Patents

Literature

Hiro is an intelligent assistant for R&D personnel, combined with Patent DNA, to facilitate innovative research.

173results about How to "Short replacement time" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

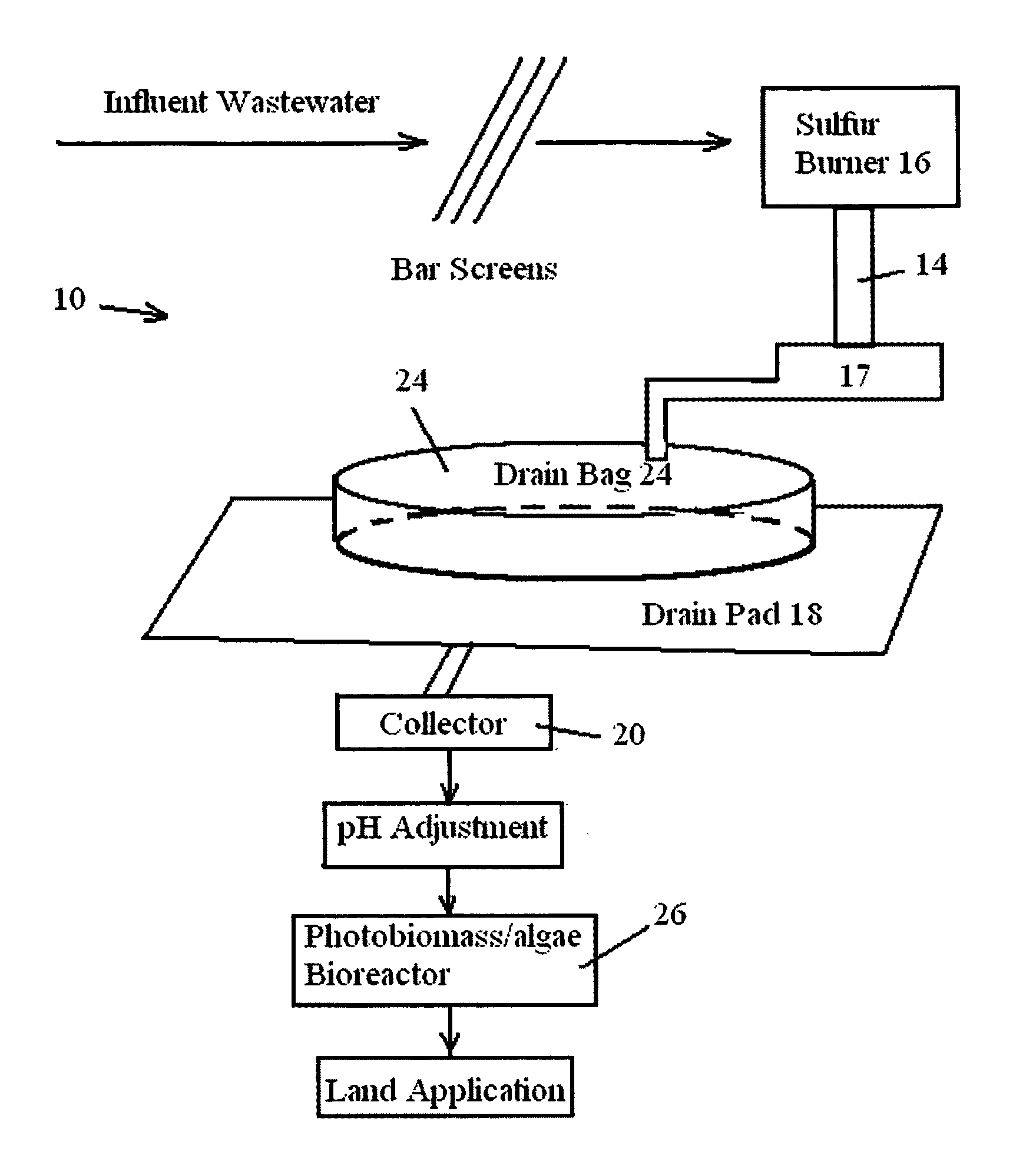

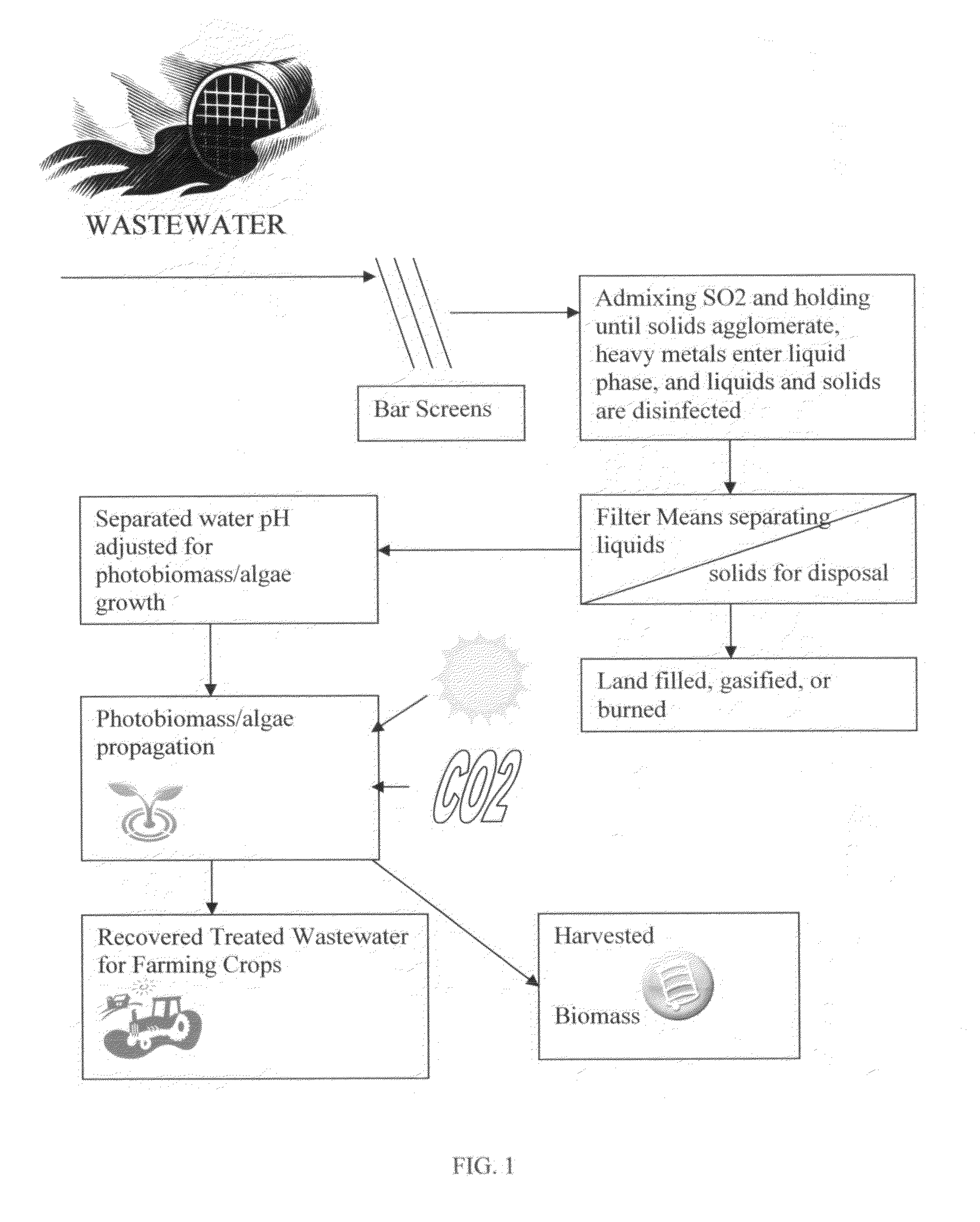

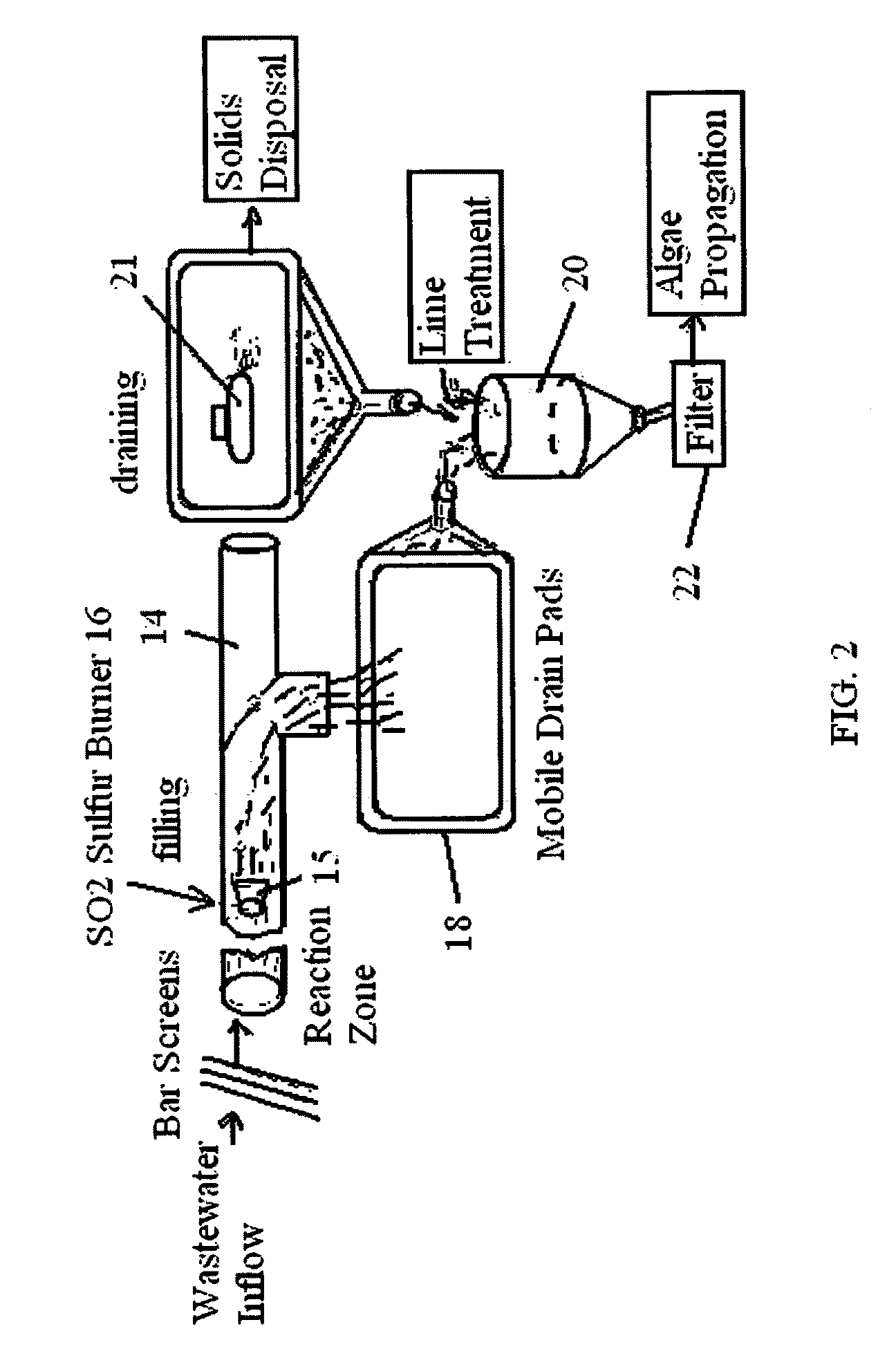

Wastewater photo biomass/algae treatment method

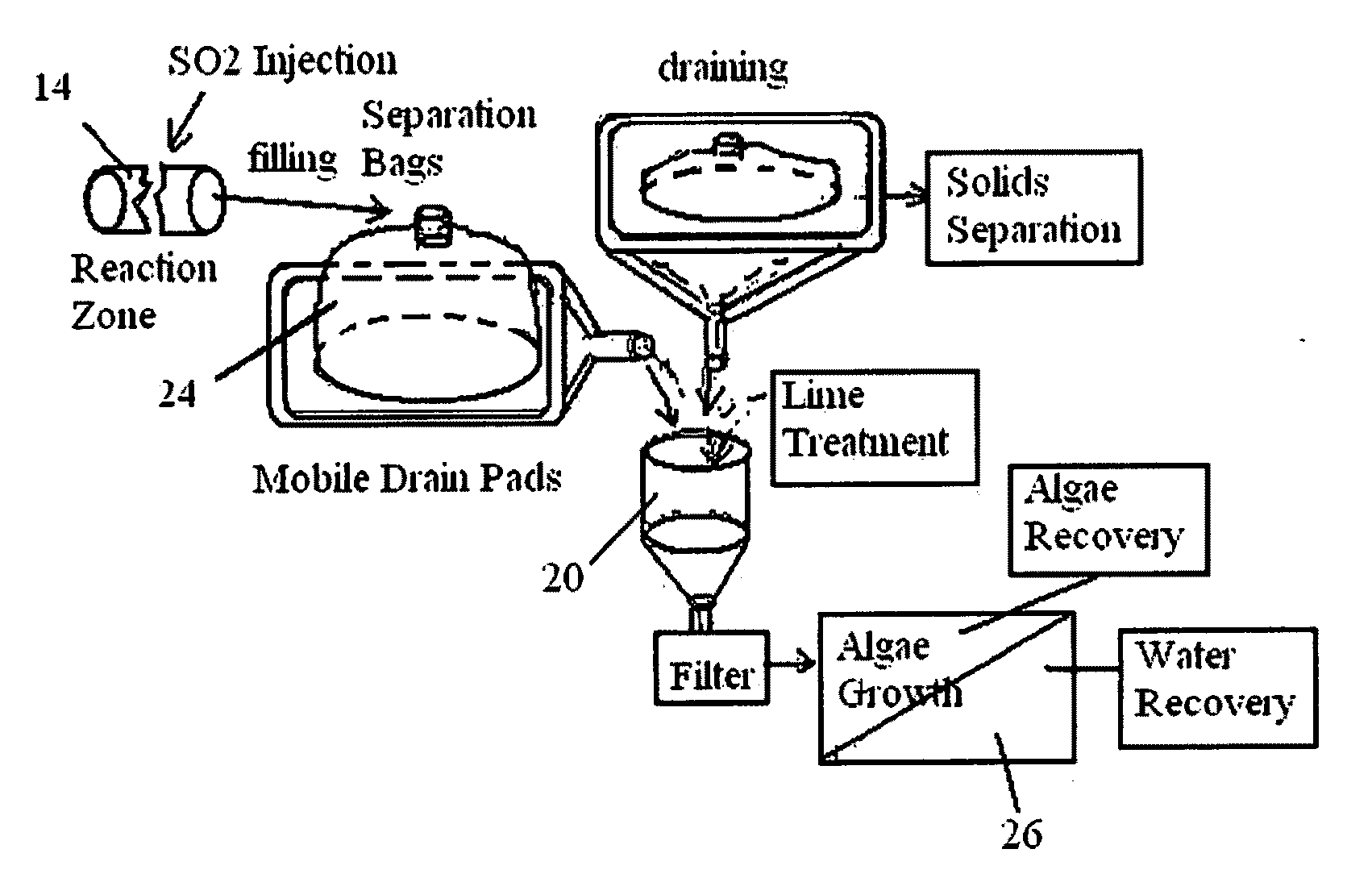

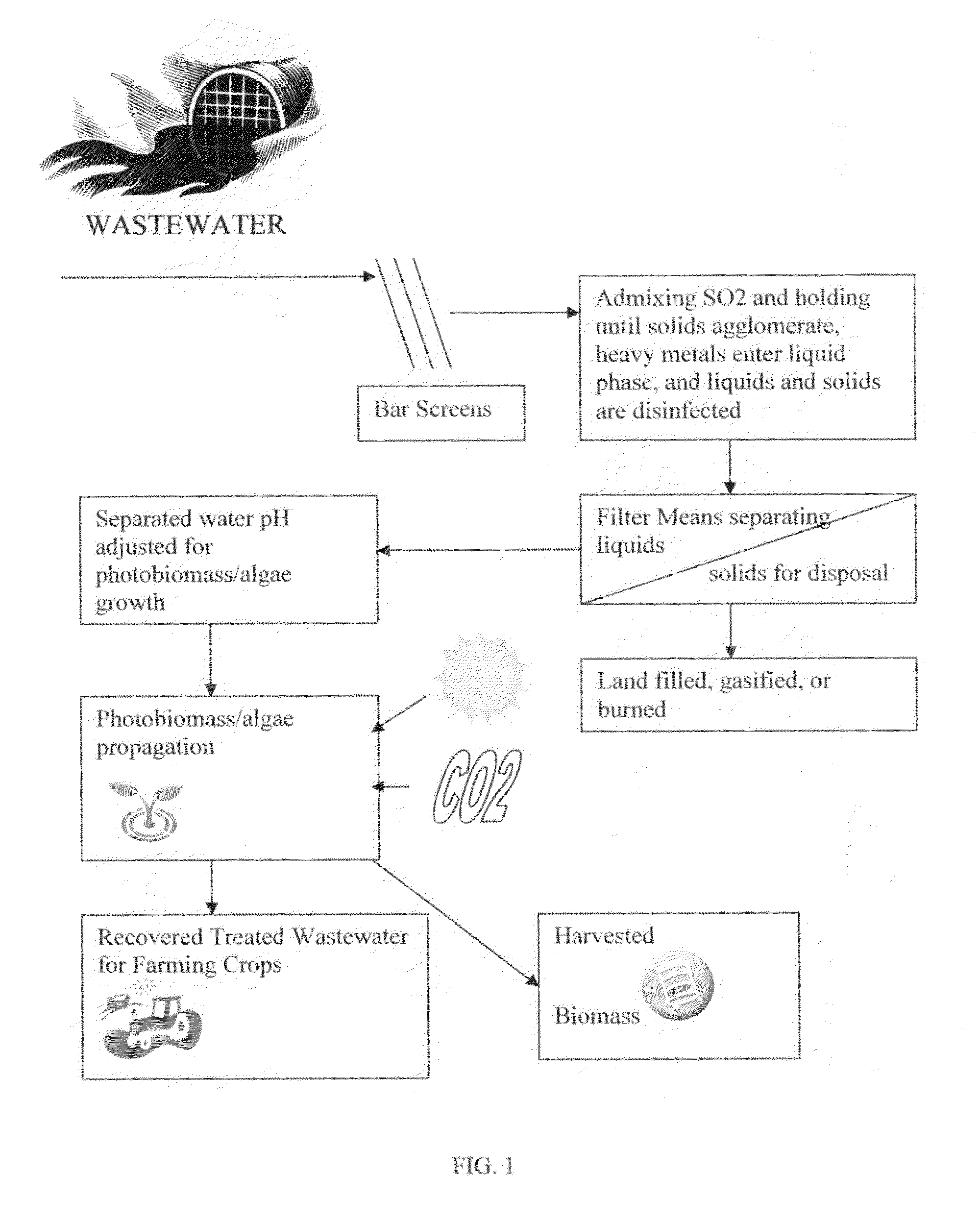

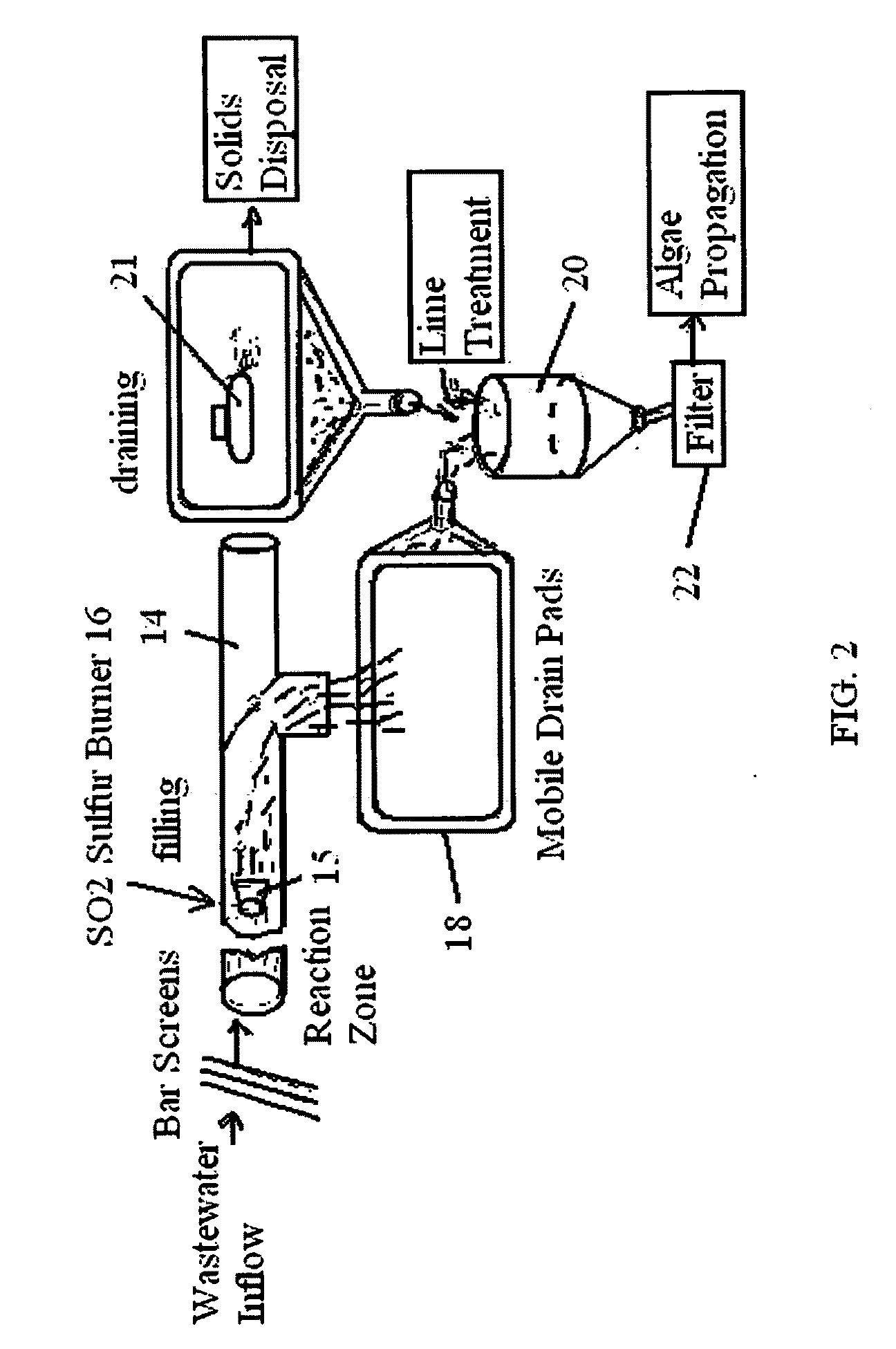

ActiveUS20090294354A1Minimizing stream eutrophicationPrevent eutrophicationUnicellular algaeEnergy based wastewater treatmentCarbon creditBiofuel feedstock

A treatment method for wastewater employing sulfur dioxide and lime chemical dewatering technology in conjunction with an environmental photo biomass / algae biological treatment system growing photo biomass / algae to reduce dissolved solids, heavy metals, and ammonia in the wastewater to produce recovered treated wastewater for vegetation consumption, biofuel feedstock, and biofuel and carbon credits.

Owner:EARTH RENAISSANCE TECH

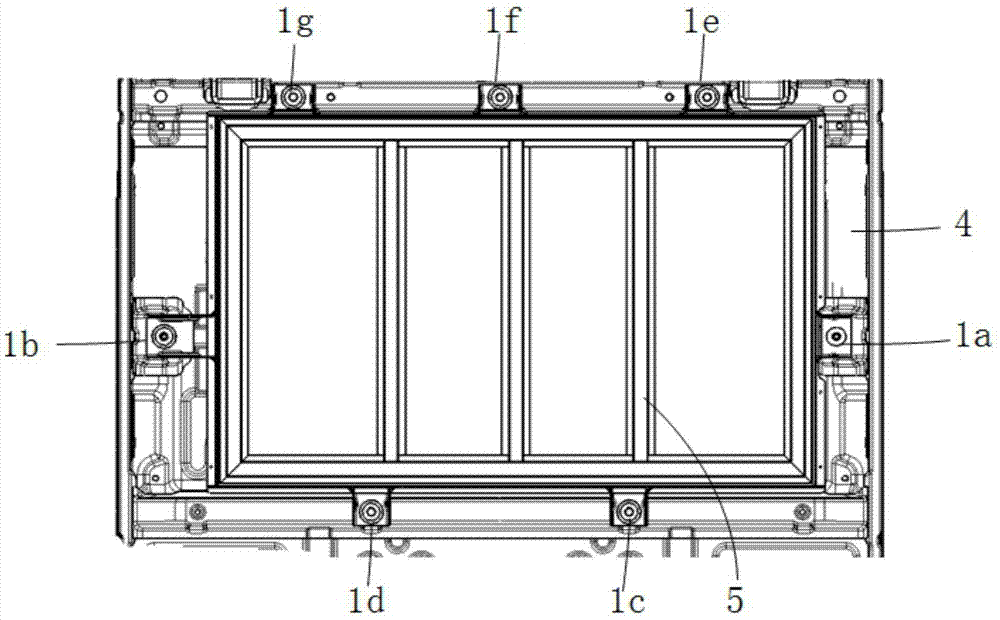

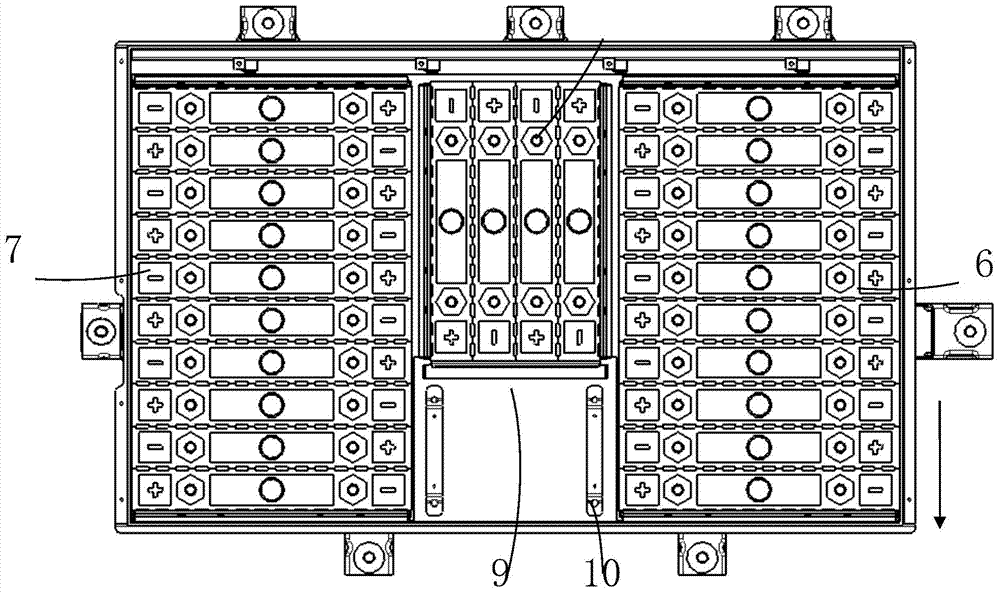

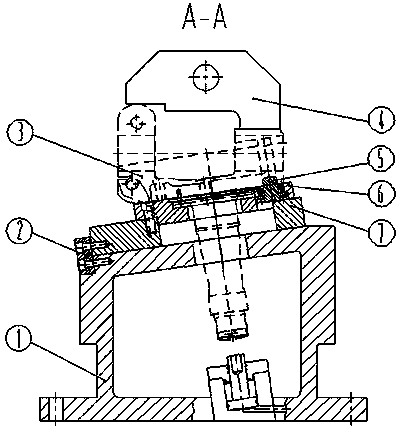

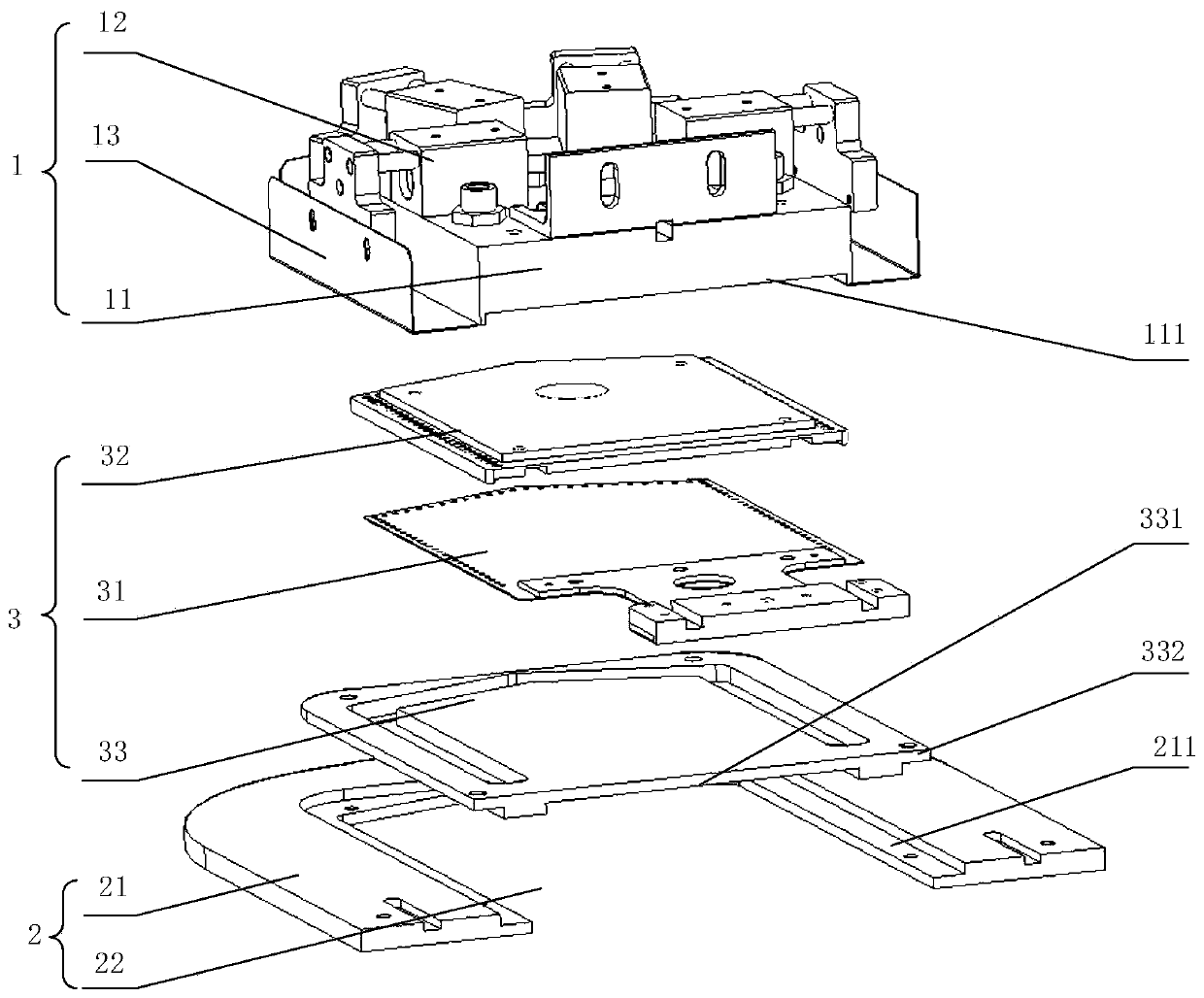

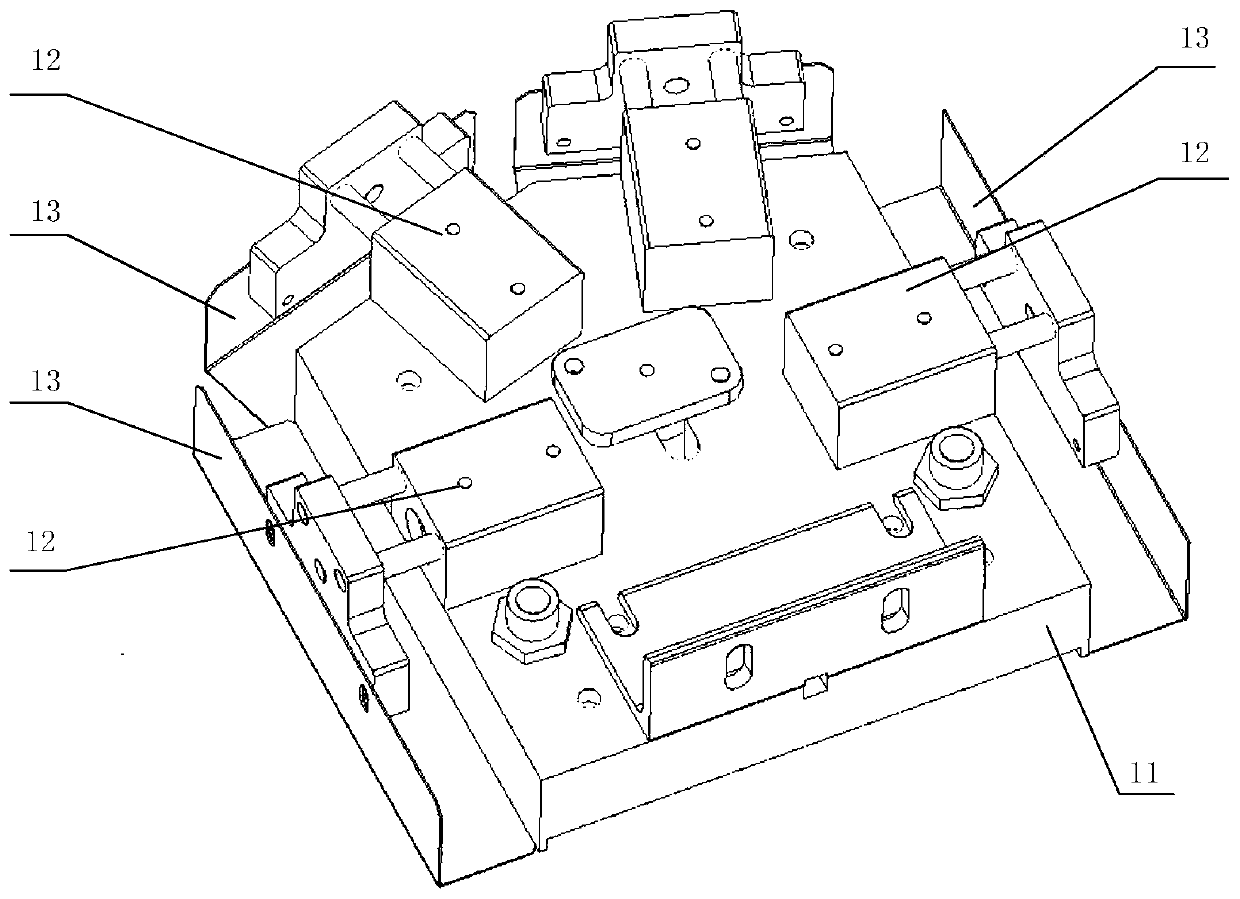

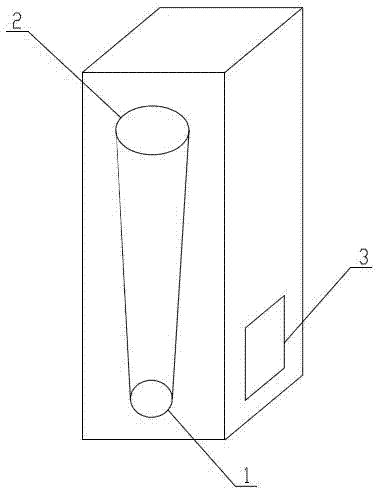

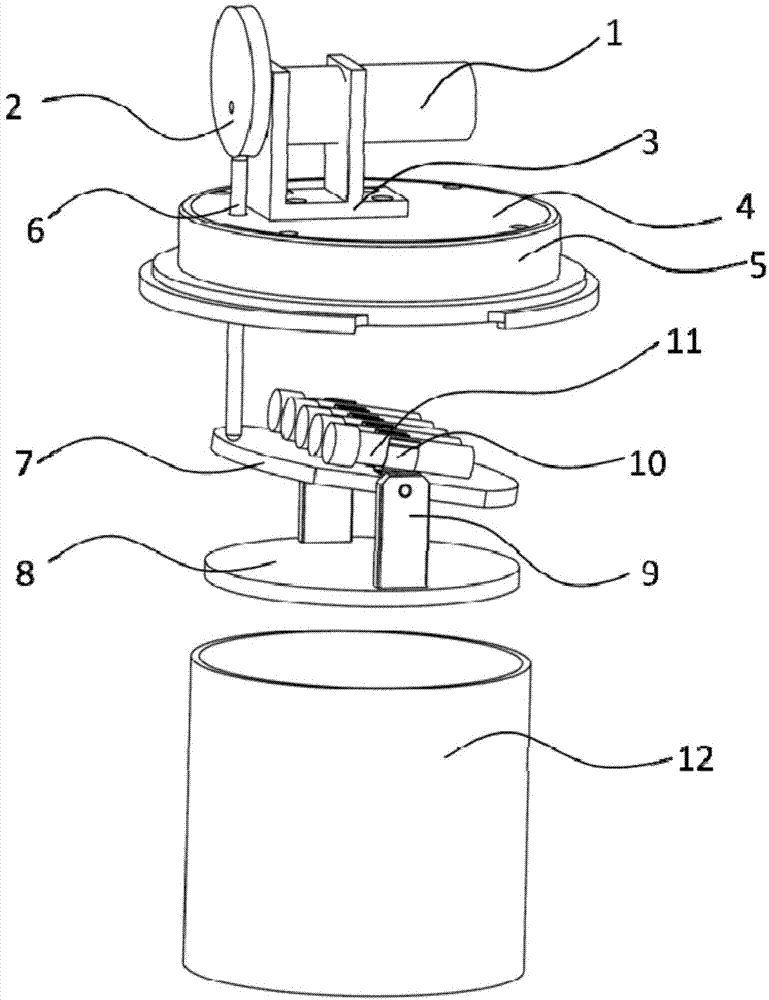

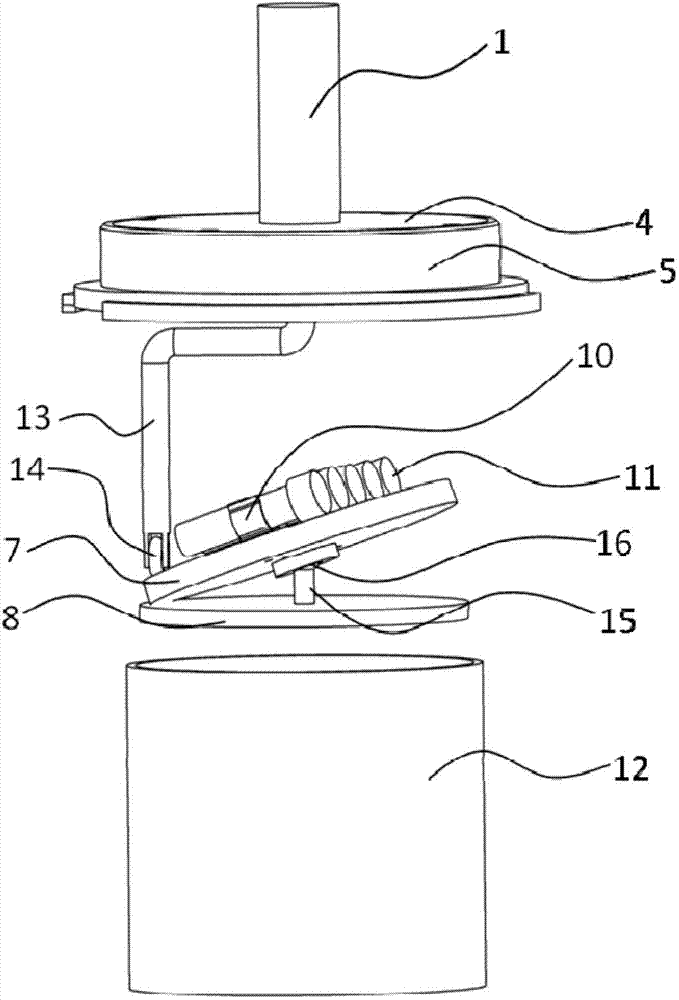

Cell box convenient for cell installation positioning and with damping mechanism

ActiveCN103500805AEasy to fixReasonable structureCell lids/coversBatteriesInterference fitGravity center

A disclosed cell box convenient for cell installation positioning and with a damping mechanism comprises a cell box main body, an electro-insulating rubber gasket and an upper cover; the interior of the cell box main body is provided with an installation positioning assembly, and the exterior of the cell box main body is provided with the damping mechanism; the installation positioning assembly comprises a plurality of welding small supports, metal draw hooks, hook cushion blocks and installation nuts; the damping mechanism comprises a plurality of installation supports, annular rubber sleeves and steel pin bushes; the installation supports are welded at the outer walls of the side plates of the cell box main body; each installation support is provided with an installation hole; and one annular rubber sleeve with big top and small bottom is installed in the installation hole, and the center of the annular rubber sleeve is provided with the steel pin bush by interference fit. The beneficial effects of the cell box comprise that: the cell box is reasonable in structure and convenient for cell installation, and cells are fixed firmly; the cell box not only is capable of realizing rapid installation positioning, but also is capable of ventilating and dissipating heat; the cell box is electro-insulated, waterproof, safe and reliable; and the cell box is provided with the damping mechanism, is fast in replacing time, is beneficial to the gravity center balance of vehicles, and the production cost is relatively ideal.

Owner:LAUNCH DESIGN INC LTD

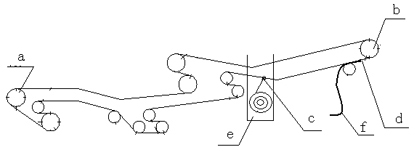

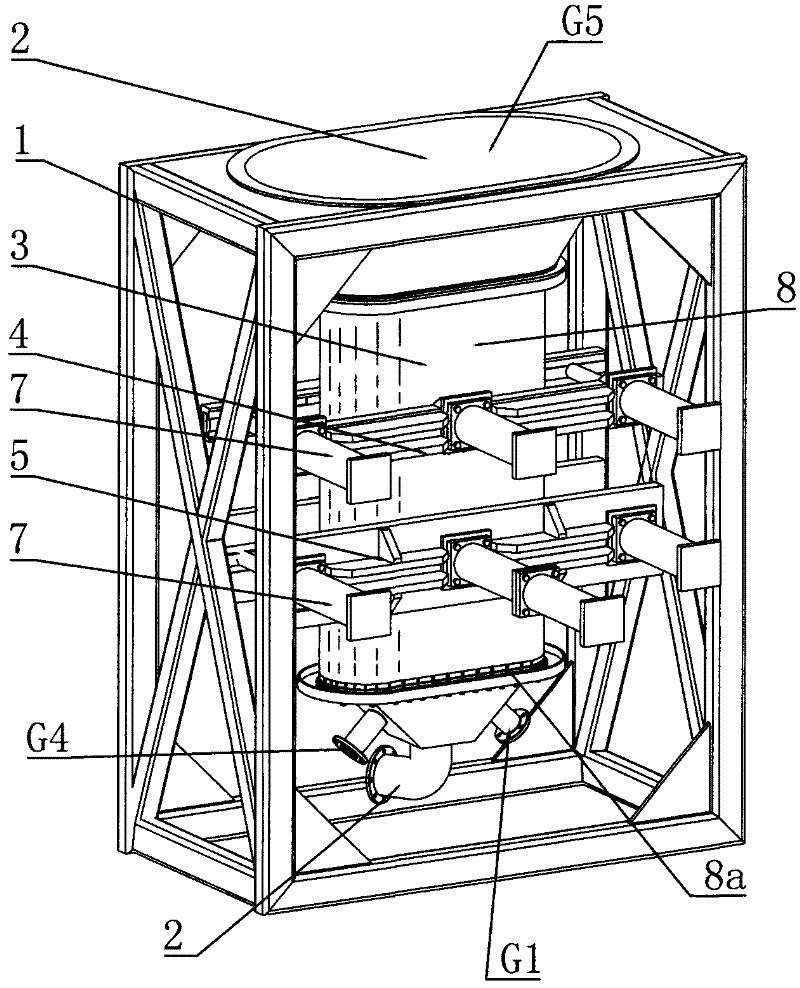

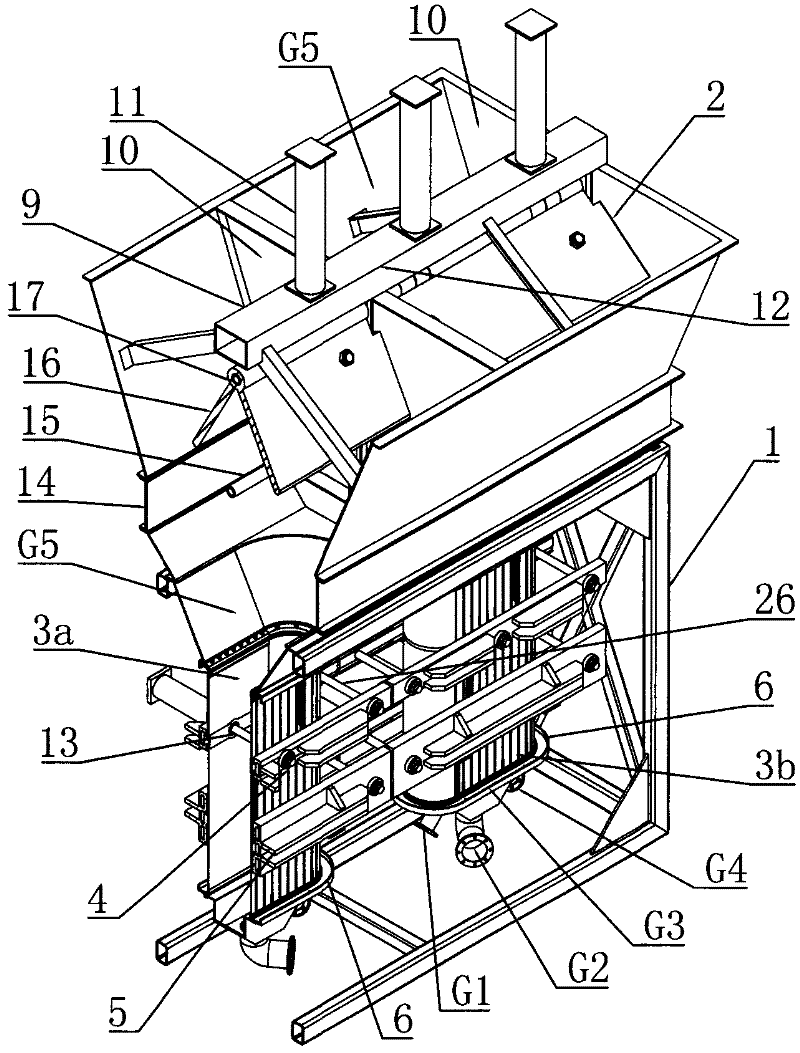

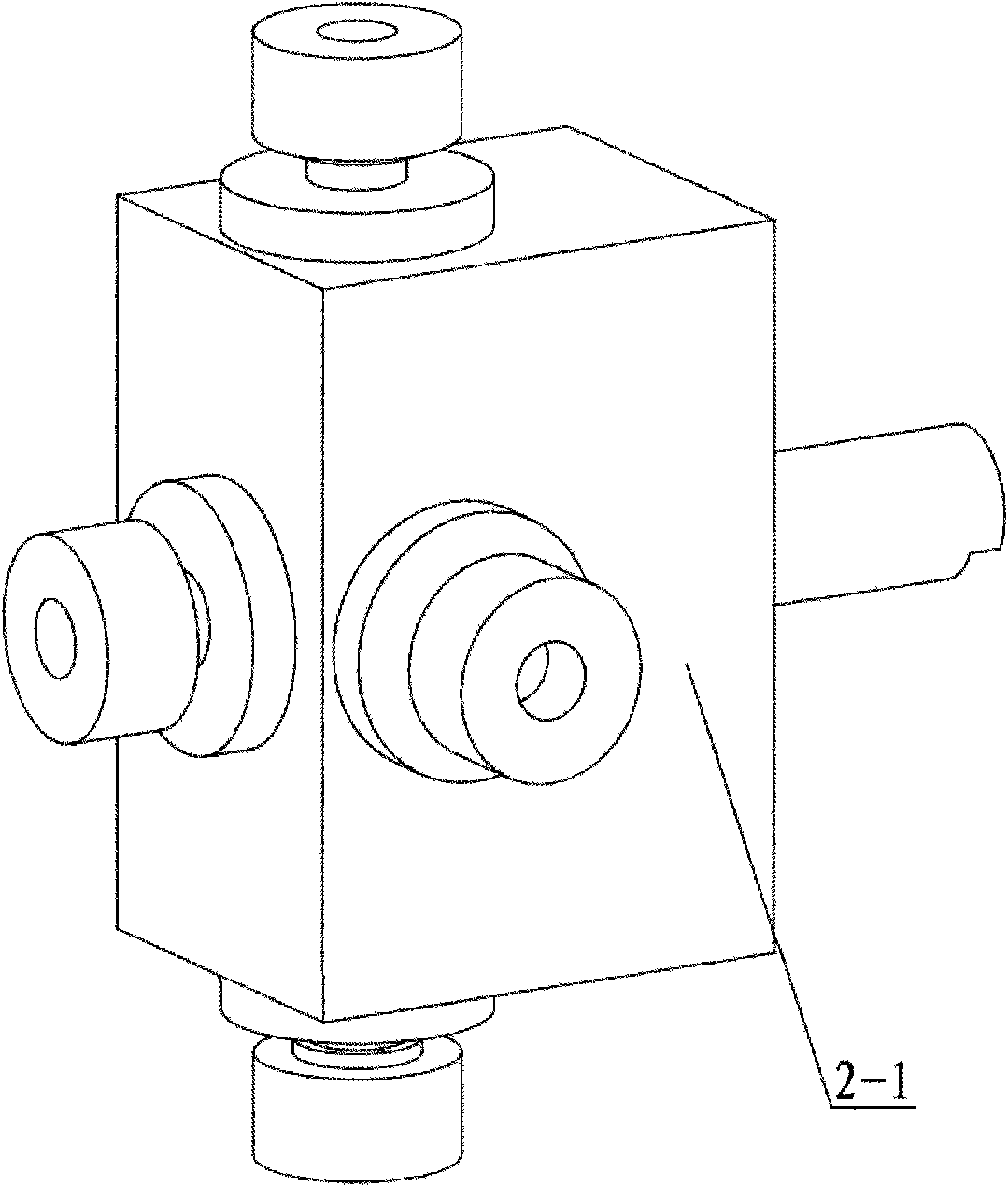

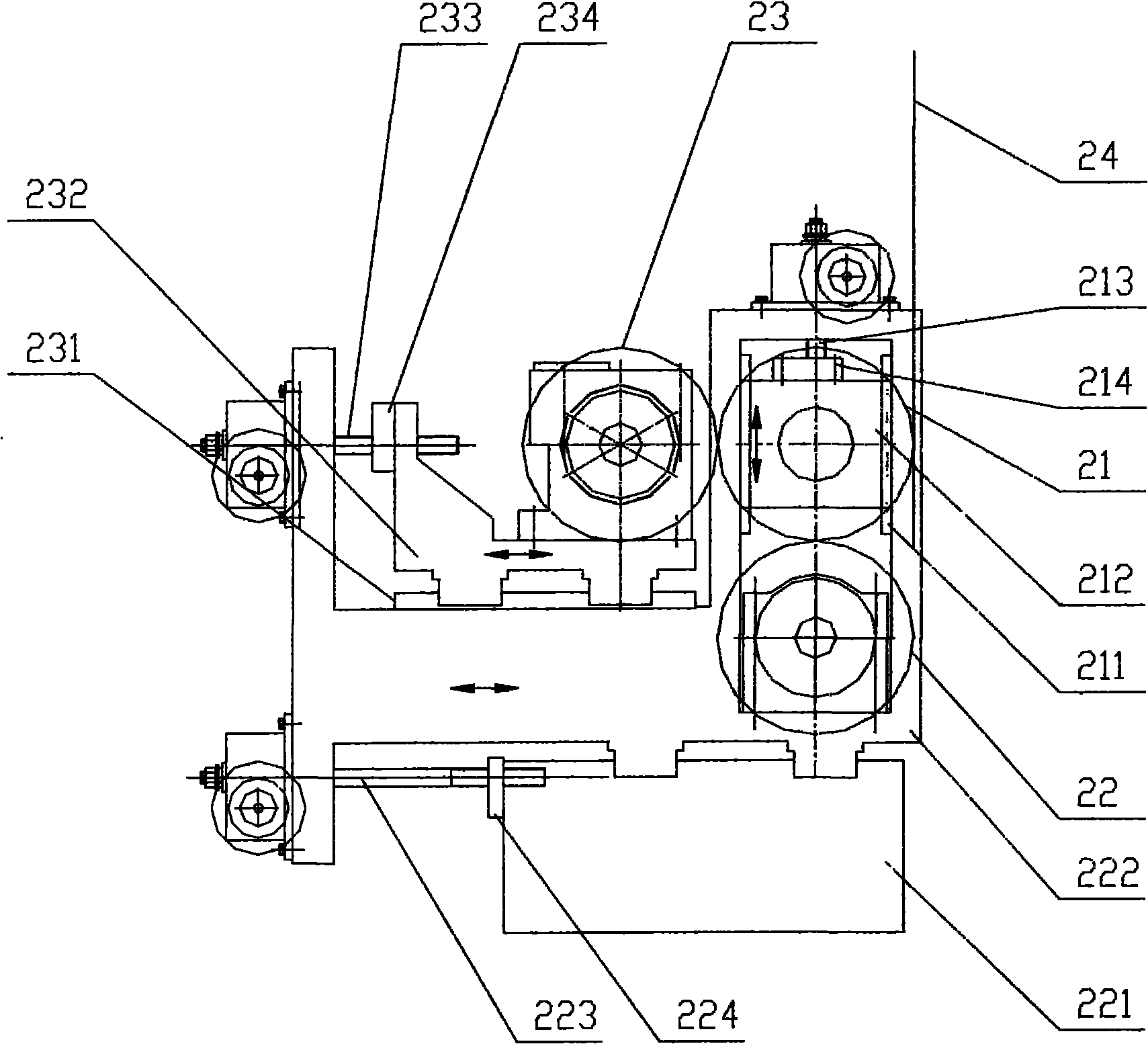

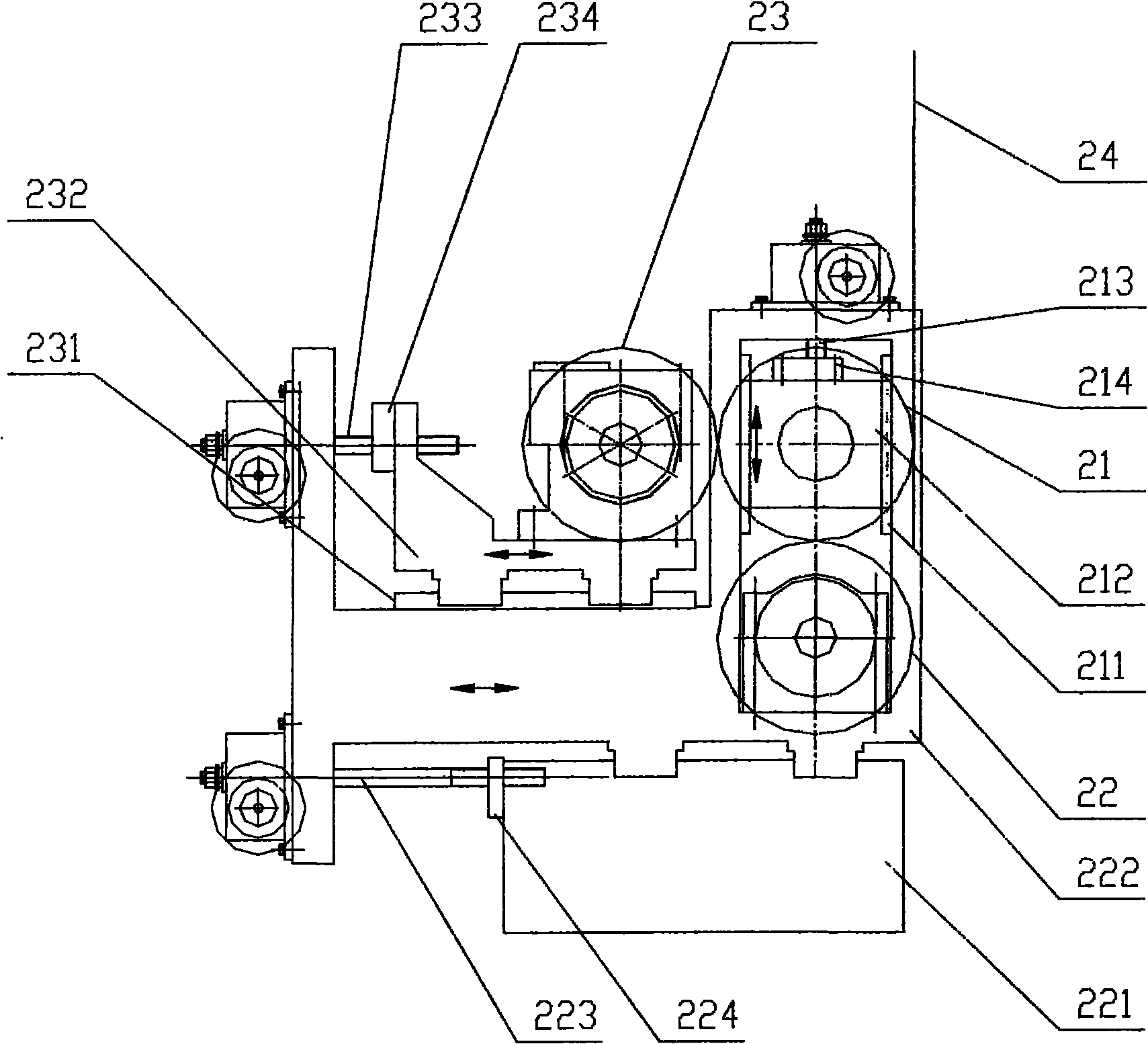

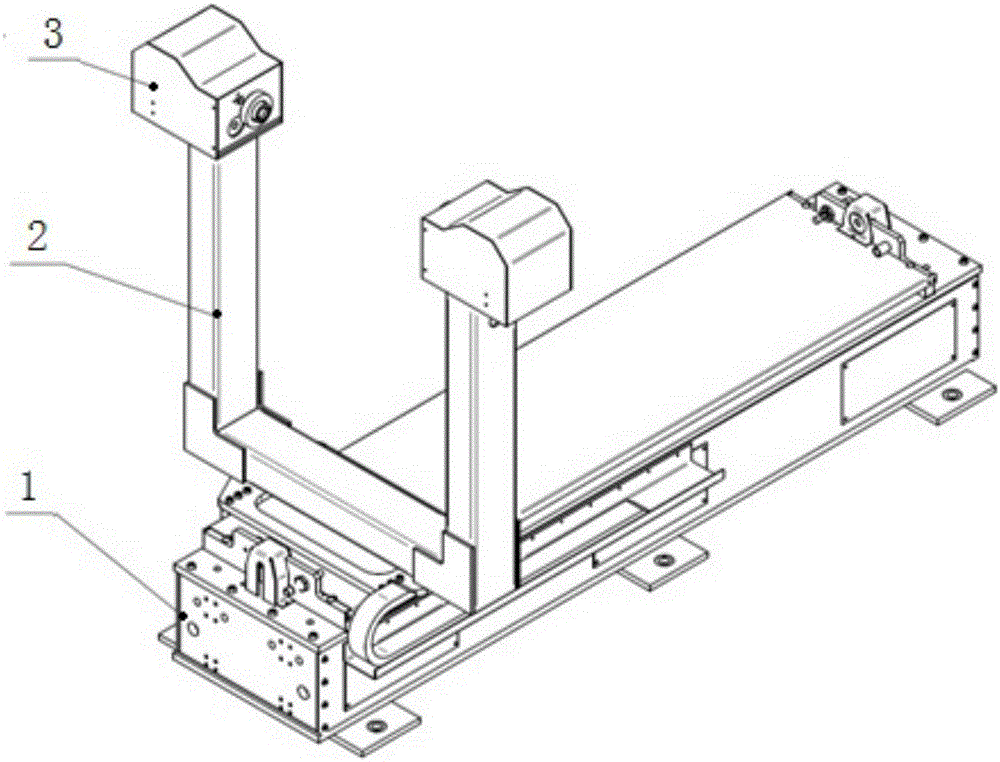

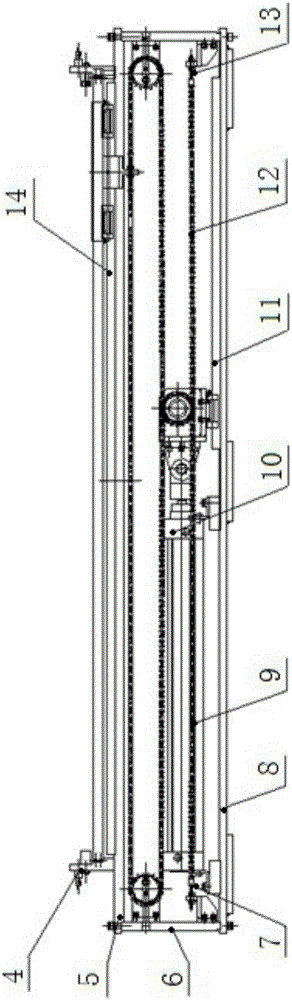

Battery changing device for commercial electric vehicle and electric conversion system

ActiveCN102040010AImprove replacement efficiencyShort replacement cycleCosmonautic condition simulationsCharging stationsElectricityElectrical battery

The invention relates to a battery changing device for a commercial electric vehicle. The device comprises a main frame, a positioning mechanism, a rotating mechanism, a lateral displacement mechanism and a push mechanism, wherein the positioning mechanism consists of a vertical positioning mechanism and a horizontal positioning mechanism; the vertical positioning mechanism is arranged in the main frame, and the horizontal positioning mechanism is arranged on the lower part of the main frame; the rotating mechanism is arranged on the lower part of the vertical positioning mechanism; the lateral displacement mechanism is arranged on the rotating mechanism; and the push mechanism is arranged on the lateral displacement mechanism. The invention also relates to an electric conversion system comprising the battery changing device. The battery changing device can automatically change a battery pack of the electric commercial vehicle; the process of assembling and disassembling the whole battery pack is completed by the battery changing device, is convenient, and has short changing time; the efficiency of battery changing is improved, so multiple times of battery changing can be completed in a unit time, the period of battery changing is shorter, a charger can charge electricity more sufficiently and has higher utilization.

Owner:STATE GRID CORP OF CHINA +1

Method for replacing rubber belt by long-distance steel cord rubber belt conveyor

The invention relates to a maintenance technology of underground equipment of a coal mine, in particular to a method for replacing a rubber belt of a long-distance steel cord rubber belt conveyor, solving the problem of replacement of the underground long-distance rubber belt of the coal mine. The method comprises the following steps of: stopping; punching cards on a machine end and a lower rubber belt; lifting an upper rubber belt positioned on a certain position; disassembling a rack positioned on the position; installing a rubber belt winder on the position; cutting the lower rubber belt on the machine end and the position; connecting a new rubber belt with an old rubber belt; disassembling the cards positioned on the machine end and the lower rubber belt; pulling the old rubber belt for m meters, then cutting the old rubber belt of m meters, winding the old rubber belt of m meters, and forking an old rubber belt coil by a forklift so as to complete one rubber belt replacement unit; and sequentially operating for a plurality of times till rubber belt replacement is completed. The invention has the characteristics of shortest replacing time, overlength-distance fast belt replacement.

Owner:SHANXI JINCHENG ANTHRACITE COAL MINING GRP CO LTD

Wastewater photo biomass/algae treatment method

ActiveUS8097168B2Avoid lostImprove securityUnicellular algaeSedimentation separationVegetationWastewater

A treatment method for wastewater employing sulfur dioxide and lime chemical dewatering technology in conjunction with an environmental photo biomass / algae biological treatment system growing photo biomass / algae to reduce dissolved solids, heavy metals, and ammonia in the wastewater to produce recovered treated wastewater for vegetation consumption, biofuel feedstock, and biofuel and carbon credits.

Owner:EARTH RENAISSANCE TECH

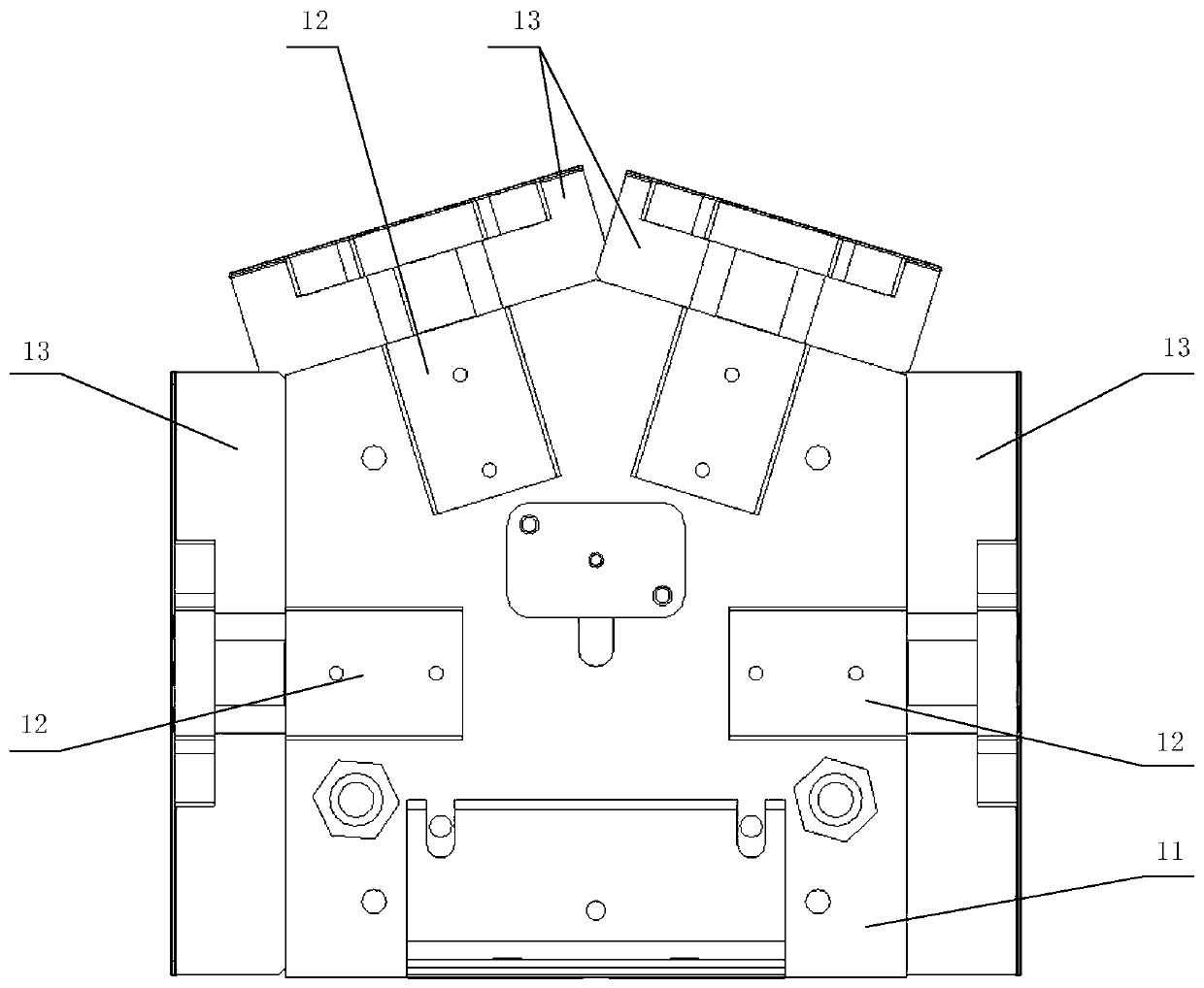

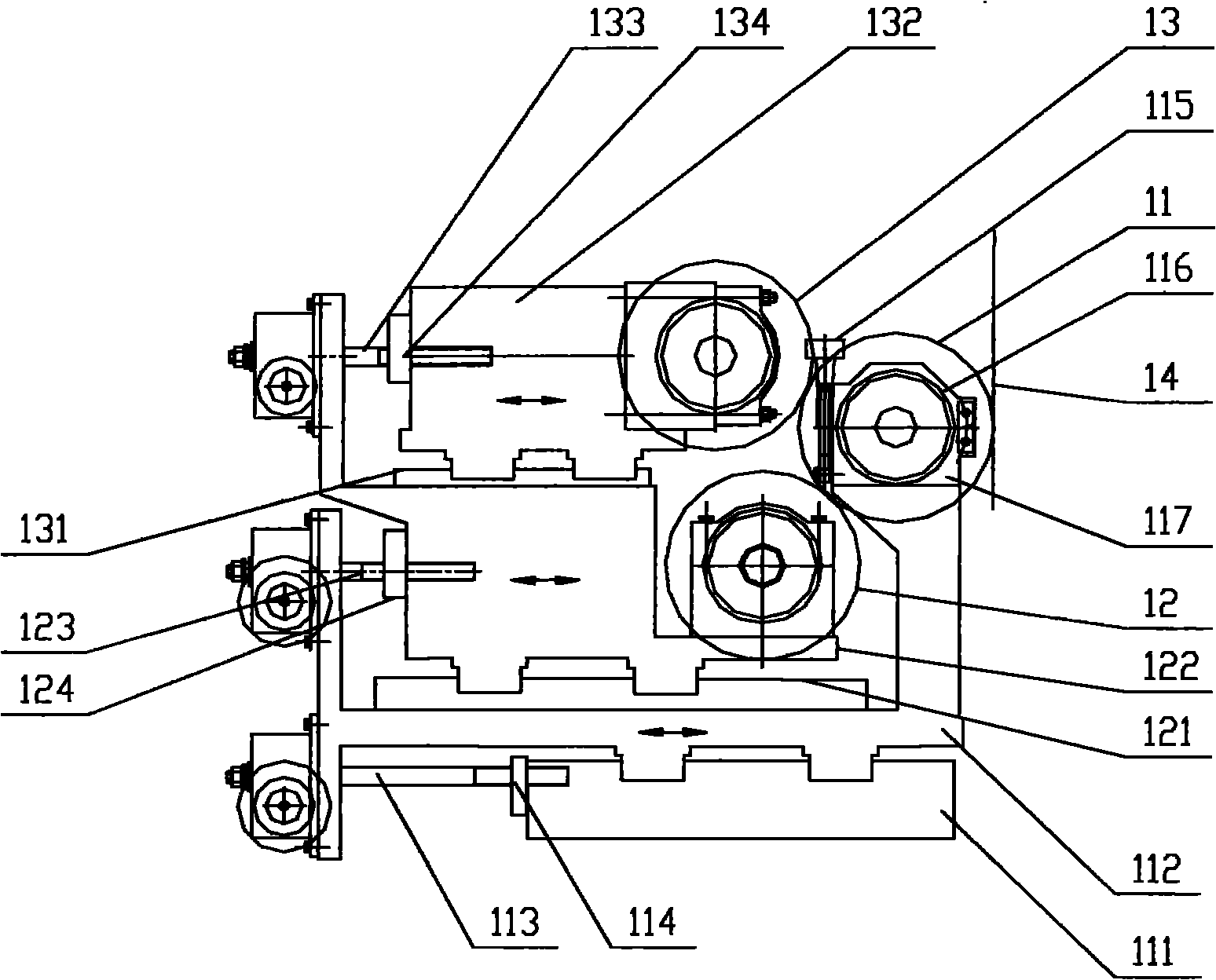

Flexible quick-changing locating device

InactiveCN104339202ASave storage spaceEasy to managePositioning apparatusMetal-working holdersEngineeringUltimate tensile strength

The invention discloses a flexible quick-changing locating device. The flexible quick-changing locating device is suitable for flexibly producing different kinds of steering knuckles. A fixture body is fixed with a machine tool workbench through keys and bolts, the fixture body is provided with lateral and front locating plates, the lateral and front locating plates are respectively connected with the fixture body and an angle plate through bolts, the angle plate is connected with the fixture body through bolts, a locating plate is located through locating pins and angle plate bayonets and fixed on the angle plate through bolts, a workpiece is located on the locating plate through the locating pins and bayonets of the locating plate and compressed through a press block, the press block is fixed on a connecting bar through bolts, the connecting bar is connected with an oil cylinder push rod through bolts, and the oil cylinder push rod controls the compressing and loosening of the press block through the hydraulic system under program control. According to the flexible quick-changing locating device, the user only needs to change the locating element when changing varieties, the tool storage space can be reduced, the tool management is facilitated, the locating mode is practical, the locating precision is high, the labor intensity of the operator for changing the fixture is greatly alleviated, the operation is facilitated, the change time is short, and the production efficiency is effectively improved.

Owner:DONGFENG DANA AXLE

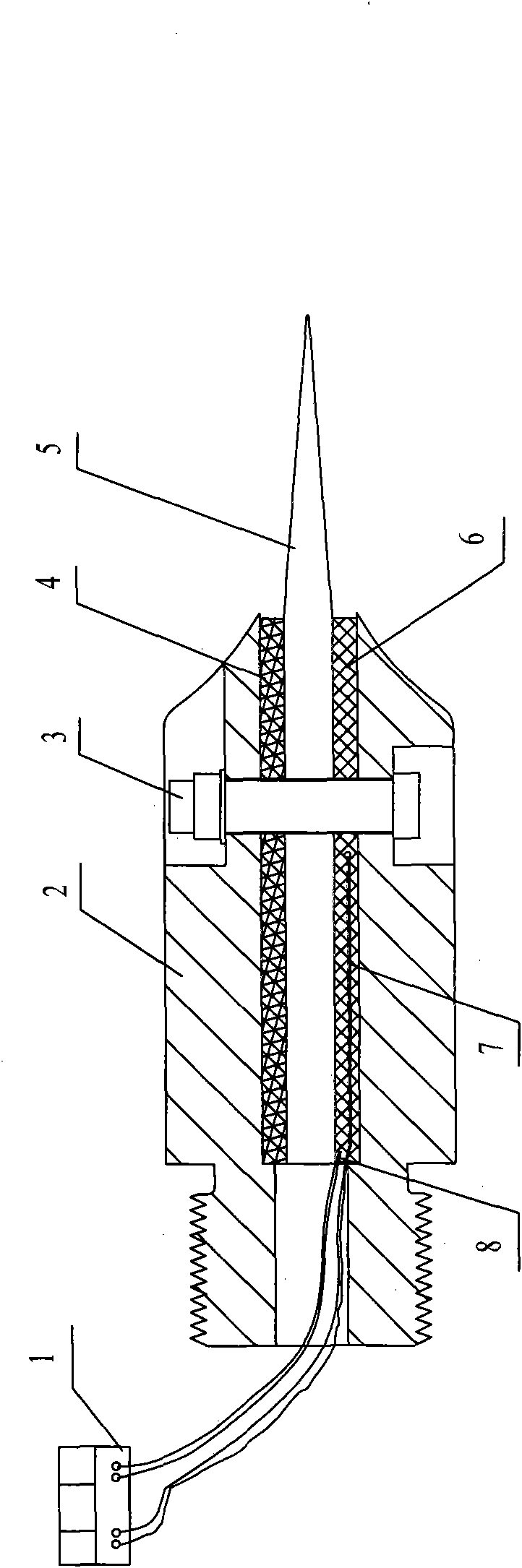

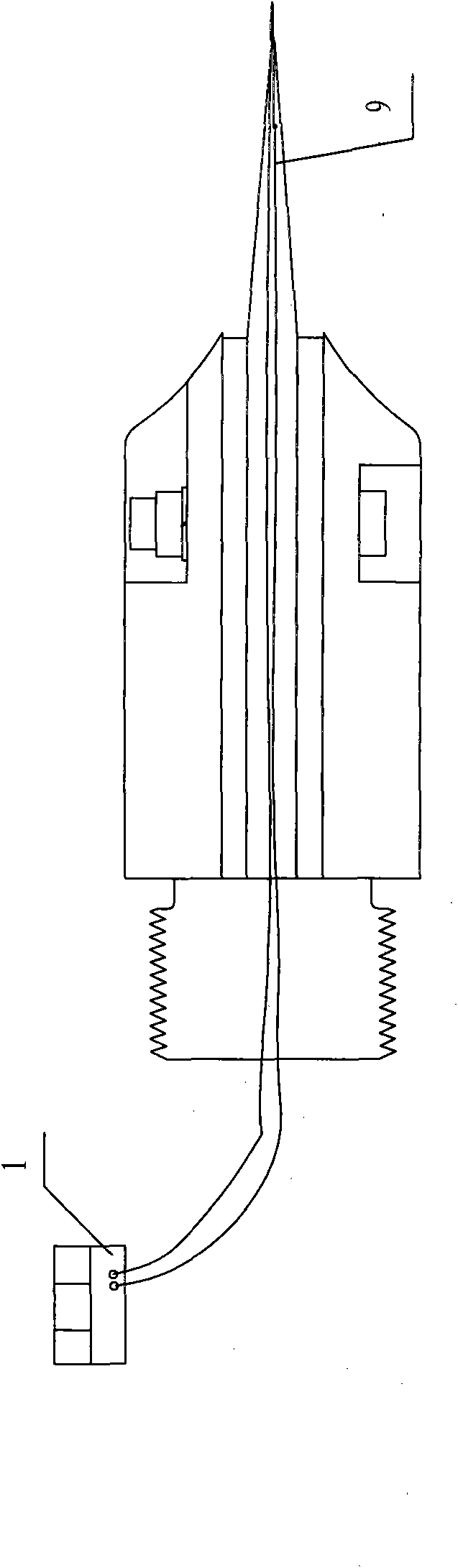

Thermal cutting shear and cutting method thereof

InactiveCN101992473ATemperature is directly measured and controlledTemperature measurement and controlMetal working apparatusRubber materialTemperature control

The invention relates to a thermal cutting shear and a cutting method thereof, and a flat arrangement type heating mode in fixture bodies is adopted to enhance the heating efficiency and the heat transfer speed and effectively control the operating temperature when the front end of a cutting edge carries out the cutting so as to enhance the cutting quality of the rubber material, and the quality of the joint and the stitching among various materials. The cutting shear comprises a group of the fixture bodies and shear bodies clamped and fixed among the fixture bodies, wherein at least one flat plate type heating plate is lined among the fixture bodies and the bases of the shear bodies; a heat source temperature sensor is arranged in the heating plate and is connected with an external power supply and a temperature control meter through a power supply wire; and a shear body temperature sensor is arranged in the cutting edge part of the shear bodies.

Owner:MESNAC

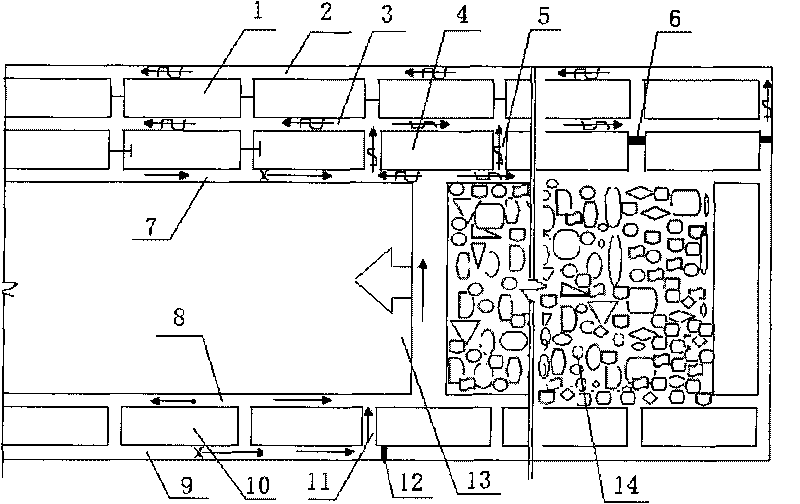

Ventilating system arranged in U+H shape under coal mine

ActiveCN101718208ASuitable for miningLow ventilation resistanceTunnel/mines ventillationCoalH shaped

The invention relates to a ventilating system arranged in U+H shape under the coal mine, in particular to a ventilating systems arranged in U+H shape under the high methane coal mine, aiming at solving the problem of the ventilating system in the process of stoping the face of the coal mine. The ventilating system comprises a stoping face. One side of the stoping face is provided with a belt conveying and air intaking way and an auxiliary conveying and air intaking way in sequence, and the other side is provided with an auxiliary conveying and air intaking way, a first air returning way and a second air returning way in sequence. The belt conveying and air intaking way and the two auxiliary conveying and air intaking ways intake air and return air after being communicated with the first air returning way and the second air returning way through a channel arranged in front of the stoping face. Therefore, the ventilating system which is arranged in U+H shape and intakes air for three times and returns air for two times is formed.

Owner:SHANXI JINCHENG ANTHRACITE COAL MINING GRP CO LTD +1

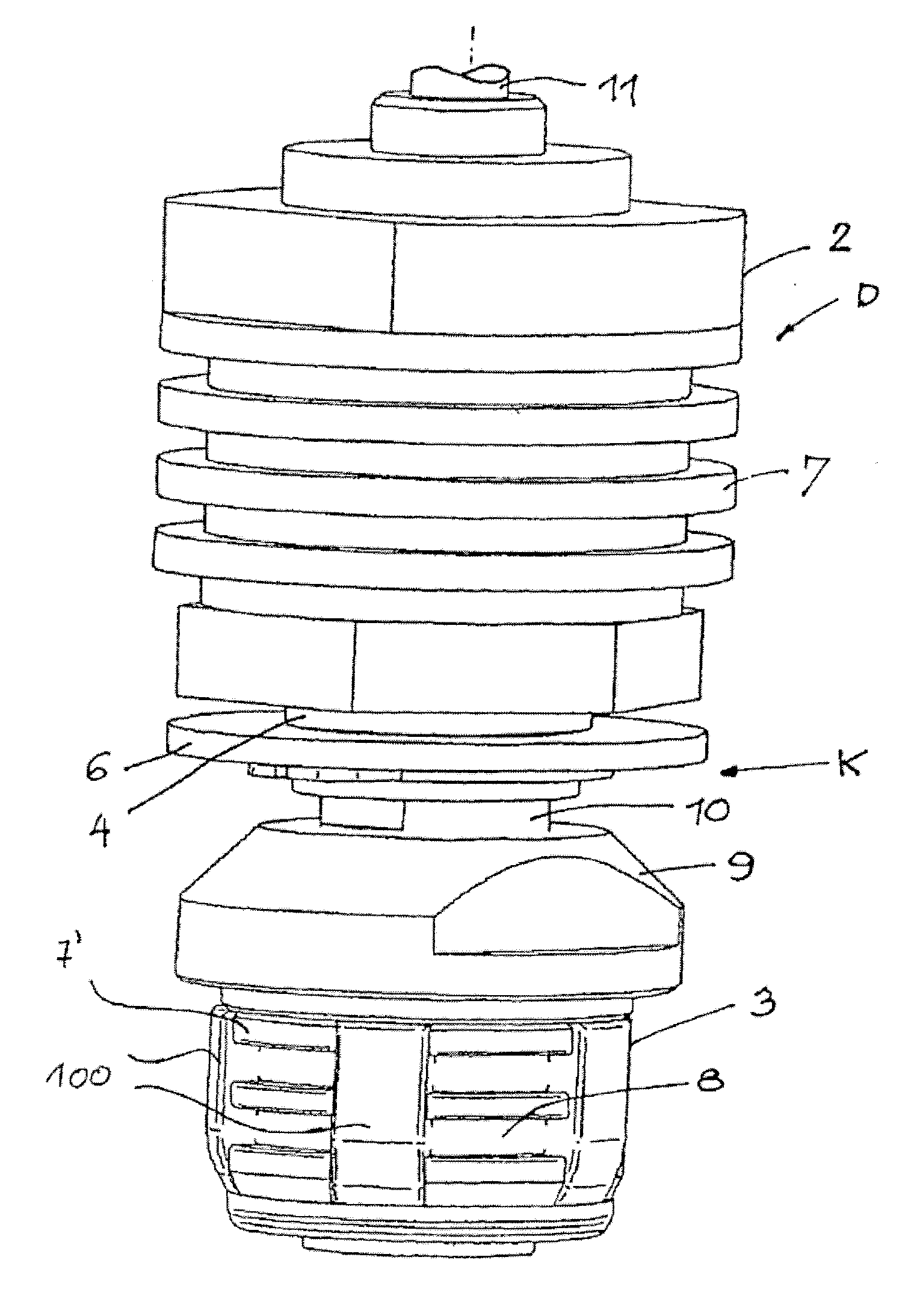

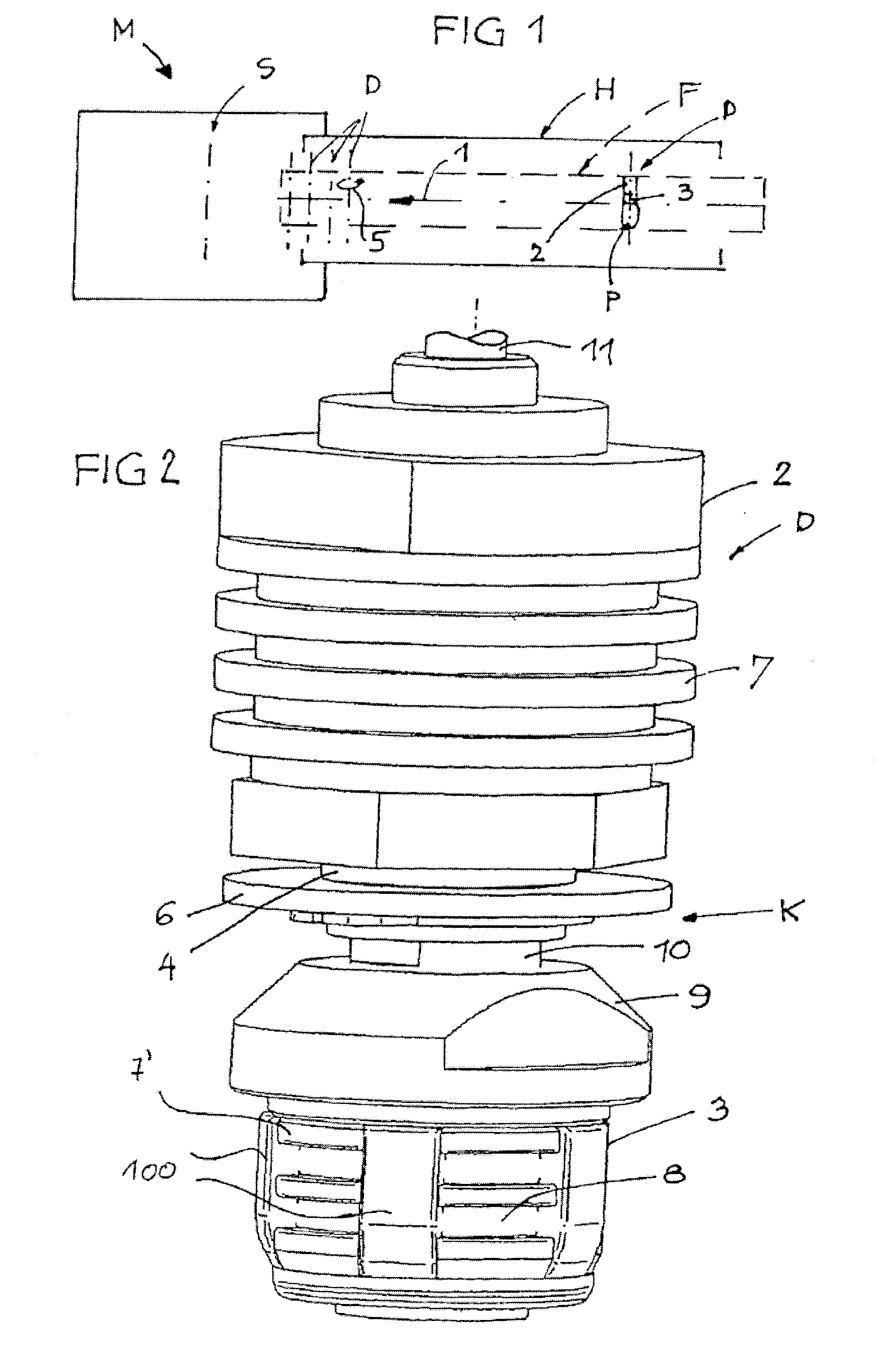

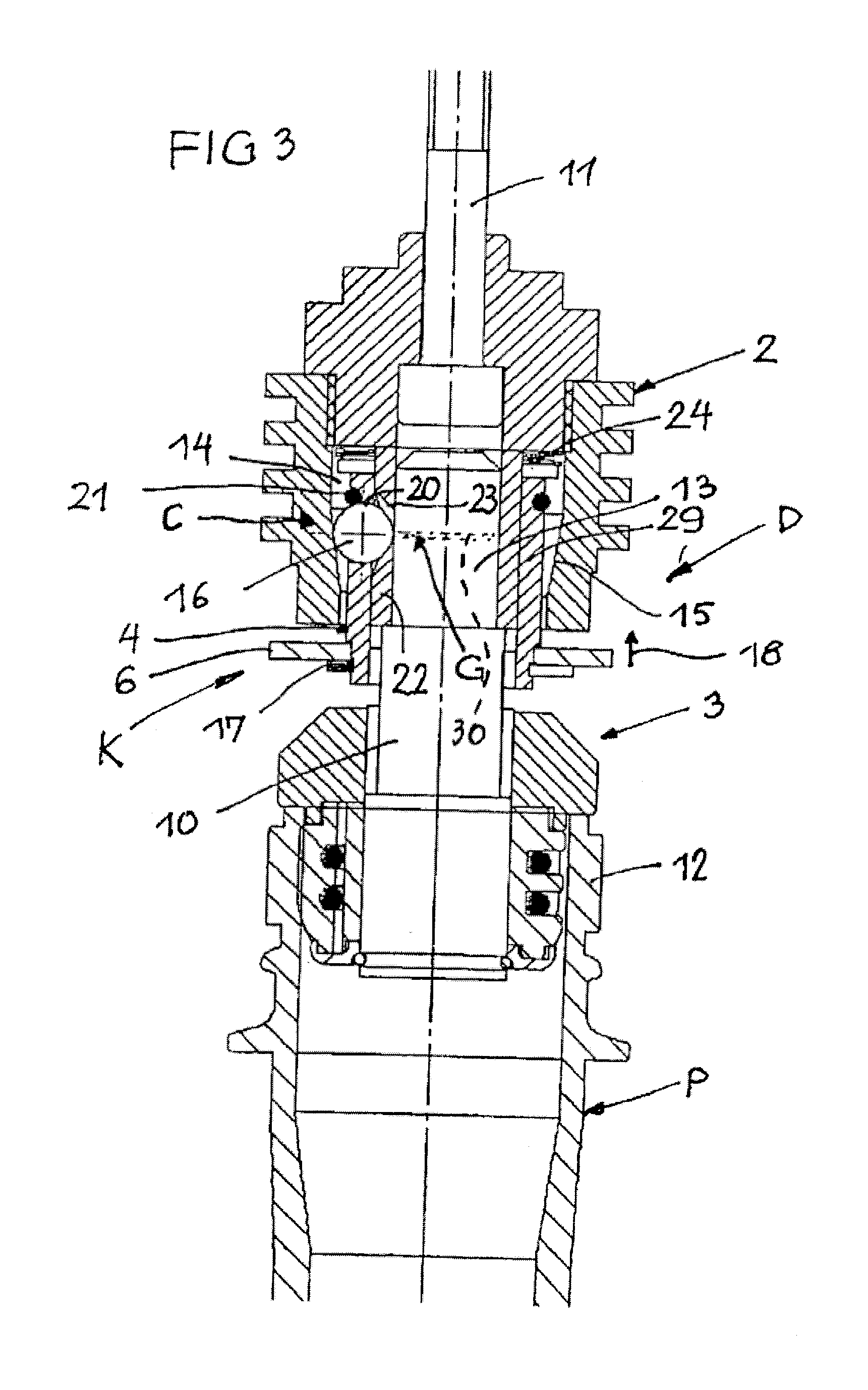

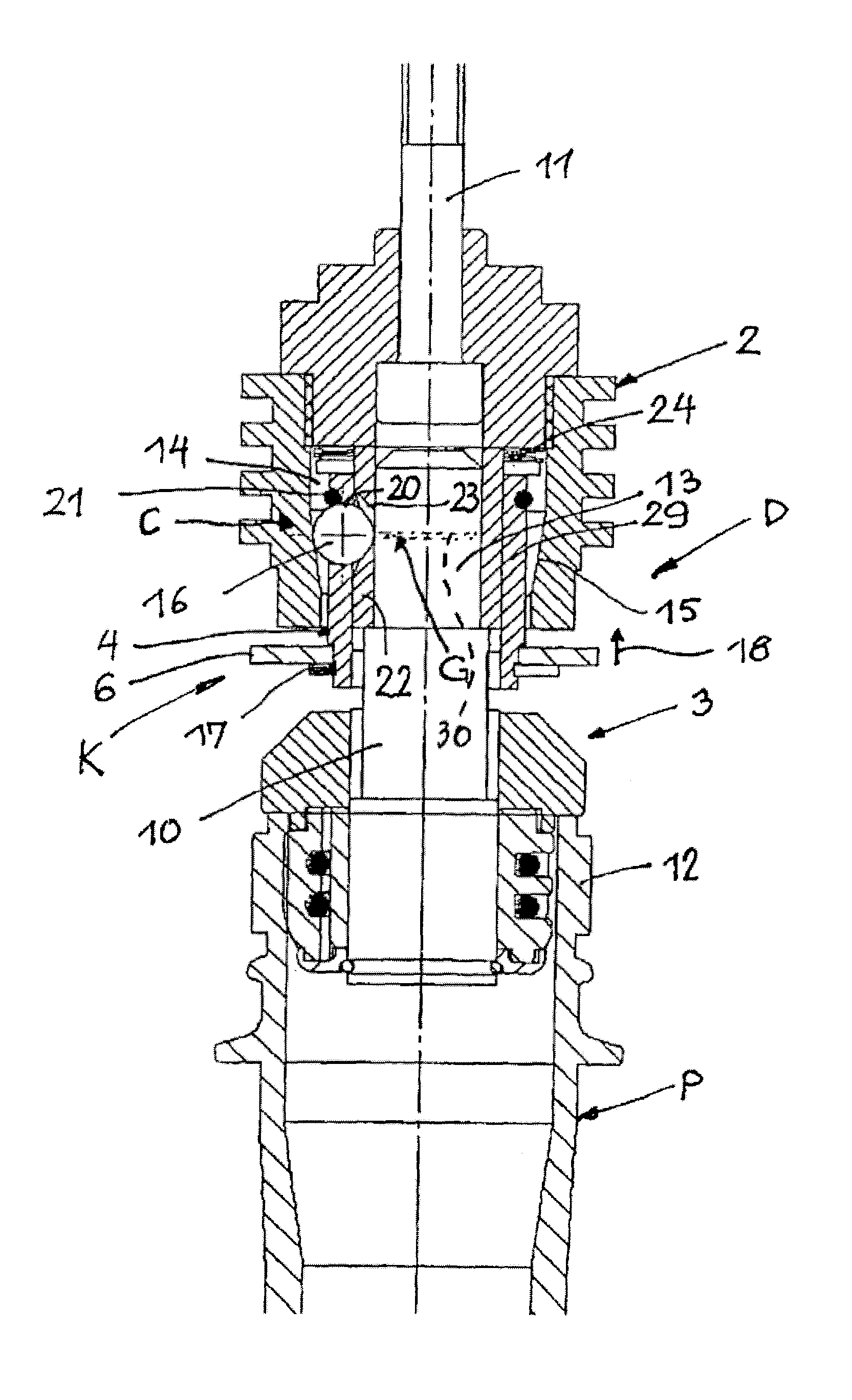

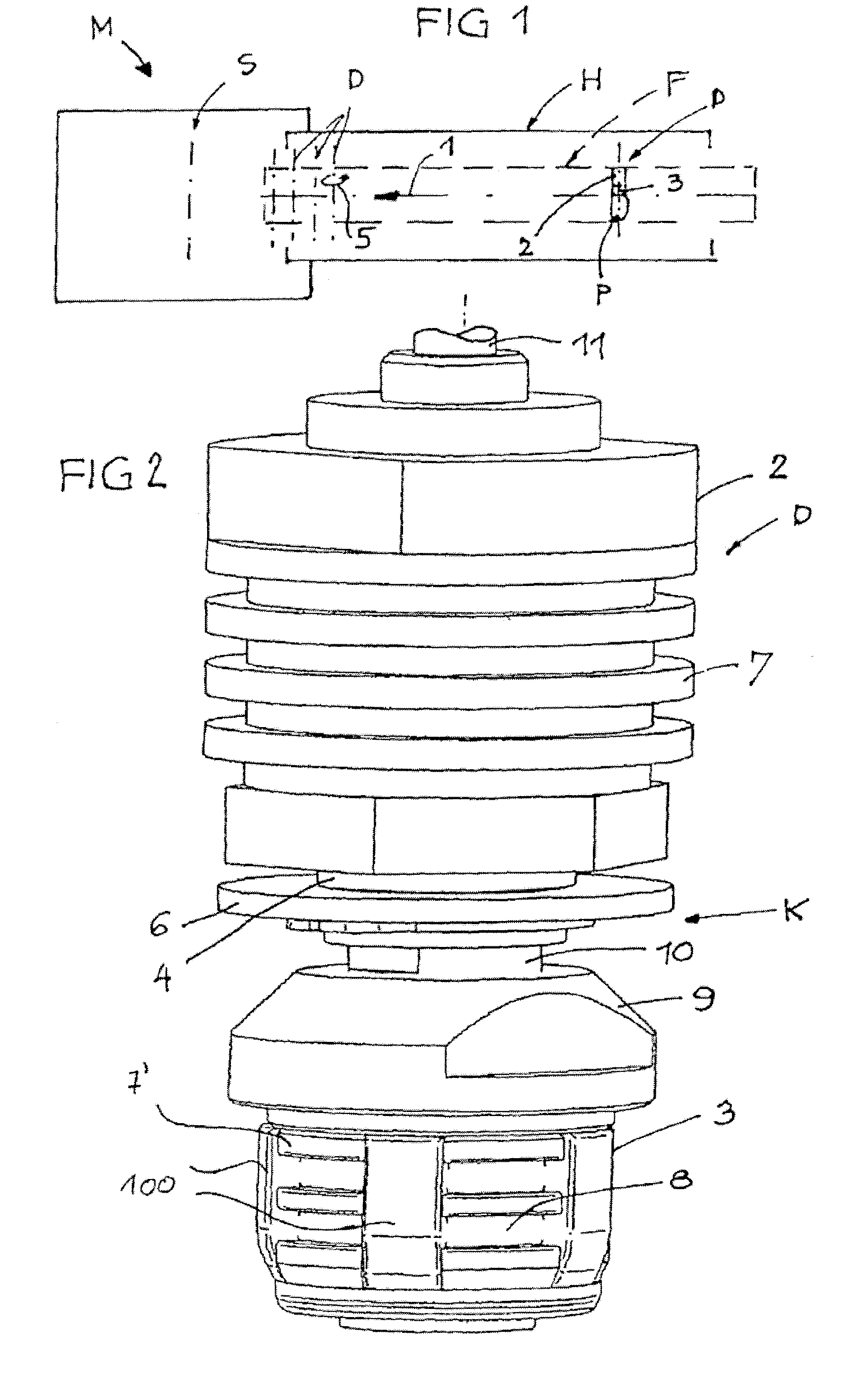

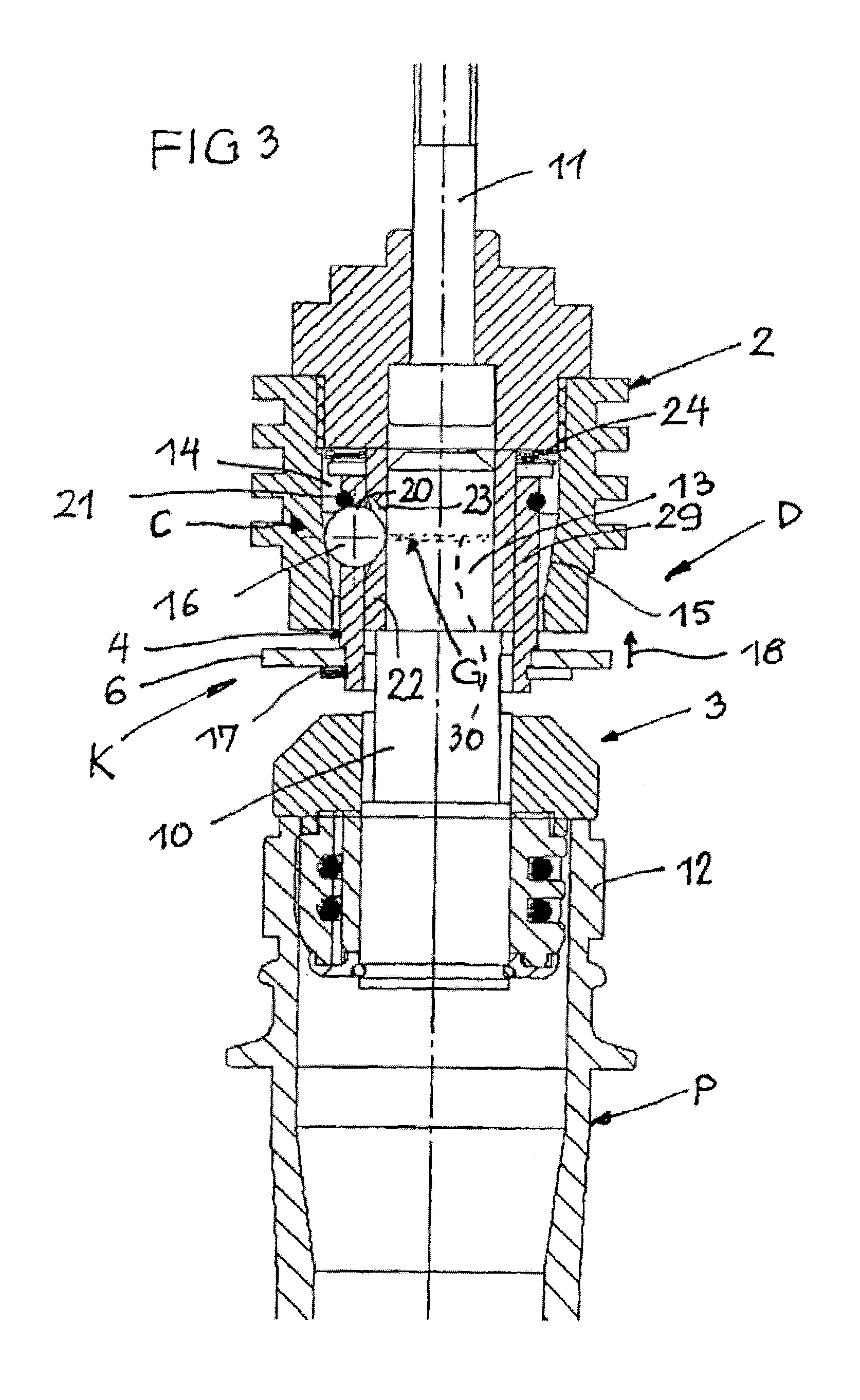

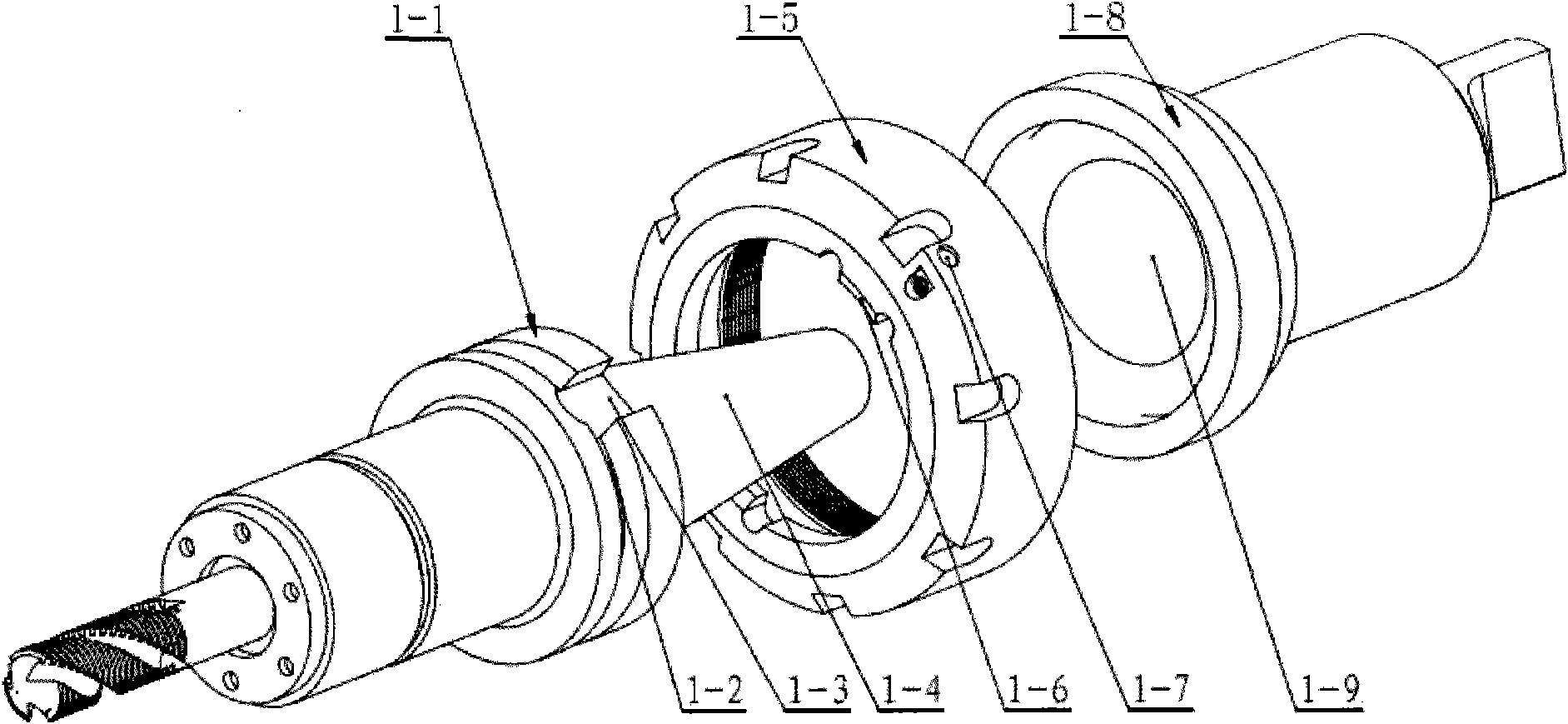

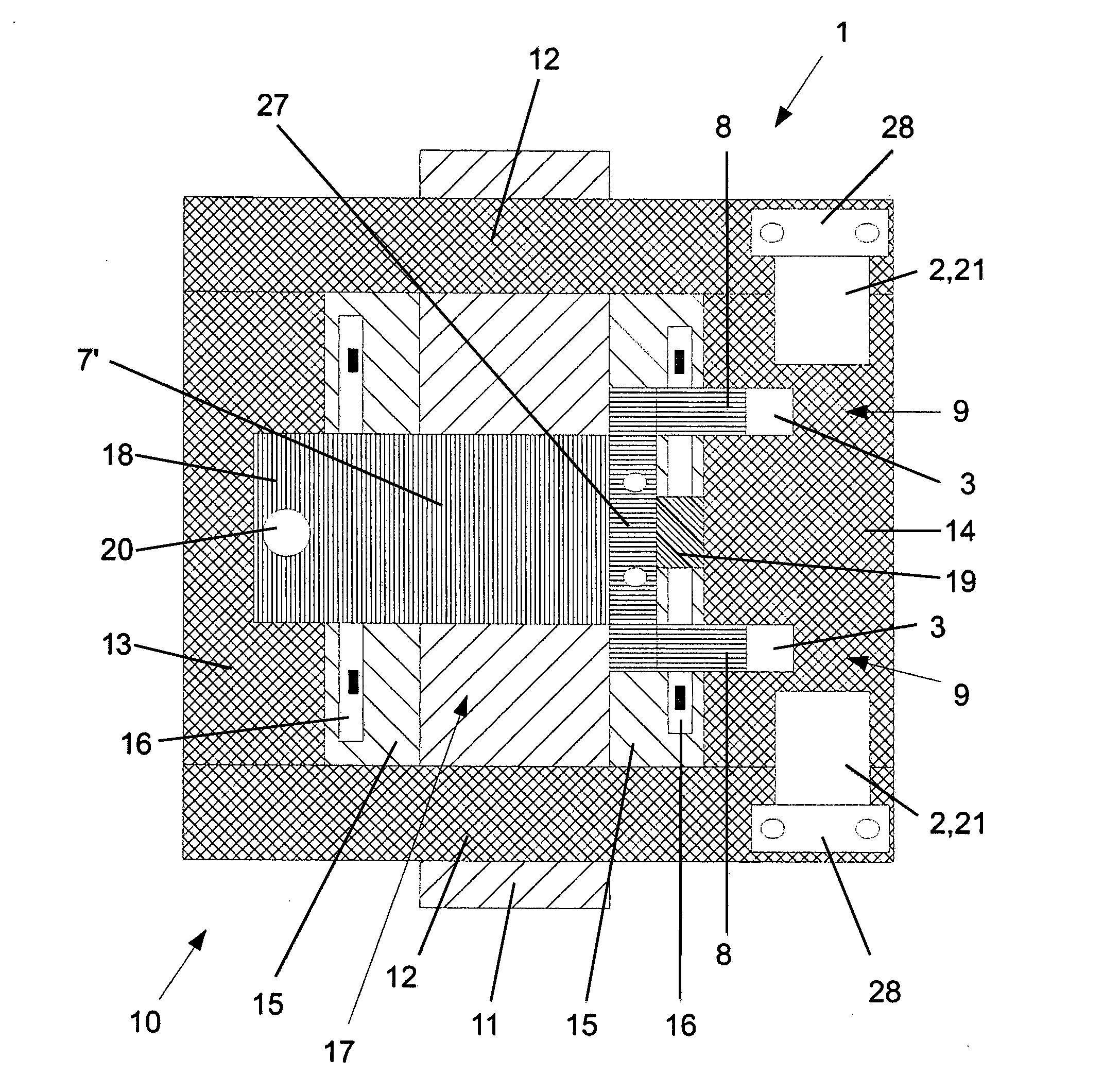

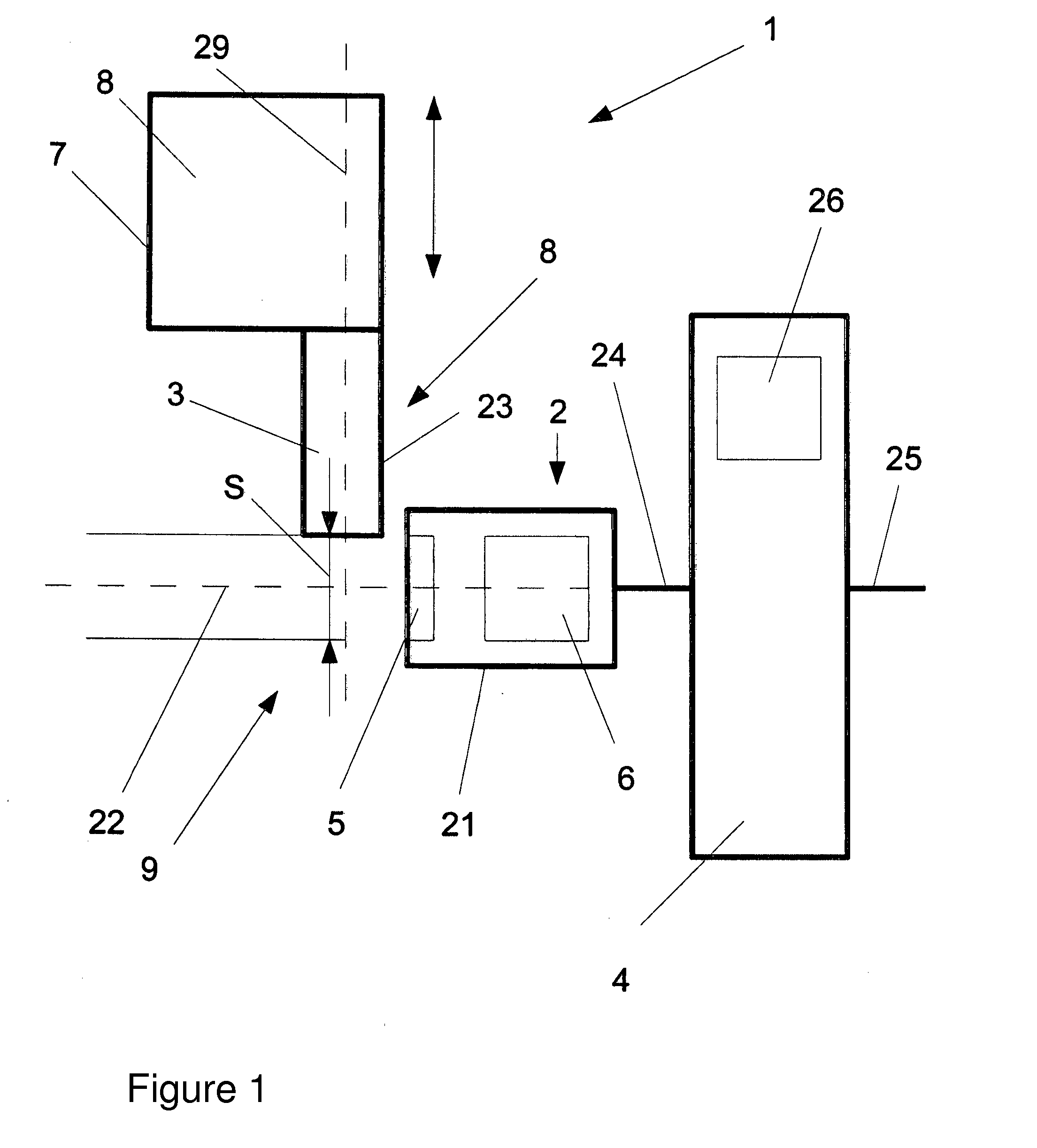

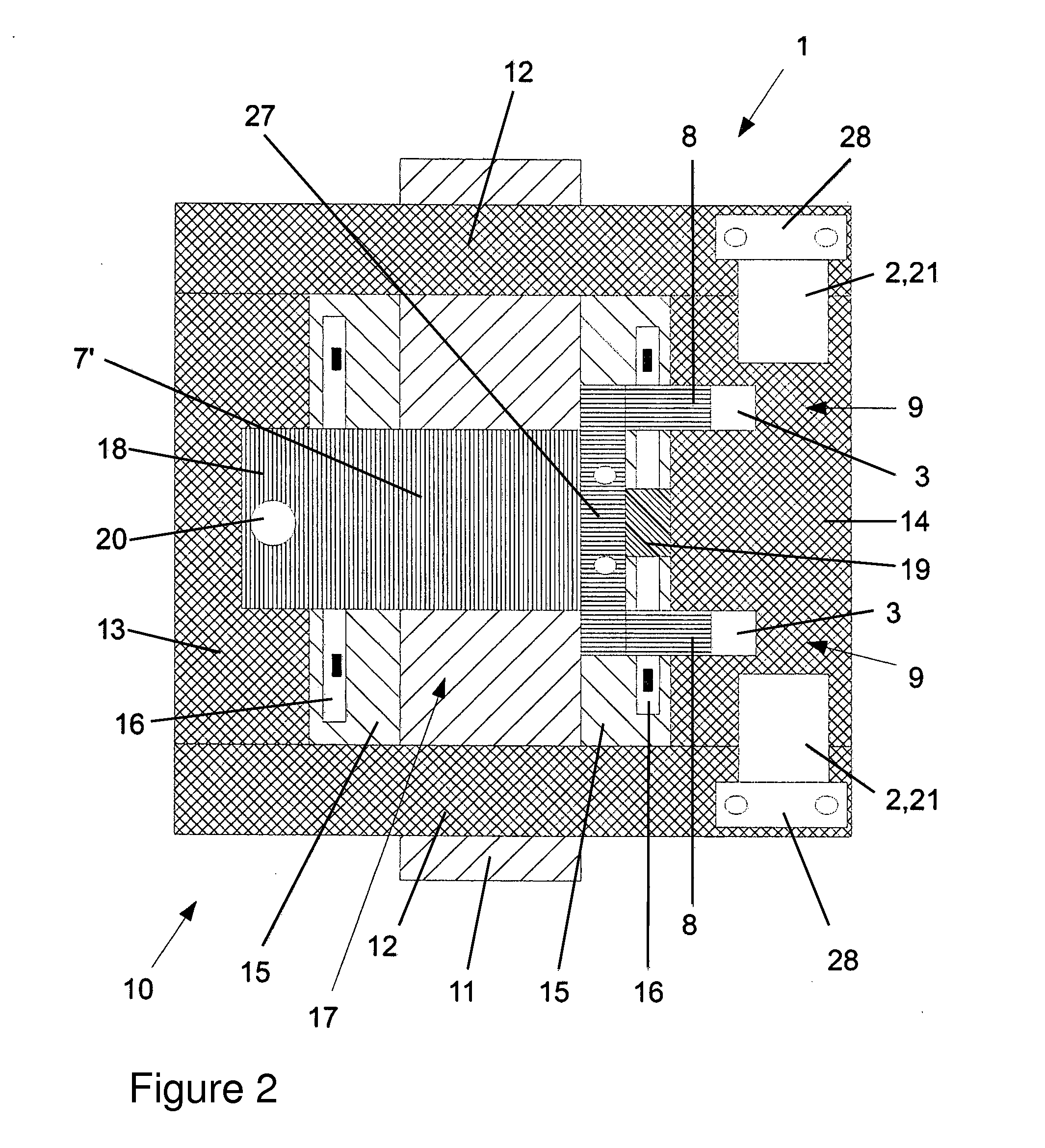

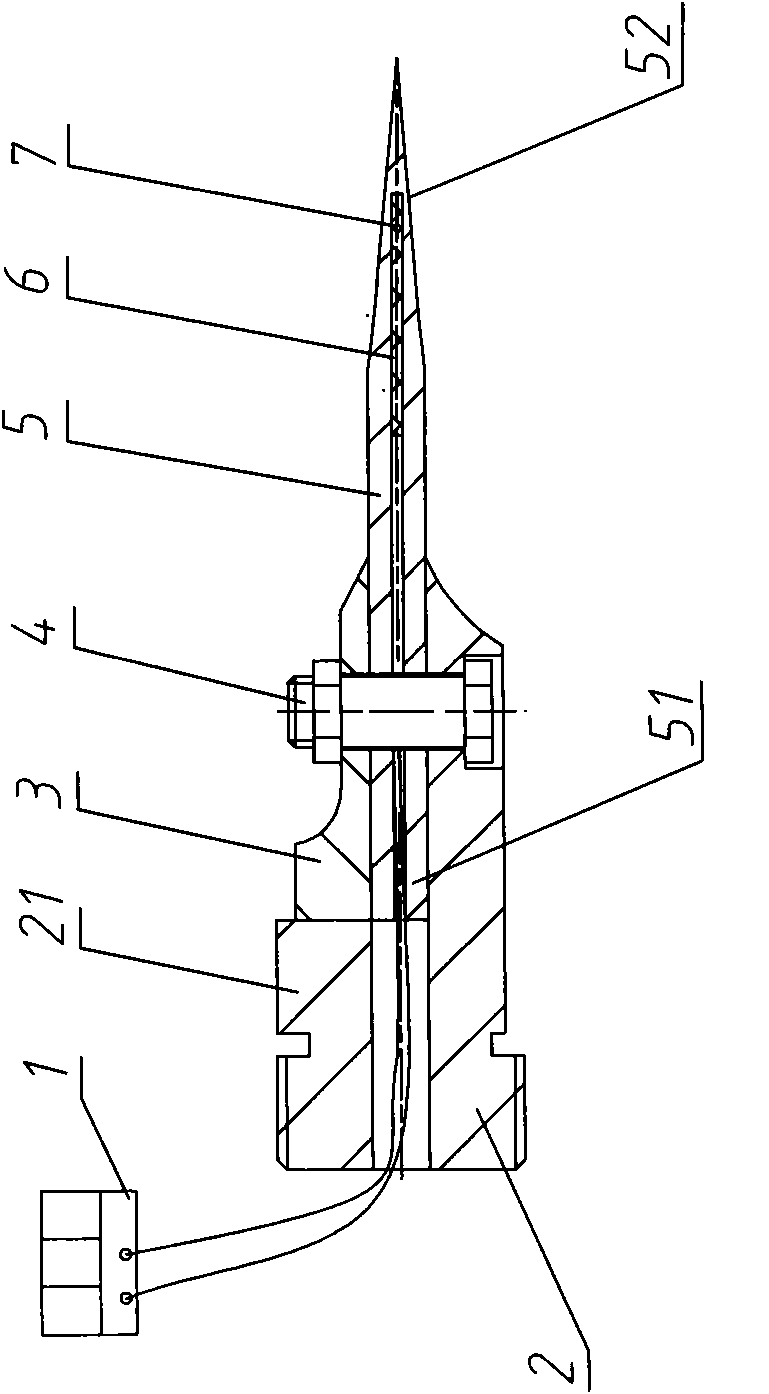

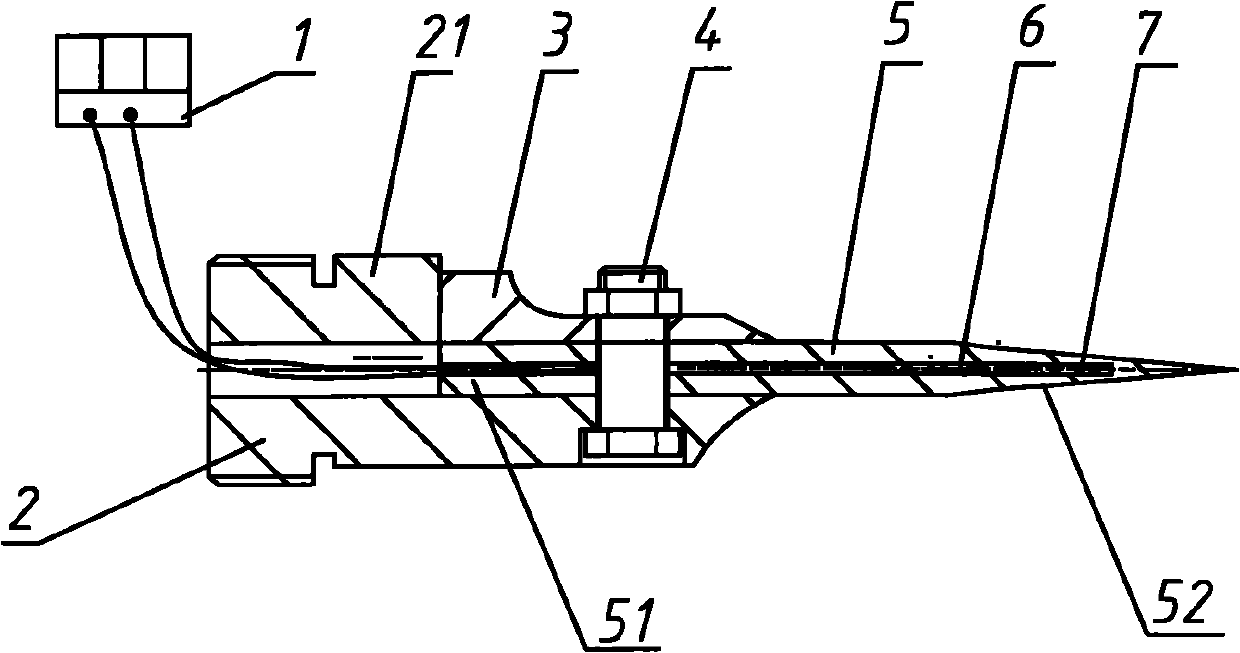

Blow molding machine for containers and mandrel holder

InactiveUS20110120840A1Short replacement timeImprove retentionConveyor partsRotary conveyorsBlow moldingCoupling

A blow molding machine for containers, having a conveyor path carrying a mandrel holder and pre-forming mandrels attached to the mandrel holders in an exchangeable manner by means of removable couplings, wherein each coupling has a mandrel clamping mechanism and a releasing element accessible form outside that can be adjusted at least relative to the mandrel holder for releasing the clamping mechanism. In the mandrel holder, particularly for use in a blow molding machine, the mandrel clamping mechanism is designed with a ball joint lock, and the ball joint lock can be released by means of a releasing element in order to exchange a performing mandrel.

Owner:KRONES AG

Blow molding machine for containers and mandrel holder

InactiveUS8567589B2Short replacement timeImprove retentionControl devices for conveyorsMechanical conveyorsBlow moldingCoupling

A blow molding machine for containers, having a conveyor path carrying a mandrel holder and pre-forming mandrels attached to the mandrel holders in an exchangeable manner by means of removable couplings, wherein each coupling has a mandrel clamping mechanism and a releasing element accessible form outside that can be adjusted at least relative to the mandrel holder for releasing the clamping mechanism. In the mandrel holder, particularly for use in a blow molding machine, the mandrel clamping mechanism is designed with a ball joint lock, and the ball joint lock can be released by means of a releasing element in order to exchange a performing mandrel.

Owner:KRONES AG

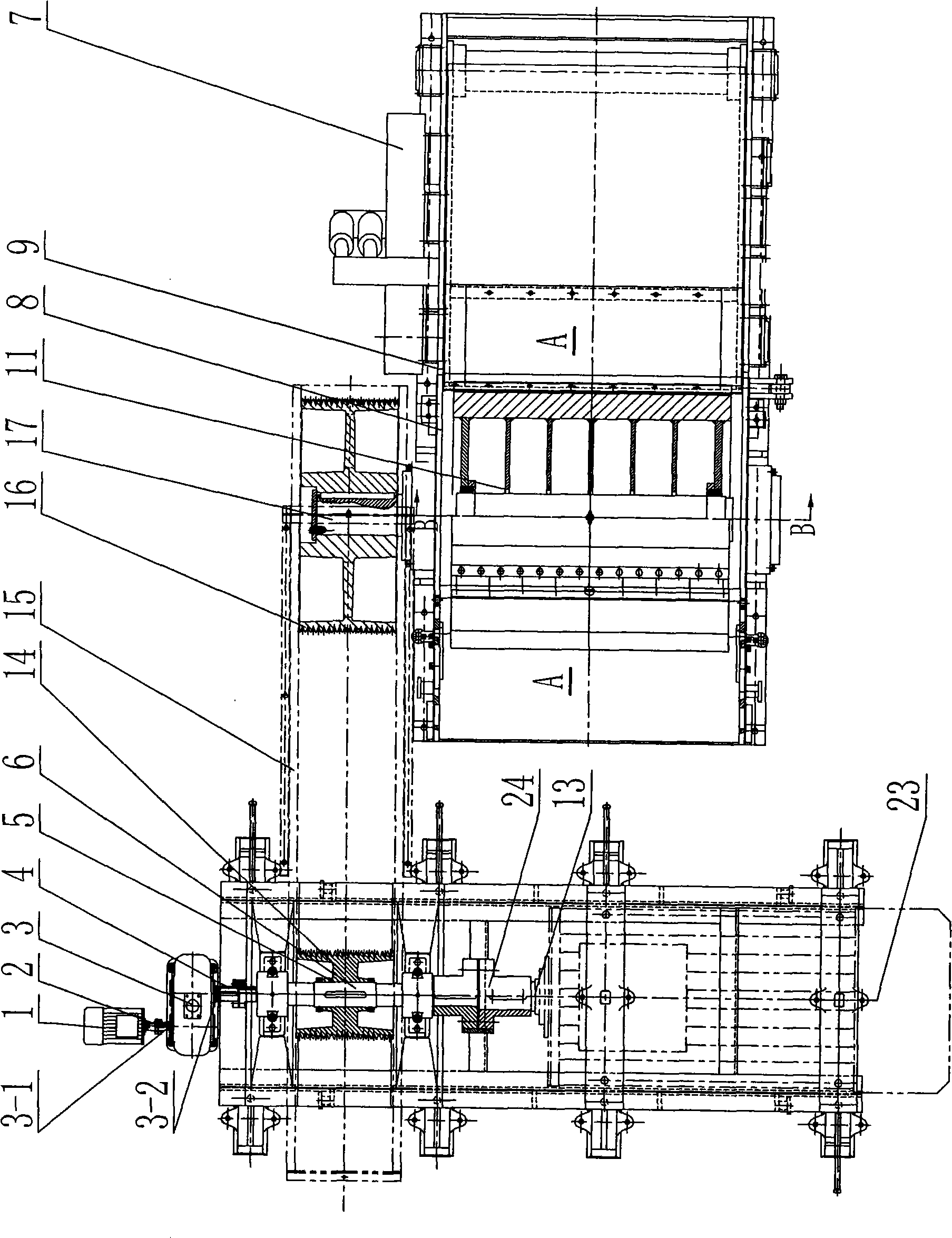

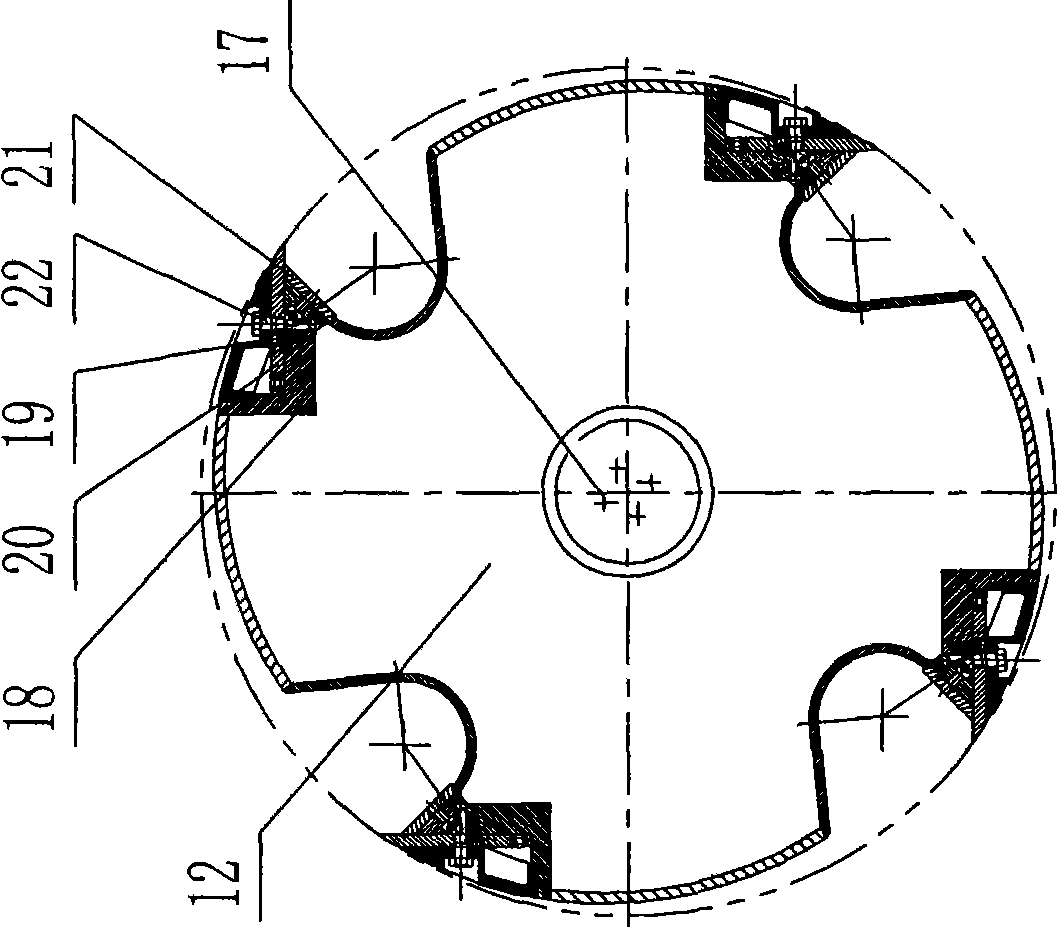

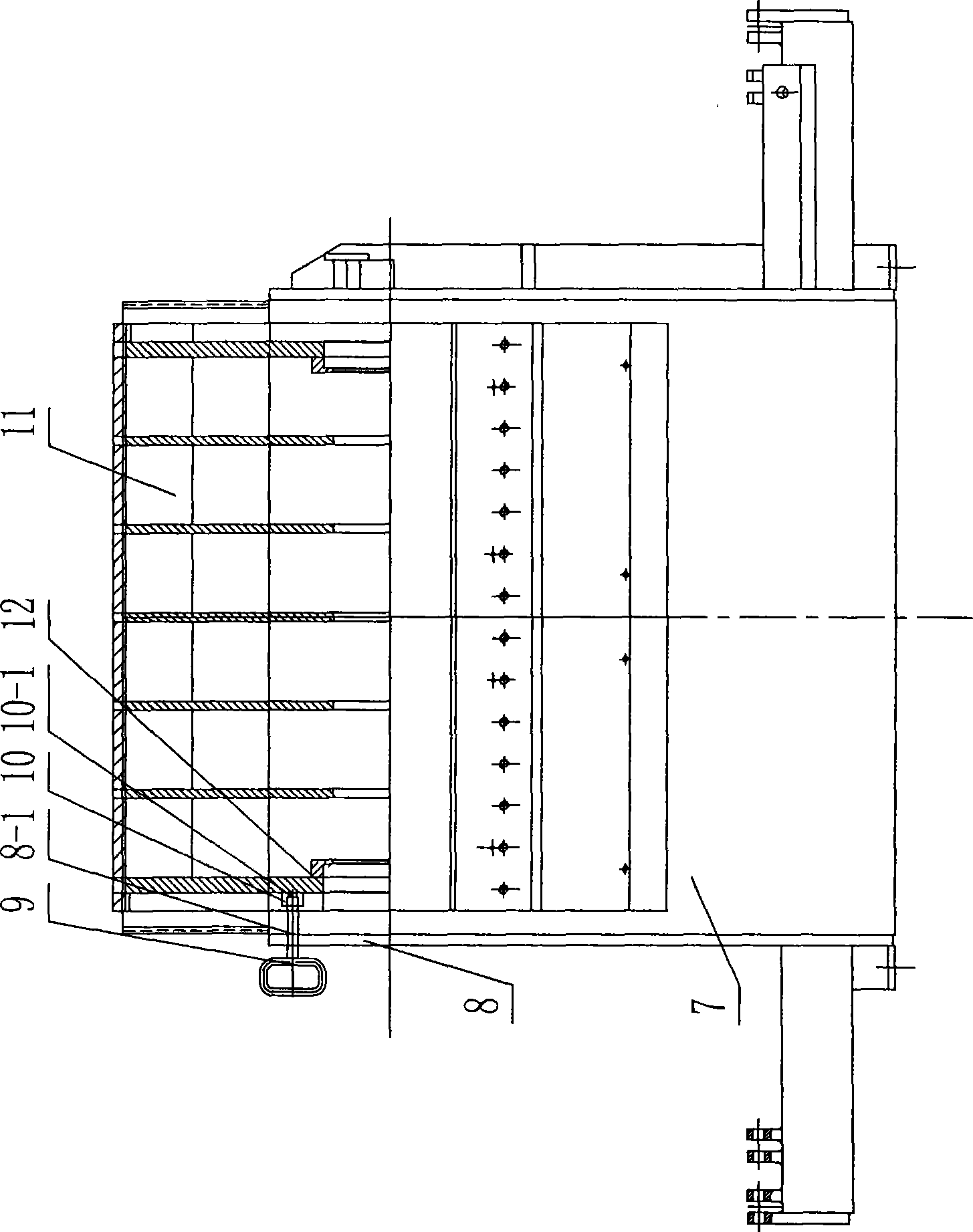

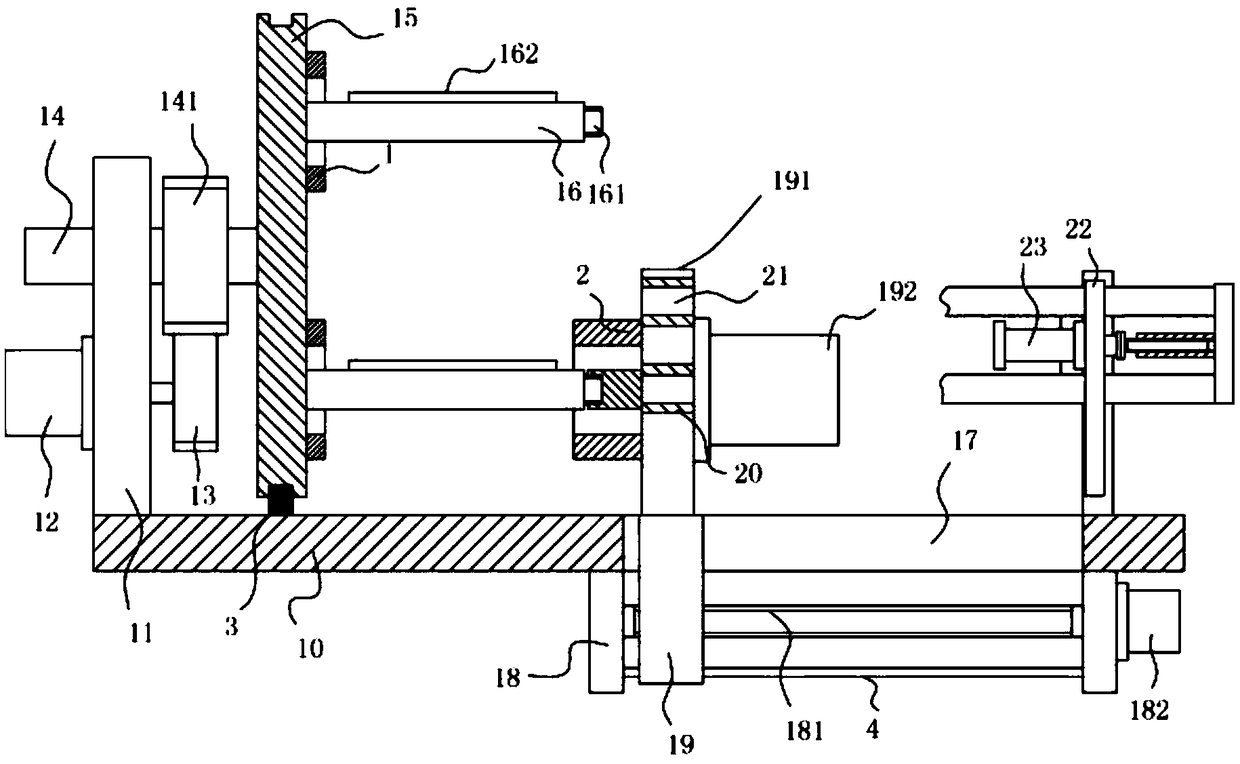

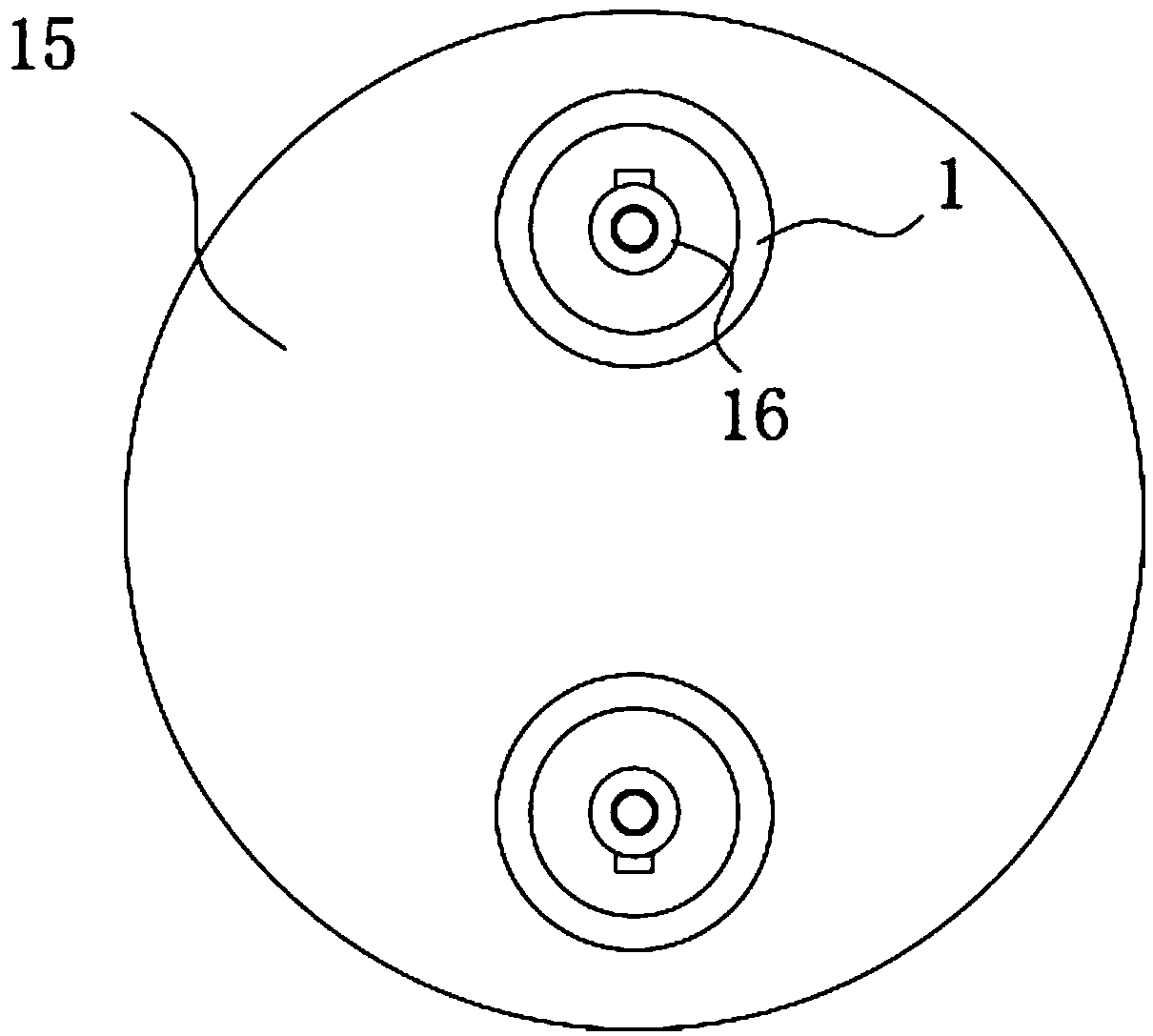

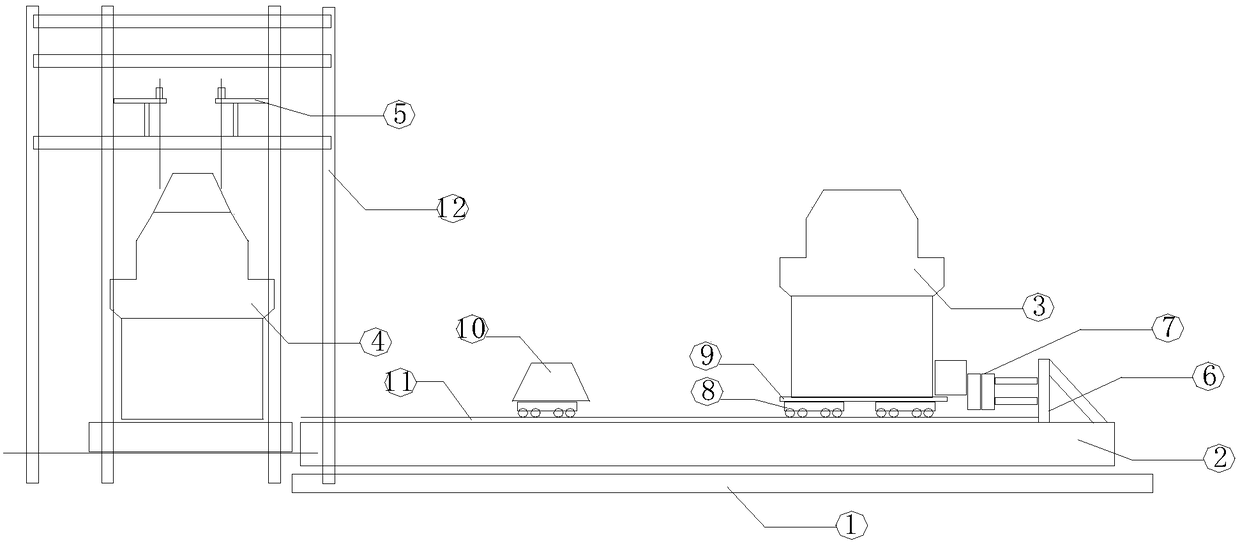

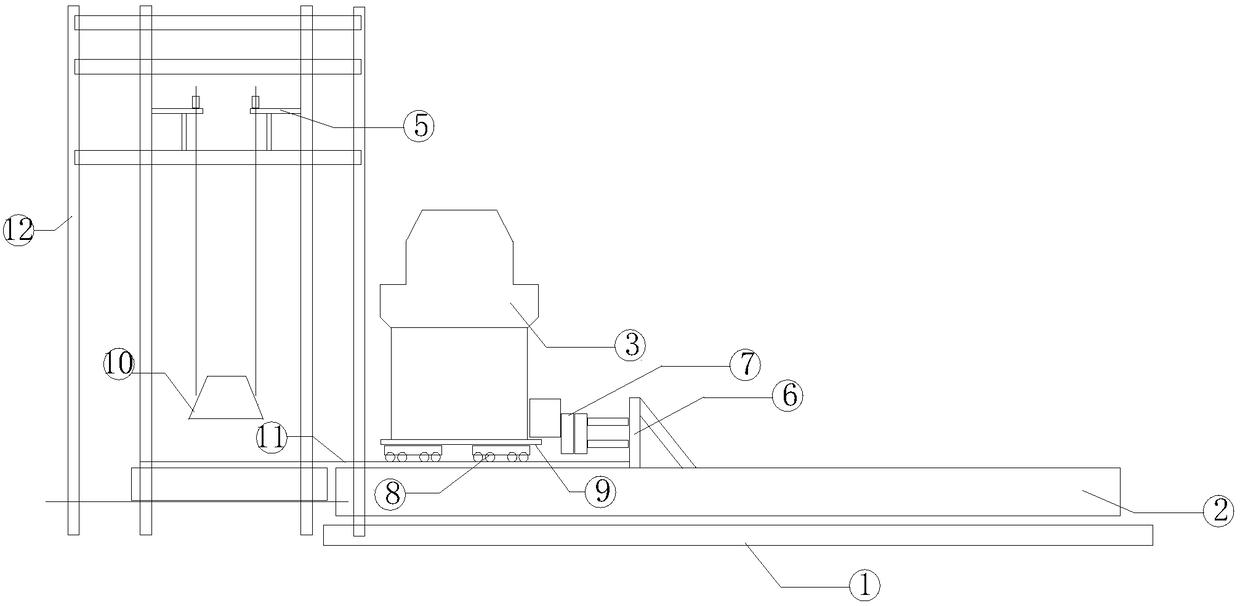

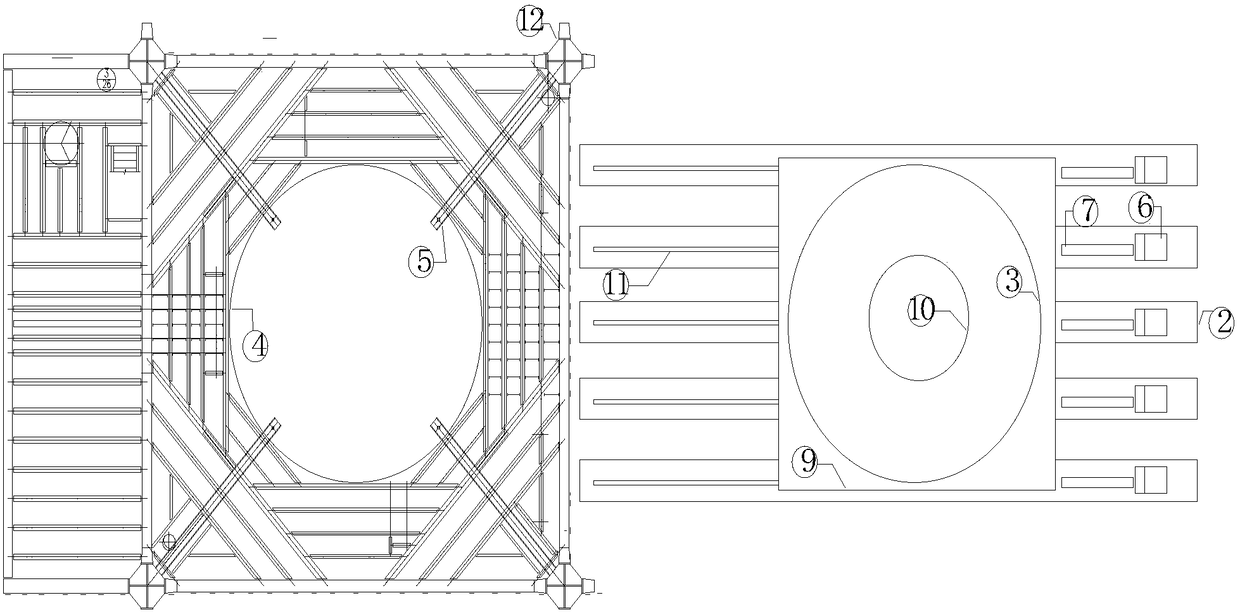

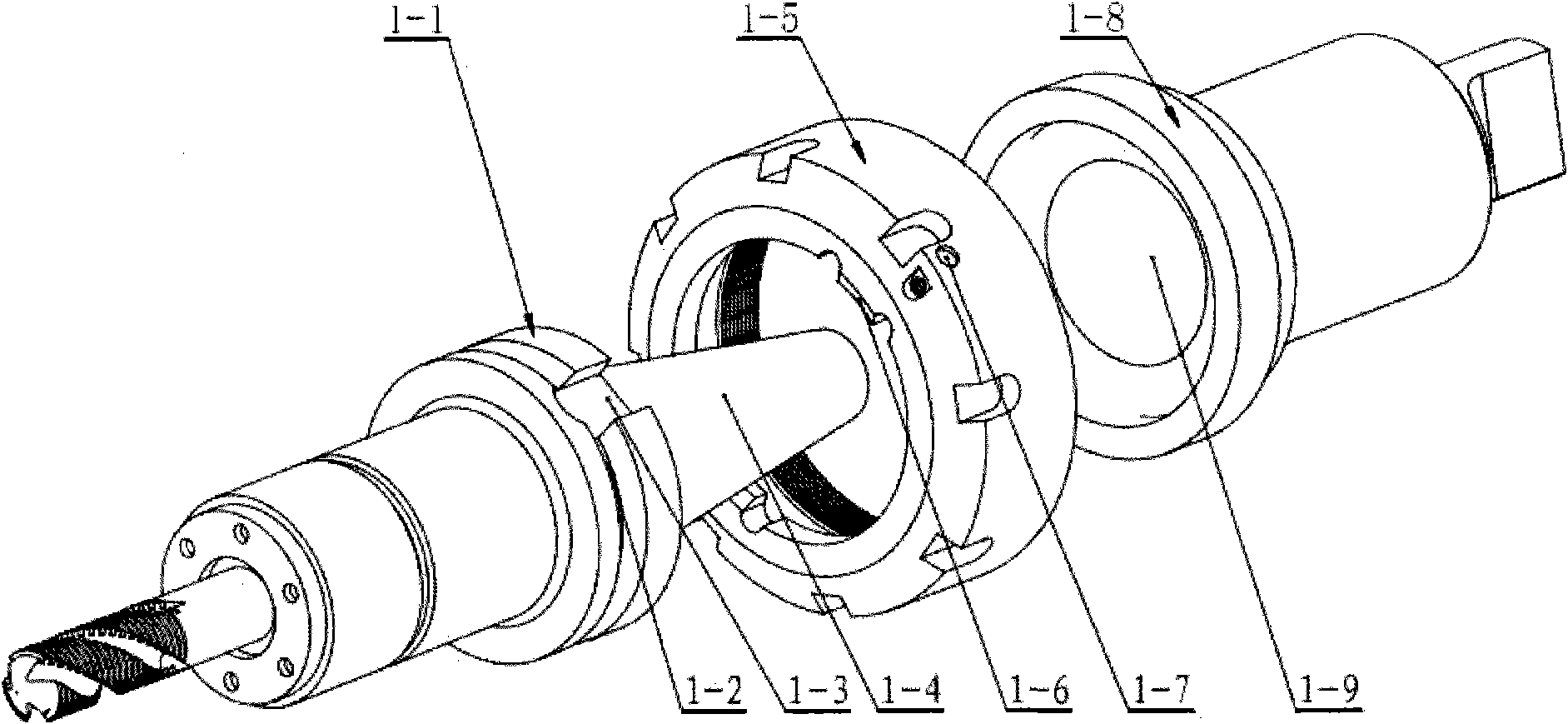

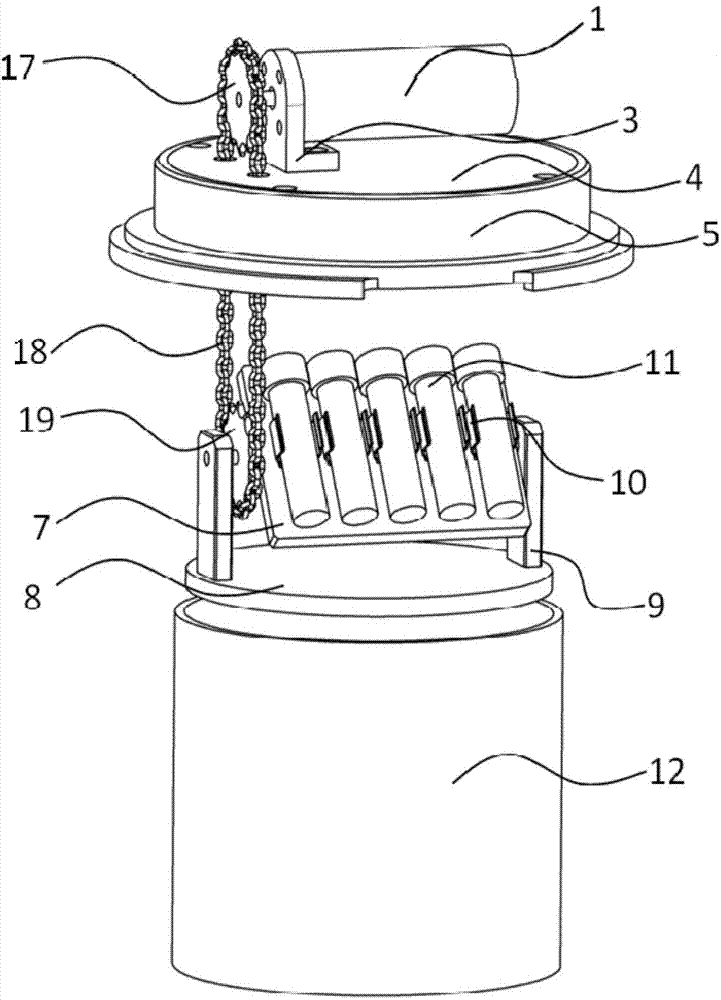

Auxiliary tool changing device of drum type chipper

ActiveCN101474815ARealize rotation automationReduce labor intensityVeneer manufactureElectromagnetic clutchCoupling

The present invention relates to a drum chipper, and particularly relates to an auxiliary cutter changing device of drum chipper. The auxiliary cutter changing device of drum chipper comprises an inserted pin (9), a positioning block (10) and a chipper base hole (8-1). The positioning block (10) is installed on a lining board (12) at the end plane of cutter roller (11). A positioning hole (10-1) is provided on the positioning block (10). The chipper base hole (8-1) is installed on a chipper base side plate (8). The auxiliary cutter changing device of drum chipper also comprises an auxiliary cutter changing motor (1), a coupling (2), a speed reducer (3) and an electromagnetic clutch (4). The auxiliary cutter changing motor (1) is connected with an input shaft (3-1) of speed reducer (3) through the coupling (2). The electromagnetic clutch (4) is installed between the output shaft (3-2) of speed reducer (3) and a main shaft (6) of drum chipper driving device (5). The auxiliary cutter changing device of drum chipper according to the invention has the advantages of: (1) time saving, labor saving, and short changing time; (2) greatly increased production efficiency.

Owner:江苏保龙机电制造有限公司

new floor mat

InactiveCN103510687BEasy to replace and maintainShort replacement timeBuilding constructionsFootwear cleanersEngineeringWorkload

Owner:吴岸中

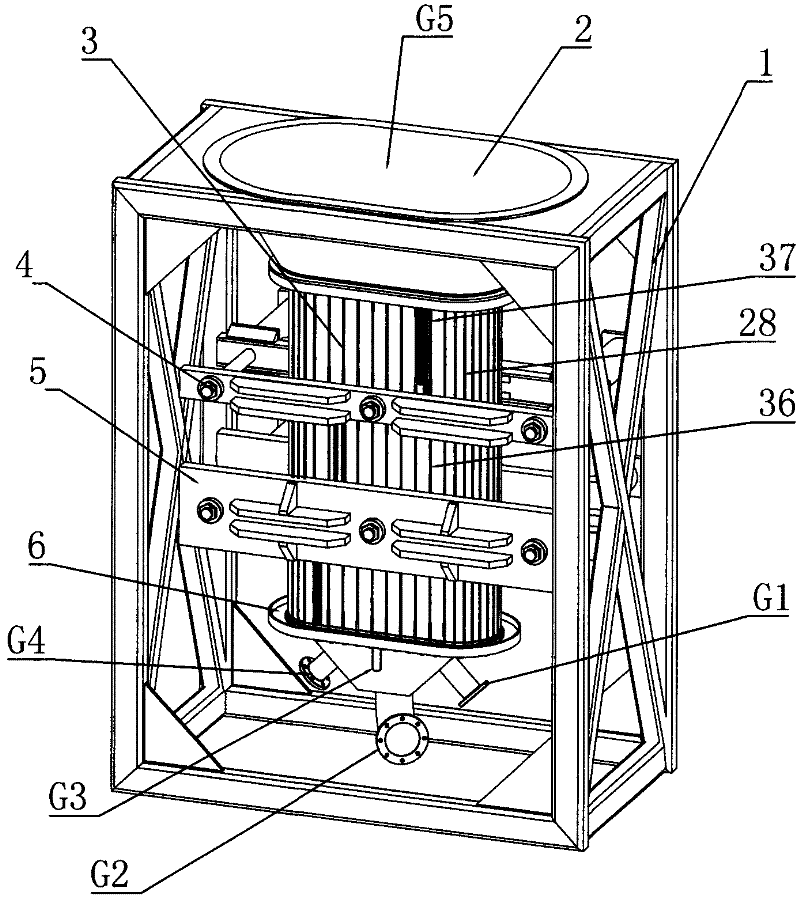

Apparatus for sludge undertaking, flexible pipe extruding dewatering and transportation, and system thereof

InactiveCN102249509ALess investmentSmall footprintSludge treatment by de-watering/drying/thickeningSludgeControl system

The invention relates to an apparatus for sludge undertaking, flexible pipe extruding dehydration and transportation, and a system thereof. The apparatus comprises a frame, a material undertaking cabin, transporters, a pipeline system, a filtrate discharging system and a control system. The transporter comprises a flexible pipe filter cell, a filter cell switch mechanism and an extruding mechanism. The invention respectively discloses two work ways that: the work way 1, the material undertaking cabin is arranged on a material outlet of a dewaterer, the undertaken sludge is filled in the flexible pipe filter cell, the filter cell switch mechanism is closed, the extruding mechanism is adopted for clamping the filter cell to carry out deep dewatering, the sludge is extruded to a transportation pipe to be discharged after complete the dewatering; the work way 2, the undertaken sludge is filled in the flexible pipe filter cell through a pump, then the extruding mechanism is adopted for clamping the filter cell to carry out dewatering, the filter cell switch mechanism is opened after complete the dewatering, the dried sludge in the filter cell is extruded into the material undertaking cabin; after the amount of the sludge is stored in the material undertaking cabin, the work way 1 is performed when the sludge requires to be transported, then the dried raw materials is extruded to the transportation pipe to be discharged after carrying out the dewatering again. The material dewatering and transporting tasks are completed automatically through repeating the steps provided by the work way 1 or the work way 2.

Owner:天津市石化通用机械研究所有限公司

Patch pocket sewing machine and patch pocket die

ActiveCN109930307AReduce in quantityIncrease productivityWork-feeding meansPressersEngineeringMaterial transfer

The invention discloses a patch pocket die. The die comprises a folding component used for folding out pocket cut-part turnup, a material transferring component used for transferring clothing cut-parts, and multiple die pressing components which have different specifications and are alternatively arranged between the folding component and the material transferring component, each die pressing component comprises a support template used for supporting the pocket cut-parts, a folding female die and a pressing template; the folding female die is detachably fixedly arranged at the bottom of the folding component so as to be pressed to the support template along with the folding component before folding and flanging to extrude the pocket cut-parts to a folding female die with the same shape asa supporting template; the pressing template cooperates with the material transferring component so as to press the pocket cut-parts with the turnup to the clothing cut-parts. Due to the fact that thedie pressing components have multiple specifications, when a pocket of one specification is replaced, only one die pressing component is needed, other parts do not need to be replaced, the number ofparts needing to be replaced is less, the replacement time is short, and the replacement speed is high; therefore, the production cost can be lowered while the production efficiency can be improved. The invention further discloses a patch pocket sewing machine comprising the patch pocket die.

Owner:JACK SEWING MASCH CO LTD

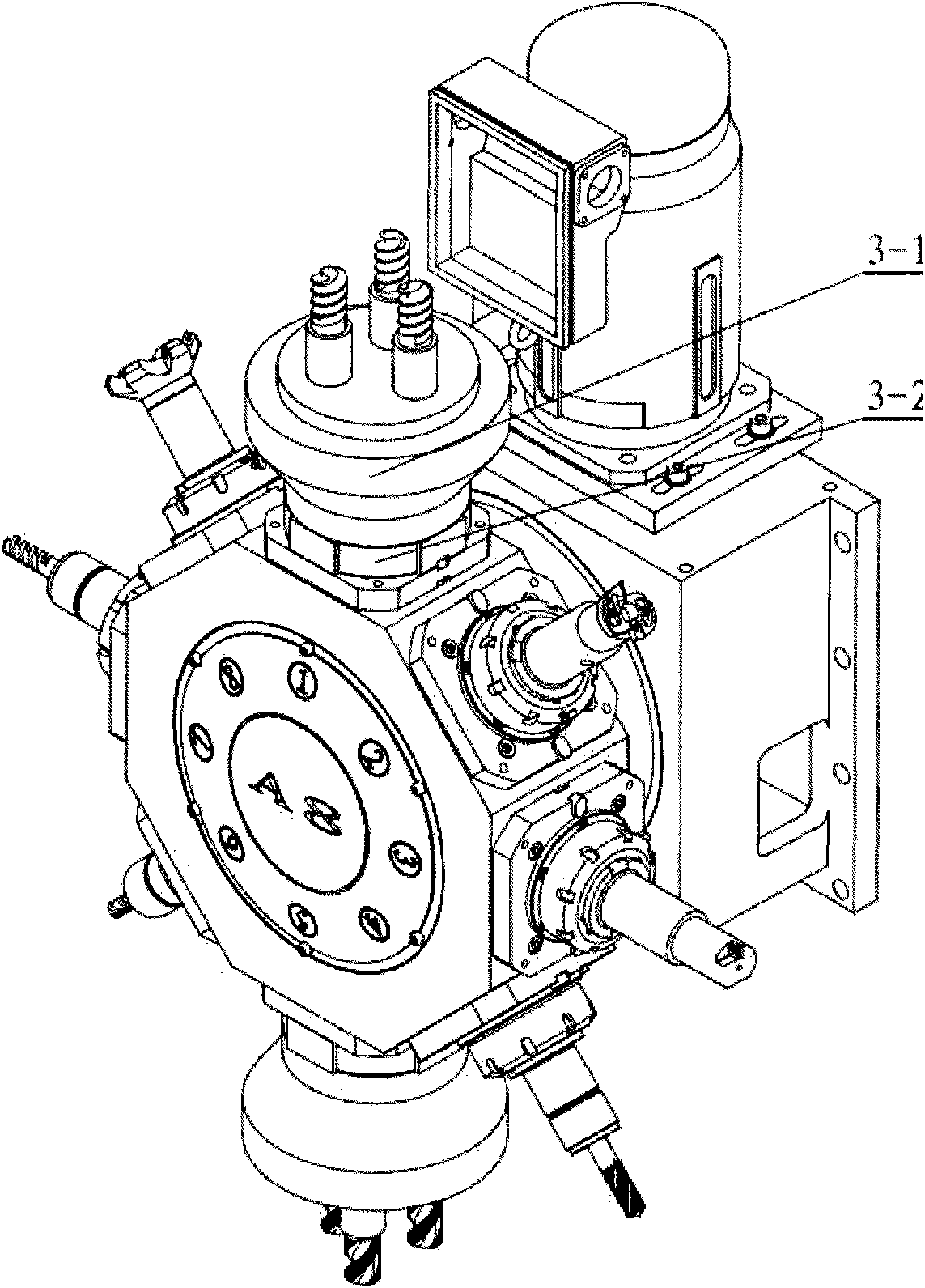

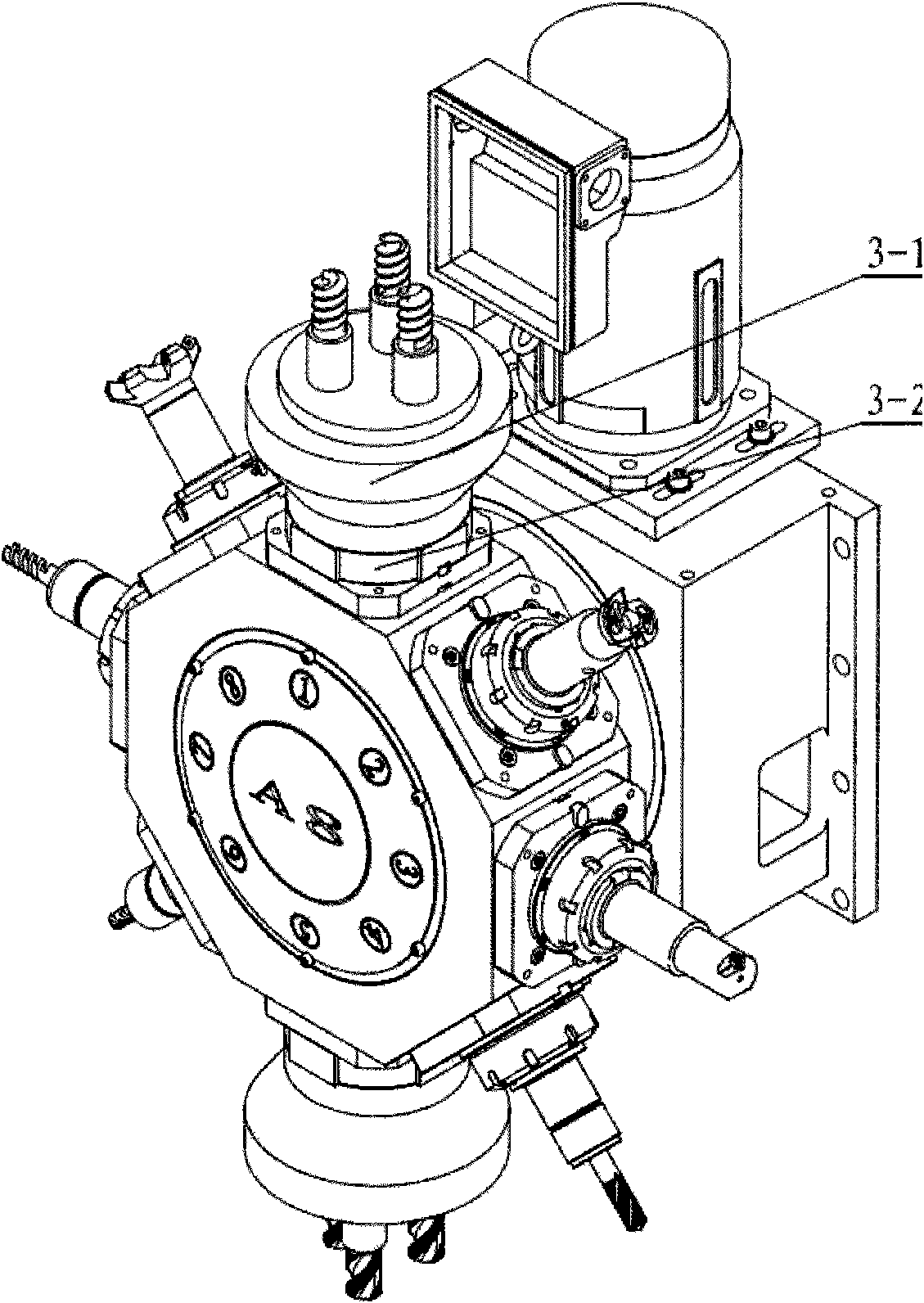

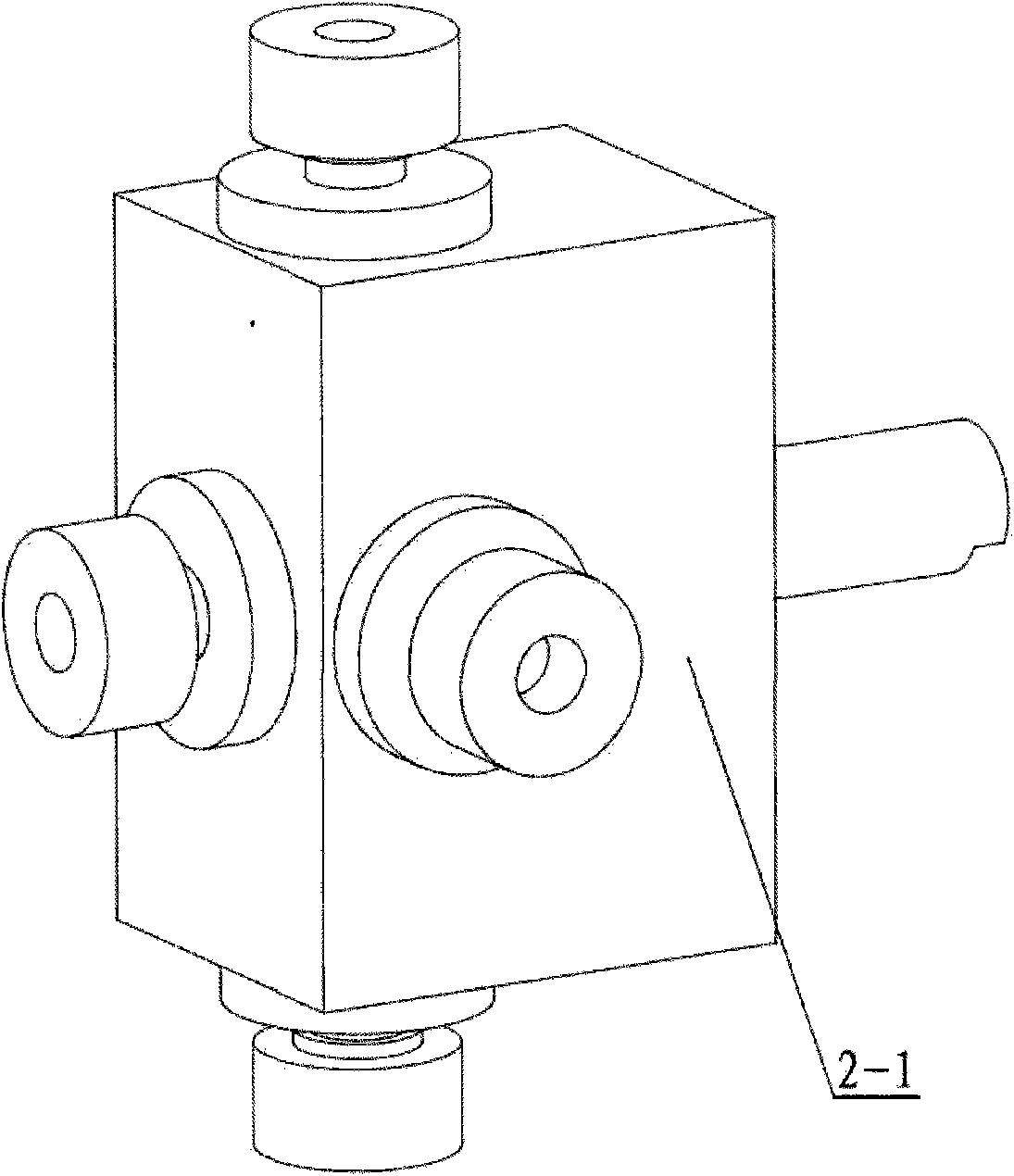

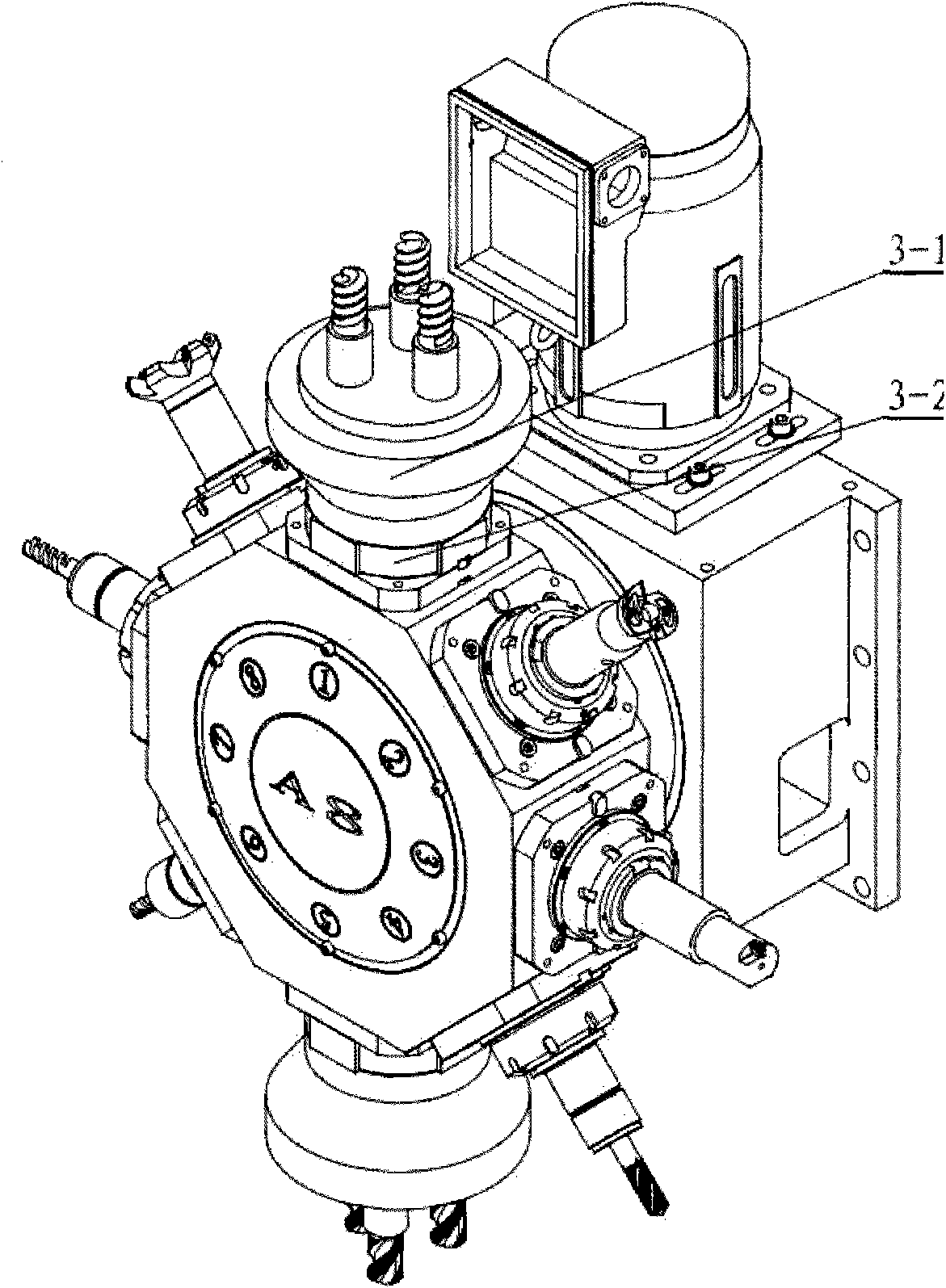

Rotary tool turret and rotation method

The invention relates to a turret type rotary tool turret used for turning and milling tool turrets and machining centers of NC lathes and a rotation method. A toolholder adopts the locking structure of a locknut and uses a V-shaped groove of a V-shaped groove toolholder; the V-shaped groove toolholder is locked by rotating the locknut clockwise and is loosened by rotating the locknut counterclockwise so as to be convenient for realizing the functions of installing, fixing and taking out the V-shaped groove toolholder and replacing multi-spindles; spindle transmission adopts the straight concave-convex connection transmission type; the tool turret rotation adopts the structure of a three-plate clutch which is driven to rotate by a high-precision worm gear and a worm. The invention has the following advantages: 1. short replacement time, fast speed and convenient replacement of V-shaped groove toolholders; 2. good functions of installing and replacing multi-spindles, one-time completion of drilling and tapping, shortened operation time and greatly improved machining efficiency; 3. great bearing capacity, good structure rigidity, long service life, simple machining, low manufacturing cost and convenient equipment maintenance and repair; 4. high rotary precision and good stability.

Owner:杭州长虹机械制造有限公司

Method for manually replacing bucket type elevator belt

The invention discloses a method for manually replacing a bucket type elevator belt, which comprises the following steps that: firstly, a new belt is conveyed to the tail part of a bucket type elevator, tail observing openings arranged at both sides of the bucket type elevator are opened, and an old belt is disconnected at the tail wheel part of the bucket type elevator from one tail observing opening; then, the prepared new belt is connected with the corresponding broken end of the old belt through the tail observing opening; and workers carry out turning at the head wheel part of the bucket type elevator until the old belt is completely output from the other tail observing opening, the connecting part of the new belt and the old belt is disconnected, and finally, two disconnected ends of the new belt are connected. The method has the beneficial effects that the bucket type elevator belt is replaced by a manual turning method, the work procedure of removing a protecting cover arranged at the head wheel part of the bucket type elevator is omitted, the whole process is simple and is easy to operate, the safety factor is high, the replacement time is short, and the normal production is not influenced.

Owner:XINXING DUCTILE IRON PIPES CO LTD

Rotary tool turret matching NC turning and milling center and machining method

The invention relates to a rotary tool turret matching an NC turning and milling center and a machining method. The rotary tool turret comprises a turning and milling tool turret; a servo motor in the turning and milling tool turret drives a spindle transmission shaft through a transmission mechanism; the connecting end of the spindle transmission shaft is a beeline-shaped groove which is matched with a beeline-shaped raised head of a beeline-shaped flat head toolholder seat by splicing and drives a tool on the rotary tool turret to be machined; the beeline-shaped flat head toolholder seat in the tool turret is matched with a guide holder beeline-shaped guide groove on a guide holder and rotates along the guide holder. The invention has the following advantages: 1. short replacement time, fast speed and convenient replacement of V-shaped groove toolholders; 2. good functions of installing and replacing multi-spindles, one-time completion of drilling and tapping, shortened operation time and greatly improved machining efficiency; 3. great bearing capacity, good structure rigidity, long service life, simple machining, low manufacturing cost and convenient equipment maintenance and repair; 4. high rotary precision and good stability.

Owner:杭州长虹机械制造有限公司

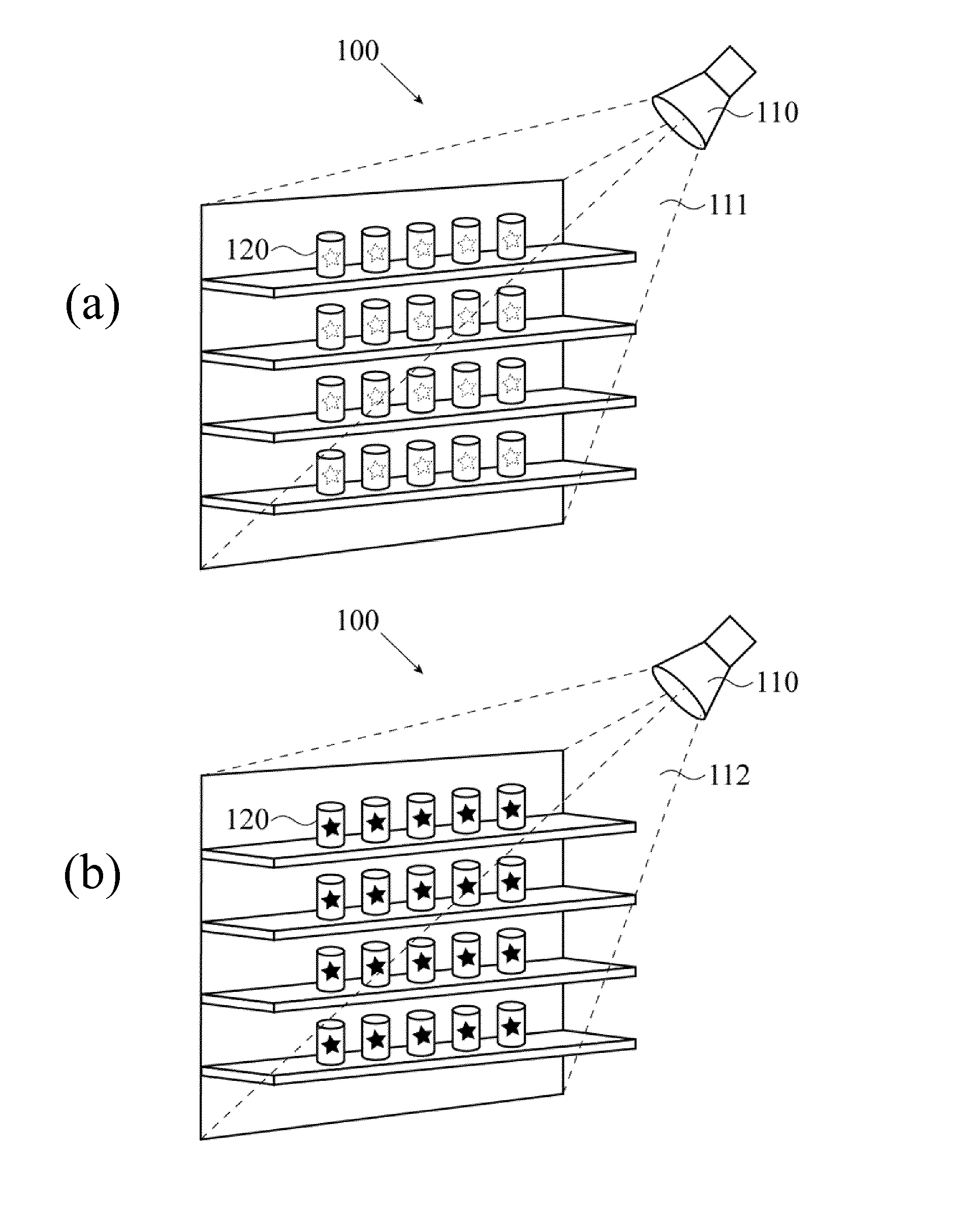

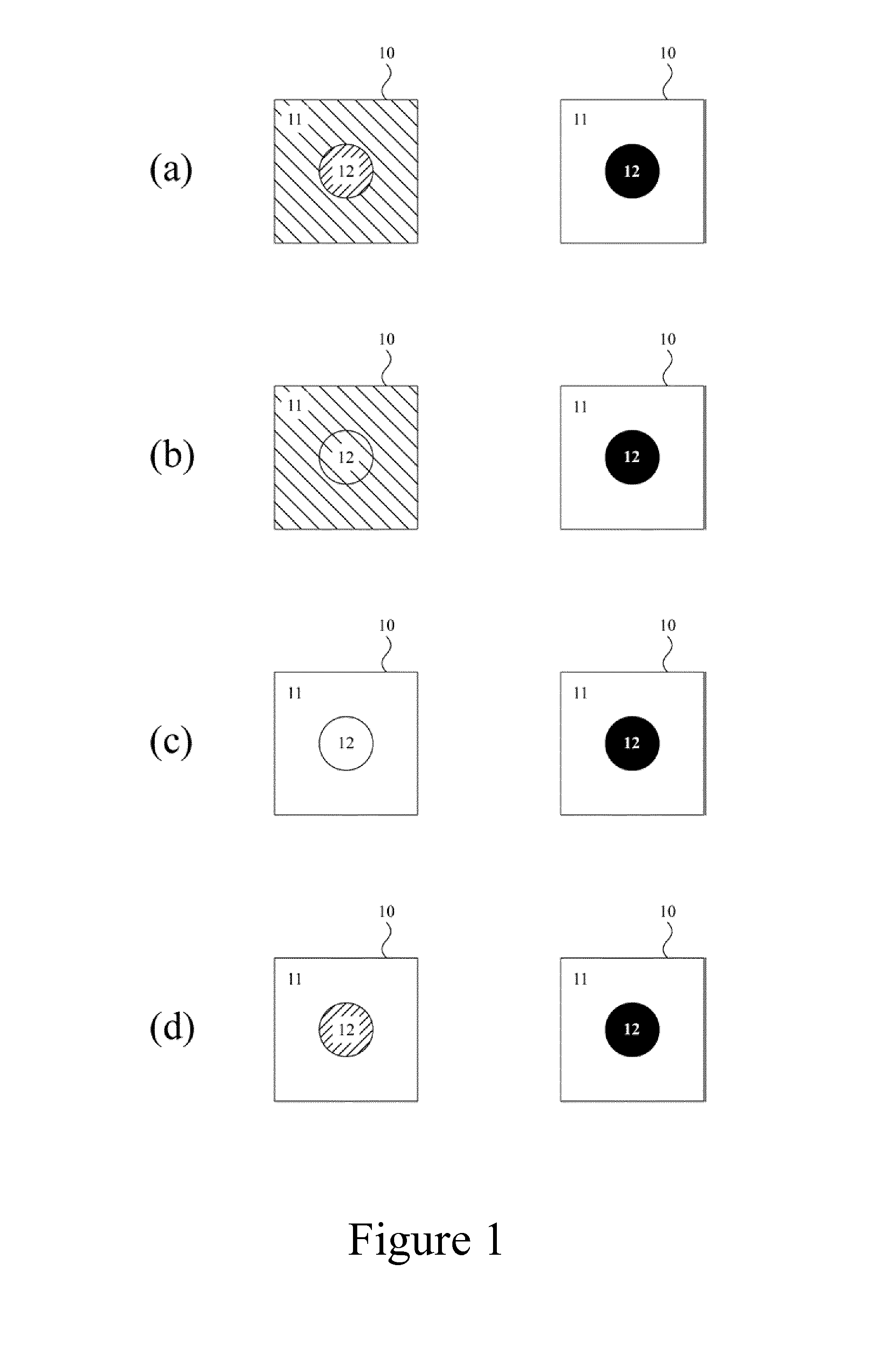

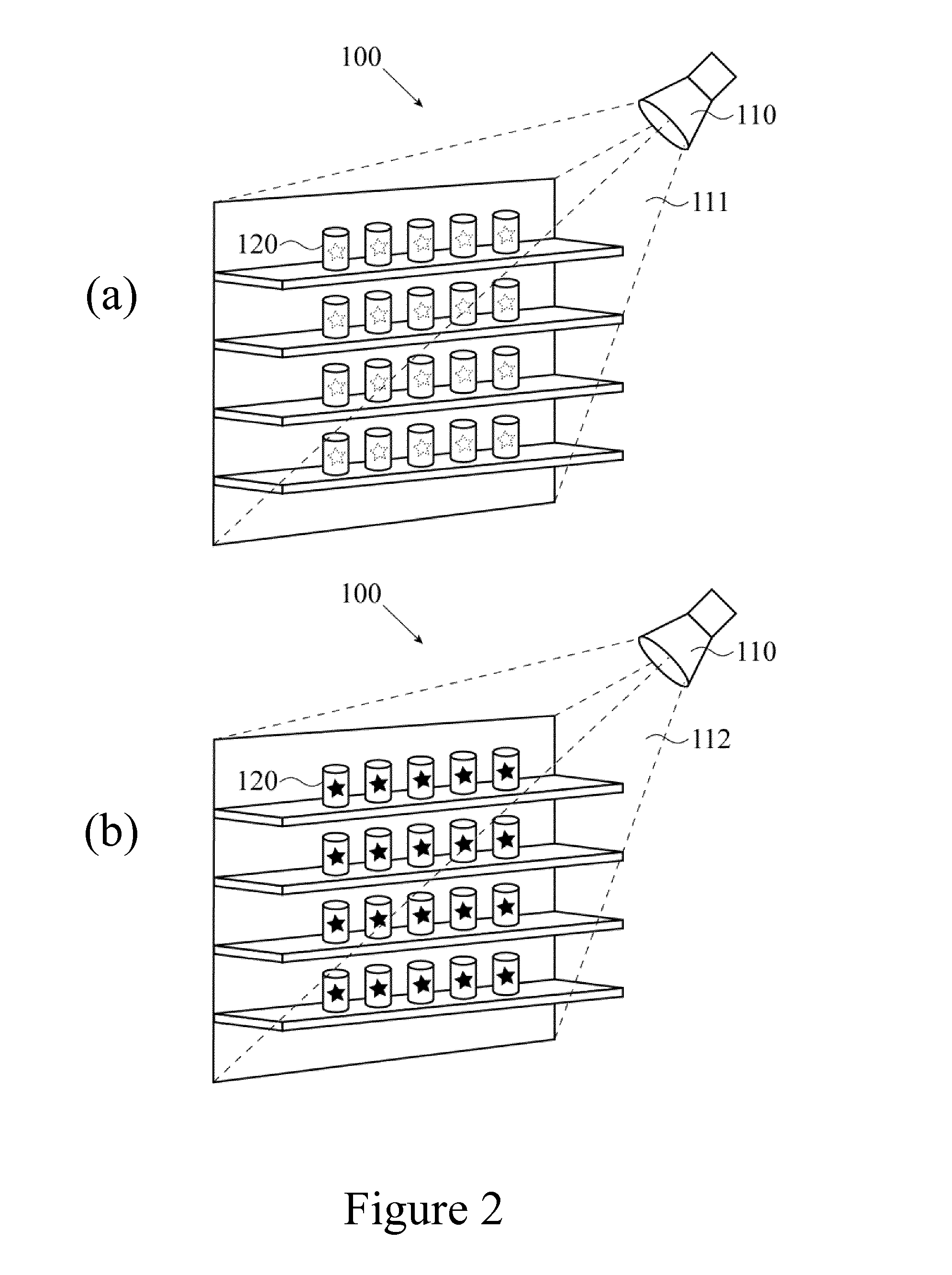

Arrangement for changing the visual appearance of a target object

ActiveUS20160025304A1Short replacement timeAvoid changeLighting applicationsMechanical apparatusLighting systemLight spectrum

The invention relates to an arrangement (100) comprising a lighting system (110) and a target object (120), wherein the lighting system (110) is arranged to illuminate a target surface of the target object (120) with a primary light output (111) and with a secondary light output (112). Each of these light outputs has an illumination spectrum representing a color. The two illumination spectra are different, but the two colors are substantially the same. The target surface has a first target surface area and a second target surface area. When the first and second target surface areas are illuminated with the primary light output (111), they have a contrast that is lower than when they are illuminated with the secondary light output (112). The arrangement of the invention can be used for atmosphere creation or for attracting attention to the target object (120).

Owner:SIGNIFY HOLDING B V

Small-scale copper wire winding mechanism with automatic shearing device

InactiveCN108840174AImprove efficiencyProcessing does not affectFilament handlingCopper wireMechanical engineering

The invention discloses a small-scale copper wire winding mechanism with an automatic shearing device. The small-scale copper wire winding mechanism comprises a main base plate, a moving straight slotis formed in the right bottom surface of the main base plate, and lower supporting plates are fixed to the bottom surface of the main base plate of the left and right sides of the moving straight slot. Two ends of a horizontal screw rod are hinged to the two lower supporting plates through bearings, wherein a moving motor is fixed to the outside wall of one of the two lower supporting plates. A moving block is connected to the horizontal screw rod in a threaded mode, and the upper portion of the moving block is sleeved with the moving straight slot in an inserted mode. A locating plate is fixed to the top surface of the moving block and located above the main base plate, two guide blocks are fixed to the front wall surface of the locating plate, and horizontal guide through holes are formed in the guide blocks. Two small barrel bodies can be mounted, a small barrel body can automatically shear off a winding connecting end after finished, the finished small barrel body is located abovethrough a main circular rotating plate rotating, the small barrel body to be finished is located below and automatically fixes to process, the efficiency is high, the replacement time of the middle part is short, and the efficiency is high.

Owner:FOSHAN XUNAOJIE AUTOMATION TECH CO LTD

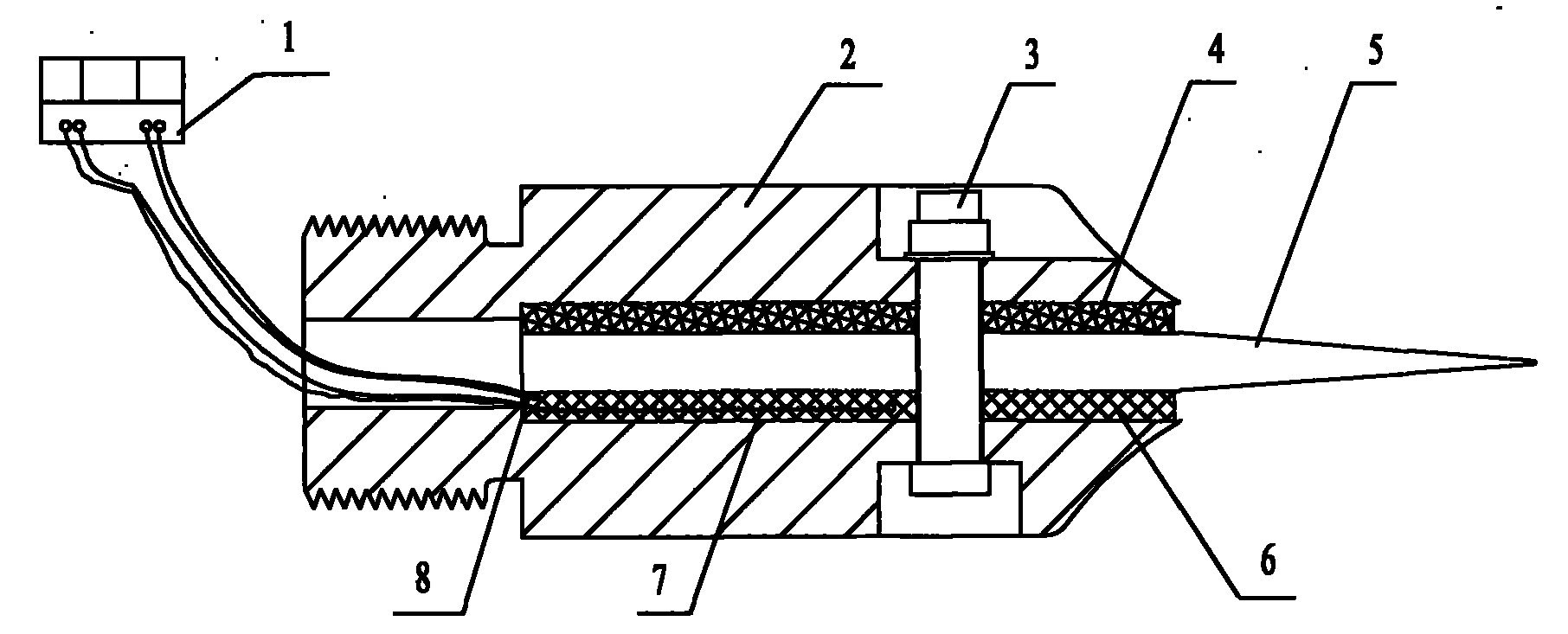

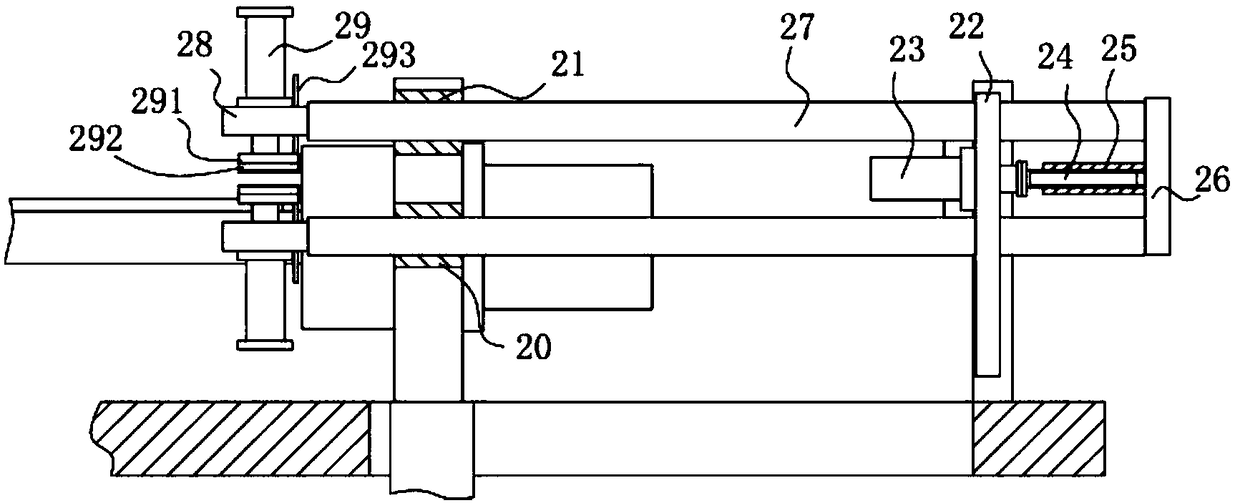

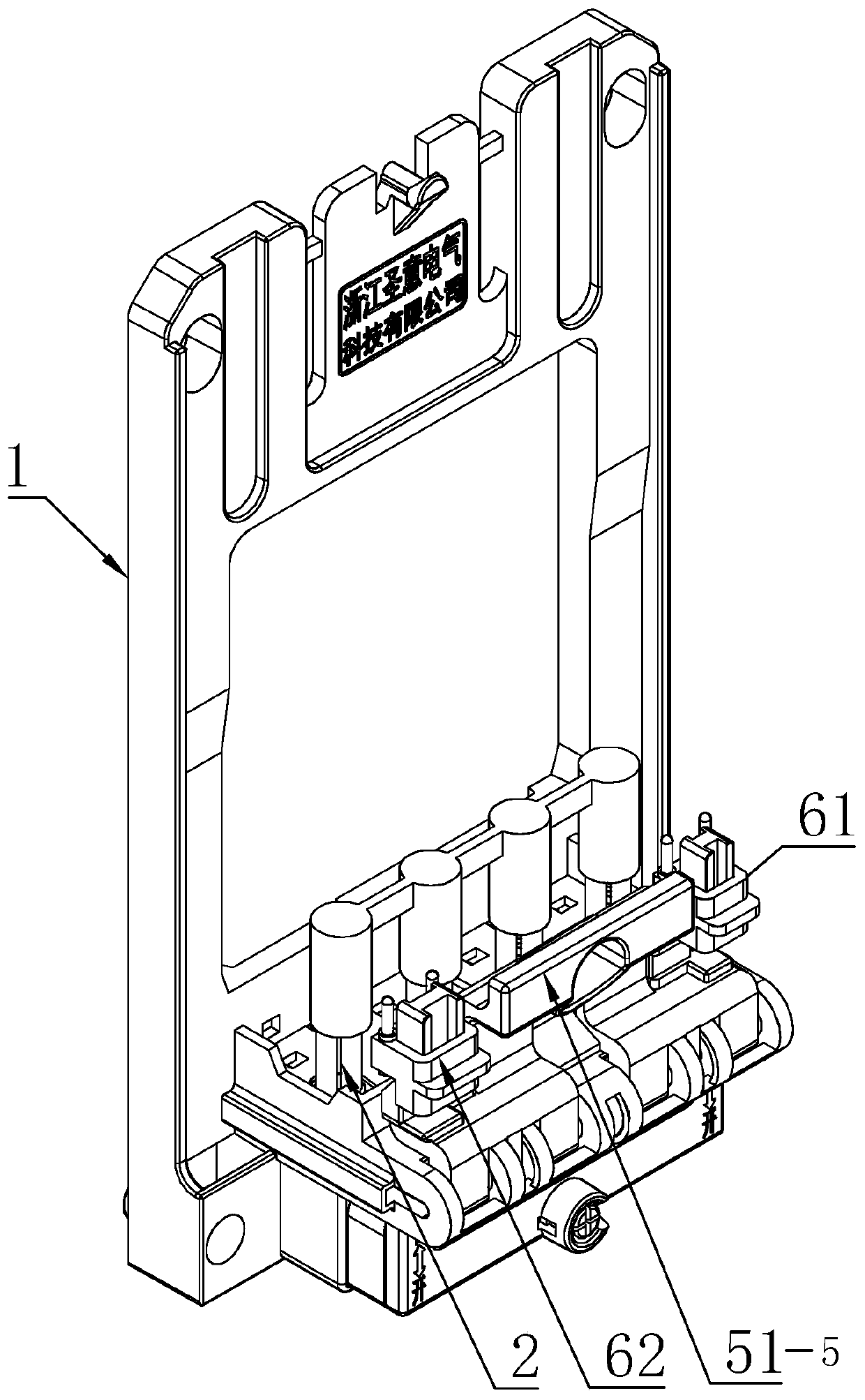

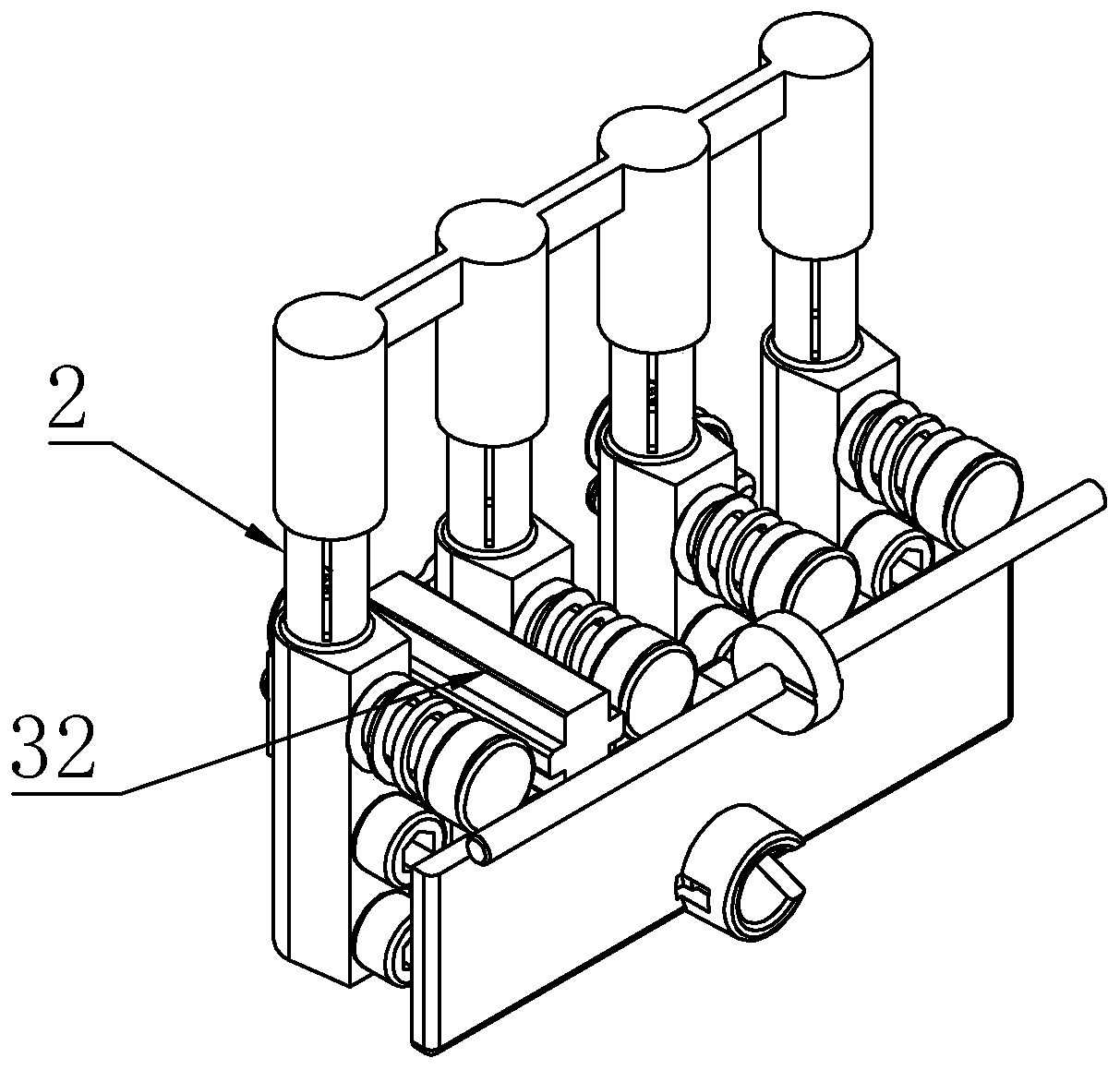

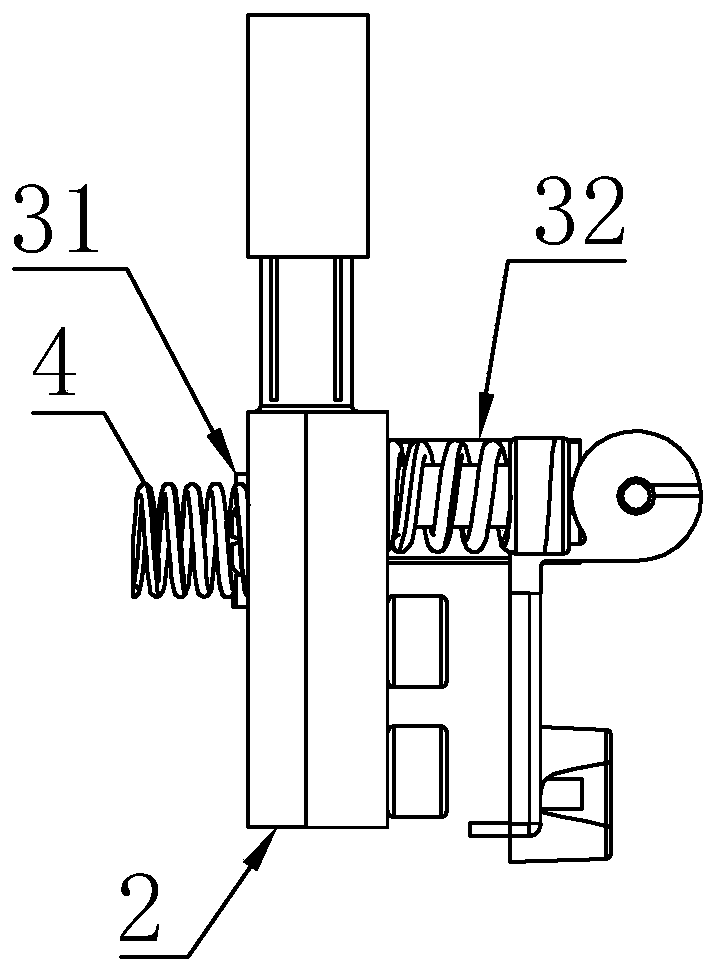

Connector capable of realizing replacement of electric energy meter without interrupting power supply

PendingCN111413531AShort replacement timeImprove efficiencyTime integral measurementElectric energyStructural engineering

The invention discloses a connector capable of realizing replacement of an electric energy meter without interrupting power supply. The connector is technically characterized by comprising a base anda plurality of plugs embedded in the base, wherein a movable connecting assembly is arranged in the base; the connecting assembly comprises a contact bridge and a push rod which are connected with each other; the contact bridge can be in contact connection with or separated from the plug by moving the push rod; a reset spring is arranged between the connecting assembly and the base; and a handle driving all push rods to move at the same is mounted on the base. The electric energy meter can be replaced without power failure, the replacement time is short, the efficiency is high, the daily lifeof people is not influenced, the application range is wide, the replacement process is convenient, safety and reliability are realized, a special short circuit tool does not need to be carried, and the use is convenient.

Owner:浙江圣意电气科技有限公司 +1

Measuring Arrangement for Brake Application Force Measurement of a Disc Brake and a Corresponding Disc Brake

ActiveUS20150027817A1Reduces installation expenditure and installation spaceEasily attachBraking element arrangementsAxially engaging brakesDisc brakeEngineering

Owner:KNORR-BREMSE SYST FUER NUTZFAHRZEUGE GMBH

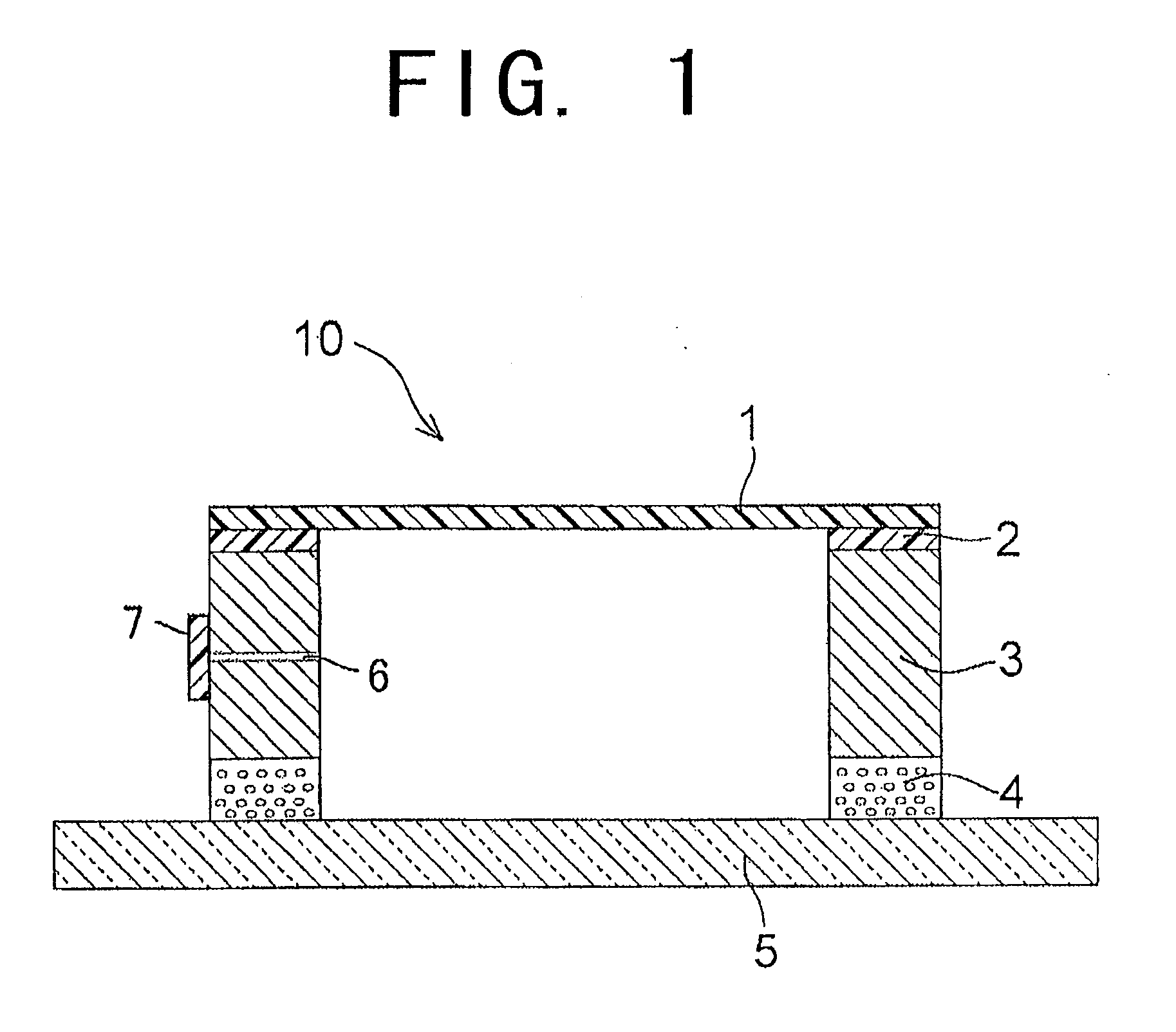

Pellicle for lithography

ActiveUS20110129767A1Prevent degradationEasy to peelSemiconductor/solid-state device manufacturingOriginals for photomechanical treatmentLithographic artistDecomposition

A pellicle 10 for lithography includes a pellicle frame 3, a pellicle membrane 1 adhered onto the upper end surface of the pellicle frame 3 and an agglutinant layer 4 formed on the lower surface of the pellicle frame 3 and the agglutinant layer 4 is formed by hardening a curable composition containing a straight chain perfluoro compound having a perfluoro structure in a main chain. The thus constituted pellicle 10 generates only a small amount of a decomposition gas even when it is used for a long time, thereby preventing solid-like foreign materials from separating out on a pattern region of a photomask 5 and can suppress degradation of an the agglutinant agent contained in an agglutinant layer 4 to be used for fixing a photomask 5 to the pellicle frame 3. Further, this pellicle 10 can be easily peeled off from a photomask 5 and replaced with a new one.

Owner:SHIN ETSU CHEM IND CO LTD

Steering knuckle master pin hole flexible positioning machining system.

InactiveCN104338958AHigh degree of flexibilityLess investmentPositioning apparatusMaintainance and safety accessoriesProduction lineNumerical control

The invention discloses a steering knuckle master pin hole flexible positioning machining system and relates to the technical field of automobile manufacturing. A worktable is provided with a quick-changing clamping fixture with a bottom surface provided with a key groove, and the quick-changing clamping fixture is fixed onto the worktable of a boring machine through keys and bolts; a workpiece is clamped on the quick-changing clamping fixture; a tool is connected with a boring machine spindle through a taper shank, the boring machine spindle drives the tool to rotate under the control of the numerical control procedure of a spindle motor, and a feed motor drives the tool to move transversely under the control of the numerical control procedure; the boring machine is provided with a boring head tool changer controlled by a tool-changing system; a cooling system is arranged inside the boring machine spindle; the spindle motor, the boring head tool changer, the tool-changing system, boring machine spindle, the boring tool, the workpiece, the worktable, the quick-changing clamping fixture and the feed motor are arranged inside a protective device in a closed mode. According to the steering knuckle master pin hole flexible positioning machining system, numerical control tool changing technology and quick-changing positioning technology are applied to simultaneous machining of different sizes and shapes of master pin holes or stepped master pin holes of steering knuckles of different varieties, working procedure flexibility and production efficiency of a production line are effectively improved and production line investment is reduced.

Owner:DONGFENG DANA AXLE

Off-line assembly and push-conveying method of large-capacity blast furnace body

InactiveCN109457073AShort overhaul intervalExtend your lifeBlast furnace componentsBlast furnace detailsButt weldingEngineering

The invention relates to an off-line assembly and push-conveying method of a large-capacity blast furnace body. The off-line assembly and push-conveying method comprises the following steps: a, makinga push-conveying platform foundation on an open ground linearly corresponding to an original old blast furnace body; b, mounting a plurality of push-conveying steel beams on the push-conveying platform foundation, paving steel rails on the push-conveying steel beams, and arranging a power moving trolley on the steel rails; c, on the open ground linearly corresponding to the original old blast furnace body, making a new blast furnace body on the top surface of the power moving trolley; d, mounting a hydraulic push-conveying device and a hydraulic jacking device on the back side of the new furnace body; e, mounting a hydraulic lifting device on the top steel beam of a framework of the blast furnace body; f, pushing the new blast furnace body to a design position; g, utilizing the hydrauliclifting device to lower the upper structure of the new furnace body and enable the upper structure to be abut joint with a lower structure and carrying out butt welding; and h, and carrying out concrete pouring on the new blast furnace body. The method is suitable for the repair of the large-capacity blast furnace body and the change of the furnace body structure. Production can be prevented frombeing affected, so that the repair period of the blast furnace body is short, and the production halt time is short.

Owner:MCC TIANGONG GROUP

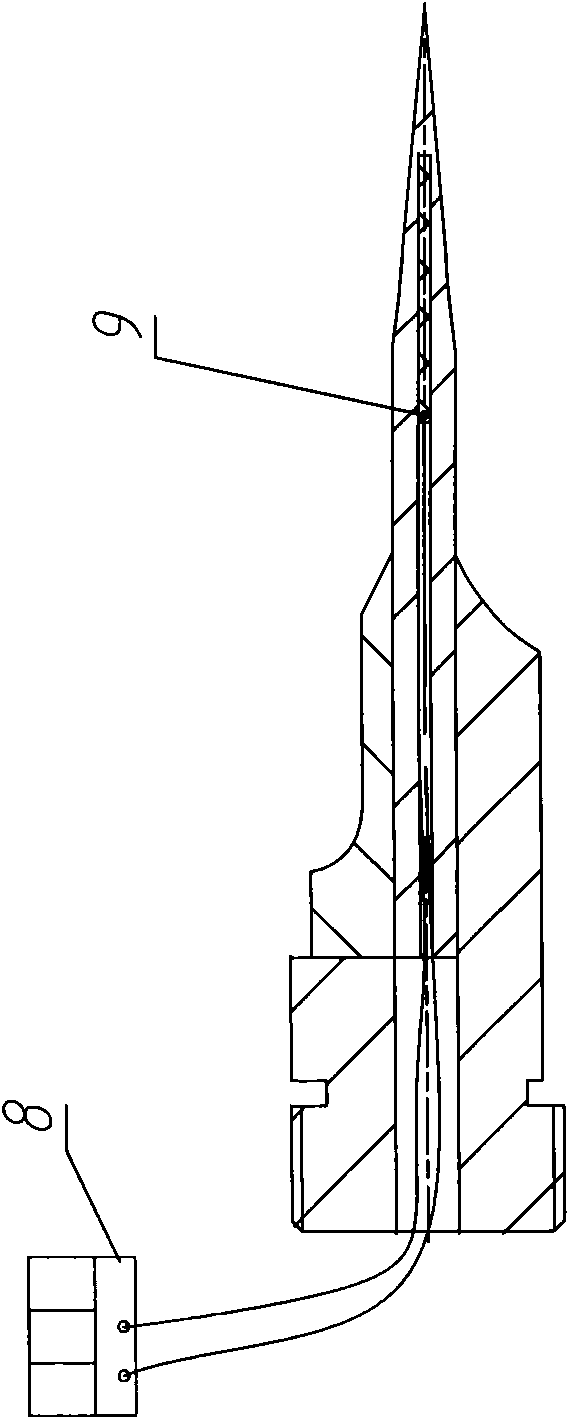

Internally conductive hot cut-off knife and method thereof

InactiveCN102476393AHeating up fastAccurate perception fastMetal working apparatusTemperature controlHeat transmission

The invention provides an internally conductive hot cut-off knife and a method thereof. A heat supply element and a temperature sensor are installed in the interior of a knife edge part of a knife body so that produced heat energy is acted on a knife edge directly and cutting operation is performed while hot melting is performed on the surface of a sizing material; and the heat source is installed on the knife edge part for performing the cutting operation directly, obvious heat loss is avoided without long distance heat transmission, thereby saving energy effectively. The internally conductive hot cut-off knife comprises a lower fixture body, an upper fixture body and the knife body, wherein the knife body comprises a base part clamped and fixed between the lower fixture body and the upper fixture body and the knife edge part for cutting on the surface of the sizing material; and the heat supply element for directly acting the heat energy on the knife edge and the temperature sensor which is used for connecting with an external power supply and a temperature control instrument and detecting work temperature on the surface of the knife edge are installed in the knife edge part.

Owner:MESNAC

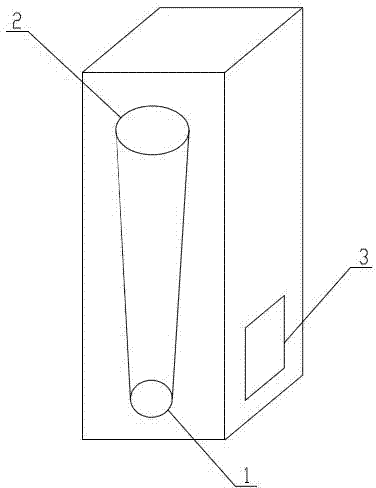

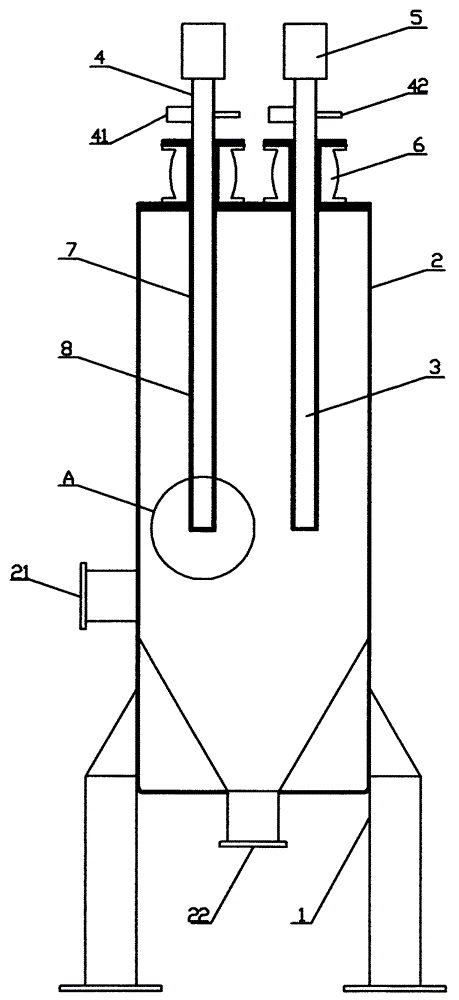

A tubular concentration device

ActiveCN104056479BSpeed up sheddingQuick and complete sheddingStationary filtering element filtersSludgePapermaking

Owner:杭州安永环保科技有限公司

Rotary tool turret special for NC turning and milling center and rotation method

The invention relates to a turret type rotary tool turret special for an NC turning and milling center and for turning and milling tool turrets and machining centers of NC lathes and a rotation method. A toolholder adopts the locking structure of a locknut and uses a V-shaped groove of a V-shaped groove toolholder; the V-shaped groove toolholder is locked by rotating the locknut clockwise and is loosened by rotating the locknut counterclockwise so as to be convenient for realizing the functions of installing, fixing and taking out the V-shaped groove toolholder and replacing multi-spindles; spindle transmission adopts the straight concave-convex connection transmission type; the tool turret rotation adopts the structure of a three-plate clutch which is driven to rotate by a high-precision worm gear and a high-precision worm. The invention has the following advantages: 1. short replacement time, fast speed and convenient replacement of V-shaped groove toolholders; 2. good functions of installing and replacing multi-spindles, one-time completion of drilling and tapping, shortened operation time and greatly improved machining efficiency; 3. great bearing capacity, good structure rigidity, long service life, simple machining, low manufacturing cost and convenient equipment maintenance and repair; 4. high rotary precision and good stability.

Owner:HANGZHOU BAKER MASCH CO LTD

Coating machine of prepainted steel sheet

InactiveCN102029239AEasy to disassembleEasy and accurate disassemblyLiquid surface applicatorsCoatingsAgricultural engineeringSteel belt

The invention discloses a coating machine of a prepainted steel sheet. The coating machine main consists of a coating roll, a coating roll adjusting device, a coating sticking roll, a coating sticking roll adjusting device, a metering roll and a metering roll adjusting device, wherein, the coating roll and the coating sticking roll are not aligned but staggered in the vertical direction, and the coating roll inclines towards the outside of the coating sticking roll; during adjusting the clearance between the coating roll and a steel belt, the clearance between the coating roll and the coating sticking roll and the clearance between the coating roll and the metering roll are kept unchanged; and during adjusting the clearance between the coating sticking roll and the coating roll, the clearance between the coating roll and the metering roll is kept unchanged. In the invention, a bearing seat used for the coating roll is of a quick disassembly type, i.e., the bearing seat can be opened after a fastening bolt is loosened; and after the original coating roll is replaced with a new coating roll, the fastening bolt is screwed down to completely assemble the coating roll.

Owner:无锡东和薄板装备制造有限公司

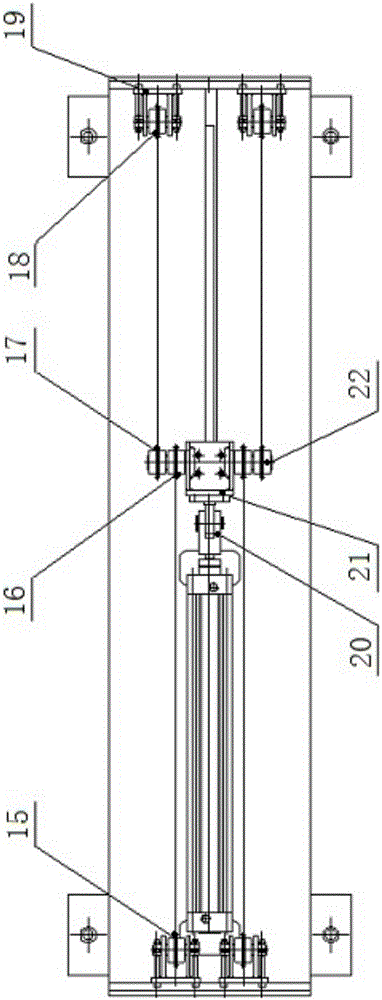

Automatic tooling replacement device

The invention discloses an automatic tooling replacement device which comprises a fixed base, a tooling support and a fast replacement device, wherein the fixed base is mounted on the ground, the tooling support is arranged on the fixed base, the fast replacement device is loaded at the top end of the tooling support, the fixed base is provided with a double-acting structure, the double-acting structure is provided with a cylinder for driving a chain wheel and a chain and drives the tooling support to rapidly enter and exit, the tooling support is provided with double positions, the fast replacement device comprises a second cylinder and an automatic fast replacement disk, and the second cylinder drives the automatic fast replacement disk to automatically lock and unlock. According to the automatic tooling replacement device, by the aid of a double-acting translation mode of the chain wheel and the chain driven by the cylinder and the fast replacement device, a tooling can be automatically replaced by programming, manual operation is omitted, and the automatic tooling replacement device is innovative. The automatic tooling replacement device is compact in integral structure, small in occupied space, easy to maintain and cannot be limited by sound insulation protection of a whole press line, replacement time of the tooling is short, replacement efficiency of the tooling is high, and economic benefits of enterprises can be improved.

Owner:JIER MACHINE TOOL GROUP

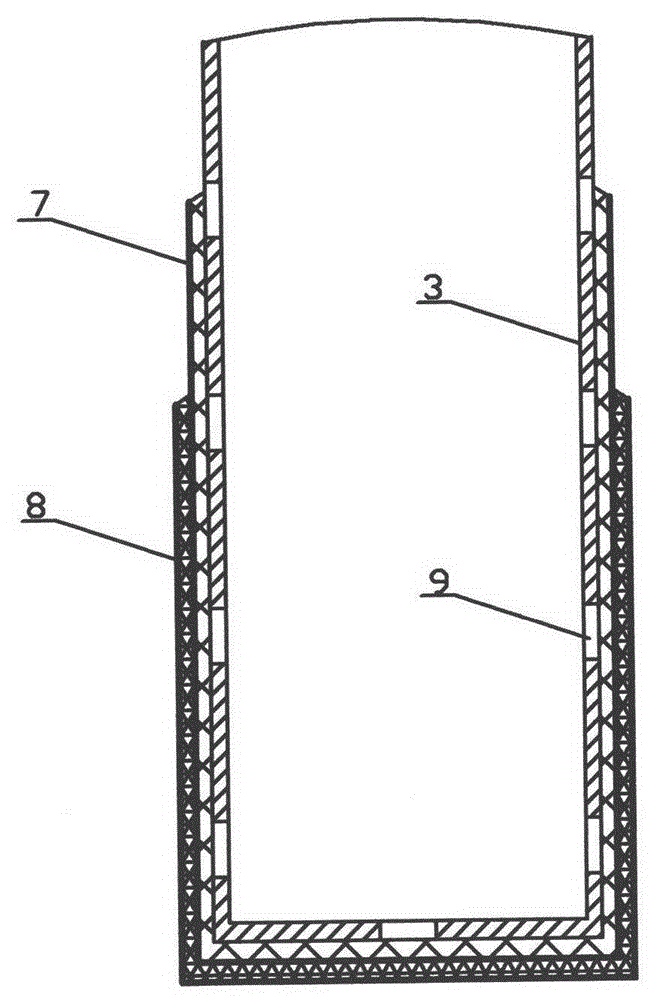

Shaking table device

ActiveCN104330290ASpeed up penetrationShort replacement timeShaking/oscillating/vibrating mixersPreparing sample for investigationEngineeringSample chamber

The invention relates to a shaking table device which comprises a shaking table for carrying a sample, a sample chamber cover, and a shaking table driving device; and the shaking table driving device is arranged on the sample chamber cover, is connected with the shaking table through a connecting piece passing through the sample chamber cover, and is used to drive the connecting piece movement to drive the shaking table to shake. The shaking table device provided by the invention can increase the penetration velocity of a replacement liquid by cooperation of the shaking table driving device and the shaking table, and can greatly shorten the replacement time of the replacement liquid.

Owner:INSITUTE OF BIOPHYSICS CHINESE ACADEMY OF SCIENCES

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com