Method for evaluating conditions of blast furnace

An evaluation method and technology of blast furnace conditions, applied in the direction of comprehensive factory control, comprehensive factory control, electrical program control, etc., can solve the problems of difficult evaluation methods, single application range, and inability to promote, and achieve simple and reliable methods, good effects, Effect of reducing energy consumption

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0017] The present invention will be described in further detail below in conjunction with the accompanying drawings.

[0018] A method for evaluating blast furnace condition of the present invention comprises the following steps:

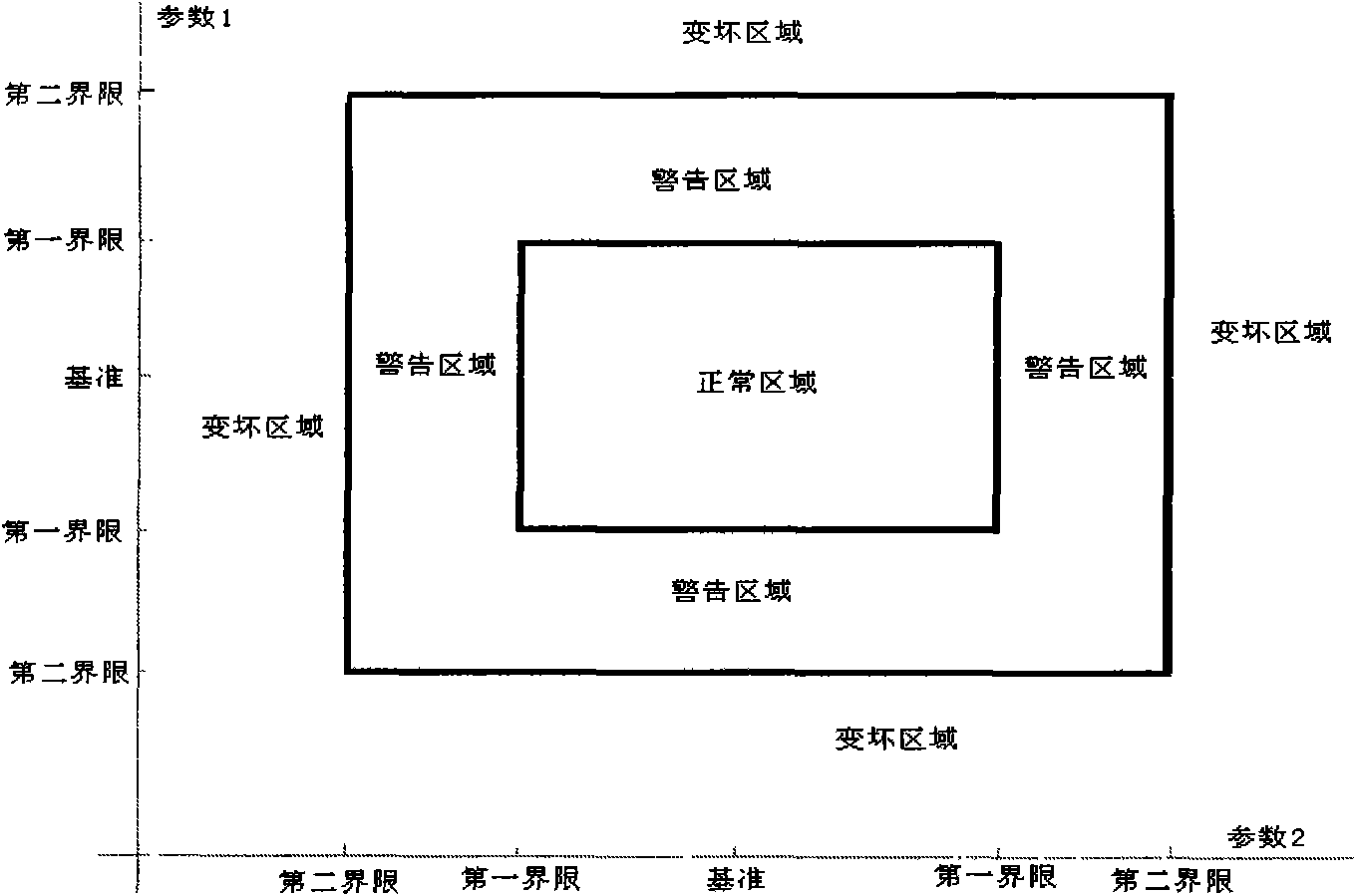

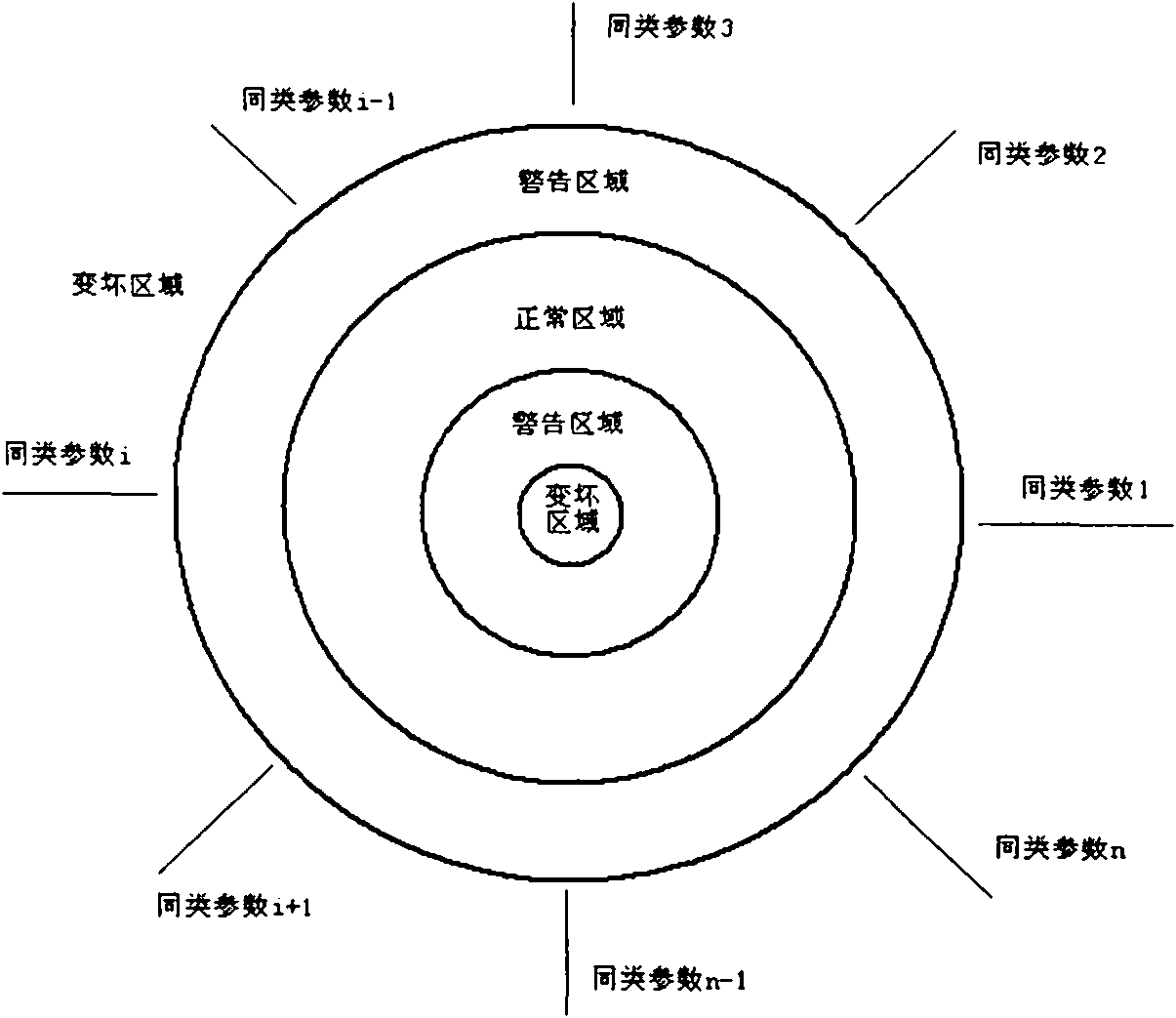

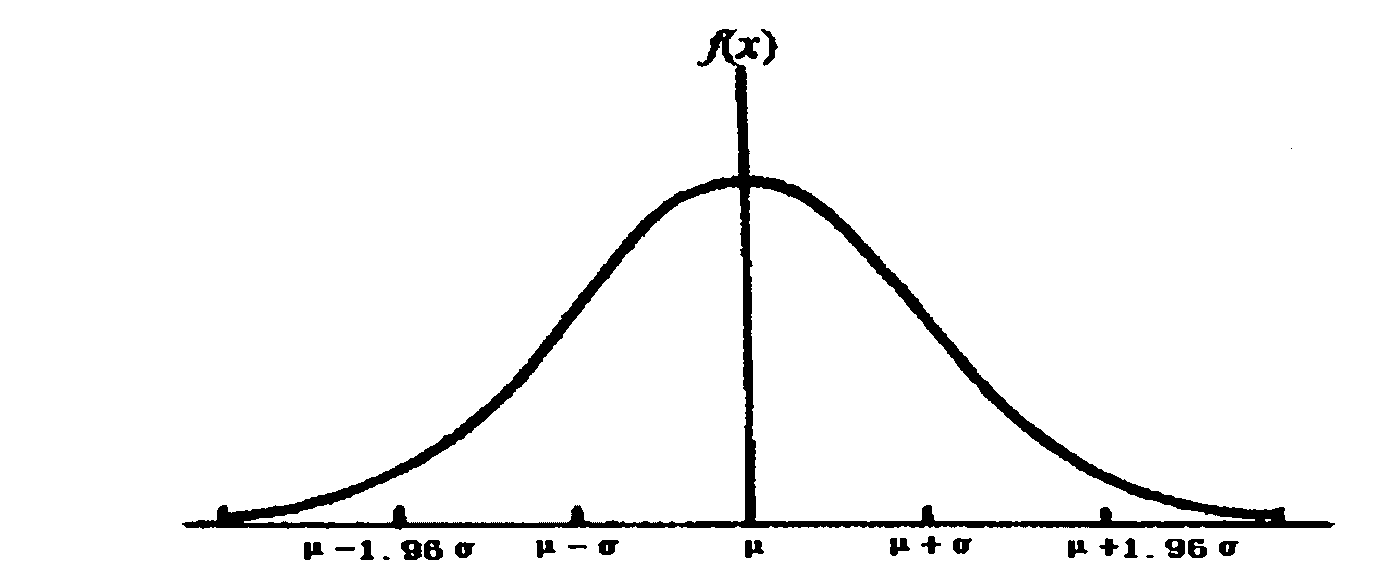

[0019] 1) The short-term, medium-term and long-term work will represent the eight main aspects of blast furnace production, including heat state, air supply fluctuation, gas flow distribution, air flow fluctuation, hearth state, slag shedding, probe and sliding material, and material speed. The status is evaluated on the basis of two different types of production parameters related to it or a variety of similar parameters related to it. The parameters and time of various aspects are determined as follows:

[0020] (1) Thermal state evaluation takes the theoretical combustion temperature of the current tuyere and the silicon content of the current molten iron as the short-term evaluation, the theoretical combustion temperature of the previous hour a...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com