Patents

Literature

Hiro is an intelligent assistant for R&D personnel, combined with Patent DNA, to facilitate innovative research.

137results about How to "Processing does not affect" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

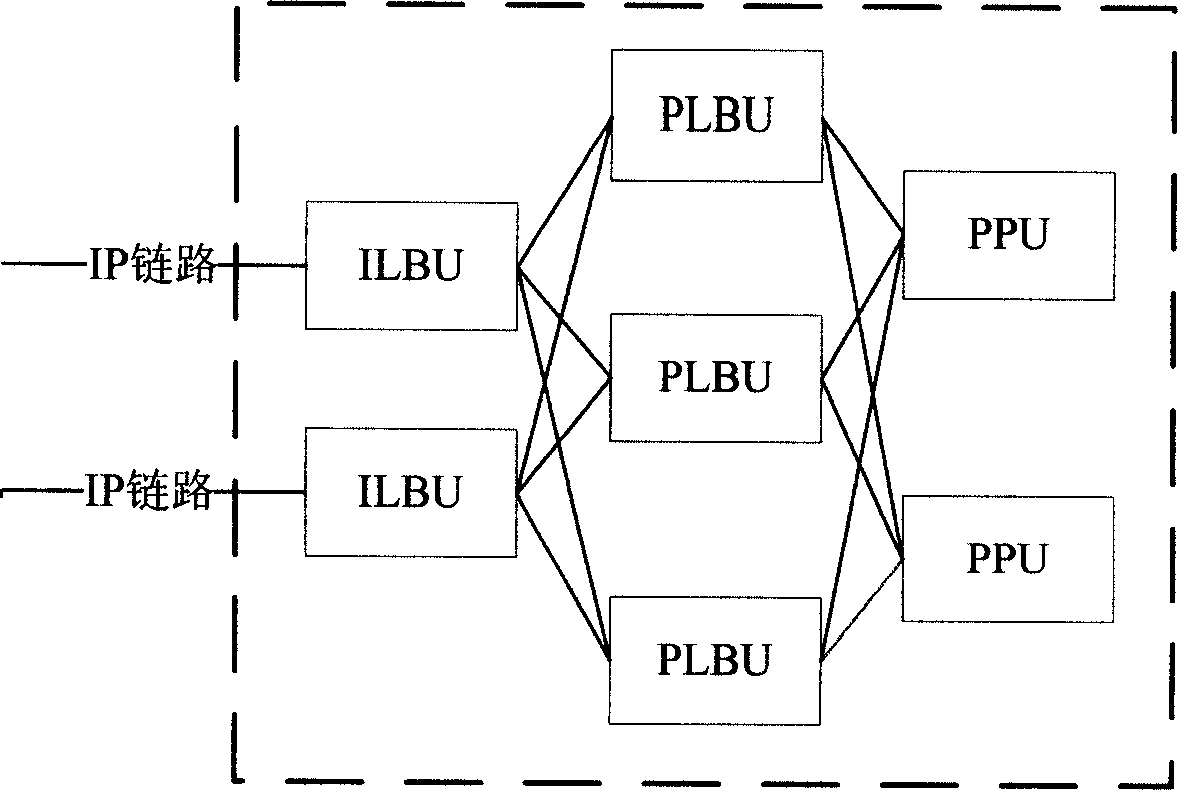

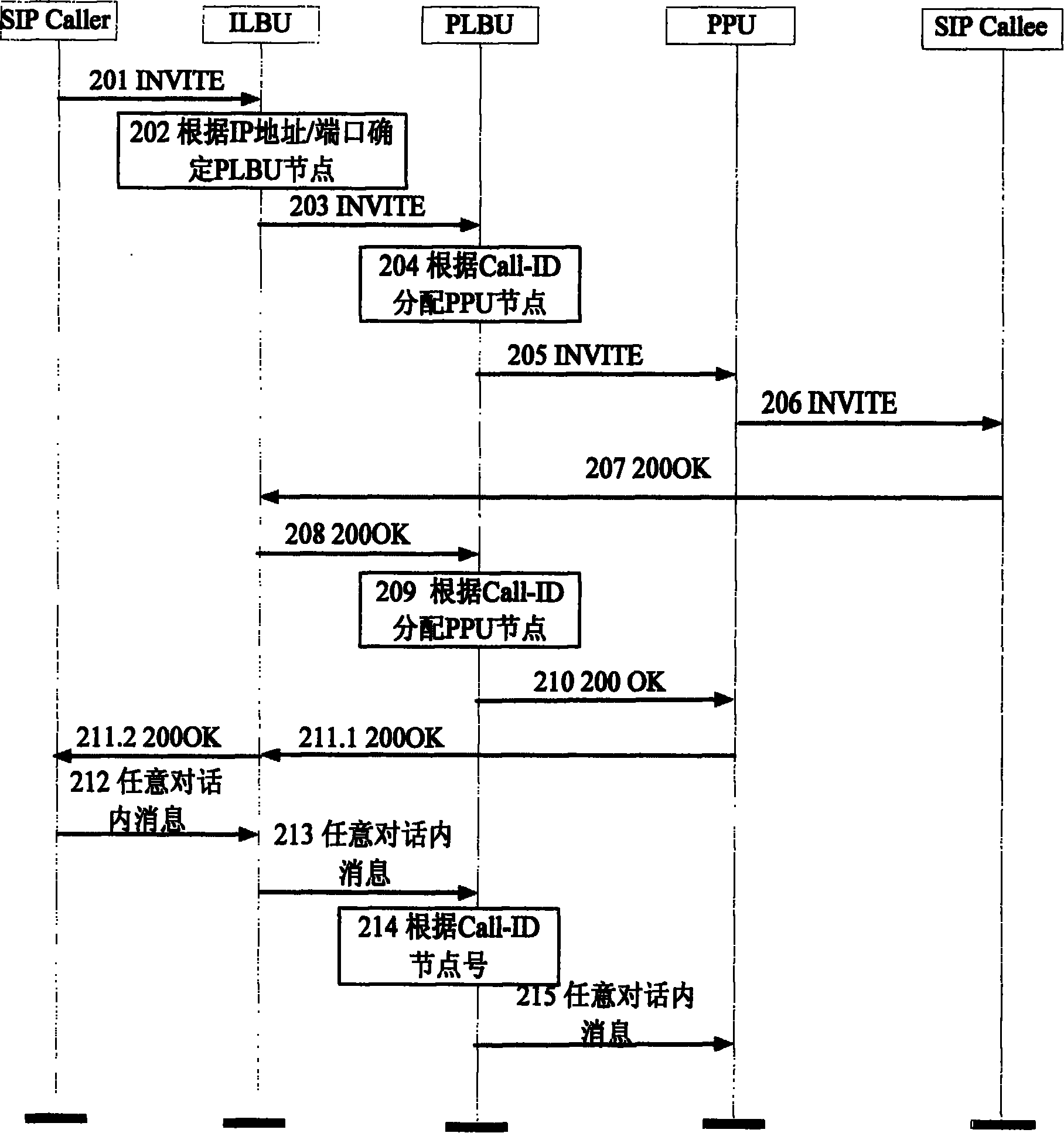

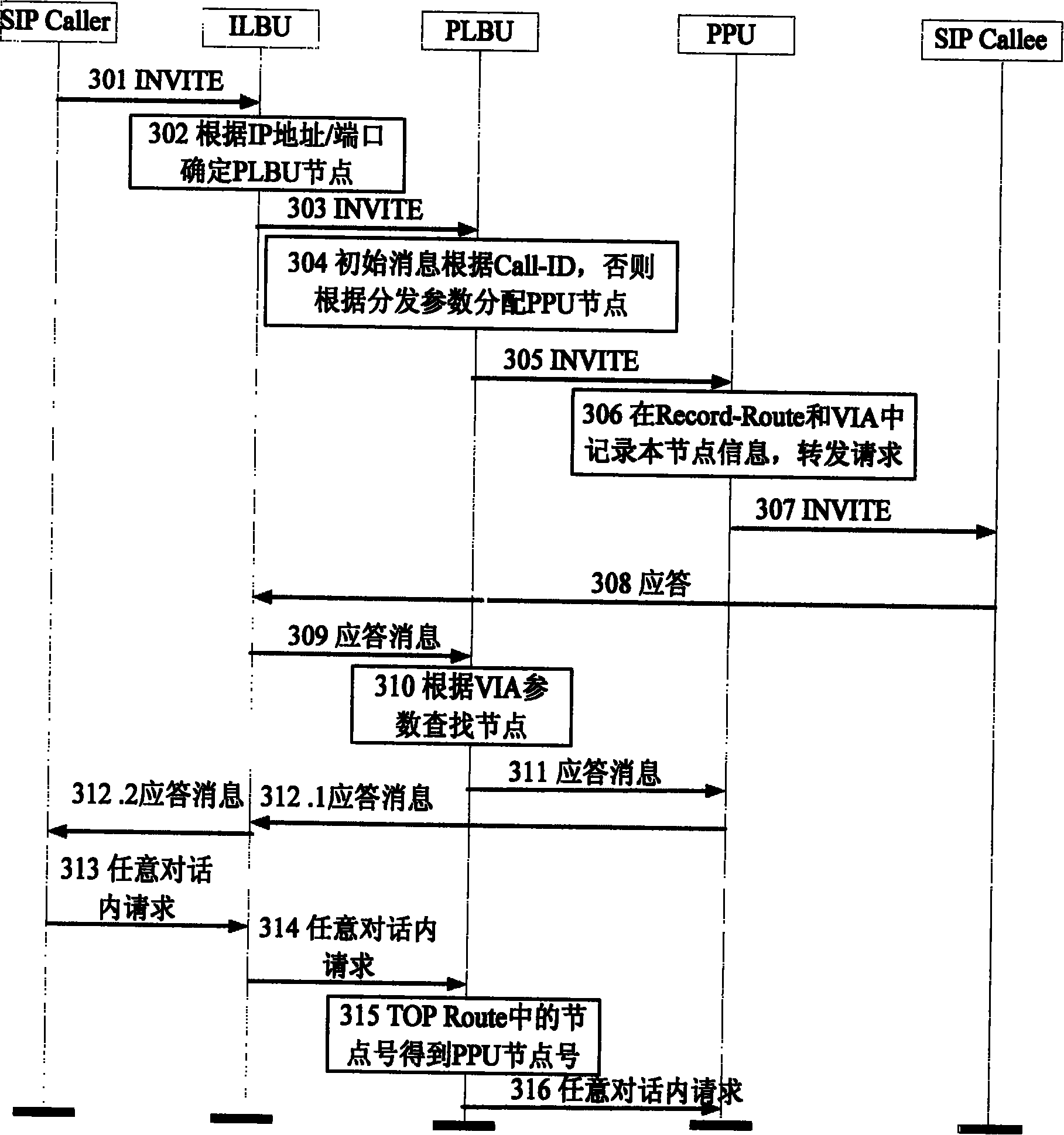

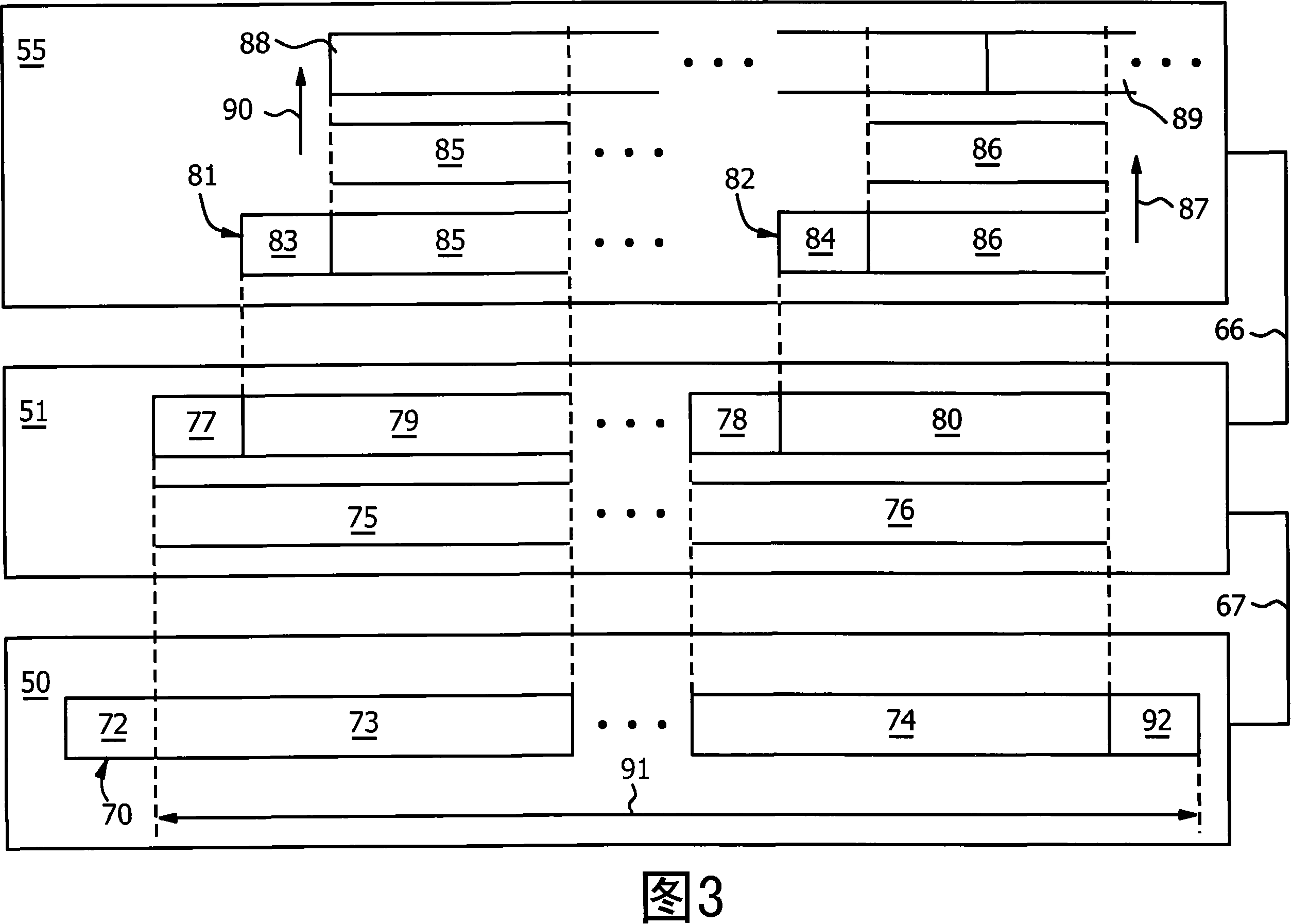

Method fro dynamic load balance in distributed system based on session origination protocol

ActiveCN101166176AProcessing does not affectKeep statelessTransmissionSession Initiation ProtocolDistributed computing

SIP entity initiates message of SIP request. Receiving SIP message, ILBU sends the message to a PLBU process node based on address or port number of message. Decoding the SIP message, PLBU determines whether the message is a request on inside or outside conversation, or a response in order to carry out different processes. The method improves shortcoming of current fixed type HASH algorithm, and meanwhile keeps characteristic of no state of distributing procedure self. In the invention, no meter increasing or decreasing nodes in the system or adjusting distributing strategy of system will not influence on processing message of conversation so as to raise reliability and scalability of system greatly.

Owner:ZTE CORP

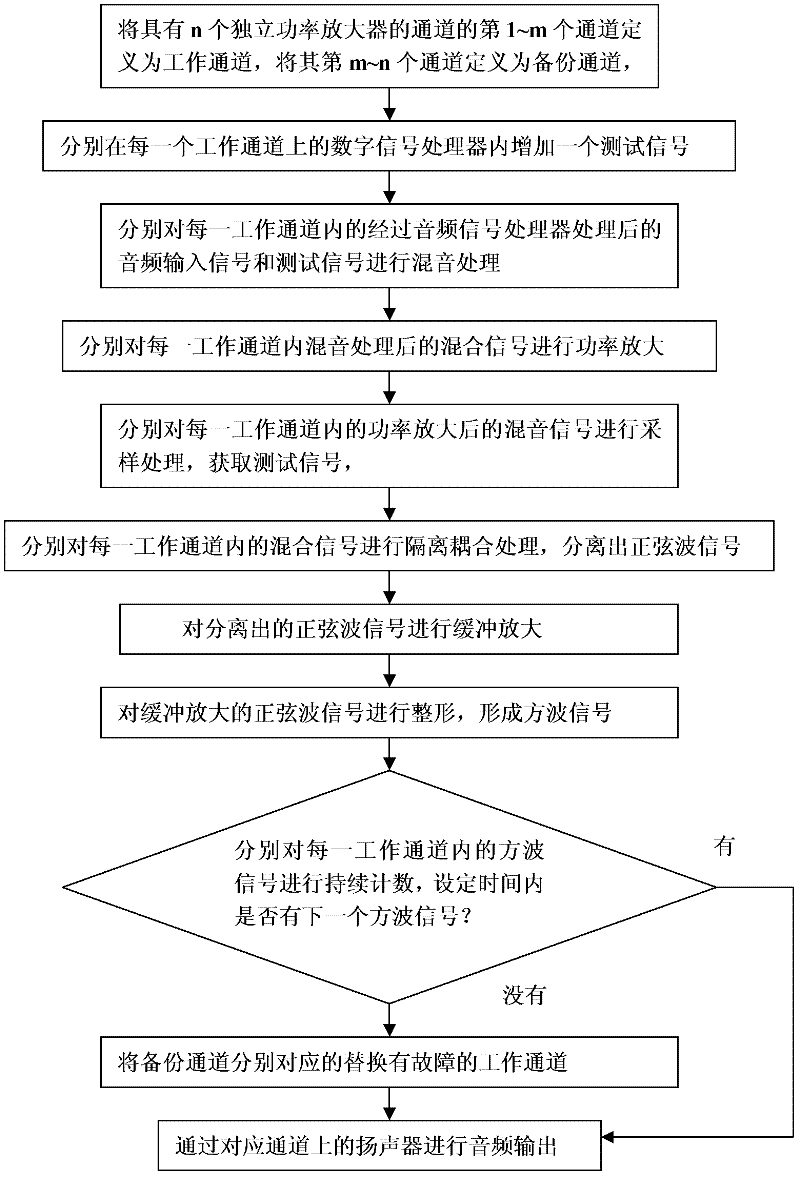

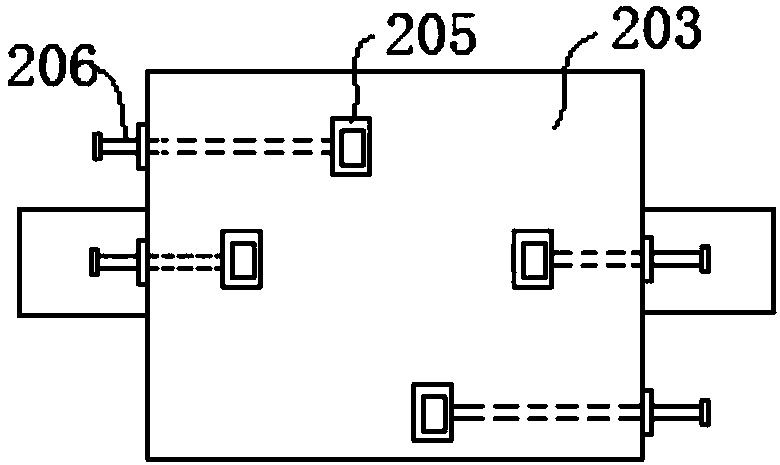

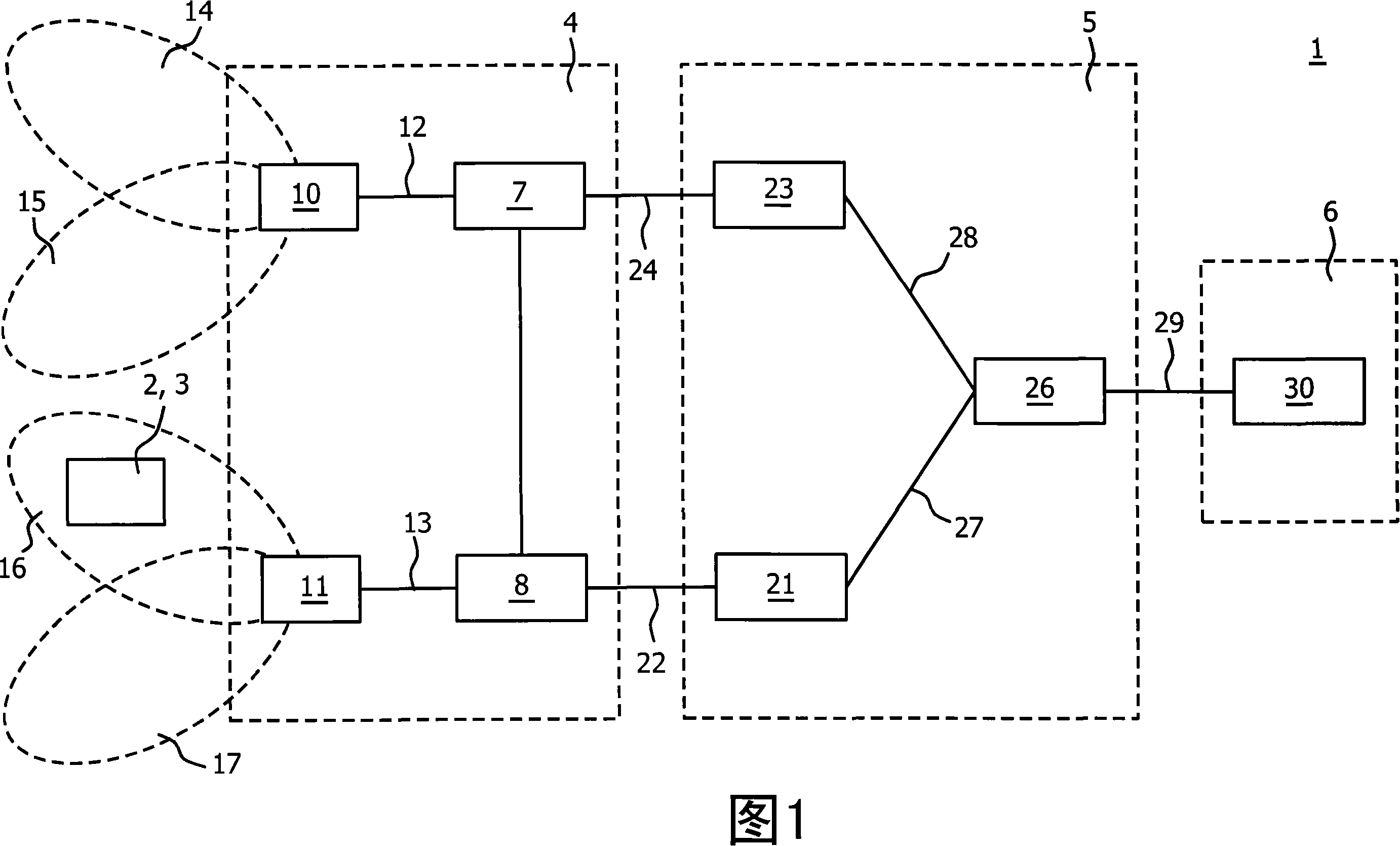

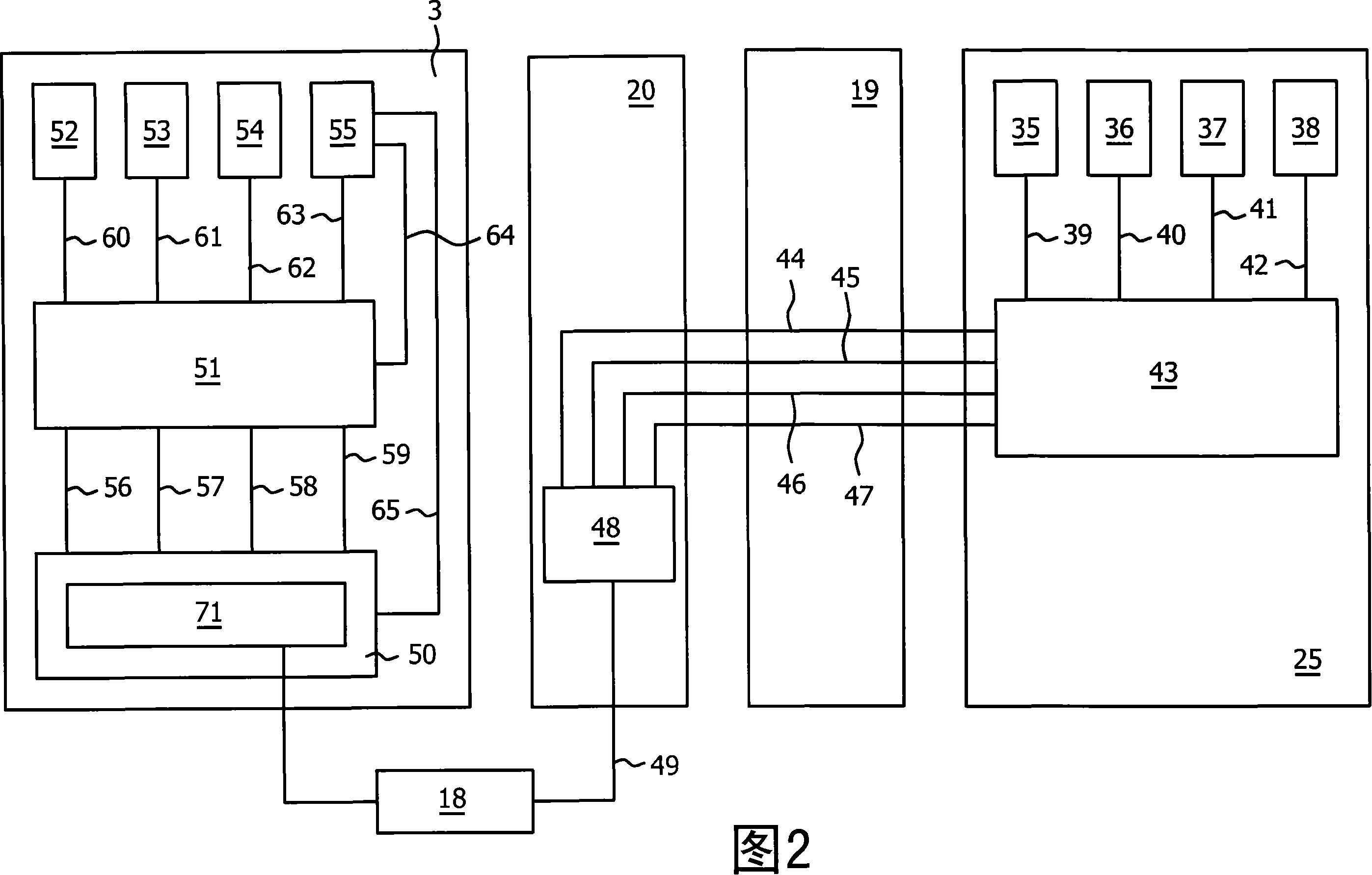

Hot backup method and hot backup device for multi-channel power amplifier

ActiveCN102231621AEffect does not affectProcessing will not affectAmplifier combinationsAmplifier protection circuit arrangementsManagement unitAudio power amplifier

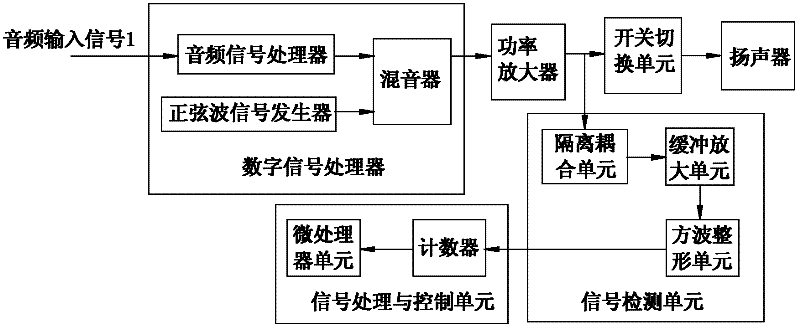

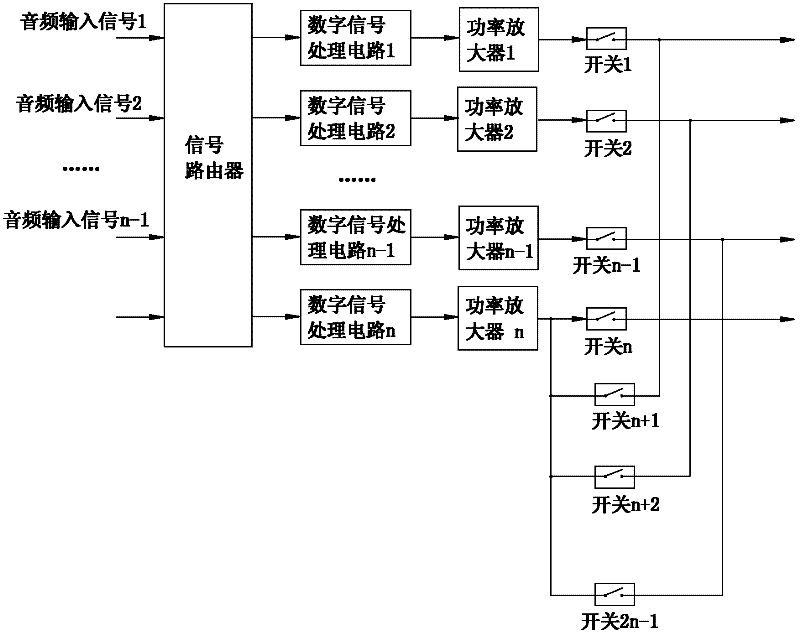

The invention discloses a hot backup method and a hot backup device for a multi-channel power amplifier with an automatic failure detection function and an automatic failure backup function. A plurality of independent channels of the power amplifier are divided into working channels and backup channels; a test signal is added to the input end of each working channel; signal detection units monitor and sample the output end of the power amplifier on each working channel in real time; if the signal detection unit on each working channel can continuously detect the test signal, the power amplifier on the working channel is proved to work normally; and if the signal detection unit on a certain working channel cannot continuously detect a sampling signal, the power amplifier on the working channel is proved not to work normally, and a signal processing and control unit and a switching management unit correspondingly replaces the power amplifier on the failing working channel by the power amplifier on the backup channel to ensure a loudspeaker on the working channel still can work normally.

Owner:GUANGZHOU LEAFUN CULTURE SCI & TECH

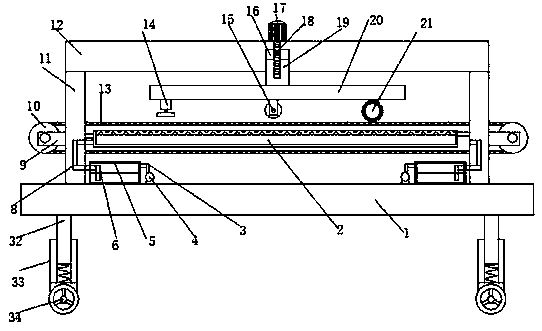

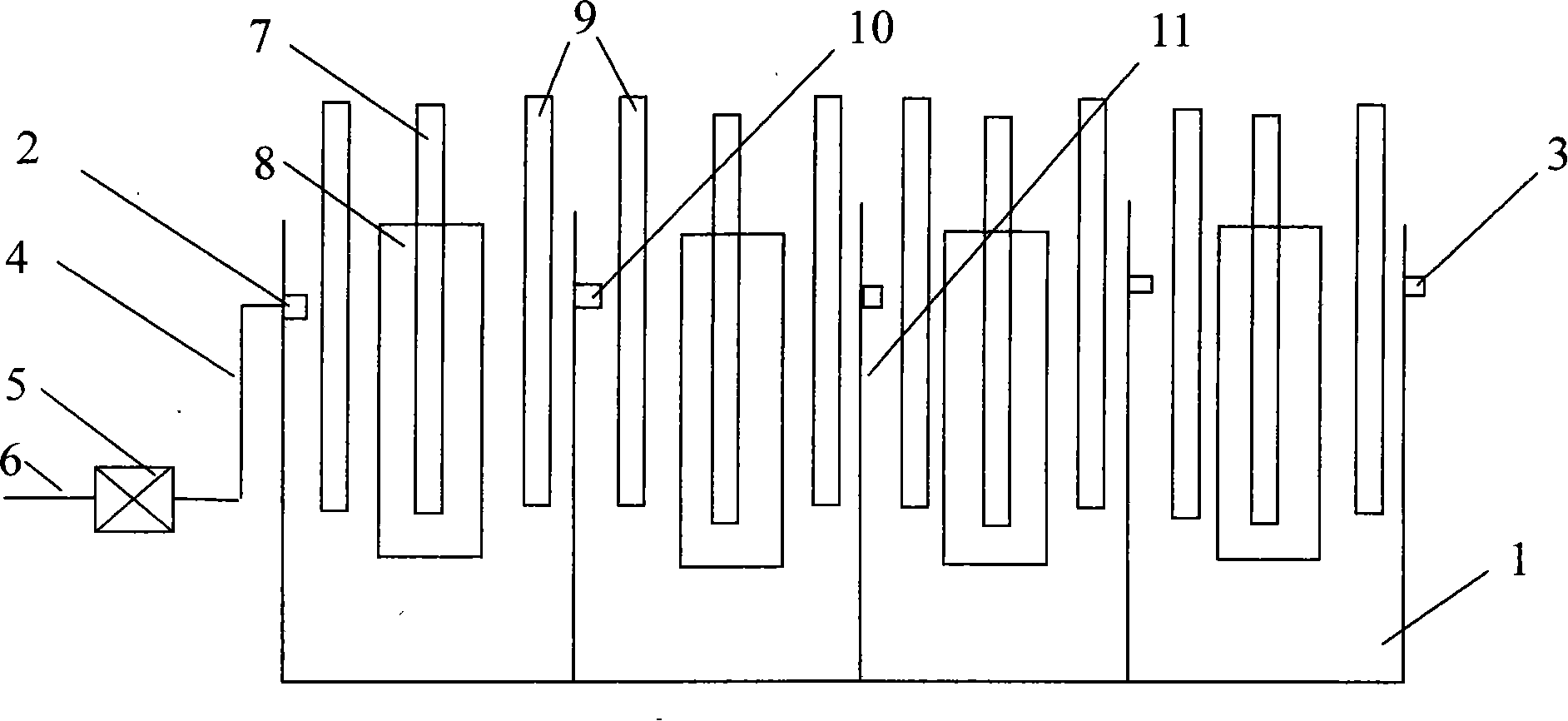

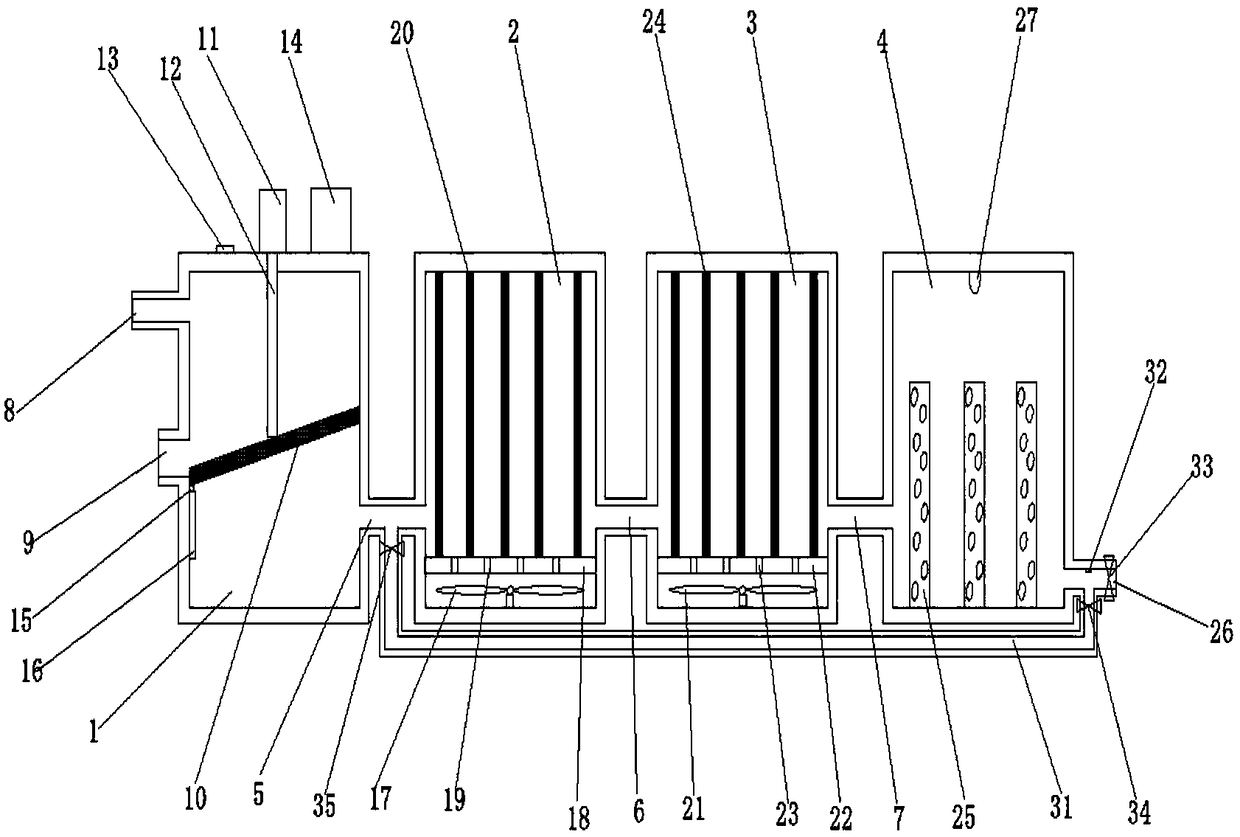

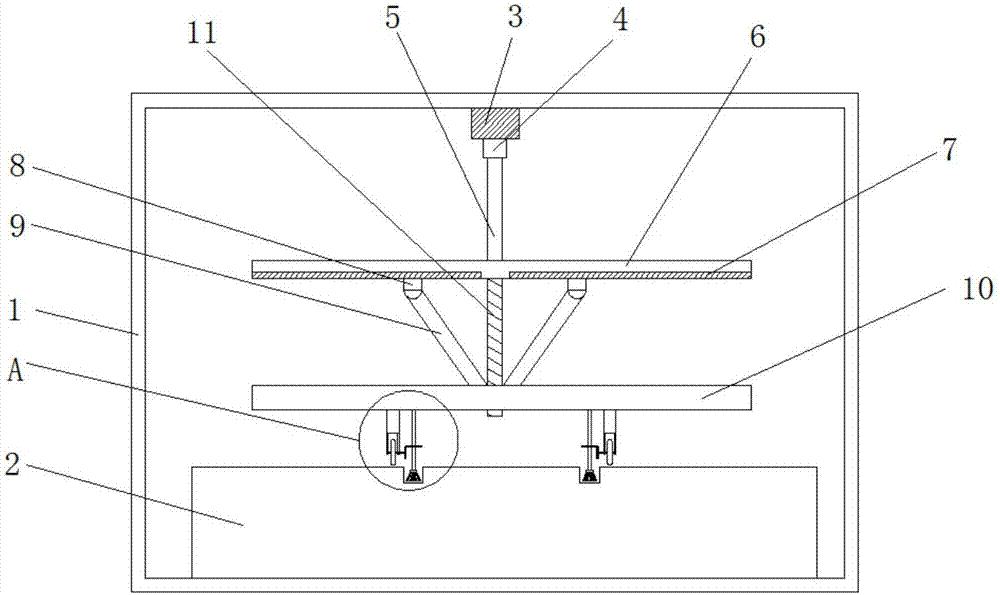

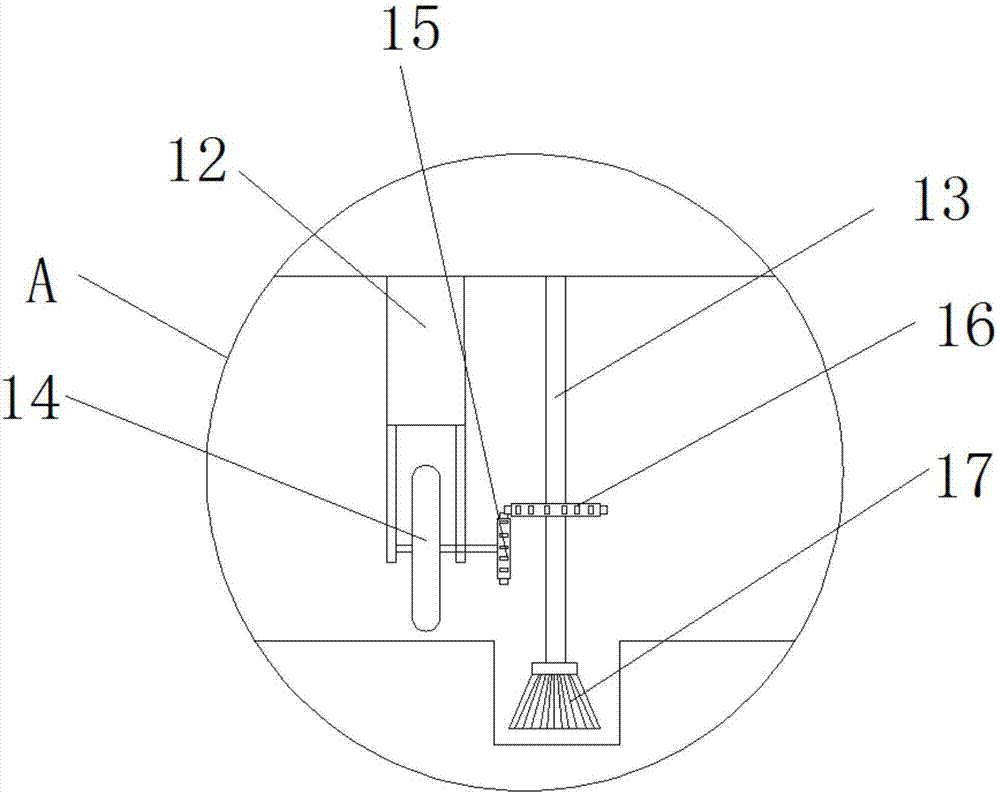

Dedusting device for leather processing

InactiveCN109174718ASimple structureImprove processing efficiencySkins/hides/leather/fur manufacturing apparatusDirt cleaningAssembly lineEngineering

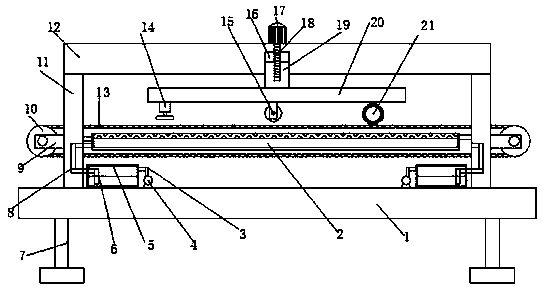

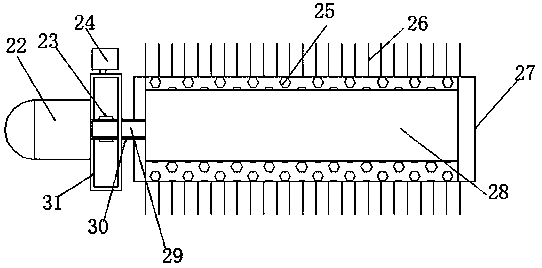

The invention discloses a dedusting device for leather processing. The dedusting device comprises a worktable. Supporting legs are arranged on the two sides of the lower end of a base. A mounting plate is arranged above the base, and the two sides of the lower end of the mounting plate are connected with the worktable through supporting plates to be fixed. A conveyor belt is arranged between the mounting plate and the worktable, and the two ends of the conveyor belt are connected with the supporting plates through fixing rods to be fixed. Ventilating holes are evenly formed in the belt surfaceof the conveyor belt. The dedusting device is simple and reasonable in structure, conveying can be conducted through the conveyor belt, and then leather is sequentially processed through a dust raising mechanism, a wiping mechanism and a polishing mechanism below a lifting plate; the assembly line processing mode improves the processing efficiency greatly, meanwhile the leather can be fixed to the surface of the conveyor belt through the generated negative pressure, and the fixing mode cannot influence processing for the surface of the leather; and additionally, a negative-pressure dedustingmechanism can further suck raising dust, thus pollution of the device to the environment is lowered, and practicability is high.

Owner:温州晨曦工艺品有限公司

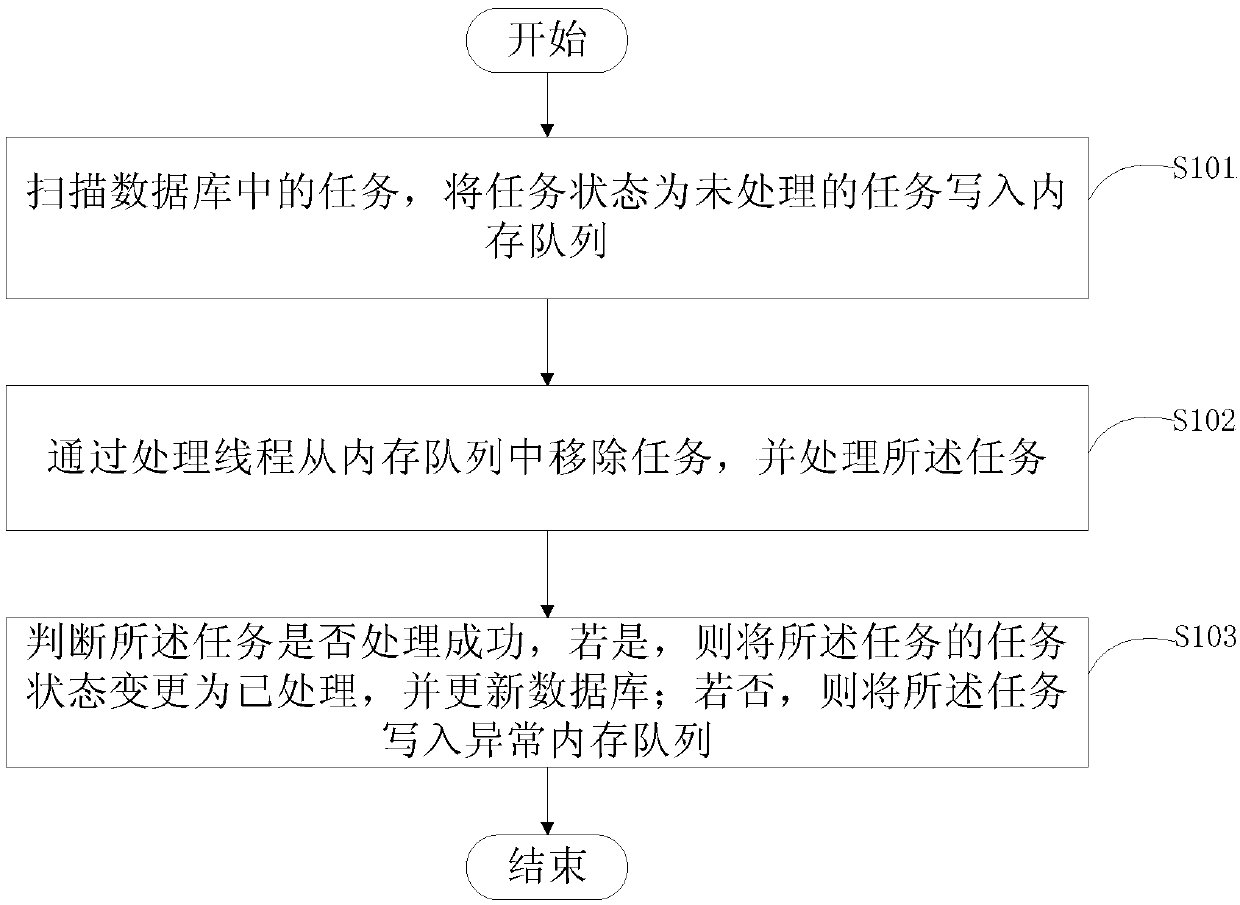

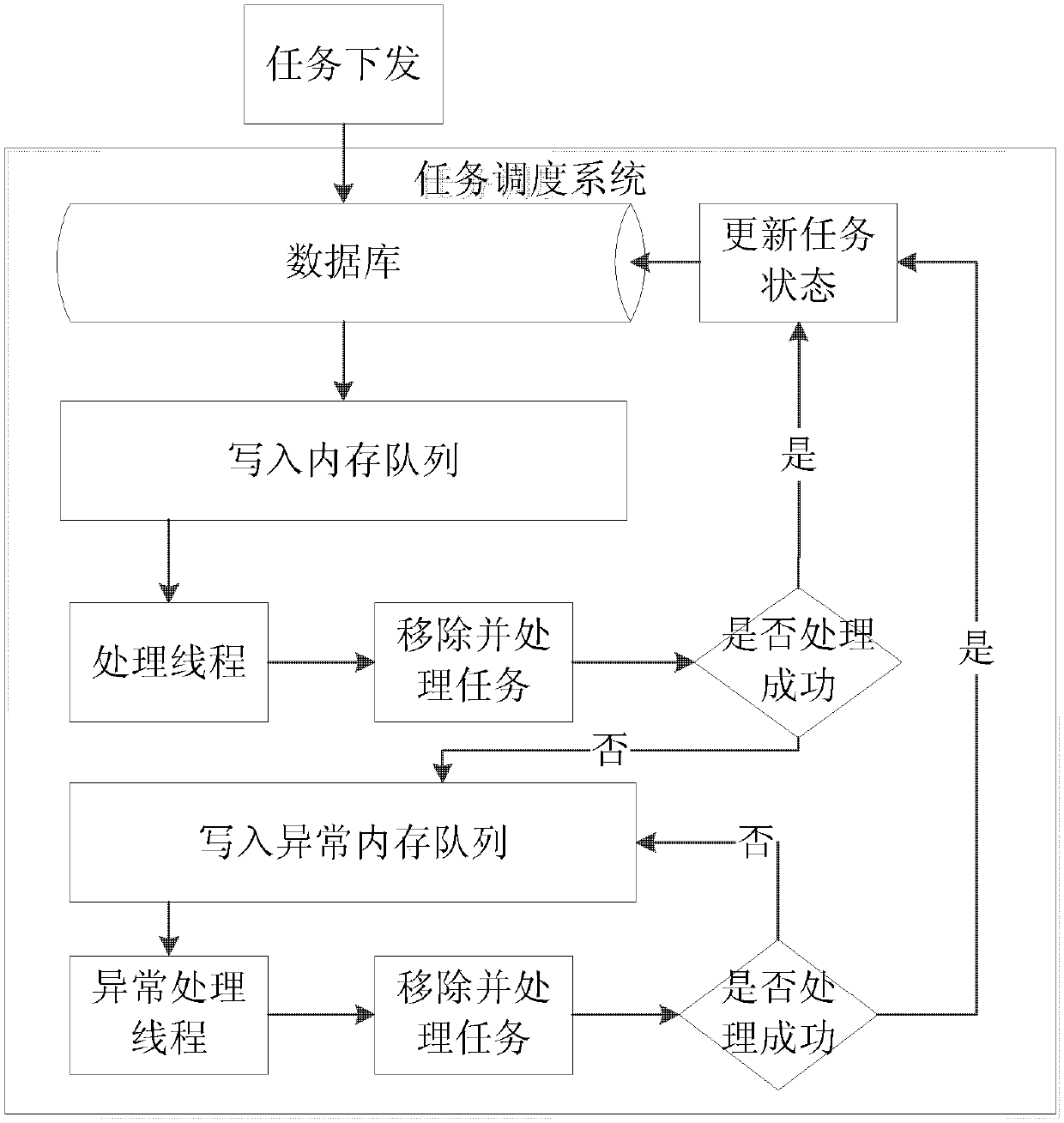

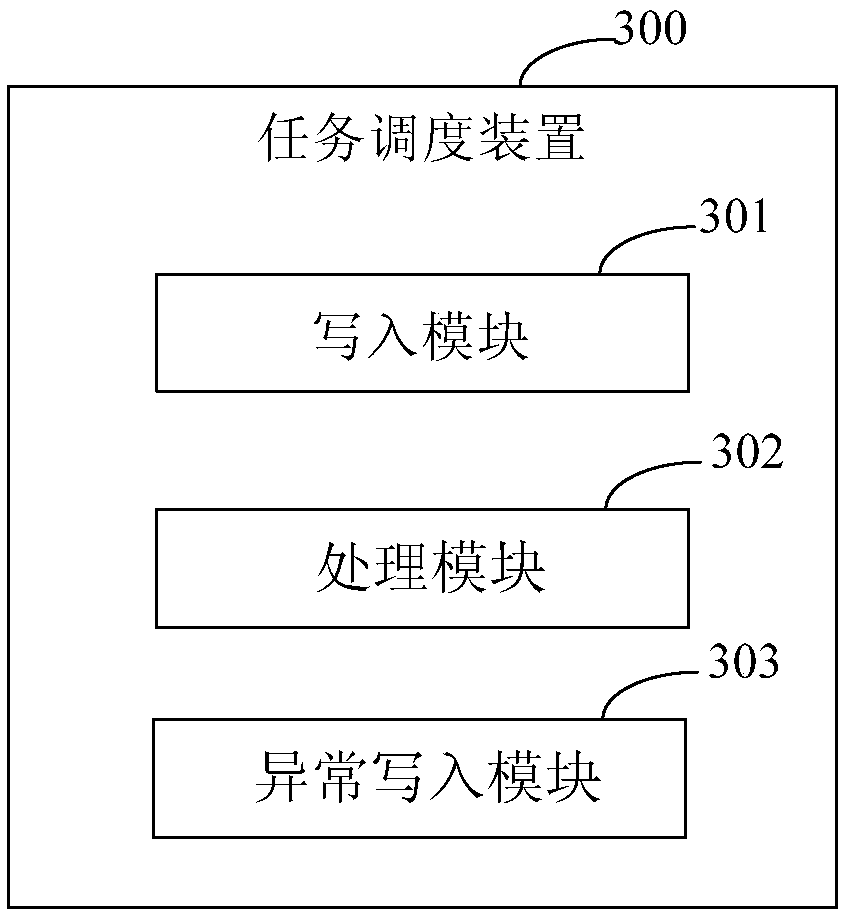

Task scheduling method and device

InactiveCN110245011AGuaranteed reliabilityImprove efficiencyDatabase updatingResource allocationOperating system

The invention discloses a task scheduling method and device, and relates to the technical field of computers. A specific embodiment of the method comprises the following steps: scanning tasks in a database, and writing the tasks with unprocessed task states into a memory queue; removing the task from the memory queue through a processing thread, and processing the task; judging whether the task is successfully processed or not, if yes, changing the task state of the task into a processed task state, and updating a database; and if not, writing the task into an abnormal memory queue. According to the embodiment, the problems of reliability and high efficiency of information interaction between systems can be solved.

Owner:BEIJING JINGDONG SHANGKE INFORMATION TECH CO LTD +1

Method for protecting non-processed workpiece surface by utilizing passivation metal coating in electrochemical machining

InactiveCN104384636AProcessing does not affectUnaffected by stray corrosionElectrochemical machining apparatusMetal coatingElectrolysis

The invention relates to a method for protecting a non-processed workpiece surface by utilizing a passivation metal coating in electrochemical machining. The method comprises the following steps: step 1, coating the surface of an initial workpiece with a layer of passivation metal coating by adopting a thermal spraying technology or an electrochemical deposition method; step 2, removing a workpiece material by utilizing an electrochemical machining way; step 3, removing the passivation metal coating after the machining is completed; step 4, washing a component. The method has an important significance in reducing stray corrosion in the electrochemical machining and improving the machining precision.

Owner:NANJING UNIV OF AERONAUTICS & ASTRONAUTICS

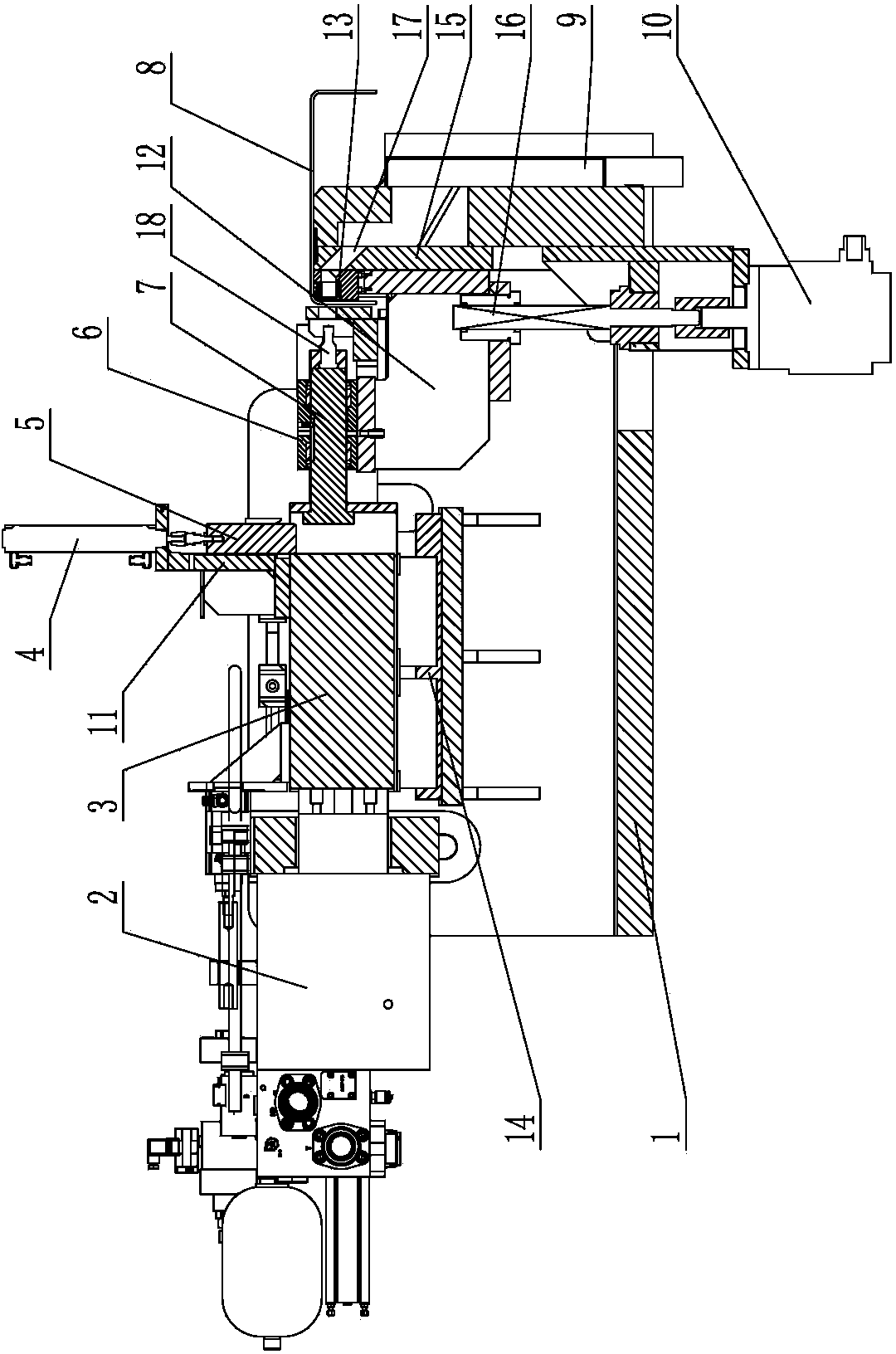

Static pressure main shaft movement precision on-line test method based on laser dynamic interferometer

InactiveCN105004515AProcessing process in real timeProcessing does not affectMachine part testingImaging analysis3d image

The invention discloses a static pressure main shaft movement precision on-line test method based on a laser dynamic interferometer. A high-precision standard planar crystal is installed on an upper end surface of a direct-driven ultra-precision static pressure main shaft rotor and employed as a measuring reference. The high-precision standard planar crystal revolves along with the main shaft rotor and reflects a real revolution state of a main shaft. By utilization of the characteristic that a laser dynamic interferometer is not sensitive to vibration, the three-dimensional image of the surface of the high-precision standard planar crystal at the end part when the main shaft rotor revolves is obtained in real time, then the image collected by the dynamic interferometer is transmitted to a computer, image analysis and processing are carried out, movement error evaluation is carried out, and therefore on-line measurement of main shaft movement precision is achieved. The on-line test method can achieve real-time on-line measurement of dynamic performances of an ultra-precision static pressure main shaft rotor in a real processing state, a machining process of an ultra-precision machine tool is not affected, and the generation mechanism of the main shaft revolution movement rule during the machine tool cutting process can be reflected.

Owner:HARBIN UNIV OF SCI & TECH

Device for processing foreign ion in chromium plating liquid

The invention provides a processing equipment of foreign ion in chromeplating solution, which comprises an electrolytic bath which is provided with a liquid inlet and a liquid outlet, wherein, the liquid outlet is communicated with the electrolytic bath of a chromium plating equipment and the liquid inlet is communicated with the liquid outlet pipe of a pump; a liquid inlet pipe of the pump is communicated with the electrolytic bath in which an enamel diaphragm electrolyzer is arranged; the electrolyzer comprises a negative plate, a positive plate and an electrolytic drum. The processing equipment of foreign ion in chromium plating bath provided by the invention can carry out the processing of foreign ion in chromeplating solution under the situation that chromium plating production does not stop, thereby realizing the processing of foreign ion in chromeplating solution without influencing the chromium plating production.

Owner:徐建中

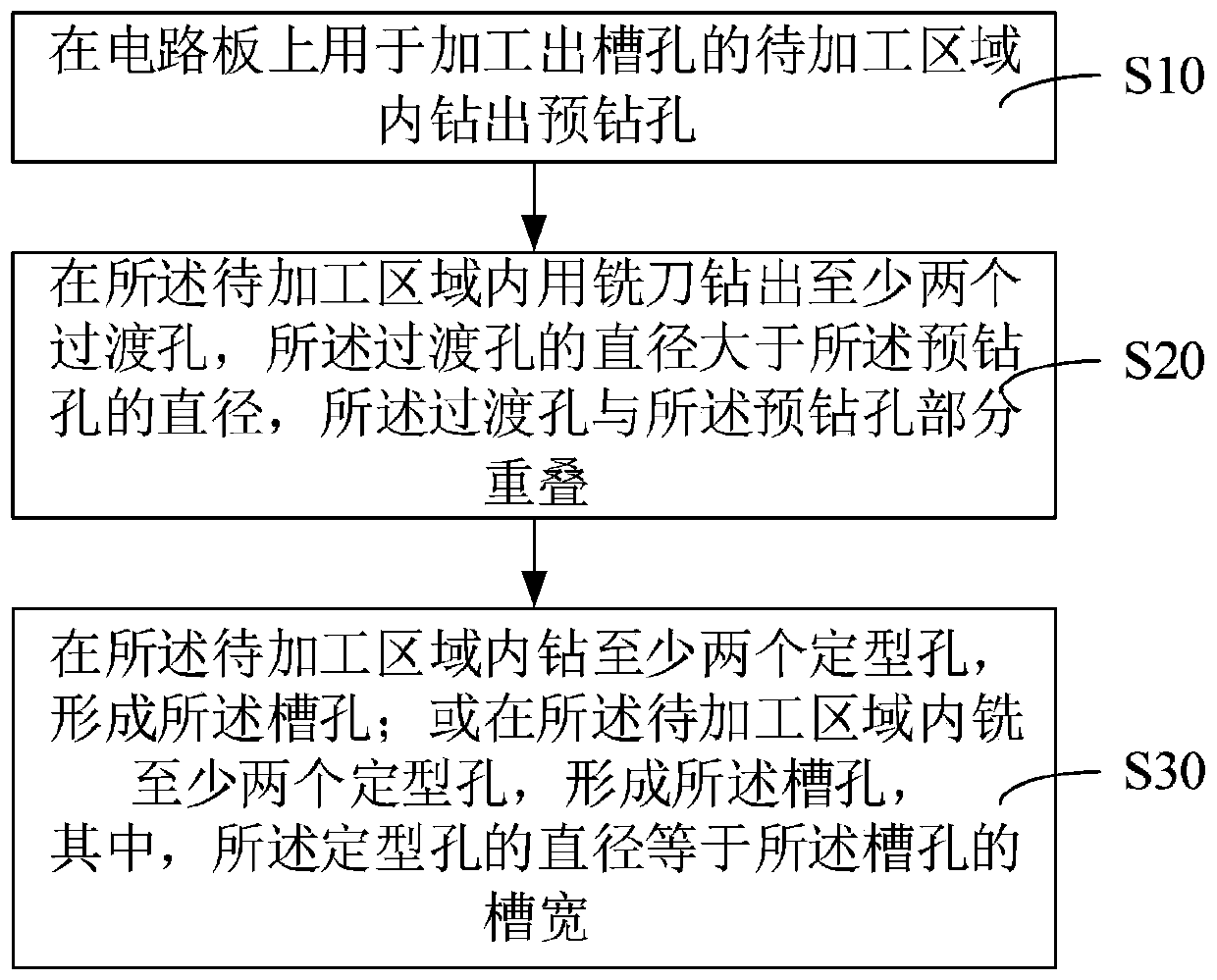

Slotted hole machining method and circuit board

InactiveCN109819593AImprove qualityReduce uneven forcePrinted circuit manufactureMilling cutterDrill hole

The invention discloses a slotted hole machining method and a circuit board. The slotted hole machining method comprises the following steps that pre-drilled holes are drilled in a to-be-machined area, used for machining a slotted hole, of the circuit board; and at least two transition holes are drilled in the to-be-machined area by a milling cutter, wherein the diameter of each transition hole islarger than that of the corresponding pre-drilled hole, and the transition holes and the pre-drilled holes are partially overlapped. According to the slotted hole machining method, chippings generated in the milling process can be discharged from the pre-drilled holes; meanwhile, part of materials in the to-be-machined area can be removed in the milling process; when a slotted hole is formed in the to-be-machined area in the follow-up process, materials required to be removed in the to-be-processed area are reduced; the situation that a cutter head is stressed unevenly during machining can bereduced, the cutter head cannot deviate, the product quality is improved, and in the milling process, even if materials around the milling cutter are distributed unevenly, due to the fact that the milling cutter is high in rigidity, not prone to stress deviation and good in machining effect, subsequent machining cannot be affected, and the product quality can be improved.

Owner:GUANGZHOU FASTPRINT CIRCUIT TECH +1

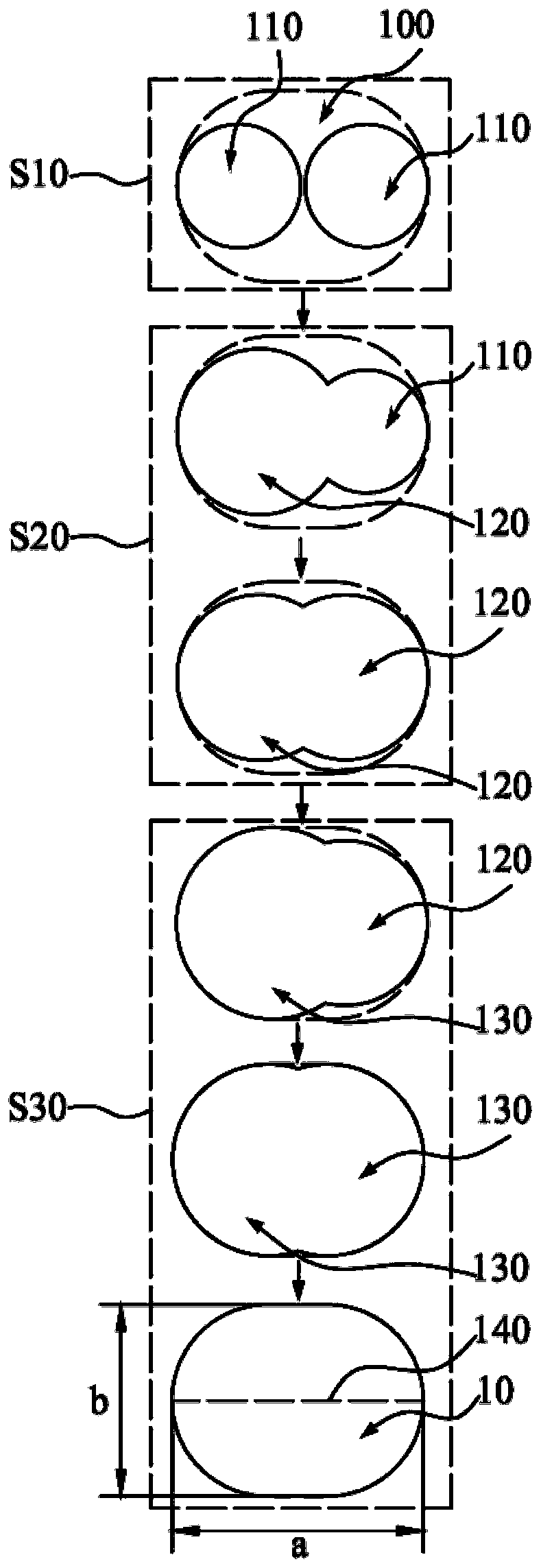

Substrate processing apparatus, pressure control method for substrate processing apparatus

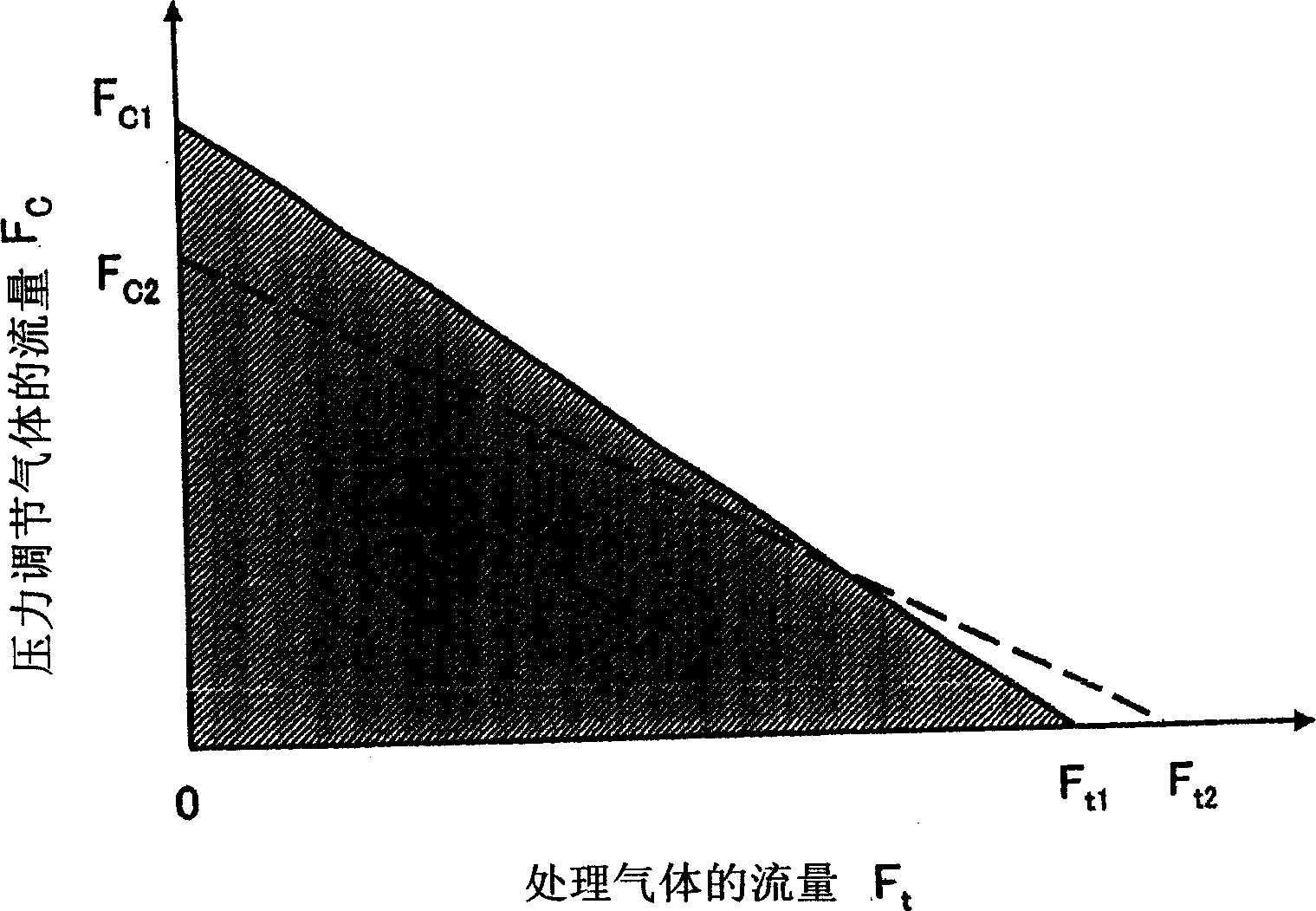

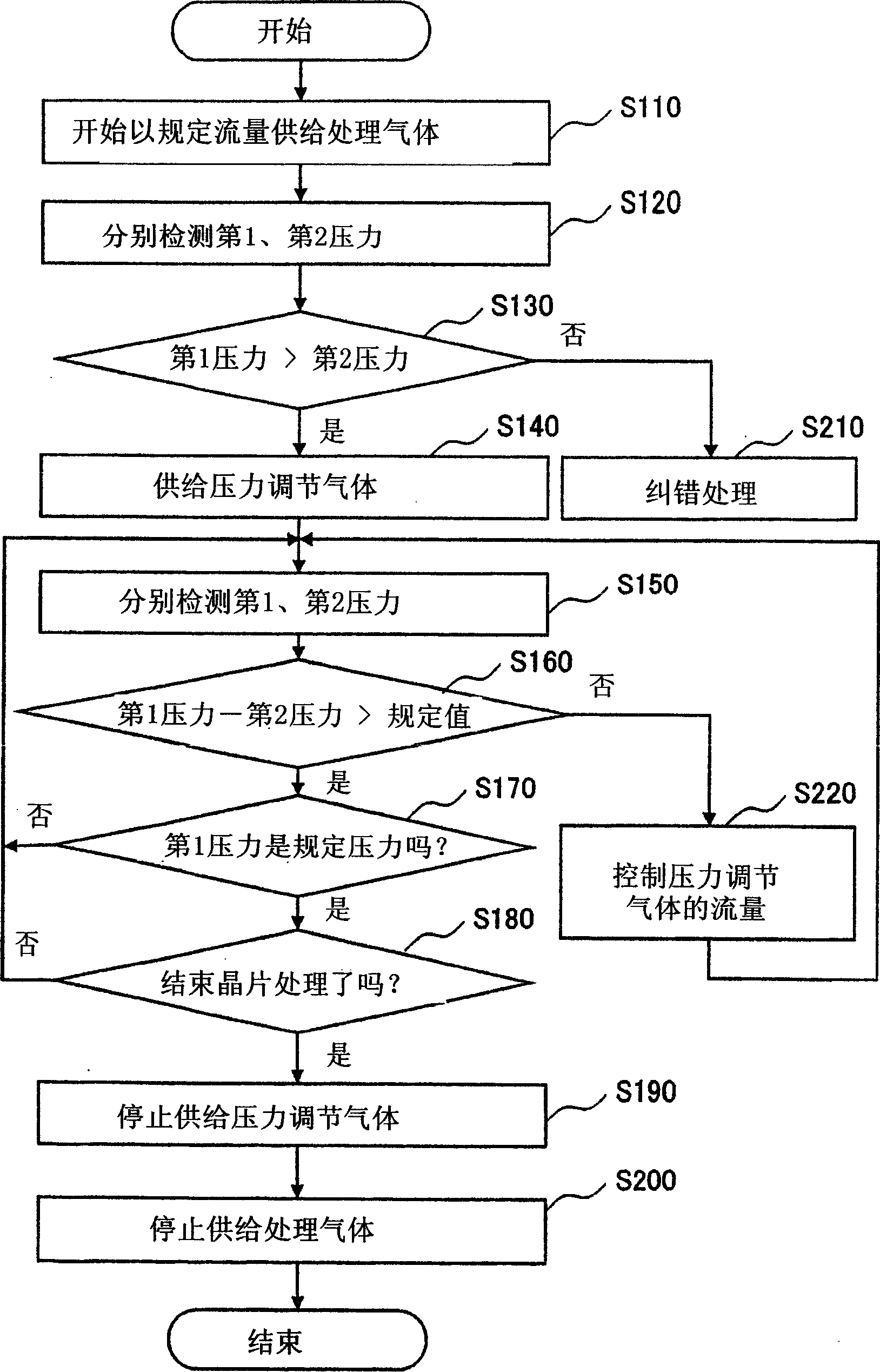

InactiveCN1767146AProcessing will not affectControl pressureVacuum evaporation coatingSputtering coatingProcess engineeringProduct gas

The present invention relates to a substrate processing apparatus and a substrate processing method capable of controlling the pressure in a processing chamber without controlling the exhaust volume of the processing chamber without affecting substrate processing. The device is provided with: a processing chamber 102 that uses processing gas to process the substrate to be processed; divides the processing chamber into a processing space 102A for processing the substrate to be processed and an exhaust space 102B for discharging the gas in the processing chamber, and has a plurality of communicating processing chambers. The baffle plate 130 of the ventilation hole 132 of the space and the exhaust space; the processing gas supply mechanism 140 for supplying the processing gas to the processing space in the processing chamber; Regulating gas supply mechanism 150; when the processing gas is supplied from the processing gas supply mechanism, the pressure regulating gas is supplied through the pressure regulating gas supply mechanism to make the pressure of the processing space reach a preset pressure. Pressure controller 180.

Owner:TOKYO ELECTRON LTD

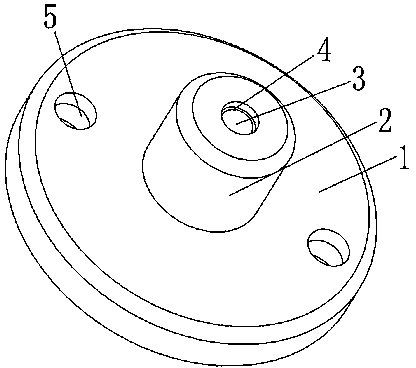

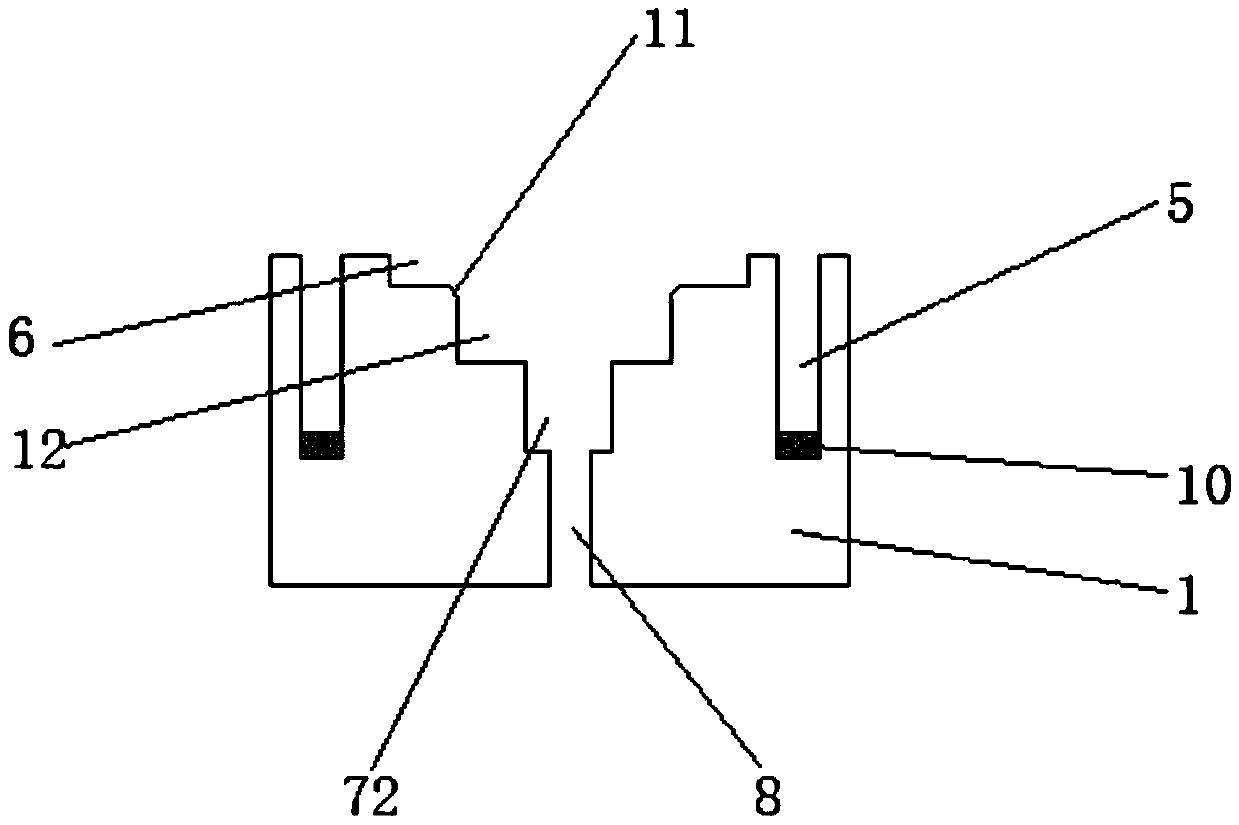

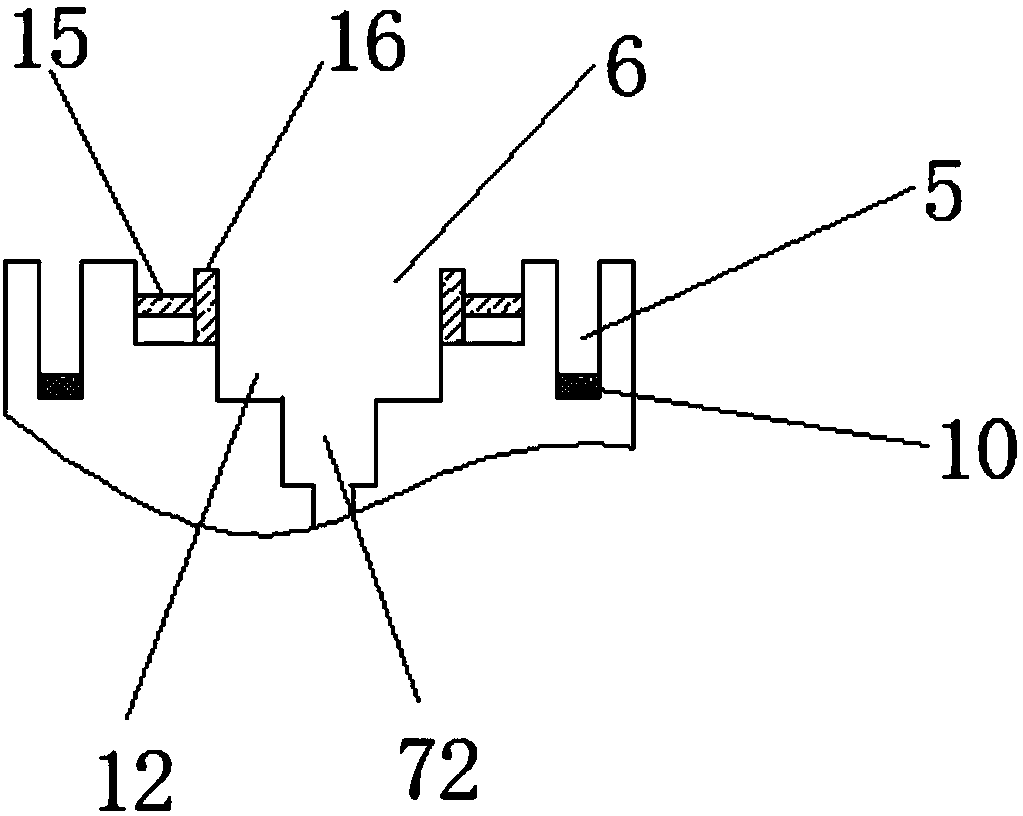

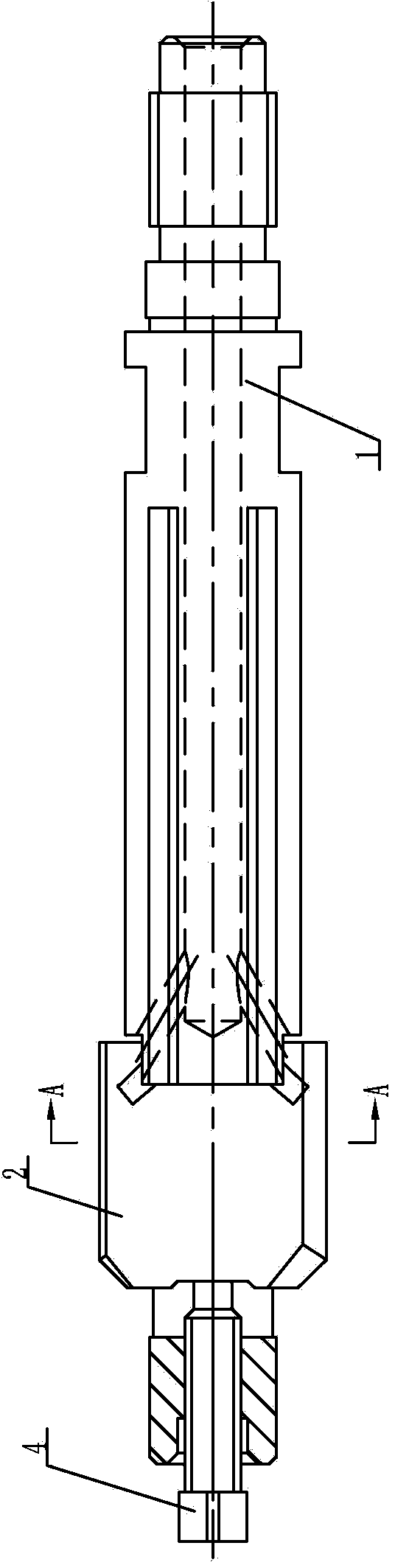

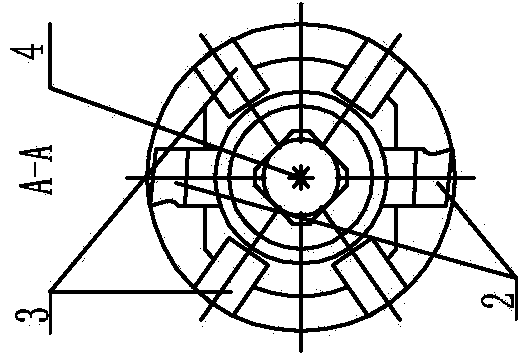

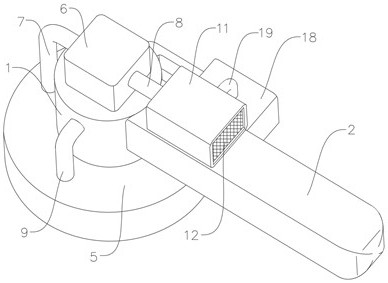

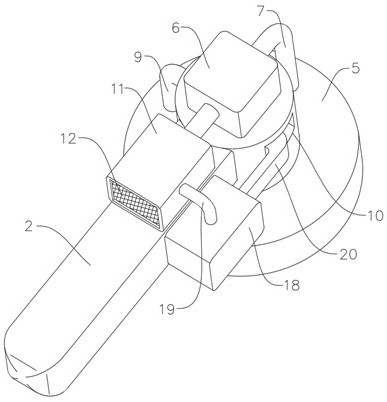

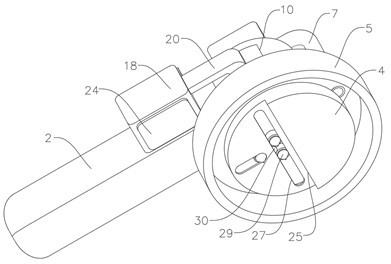

Riveting square jig metal pin positioning mechanism

InactiveCN103737231APositioning does not affectPrecise positioningWelding/cutting auxillary devicesAuxillary welding devicesEngineeringMachining

The invention discloses a riveting square jig metal pin positioning mechanism. The riveting square jig metal pin positioning mechanism comprises a circular base and is characterized by comprising a column-shaped positioning portion; the column-shaped positioning portion is arranged at the top of the circular base; a through hole is formed from the top of the column-shaped positioning portion and the bottom of the circular base; a surrounding limit plates are arranged inside the hole of the column-shaped positioning portion. The riveting square jig metal pin positioning mechanism has the advantages of solving the problems that, in the prior art, during the process that the metal pin rear end is connected with a connecting wire in a riveting mode, a riveting portion is misplaced caused by metal pin shaking, the riveting effect is influenced, and great trouble is brought to the machining, being simple in structure and convenient to use, enabling the metal pin to be rapidly positioned and maintaining the metal pin to be stable during the riveting process.

Owner:KUNSHAN FOR EASIER AUTOMATION TECH

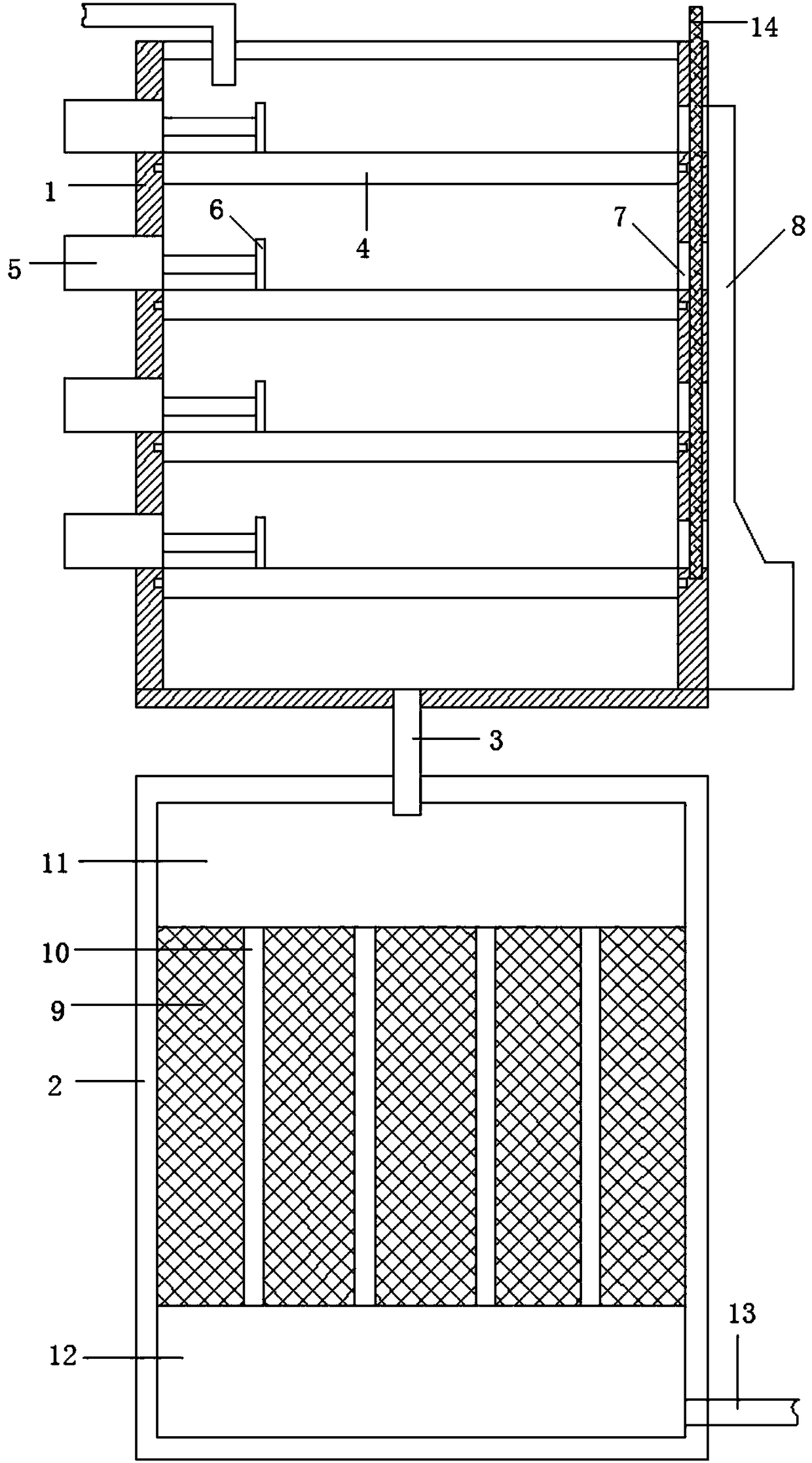

Rare-earth wastewater treatment device

InactiveCN107487896AProcessing does not affectEasy to handleSpecific water treatment objectivesTreatment involving filtrationRare earthWastewater

The invention relates to a treatment device, in particular to a rare-earth wastewater treatment device and aims to solve the technical problem of providing a rare-earth wastewater treatment device which is time and labor saving and good in treatment effect and furthermore rare-earth wastewater meets emission standards without affecting environments around. To solve the technical problem, the rare-earth wastewater treatment device comprises support legs, a stirring tank, a tank cover, a filtering frame and the like, wherein the support legs are symmetrically mounted on the left side and the right side of the bottom outside the stirring tank; a first liquid outlet is connected with the middle of the bottom of the stirring tank; the first liquid outlet tube is communicated with the stirring tank. Due to a sucking device, operators do not need to pour wastewater into the frame for treatment, the time and the labor are saved, the frame and the stirring tank can be internally washed through a washing device, a next time of wastewater treatment is not affected, and the effects that the time and the labor are saved, a good treatment effect is achieved, the rare-earth wastewater can meet emission standards and the environment around is not affected are achieved.

Owner:赣州清亦华科科技有限公司

Standard plane type ultra-precise direct-drive hydrostatic spindle dynamic property on-line testing method

ActiveCN103344425AProcessing process in real timeReal-time dynamic performanceMachine part testingStandard planeData acquisition

The invention relates to the field of testing of hydrostatic spindle properties, in particular to a standard plane type ultra-precise direct-drive hydrostatic spindle dynamic property on-line testing method. The method solves the problem that an existing method cannot achieve on-line testing of the dynamic properties of an ultra-precise direct-drive hydrostatic spindle. The method comprises the steps that a high-precision standard plane is installed on the upper end portion of a rotor of the direct-drive ultra-precise hydrostatic spindle and serves as a measurement standard, a high-precision displacement sensor is adopted to measure the displacement changes between the standard plane and the high-precision displacement sensor when the spindle rotates, through the signal amplification of the sensor and a data collecting system, the measured displacement variable quantity is converted into digital signals, then the digital signals are fed into a computer to be analyzed and processed, and therefore the on-line measurement of the ultra-precise direct-drive hydrostatic spindle dynamic properties is achieved. The method can achieve the real-time and on-line measurement of the dynamic properties of the ultra-precise direct-drive hydrostatic spindle under the actual machining condition, and the machining process of an ultra-precise machine tool is not affected.

Owner:HARBIN INST OF TECH

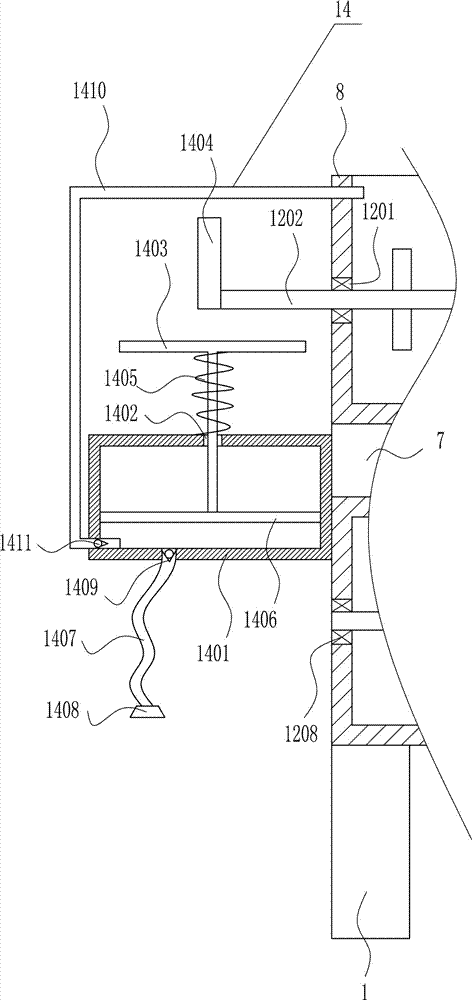

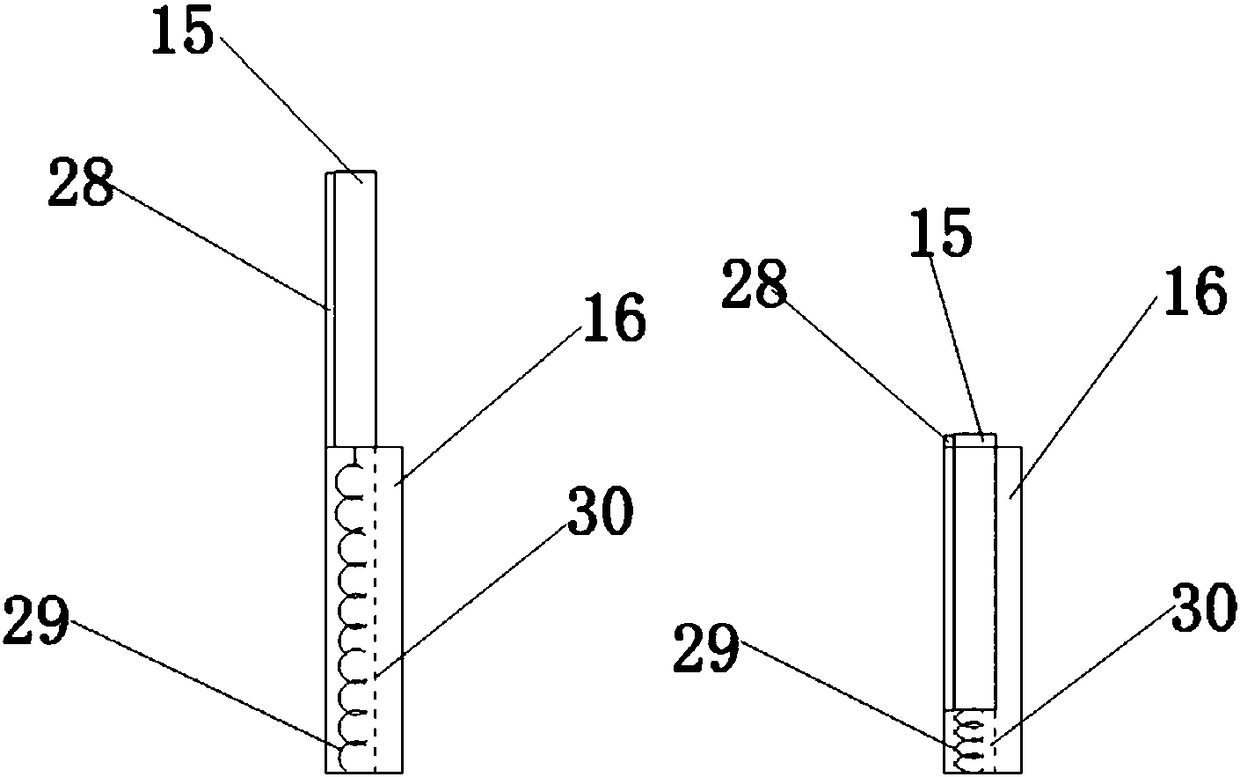

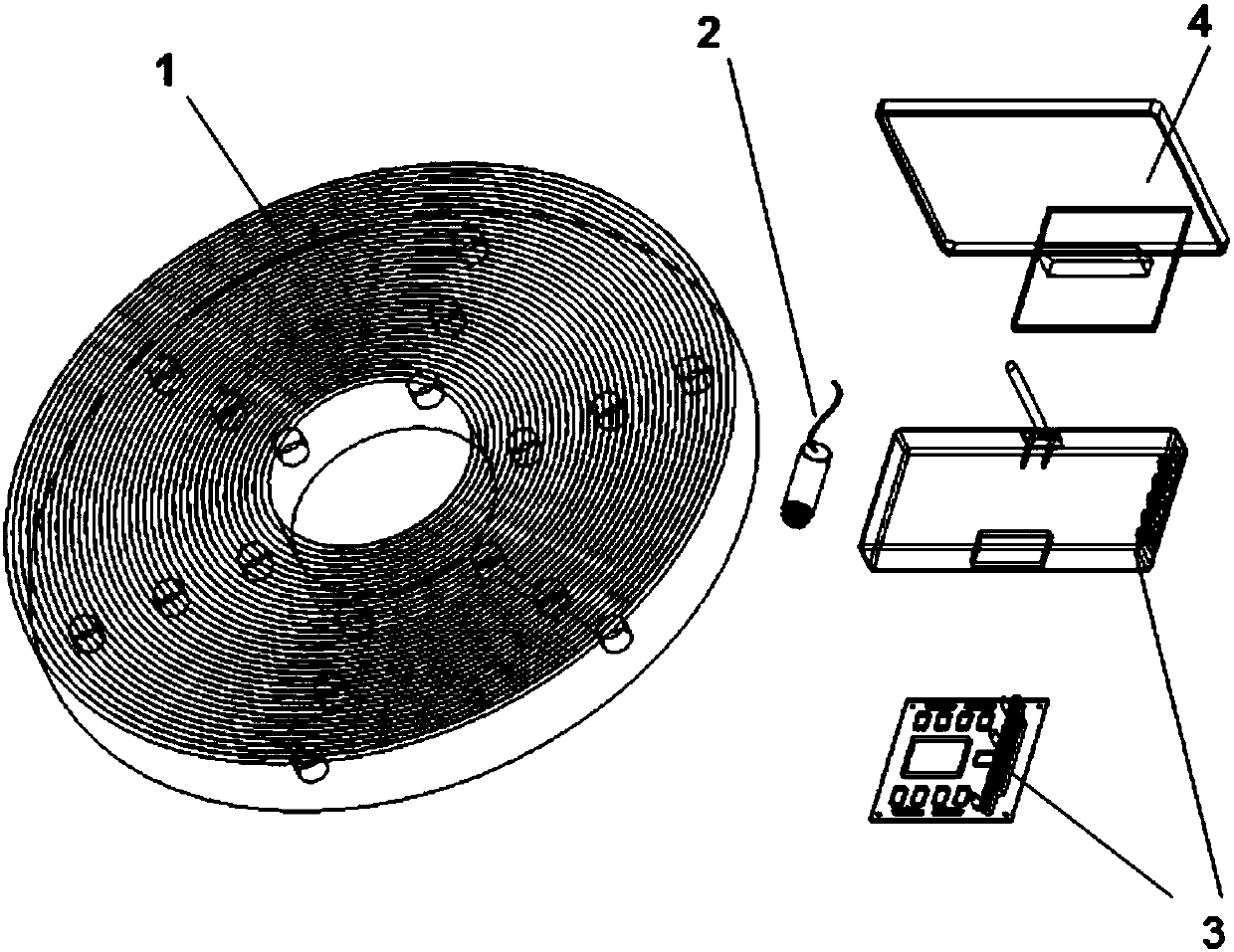

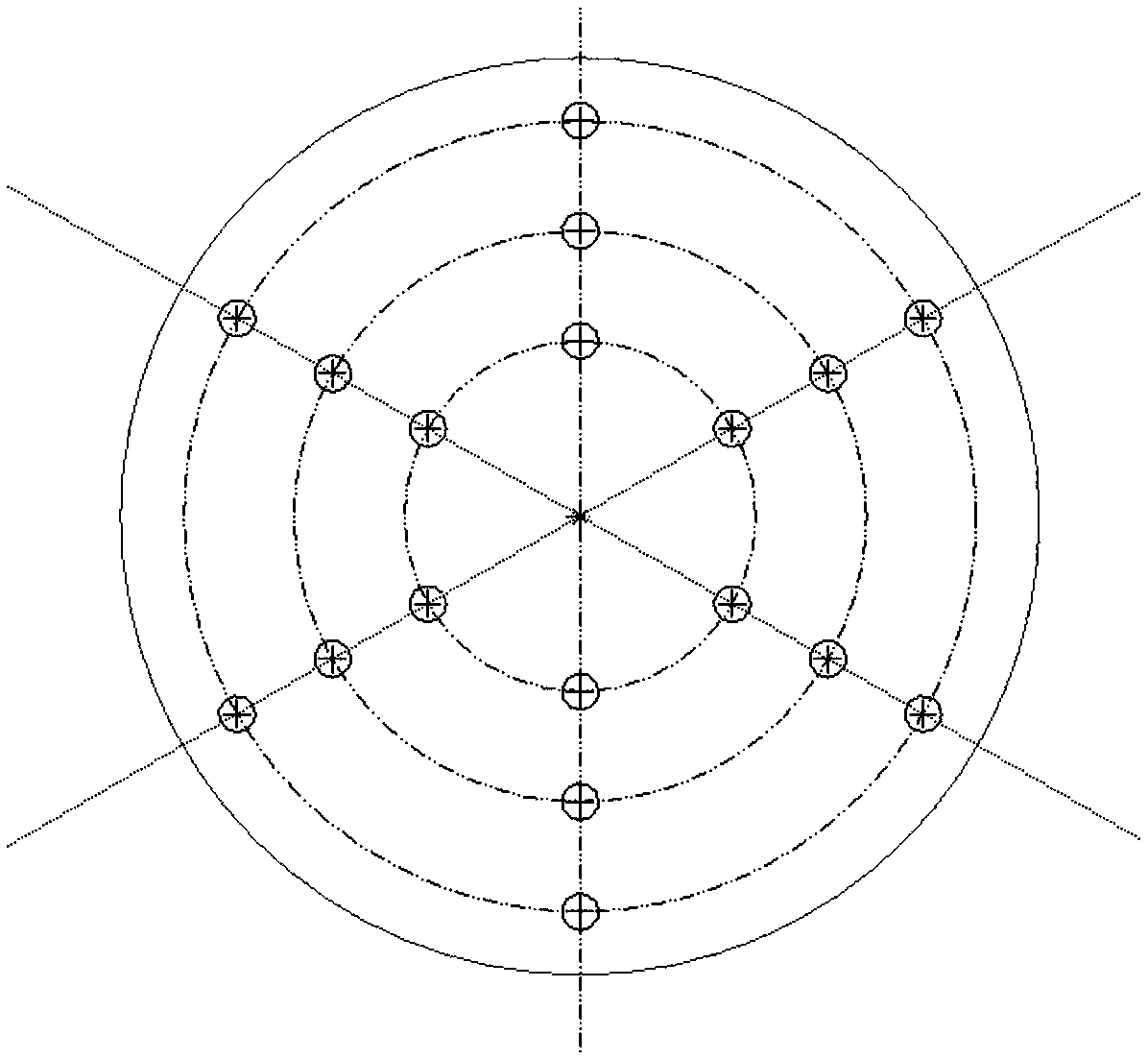

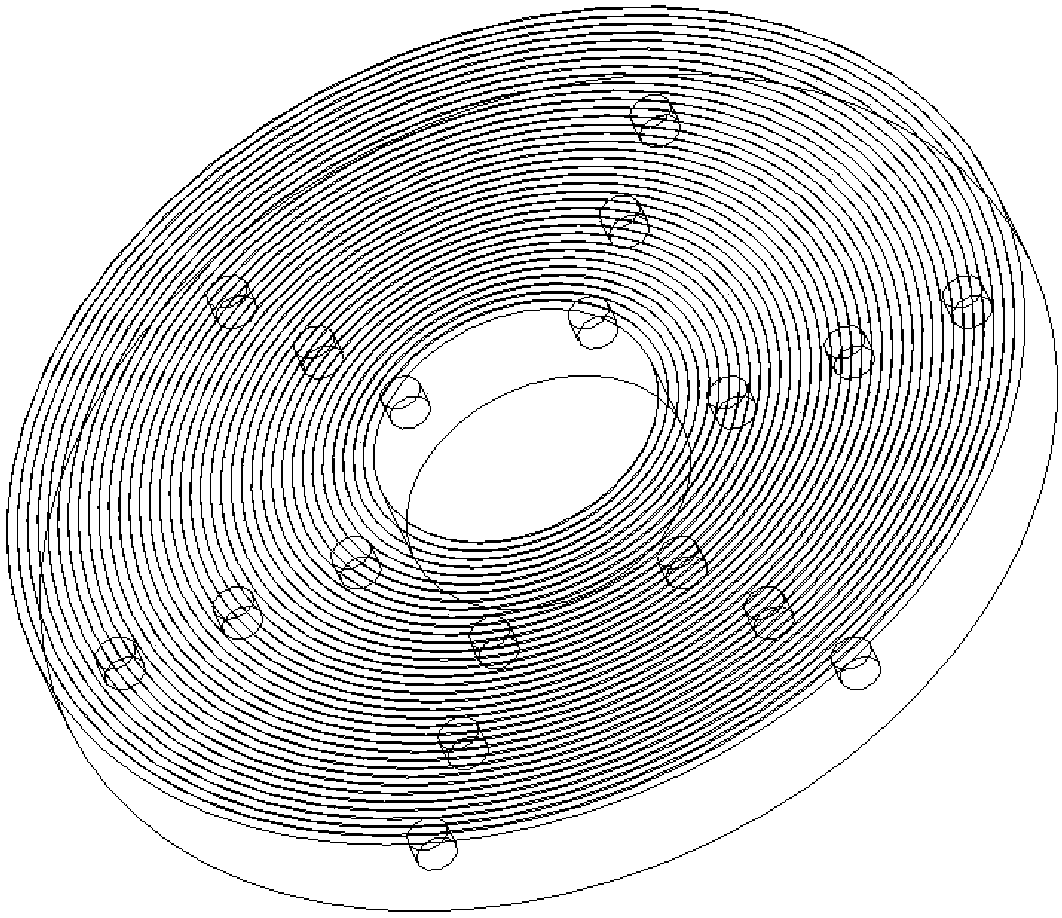

Small-scale copper wire winding mechanism with automatic shearing device

InactiveCN108840174AImprove efficiencyProcessing does not affectFilament handlingCopper wireMechanical engineering

The invention discloses a small-scale copper wire winding mechanism with an automatic shearing device. The small-scale copper wire winding mechanism comprises a main base plate, a moving straight slotis formed in the right bottom surface of the main base plate, and lower supporting plates are fixed to the bottom surface of the main base plate of the left and right sides of the moving straight slot. Two ends of a horizontal screw rod are hinged to the two lower supporting plates through bearings, wherein a moving motor is fixed to the outside wall of one of the two lower supporting plates. A moving block is connected to the horizontal screw rod in a threaded mode, and the upper portion of the moving block is sleeved with the moving straight slot in an inserted mode. A locating plate is fixed to the top surface of the moving block and located above the main base plate, two guide blocks are fixed to the front wall surface of the locating plate, and horizontal guide through holes are formed in the guide blocks. Two small barrel bodies can be mounted, a small barrel body can automatically shear off a winding connecting end after finished, the finished small barrel body is located abovethrough a main circular rotating plate rotating, the small barrel body to be finished is located below and automatically fixes to process, the efficiency is high, the replacement time of the middle part is short, and the efficiency is high.

Owner:FOSHAN XUNAOJIE AUTOMATION TECH CO LTD

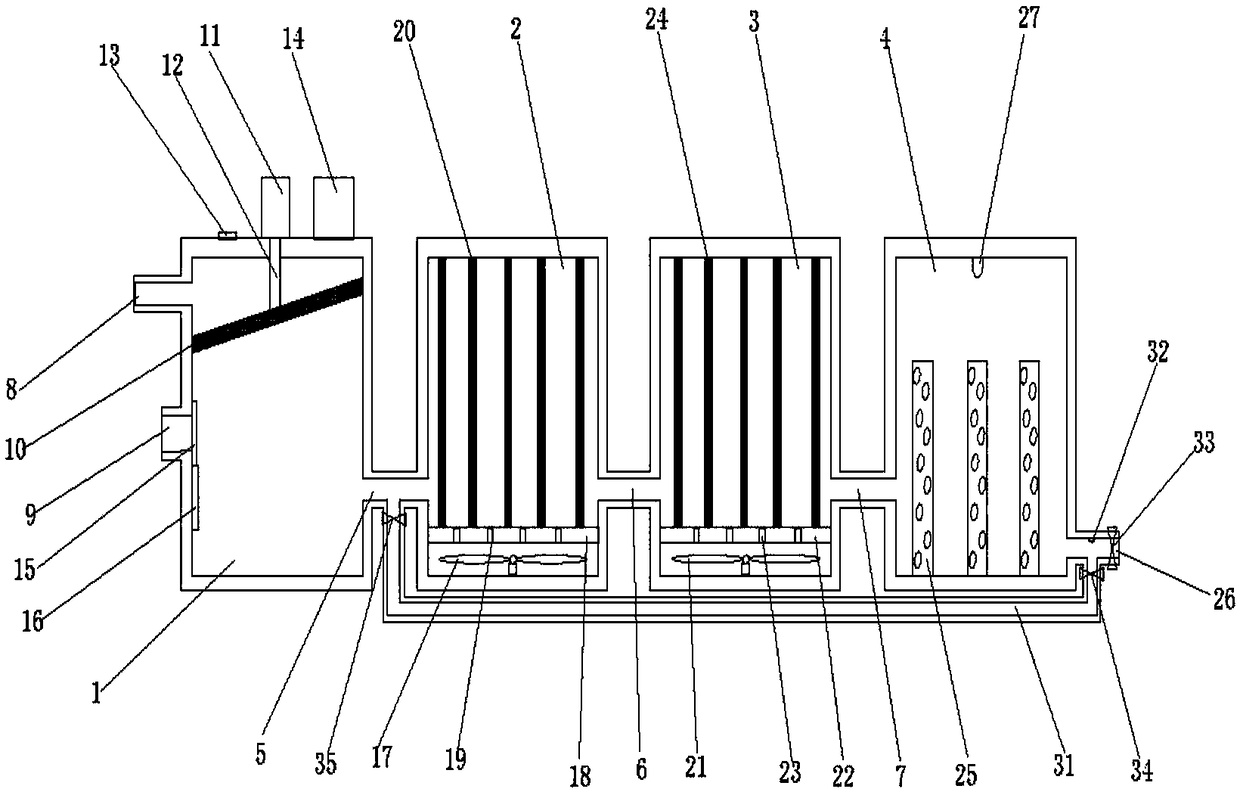

Efficient integrated sewage treatment system

InactiveCN108285242AProcessing does not affectImprove processing efficiencyWater treatment parameter controlWater/sewage treatment by irradiationSewage treatmentPollutant

The invention provides an efficient integrated sewage treatment system comprising a filter tank, an anaerobic tank, an aerobic tank and a purification tank, wherein the filter tank and the anaerobic tank are connected by a first communication pipe, the anaerobic tank and the aerobic tank are connected by a second communication pipe, the aerobic tank is connected to the purification tank through athird communication pipe, a water inlet is arranged on the upper portion of the side of the filter tank, a drain outlet is arranged on the lower portion of the water inlet, a linear motor is fixedly mounted on the top of the filter tank, and a push rod of the linear motor passes through the top of the filter tank, and is fixedly connected to a filter screen plate. The fine mesh filter screen platein the filter tank can filter solid pollutants in a suspended state in sewage, the fine mesh filter screen plate can realize automatic backwash cleaning without disassembly, and does not affect normal sewage treatment, the sewage treatment efficiency is improved, and an anaerobic biofilm in the anaerobic tank can remove organic pollutants in colloid and dissolved states in the sewage.

Owner:HUZHOU YOUCHUANG TECH CO LTD

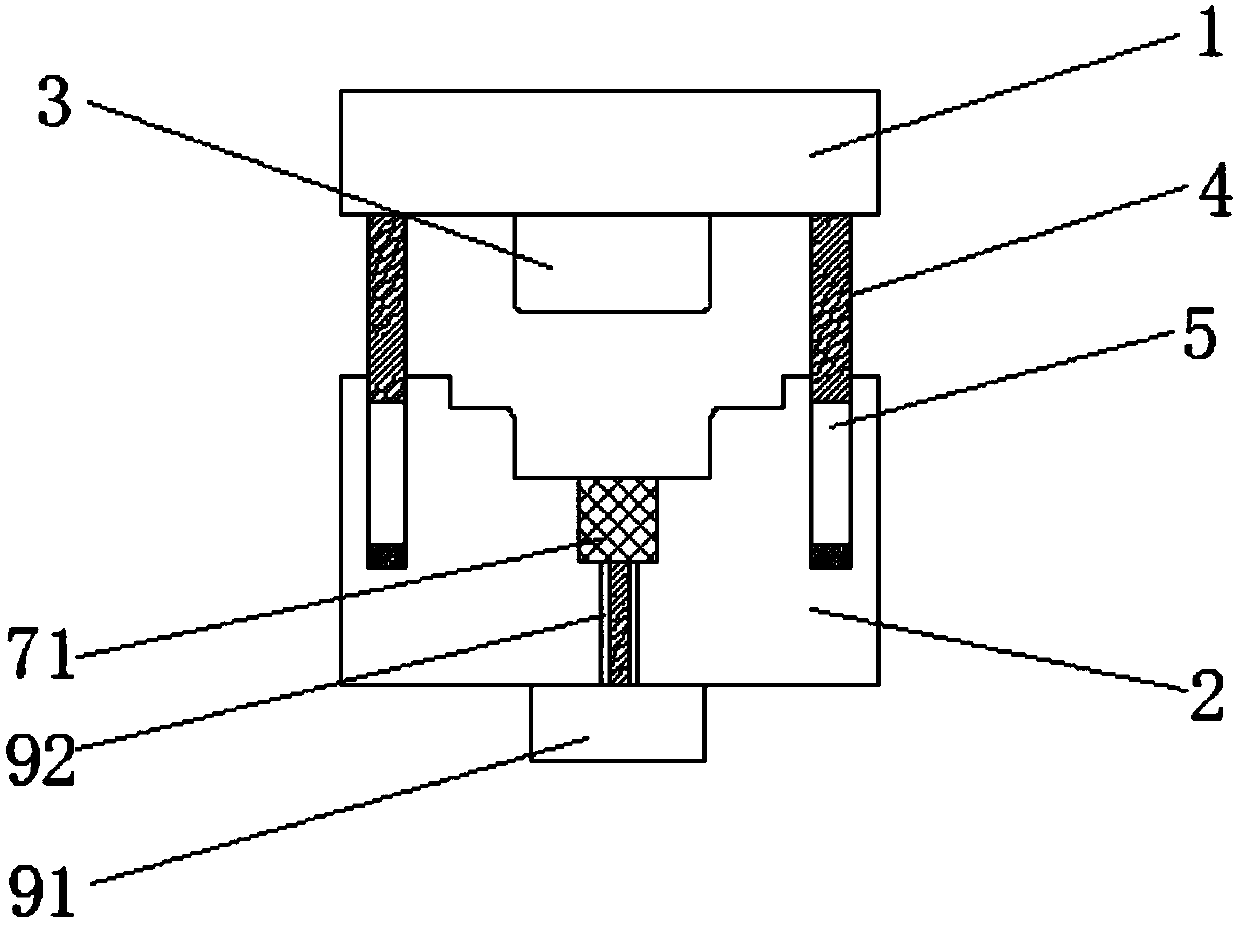

Automobile part cold extrusion die convenient for taking parts

The invention discloses an aluminum alloy section bar cold extrusion die with for taking out parts. The cold extrusion die comprises an upper die, a lower die, a push block and an air pump; the upperdie is arranged on the right upper surface of the lower die, the lower surface of the upper die is provided with an extrusion die head, the upper surface of the lower die is partially downward dent toform a placing groove, and a molding groove matched with the extrusion die head is arranged in the placing groove; a containing cavity matched with the push block is further arranged in the molding groove, the push block is arranged in the containing cavity, the upper surface of the push block is flush with the bottom surface of the molding groove, a through channel formed by downward denting isfurther distributed in the containing cavity, the air pump is fixed on the lower surface of the lower die, and a piston rod of the air pump penetrates through channel to be connected to the push block. The aluminum alloy section bar extrusion die effectively improves the strength of products and the use rate of materials, and the products are convenient to take out.

Owner:芜湖禾田汽车工业有限公司

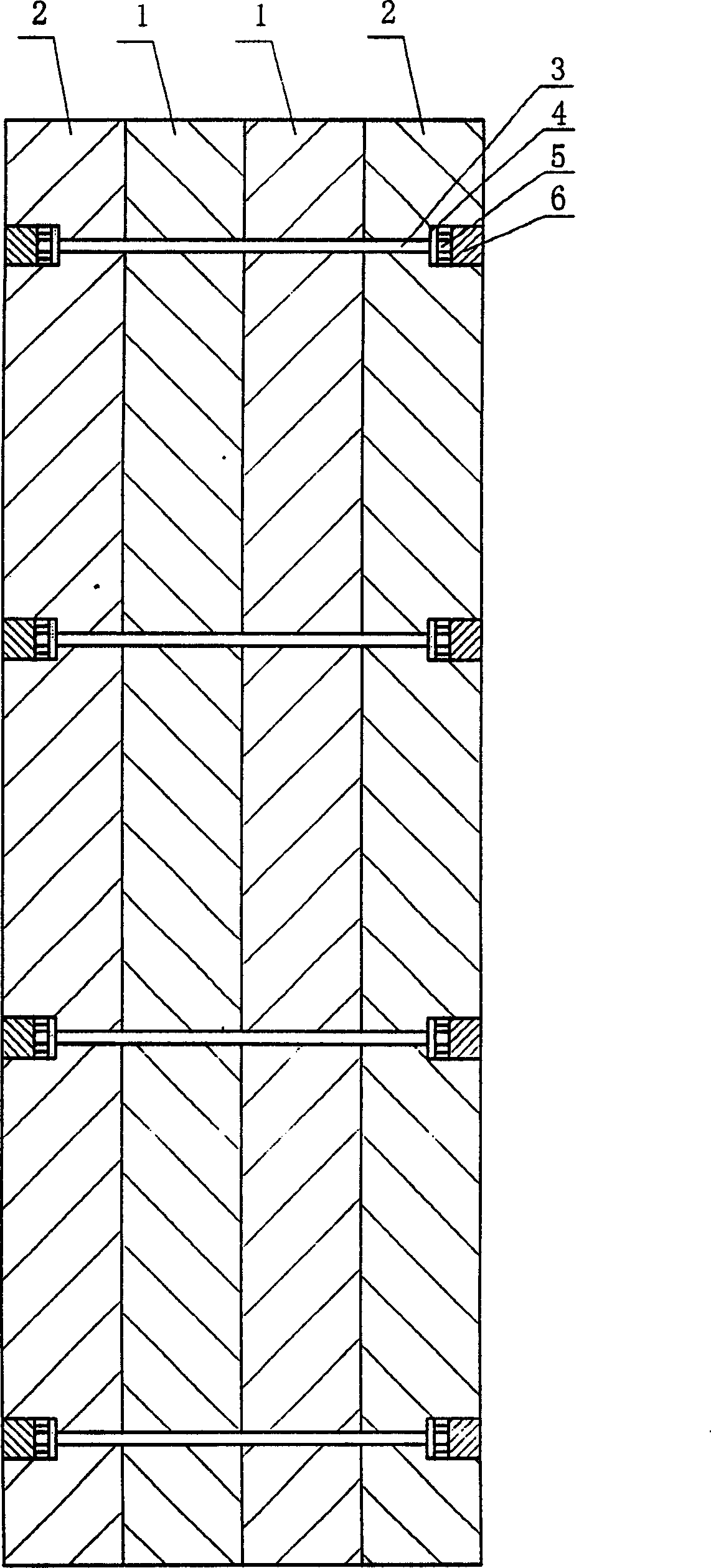

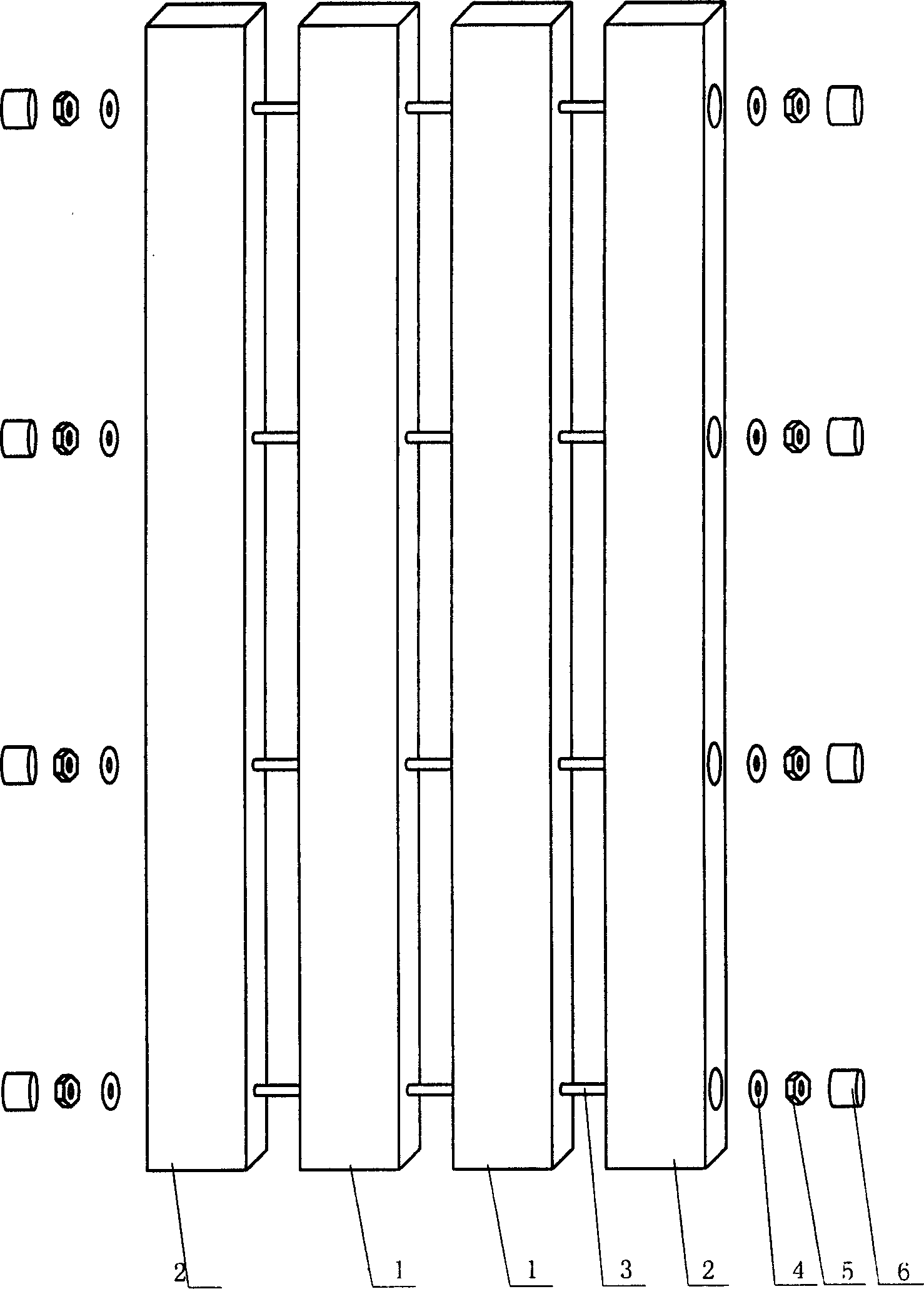

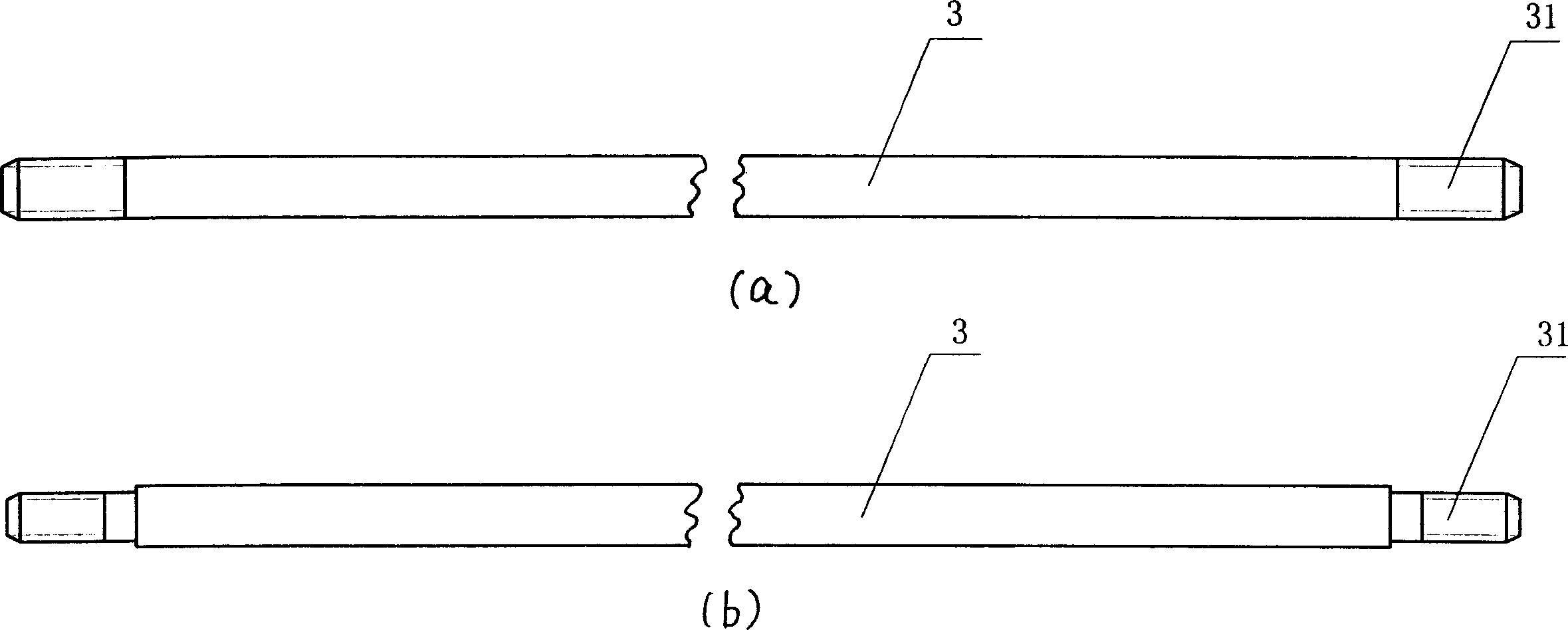

Making-up wooden plate

Owner:陈万利 +3

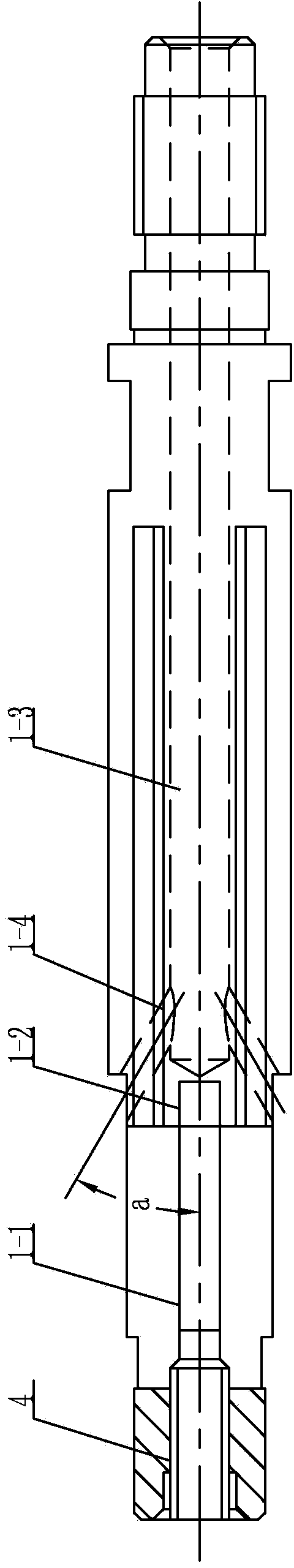

Boring tool used for machining deep holes of turbine sleeves and deep hole machining method

InactiveCN103934487AExtended service lifeEasy to useBoring barsBoring/drilling machinesEngineeringMachining process

The invention relates to a boring tool used for machining deep holes of turbine sleeves and a deep hole machining method in order to solve the problems that in the deep hole machining process in the prior art, the axes of holes are prone to inclination, guiding deviation and vibration happen easily in the machining process, a tool is poor in heat dissipation conditions, the durability of the tool will be reduced because the cutting temperature rises, cuttings are difficult to discharge, and not only may machined surfaces be scratched, but also the tool may suffer tipping or even break in serious conditions. The boring tool comprises a boring cutter bar, a boring cutter and four guide blocks. A long groove and two clamping grooves are machined in the left end of the boring cutter bar to the right, a cooling liquid circulating hole is machined in the right end of the boring cutter bar to the left, a plurality of cooling liquid spray holes are evenly machined in the left end of the cooling liquid circulating hole in the radial direction, the boring cutter penetrates through the long groove to be clamped in the two clamping grooves in the boring cutter bar, and the four guide blocks are arranged on the boring cutter bar. The boring tool is used for machining deep holes of turbine sleeves.

Owner:HARBIN TURBINE

Large-span flexible cable supporting photovoltaic system

InactiveCN106936375AProcessing does not affectAchieve double harvestPhotovoltaic supportsPhotovoltaic energy generationAgricultureFlexible cable

The invention discloses a large-span flexible cable supporting photovoltaic system, which comprises photovoltaic modules, inhaul cables, stabilizing rods, cross beams, stand columns, oblique pull rods, bearing platforms, prestressed tubular piles, ground beams and a damping device. The large-span flexible cable supporting photovoltaic system is characterized by fully utilizing idle solar energy resources above places such as fish ponds, farmland or sewage treatment plants, setting up a solar photovoltaic assembly thereon, having the feature of ''one place for dual purposes'', adopting the inhaul cables as supporting structures of the solar photovoltaic assembly, achieving the purpose that the photovoltaic industry and other activities developed thereunder such as fishery, agriculture or sewage treatment operation do not interfere with one another, effectively improving the rigidness of the entire system through forming a criss-crossed supporting network by means of the inhaul cables and the stabilizing rods, being capable of dissipating the vibration energy of the inhaul cables by installing the damping device at a midspan position of the inhaul cables preferentially, and ensuring the safety of the photovoltaic assembly.

Owner:ZHUHAI SINGYES GREEN BUILDING TECH +2

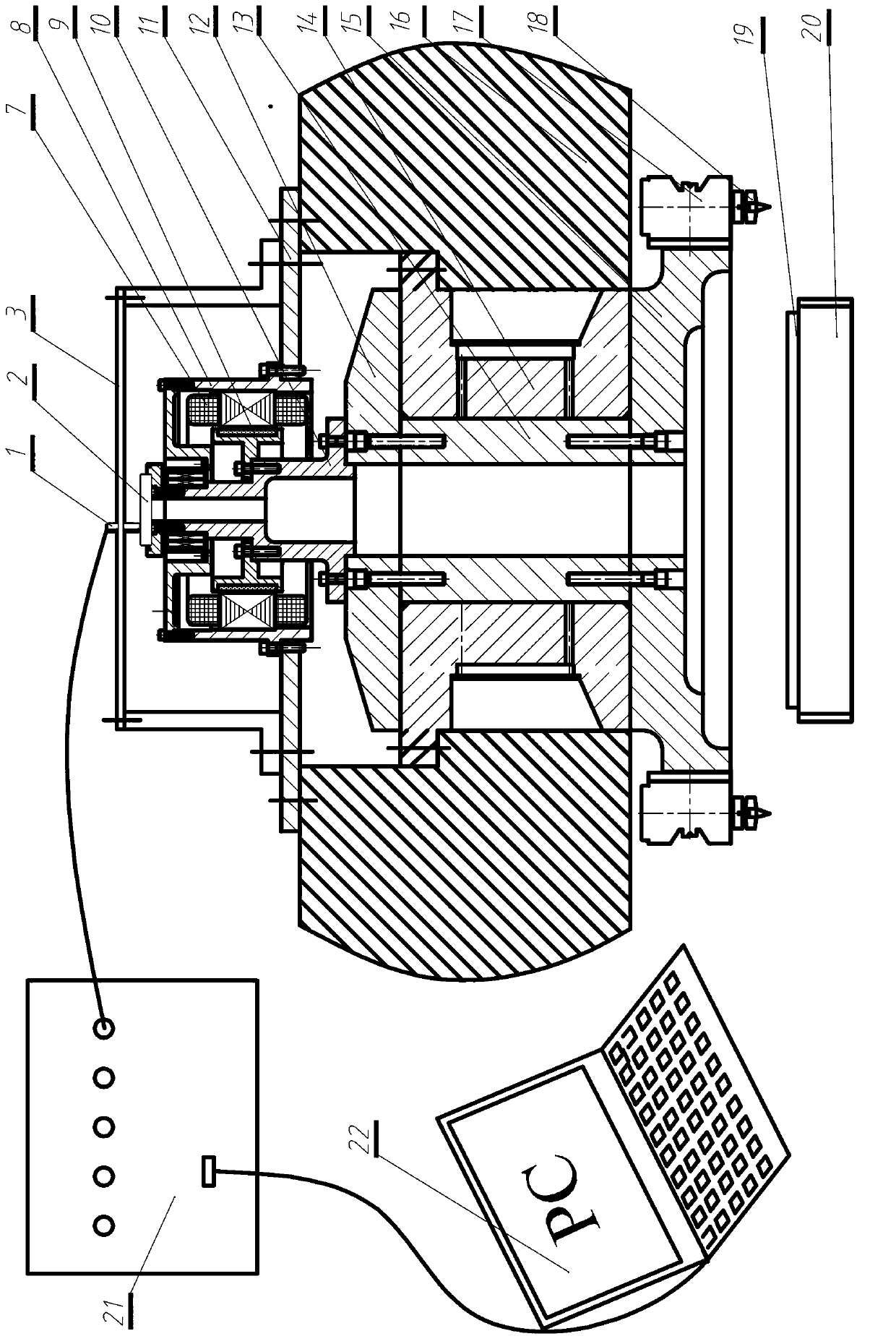

Copper plate polishing temperature on-line detection device

PendingCN107621312AQuick responseImprove timelinessThermometer detailsRadiation pyrometryWireless transmissionCopper

The present invention discloses a copper plate polishing temperature on-line detection device which comprises a copper plate, temperature sensors, a wireless data acquisition system and a display screen. The temperature sensors are distributed on the copper plate to measure the temperatures of different positions at the copper plate. The display screen displays the temperatures of different positions at the copper plate. The real-time online monitoring of the temperature of the copper plate in a processing process can be carried out, the copper plate surface temperature in a large size copperplate polishing process is accurately measured, the distribution law of the copper plate surface temperature is obtained, the device has an important meaning for controlling copper polishing surface shape precision and improving surface shape precision of a thin-plate part, and a cooling structure is optimized by the distribution law. The wireless data acquisition system comprises an acquisition module, a wireless transmission module and a wireless signal receiving module, and the copper plate polishing processing is not affected by the setting of the detection device by using wireless transmission.

Owner:HUAQIAO UNIVERSITY

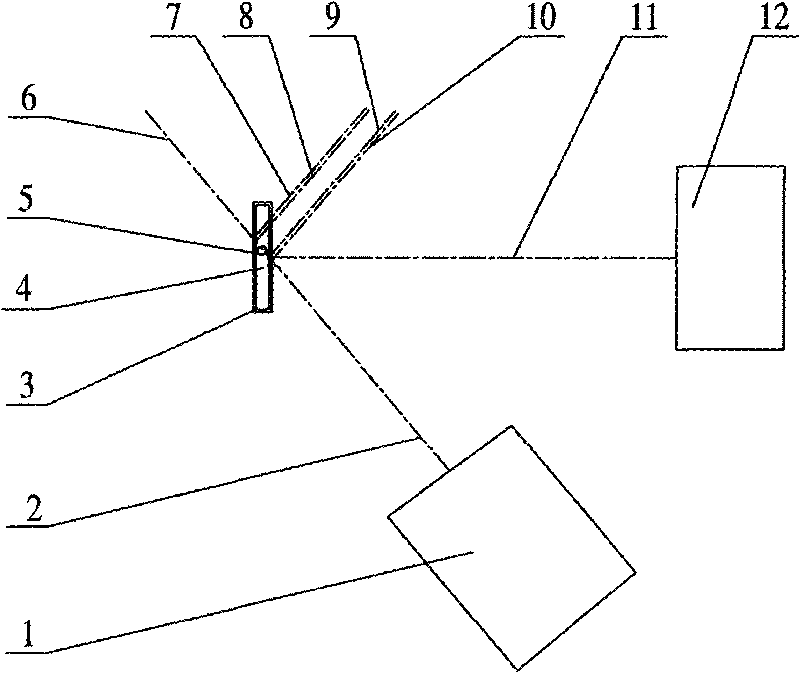

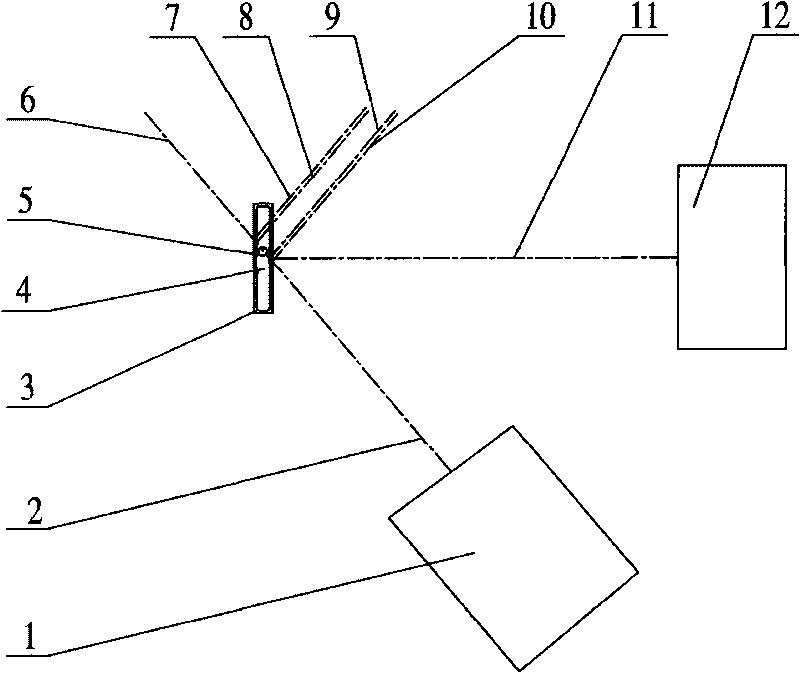

Inclined fluorescence excitation and detection light path device

InactiveCN101706432AImprove signal-to-noise ratioSimple position adjustmentFluorescence/phosphorescenceAcute angleFluorescence

The invention provides an inclined fluorescence excitation and detection light path device, which relates to a fluorescence excitation and detection device. The device comprises a sample room, an exciting light generator and a fluorescence detection device, wherein a detection light path faces one surface with a wider cross section side length of the sample room and is orthogonal with the surface, and the width of an exciting light beam is not less than that of a viewing field covering a microscopic object side. The inclined fluorescence excitation and detection light path device is characterized in that the exciting light generator is inclined on one side of the sample room, an excitation light path of the exciting light generator is in acute angle intersection with a detection light path of the fluorescence detection device in the center of the cross section of the sample room, and the following conditions are met: the intersection angle of the excitation light path and the detection light path is between 20 and 70 degrees, and the inclination angle ensures that the exciting light does not enter the fluorescence detection light path and also ensures that the reflected light of the exciting light does not enter the fluorescence detection device. The inclined fluorescence excitation and detection light path device has the advantages of effectively preventing the exciting light from entering a fluorescence signal detection device through transmission and reflection, reducing scattered exciting light to enter the fluorescence signal detection device and to cause strong interference light to the utmost extent, and greatly improving the noise-signal ratio of detection; and the integral form and position adjustments of the exciting light are simpler.

Owner:FUJIAN NORMAL UNIV

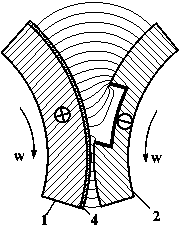

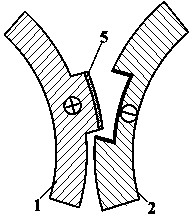

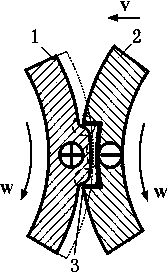

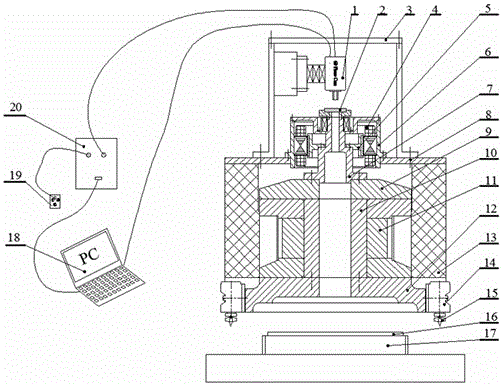

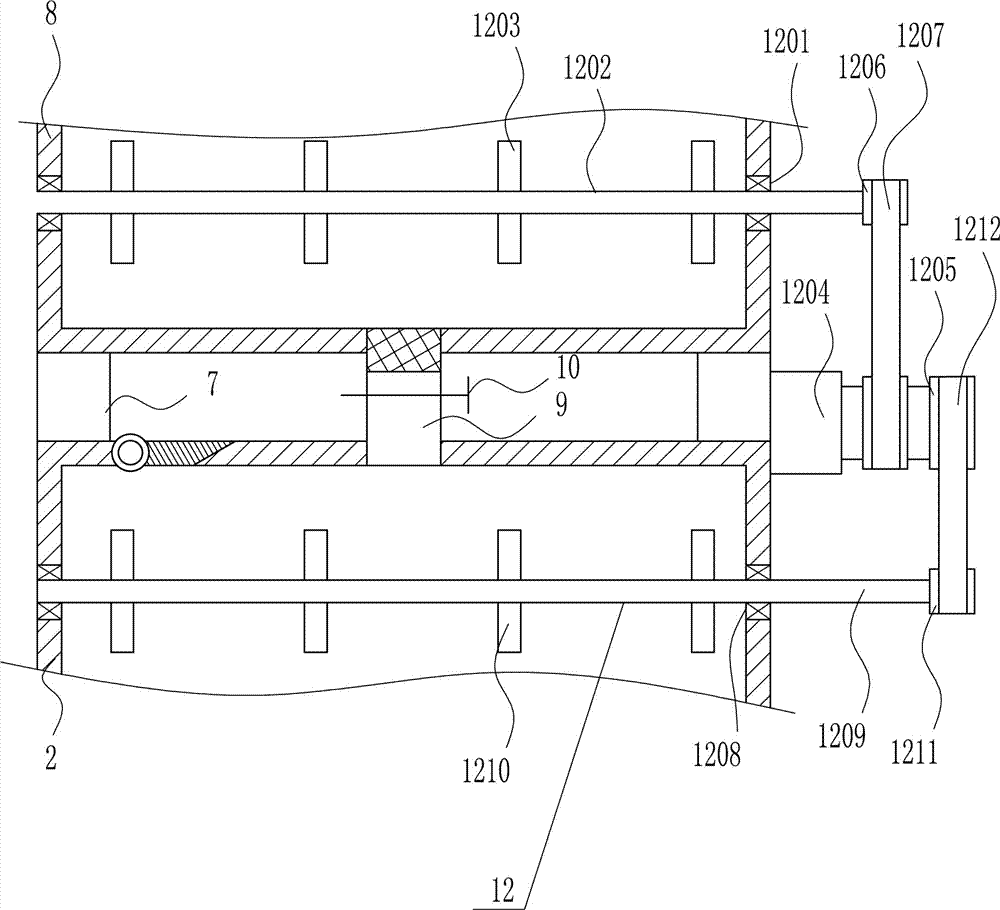

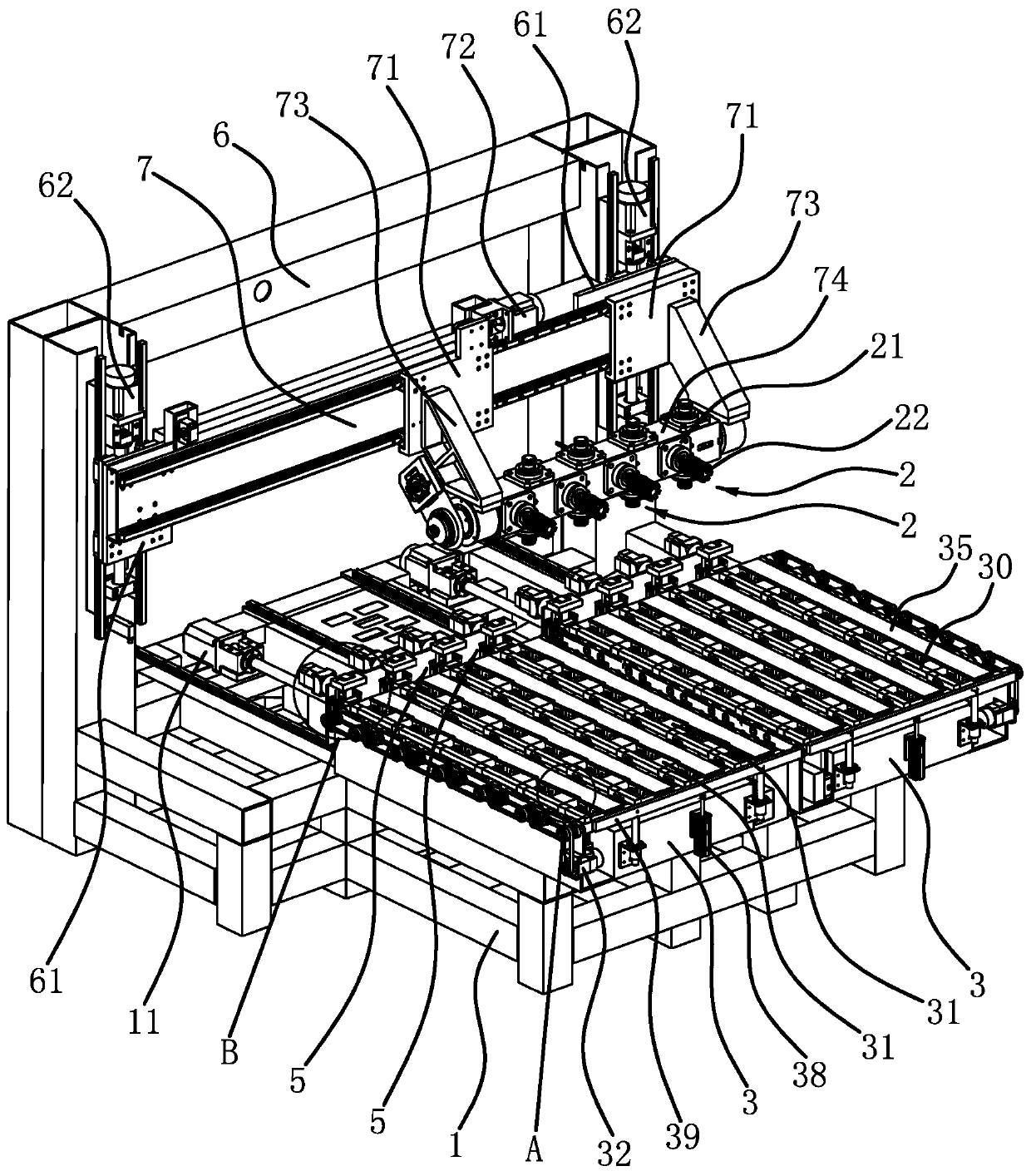

Wing surface punching device of automobile U-shaped beam

ActiveCN103433357ALow powerSmall passive inertiaPerforating toolsMetal-working feeding devicesPunchingShaped beam

The invention discloses a wing surface punching device of an automobile U-shaped beam, and belongs to the field of punching machine tools. The wing surface punching device of the automobile U-shaped beam comprises a main sliding block arranged on a machine frame. A die assembly is arranged corresponding to the main sliding block, the die assembly comprises a plurality of male dies and a plurality of female dies which correspond to one another, and the male dies are arranged inside a male die guide holder. Male die push rods which abut against one ends of the male dies respectively are arranged inside the male die guide holder. The male die guide holder and the female dies are mounted on a die holder support. The main sliding block is fixedly connected with a cylinder support, the cylinder support is provided with a plurality of die selection cylinders, the lower ends of piston rods of the die selection cylinders are connected with die selection push blocks, and the die selection push blocks are correspondingly arranged between the sliding block and the male dies. A die set guide plate is arranged at the position, corresponding to the side face of the die holder support, of the machine frame. A blanking channel is arranged in the position, corresponding to the positions of the female dies, of the die set guide plate. A lifting motor is arranged on the lower side of the die holder support on the machine frame, and the upper end of a spindle of the lifting motor is connected with the bottom of the die holder support through a ball screw mechanism. By means of the wing surface punching device of the automobile U-shaped beam, waste blanking is convenient, feeding can not be affected, and machining energy consumption is low.

Owner:JIANGSU JINFANGYUAN CNC MACHINE CO LTD

Movable self-cleaning wastewater treatment device

PendingCN108423862AProcessing does not affectImprove processing efficiencyTreatment involving filtrationMultistage water/sewage treatmentSlagSewage treatment

The invention discloses a movable self-cleaning wastewater treatment device. The device comprises a filtering chamber and an adsorbing chamber which are connected through a communication pipe, whereina plurality of filtering layers are arranged in the filtering chamber from top to bottom; a long rod cylinder is arranged on one side of each filtering layer; the front end of a piston rod of each long rod cylinder is equipped with a scrapping plate which clings to the upper surface of each filtering layer; an impurity outlet is formed in the sidewall of another filtering layer; an adsorbing layer is arranged in the middle of the adsorbing chamber. According to the device, the movable wastewater treatment mode is carried out; a filtering net can be automatic to flush slag and be washed without dismounting, and the normal wastewater treatment is not influenced, so that the wastewater treatment efficiency is improved.

Owner:安徽蓝创环保科技发展有限公司

Coating material replacing hard chromium plating and method for carrying out laser cladding by using coating material

InactiveCN107267978ABarrier contactAvoid Pore CracksMetallic material coating processesImpurityMetal

The invention relates to a coating material replacing hard chromium plating and a method for carrying out laser cladding by using the coating material, and belongs to the technical field of restoration. The coating material comprises C, Cr, Ni, impurities and Fe. The method comprises the steps that elemental metal is atomized to obtain the coating material for replacing the hard chromium plating, and a final finished workpiece is obtained through cleaning, laser outputting, cladding and post-treatment. According to the coating material and the method, the laser cladding technology is adopted, a uniform and dense metal coating is formed on the surface of a substrate, and therefore the generation of pore cracks is completely avoided, and the contact between water and the substrate is completely obstructed.

Owner:WUXI ZHOUXIANG LASER MACHINERY

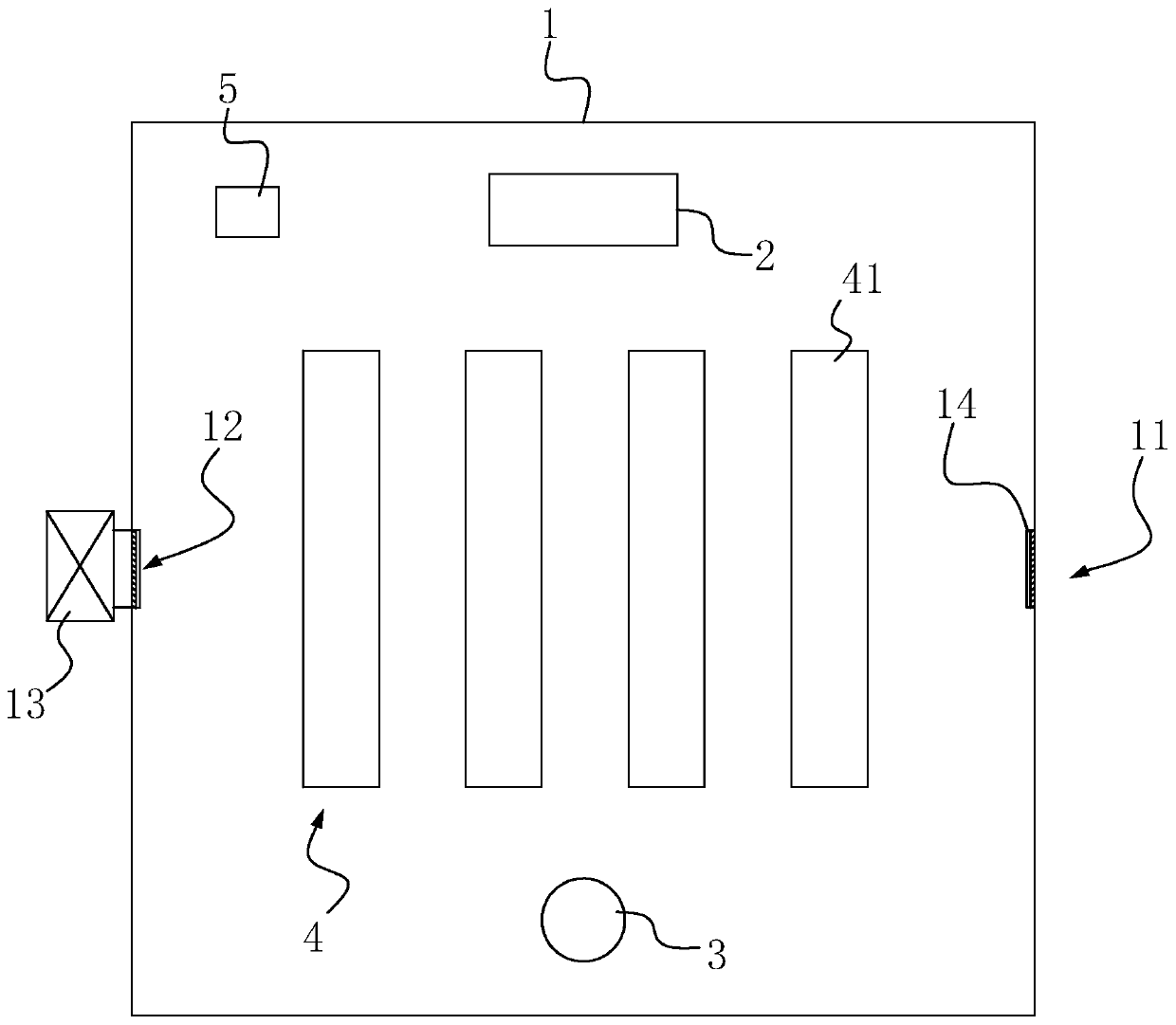

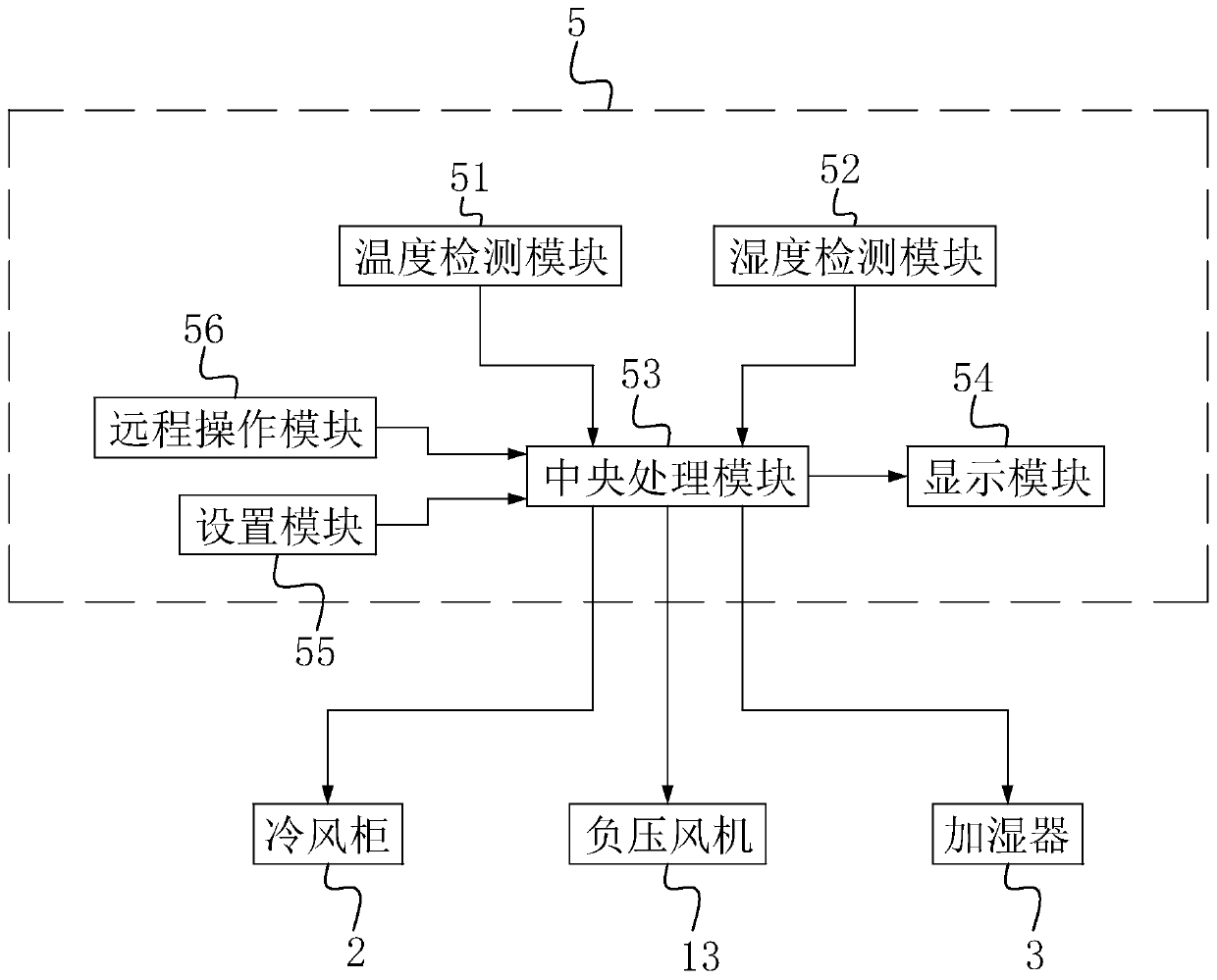

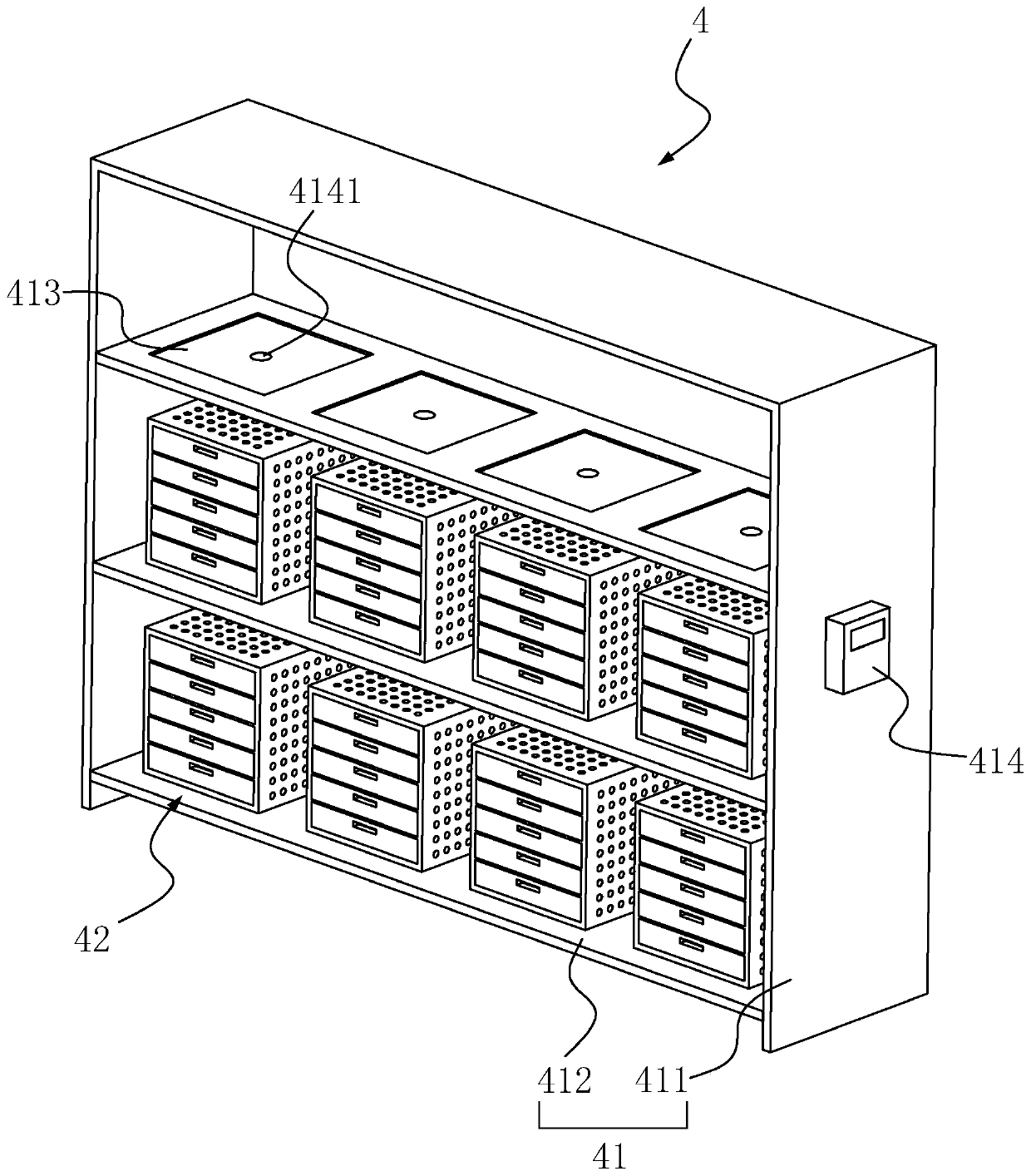

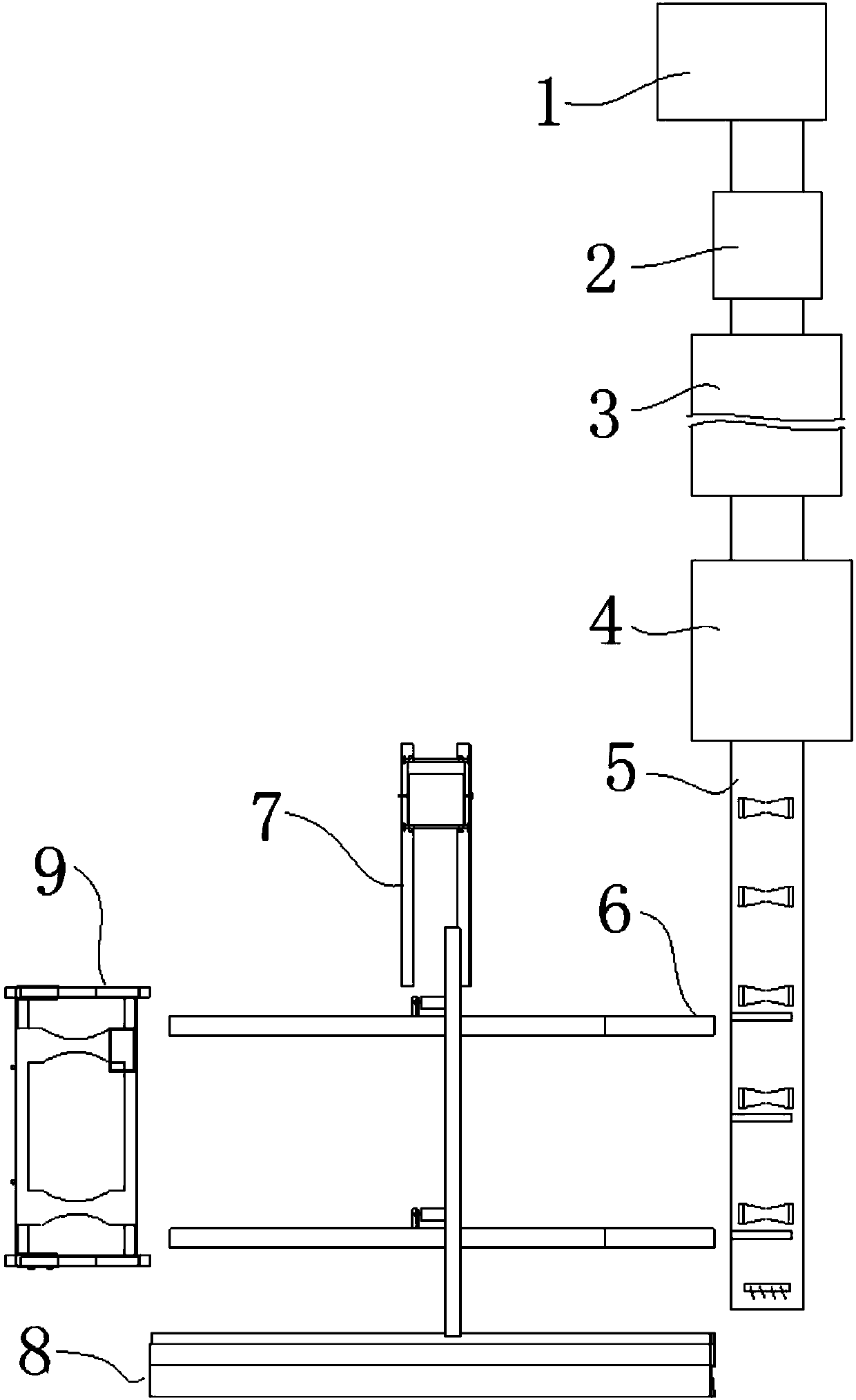

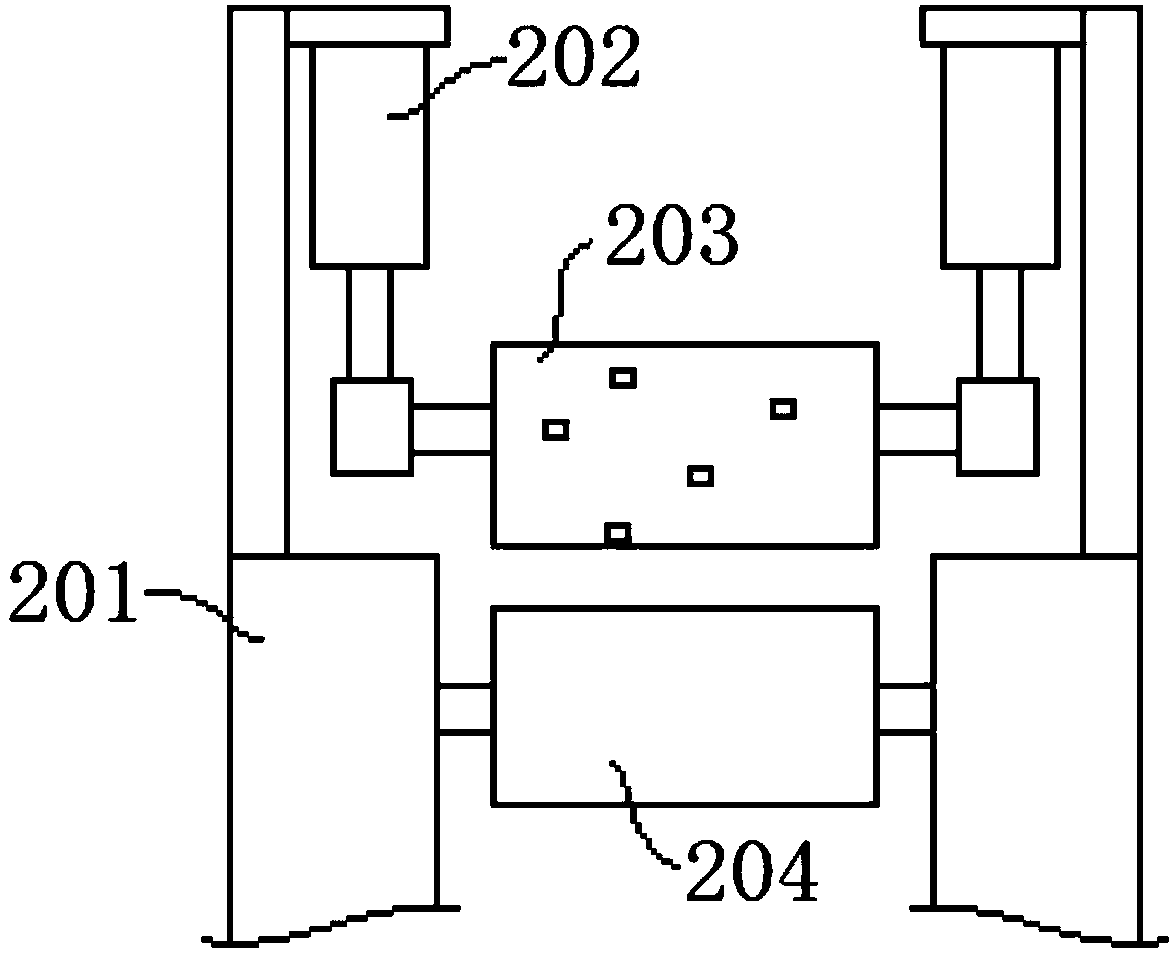

Intelligent apple refrigeration system

InactiveCN110686447AImprove ventilationWell refrigeratedLighting and heating apparatusStationary refrigeration devicesCold airCool storage

The invention relates to an intelligent apple refrigeration system, and belongs to the technical field of refrigeration systems. The main point of the technical scheme is that the intelligent apple refrigeration system comprises a refrigeration chamber, a cold air cabinet arranged in the refrigeration chamber and a plurality of apple storage devices arranged in the refrigeration chamber in a nested mode, wherein each apple storage device comprises a placement shelf and a plurality of storage boxes arranged on the placement shelf, ventilation holes which run through the peripheral wall of eachstorage box are formed in the peripheral wall of each storage box, a plurality of storage trays used for placing apples are arranged in each storage box from the top down, an air inlet communicating with the outside world is formed in a wall on one side, parallel to the placement shelves, of the refrigeration chamber, a negative pressure air outlet connected with a negative pressure draught fan isformed in a wall on one side, far away from the air inlet, of the refrigeration chamber, and sealing doors used for sealing the air inlet and the negative pressure air outlet are respectively arranged on the positions of the air inlet and the negative pressure air outlet. The intelligent apple refrigeration system can regulate ventilation conditions of apple storage according to characteristics of the apples, and can meet storage requirements of the apples different in characteristic.

Owner:栖霞德丰食品有限公司

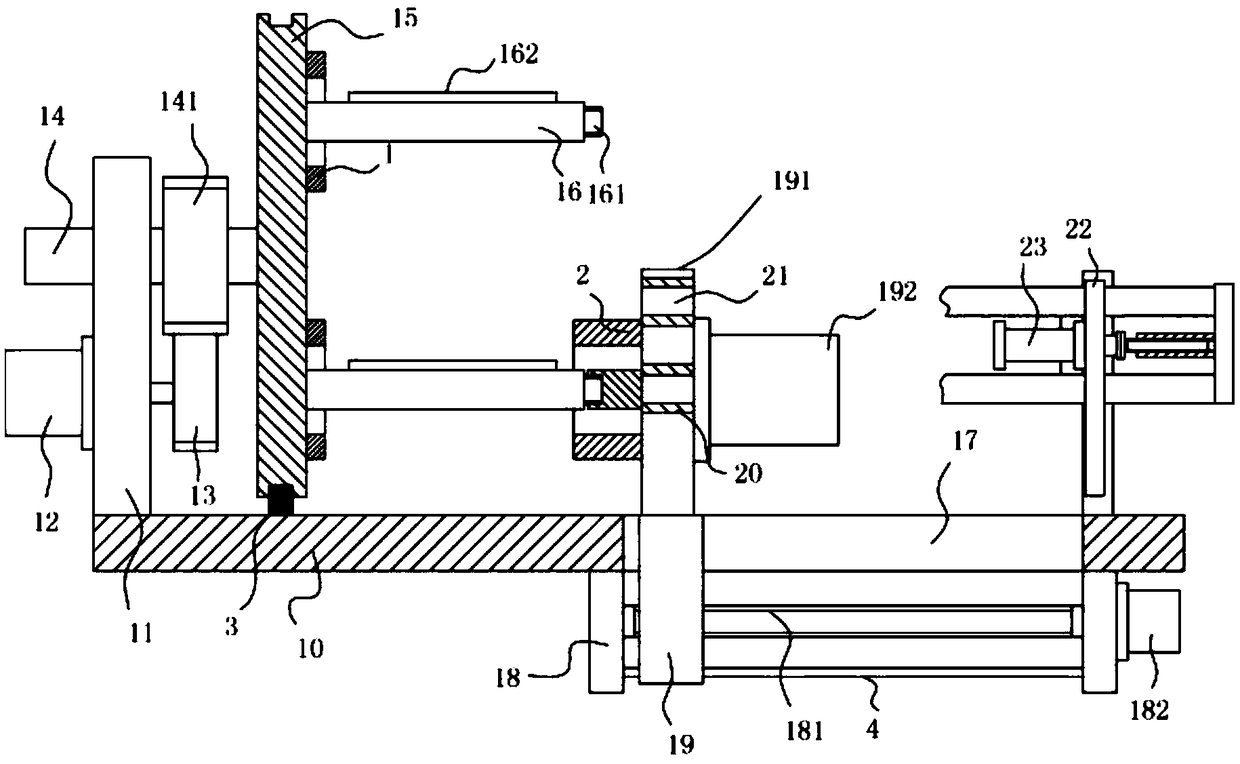

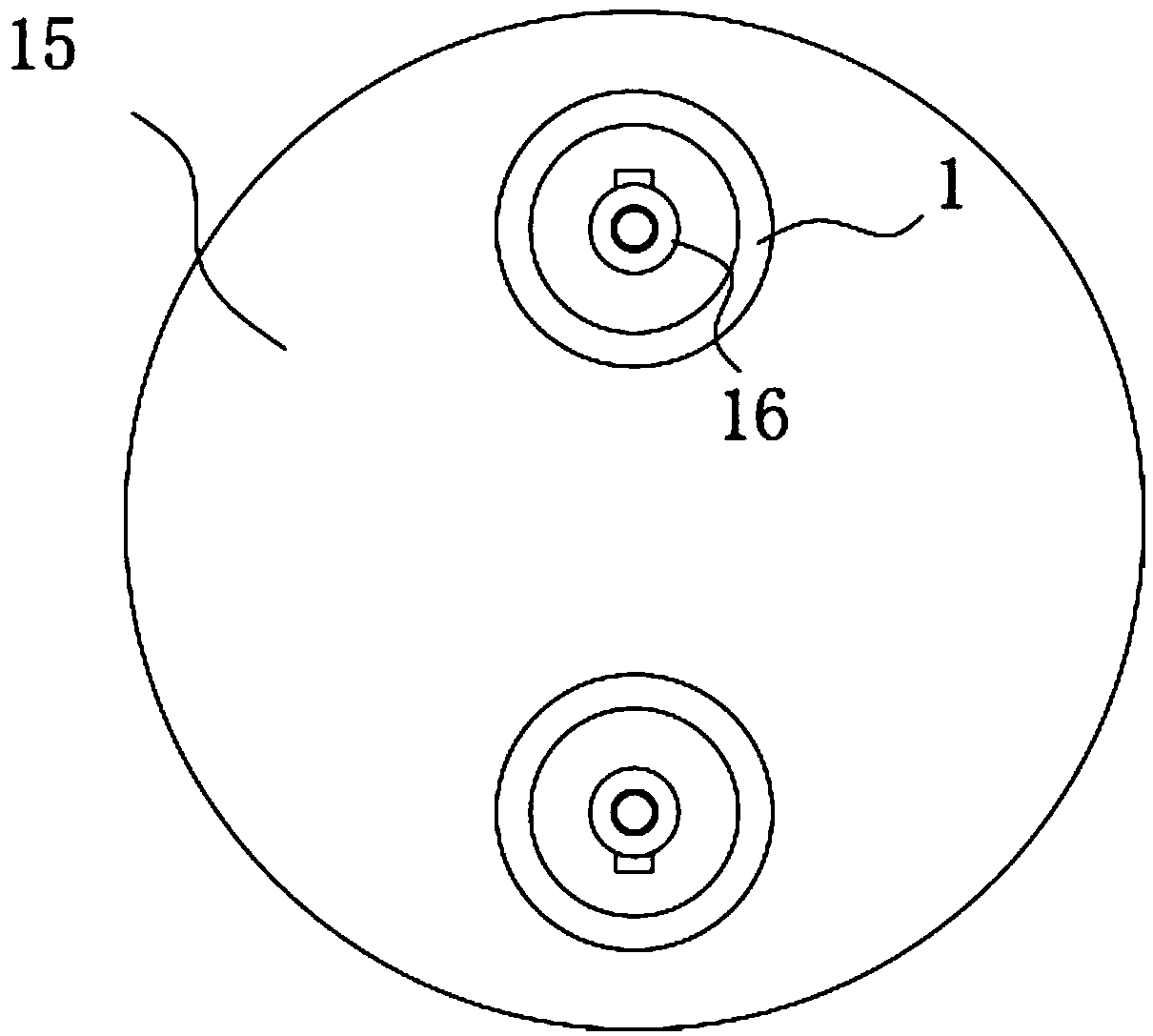

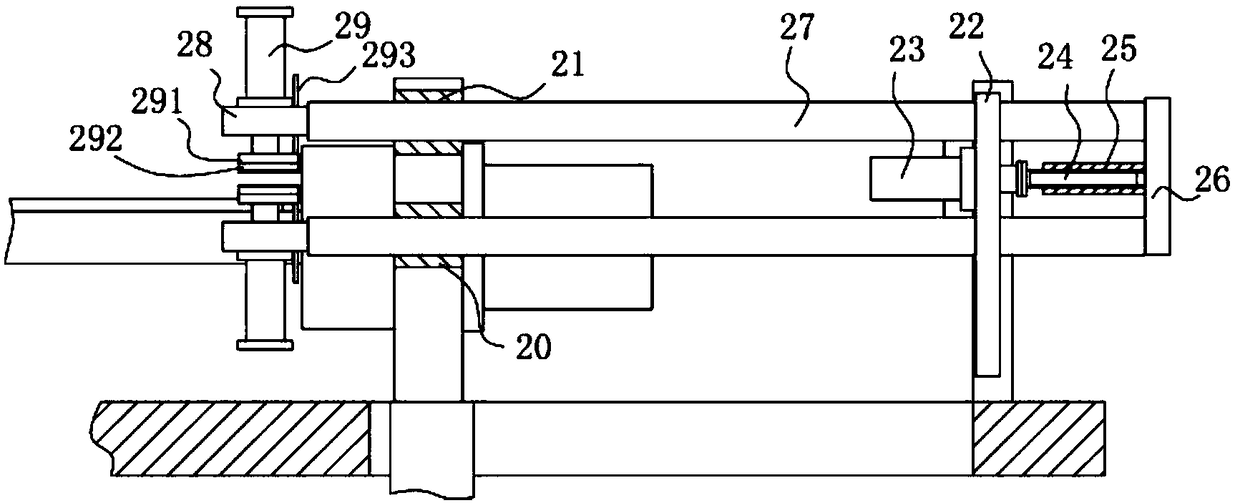

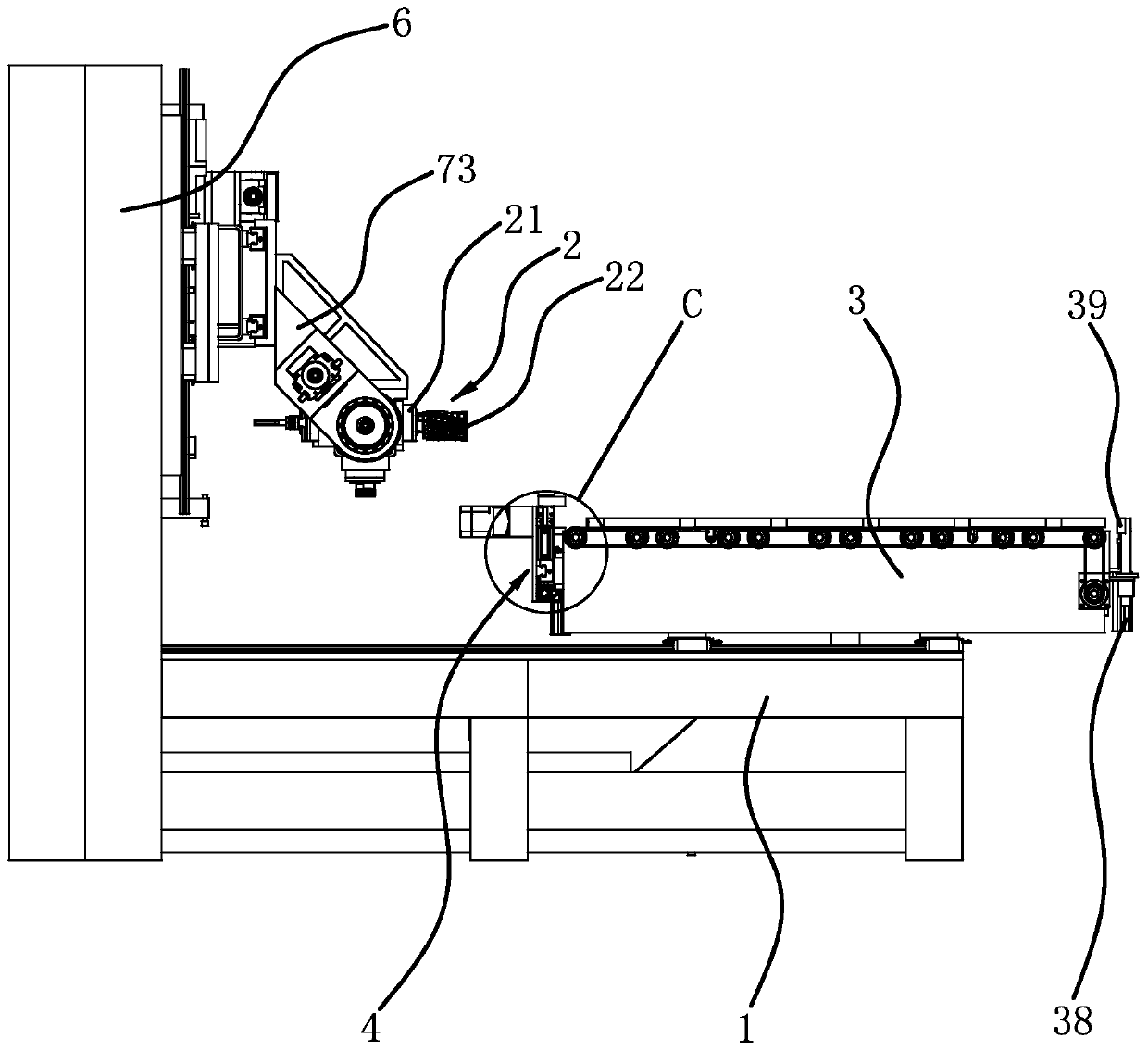

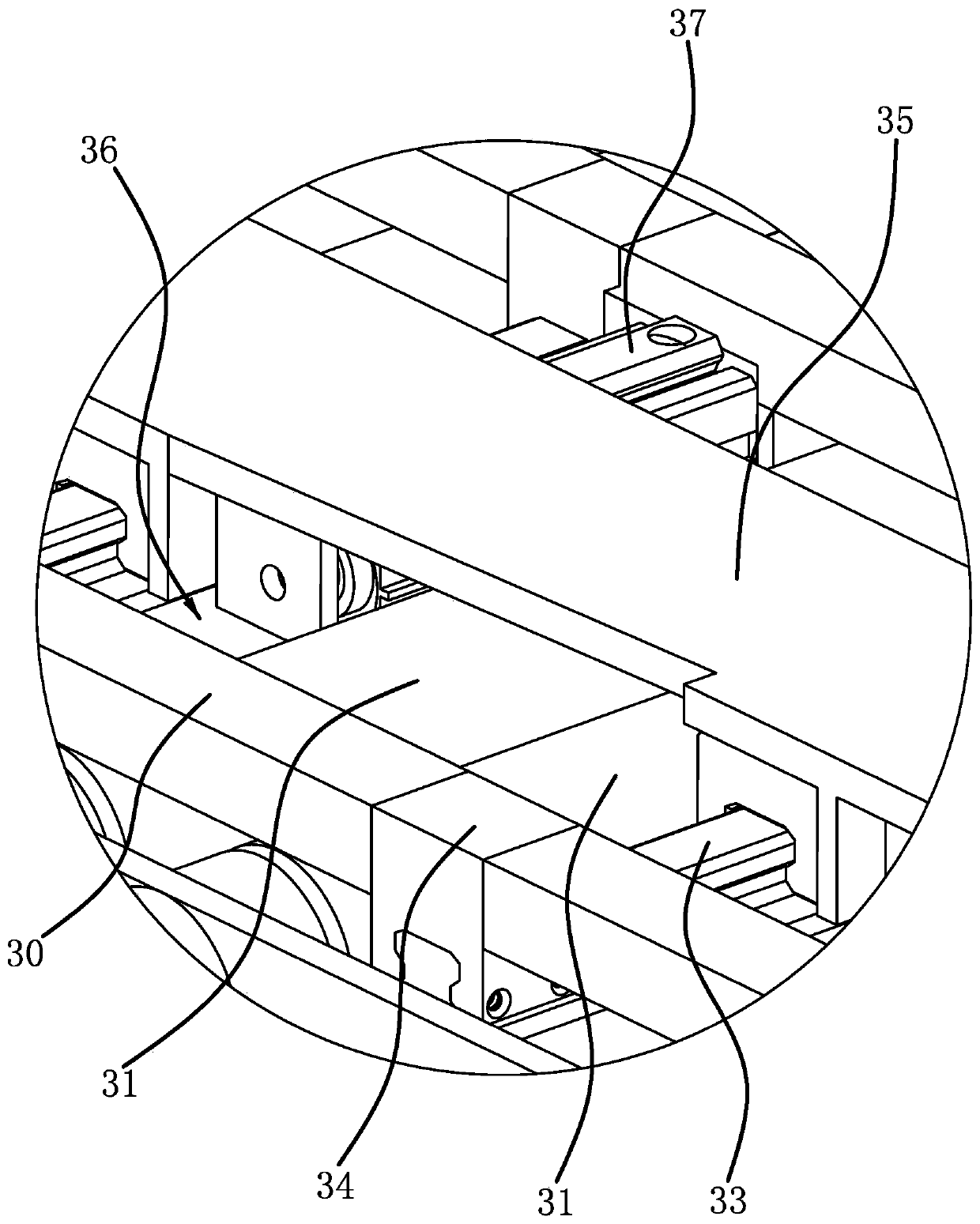

Steel pipe machining system with automatic coding function

ActiveCN107855779AProcessing does not affectNo deformationOther manufacturing equipments/toolsMetal working apparatusAgricultural engineeringMachining system

The invention discloses a steel pipe machining system with the automatic coding function, and belongs to the field of steel pipe machining. The system comprises an unwinding mechanism, a winded welding mechanism, a cutting mechanism, a transmission mechanism, a coding mechanism, a discharging mechanism, a chamfering mechanism and a transport vehicle; the unwinding mechanism enables a rolled boardto be flatly spread, the board is coded through the coding mechanism, and then the board is conveyed to the winded welding mechanism, after welding, the steel pipes are cut into the fixed length through the cutting mechanism, and then the board enters the transmission mechanism, the discharging mechanism is matched with the transmission mechanism, the chamfering mechanism is arranged on one side of the discharging mechanism, the transport vehicle is arranged at the tail end of the discharging mechanism, and after being chamfered, steel pipes are bundled and transported on the transport vehicle. According to the machining system, machining is achieved, coding, cooling, oil removal, discharging, water filtering and other processes can be automatically carried out, coding lettering and cooling of the steel pipe are well carried out, the conveying and transport mechanism is tight in linkage, and the machining quality and the machining efficiency of the steel pipes are greatly improved.

Owner:ANHUI SHUNXIN PRECISION TUBE MFG CO LTD

Chip removal device for lathe bed of numerical control machine tool

InactiveCN107363623AClean up thoroughlyAvoid reduction in processing efficiencyMaintainance and safety accessoriesEngineeringMachine tool

The invention discloses a chip removal device for a lathe bed of a numerical control machine tool. The chip removal device comprises a machine tool body, the lathe bed is welded to the bottom of the machine tool body, a rail is arranged at the position of the middle of an inner wall of the top of the machine tool body along the width direction, a moving unit is movably mounted in the rail, the bottom of the moving unit is connected with one end of a fixing rod, the other end of the fixing rod is connected with a first support plate, sliding chutes are symmetrically arranged in two sides of the lower surface of the first support plate, one slider is movably arranged in each sliding chute, bottoms of the sliders are hinged to one ends of connecting rods, the other ends of the connecting rods are hinged to the upper surface of a second support plate, and a through hole is formed in the middle of the second support plate. By the arrangement, chips in a machining groove of the lathe bed of the numerical control machine tool can be removed automatically, machining of the numerical control machine tool is unaffected, reduction in machining efficiency is avoided, and running of the machine tool is protected to some extent.

Owner:成都捷科菲友信息技术有限公司

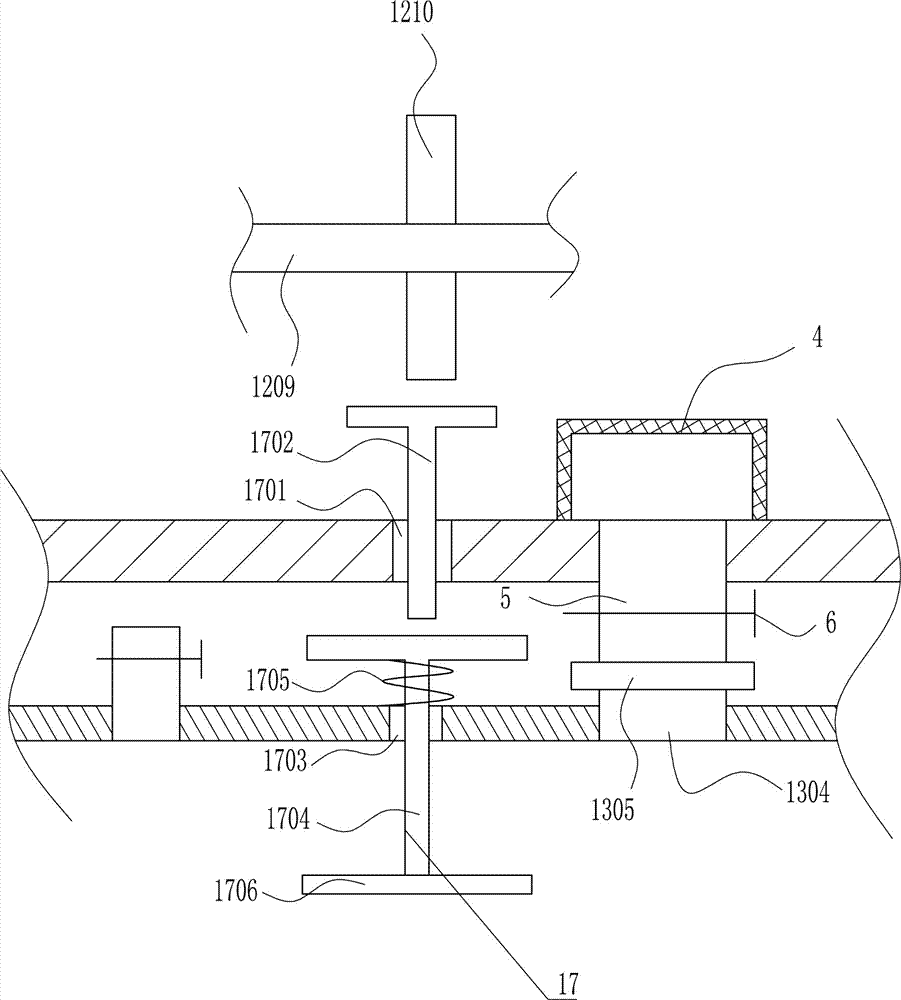

Turnover mechanism of engraving and milling machine

PendingCN110480759ARealize automatic processingProcessing does not affectMulti-purpose machinesProfiling/shaping machinesEngravingMachining

The invention provides a turnover mechanism of an engraving and milling machine, belongs to the technical field of machining equipment, and solves the problem that an existing engraving and milling machine is hard to automatically machine different side faces of a wood material efficiently. According to the turnover mechanism of the engraving and milling machine, the engraving and milling machinecomprises a rack and a machining assembly arranged on the rack. A machining platform capable of conveying the wood material longitudinally is also arranged on the rack, the machining assembly can translate three-dimensionally relative to the machining platform, the overturn mechanism comprises a clamp capable of clamping the wood material and driving the wood material to overturn, a moving assembly is arranged on the machining platform, the clamp is arranged on the moving assembly, the moving assembly can drive the clamp to move along a vertical direction, and the clamp is located at one longitudinal end of the machining platform. The turnover mechanism of the engraving and milling machine can machine different side faces of the wood material automatically.

Owner:吴善旺

Receiver apparatus and method for receiving data units over a channel

ActiveCN101151872AEasy to handleProcessing delayError prevention/detection by using return channelNetwork traffic/resource managementControl layerRadio Link Control

When transmitting medium access control protocol data units for the high speed downlink shared channel over a plurality of hybrid automatic repeat request processes, one of the processes can be in a retransmission procedure. In this case, stalling of the transmission can occur, because the medium access control layer for the high speed downlink shared channel of the receiver apparatus (3) buffers the following packet data units, when a preceding protocol data unit is waiting in the stalled process. To enable an early processing of the already received data, the receiver apparatus determines, whether the next expected service data units for a higher layer such as a radio link control layer, are included in the already received packet data units by taking into account the sequence number for the higher layer. Therefore, the medium access control layer for the high speed downlink shared channel accesses the data of the service data unit for the higher layer.

Owner:KONINKLIJKE PHILIPS ELECTRONICS NV

A kind of wall polishing equipment for decoration engineering

ActiveCN113510551BTake away in timeWon't leakPlane surface grinding machinesGrinding/polishing safety devicesElectric machinePolishing

The invention discloses a wall grinding device for decoration engineering, comprising a main box, a handle is fixed on the outer wall of the main box, a motor is fixed on the inner bottom of the main box, and an output shaft of the motor penetrates the main box The bottom of the handle is fixed with a polishing plate, the outer wall of the main box is fixed with a protective cover, the upper end of the main box is provided with a pumping mechanism, the side wall of the handle is fixed with an exhaust box and a dust box, the A dust removal mechanism and a dust collection mechanism are respectively provided inside the exhaust box and the dust collecting box. The advantage is that the dust generated by cleaning will accumulate inside the protective cover, so that it will not escape at will, which can protect the construction environment and the safety of users, and the dust generated by processing can be taken away in time without affecting processing. When the overall position of the equipment is changed, it will not cause dust leakage, which is convenient for the use of continuous replacement.

Owner:南通东泓建筑装饰工程有限公司

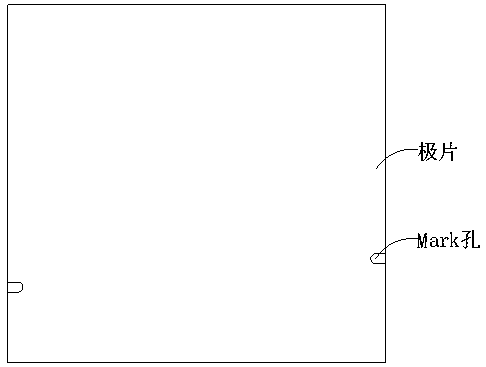

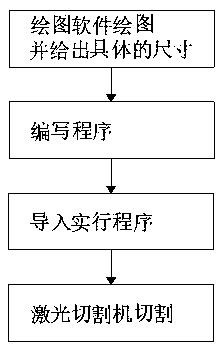

Method for improving strength of pole piece of square lithium ion battery after Mark hole drilling

InactiveCN110931705AHigh strengthReduce the concentration of weak linksElectrode manufacturing processesSecondary cellsWinding machineElectrical battery

The invention provides a method for improving the strength of a pole piece of a square lithium ion battery after Mark hole drilling, and relates to the technical field of electric power. The inventiondiscloses a method for improving the strength of a pole piece of a square lithium ion battery after Mark hole drilling. The method comprises the following steps: S1, drawing a cutting pattern row ofthe lithium ion battery for punching Mark holes in two sides, and arranging circular grooves of the Mark holes on the edges of tabs (the pattern row of the Mark holes is drawn by adopting laser drawing software when the punching pattern row of the Mark holes is drawn); and S6, removing waste generated in the machining process in time, so that the waste is prevented from being sucked into the punched position, and machining deviation is avoided. Program parameters can be adjusted through the steps of S2, S3 and the like, the punching mode of the parallel positions of the two sides of the pole piece is changed into the two-side staggered punching mode, the lower limit of specific optimization may have a certain difference, and the higher the tensile strength of the pole piece depends on theMark hole size recognition capacity of a winding machine, therefore, it can be seen that the purpose of preventing strip breakage during Mark hole punching can be achieved.

Owner:安徽益佳通电池有限公司

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com