Off-line assembly and push-conveying method of large-capacity blast furnace body

A blast furnace, large-volume technology, applied to blast furnaces, blast furnace details, blast furnace parts, etc., can solve problems such as large safety hazards, difficult lifting of components, and long shutdown time

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

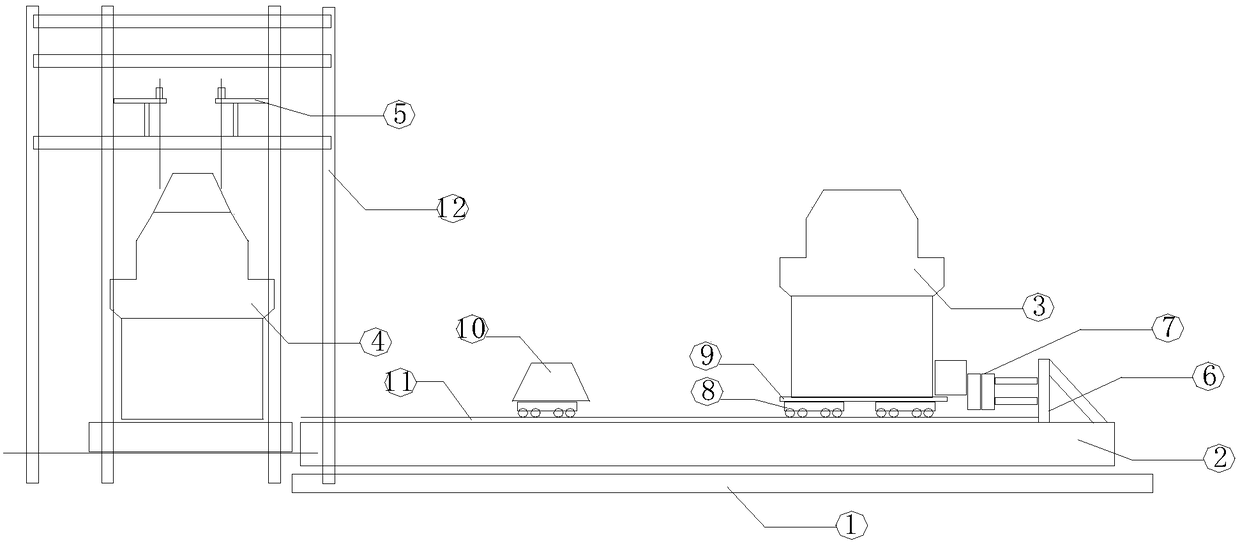

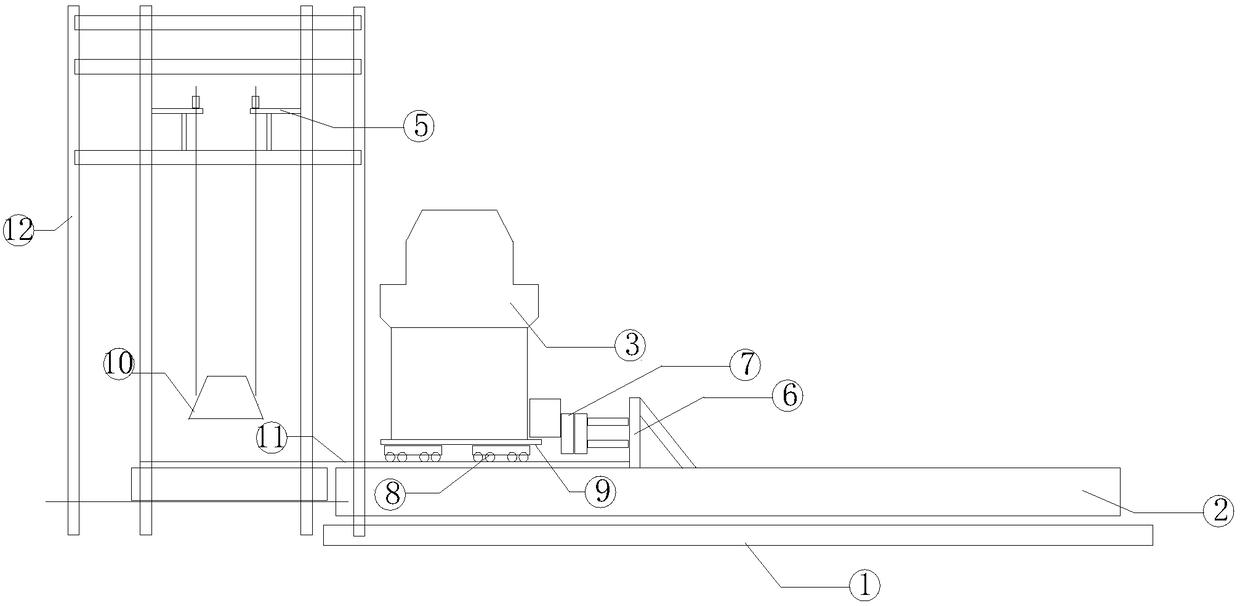

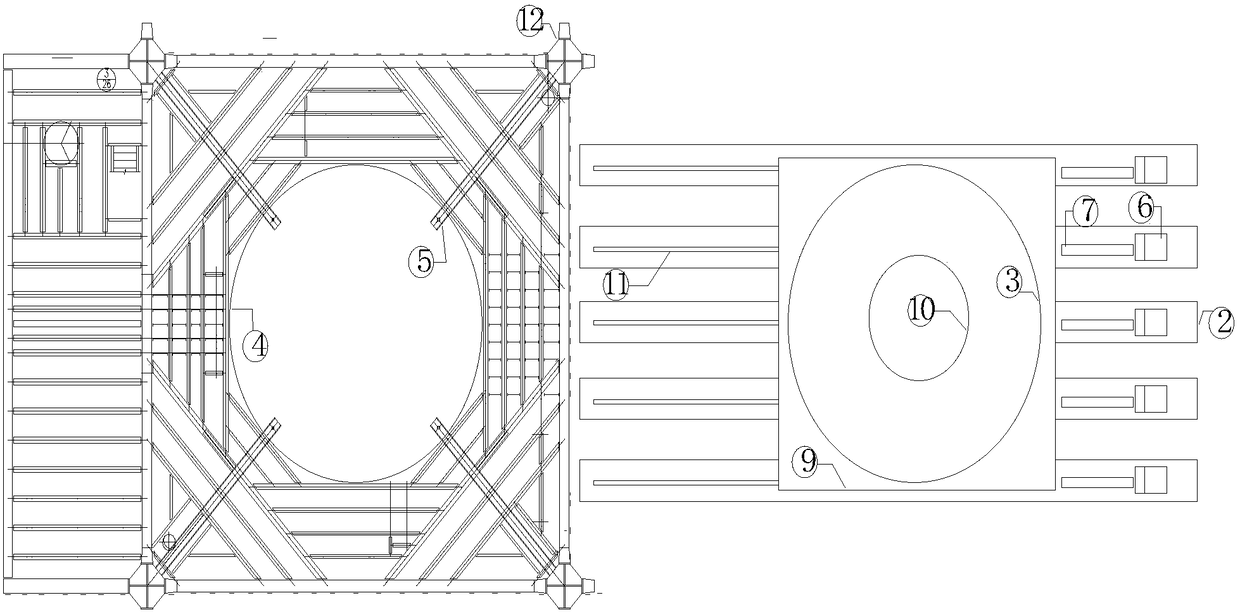

[0028] A method for offline assembly and moving of a large-volume blast furnace body, comprising the following steps:

[0029] 1. First make five reinforced concrete cast-in-place beams on the open space corresponding to the straight line of the original old blast furnace body as the foundation of the moving platform.

[0030] 2. Install a number of moving steel beams on the basis of the moving platform, and use steel supports to tie them firmly. The moving steel beams are made of steel plates, and steel rails are laid on them, and multiple sets of power mobile vehicles are set on the steel rails;

[0031] 3. On the open space corresponding to the straight line of the original old blast furnace body, a new blast furnace body is rebuilt on the power mobile car on the rail. The bottom plate of the furnace shell is directly placed on the power mobile car, and the furnace body is lined Together with the completion of the new furnace body masonry;

[0032] 4. Install the external ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com