Automatic deviation-rectifying method and device for band steel uncoiling

An automatic deviation correction and steel coil technology, applied in the field of cold-rolled steel, can solve the problems of strip steel tearing, limited deviation-correcting ability, and rubbing equipment, etc., and achieve the effects of stable production, simple structure, and convenient installation.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Example Embodiment

[0024] Example 1

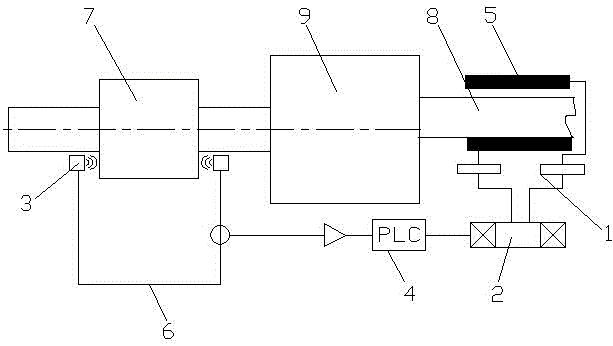

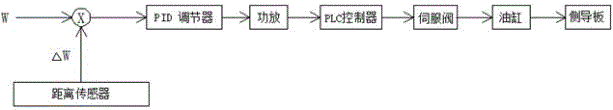

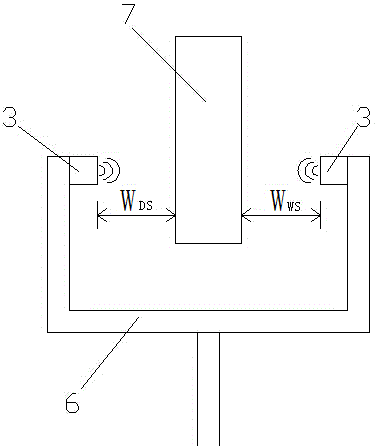

[0025] like figure 1 , 2 As shown, an automatic deviation correction device for uncoiling of strip steel includes a moving oil cylinder 1, a servo valve 2, a pair of distance sensors 3, a PLC controller 4 and a side guide plate 5, and the pair of distance sensors 3 are installed on the steel plate through a bracket 6. On both sides of the coil 7, the steel coil 7 is uncoiled by the uncoiler 9, and the strip steel 8 passes through the side guide plate 5, and the moving oil cylinder 1 drives the side guide plate 5 to move along the width direction of the strip steel 8; the servo valve 2 controls the connection In the moving cylinder 1, the distance sensor 3 is electrically connected to the input end of the PLC controller 4, and the PLC controller 4 is connected to the servo valve 2 under control. In this embodiment, the distance sensor 3 is an ultrasonic distance sensor. A pair of distance sensors 3 detect the distance between the two sides of the steel coil...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com