Patents

Literature

Hiro is an intelligent assistant for R&D personnel, combined with Patent DNA, to facilitate innovative research.

710results about How to "Does not affect production" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

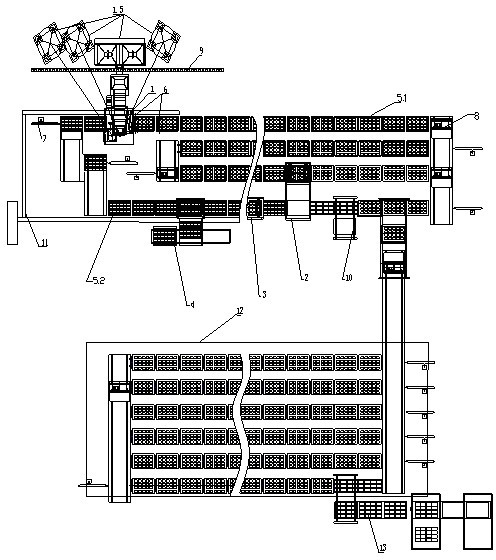

Production line for self-insulation building blocks

InactiveCN102555052AReduce occupancyReduce consumptionDischarging arrangementCeramic shaping plantsProduction lineBrick

The invention relates to a tool used in an insulation brick manufacturing process, in particular to a production line for self-insulation building blocks, which comprises a stirring machine. The production line is characterized in that automatic metering devices are arranged on a feeding port and at the bottom of the stirring machine, a production track capable of automatically conveying molds isdisposed below a distributing port of the stirring machine, a stripper is further arranged on the production track and is spaced from the stirring machine by a proper distance, a return track and a track leading into a maintenance area are respectively disposed on two sides of the other end of the stripper, the return track sequentially penetrates through a cleaning area, an oil injection area and a core setting area, a link plate machine is arranged at the other end of the maintenance area, and a manipulator is disposed at the other end of the link plate machine. The production line is high in production efficiency and annual yield, occupied land area and workshop investment are reduced, operating expense is saved, and the production line can operate continuously.

Owner:张建兴

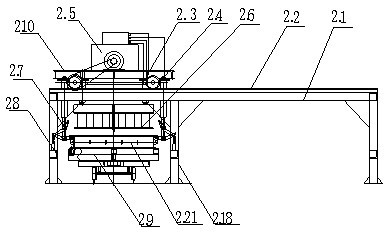

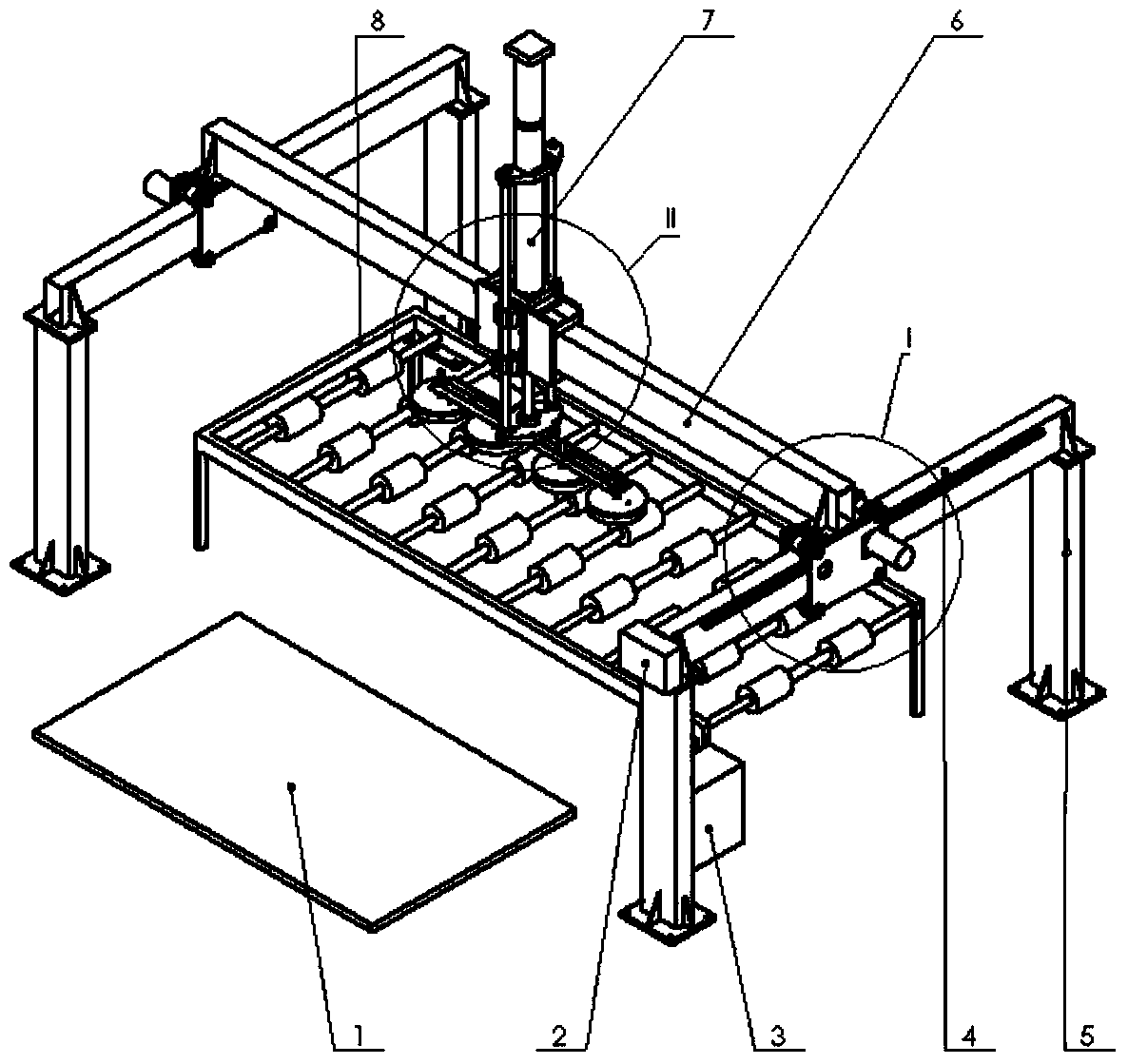

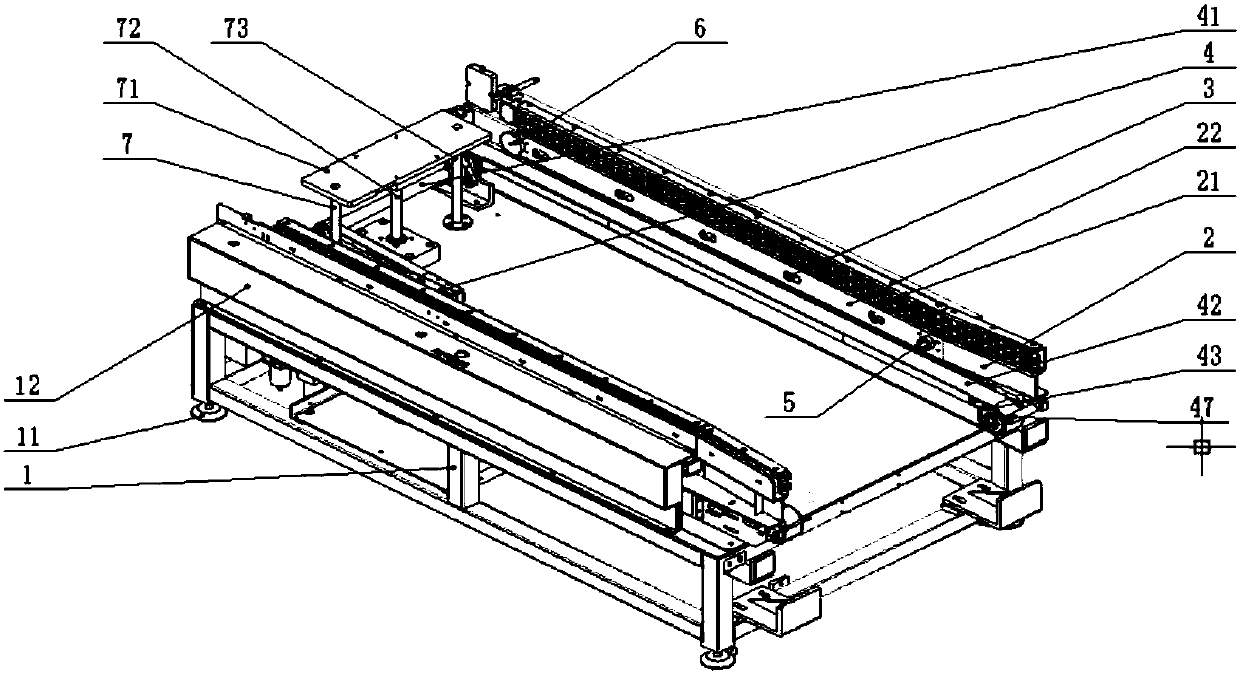

Device and method for automatic feeding and discharging of stone slabs

ActiveCN104176498ARealize automatic crawlingAchieve horizontal movementGrinding machine componentsConveyor partsMechanical engineeringTransverse beam

Owner:RIZHAO HEIN SAW

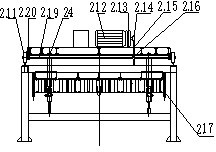

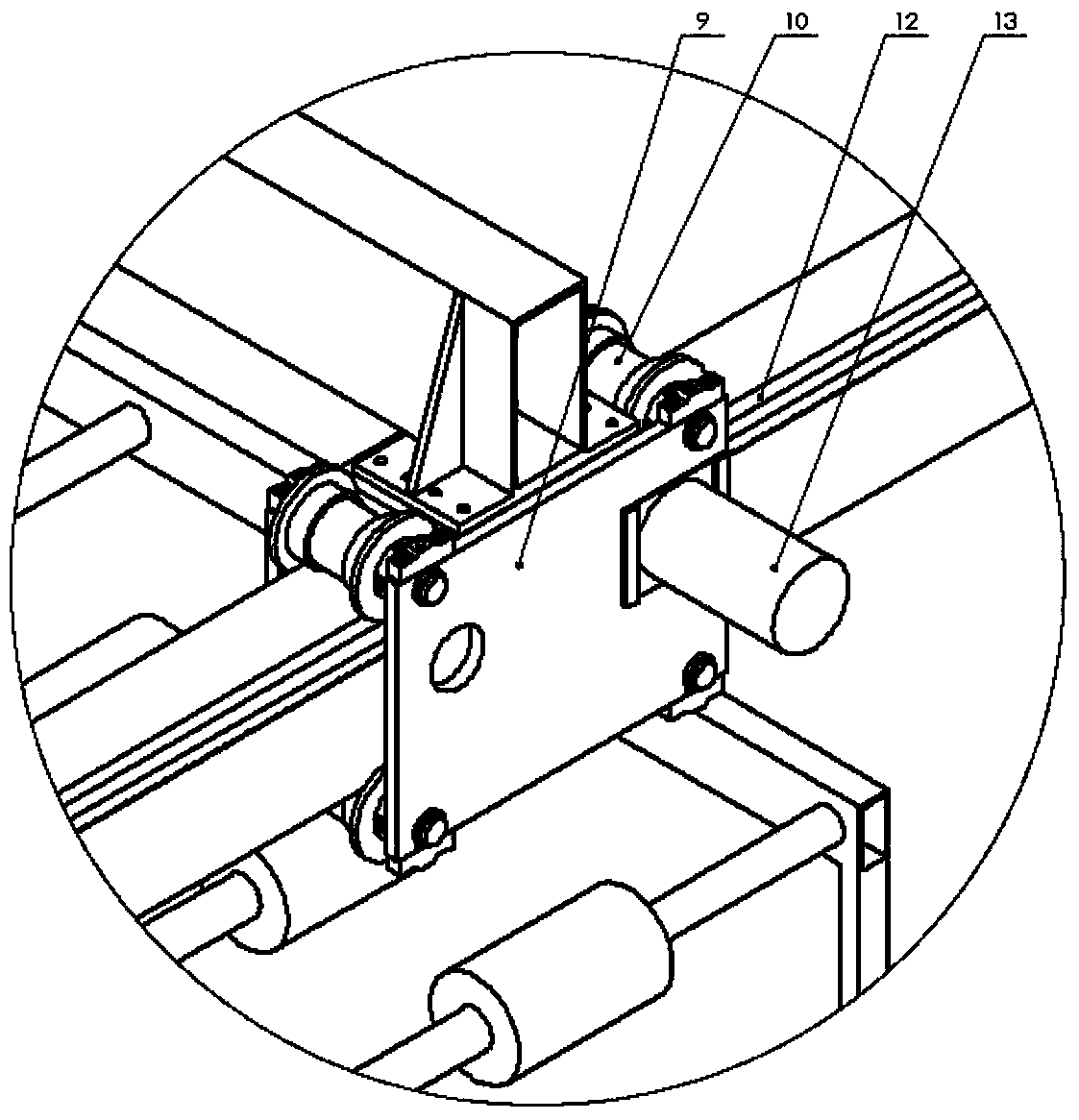

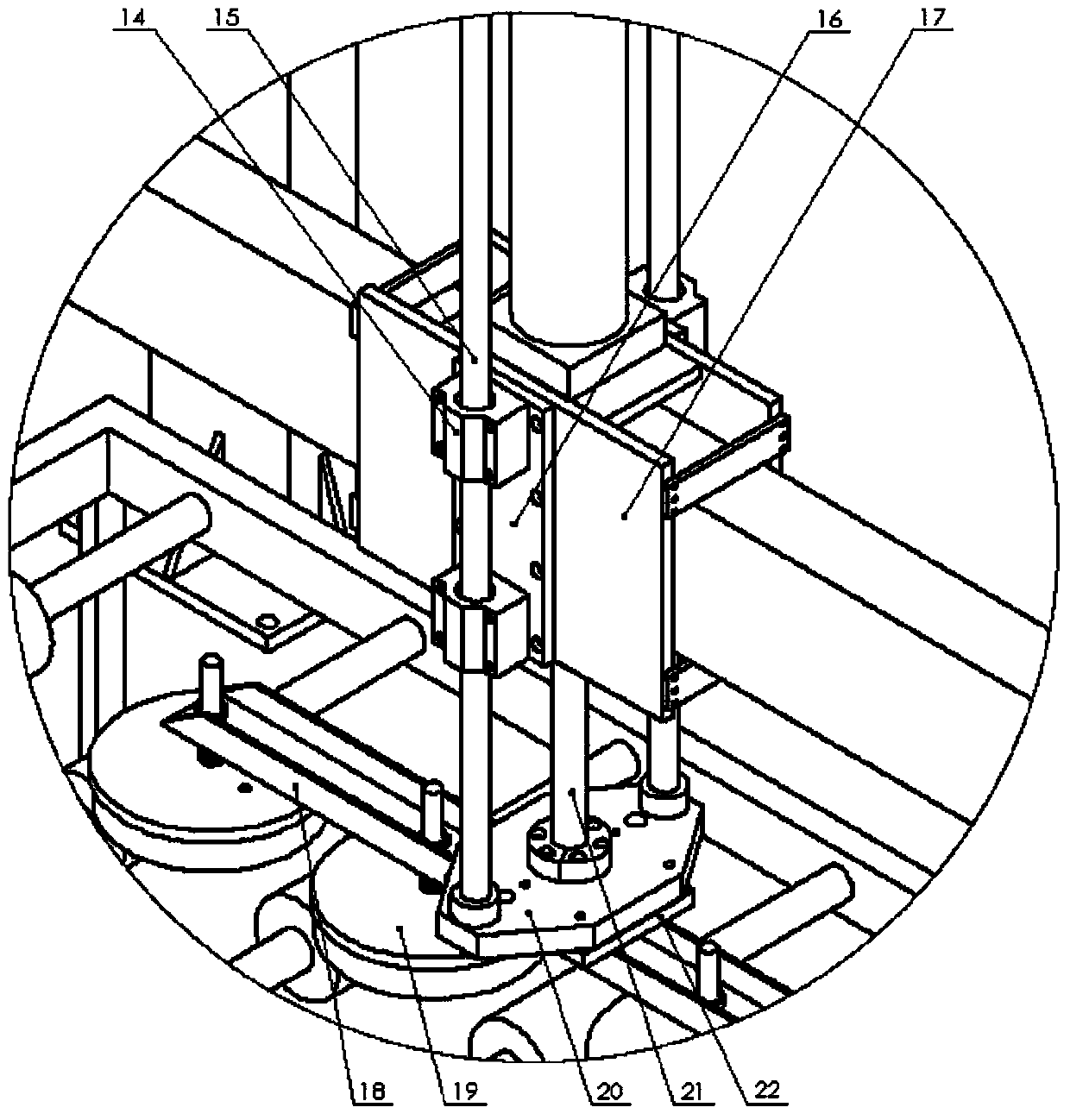

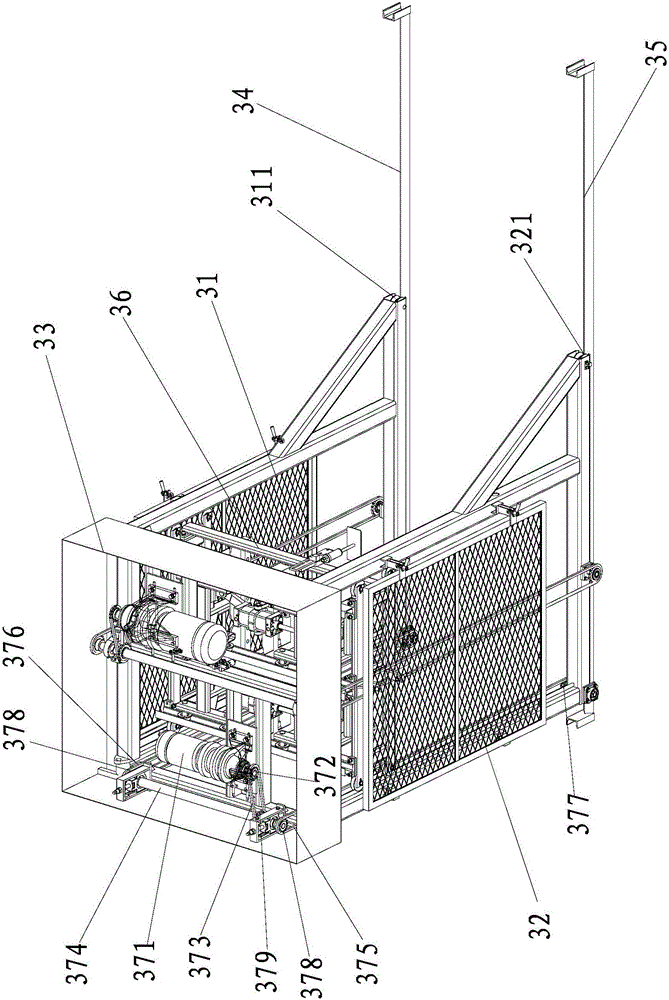

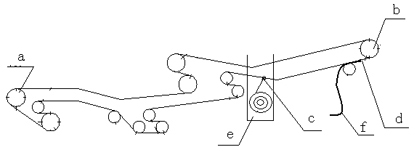

Automatic offline stacking production line

ActiveCN105947686AArrangement requirements are simpleDoes not affect productionStacking articlesProduction lineBrickwork

The invention provides an automatic offline stacking production line. The automatic offline stacking production line comprises a first conveying line, a second conveying line, clamping board devices, a third conveying line, a first brick pushing mechanism, a first brick placing board, a second brick placing board, a second brick pushing mechanism, a fourth conveying line and a stacking device, wherein the first conveying line conveys a whole stack of board bricks; the second conveying line conveys single board bricks; the clamping board devices are positioned at the first conveying line and the second conveying line and are used for clamping and releasing the single board bricks; the third conveying line is connected with the second conveying line and supporting boards are stacked on the third conveying line and are conveyed by the third conveying line; the first brick pushing mechanism is positioned at the second conveying line and separates brick bodies from the supporting boards; the first brick placing board is used for collecting the brick bodies of the first brick pushing mechanism; the second brick placing board is positioned beside the first brick placing board and is used for collecting the brick bodies on the first brick placing board; the second brick pushing mechanism is positioned at the second brick placing board; the fourth conveying line is positioned on one side of the second brick placing board and conveys a stack of brick bodies out; and the stacking device clamps the brick bodies from the second brick placing board and places the brick bodies on the fourth conveying line. Compared with the prior art, the automatic offline stacking production line has the advantages that a whole technological process is not associated with a brickwork production line, offline stacking and assembling stacking are realized, brick stacks with various sizes can be stacked, the application range is wide, and the production efficiency is high.

Owner:FUJIAN QUNFENG MACHINERY

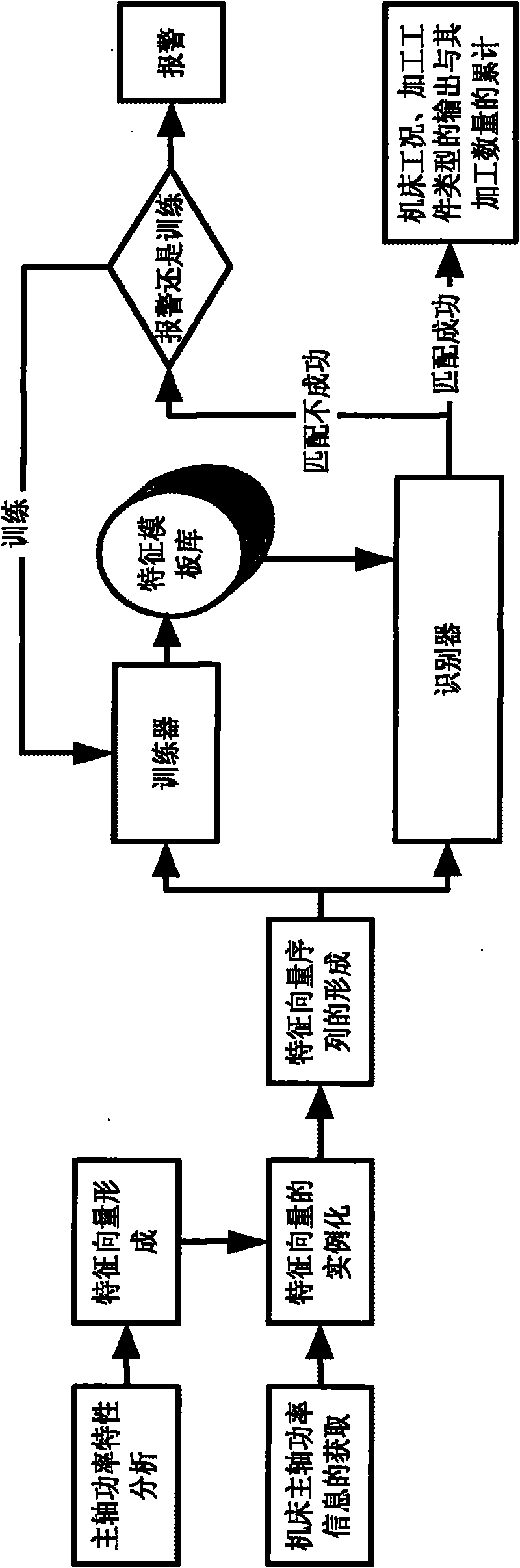

Method for automatically identifying and monitoring on-line machined workpieces of numerical control machine tool

InactiveCN101710235AGet simple and reliableEasy to installProgramme controlComputer controlFeature vectorNumerical control

The invention discloses a method for automatically identifying and machining and monitoring on-line machined workpieces of a numerical control machine tool, which comprises the steps that: firstly, the possible spindle machining power information when different on-line workpieces are machined is subjected to the processes of the selection of machining feature vectors, the formation of a feature template sequence, time warping, the calculation of matching distance, the clustering of the distance and the like to form a multi-workpiece characteristic template base; when the workpeices are machined, the acquired workpiece real-time machining power information is processed to form a feature vector sequence; the sequence is subjected to processing of the time warping, the calculation of the matching distance and the like with templates in the characteristic template base; and the type of the machined workpieces can be judged and the machining number is accumulated or the machining parameters of the machining process are monitored according to the matching distance and a set threshold value.

Owner:CHONGQING UNIV

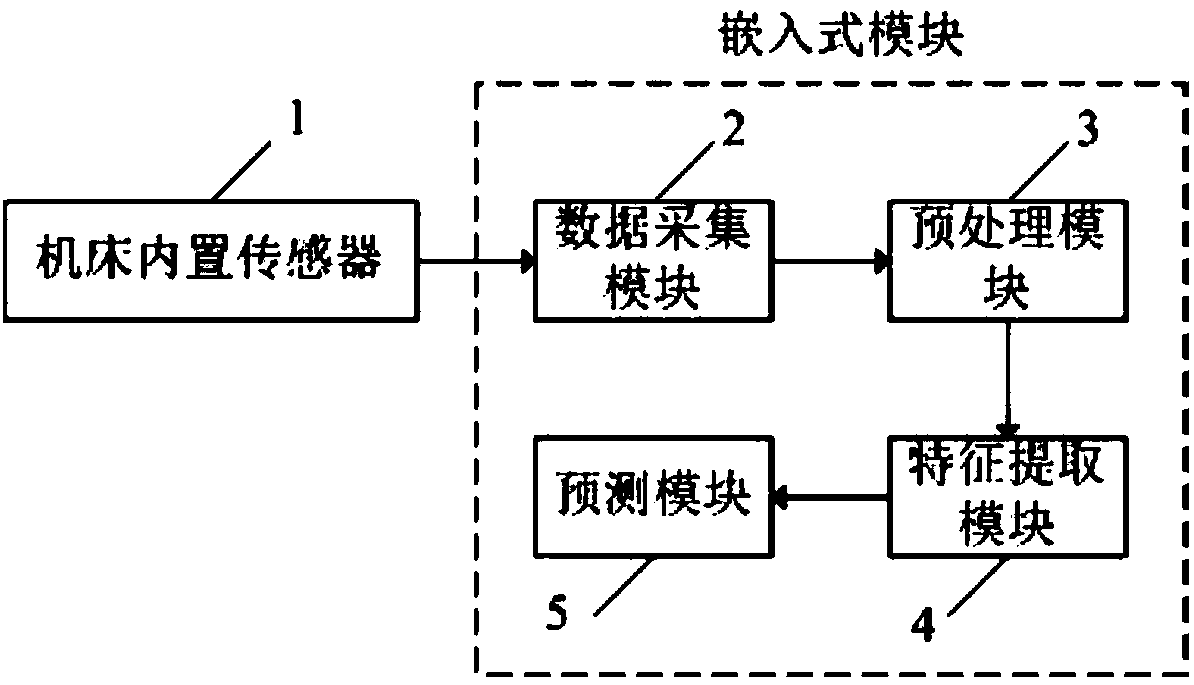

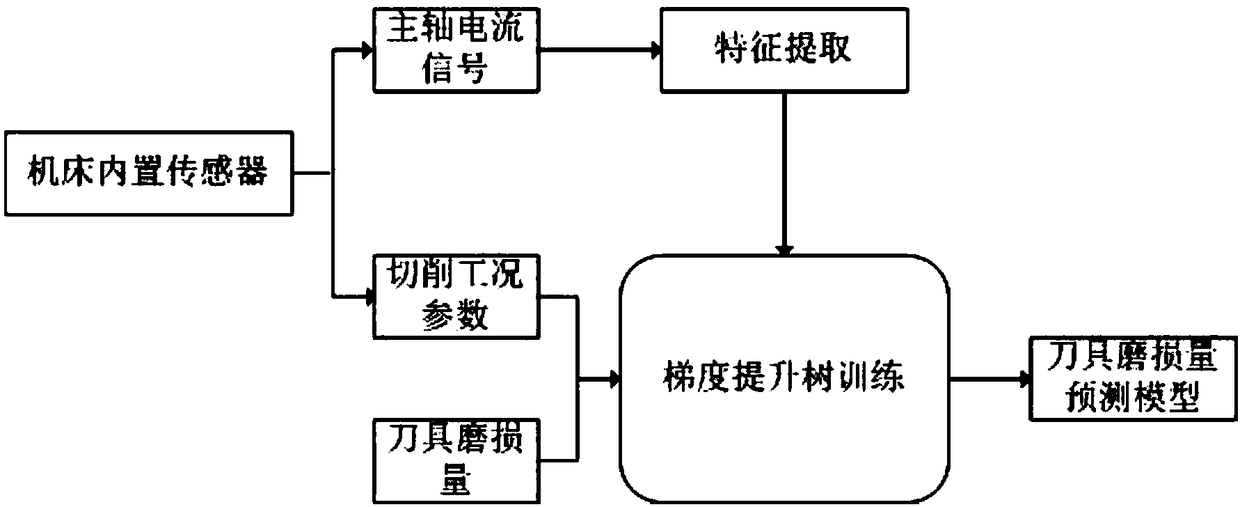

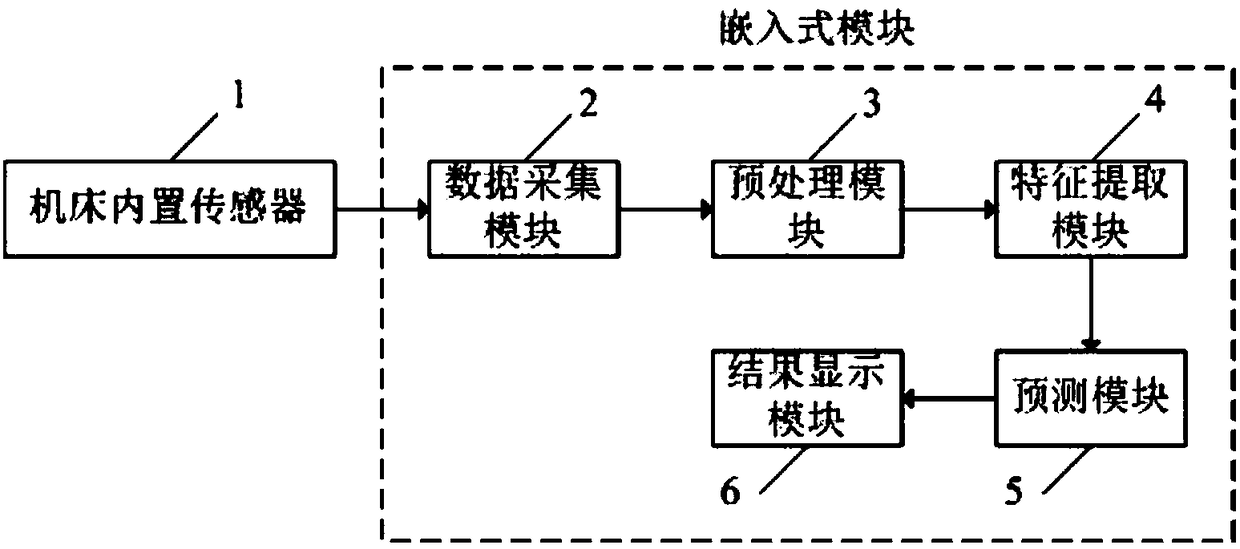

Prediction system and method for life of machine tool cutter

InactiveCN108536938AEasy to operateEasy to installDesign optimisation/simulationSpecial data processing applicationsPower flowFeature extraction

The invention discloses a prediction system and method for the life of a machine tool cutter. The prediction system comprises a built-in machine tool sensor, a data acquisition module, a preprocessingmodule, a feature extraction module, and a prediction module, wherein the built-in machine tool sensor is connected to the data acquisition module, the data acquisition module is connected to the preprocessing module, the preprocessing module is connected to the feature extraction module, and the feature extraction module is connected to the prediction module. The method comprises the following steps: a spindle current signal and cutting condition parameter of a machine tool are measured; the spindle current signal and the cutting condition parameter are acquired; the spindle current signal is preprocessed; a feature value is extracted from the preprocessed spindle current signal; and according to the spindle current signal feature value and the cutting condition parameter, the remainingservice life of a cutter is predicted. The prediction system and method for the life of the machine tool cutter disclosed by the invention can obtain a relatively good prediction result with lower cost under the condition of not affecting production.

Owner:SHANGHAI JIAO TONG UNIV

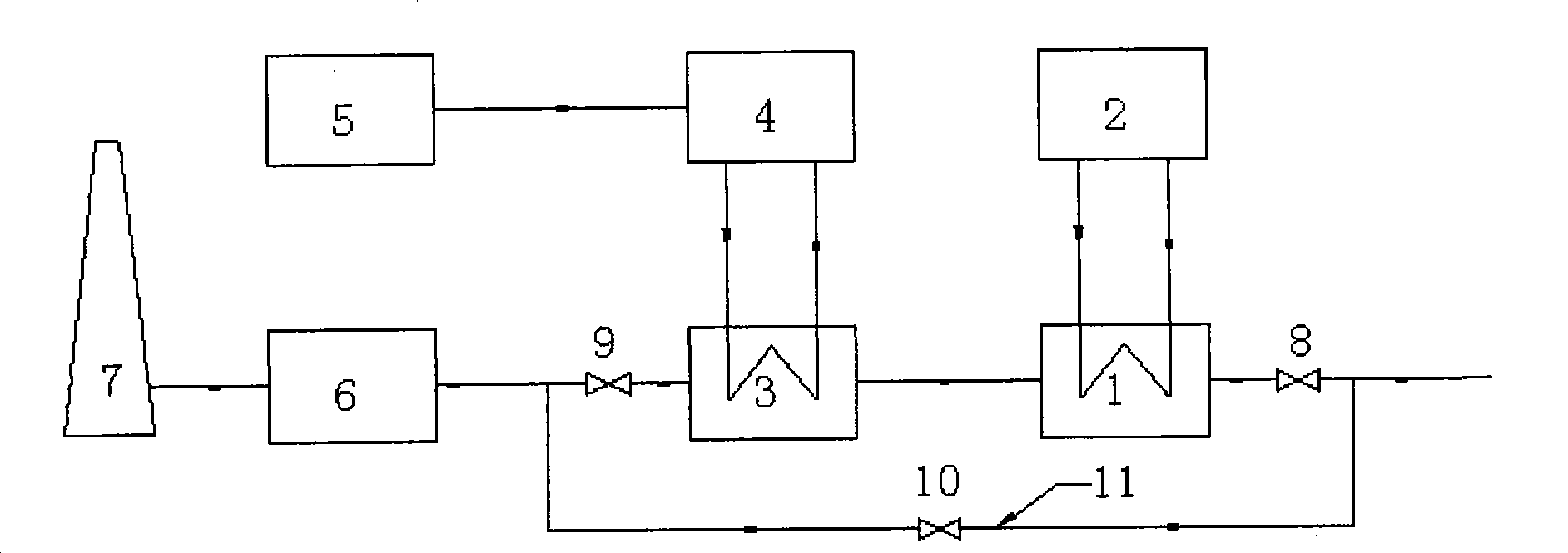

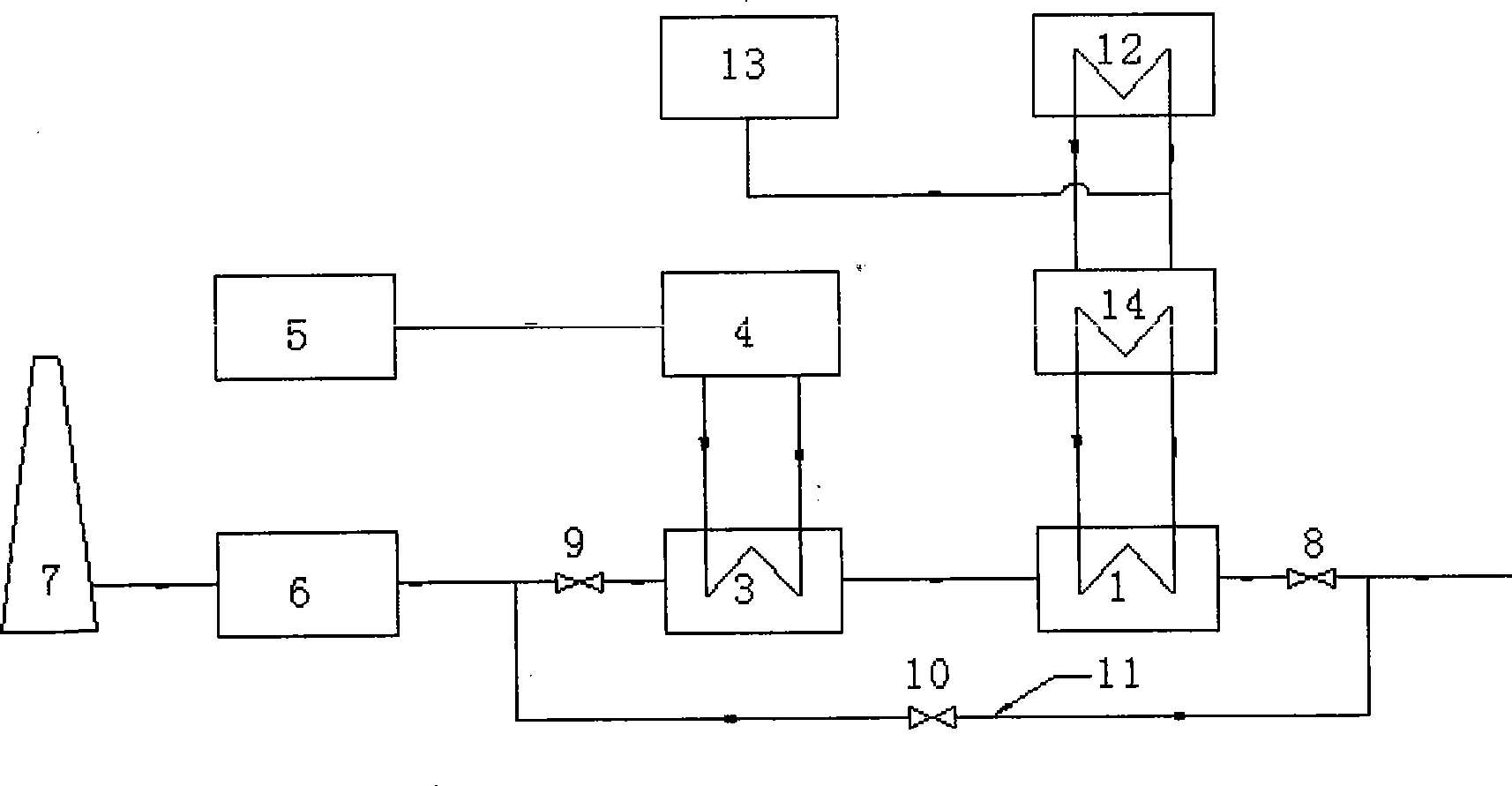

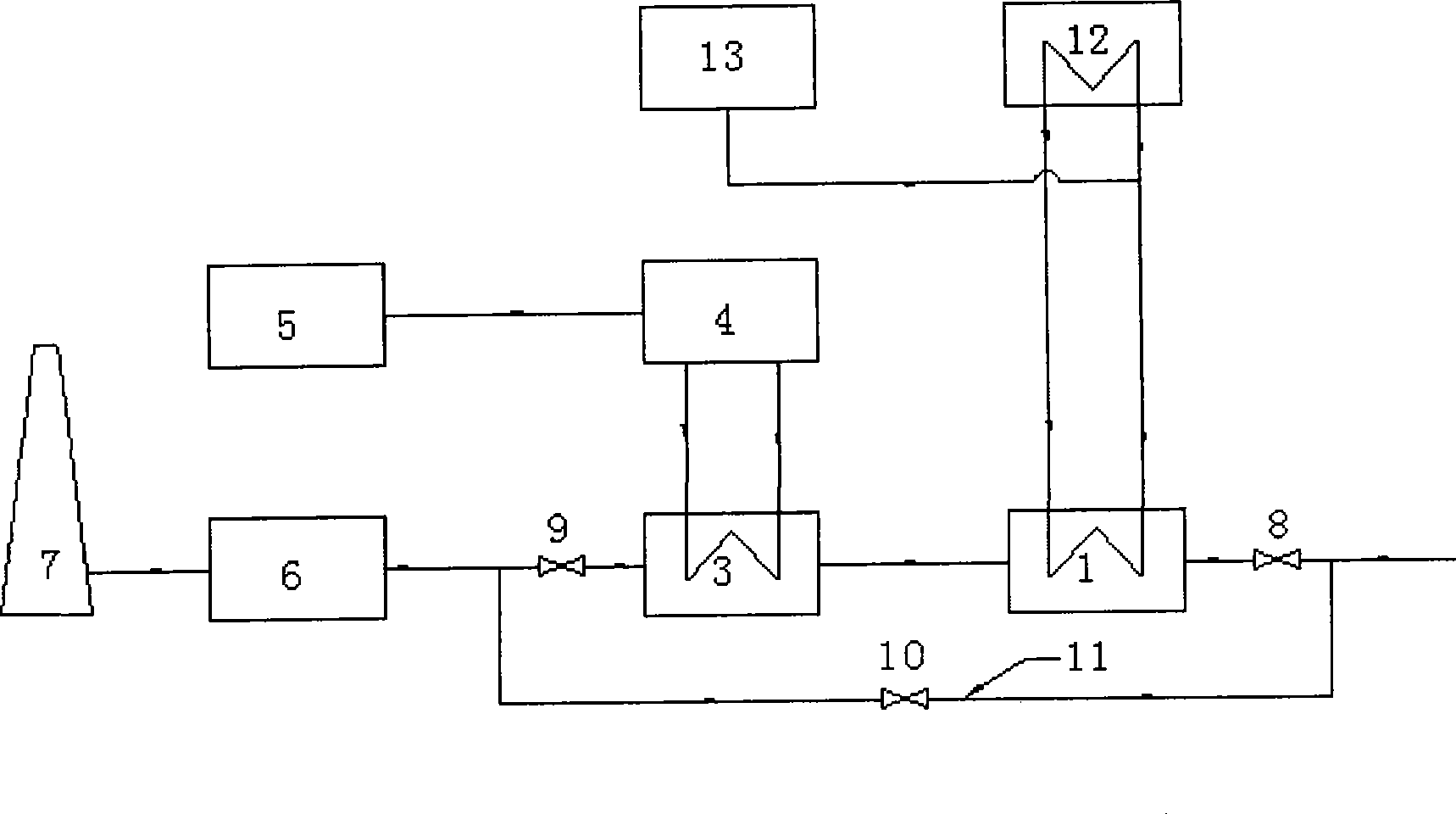

System and method for utilizing residual heat of electrolyzer low temperature flue gas

ActiveCN101435089AImprove work efficiencyMeet different needsHeat recovery systemsIncreasing energy efficiencySocial benefitsElectrolysis

The invention discloses a system and a method for utilizing low-temperature flue gas afterheat of an electrolytic bath. The system mainly comprises a heating system, a cooling system, a dust collecting device and a fume extractor, and utilizes energy cascade utilization, low-temperature afterheat recovery and a heat exchanger to absorb heat by classification from low-grade flue gas for cooling, heating and heat using of technological process. The method includes the following steps: when the low-temperature flue gas afterheat of the electrolytic bath passes through the heat exchanger, the heat exchanger is used for absorbing the heat in the flue gas, and converting the absorbed heat into liquid or steam to utilize, the dust collecting device is used for collecting dust in the flue gas after heat release and temperature reduction, and then the flue gas after dust collection is exhausted by the fume extractor. The invention solves the problem of utilization of the low-temperature flue gas afterheat of the electrolytic bath, realizes continuous supply of cooling and heating, can improve the dust collecting system efficiency of the electrolytic bath, save energy, lower consumption, reduce pollutants discharge, expand utilization ways of afterheat and reduce the production cost of enterprises, and has remarkable economic, environmental and social benefits.

Owner:北京佰能电气技术有限公司

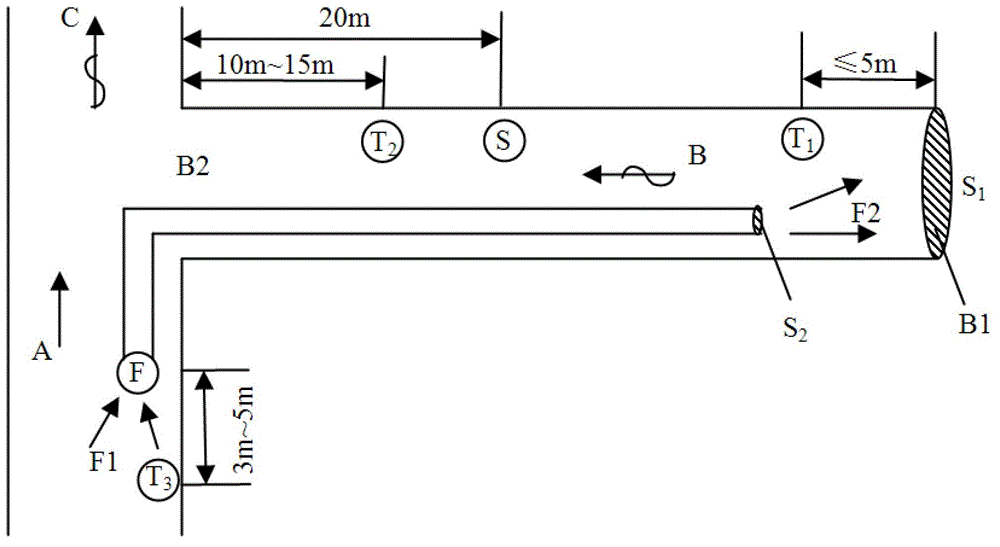

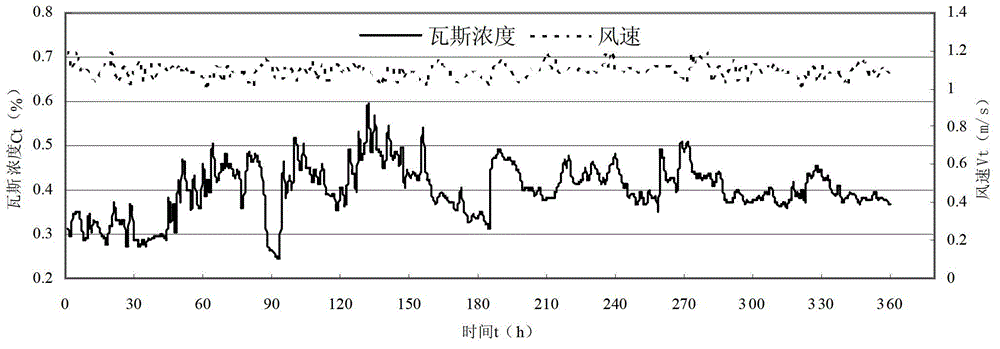

Method for analyzing coal and gas outburst risk in real time

InactiveCN102979579AReal-time continuous analysis of highlighted risksImprove forecast accuracyMining devicesMonitoring dataCoal

The invention relates to a method for analyzing coal and gas outburst risk in real time. The method comprises the steps of: first, arranging an air velocity sensor which is 20m far away from an outlet of an excavation roadway of a coal mine based on a current safety monitoring system of the coal mine; then, obtaining real time concentration of methane and real time air velocity of mixed air flow of a headwork face from monitoring data of the system; then, obtaining the sectional area of the headwork face and the cross sectional area of an air outlet of an hair dryer by consultation or measurement; then, calculating corresponding real time gas gushing amount per minute in the normal exploitation process according to the data; and finally, obtaining required data required according to the steps, and calculating coal and gas outburst risk analysis indexes with 15 days as a calculating period, wherein the outburst risk analysis indexes comprise crustal stress index id, gas pressure index ip, gas content index iw and coal desorption characteristic index ix.

Owner:TIANDI CHANGZHOU AUTOMATION +1

Method for producing gas fuel and byproduct cellulase by using biomass containing lignocellulose through fermentation

InactiveCN101544990ADoes not affect productionLow costMicroorganism based processesWaste based fuelGramPopulation

The invention discloses a method for producing a gas fuel and a byproduct cellulase by using a biomass containing lignocellulose through fermentation, which comprises the following steps: adding the biomass containing the lignocellulose subjected to sterilization treatment into a fermentation vessel to be used as a fermentation medium; inoculating microorganism capable of producing cellulase under anaerobic condition for anaerobic culture to make the activity of the cellulase in the fermentation vessel more than 1 IU / gram; hydrolyzing fermented substances, entering a digestion vessel and inoculating microbial population of methanogen and hydrogen-producing acetogen for anaerobic culture; and producing combustible gas by the fermentation vessel and the digestion vessel. The method converts various micromolecular organic substances such as acetic acid, glycerol, alcohol and the like generated by hydrolysate in the fermentation vessel into methane in the digestion vessel through microorganism fermentation with an energy conversion rate of more than 90 percent, so the method converts the biomass into the gas fuel, has high conversion rate and low energy consumption, and is an excellent technique for converting the biomass into the fuel.

Owner:UNIV OF SCI & TECH OF CHINA

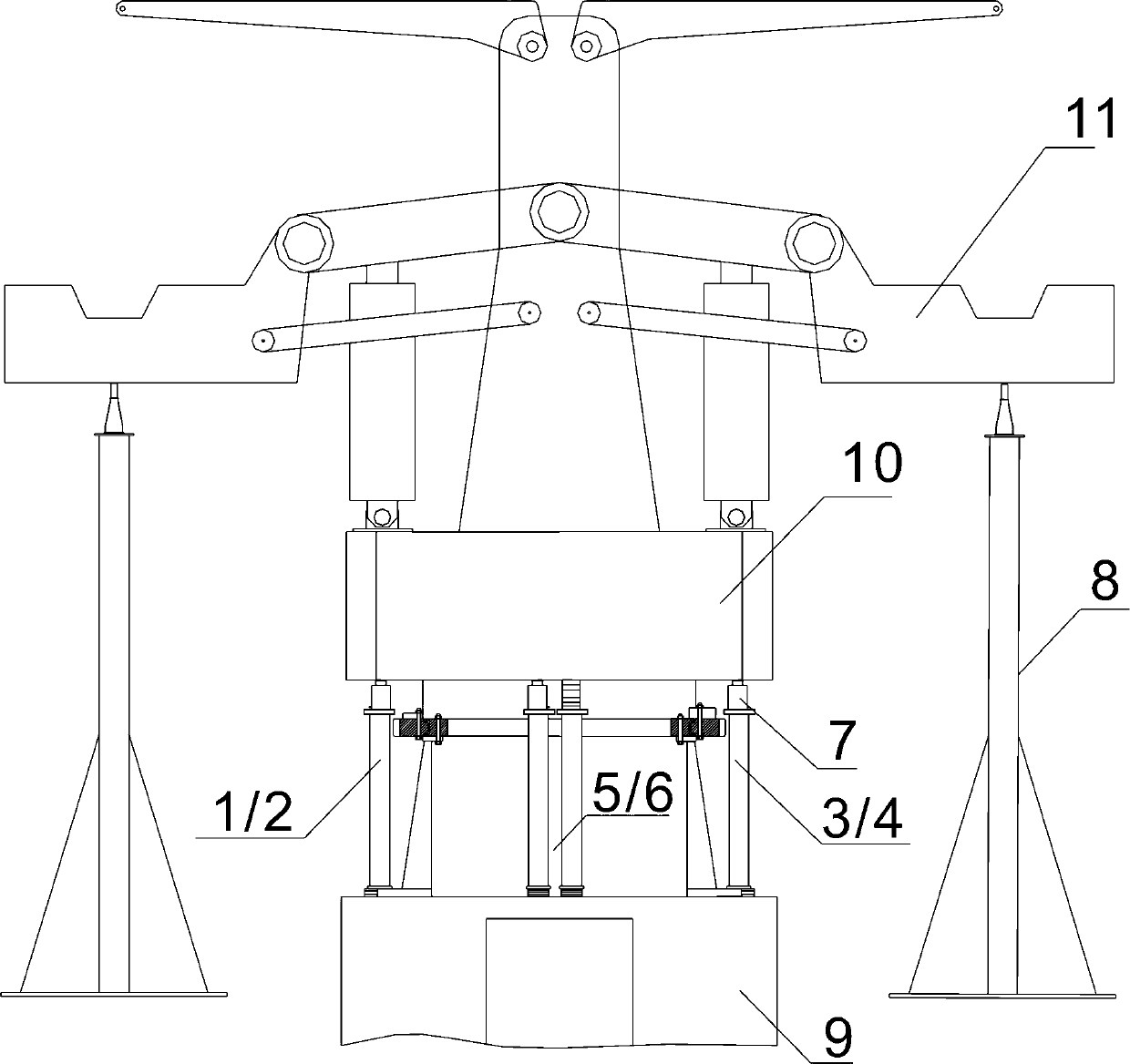

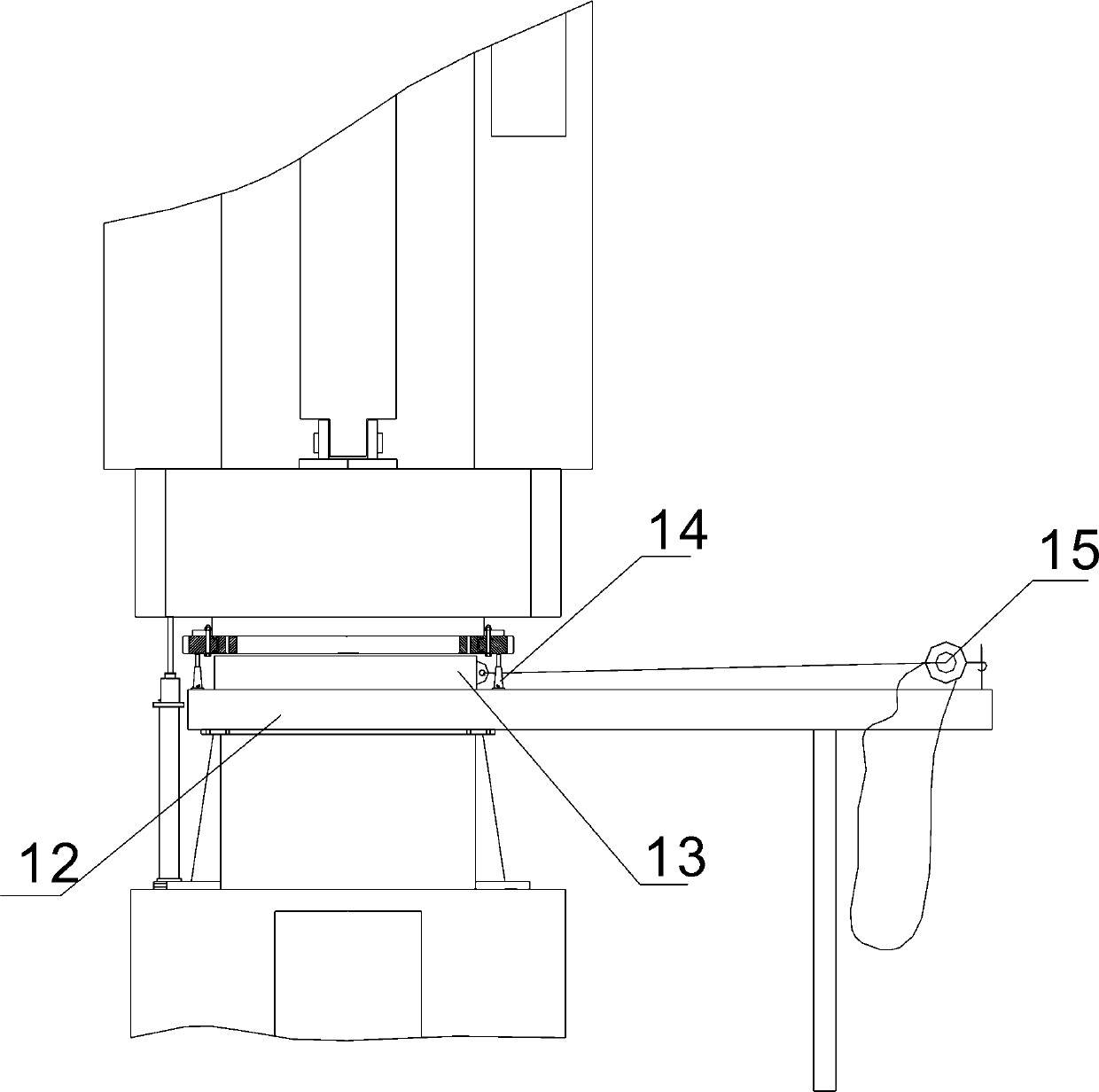

Method for installing converter in plug-in mode

InactiveCN101812564AEasy constructionStrong operabilityManufacturing convertersEngineeringPlant Structures

The invention relates to a method for installing a converter in a plug-in mode, in particular to a method for installing a converter body by matching a travelling crane with a hoist. The method comprises the following steps of: arranging the hoist and a hoisting point; installing a bearing base; hoisting a backing ring; installing a tilting mechanism; hoisting the converter body; regulating the converter body; and installing a supporting device. The invention does not need to demolish a finished plant structure, use a complex hoisting machine and increase the construction investment, reduces the operating cost of special machines and tools and the costs of materials, manufacture, installation, and the like of supporting devices, slideways and hoisting tools, thereby saving the cost; and in addition, the invention has short practical hoisting time and high operability, is suitable for improving and increasing the converter inside an old plant and is especially suitable for implement when the traditional integral installation method can not be used for construction due to a narrow construction field when the construction of the plant structure is finished or an old converter is improved without influencing the production of an owner.

Owner:CHINA FIRST METALLURGICAL GROUP

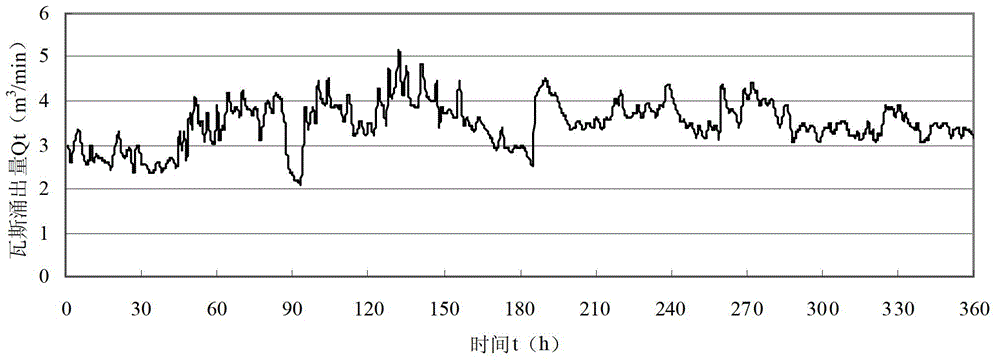

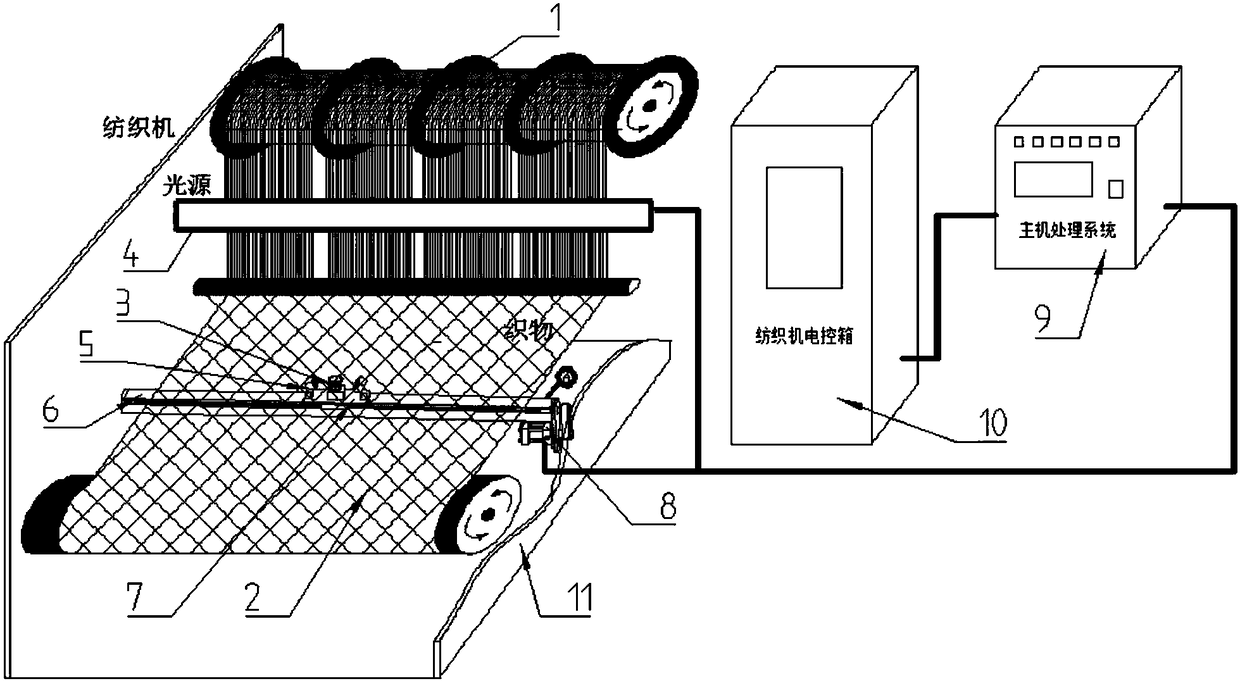

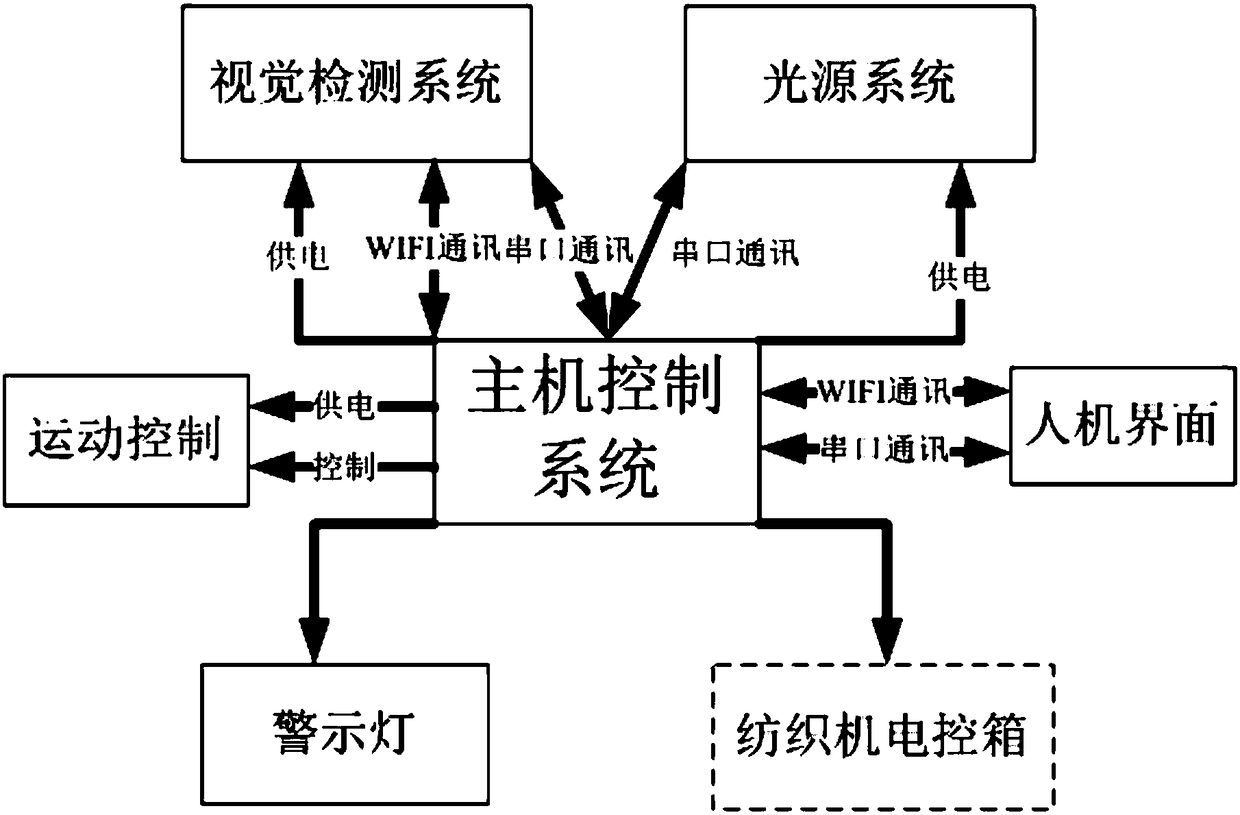

On-line fabric defect detection device for warp knitting machines

PendingCN108318496ABlemish characteristic responseImprove image qualityOptically investigating flaws/contaminationFailure rateControl system

The invention discloses an on-line fabric defect detection device for warp knitting machines, which comprises a support assembly, a camera assembly, light sources, and a host control system. The on-line fabric defect detection device for warp knitting machines is characterized in that the light sources are a first light source and a second light source, the first light source is located over a fabric on a warp knitting machine, the supporting assembly comprises a guide way and a drive device, the drive device can drive the second light source and the camera assembly to synchronously slide to and fro along the guide way, the second light source and the camera assembly are located under the fabric on the warp knitting machine, and while sliding to and fro along the guide way, the camera assembly can acquire the image of the fabric; because the adopted moving shooting technique can shorten object distance, imaging quality can be ensured, and a good detection effect can be achieved. Sincethe moving shooting technique is adopted, the number of cameras is reduced, the on-line fabric defect detection device for warp knitting machines is convenient and flexible to mount, the structure ofthe device is simplified, the failure rate is low, multi-angle shooting can be carried out, the detection rate is greatly increased in comparison with the detection rate of the prior art, the false detection rate is greatly decreased, the labor intensity of workers is decreased, and the quality of products is greatly increased.

Owner:HAINING CITY KEWEI IND ELECTRONICS SCI & TECH

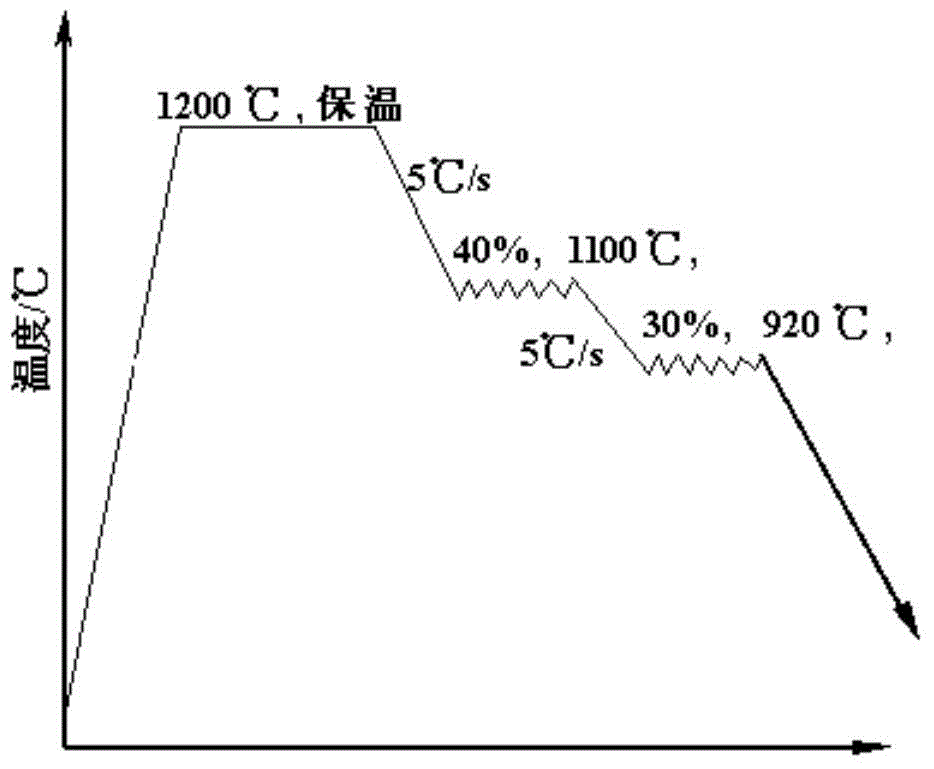

Production method for solving strip breakage of P-containing high-strength IF (Intermediate Frequency) hot rolling strip steel while withdrawal and straightening

ActiveCN103551382APerformance is not affectedLow costTemperature control deviceMetal rolling arrangementsTemperature controlIntermediate frequency

The invention provides a production method for solving strip breakage of a P-containing high-strength IF (Intermediate Frequency) hot rolling strip steel while withdrawal and straightening and relates to the technical field of steel rolling. In the hot-rolling process, a continuous casting sheet billet is heated by adopting a hot charging system, the hot-charging temperature is controlled to be 600-700DEG C, so that the segregation of an element P in the continuous casting process and the grain-boundary segregation of the element P in the cooling process of the sheet billet are avoided; the laminar flow cooling after finish rolling adopts a forepart intensive cooling mode and the cooling speed of strip steel is controlled to be 30-50DEG C / s; the coiling temperature is controlled to be 700+ / -10DEG C, so that the grain-boundary segregation of the element P is suppressed by high-temperature coiling. According to the production method for solving the strip breakage of the P-containing high-strength IF hot rolling strip steel while withdrawal and straightening, which is provided by the invention, under the conditions of not increasing the alloy cost, not influencing the production and not influencing the performances of the strip steel, the withdrawal and straightening and the strip breakage of the strip steel can be prevented by finely tuning the hot charging temperature, the coiling temperature, the cooling speed of the steel strip and other parameters in the rolling process. The method is simple and remarkable effects are realized.

Owner:SHOUGANG CORPORATION

Arc extinction brush and method for eliminating electric arc of power generator with this arc-extinction brush

InactiveCN101237108ADoes not affect productionNo need to shed loadRotary current collectorCurrent collector maintenanceIndiumSilver iodide

The present invention relates to an arc extinction brush, comprising a solid mixture brush body, wherein, the solid mixture brush body consists of a solid lubricant, wax, and a fast film formation substance; the solid lubricant is any of tin, lead, indium, cadmium, silver and oxides thereof; the fast film formation substance is any of molybdenum disulfide, tungsten disulfide, silver iodide, lithium carbonate, barium carbonate or sodium silicate. The present invention also comprises a method of using the arc extinction brush to eliminate electric arc of brushes for generators. The arc extinction brush is used to replace a brush to participate in motor operation and is matched with the operation of eliminating a bad oxide film, and after the arc extinction brush is repeatedly put into operation, the arc extinction brush can help form a good oxide film, so as to eliminate electric arc of brushes for generators and to reduce the sliding friction and self-vibration of brushes.

Owner:黄继林

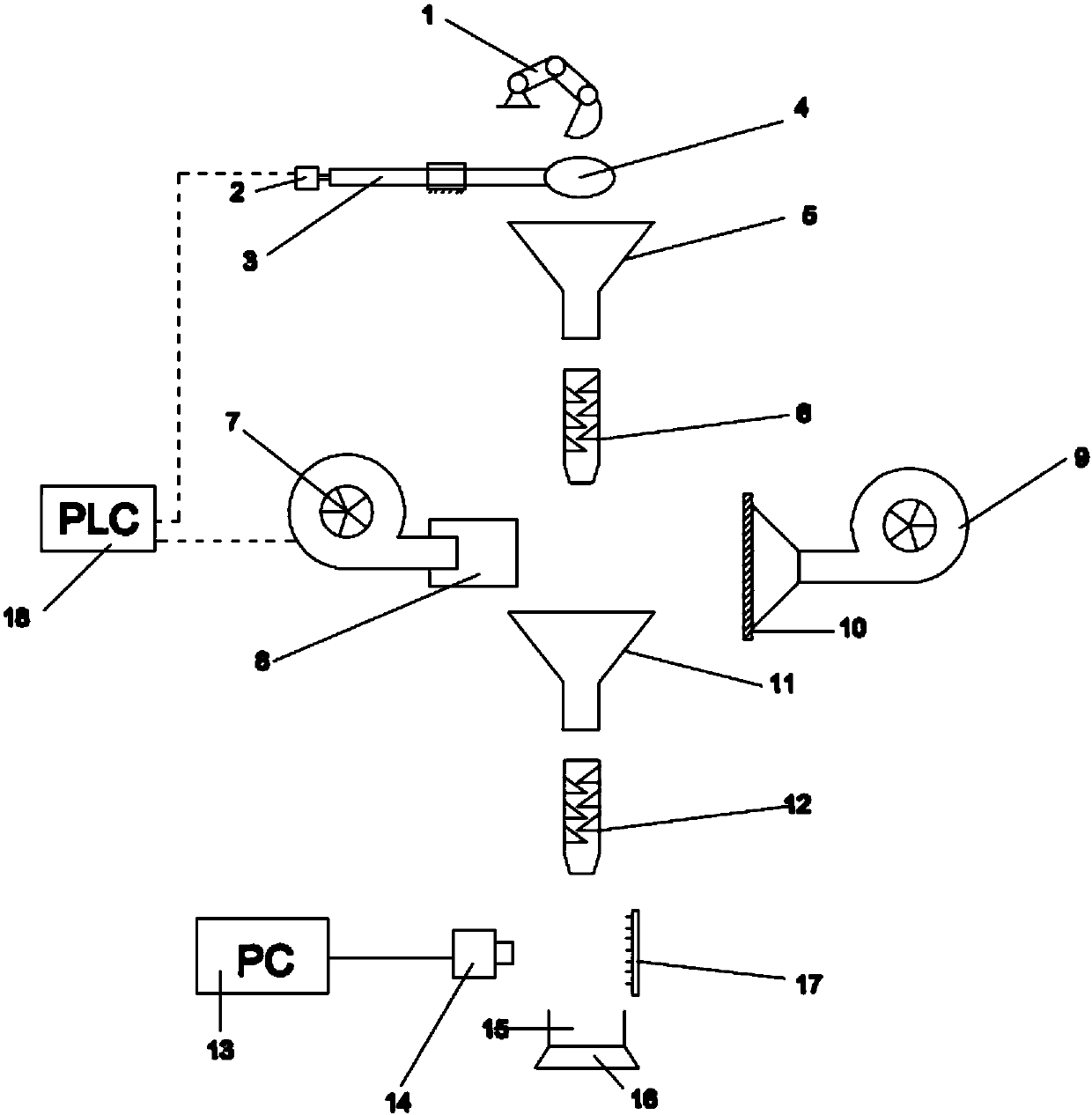

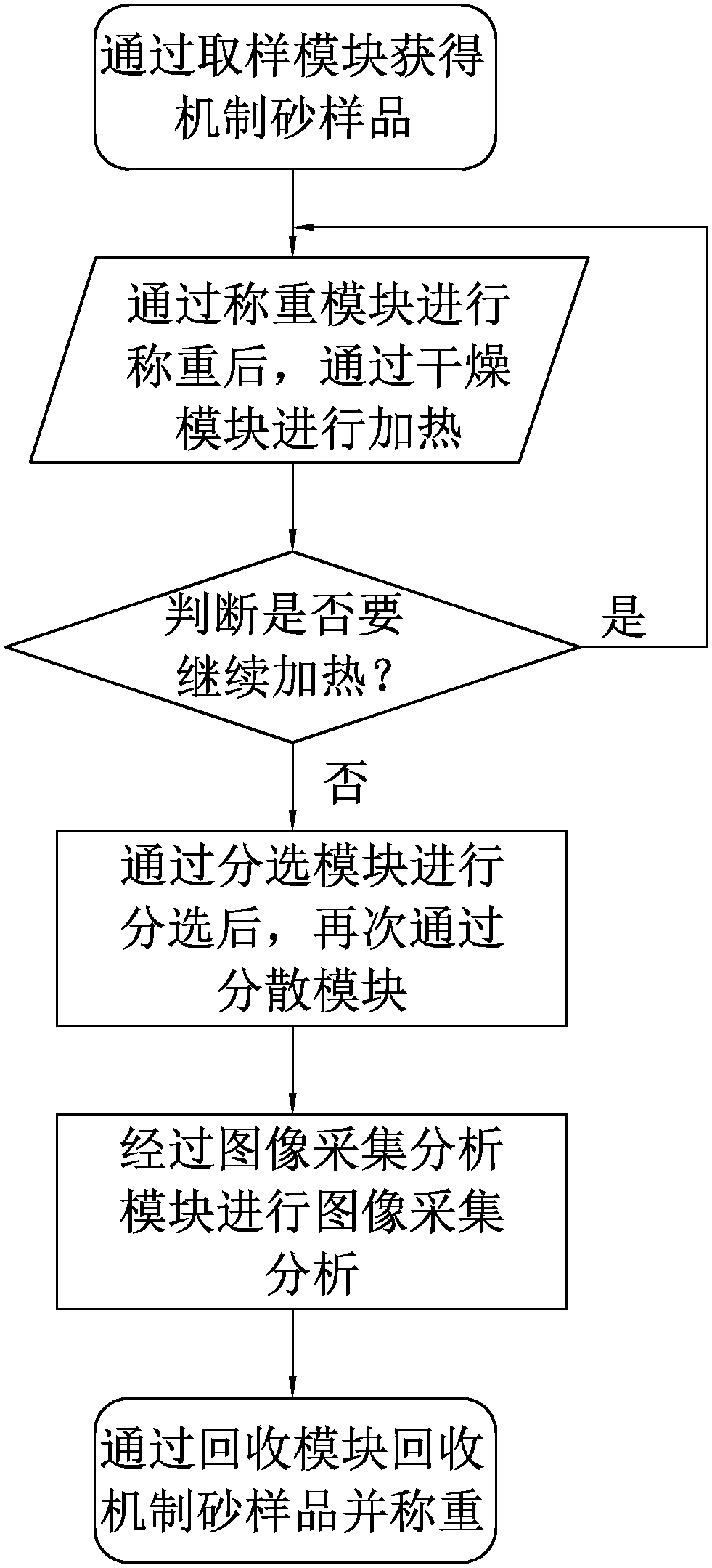

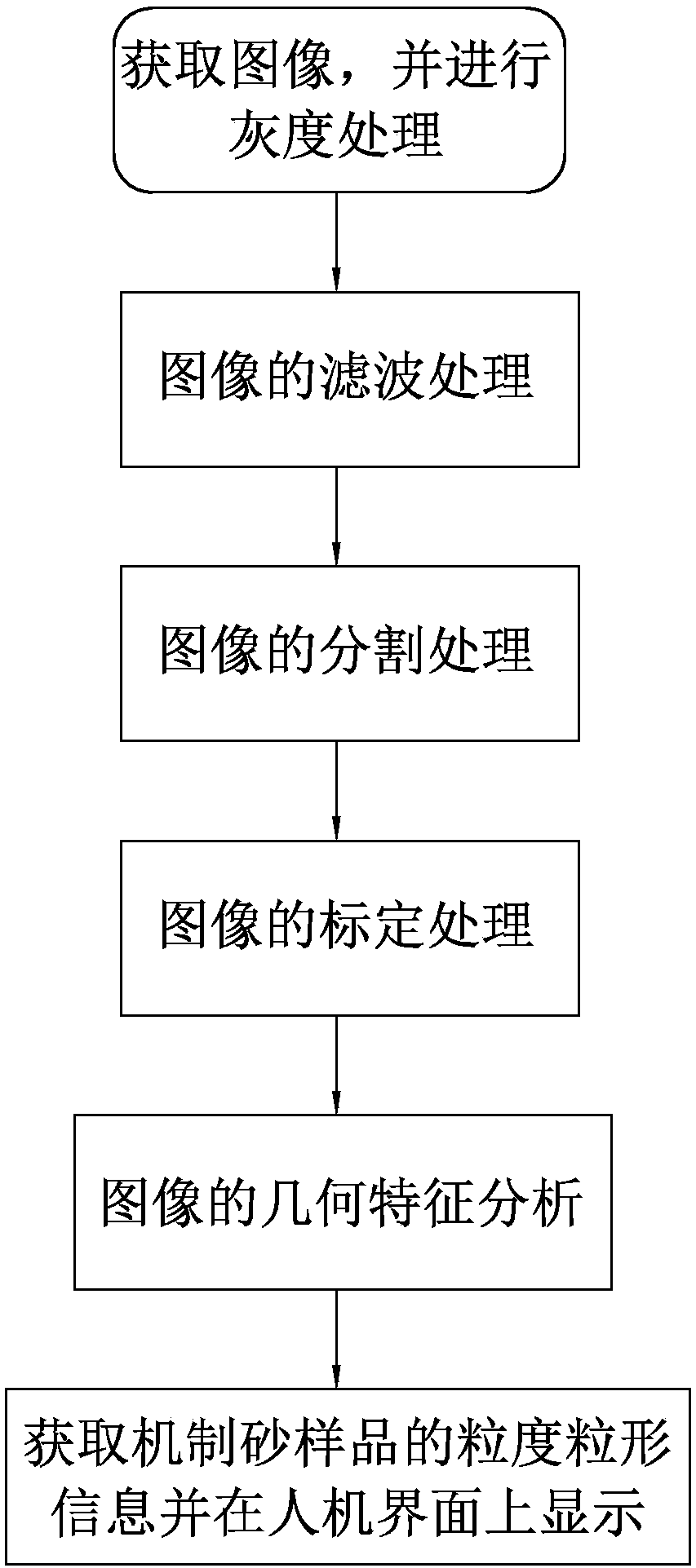

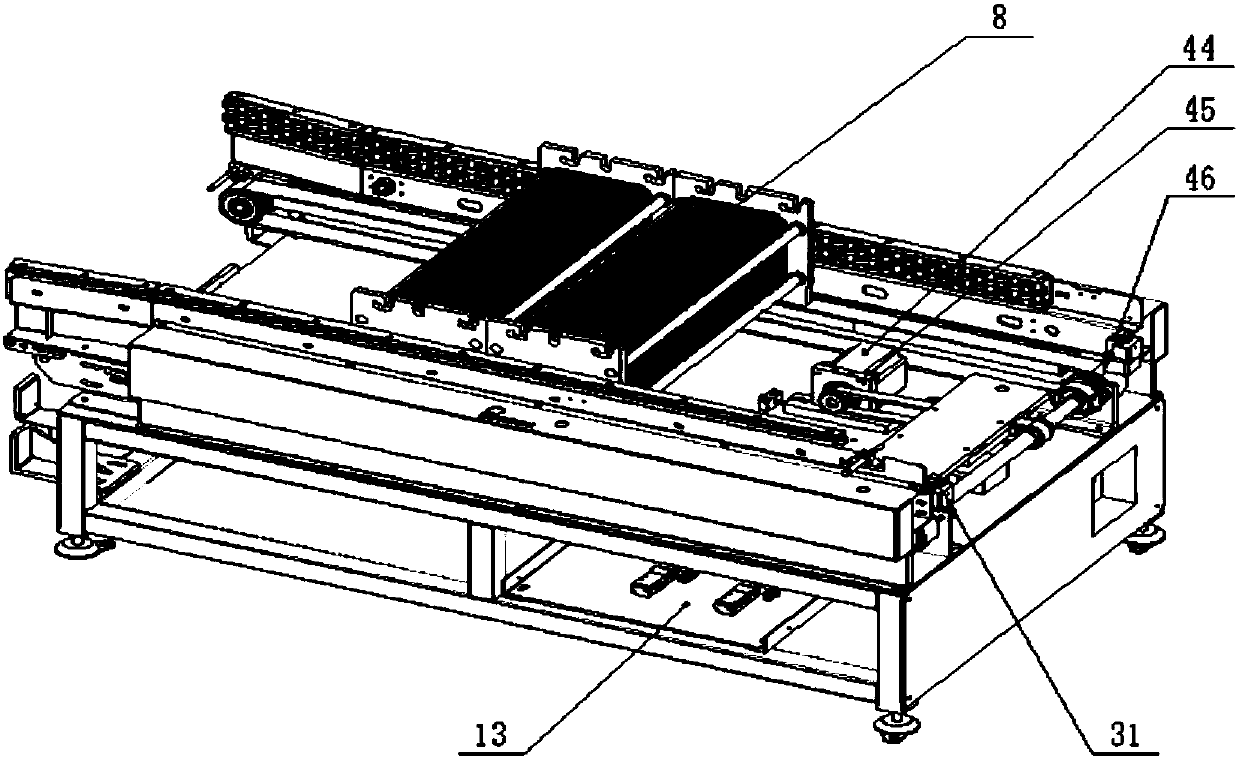

Online detection device and online detection method for machine-made sand

PendingCN107727540ARealize online detectionFast online detectionWeighing by removing componentParticle size analysisProcess engineeringSand sample

The invention discloses an online detection device and an online detection method for machine-made sand. The online detection device comprises a control module, a sampling module, a weighing module, adrying module, a sorting module, a dispersing module, an image collecting and analyzing module and a recycling module. The control module is in signal connection with the sampling module, the weighing module, the drying module and the sorting module respectively. Machine-made sand samples pass the weighing module, the drying module, the dispersing module, the image collecting and analyzing moduleand the recycling module downwardly sequentially along the vertical direction after being acquired by the sampling module, and information, such as particle shapes and diameters, of the returned machine-made sand samples is measured automatically. The online detection device and the online detection method have the advantages that rapid online detection of fineness and shape of the machine-made sand can be realized, grading conditions of the machine-made sand of a machine-made sand production line can be reflected timely, and economic loss caused by sand diameter disqualification of the machine-made sand is avoided.

Owner:HUAQIAO UNIVERSITY

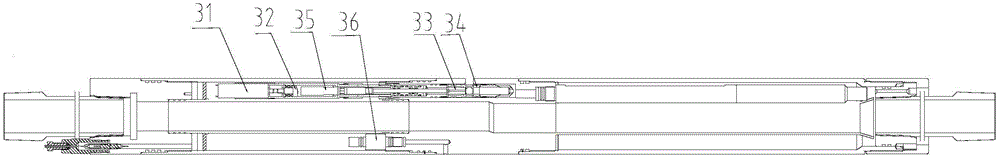

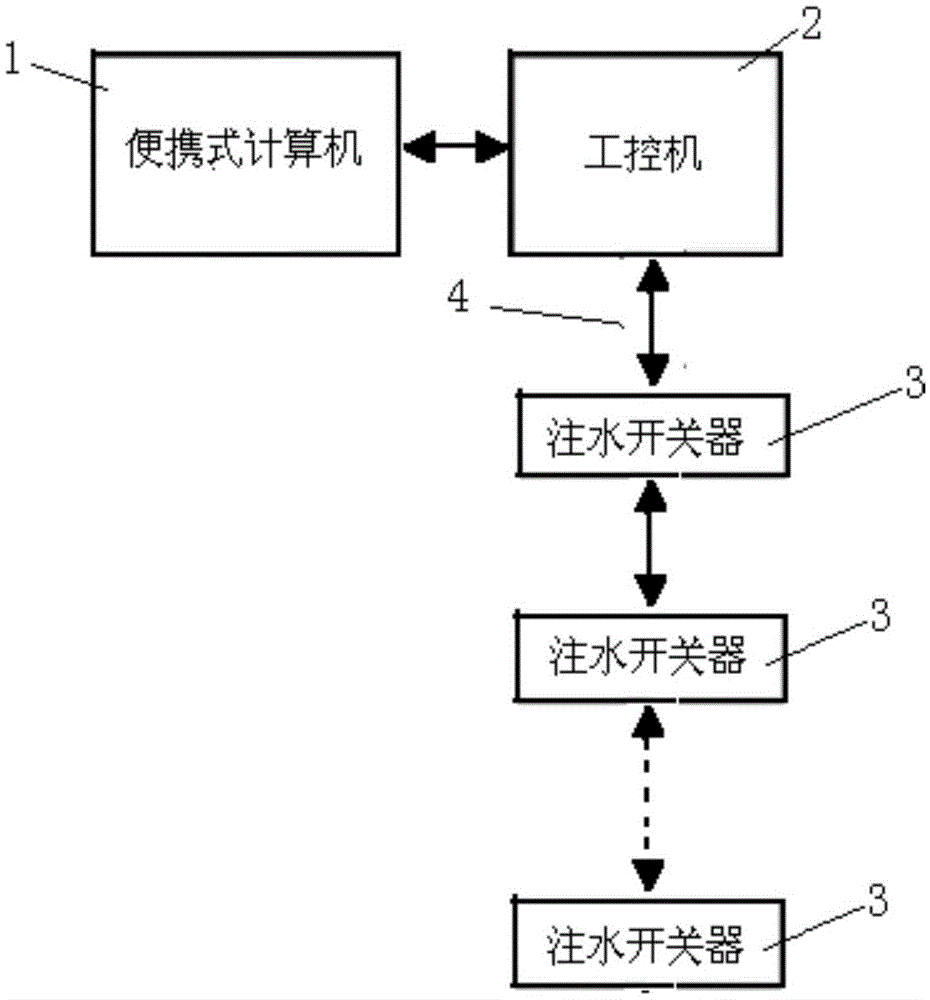

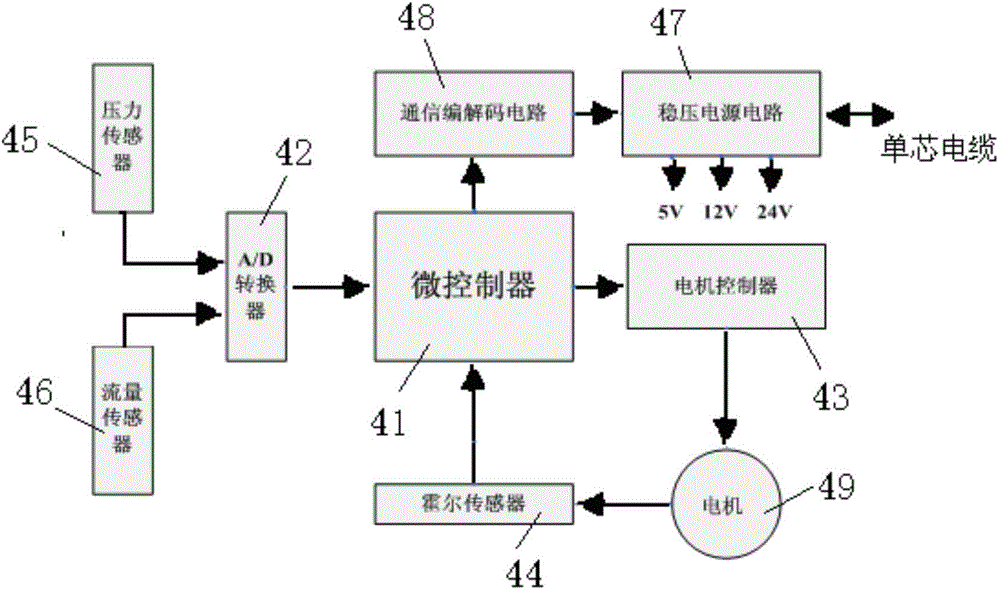

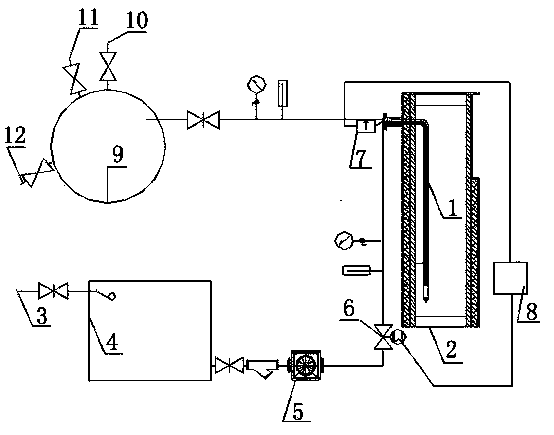

Water injection well regulation system and control method thereof

The invention discloses a water injection well regulation system which comprises a portable computer positioned on a well, an industrial personal computer on the well, multiple water injection switchgears positioned below the well, and single-core cables connected with the industrial personal computer and the water injection switchgears, wherein each water injection switchgear comprises an electric control water injection mechanism; and each electric control water injection mechanism comprises a motor, a thread bushing, a valve element, a valve seat, a pressure sensor, a flow sensor and a temperature sensor arranged in a water injection switchgear shell, and a control circuit board which controls the action of the motor and acquisition and transmission of pressure, flow and temperature signals. According to the water injection well regulation system disclosed by the invention, the underground parameters can be detected in real time, the overload condition of the motor is detected in real time, the power circuit is stable in performance, the water injection switchgears and the water well valves are controlled in real time according to the underground parameters, and long-term reliable operation of the system can be ensured. The invention also provides a method for controlling the water injection well regulation system.

Owner:BEIJING SISHENGDA PETROLEUM EQUIP TECH

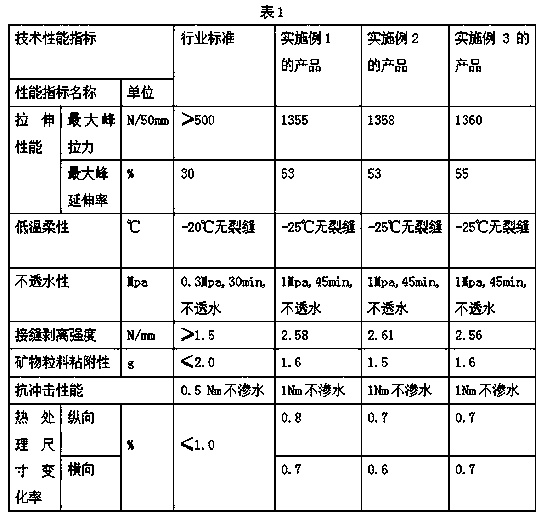

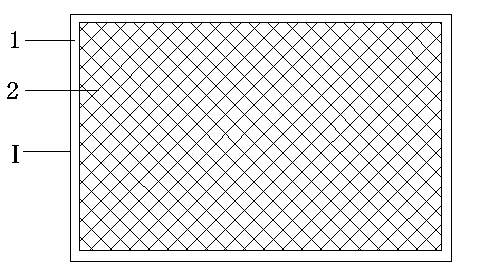

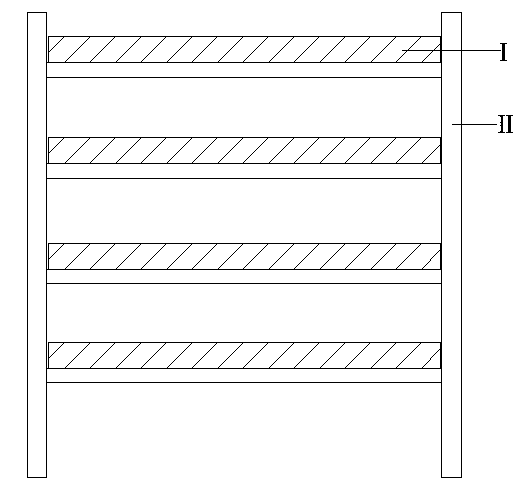

Modified asphalt waterproof coiled material with root penetration resistance and production method of coiled material

InactiveCN107933035AImprove the interface binding forceImprove adhesionAntifouling/underwater paintsRoof covering using flexible materialsWater leakageIsolation layer

The invention relates to a modified asphalt waterproof coiled material with root penetration resistance. The waterproof coiled material has a five-layer structure, and the waterproof coiled material is sequentially provided with an upper surface isolation layer, an upper modified asphalt layer, a base material layer, a lower modified asphalt layer and a lower surface isolation layer from the top to the bottom; and the upper modified asphalt layer and the lower modified asphalt layer are separately prepared from a modified asphalt. The modified asphalt waterproof coiled material with root penetration resistance produced by the invention has greatly improved performance such as root penetration resistance, tear resistant strength, binding performance, water resistance and aging resistance, higher elongation at break, and a simple production process, and overcomes the disadvantages of tedious production, poor binding performance and the like of a traditional waterproof coiled material. According to the invention, the waterproof coiled material produced by the method is used in building, the binding strength of the waterproof coiled material and the base surface of a building is large,the waterproof and root penetration resistant effects are good, the phenomena of water seepage and water leakage of a waterproof coiled material are effectively prevented, and the product has dual functions of waterproofing and preventing plant root penetration.

Owner:GUANGXI WUXUAN JINPAI WATERPROOF MATERIAL SCI & TECH CO LTD

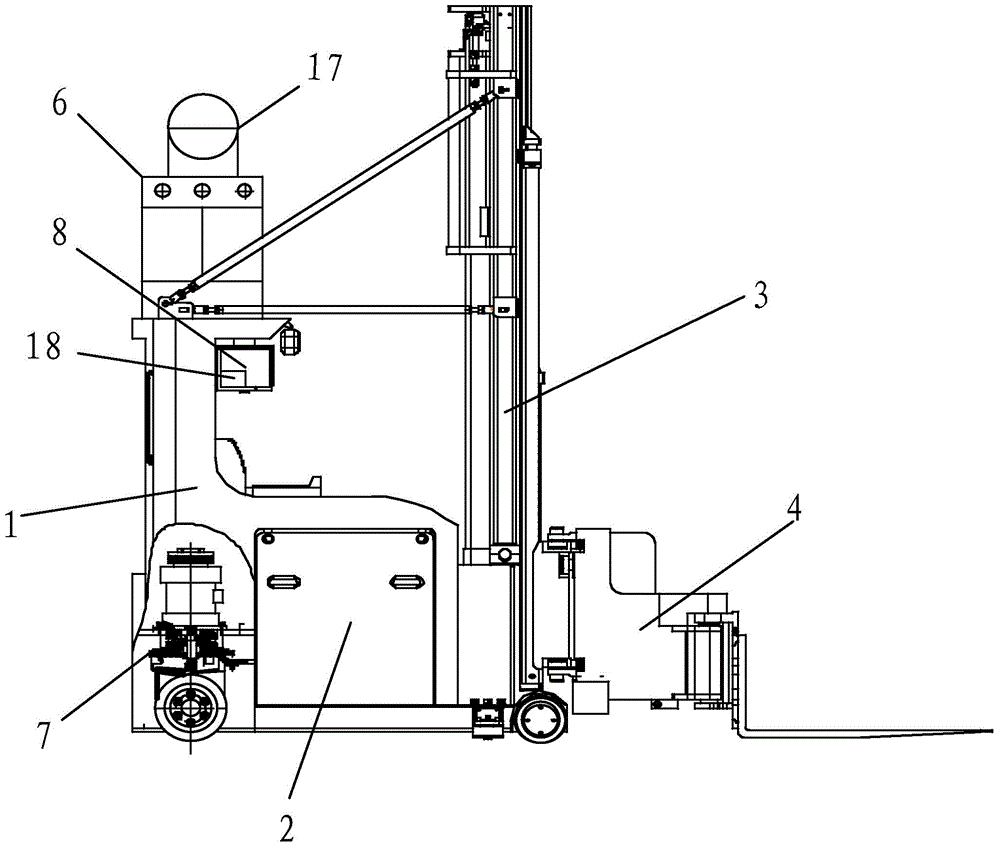

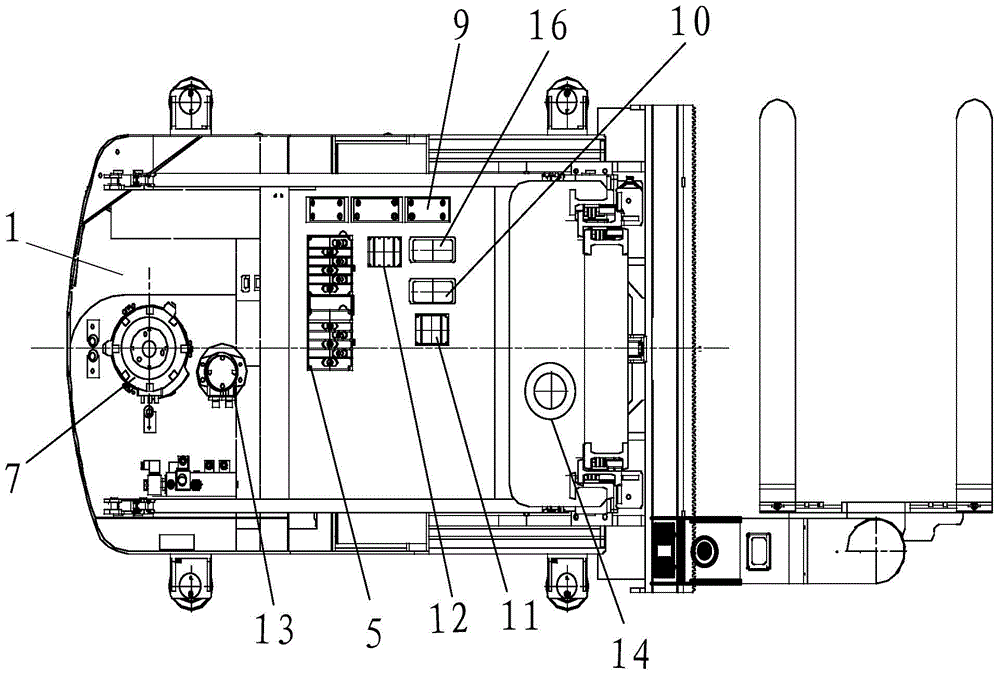

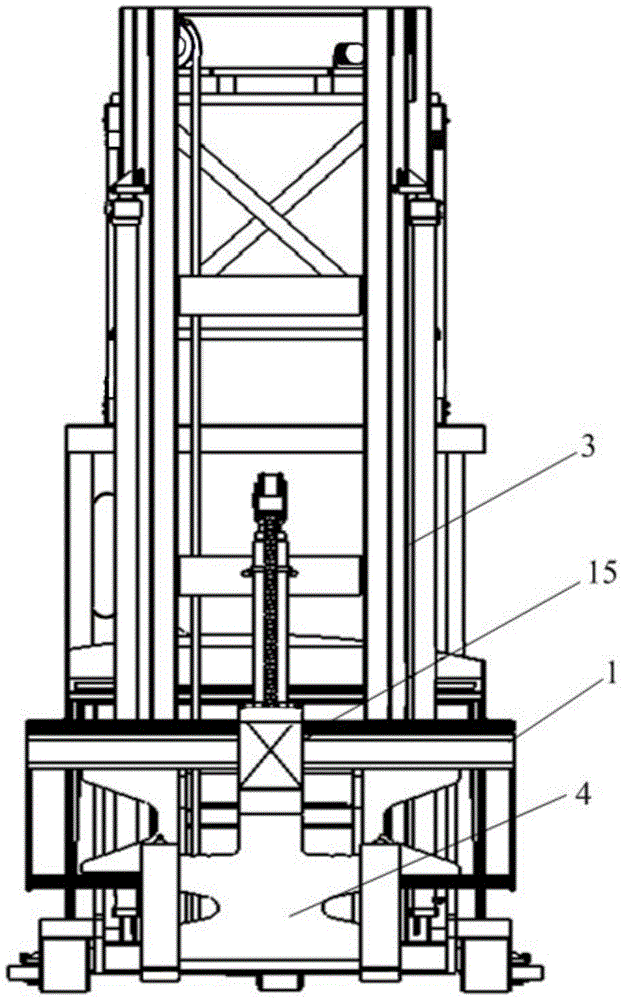

Unmanned electric trackless three-direction stacking forklift truck

ActiveCN104442452ARealize wireless transmissionRealize long-distance and large-scale workSpeed controllerLifting devicesNavigation systemElectrical design

The invention provides an unmanned electric trackless three-direction stacking forklift truck which is provided with a truck body and a power source arranged on the outer side of the truck body. The front end of the truck body is provided with a working device, and the working device is provided with a three-direction stacking truck head. A vehicle controller PLC controlling a single unmanned vehicle to run is arranged in a truck body cab, and a vehicle Ethernet wireless signal receiver is arranged at the left end of the top plane of the truck body. The vehicle controller PLC is connected with the vehicle Ethernet wireless signal receiver and is in data communication with the vehicle Ethernet wireless signal receiver, and the vehicle controller PLC is connected with a mechanism assembly which is arranged on the truck body and used for monitoring, detecting, displaying, driving and controlling the running state of the truck body to achieve automatic assembling and disassembling of the truck body. The unmanned electric trackless three-direction stacking forklift truck is simple and compact in structural design and convenient to manufacture, install and debug, and the safety protection function can be taken into full consideration. Full-automatic unmanned driving control and information collection are achieved on the forklift truck, electrical design is reliable, object overload characteristics are good, an automatic navigation system is high in precision, tracks do not need to be laid, and operation is stable.

Owner:宝鸡赫威特机械科技有限公司

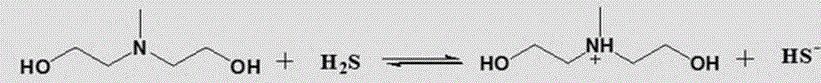

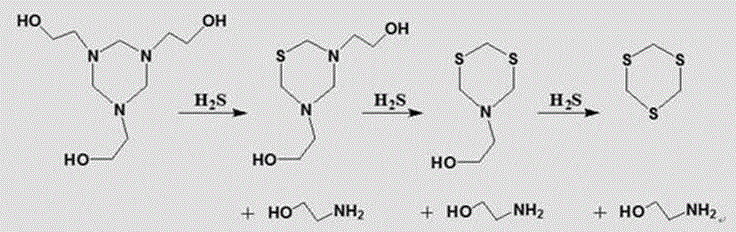

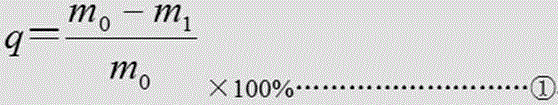

Desulfurizer used for extraction of crude oil containing hydrogen sulfide and treatment of sewage containing hydrogen sulfide

ActiveCN105112087AGet rid of usabilityGet rid of performance constraintsWater/sewage treatment by degassingRefining with aqueous alkaline solutionsSodium acetateNuclear chemistry

The invention discloses a desulfurizer used for extraction of crude oil containing hydrogen sulfide and treatment of sewage containing hydrogen sulfide. The desulfurizer comprises, by mass, 25 to 40% of hydroxyethyl-hexahydro-s-triazine, 5 to 10% of micro-molecular alcohol, 1 to 2% of an osmotic agent sodium sulfosuccinate, 1 to 2% of acetic acid, 0.1 to 0.2% of sodium acetate and 0.02 to 0.04% of an antifoaming agent, with the balance being water, wherein the micro-molecular alcohol is methanol, or ethanol or a mixture of methanol and ethanol, and the antifoaming agent is a water-soluble polyether or silicone oil antifoaming agent. The desulfurizer provided by the invention has a simple formula, is intermiscible with water in any ratio and can effectively reduce hydrogen sulfide in crude oil or sewage; the desulfurizer rapidly reacts with hydrogen sulfide and a reaction product is soluble in water and does not block a pipeline; moreover, an s-triazine main agent has good scale-inhibition, anti-scale and sterilization properties; and the hydrogen sulfide removing agent in the invention overcomes the problems that an alcamine desulfurizer has rapidly reduced desulphurization efficiency at high temperature and hydrogen sulfide removed through reaction may be reversibly released again, and has a temperature application range of 0 to 120 DEG C.

Owner:新疆天普石油天然气工程技术有限公司

Saffron crocus planting method

InactiveCN103814734ADoes not affect productionIncrease productionSeed and root treatmentHorticultureEconomic benefitsCrocus

The invention relates to a saffron crocus planting method. The saffron crocus planting method comprises the steps of outdoor corm breeding: saffron crocus corm can be transplanted in an outdoor field in last November and can be removed from soil in next May; indoor bloom cultivation: from the middle of May to mid-to-end of June, seedballs are in a complete dormancy period, and the room temperature needs to be up to 30 DEG C and needs to be maintained for more than 20 days; from the end of June to the last ten days of July, the room temperature needs to be maintained in 23-28 DEG C, the relative humidity is 80%, the indoor environment is in sun shading, and the illumination is avoided; from August to the middle of September, the room temperature needs to be maintained in 23-27 DEG C, the relative humidity is 75%-85%, the indoor environment is in sun shading, and the illumination is avoided; from the end of the middle of September to the last ten days of October, white parts are presented by main sprouts of the corm, the room temperature is maintained in 20-25 DEG C, and the relative humidity is 80%; from the end of October to the middle of November, the room temperature is 15-18 DEG C, the humidity is 75%, and the indoor environment is not in sun shading any more. According to the saffron crocus planting method disclosed by the invention, the yield is high, the quality is good, and the economic benefit is good.

Owner:嘉兴市秀洲区天禾藏红花专业合作社

Method for replacing rubber belt by long-distance steel cord rubber belt conveyor

The invention relates to a maintenance technology of underground equipment of a coal mine, in particular to a method for replacing a rubber belt of a long-distance steel cord rubber belt conveyor, solving the problem of replacement of the underground long-distance rubber belt of the coal mine. The method comprises the following steps of: stopping; punching cards on a machine end and a lower rubber belt; lifting an upper rubber belt positioned on a certain position; disassembling a rack positioned on the position; installing a rubber belt winder on the position; cutting the lower rubber belt on the machine end and the position; connecting a new rubber belt with an old rubber belt; disassembling the cards positioned on the machine end and the lower rubber belt; pulling the old rubber belt for m meters, then cutting the old rubber belt of m meters, winding the old rubber belt of m meters, and forking an old rubber belt coil by a forklift so as to complete one rubber belt replacement unit; and sequentially operating for a plurality of times till rubber belt replacement is completed. The invention has the characteristics of shortest replacing time, overlength-distance fast belt replacement.

Owner:SHANXI JINCHENG ANTHRACITE COAL MINING GRP CO LTD

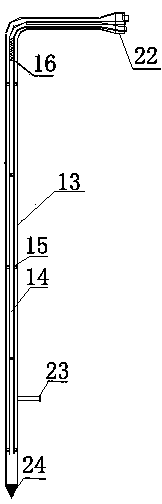

Ascending pipe waste heat insertion-type temperature control thermal expansion decoking heat pipe guiding-out method and device

ActiveCN104059676AUnique structureComplete anti-coking technologyBoiler cleaning apparatusEnergy inputPipingEngineering

The invention relates to an ascending pipe waste heat insertion-type temperature control thermal expansion decoking heat pipe guiding-out method and device, and belongs to the technical field of coking furnace ascending pipe raw gas waste heat recycling. According to the technical scheme, a steam outlet pipe (13) and a water inlet pipe (14) are bent together to be of an L-type structure (1), the end of the horizontal segment of the L-type structure is provided with a detachable connector (22), the end of the perpendicular segment is provided with an anti-coking head (24), the steam outlet pipe is connected with a steam pocket (9), the water inlet pipe is connected with a water inlet system, raw gas and the water inlet pipe are isolated through the steam outlet pipe, the temperature of the exterior of the steam outlet pipe is not lower than the coking temperature, and meanwhile steam ascends gradually to heat inflowing water, so that the inflowing water is completely gasified. According to the ascending pipe waste heat insertion-type temperature control thermal expansion decoking heat pipe guiding-out method and device, the temperature is detected through a high-temperature thermocouple in the heat exchange process, the water yield of the inflowing water is controlled, and therefore coking of the exterior of the device is avoided; raw gas waste heat can be recycled, completely independent installation is achieved, the problems that a heat exchange device inside an ascending pipe is prone to coking, the ascending pipe is prone to explosion, installation is difficult, and the replacement and maintenance cost is high are solved, and the heat exchange amount is large.

Owner:TANGSHAN BAOKAI TECH

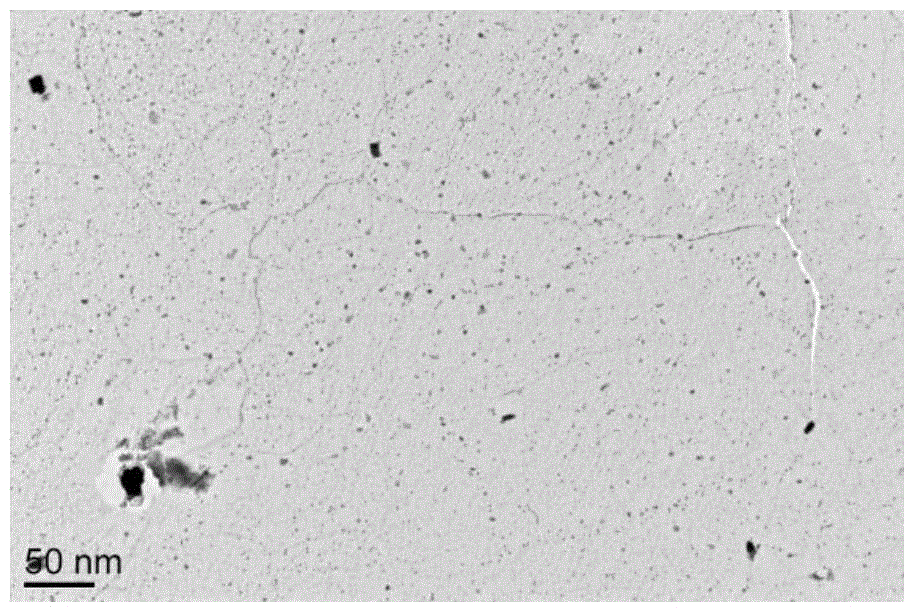

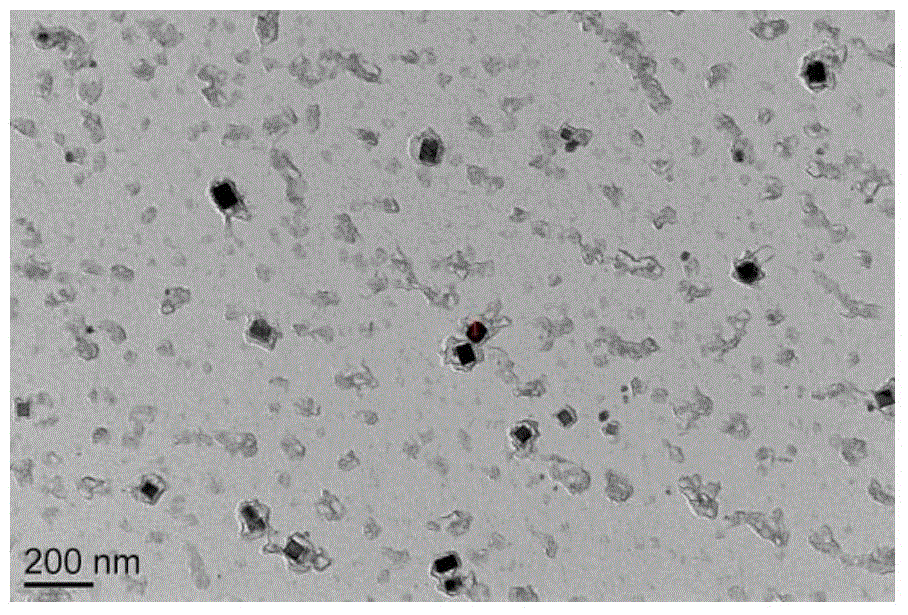

Catalyst for regenerating anthraquinone degradation products and preparation method thereof

ActiveCN101455959AFacilitate the reduction and regeneration reactionDoes not affect productionPhysical/chemical process catalystsPseudoboehmiteAluminium hydroxide

The invention discloses a catalyst for anthraquinone degradation product regeneration, wherein the content of alumina in the catalyst is 93 to 97 wt percent; the content of macropore above 75 nanometers in the catalyst is more than 5 percent; moreover, pore volume is more than 0.42ml / g, and micropore size distribution is mainly concentrated between 50 and 100. The invention also discloses a preparation method of the catalyst. The method comprises: a, crushing and roasting aluminium hydroxide to obtain raw powder; b, mixing the 85 to 95 wt percent raw powder obtained after roasting with 5 to 15 wt percent pseudoboehmite to prepare pellet on a pelleter; c, feeding the obtained pellet into rolling or rotating equipment to carry out surface treatment; d. storing the pellet at room temperature after surface treatment; e, carrying out water washing of the pellet obtained after storing in step d, by use of water below 80 DEG C; and f, roasting the pellet after water washing. The catalyst ensures that the reduction regeneration yield of anthraquinone degradation product reaches above 10 g / L, and effectively inhibits side reaction; moreover, product abrasion wear is less than 0.3 percent.

Owner:GUIZHOU BRANCH CHINA ALUMINUM IND

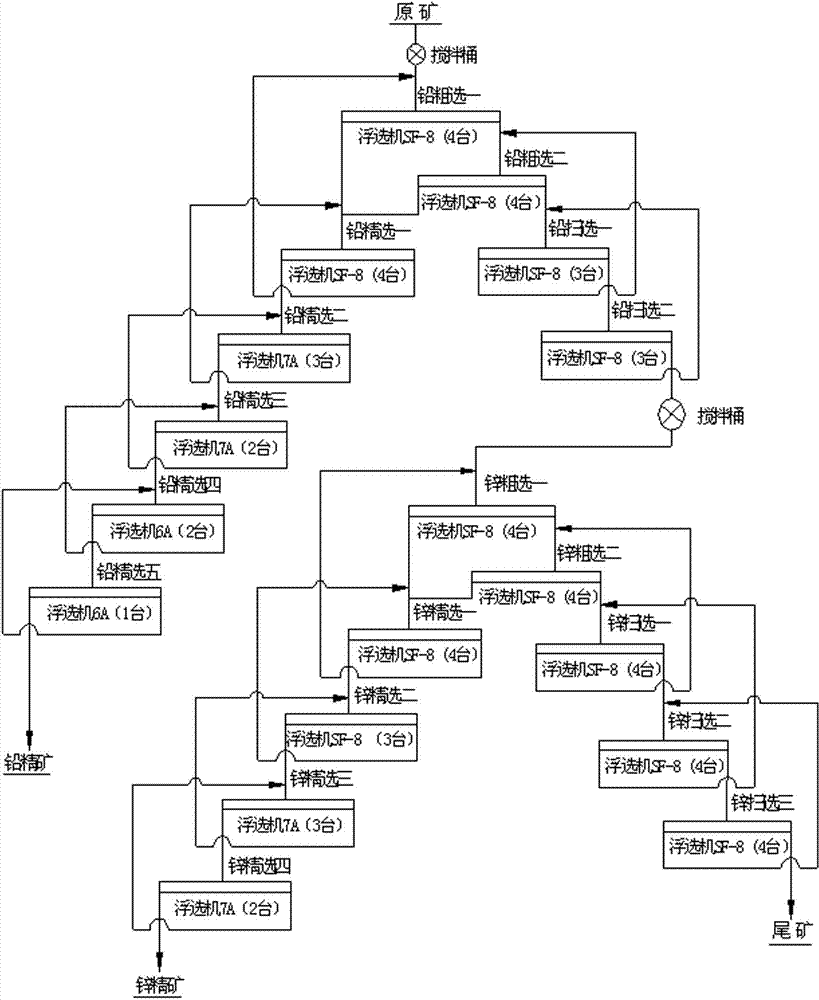

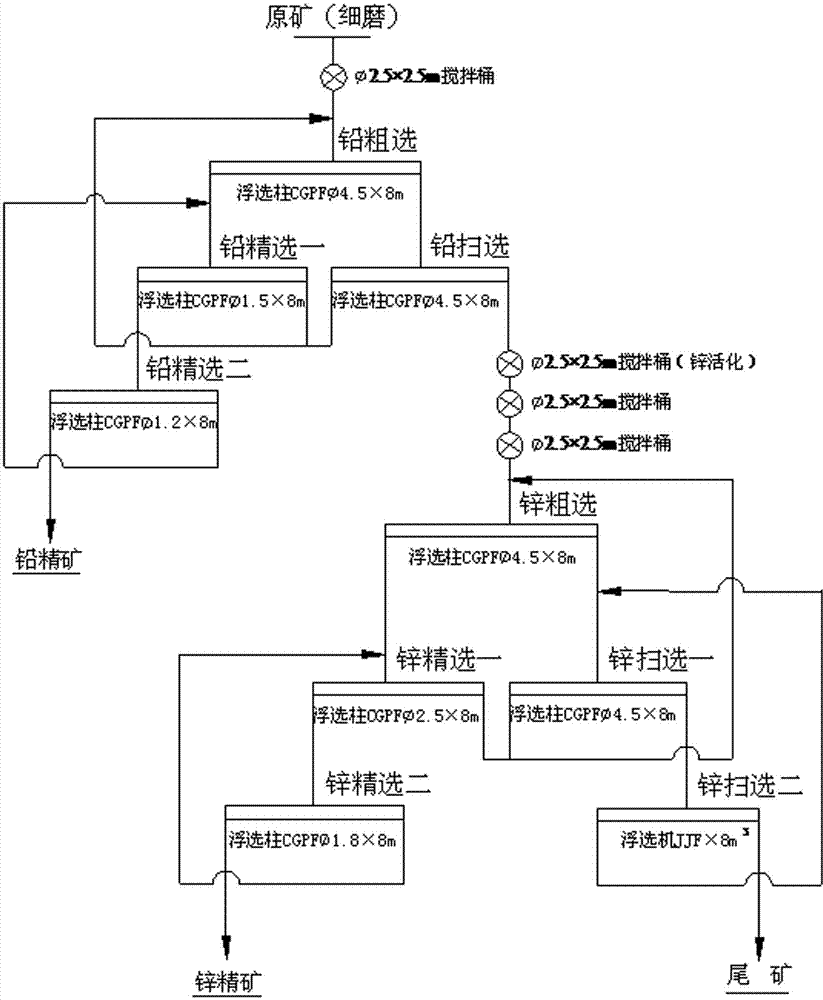

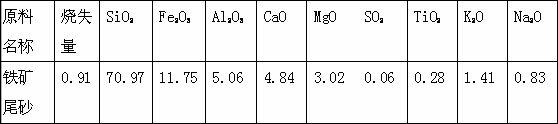

Technology for flotation of lead and zinc sulfide ores through inflatable floatation columns

ActiveCN103934117AImprove beneficiation efficiencyHigh enrichment ratioFlotationMineralogyMining engineering

The invention discloses a technology for floatation of lead and zinc sulfide ores through inflatable floatation columns. The floatation columns are fully utilized, and the method includes the steps of ore grinding, mixing of ore pulp and flotation reagents, rougher flotation operation, concentration operation, scavenging operation and the like. The method is based on the flotation column three-phase flow mechanics theory, through process mineralogy research and technological process research of low-grade, complex and refractory lead and zinc sulfide ores of mines and research and improvement on an inflatable flotation column device, the flotation columns are successfully applied to the flotation technology of low-grade, complex and refractory lead and zinc sulfide ores, and the technological process that the floatation columns are adopted in all the flotation operations of rougher flotation, concentration and scavenging of lead and zinc sulfide ores is achieved. The technology has the advantages that the automation degree is high, labor intensity of workers is low, ore flotation efficiency is high, the technological process is simple, production indexes are stable, maintenance is convenient, building investment and production cost are low, consumption of the reagents is saved by about 10%, electricity consumption is saved by about 20 %, and water consumption is saved by about 20 %.

Owner:GUANGXI ZHONGJIN LINGNAN MINING CO LTD

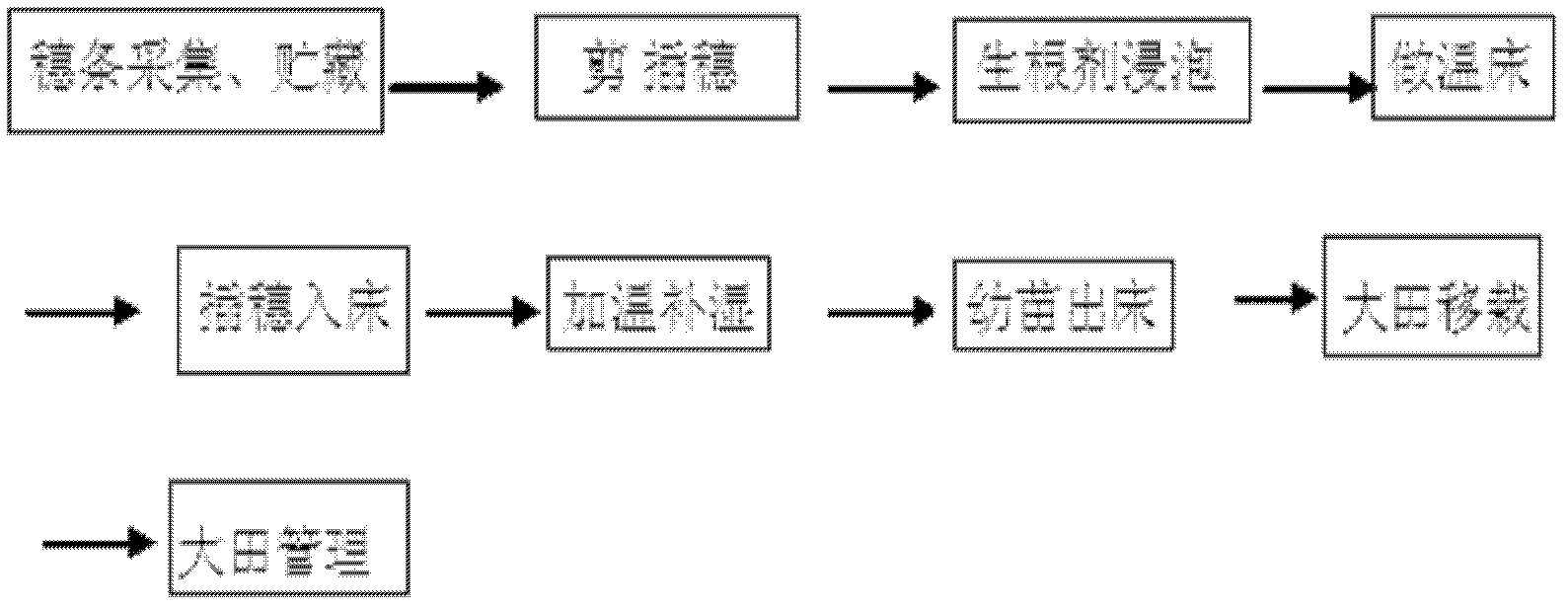

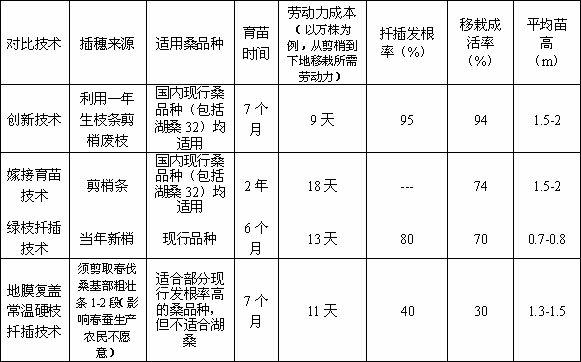

Method for rapidly culturing improved mulberry seedlings by using sheared waste mulberry branches

The invention belongs to the technical field of the mulberry seedling culturing and the orchard constructing. In spring, the sheared waste mulberry branches are used for the hard branch hotbed cottage by applying the modern agricultural technology so that the matrix components are optimized, the nutrients are diversified, the cottages can root rapidly and survive, the rooting rate / survival rate of the cottages are greatly improved, and the mulberry seedlings can be transplanted in the field to grow or construct the orchard. The method has the advantages of rapid mulberry seedling culturing and orchard constructing, low cost, high rooting rate of cottages, high survival rate of the mulberry seedlings transplanted in the field, very wide source of cottages and simple technical process and being convenient to popularize and apply.

Owner:HUOSHAN SINONG SILK HOME TEXTILES CO LTD

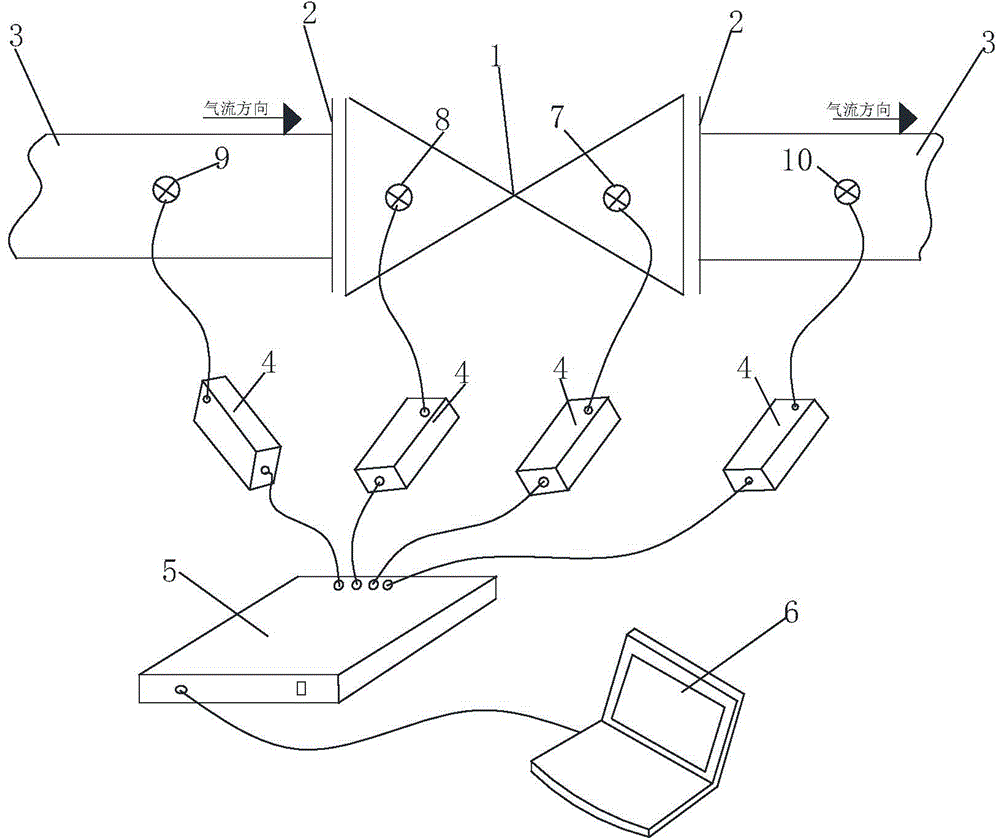

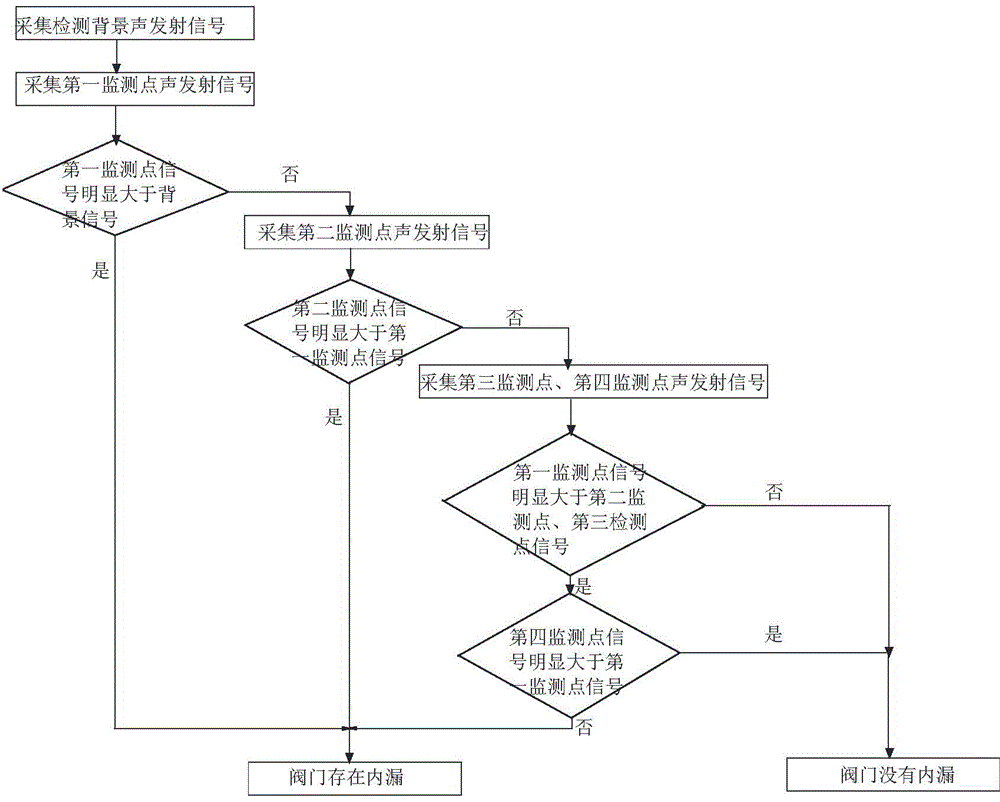

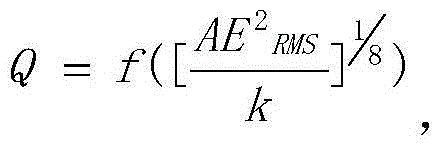

Gas valve inner leakage detection method based on acoustic emission signal processing

ActiveCN104458152ALow costImprove detection efficiencyDetection of fluid at leakage pointData acquisitionEngineering

The invention discloses a gas valve inner leakage detection method based on acoustic emission signal processing. Firstly, an acoustic emission sensor is used for collecting signals, filtering processing is conducted through a signal amplifier, enhanced acoustic emission analog signals are obtained, converted into digital signals through a data acquisition card and sent to a computer, and the computer records root-mean-square value parameters of the acoustic emission signals in real time; a one-point method acoustic emission signal collection inner leakage analyzing and judging method, a two-point method acoustic emission signal collection inner leakage analyzing and judging method and a four-point method acoustic emission signal collection inner leakage analyzing and judging method are adopted in sequence, and whether inner leakage exists on a valve or not is judged according to the root-mean-square value of valve inner leakage acoustic emission signals. The gas valve inner leakage detection method is applied to the field of gas valve inner leakage detection, has high practicability, is reasonable in cost and high in detection efficiency, does not affect normal production and reduces the influences, on production detection, of industrial noise.

Owner:CHINA PETROLEUM & CHEM CORP QINGDAO RES INST OF SAFETY ENG +1

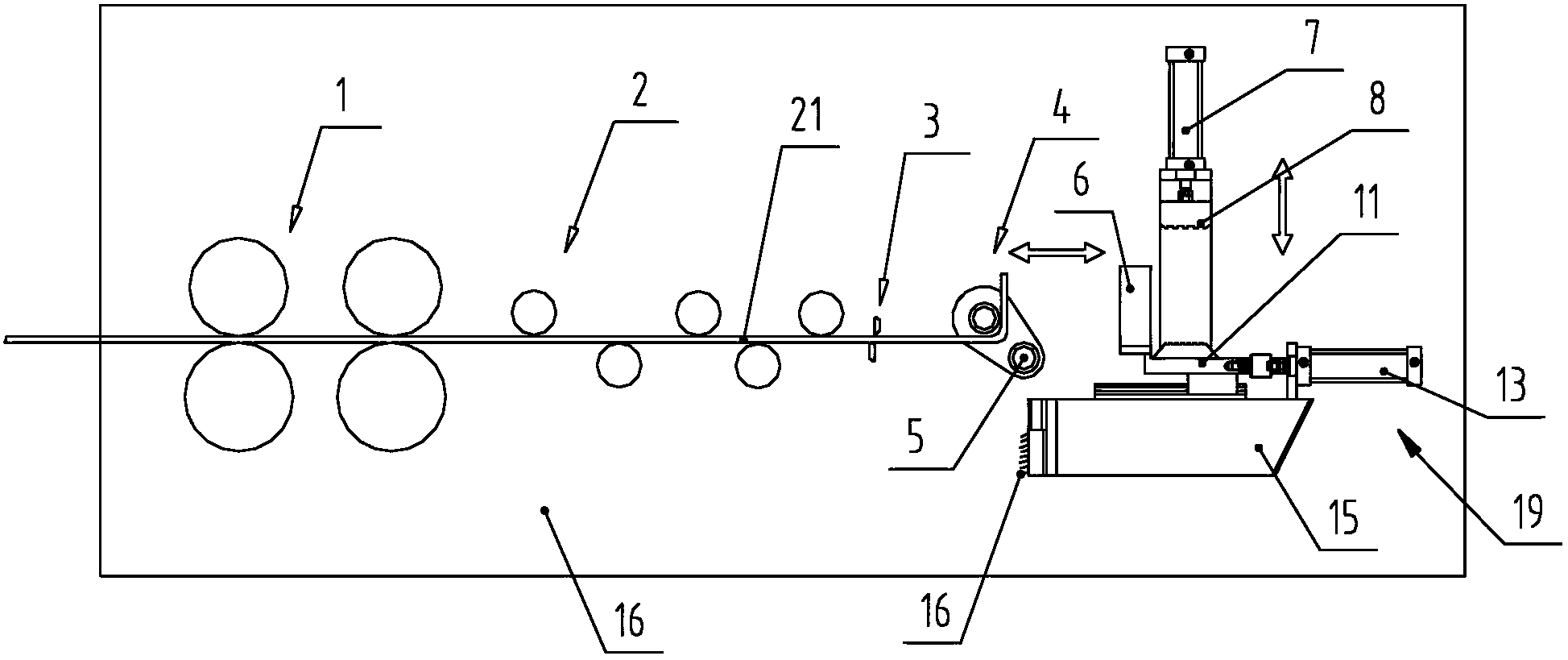

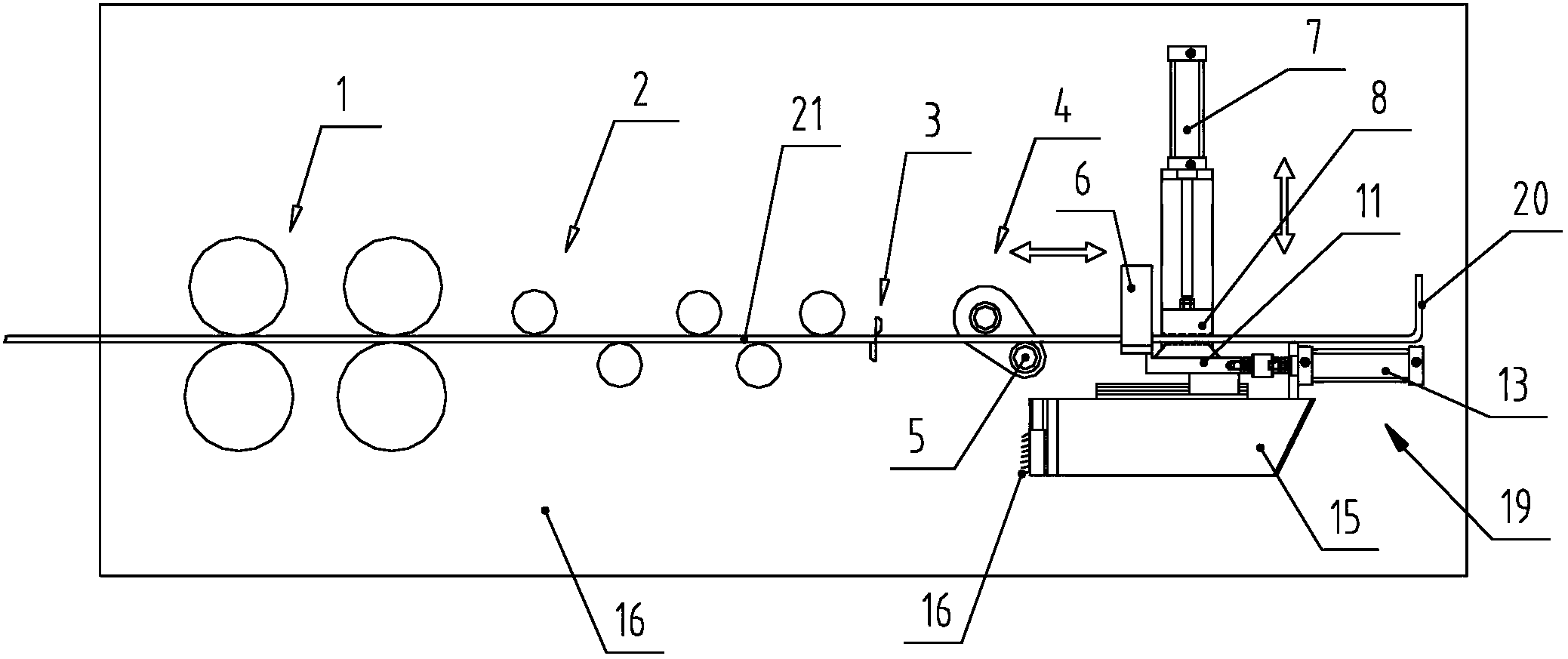

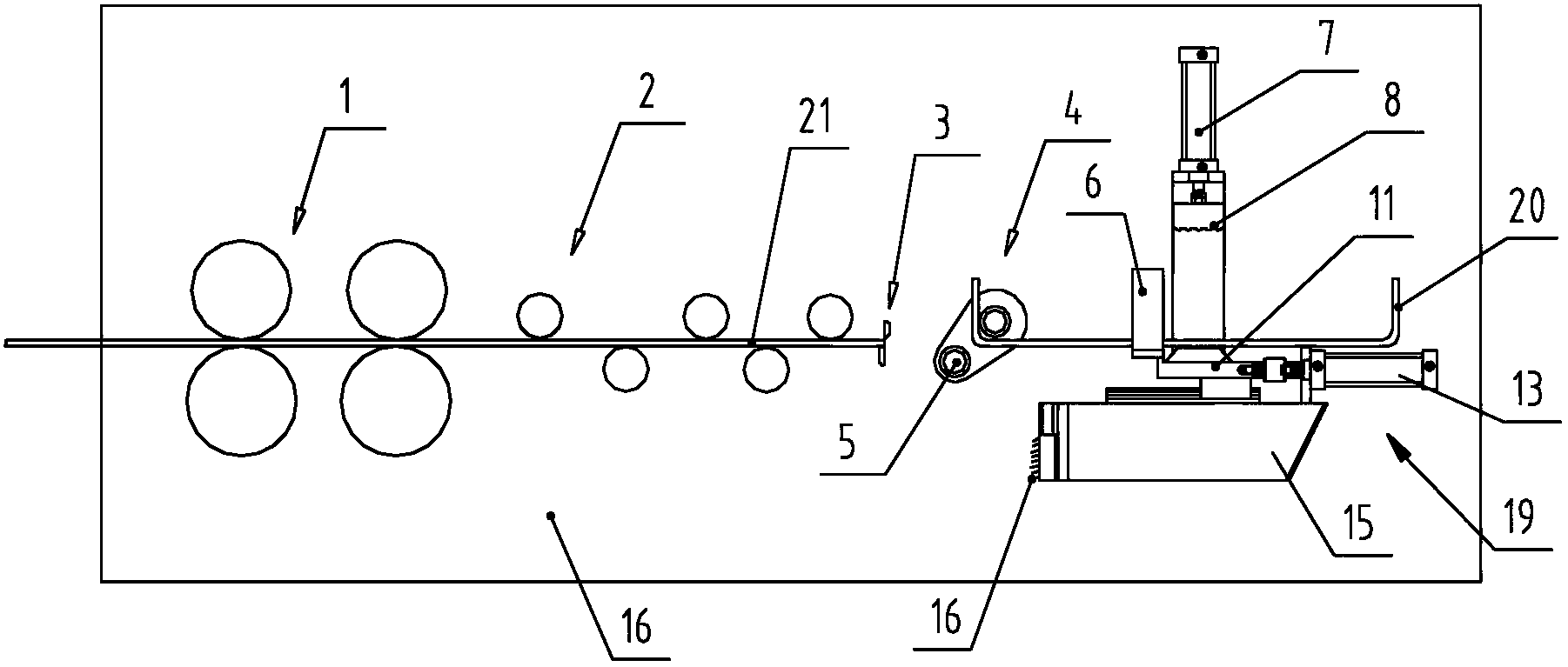

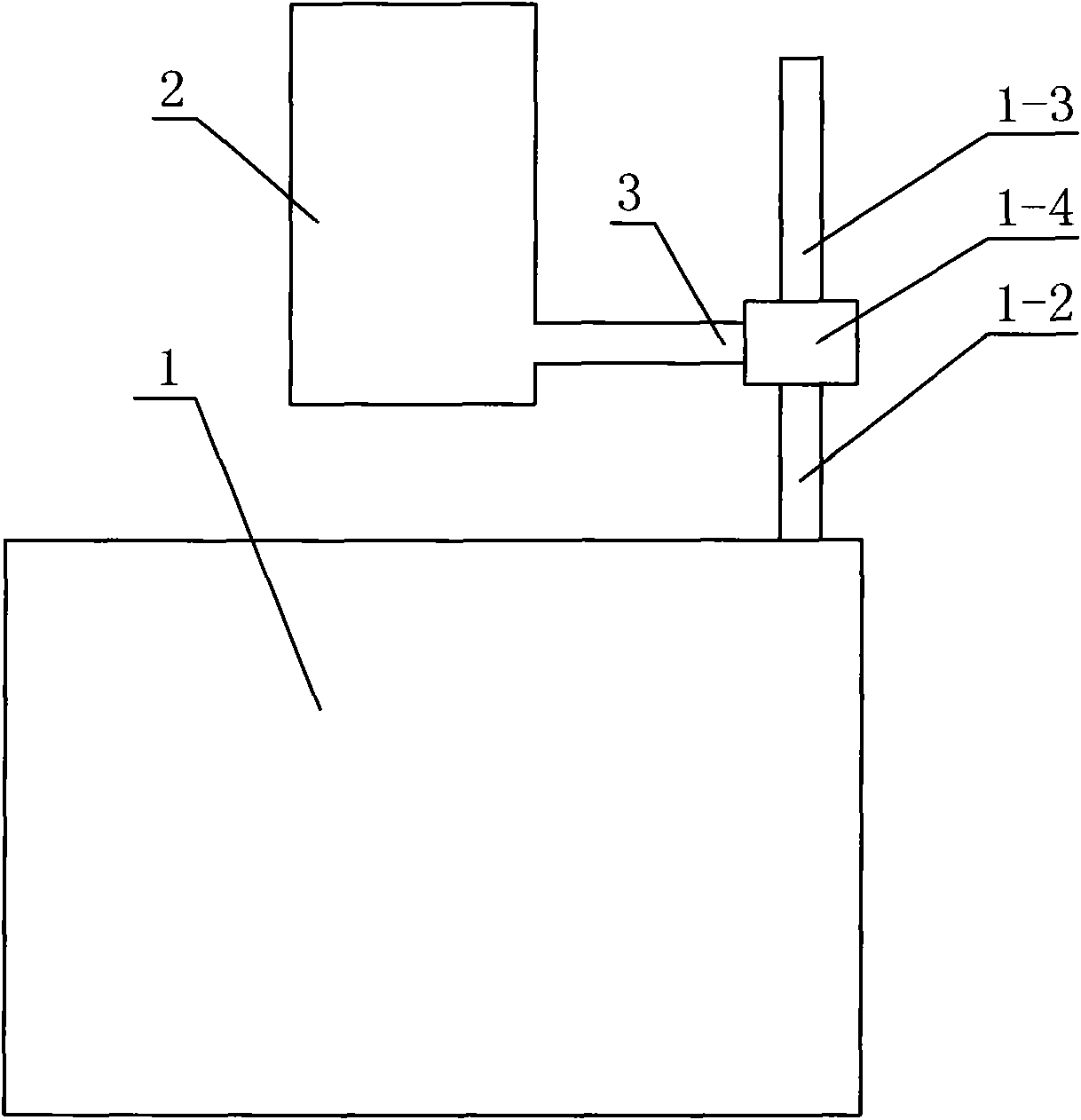

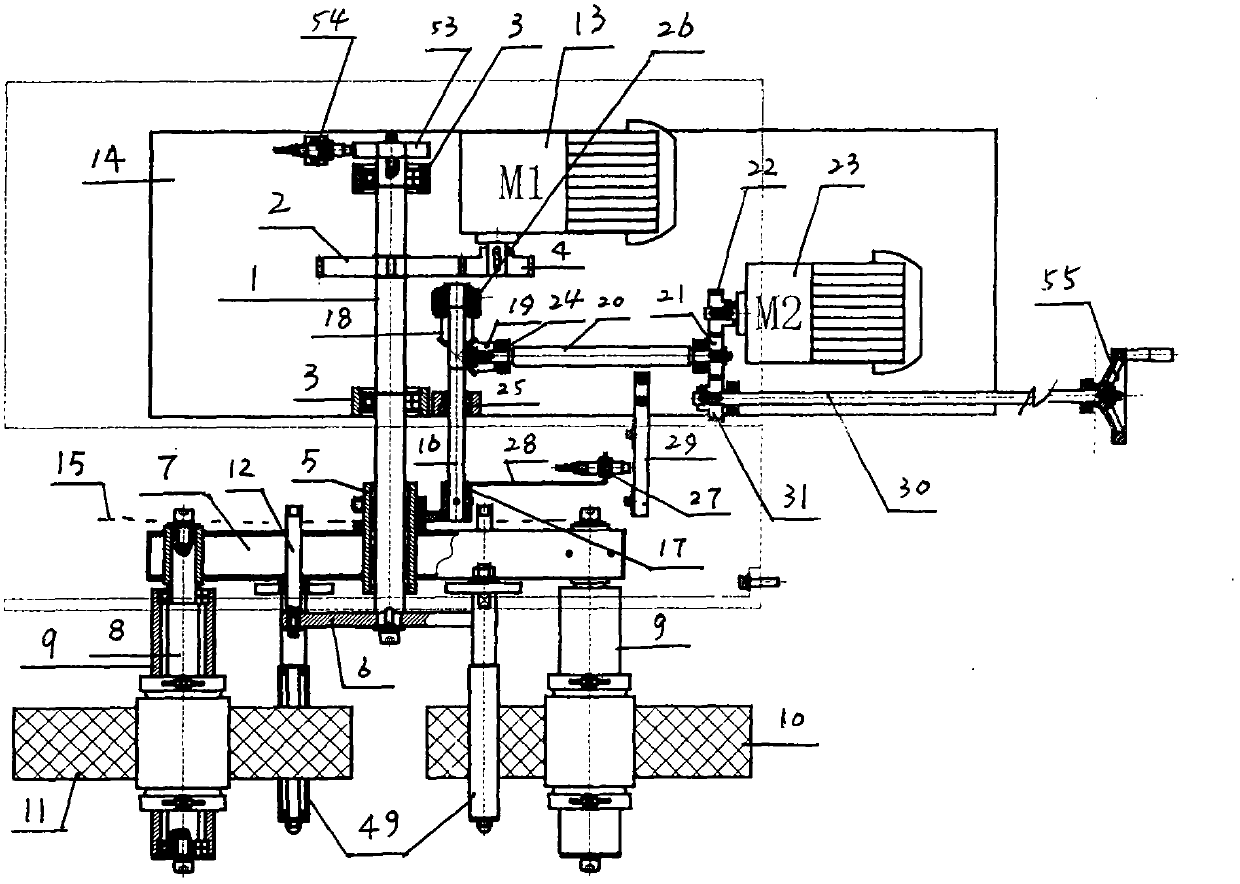

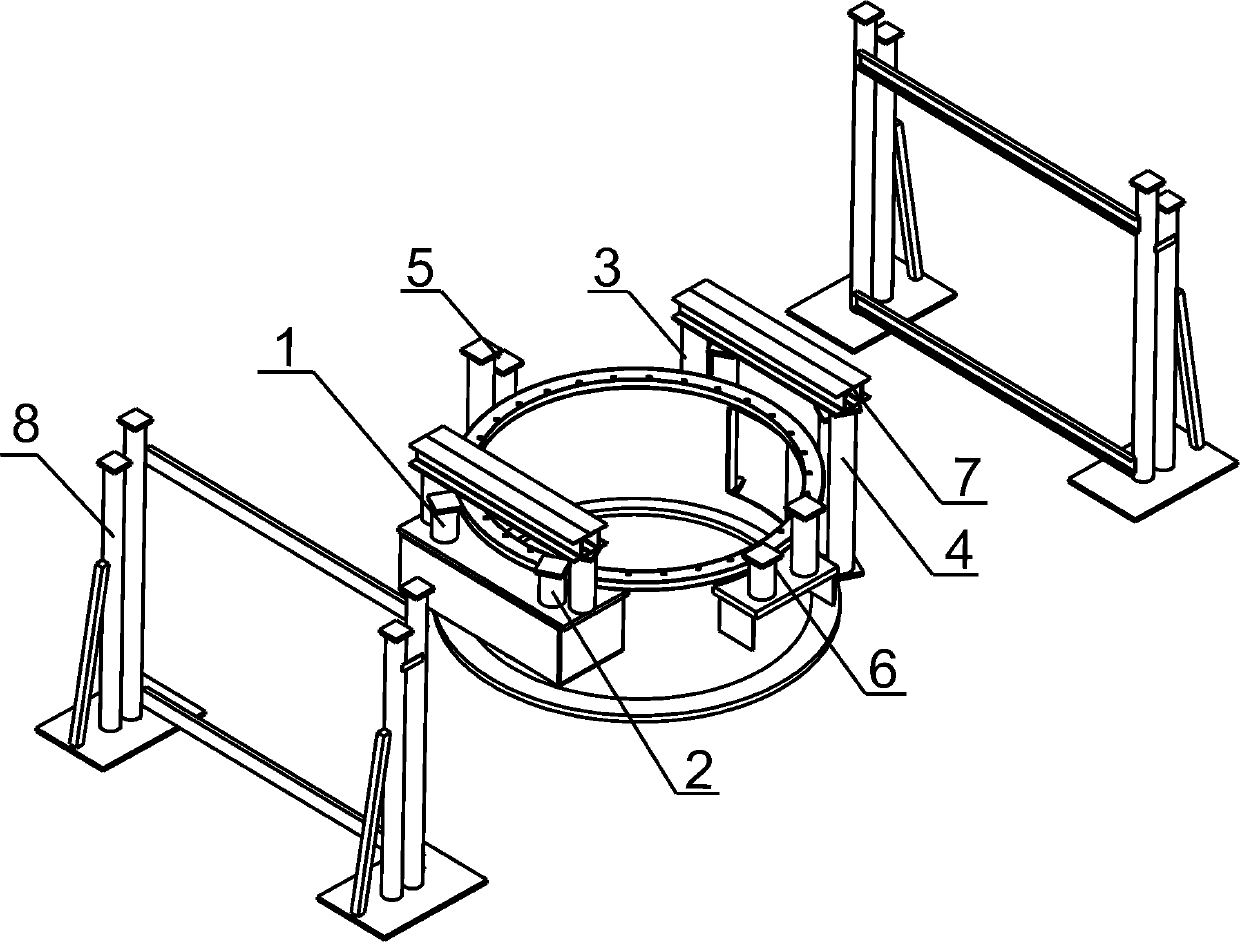

Multifunctional reinforcing steel bar automatic hoop-bending machine bending from two ends of reinforcing steel bar

The invention discloses a multifunctional reinforcing steel bar automatic hoop-bending machine bending from the two ends of a reinforcing steel bar. The multifunctional reinforcing steel bar automatic hoop-bending machine comprises a machine frame, wherein a traction mechanism, a straightening mechanism, a shearing mechanism and a bidirectional bending mechanism are axially arranged on the machine frame along the upstream of the reinforcing steel bar sequentially; a multifunctional mechanism is also arranged on the machine frame on the upstream of the bidirectional bending mechanism; the multifunctional mechanism comprises a compression moving mechanism, a material-pushing mechanism and an overall retraction mechanism; the material-pushing mechanism is used for pushing a hoop bar which is formed in a bending way; and the overall retraction mechanism is used for pulling the compression moving mechanism and the material-pushing mechanism into the inner side of a machine shell panel or pushing the compression moving mechanism and the material-pushing mechanism to a working position. The multifunctional reinforcing steel bar automatic hoop-bending machine has the beneficial effects that the other end of the reinforcing steel bar which is sheared by the shearing mechanism can be bent, long hoop bar products with hooks at the two ends can be bent rapidly and at one time, the requirement of production is met, and the production efficiency is high. The multifunctional reinforcing steel bar automatic hoop-bending machine is simple in structure, low in cost, high in adaptability, wide in production range, and has complete functions.

Owner:TJK MACHINERY TIANJIN

Continuous cleaning device for vacuum pump and method thereof

The invention discloses a continuous cleaning device for a vacuum pump and a method thereof. The device comprises a cleaning solution supply system, wherein the cleaning solution supply system is provided with a cleaning solution storage barrel filled with cleaning solution, a cleaning solution delivery pipeline and a switching valve arranged on the cleaning solution delivery pipeline; the cleaning solution delivery pipeline is connected with the cleaning solution inlet which is arranged on the pump body of a vacuum pipe and communicated with the inner cavity of the pump body; or the cleaning solution delivery pipe and the work solution delivery pipeline of the vacuum pump are connected with the inlet of a shuttle valve; and the outlet of the shuttle valve is connected with a work solution inlet on the pump body of the vacuum pump. By using the method, the work solution is regularly changed into the cleaning solution to clean the inside of the vacuum pump. The continuous cleaning device for the vacuum pump and the method need not halting in a cleaning process without influencing production or detaching equipment, save time and labor and have no consumption on equipment. Therefore, the device and the method ensure that the vacuum degree of the vacuum pump is not reduced, and the product quality is ensured.

Owner:常州丰盛光电科技股份有限公司

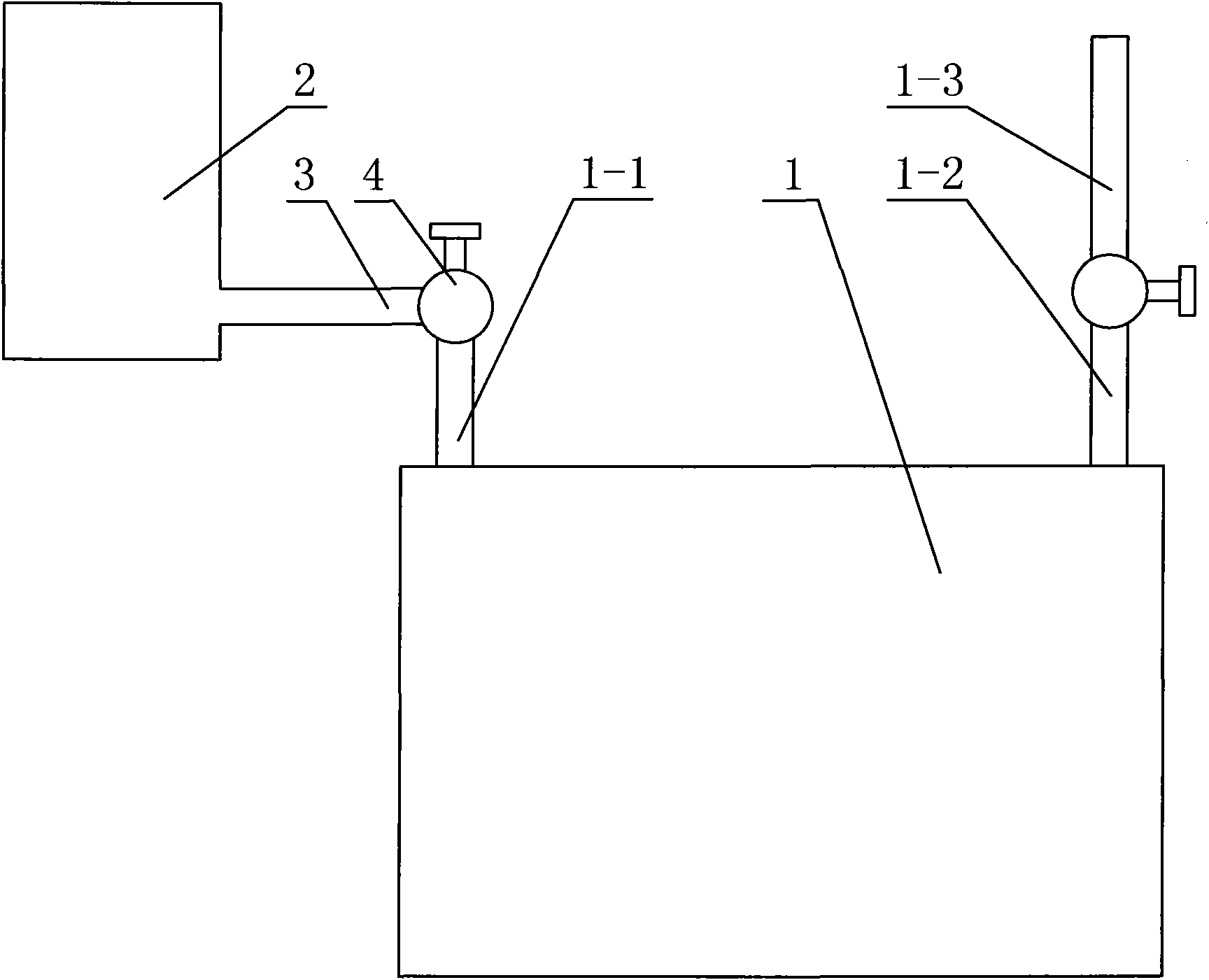

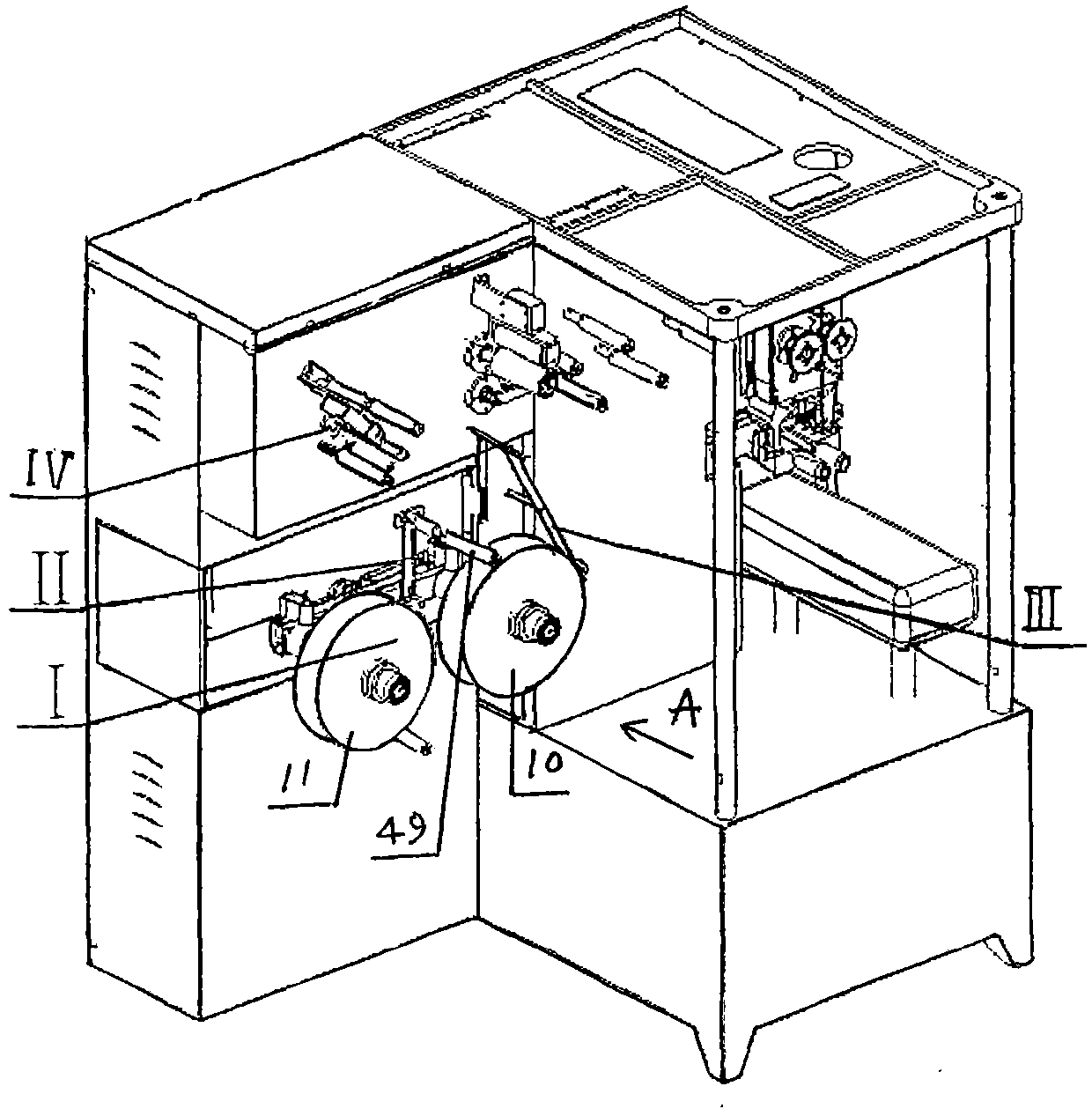

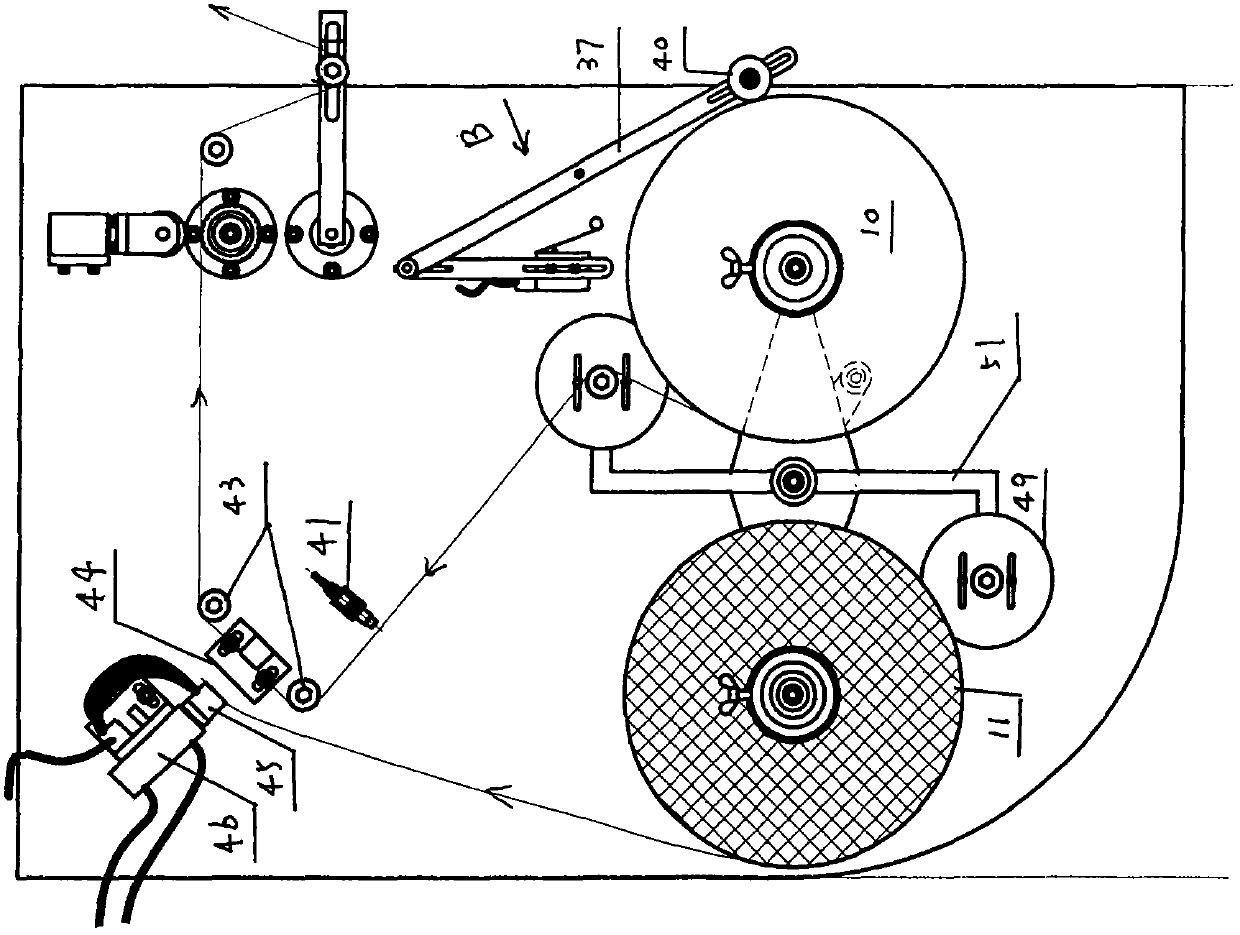

Automatic membrane change device of automatic filling binding machine

ActiveCN103738535AAvoid wastingEasy to makeWrapping material feeding apparatusWebs handlingMembrane switchBiomedical engineering

The invention discloses an automatic membrane change device of an automatic filling binding machine and belongs to the field of food machinery. The automatic membrane change device of the automatic filling binding machine realizes to change membrane automatically. The automatic membrane change device of the automatic filling binding machine comprises a membrane roll change device I which is provided with a membrane roll (10) in use and a spare membrane roll (11) and further comprises a membrane deviation correcting device II, a membrane number reduction detecting device III and a pneumatic membrane switching device IV, when the membrane reduction detecting device detects that the membrane on the membrane roll (10) is reduced by a certain degree, the automatic membrane change device enables the speed to be reduced automatically to prepare for changing membrane; when a photoelectric membrane sensor (41) perceives the end of the membrane roll (10) in use, the front end of the spare membrane roll (11) is bonded with the end of the membrane roll (10) in use through a cylinder (46), the 180 degrees position change is finished through a roll change shaft (1), and accordingly the membrane change is finished. The automatic membrane change device of the automatic filling binding machine is capable of substituting manual membrane change and making full use of membranes so that the waste is avoided, and moreover, the membrane change is finished without stopping the automatic filling binding machine, so that the production is not influenced; the automatic membrane change device of the automatic filling binding machine is easy to manufacture, assemble, disassemble, regulate and maintain and is convenient to operate.

Owner:BEIJING AEROSPACE ORIENTAL TECH DEVCO

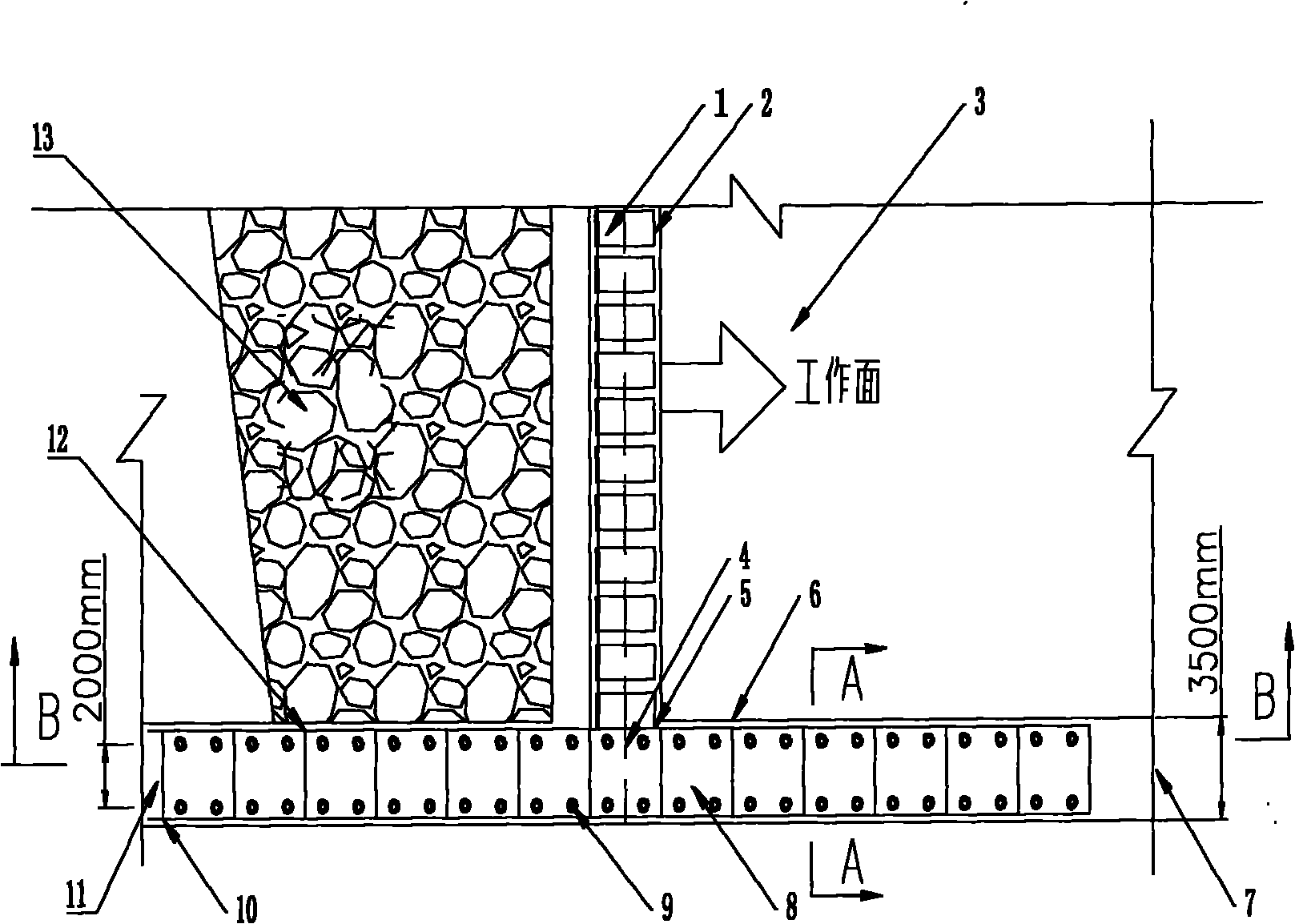

Method for significant reduction of bracket support of gob-side roadway of fully-mechanized mining face

The invention discloses a method for significant reduction of bracket support of the gob-side roadway of a fully-mechanized mining face, which solves the problems of the prior art. In the specific technological scheme, brackets are directly applied to support a roadway, each group of brackets are arranged continuously as a whole along a track gate and is more than 30-35 meters away from the advance face of the track gate, and the uninterrupted installation of the brackets is performed along with advancement in face exploitation; and when the advancement length in the face exploitation is 1.5-2.5 times longer than the face length, the brackets are withdrawn from the beginning of the air return roadway of the working area along the bracket withdrawing direction, and the withdrawn brackets are continuously arranged in the track gate along the bracket arranging direction so as to be recycled in the advance support of the mining face. The invention has the advantages that: the support strength is high, and the amount of reduced plungers is large, thereby reducing the roadway maintenance workload; the brackets can be recycled, and the removal and recovery of the brackets can be performed synchronously with the face mining without influencing the production; and the invention facilitates the rapid restoration of the roadway in tunneling construction.

Owner:DALIAN UNIV

Conveying and temporary storage workstation device with guiding function

The invention discloses a conveying and temporary storage workstation device with a guiding function. The conveying and temporary storage workstation device comprises a machine frame, guiding mechanisms on the two sides, a detecting mechanism, a motor conveying mechanism, a blocking mechanism, a positioning mechanism and a jacking mechanism. The machine frame is a total support of the device. Allthe mechanisms are fixed on the machine frame. Double-row counting frame fences are used as guiding plates on the two sides, and the front ends of the guiding plates are in butt joint with a horn opening with the angle being 5 degrees, so that flower baskets enter the workstation device conveniently. The workstation device has the advantages that manual work can be replaced with an automatic machine, harm of toxic and harmful gas to bodies of operators can be reduced, the efficiency is greatly improved, the device does not need to be stopped in 24 hours, in addition, losses caused by human negligence can be prevented, production is not affected by leakage of toxic and harmful gas, and all aspects are improved compared with traditional production modes.

Owner:HANGZHOU ZHONGWEI PHOTOELECTRICITY

Method for replacing bearing of large ladle turret

ActiveCN103341722AReduce purchasesShort manufacturing cycleMetal working apparatusEngineeringMolten steel

The invention discloses a method for replacing the bearing of a large ladle turret. The method comprises the following steps of detaching associated devices for a protective purpose and preparing an assisted strut, jacking the upper device of the large ladle turret, replacing the bearing of the large ladle turret, lowering the upper device down, and recovering the detached device. The method for replacing the bearing of the large ladle turret only relates to the basic process of setting a hydraulic jack, the upper device on the large ladle turret does not need to be detached, dedicated lifting appliances are not needed, a molten steel receiving bay crane is not needed, and a large-scale trunk crane does not need to be rent, and normal equipment production in a molten steel receiving bay is not influenced. The method for replacing the bearing of the large ladle turret is safe, reliable, saving in cost and capable of shortening construction period greatly.

Owner:CHINA FIRST METALLURGICAL GROUP

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com