Automatic cleaning device and method for converter inclined plate sedimentation tanks

A sloping plate precipitation and automatic cleaning technology, applied in cleaning methods and utensils, separation methods, precipitation separation and other directions, can solve the problems of high environmental requirements on the pool surface and cannot be cleaned to every corner of the pool, etc., to reduce the labor intensity of workers and Effectiveness of safety risk, loss reduction, and improved cleaning efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

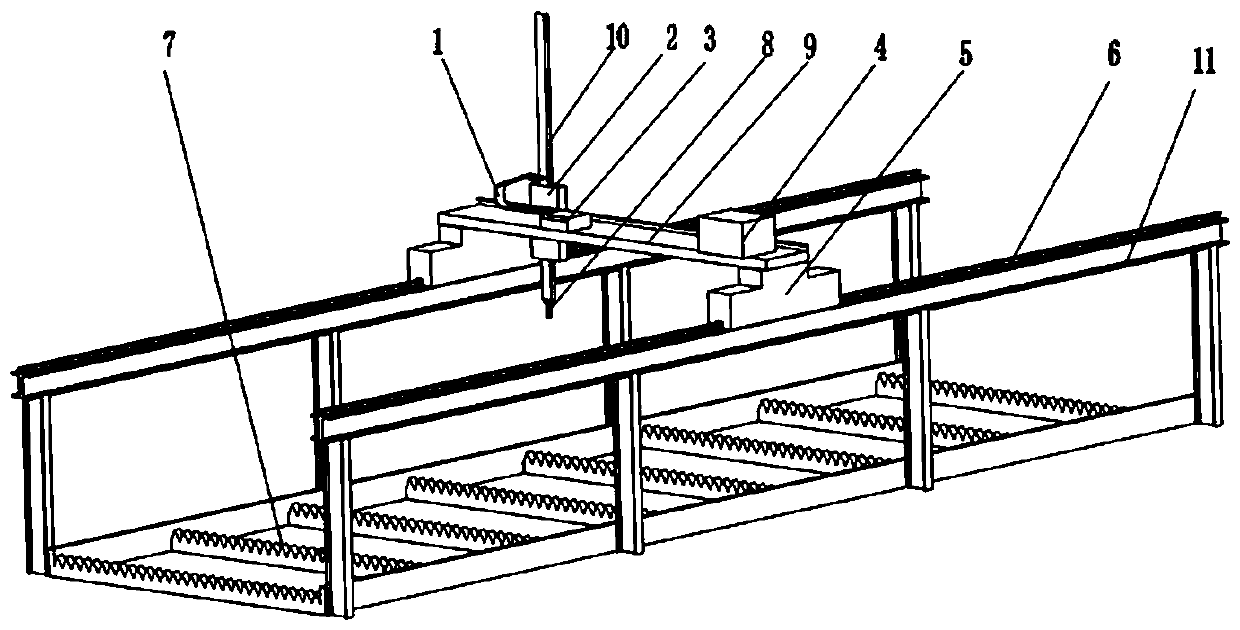

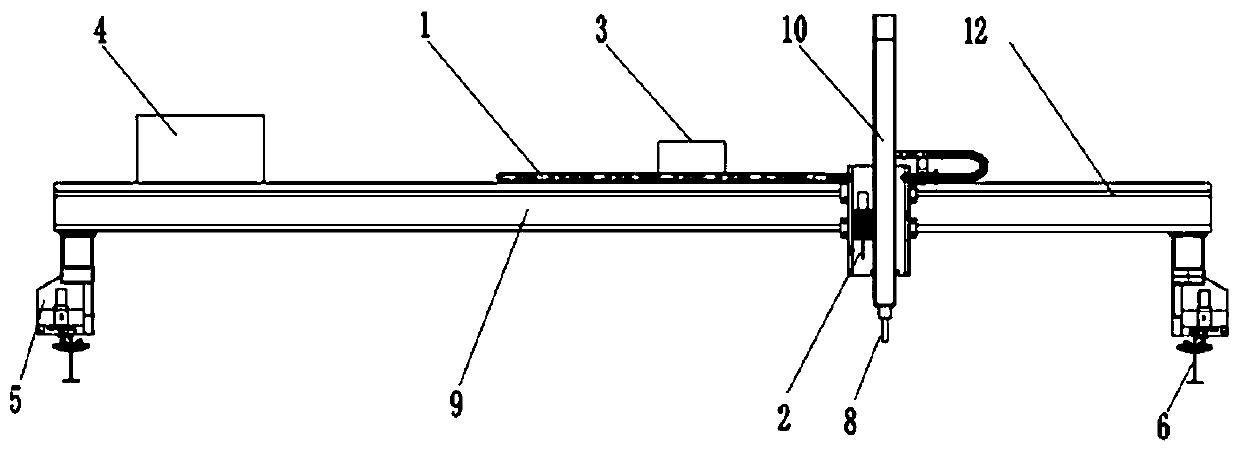

[0035] The present invention will be described in detail below in conjunction with the accompanying drawings and embodiments.

[0036] Such as Figure 1 to Figure 2 As shown, the present invention discloses an automatic cleaning device for a converter inclined plate sedimentation tank, which includes a vehicle frame 11, which is installed at the left and right ends of the sedimentation tank 7, and a longitudinal walking mechanism 5 is slidably connected to the vehicle frame 11. A transverse traveling mechanism 2 is arranged between the longitudinal traveling mechanisms 5, and a spray gun ascending and descending mechanism 10 is installed on the transverse traveling mechanism 2, and the spray gun ascending and descending mechanism 10 is equipped with a spray gun 8, and the longitudinal traveling mechanisms 5 are two sets and connected by symmetrical sliding On the longitudinal guide rail 6 assembled on the vehicle frame 11, the longitudinal guide rail 6 is I-shaped, the longitu...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com