Small-scale copper wire winding mechanism with automatic shearing device

A technology of shearing device and winding mechanism, which is used in transportation and packaging, transportation of filamentous materials, and thin material processing, etc., can solve the problems of low efficiency, long stop time, manual unloading, etc., and achieve high efficiency and improve The effect of production efficiency and short replacement time

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

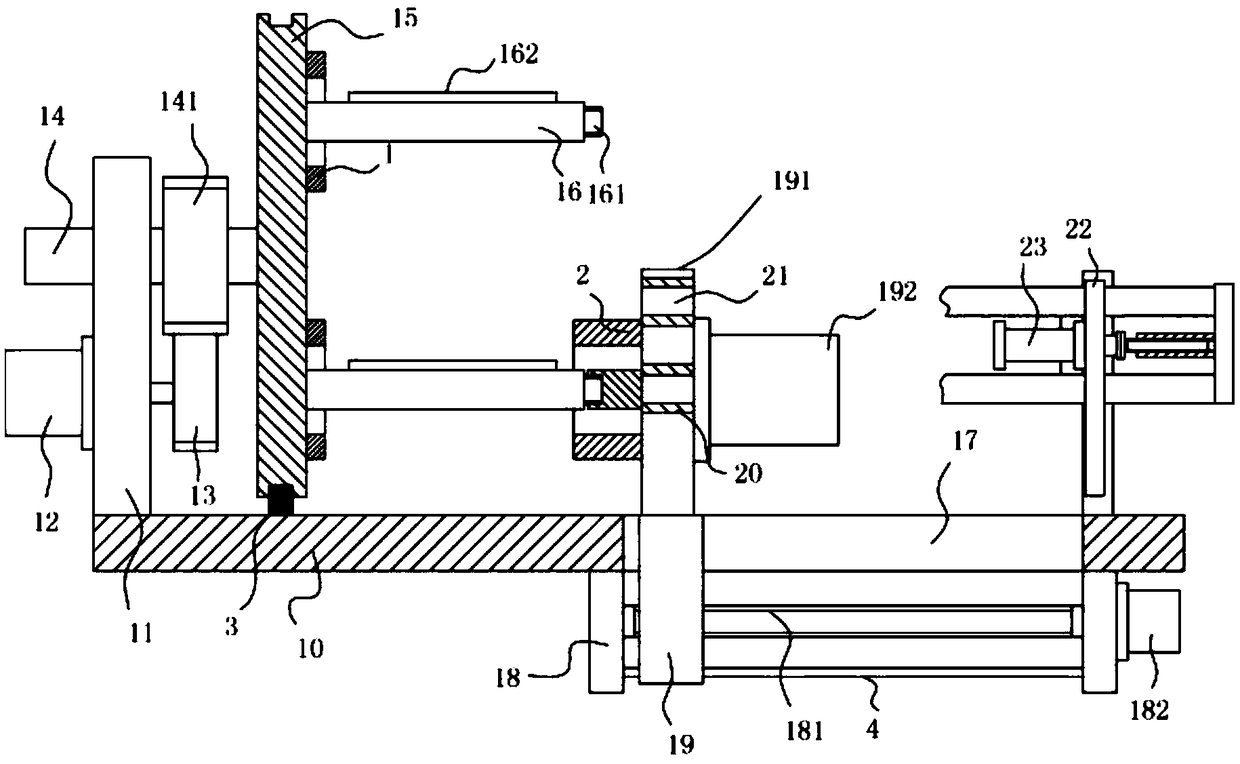

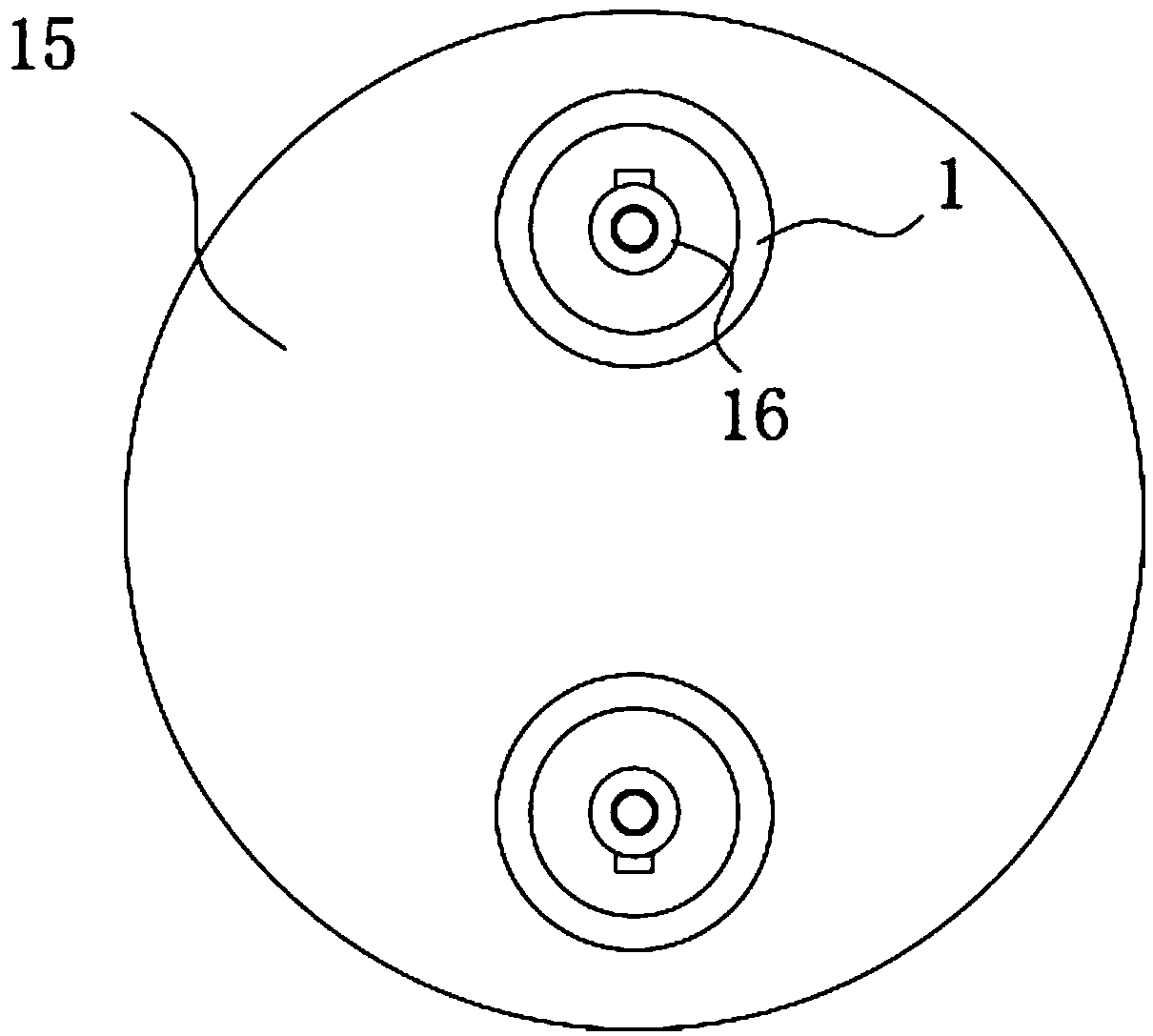

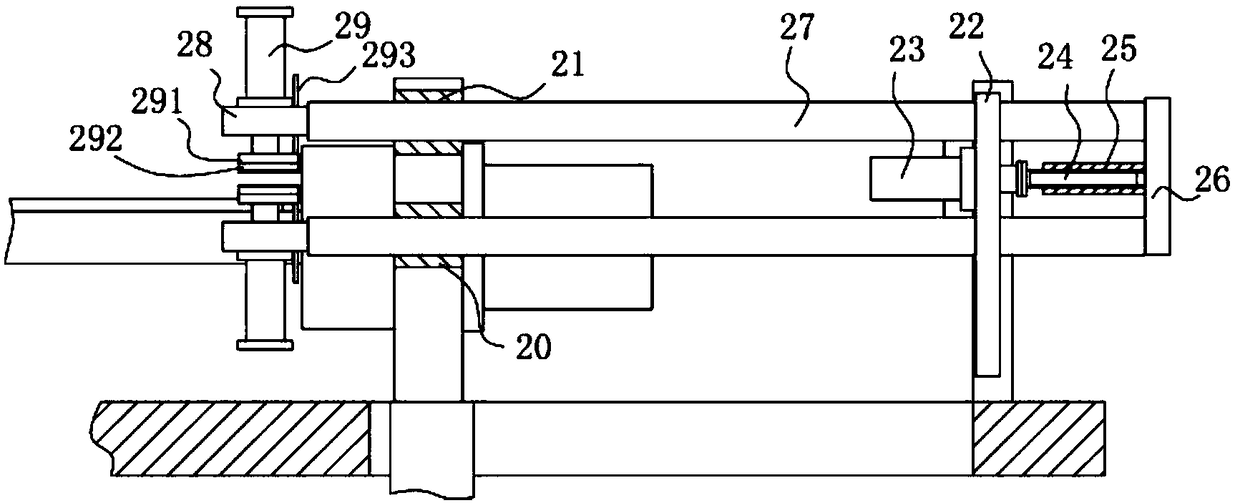

[0021] Example: see Figure 1 to Figure 3 As shown, a small-sized copper wire winding mechanism with an automatic shearing device includes a main base plate 10, a vertical support plate 11 is fixed on the left top surface of the main base plate 10, and the left side wall of the vertical support plate 11 Servomotor 12 is fixed on it, the output shaft of servomotor 12 passes through vertical support plate 11 and is fixed with driving gear 13, the top of vertical support plate 11 is hinged with rotating main shaft 14 through bearing, and the right part of rotating main shaft 14 protrudes Vertical support plate 11 is fixed with transmission gear 141, and transmission gear 141 is meshed with rotation gear 13, and the right end of rotation main shaft 14 is fixed with main circular rotary plate 15, and the top and bottom of the right side wall of main circular rotary plate 15 Both are hinged with a transverse shaft 16 through bearings, and the right end of the transverse shaft 16 is ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com