Method for automatically identifying and monitoring on-line machined workpieces of numerical control machine tool

A technology for processing workpieces and CNC machine tools, which is applied in the fields of information processing and machinery manufacturing, and can solve problems such as statistical errors and waste

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

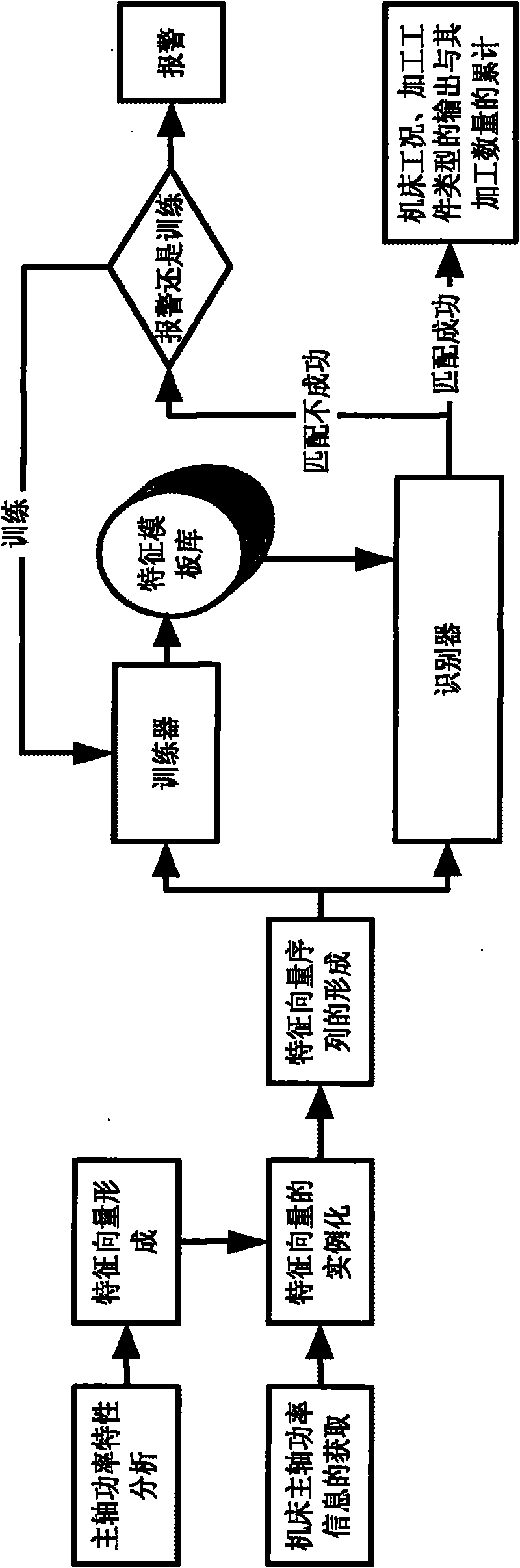

[0112] A method for automatic identification and monitoring of workpieces processed online by CNC machine tools. The automatic identification and monitoring hardware based on this method is composed of active power transmitters, serial port A / D conversion modules, and information interaction terminals. The system structure is shown in Figure 5 , the active power transmitter is installed at the input end of the spindle motor inverter of the CNC machine tool, responsible for collecting the input power signal of the machine tool spindle; the serial port A / D acquisition module is responsible for converting the analog signal into a digital signal to obtain the power value information of the workpiece processing, And the conversion result is sent to the information interaction terminal in real time. The power value sampling frequency is 20Hz and the precision is 12 bits. The information interaction terminal is responsible for processing the power information such as template extracti...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com