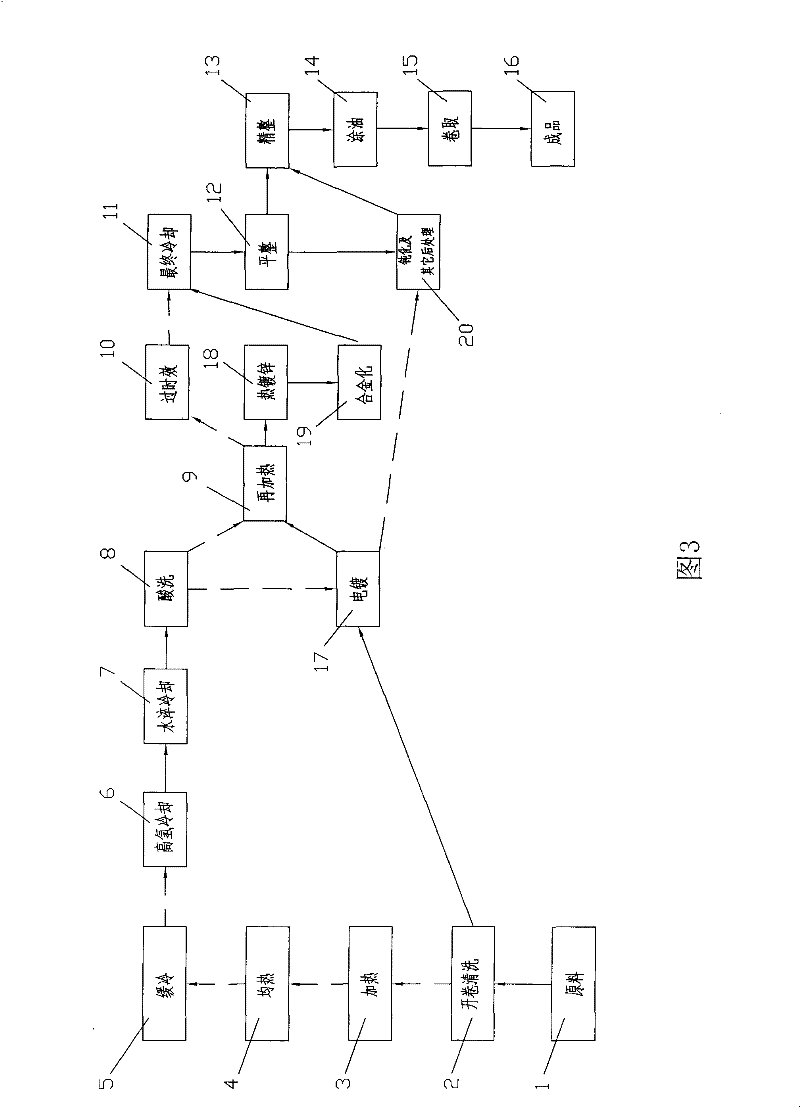

Flexible strip steel treating line suitable for producing various high-strength steel

ActiveCN101812579ARich varietyMeet actual needsHot-dipping/immersion processesElectrolysis componentsStrip steelSlow cooling

The invention discloses a flexible strip steel treating line suitable for producing various high-strength steel. The flexible strip steel treating line comprises an uncoiling working position, a washing working position, a heating working position, a soaking working position and a slow cooling working position, a jet cooling working position or a water quenching cooling working position in turn, wherein a reheating working position and then an overaging working position or a hot galvanizing working position and a cladding alloying and annealing working position are arranged after the jet cooling working position; a moveable bypass channel is arranged to connect the reheating working position and the overaging working position respectively; a final cooling working position and a flatting working position are connected after the overaging working position and the hot galvanizing working position; then, a finishing working position and an oil coating working position, or a passivating working position and other post-treatment working positions are connected; the finishing working position and the oil coating working position are connected to a coiling working position to finish a finished product; an acid cleaning working position and an electroplating working position are arranged corresponding to the water quenching and cooling working position; the reheating working position can be connected after the acid cleaning working position directly; an uncoiling and washing working position can be directly connected before the electroplating working position; and the bypass channel or a switching device is arranged after the electroplating working position to respectively and correspondingly connect the reheating working position or directly connect the passivating working position and the other post-treatment working positions.

Owner:BAOSHAN IRON & STEEL CO LTD

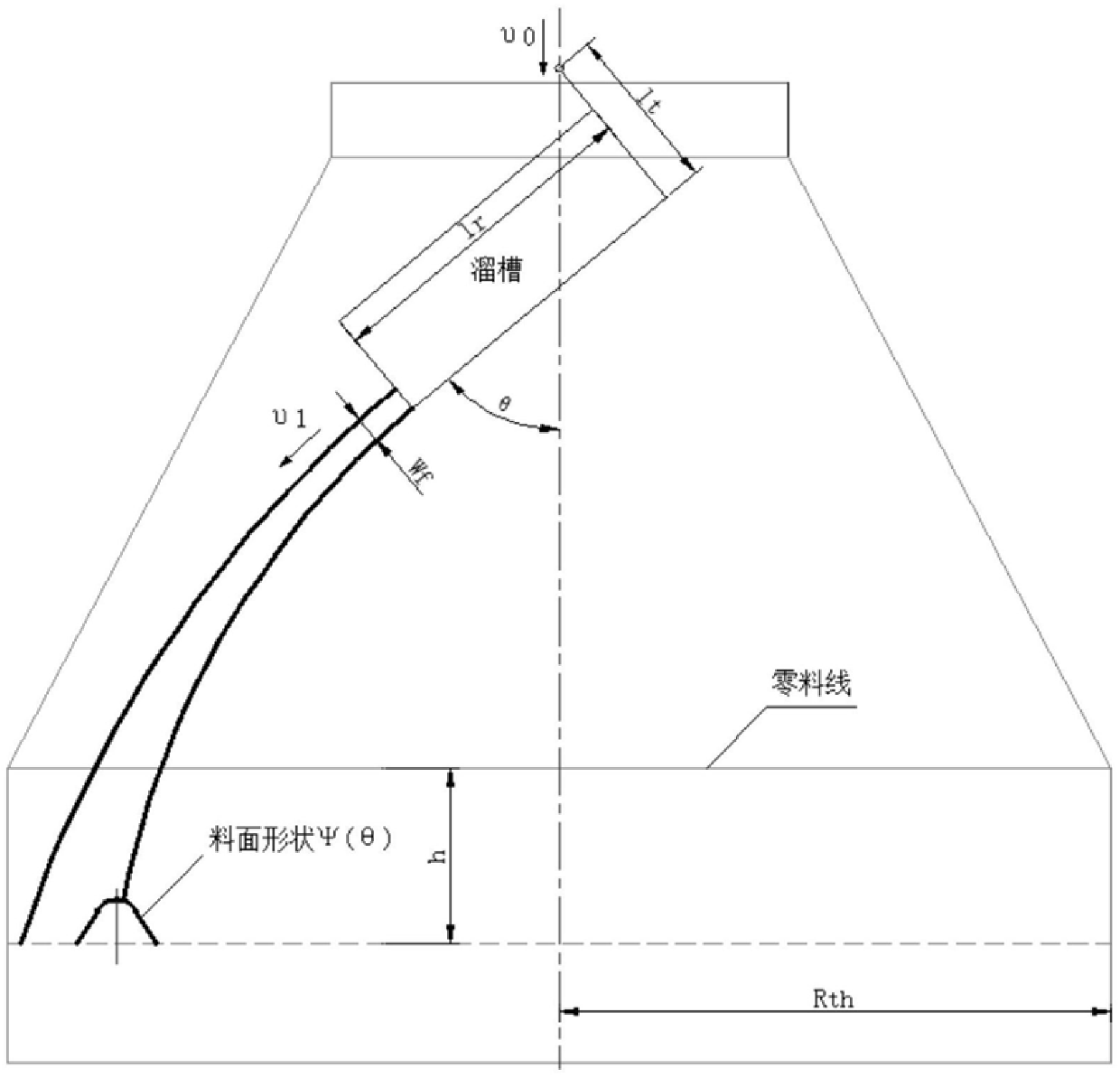

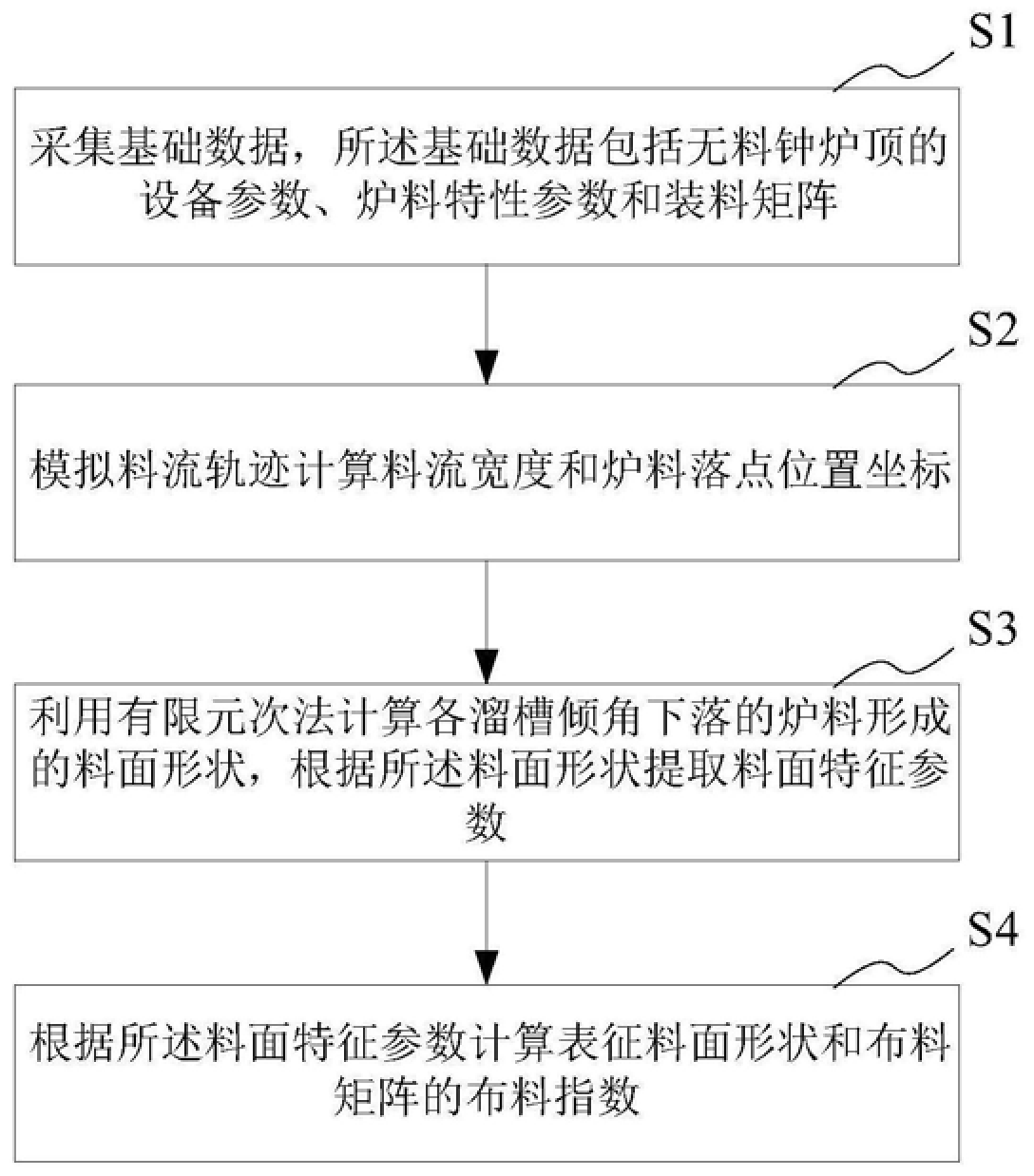

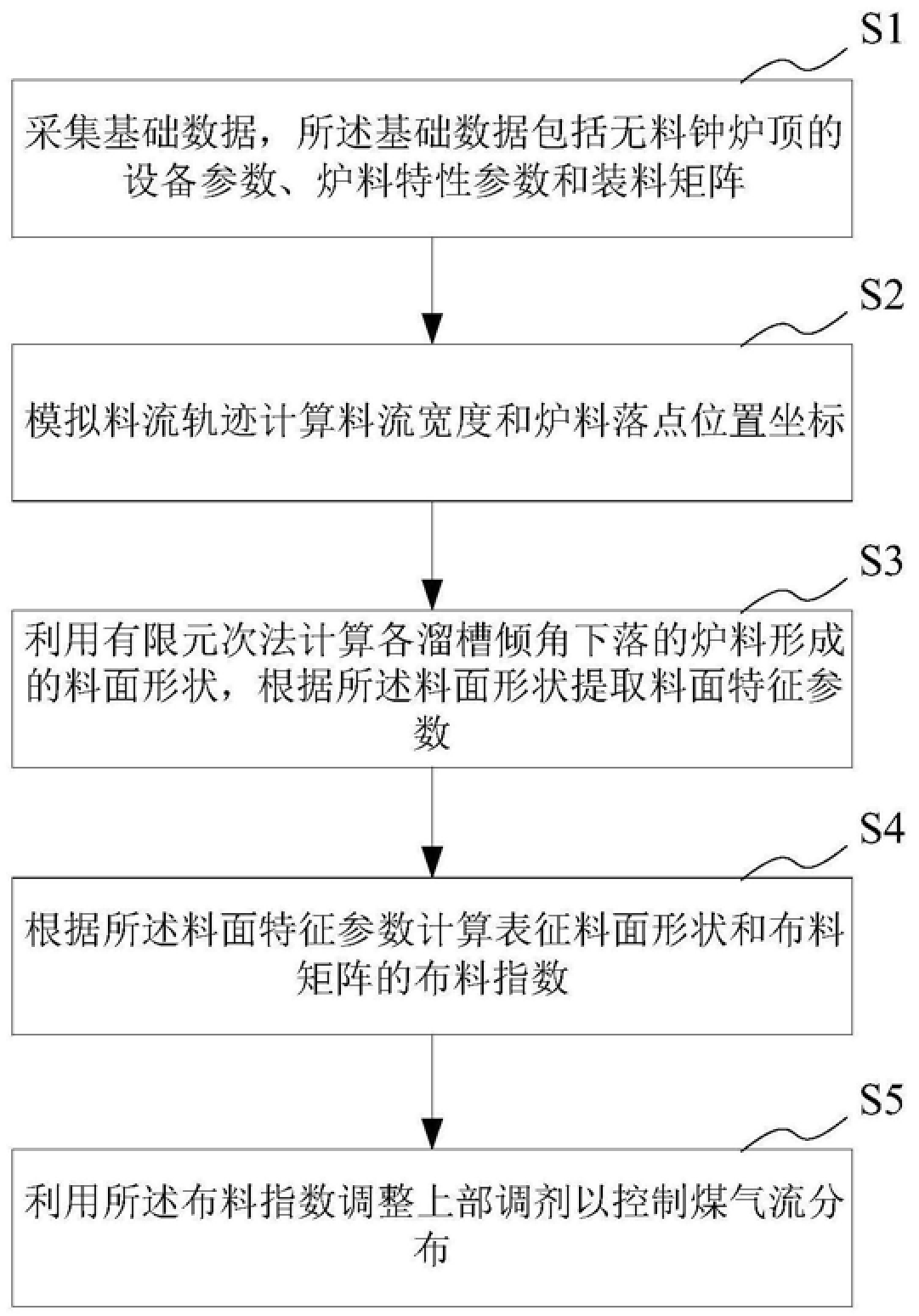

Characterization method, system, equipment and storage medium for blast furnace burden surface shape

ActiveCN110551861AImprove distributionProduction is stable and smoothBlast furnace detailsSpecial data processing applicationsDistribution matrixEngineering

The invention provides a characterization method, a system, equipment and a storage medium for a blast furnace burden surface shape. The method comprises the following steps of, collecting basic data,wherein the basic data comprises equipment parameters of a bell-less furnace top, charge characteristic parameters and a charging matrix; simulating a material flow track to calculate the material flow width and coordinate of the falling point position of the charge; calculating the shape of the material surface formed by the burden falling at the inclination angle of each chute by using a finiteelement secondary method, and extracting characteristic parameters of the material surface according to the shape of the material surface; and calculating material distribution index characterizing the material surface shape and the material distribution matrix according to the material surface characteristic parameters. According to the characterization method, the material surface shape and thematerial distribution matrix information are accurately characterized, so that a material surface shape characterization reference is provided for an operator in an upper adjustment process, the material distribution system is facilitated to be accurately and timely adjusted, the gas flow distribution is improved, and stable and smooth blast furnace production is realized.

Owner:CISDI INFORMATION TECH CO LTD

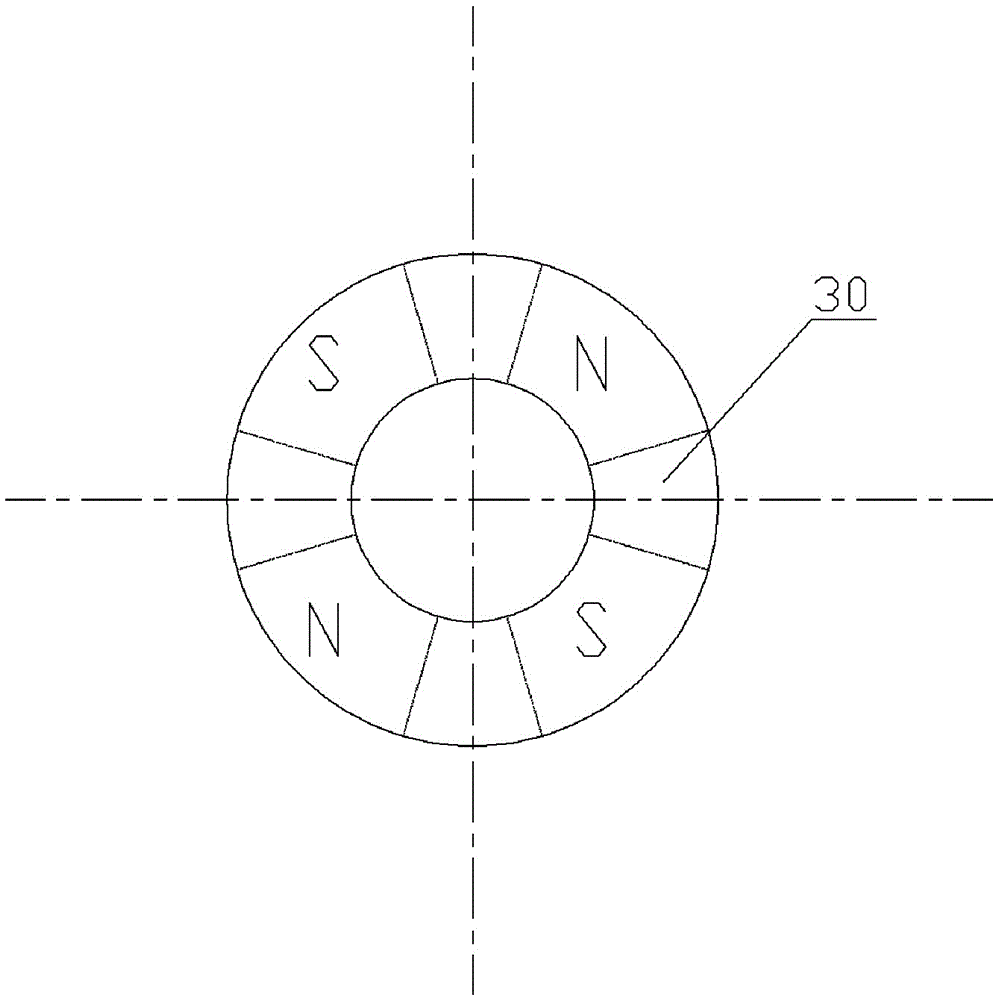

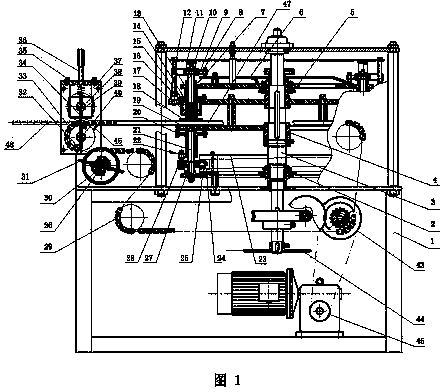

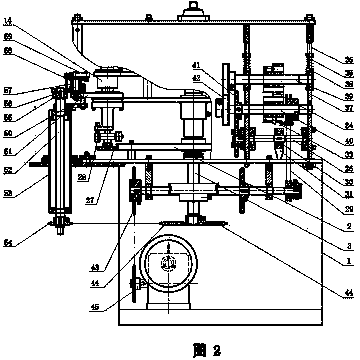

Micro motor magnetic steel assembly device

ActiveCN103872860AImprove adsorption capacityIncrease productivityMagnetic bodiesManufacturing dynamo-electric machinesMicro motorUltimate tensile strength

The invention discloses a micro motor magnetic steel assembly device which comprises a working platform and two guide rails on the working platform. A movable supporting base is arranged on the two guide rails. A third air cylinder is arranged on the movable supporting base. An installation arm parallel to the two guide rails is fixed to a piston rod of the third air cylinder. The two ends of the installation arm are provided with a first air cylinder and a second air cylinder. A first magnetic steel attraction device is arranged on a piston rod of the first air cylinder. A second magnetic steel attraction device is arranged on a piston rod of the second air cylinder. A first magnetic steel positioning base, a second magnetic steel positioning base and a shell positioning base are sequentially arranged on the working platform along the straight line. The distance between every two adjacent positioning bases is equal to the distance between the first magnetic steel attraction device and the second magnetic steel attraction device. A fourth air cylinder is installed on the working platform through a support. A piston rod of the fourth air cylinder extends downwards. A magnetizing apparatus corresponding to the second magnetic steel positioning base is arranged on the piston rod of the fourth air cylinder. According to the micro motor magnetic steel assembly device, the labor intensity of workers is reduced, and production efficiency is improved.

Owner:广安市超颖电子科技有限公司

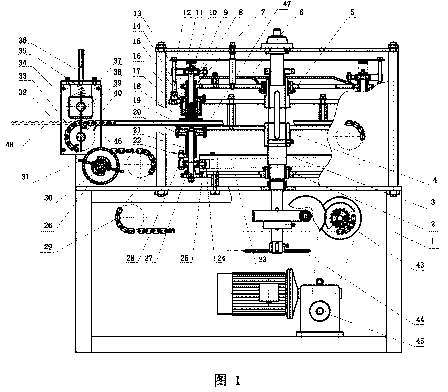

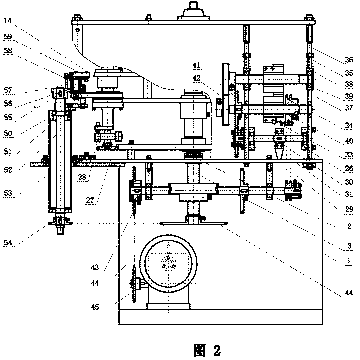

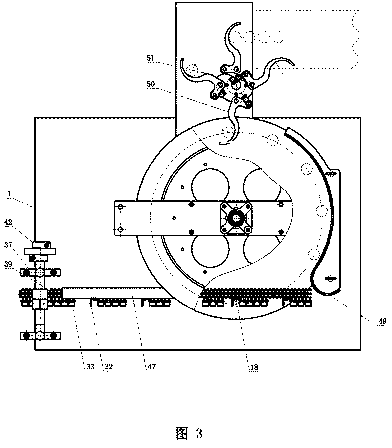

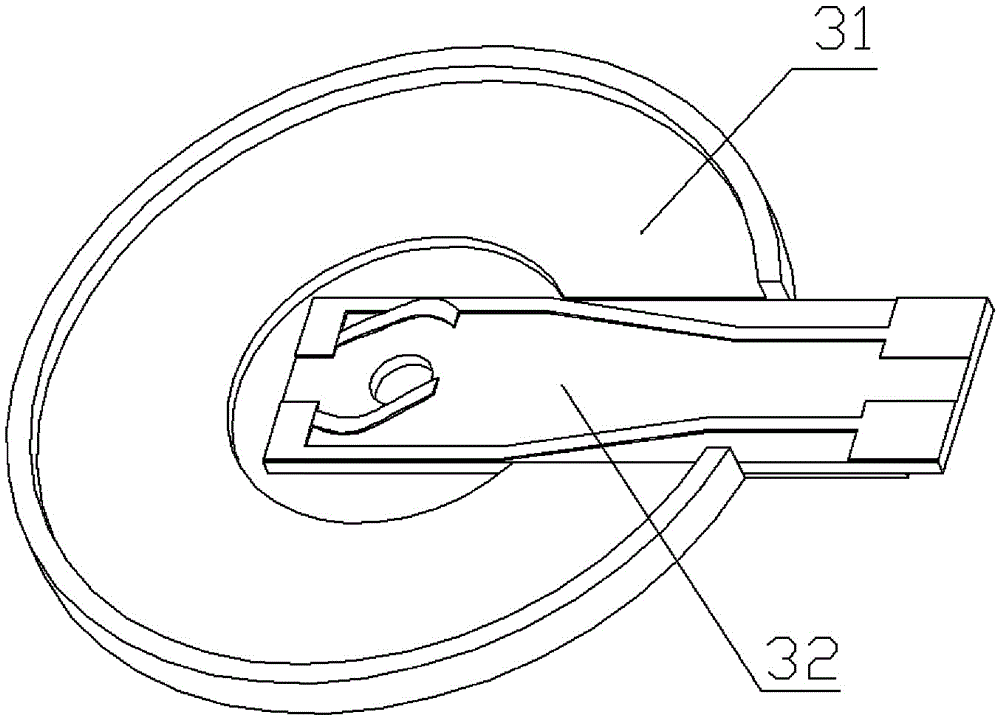

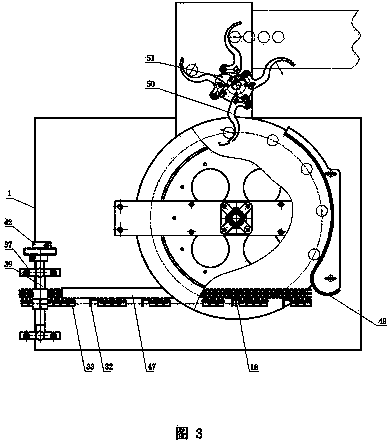

Automatic sugar coiling machine

ActiveCN103238719ARealize clamping positioningGuaranteed stabilityConfectionerySweetmeatsPulp and paper industryRotating disc

The invention discloses an automatic sugar coiling machine. The automatic sugar coiling machine comprises a frame; a cuter, a conveying belt, a central rotating disc and a shifting piece are arranged on the frame; a plurality of sets of coiling devices and sugar pressing devices which are in one-to-one correspondence are arranged on the surface of the central rotating disc; a sugar coiling pin is arranged in each coiling device; each sugar coiling pin can axially slide along the axis of the corresponding coiling device; an extruding tray is arranged in each sugar pressing device; each extruding tray can axially slide along the axis of the corresponding sugar pressing device; a sugar coiling sun gear rotating disc is fixedly arranged above the central rotating disc; a jacking sun gear rotating disc is fixedly arranged below the central rotating disc; the sugar coiling sun gear rotating disc is in mesh transmission with the coiling devices; and the jacking sun gear rotating disc is in mesh transmission with the sugar pressing devices. The automatic sugar coiling machine can automatically coil sugar sticks, and is high in production efficiency and good in product quality.

Owner:JIANGSU FLYING DRAGON FOOD MACHINERY

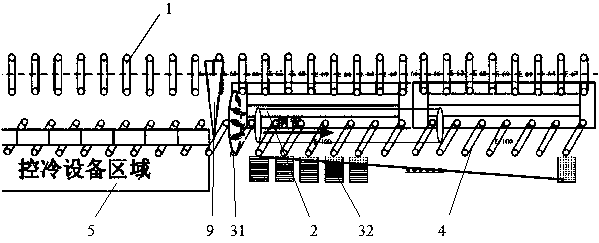

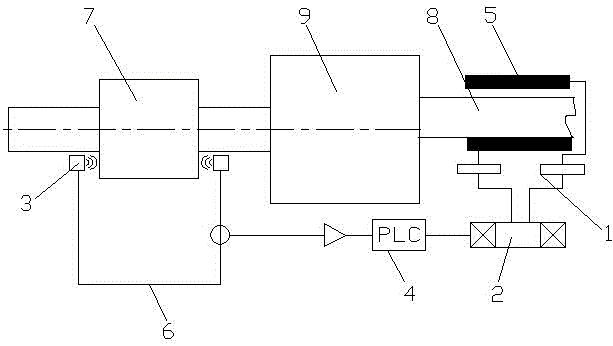

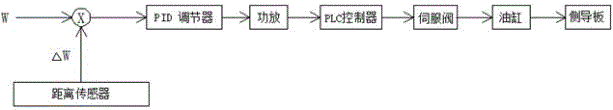

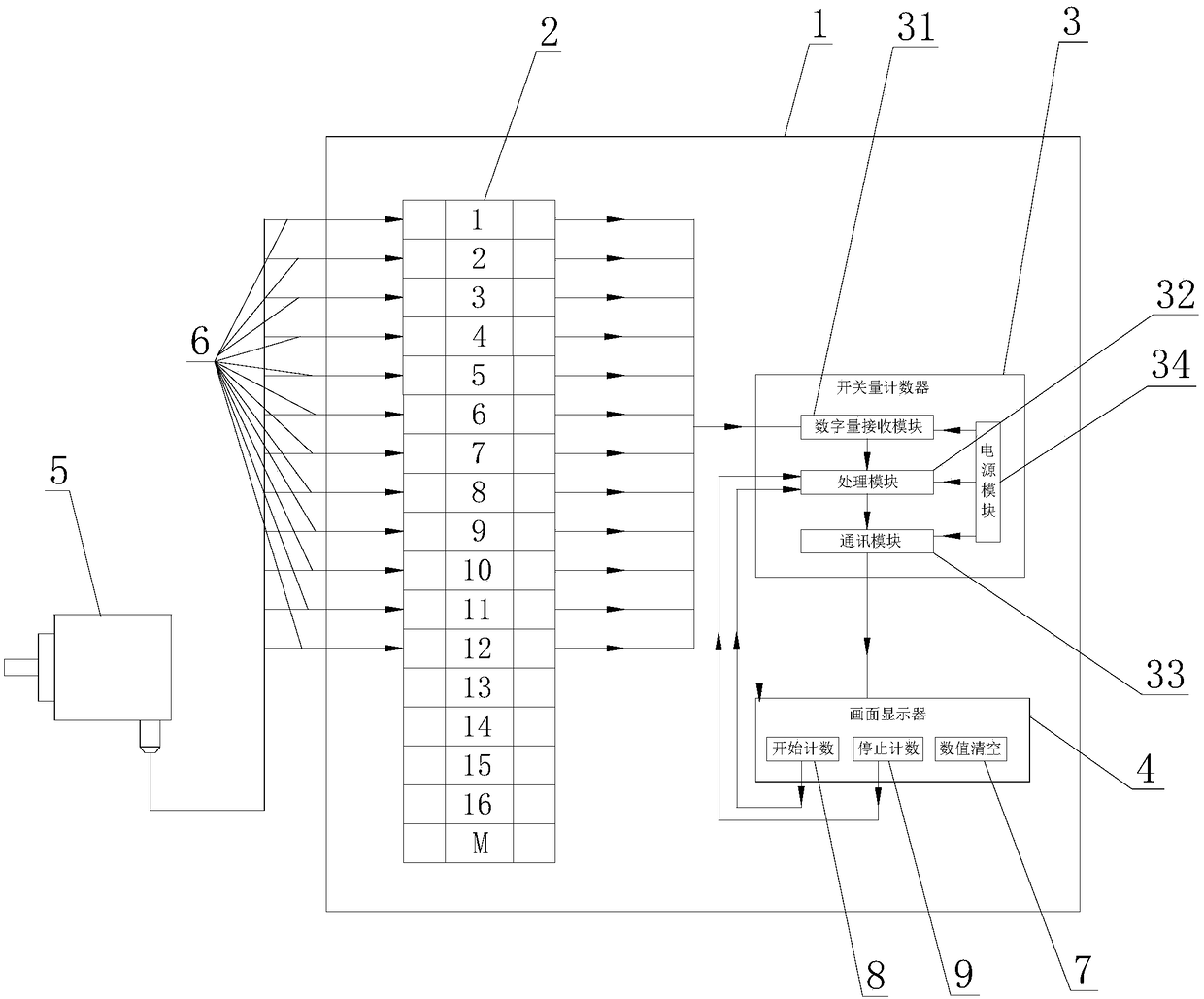

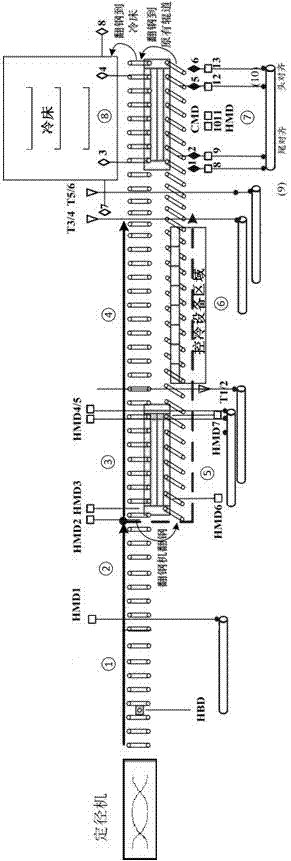

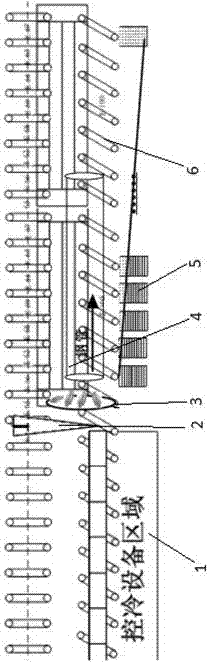

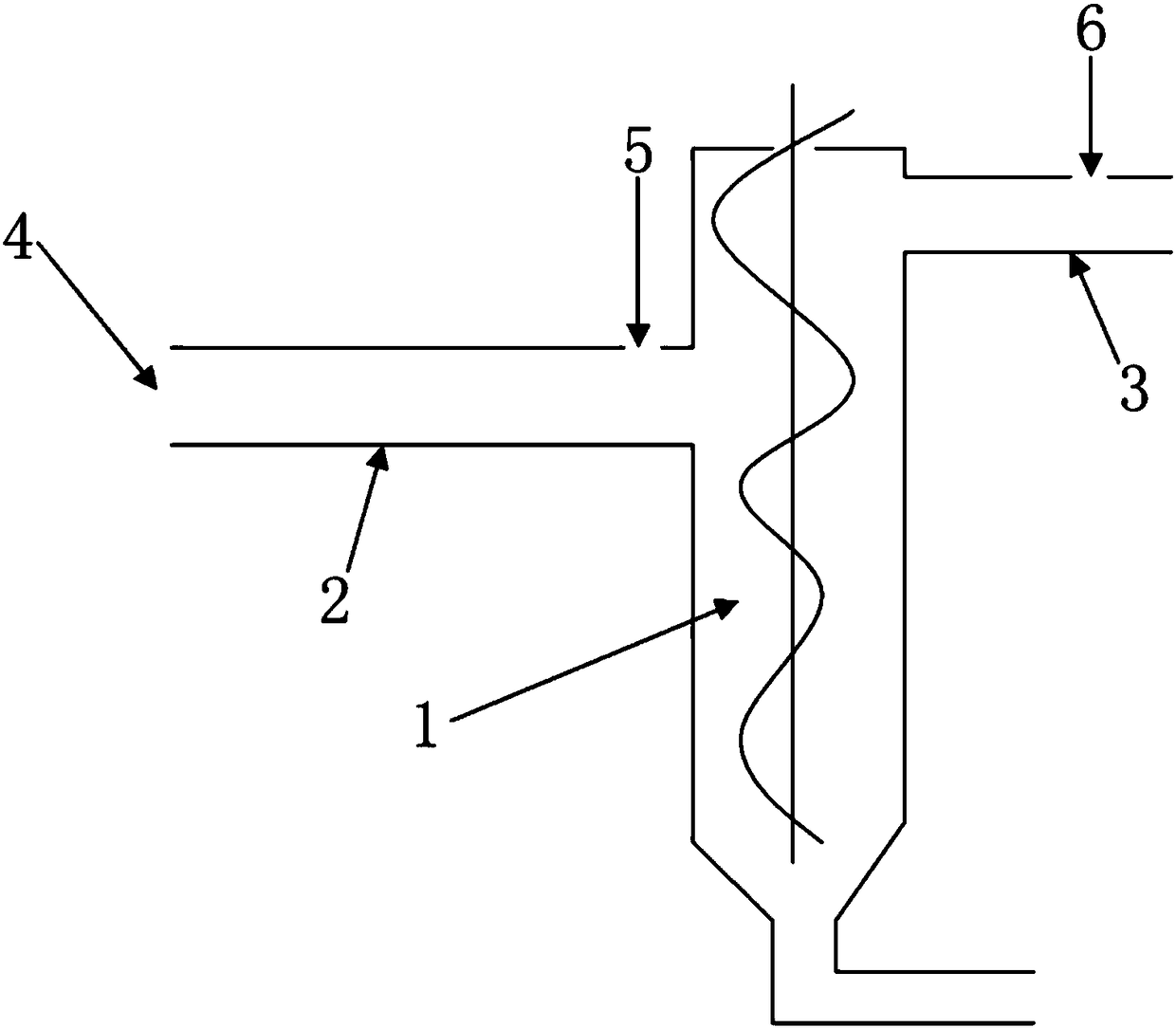

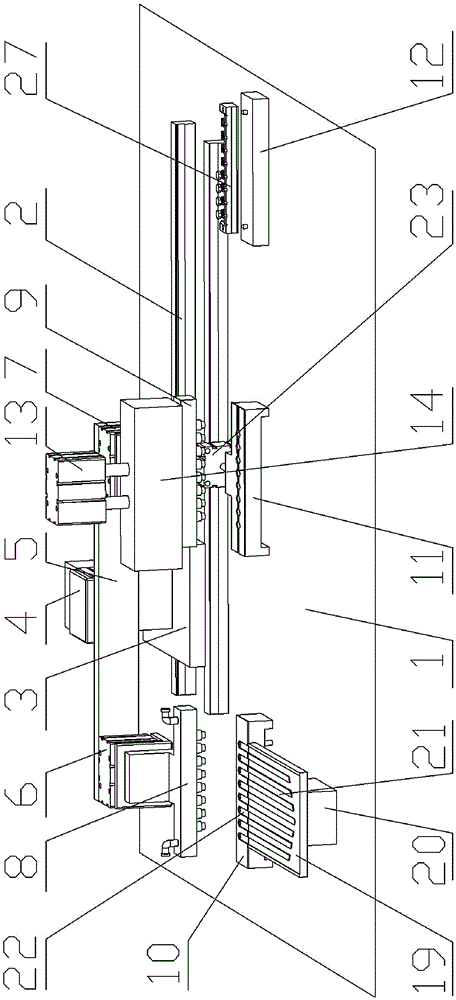

Production device and method for steel pipe online cooling

ActiveCN107971351AMeet various process requirements for online coolingDoes not affect productionTemperature control deviceMeasuring devicesAutomatic controlControl system

The invention relates to a steel pipe production online heat treatment technology, in particular to a production device and method for steel pipe online cooling. The online cooling production device is arranged beside a main conveying roller way (1) line behind a sizing mill parallelly and comprises two pipe turning mechanisms (3,6), an online cooling roller way (4) transport line and online cooling equipment (5), and thus after-rolling online uniform cooling of hot-rolling seamless steel pipes (2) can be achieved. Through reasonable arrangement of the online cooling equipment, gradient control over the radial temperature of the steel pipes is achieved; through a steel pipe online cooling process control system, full-automatic control over after-rolling online cooling of the steel pipes isachieved, and the technical requirements of steel pipe products in the aspects of the final cooling temperature, the cooling rate, pipe surface temperature uniformity, cooled pipe shapes and the likeare met; and through a steel pipe online cooling basis automatic control system, the changeable steel pipe online cooling technical processes are achieved, and stable and smooth production is guaranteed.

Owner:BAOSHAN IRON & STEEL CO LTD

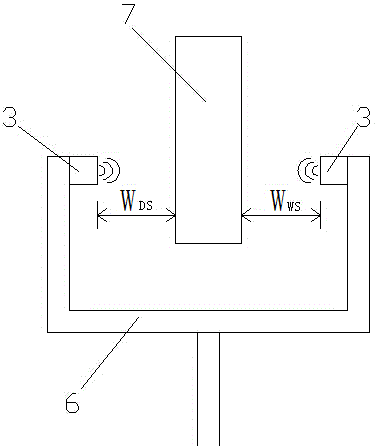

Automatic deviation-rectifying method and device for band steel uncoiling

InactiveCN106475429AProduction is stable and smoothSimple structureGuiding/positioning/aligning arrangementsWave shapeDistance sensors

Owner:BAOSHAN IRON & STEEL CO LTD

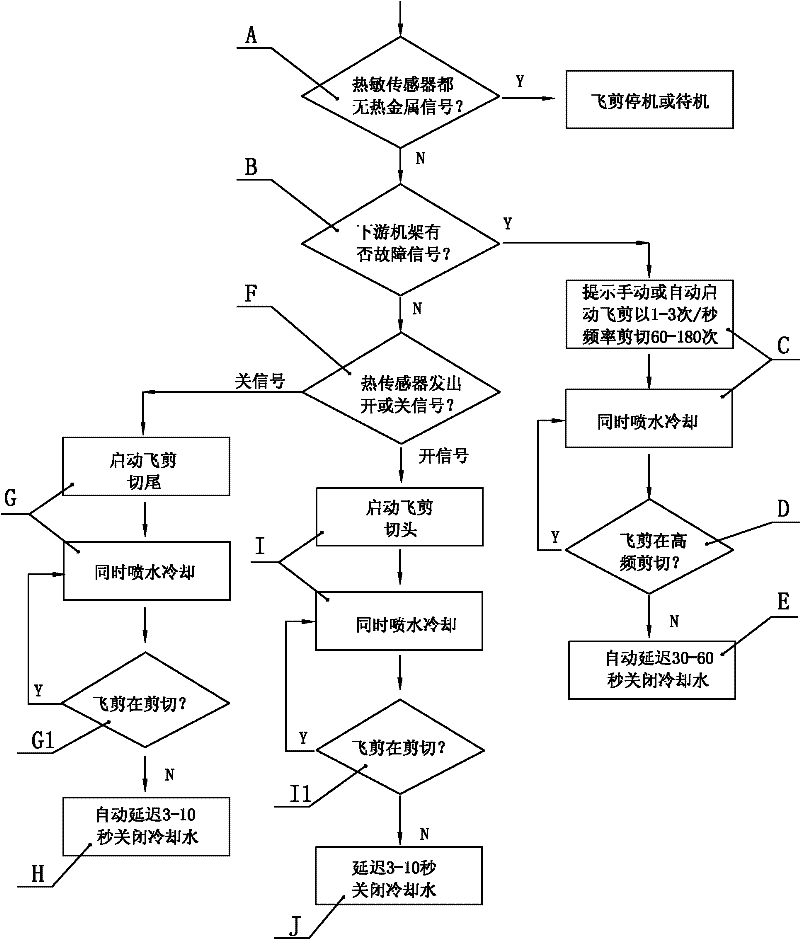

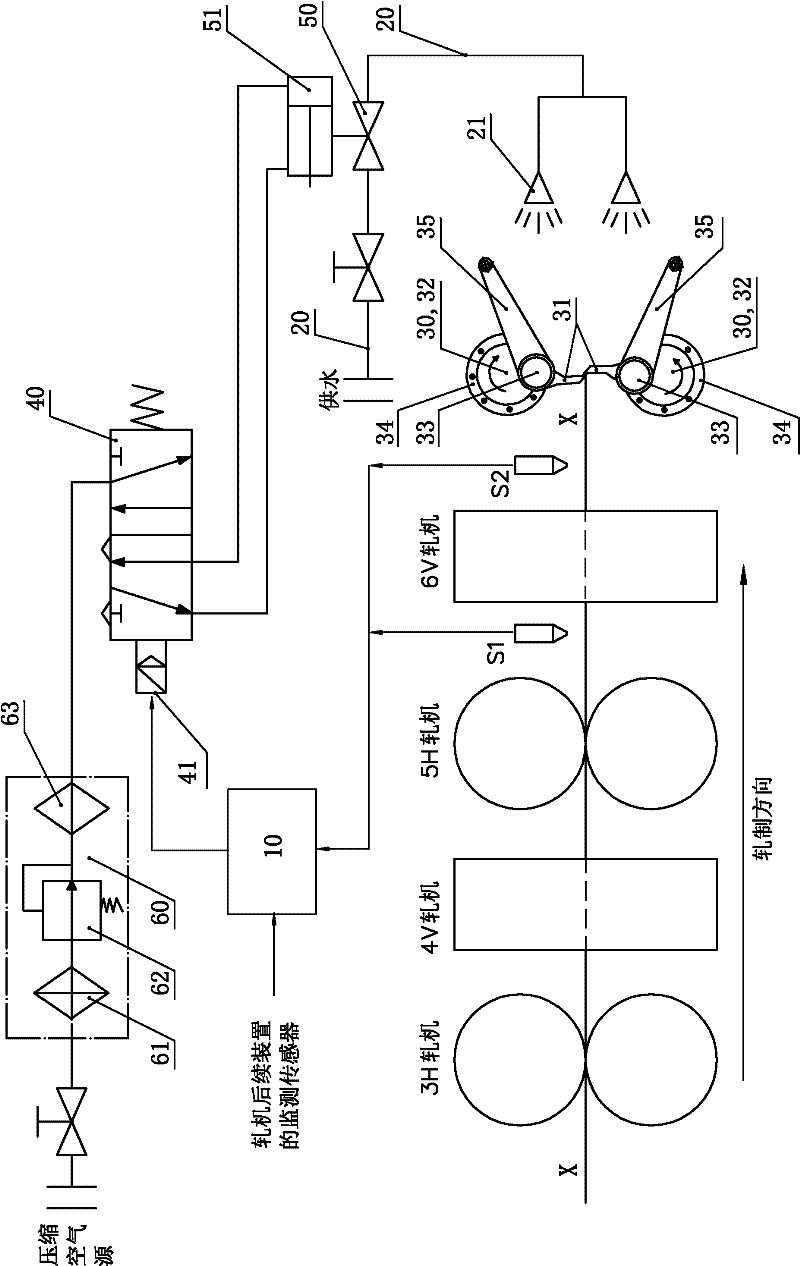

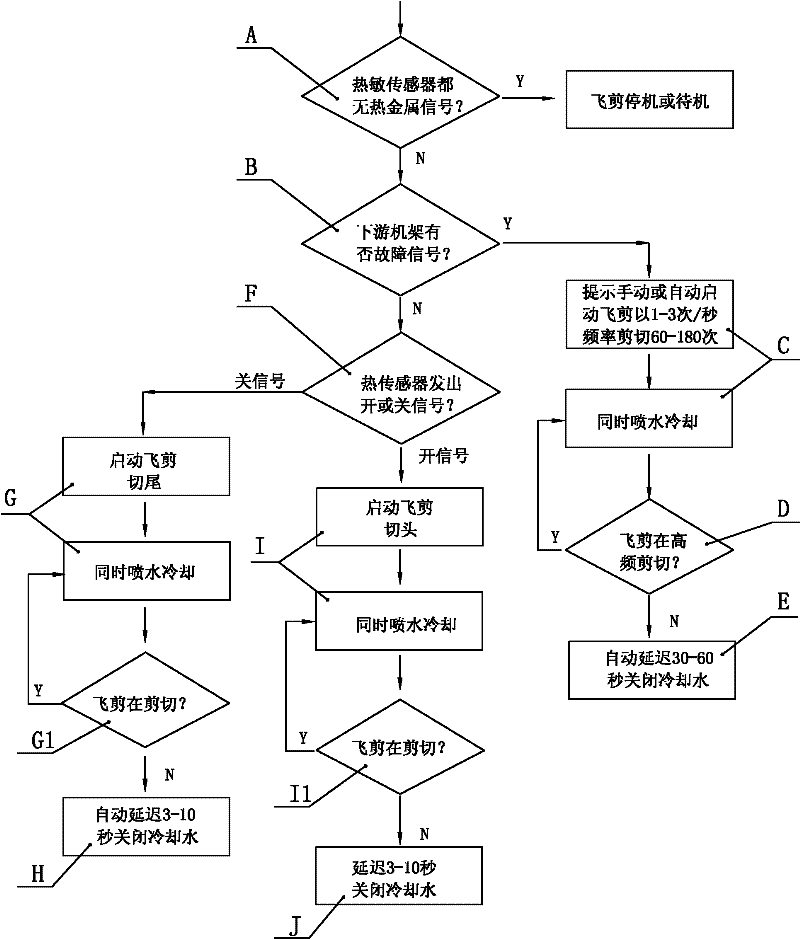

Rolling mill flying scissor blade cooling method and cooling device thereof

ActiveCN102310224AAccurate Status SignalTimely status signalMeasurement/indication equipmentsMaintainance and safety accessoriesFailure rateWire rod

The invention relates to a rolling mill flying scissor blade cooling method and a cooling device thereof. In the cooling method, a heat-sensitive sensor is arranged to detect the movement and the position of wire stocks in the process in which the wire stocks are transported to a flying scissor blade, and a detection signal is transmitted to a control circuit. The method comprises the following steps: sending out a hot metal existence / non-existence detection signal and controlling the flying scissor blade to halt or stand by; or spraying water to cool the flying scissor blade and automatically delaying the close of sprayed cooling water. According to the cooling method and the device thereof disclosed by the invention, on the premise of saving water and preventing water from splashing andinfiltering into a bearing oil seal, a more effective water cooling mode is adopted to cool the flying scissor blade, so the temperatures of the flying scissor blade as well as a cutter shaft and a crankshaft thereof can be greatly reduced, the shearing quality of flying scissors is improved, the overall working life of the blade and the flying scissors is prolonged, and the failure rate of the whole device is reduced.

Owner:SHAOGUAN IRON & STEEL GROUP CORP GUANGDONG PROV +1

Continuous-casting protection slag for CAS treated ship plate structural steel

The invention relates to continuous-casting protection slag for CAS treated ship plate structural steel. The protection slag is composed of, by weight, 30 percent to 39 percent of CaO, 24 percent to 33 percent of SiO2, six percent to 13 percent of Na2O, five percent to 9.5 percent of F, 0.9 percent to 1.9 percent of optimized elemental carbon, three percent to six percent of Al2O3, three percent to eight percent of MgO, 0.7 percent to 1.6 percent of Li2O, and 3.0 percent to 5.0 percent of Fe2O3. The viscosity of the slag is controlled between 0.07 Pa S and 0.08 Pa S. According to the physical properties of the continuous-casting protection slag, the melting point is 1020 DEG C to 1090 DEG C, the viscosity is 0.07 Pa S and 0.08 Pa S (1300 DEG C), CaO / SiO2 is 1.1 to 1.3, and H2O is smaller than or equal to 0.5 percent. According to the slag, the melting point of the slag can be reduced, the alkalinity can be improved, the unit consumption of the protection slag can be improved, the viscosity of the protection slag can be reduced, and therefore in the continuous casting process, the melting speed and the flowing-in speed are stably and dynamically balanced, and therefore lubrication of a primary blank shell of an inner plate blank of a crystallizer is ensured, and the aim of stable and smooth production of the CAS treated ship plate steel is achieved.

Owner:BAOSHAN IRON & STEEL CO LTD

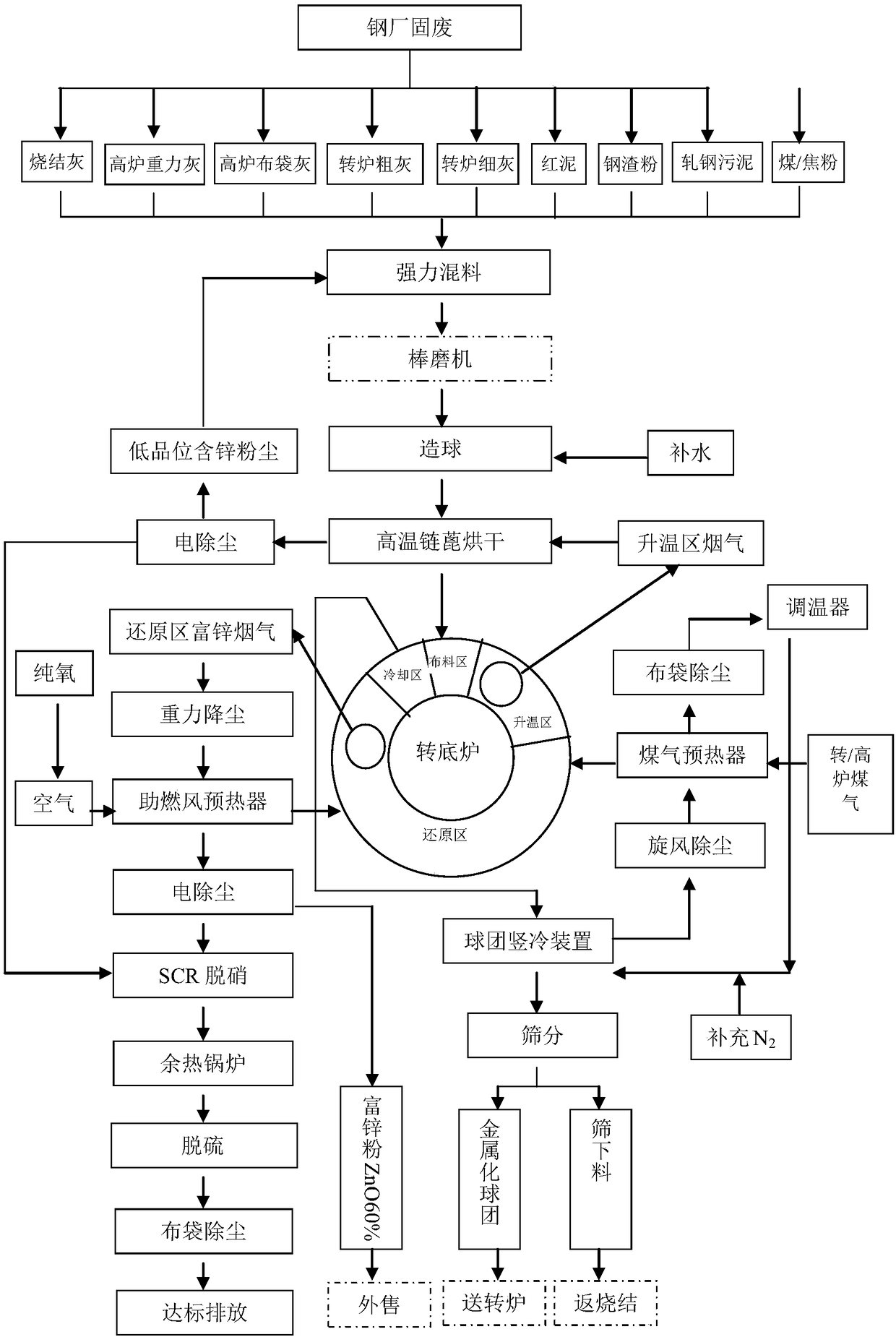

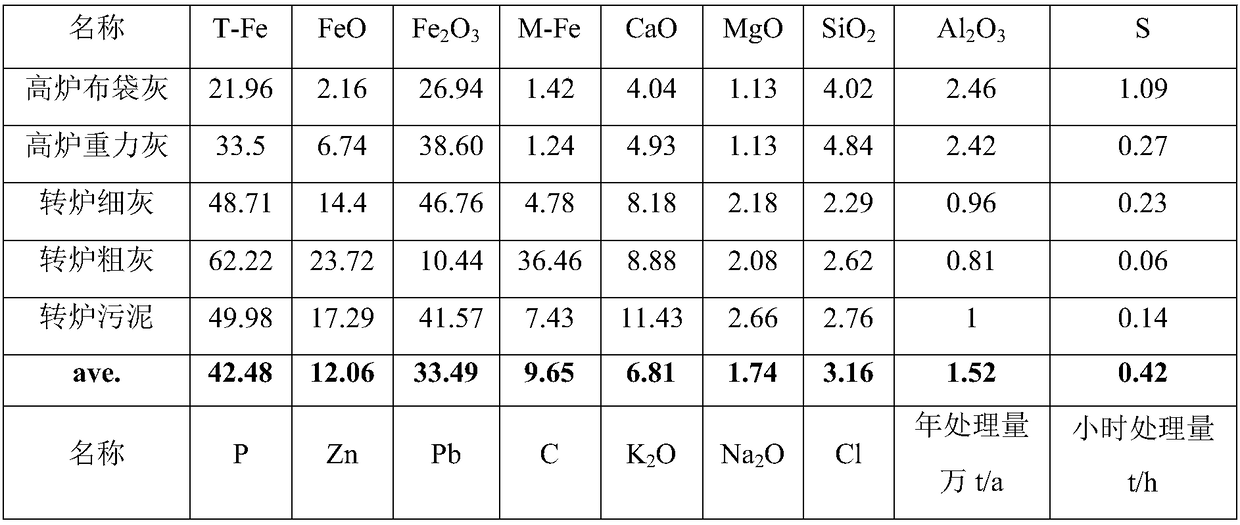

Method for treating solid waste through rotary hearth furnace

ActiveCN108611458AHigh strengthReduce pulverization rateRotary drum furnacesProcess efficiency improvementSteelmakingHearth

The invention relates to a method for treating solid waste through a rotary hearth furnace and belongs to the technical field of steel mill solid waste treatment. The problems that in the prior art, recycled zinc oxide powder is low in grade, and finished metallized pellets are high in pulverization rate are solved. The method for treating the solid waste through the rotary hearth furnace comprises the following steps of pelletizing, reduction and zinc-contained powder recycling, and a drying stage is further performed between the pelletizing and the reduction. The method for treating the solid waste through the rotary hearth furnace provided by the invention can be used for treating solid materials generated in the production processes of sintering, ironmaking and steelmaking.

Owner:钢研晟华科技股份有限公司

Using method of coke with different initial reaction temperatures in blast furnace

ActiveCN109706277AEasy to useImprove economic indicatorsBlast furnace detailsReaction temperatureEngineering

The invention discloses a using method of a coke with different initial reaction temperatures in a blast furnace.The using method comprises the following steps that 1, a coke initial reaction temperature is detected and obtained; 2, a production coke is divided into a first type of the coke and a second type of the coke; 3, material arrangement system of the blast furnace is remained unchanged, acoke material arrangement corner is divided into three parts: a center part, a middle part, and a edge part; and the second type of the coke is arranged in the middle part, and a mixing coke from thefirst type of the coke and the second type of the coke is arranged in the center part and the edge part; 4, using amount percentage by weight of the fist type of the coke in the mixing coke in the center part and the edge part is determined according to blast furnace capacity; 5, normal material arrangement is conducted; 6, when the blast furnace does not work well, using amount of the first typeof the coke in the center part and the edge part is adjusted; and 7, material arrangement is continued according to the adjusted scheme. The using method effectively solves the using problem of the coke with different initial reaction temperatures in the blast furnace, and provides reference for the application of the cokeinitial reaction temperature index in the blast furnace.

Owner:武汉钢铁有限公司

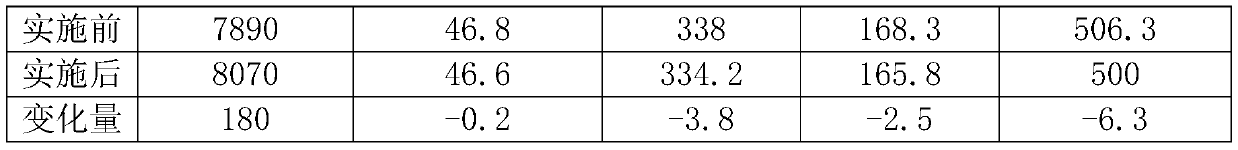

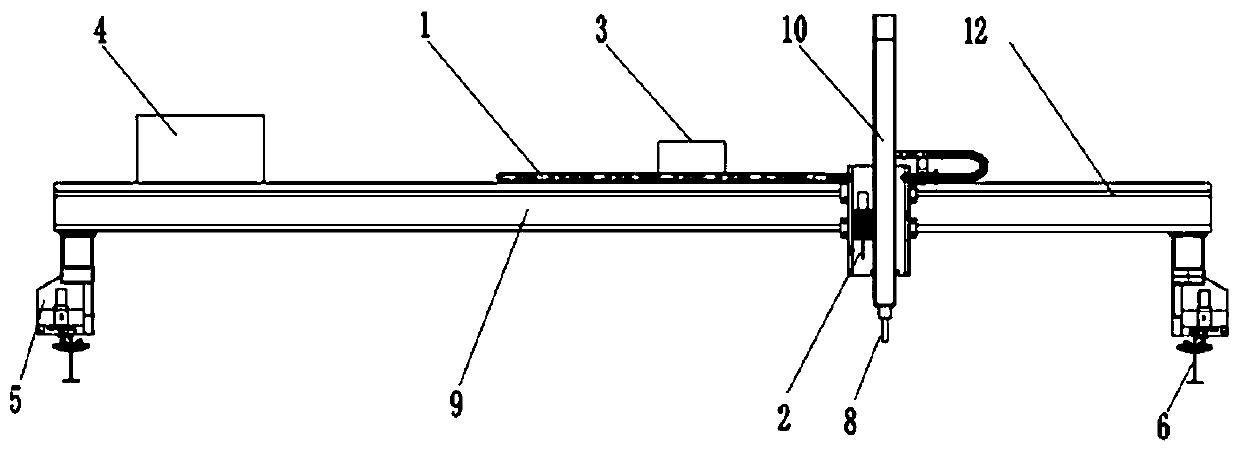

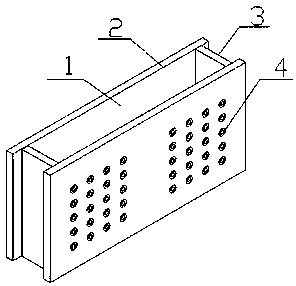

Rapid wire calibration device for photoelectric sensor

PendingCN109375039AGuaranteed normal loadingProduction is stable and smoothElectrical testingControl systemDisplay device

The invention discloses a rapid wire calibration device for a photoelectric sensor. The device comprises a back plate which is provided with a terminal row, a switch quantity counter and a picture display. The number of terminals in the terminal row is larger than or equal to the number of cables in an encoder, all the cables of the encoder can be connected to the terminal row at the same time, the output end of each terminal in the terminal row is in a signal connection with an input end of the switch quantity counter simultaneously, and an output end of the switch quantity counter is in a signal connection with an input end of a picture display. The rapid wire calibration device has the advantages that the high and the low positions of each cable in the photoelectric encoder can be quickly determined, the wire calibration operation of one photoelectric encoder can be completed in only 5 minutes, time and labor are saved, the accuracy is high, the completion rate of one time of wire calibration reaches 100%, so that the photoelectric encoder can be correctly and quickly connected to a mine slot loading control system, the normal feeding of a blast furnace is ensured, the purpose of reducing equipment delay is achieved, and stable and smooth production of the blast furnace is ensured.

Owner:JIANGSU YONGGANG GROUP CO LTD

Basic automation control system and control method for steel pipe online cooling

ActiveCN107971344ARealize fully automatic and precise controlWide range of adjustable temperature dropTemperature control deviceWork manipulationAutomatic controlEngineering

The invention relates to the online heat treatment technology for steel pipe production, in particular to a basic automatic control system and control method for steel pipe online cooling. After the basic automation control system for the steel pipe online cooling receives the setting information sent by a process control computer for the steel pipe online cooling, through mutual coordination of systems and strict logic control, and the steel pipe online cooling process is fully automatic and accurately controlled. The systems mainly include a basic control system for a steel pipe online cooling production device, a water supply system, and a hydraulic system. The steel pipe online cooling production device is in parallel with a steel pipe original rolling line system, the steel pipe online cooling production device has a wide range of adjustable temperature drop, the controllable cooling steel pipe has a large wall thickness specification, automatic control accuracy is high, and pipeshape after cooling is good; not only can be used to achieve flexible process requirements of the steel pipe online cooling, but also the offline quenching process requirement of the steel pipe can beachieved, and stable production and smooth operation are ensured.

Owner:BAOSHAN IRON & STEEL CO LTD

Control method for reducing liquid level fluctuation in hypo-peritectic steel production

ActiveCN113680983AUniform growthProduction is stable and smoothProcess efficiency improvementWater flowAlloy

The invention relates to the technical field of hypo-peritectic steel production, in particular to a control method for reducing liquid level fluctuation in hypo-peritectic steel production. The method comprises the following steps of 1) weakening peritectic reaction by adopting the following measures: A, controlling the refining heating time to be less than or equal to 10 min; B, supplementing an alloy in a refining station, and controlling the alloy supplementing amount to be smaller than 1.5 kg / t; and C, controlling the carbon content when refining is finished; 2) aiming at uniform growth of a blank shell in a crystallizer, taking the following measures of A, increasing the superheat degree of molten steel and controlling to be 20 to 50 DEG C; B, enabling the alkalinity of casting powder to be not lower than 1.35; C, controlling the flow speed of a water seam of the crystallizer to be 6.0 m / s to 8.0 m / s; and D, enabling the pulling speed to be constant; and 3) aiming at the bulging of a casting blank in a secondary cooling section, taking the following measures of A, enabling a roll gap of a casting machine before production to be + / -0.5 mm, and controlling the qualification rate of the roll gap; B, enabling the water nozzle blocking rate to be not larger than 2 percent; and C, improving the strength of secondary cooling water, wherein the secondary cooling specific water flow is larger than or equal to 0.9 kg / t. According to the control method for reducing liquid level fluctuation in hypo-peritectic steel production provided by the invention, the hypo-peritectic steel production liquid level fluctuation is reduced by 70 percent or above, and stable and smooth production is guaranteed.

Owner:ANGANG STEEL CO LTD

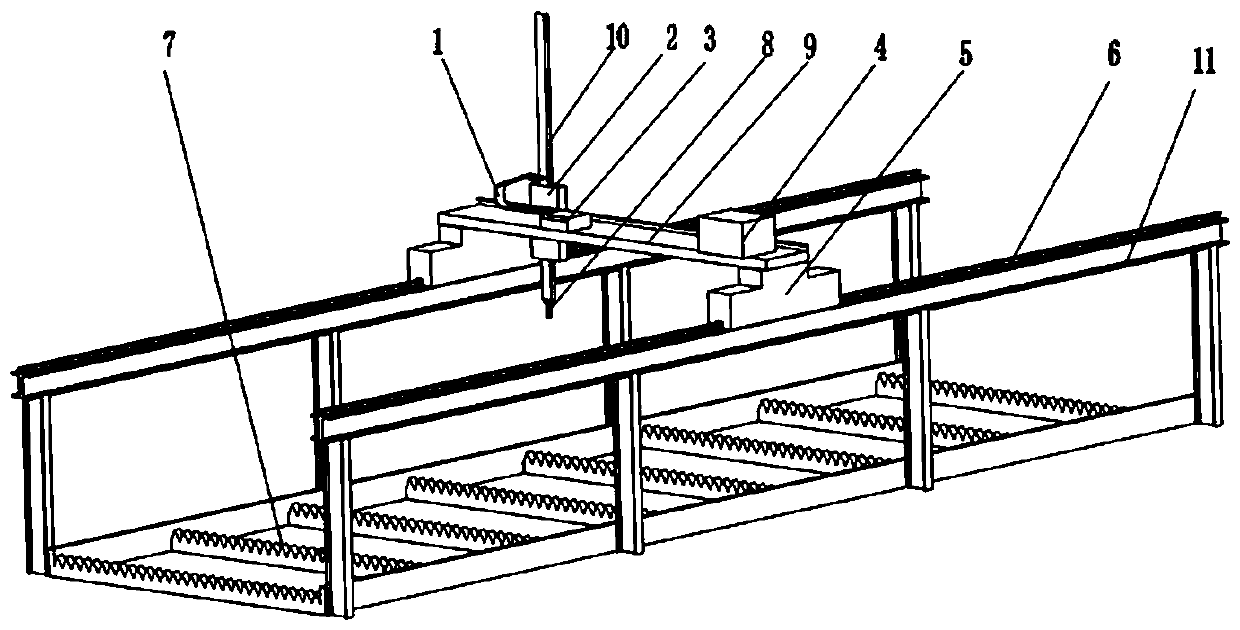

Automatic cleaning device and method for converter inclined plate sedimentation tanks

InactiveCN110652753AReduce labor intensityReduce security risksHollow article cleaningSedimentation settling tanksStructural engineeringMechanical engineering

The invention discloses an automatic cleaning device and a method for converter inclined plate sedimentation tanks. The automatic cleaning device for inclined plate sedimentation tanks comprises a frame, the frame is installed at the left end and the right end of a sedimentation tank, longitudinal walking mechanisms are slidably connected to the frame, a transverse walking mechanism is arranged between the longitudinal walking mechanisms, a spray gun ascending and descending mechanism is installed on the transverse walking mechanism, and a spray gun is installed on the spray gun ascending anddescending mechanism. According to the automatic cleaning method for converter inclined plate sedimentation tanks, cleaning speed is adjusted based on on-site mud situations, when a 'one-key start' switch is pressed, the automatic cleaning device moves on the inclined plate sedimentation tank according to a set cleaning track for cleaning, and after automatic cleaning is completed, if a certain part of the inclined plate needs to be accurately positioned and cleaned, accurate positioning and cleaning can be completed by inputting corresponding coordinates; according to the invention, the problems of low manual cleaning efficiency and safety are fundamentally solved, the labor intensity of workers is reduced, the loss caused by shutdown maintenance is reduced, and the stable and smooth production is guaranteed.

Owner:SGIS SONGSHAN CO LTD

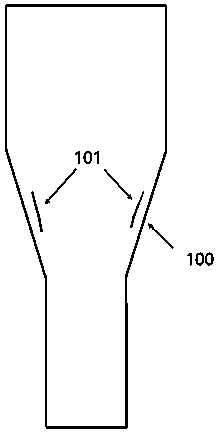

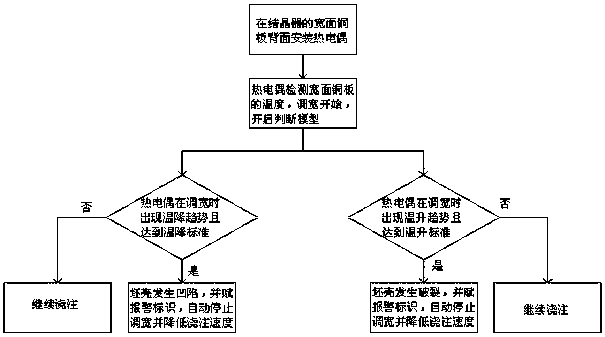

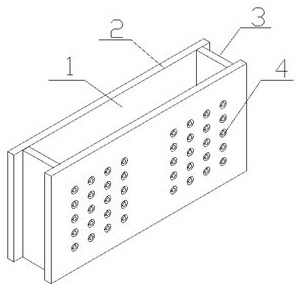

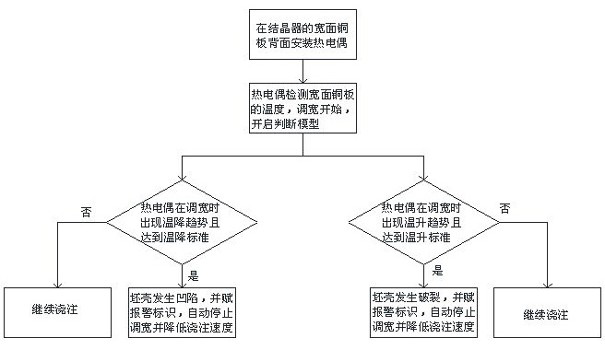

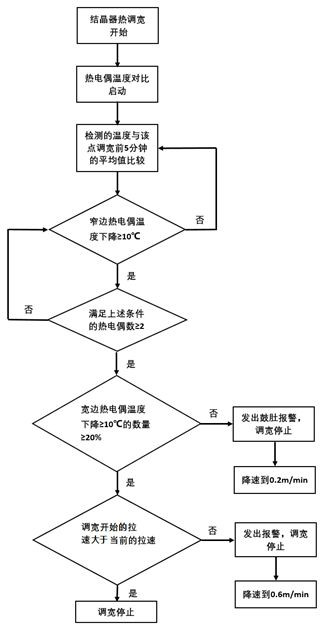

Method for avoiding breakout due to extrusion of slab shell during hot width adjustment of continuous casting mold

The invention discloses a method for avoiding breakout due to extrusion of a slab shell during hot width adjustment of a continuous casting mold. The method comprises the step 1 of installing a plurality of rows of thermocouples (4) on the back sides of two wide copper plates (2); the step 2 of detecting the temperature of the wide copper plates through the thermocouples in the casting process, starting to regulate the width, and enabling the judgment model; the step 3 of judging whether each row of thermocouples has a trend of temperature drop during width adjustment and meets the temperaturedrop standards; stopping regulating the width and reducing the casting speed if the thermocouples meet the temperature drop standards, and the slab shell is sunken and marked with a warning sign; continuing casting if the thermocouples fail to meet the temperature drop standards; the step 4 of judging whether each row of thermocouples has a trend of temperature rise during width adjustment and meets the temperature rise standards; stopping regulating the width and reducing the casting speed if the thermocouples meet the temperature rise standards, and the slab shell is cracked and marked withthe warning sign; and continuing casting if the thermocouples fail to meet the temperature rise standards. According to the method, breakout due to sinking and cracking of the slab shell extruded bynarrow copper plates can be detected in the hot width adjustment process of the continuous casting mold, and breakout accidents are avoided, so that the production is performed stably and smoothly.

Owner:BAOSHAN IRON & STEEL CO LTD

A continuous reaction device and method for amino acid surfactant

ActiveCN106345387BReduce volumeSimple process routeSequential/parallel process reactionsFlow mixersTowerSURFACTANT BLEND

The invention belongs to the field of amino acid surfactants, in particular to a high-efficiency continuous reaction device for amino acid surfactants, comprising a liquid separation tower, a pipeline synthesis reactor, and a pipeline neutralization reactor; the pipeline synthesis reactor is vertically arranged on the The middle part of the liquid separation tower, and communicated with the liquid separation tower; the pipe synthesis reactor is provided with a raw material inlet far away from the end of the liquid separation tower, and is provided with an acid inlet near the end of the liquid separation tower; The pipeline neutralization reactor communicates with the upper outlet of the liquid separation tower, and an alkali inlet is provided in the middle thereof. And disclosed its reaction method, the process route is simple, the reaction time is greatly shortened, and the whole synthesis reaction can realize continuous material input and product output, which can greatly improve production efficiency, improve reaction uniformity, and reduce side effects. Product yield, improve product quality.

Owner:JIUJIANG TINCI ADVANCED MATERIALS CO LTD

Blast furnace batching method based on final slag alkalinity

InactiveCN103014206AProduction is stable and smoothSimplify daily production adjustmentsBlast furnace detailsSlagCoal

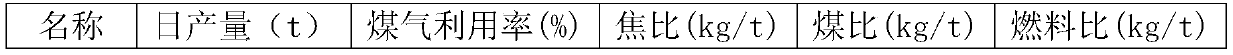

The invention provides a blast furnace batching method based on final slag alkalinity. A computational formula of the final slag alkalinity is a quotient in a division, wherein the dividend is the difference between the sum of the amount of CaO taken in by sintering ores, the amount of CaO taken in by pellet ores, the amount of CaO taken in by charging coke and the amount of CaO taken in by charging coal dusts, and the amount of CaO consumed by desulfuration; the divider is the difference between the sum of the amount of SiO2 taken in by sintering ores, the amount of SiO2 taken in by pellet ores, the amount of SiO2 taken in by charging coke and the amount of SiO2 taken in by charging coal dusts, and the amount of SiO2 commuted by Si carried away by cast iron; and the usage amount of the sintering ores and the pellet ores can be directly computed out through the formula. The blast furnace batching method based on the final slag alkalinity can effectively reduce effects of the SiO2 brought by ash in blast furnace charging fuel of charging coke, coal dusts and the like on the blast furnace final slag alkalinity, has a good and stable blast furnace final slag alkalinity, guarantees the stable smooth operation of the blast furnace production, simplifies the daily production regulation of the blast furnace and has remarkable effects on stabilizing the blast furnace productivity and reducing the blast furnace fuel consumption.

Owner:ANGANG STEEL CO LTD

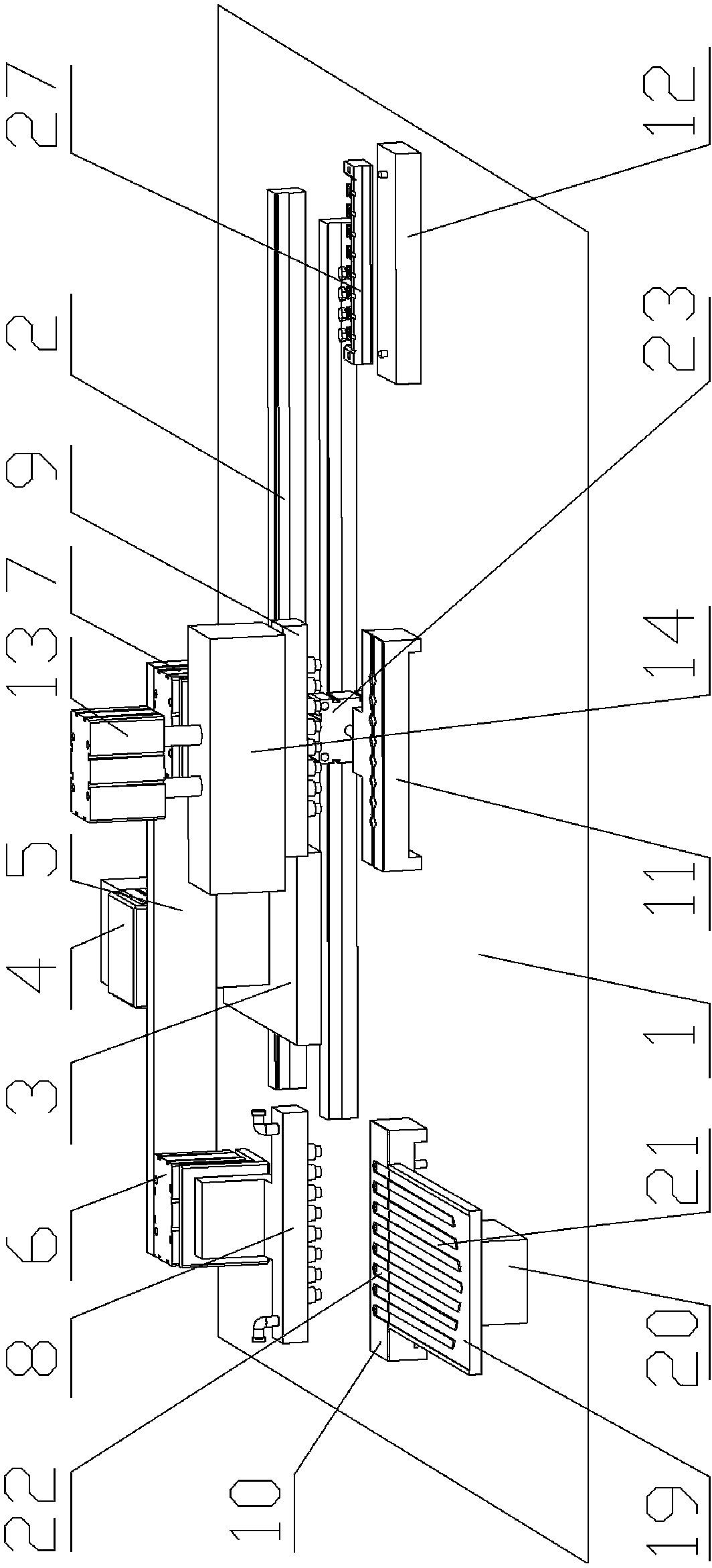

Assembly equipment for micro-motor magnets

ActiveCN103872860BAvoid deformation damageAvoid damageMagnetic bodiesManufacturing dynamo-electric machinesMicro motorEngineering

The invention discloses a micro motor magnetic steel assembly device which comprises a working platform and two guide rails on the working platform. A movable supporting base is arranged on the two guide rails. A third air cylinder is arranged on the movable supporting base. An installation arm parallel to the two guide rails is fixed to a piston rod of the third air cylinder. The two ends of the installation arm are provided with a first air cylinder and a second air cylinder. A first magnetic steel attraction device is arranged on a piston rod of the first air cylinder. A second magnetic steel attraction device is arranged on a piston rod of the second air cylinder. A first magnetic steel positioning base, a second magnetic steel positioning base and a shell positioning base are sequentially arranged on the working platform along the straight line. The distance between every two adjacent positioning bases is equal to the distance between the first magnetic steel attraction device and the second magnetic steel attraction device. A fourth air cylinder is installed on the working platform through a support. A piston rod of the fourth air cylinder extends downwards. A magnetizing apparatus corresponding to the second magnetic steel positioning base is arranged on the piston rod of the fourth air cylinder. According to the micro motor magnetic steel assembly device, the labor intensity of workers is reduced, and production efficiency is improved.

Owner:广安市超颖电子科技有限公司

Method to avoid steel breakout caused by continuous casting crystallizer heat-adjusted width billet shell being extruded

Owner:BAOSHAN IRON & STEEL CO LTD

Construction method of ladle lining

ActiveCN103157785BSmall heat capacityLow thermal conductivityMelt-holding vesselsTemperature controlHeat losses

The invention relates to a construction method of a ladle lining. The method comprises the following steps: (1) a ladle wall is cleaned; (2) fire clay is coated on the ladle wall and heat preservation plates, the heat preservation plates are sticked from seams of the bottom of the ladle and the ladle wall and along the ladle wall from bottom to top, gaps between the plates are filled with the fire clay, and the constructed heights of the heat reservation plates are equal to the height of a steel water liquid level; (3) holes are arranged between gap lines between an upper row of heat reservation plates and a lower row of heat dissipation plates and around the ladle wall every 1000-1200 millimeters at intervals, and two neighboring rows of holes are arranged in a mutually staggered mode; (4) after the heat preservation plates are constructed, fetal membranes are installed to tie permanent layer castable; and (5) after the permanent layer is tied and naturally dried, a working layer is constructed and is used in an online-mode after being baked. The method can effectively reduce heat loss of the ladling lining, improve temperature-controlling ability in the steel-making process, and ensure stable processes of production, and can also prolong service life of ladle shells, the ladle lining permanent layer and the working layer, and reduce production cost.

Owner:LAIWU IRON & STEEL GRP

Method for improving peritectic steel liquid level fluctuation of same-roll-diameter slab continuous casting machine

PendingCN114653913AImprove liquid level fluctuationsReduce surface longitudinal cracksSlab casterMechanical engineering

The invention belongs to the technical field of metallurgy, and particularly relates to a method for improving peritectic steel liquid level fluctuation of a same-roll-diameter slab continuous casting machine, which comprises the steps of crystallizer cooling water optimization, fan-shaped section secondary cooling water optimization, peritectic steel grade carbon mass fraction optimization, crystallizer narrow surface reverse taper adjustment, fan-shaped section forward arc and driving roll equipment precision detection and the like. The liquid level fluctuation condition of a crystallizer during peritectic steel production of a casting machine is effectively improved, the liquid level fluctuation can be controlled to be within plus or minus 3mm from plus or minus 15mm, meanwhile, surface longitudinal cracks of peritectic steel can be effectively reduced, a great help effect is achieved on stable and smooth production of the casting machine, casting blank quality and connection of front and back procedures, and good popularization value is achieved.

Owner:SD STEEL RIZHAO CO LTD

Straightening method of warped steel plate

ActiveCN104438458BProtection subjectHigh degree of automationMetal working apparatusGratingSheet steel

The invention discloses a straightening method of a head turning steel plate. The method comprises the following steps: when a high temperature meter detects that the steel plate is discharged from a finish mill, a turning head steel plate straightening mode is selected, the reverse correction is synchronously selected, and the state enters a semi-automatic mode; a set value of a model computer is requested, and the operation is performed by adding a head turning height according to the set value after receiving the set value; when a first grating is activated, the straightening sequence is started; when first and second gratings are activated, a position tracking and high pressure mode is started, and the steel is bitten with a speed of not higher than 0.7 m / s; when first, second and third gratings are activated, the steel plate enters a straightening machine, a steel plate stop button is pressed down to stop the steel plate, the high-pressure return is performed, and a roller gap is descended to the set position of the model computer; and when the position of the roller gap arrives at the set value of the model computer, the reverse correction is selected, and the forward straightening is performed to finish the straightening sequence. The method can set the roller gap according to the height of the steel plate turning head to guarantee normal steel biting and straightening effects.

Owner:BAOSHAN IRON & STEEL CO LTD

Technology to prevent continuous casting slab narrow side bulging

The invention discloses a process method for preventing the narrow-edge bulging of a continuous casting billet. A plurality of rows of thermocouples are mounted on a wide-surface copper plate (2) anda narrow-edge copper plate. The method comprises the following steps: that step 1, molten steel enters a crystallizer (1) and the temperature is transmitted to thermocouples; step 2, the temperature of the copper plate is recorded by the thermocouples; step 3, whether the temperature of the thermocouples in the same column on the narrow-edge copper plate is reduced to be greater than or equal to 10 DEG C is judged, and if not, the step 2 is continuously returned; if yes, the step 4 is continuously executed; step 4, judging whether the number of the thermocouples meeting the condition in the step 3 is larger than or equal to 2, and if not, and the step 3 is continuously returned ; if yes, the step 5 is continuously executed; step 5, judging whether the temperature of the wide-surface copperplate is reduced to be greater than or equal to 10 DEG C, and the number ratio of the thermocouples is greater than or equal to 20%, if yes, the step 6 is continuously executed ; if not, the step 7 is executed; step 6, width adjusting is carried out, whether the start pulling speed is greater than the current pulling rate, if yes, the width adjusting is stopped, if not, the step 8 is executed; step 7, an alarm is generated by the bulging, the width adjusting is stopped, and the pulling speed is reduced; and step 8, generally, the alarm is generated, the width adjusting is stopped, and the pulling speed is reduced.

Owner:BAOSHAN IRON & STEEL CO LTD

Flexible strip processing line suitable for producing various high-strength steel

ActiveCN101812578BRich varietyMeet actual needsHot-dipping/immersion processesFurnace typesStrip steelSlow cooling

Owner:BAOSHAN IRON & STEEL CO LTD

Automatic sugar coiling machine

ActiveCN103238719BRealize clamping positioningGuaranteed stabilityConfectionerySweetmeatsPulp and paper industryRotating disc

The invention discloses an automatic sugar coiling machine. The automatic sugar coiling machine comprises a frame; a cuter, a conveying belt, a central rotating disc and a shifting piece are arranged on the frame; a plurality of sets of coiling devices and sugar pressing devices which are in one-to-one correspondence are arranged on the surface of the central rotating disc; a sugar coiling pin is arranged in each coiling device; each sugar coiling pin can axially slide along the axis of the corresponding coiling device; an extruding tray is arranged in each sugar pressing device; each extruding tray can axially slide along the axis of the corresponding sugar pressing device; a sugar coiling sun gear rotating disc is fixedly arranged above the central rotating disc; a jacking sun gear rotating disc is fixedly arranged below the central rotating disc; the sugar coiling sun gear rotating disc is in mesh transmission with the coiling devices; and the jacking sun gear rotating disc is in mesh transmission with the sugar pressing devices. The automatic sugar coiling machine can automatically coil sugar sticks, and is high in production efficiency and good in product quality.

Owner:JIANGSU FLYING DRAGON FOOD MACHINERY

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com