Shaking table device

A technology of driving device and shaking plate, which is applied in the direction of dissolution, mixer, and preparation of test samples, etc., can solve the problems of long experimental period, slow replacement speed, and limited experimental progress speed, so as to shorten the replacement time and increase the penetration speed Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

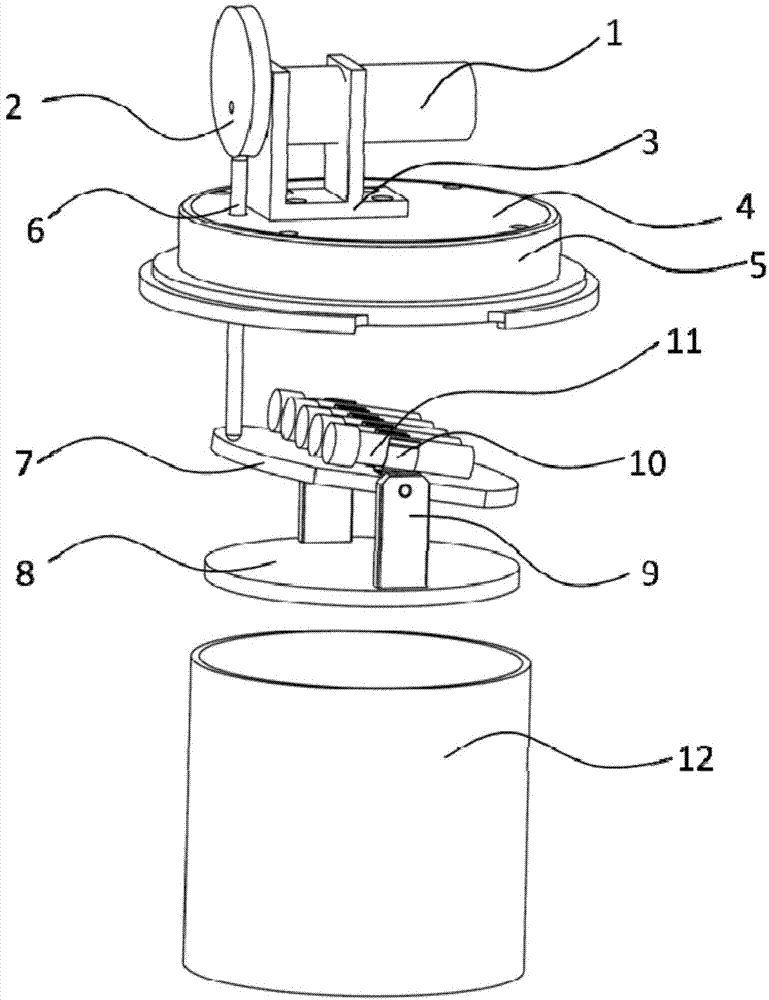

[0022] see figure 1 The shaking table driving device in the shaking table device provided by the embodiment of the present invention includes a driving motor 1 , a motor frame 3 and a cam 2 ; the driving motor 1 is fixed on the top plate 4 of the sample chamber cover 5 through the motor frame 3 . The cam 2 is connected with the driving motor 1 and the connecting piece respectively. The driving motor 1 drives the cam 2 to rotate and then drives the connecting piece to move up and down. Specifically, the connecting piece may be a connecting rod 6 . The top plate 4 is transparent for observing the situation in the sample chamber. The sample chamber cover 5 is used to cover the low-temperature chamber 12 to maintain a low-temperature environment and prevent external moisture from being polluted.

[0023] The shaker includes a shaker plate 7, a shaker support 9 and a shaker base 8. The rocking plate 7 of the shaking table is connected with the support 9 of the shaking table thr...

Embodiment 2

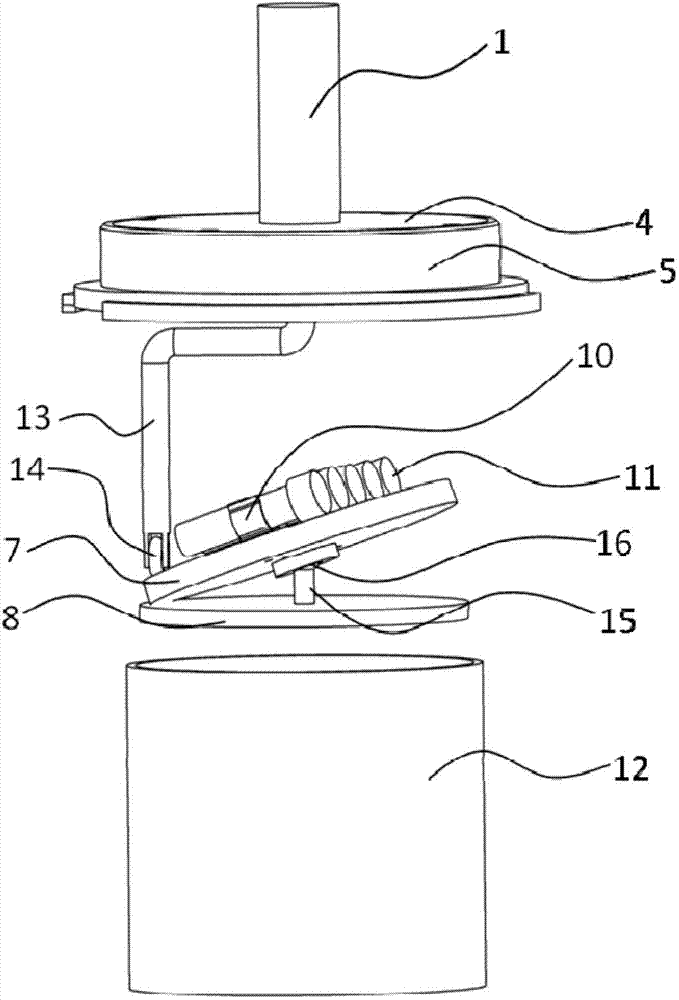

[0026] see figure 2 , the shaking table driving device in the shaking table device provided by the embodiment of the present invention includes a driving motor 1 ; the driving motor 1 is fixed on the top plate 4 of the sample chamber cover 5 . The top plate 4 is transparent for observing the situation in the sample chamber. The sample chamber cover 5 is used to cover the low-temperature chamber 12 to maintain a low-temperature environment and prevent external moisture from being polluted. The connecting piece is assembled on the shaft of the drive motor 1 . Specifically, the connecting piece may be a motor connecting rod 13 . The other end of the motor link 13 is assembled with a rolling part, i.e. a roller 14 . The shaking table comprises a shaking table rocking plate 7, a shaking table base 8, a shaking table rocking plate center support 15 and a shaking table rocking plate center support universal joint 16. The rocking table rocking plate central support 15 is fixed on...

Embodiment 3

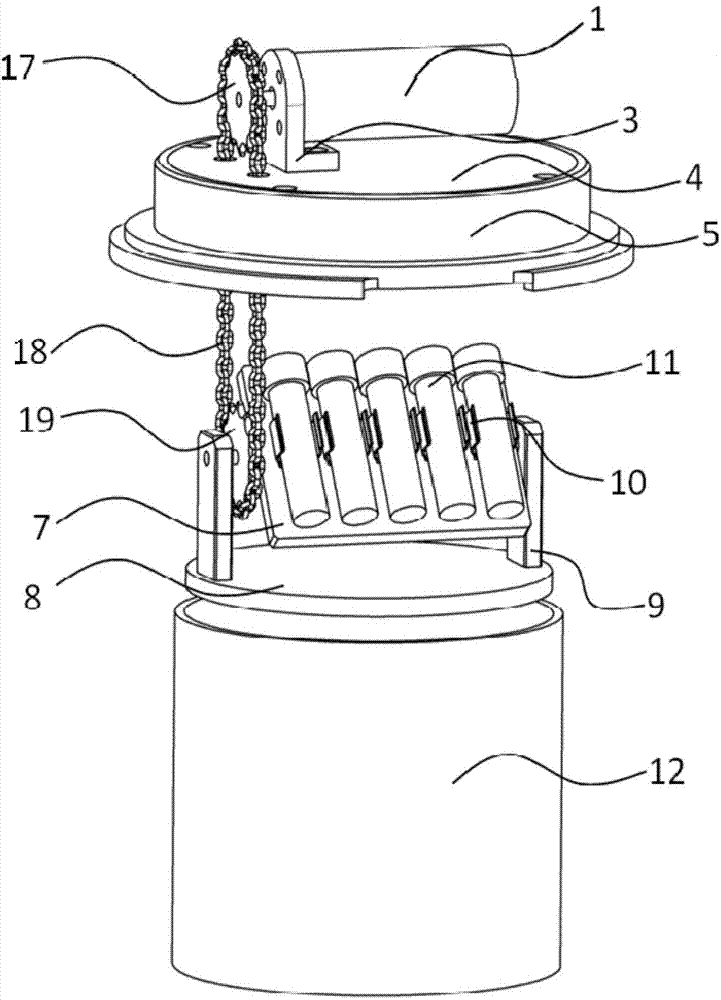

[0028] Such as image 3 As shown, the shaker in the shaker device provided by the embodiment of the present invention includes a shaker plate 7 , a shaker support 9 and a shaker base 8 . The shaking table rocking plate 7 is connected with the shaking table support 9 through a shaft, and a driven sprocket 19 is arranged on one side of the shaft. The shaker base 8 is fixedly connected with the shaker support 9 . A number of spring clips 10 are arranged on the rocking plate 7 of the shaking table for clamping the sample tube 11 .

[0029] The driving device of the shaking table includes a driving motor 1 and a motor frame 3 . The drive motor is fixed on the motor frame 3. The motor frame 3 is fixed on the top plate 4 of the sample chamber cover 5 . The top plate 4 is transparent for observing the situation in the sample chamber. The sample chamber cover 5 is used to cover the low-temperature chamber 12 to maintain a low-temperature environment and prevent external moisture f...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com