Flexible strip processing line suitable for producing various high-strength steel

A high-strength steel and processing line technology, applied in the direction of heat treatment furnace, heat treatment equipment, process efficiency improvement, etc., can solve the problem of inability to produce high-strength grade hot-dip galvanized and plated alloyed hot-dip galvanized sheets, affecting the surface quality of cold-rolled sheets Normal operation, poor surface quality of high-strength cold-rolled sheets, etc., to achieve the effect of rich product variety, low alloy content and low production cost

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

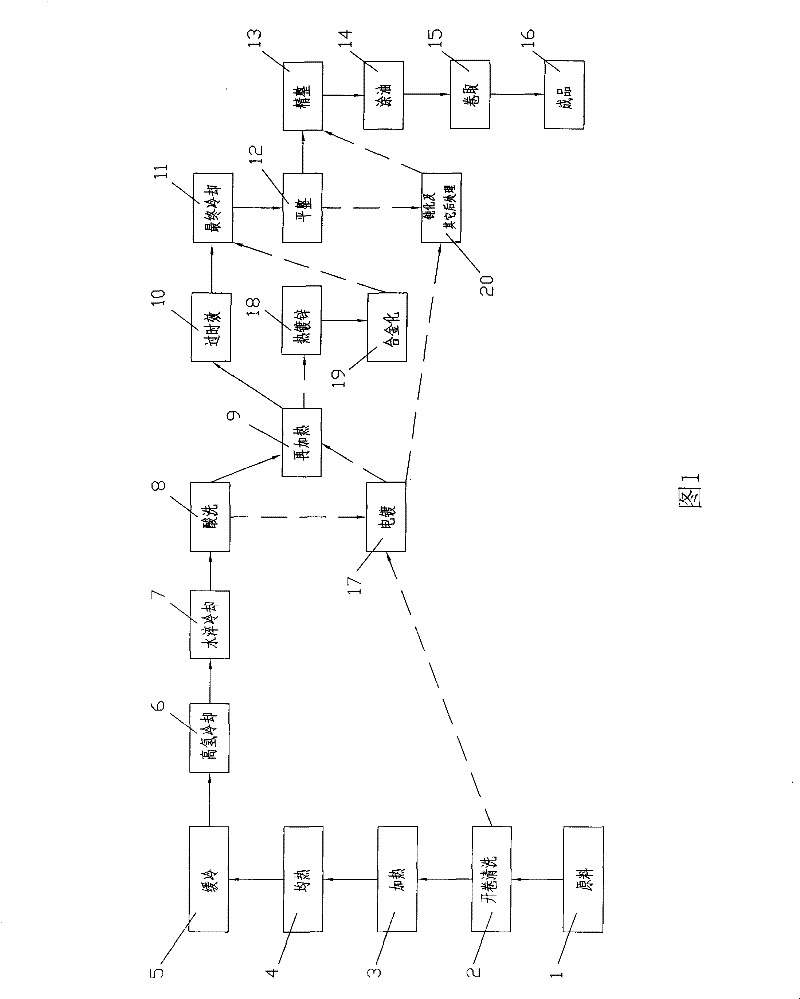

[0052] see figure 1 , the process route of this embodiment is, raw material 1-uncoiling cleaning 2-heating 3-soaking 4-slow cooling 5-jet cooling 6 (high hydrogen jet cooling)-overaging 10-final cooling 11-leveling 12-finishing 13 - Oiling and post-processing 14 - Coiling 15 - Finished product 16.

[0053] The process of the present invention can produce general cold-rolled plate and high-strength steel cold-rolled plate strengthened by phase transformation, and is especially suitable for producing cold-rolled TRIP steel and DP steel below 80 kg level, and for producing cold-rolled 80 kg-level TRIP steel and 80-kg level DP steel The process parameters are shown in Table 1. As can be seen in Table 1, for TRIP steel, it is important to control the soaking temperature, aging temperature and time of its continuous annealing, and the requirement for rapid cooling rate is not high; for high-strength DP steel, its continuous annealing The key process control parameters are soaking ...

Embodiment 2

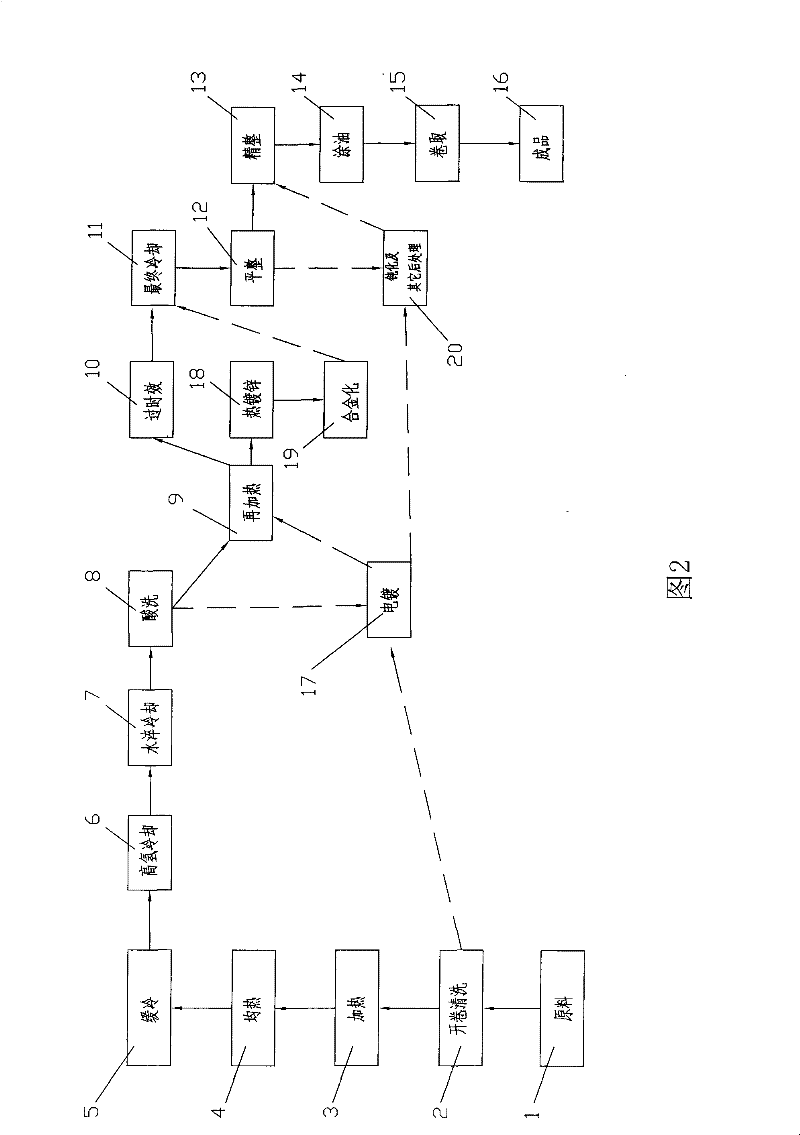

[0058] see figure 2 , the process route of this embodiment is, raw material 1-uncoiling cleaning 2-heating 3-soaking 4-slow cooling 5-jet cooling 6 (high hydrogen jet cooling)-reheating 9-overaging 10-final cooling 11-levelling 12 -finishing 13-oiling and post-processing 14-coiling 15-finished product 16.

[0059] Compared with Example 1, the process of the present invention can realize the overaging process of first low temperature and then high temperature. This process can use low-carbon aluminum-killed steel to produce mild steel products with excellent aging resistance, and produce low-carbon aluminum with excellent aging resistance. The process parameters of killed mild steel products are shown in Table 2. As can be seen in Table 2, in order to produce low-carbon aluminum-killed steel with excellent aging resistance, it is important to control the soaking temperature and aging process of its continuous annealing. High-temperature overaging process, the processing line...

Embodiment 3

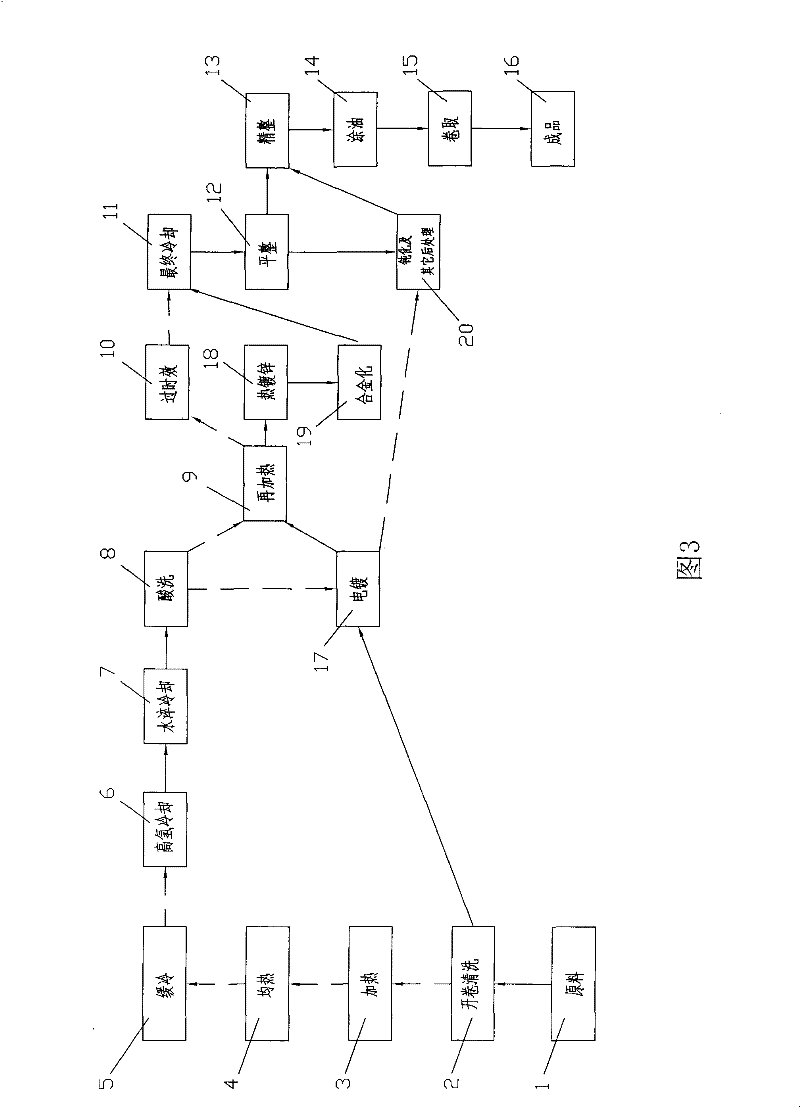

[0066] see image 3 The process route of this embodiment is, raw material 1-uncoiling cleaning 2-electroplating 17 (electroplating Fe or Ni)-reheating 9-hot-dip galvanizing 18-alloying 19-final cooling 11-leveling 12-passivation (or including coating oil) and post-processing 20-finishing 13-oiling and post-processing 14-coiling 15-finished product 16.

[0067]The process of this embodiment uses high-strength or ultra-high-strength hot-rolled pickled plates (such as hot-rolled high-strength steel) as raw materials, and by electroplating a layer of extremely thin Ni, Fe and other elements on the surface, the high-strength steel can be improved by hot-dip galvanizing. properties, and then heated to 450 ~ 550 ℃, into the zinc pot hot-dip galvanized (or alloyed with the coating), after cooling into post-processing such as leveling. Due to the short reheating galvanizing time (within one minute), the strengthening phase decomposition can be greatly reduced or even avoided, so that ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com