Patents

Literature

Hiro is an intelligent assistant for R&D personnel, combined with Patent DNA, to facilitate innovative research.

64results about How to "Effect does not affect" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

Dam termite trapping and killing bag

InactiveCN103392750AWill not die from poisoningNo carcinogenic ingredientsBiocidePest attractantsFipronilAdditive ingredient

The invention provides a dam termite trapping and killing bag. The dam termite trapping and killing bag comprises 1-5 parts of fipronil, 200-300 parts of an ingredient of plants which are favorite by termites, 5-10 parts of an attractant and 1-5 parts of a synergistic agent, wherein the ingredient of the plants which are favorite by the termites is selected from one or a mixture of pine pollen, bagasse, eucalyptus powder, camphor tree powder and pine powder, the attractant is selected from one or a mixture of glutinous rice flour, white granulated sugar and potassium sorbate, and the synergistic agent is tracking hormone or gloeophyllum trabeum. The dam termite trapping and killing bag provided by the invention does not contain carcinogenic components, is safe to people and livestock, pollution-free and very convenient to use, and can be used for attracting the termites within a 80-100m<2> area for eating, so that the termite killing effect is very remarkable.

Owner:李国亮

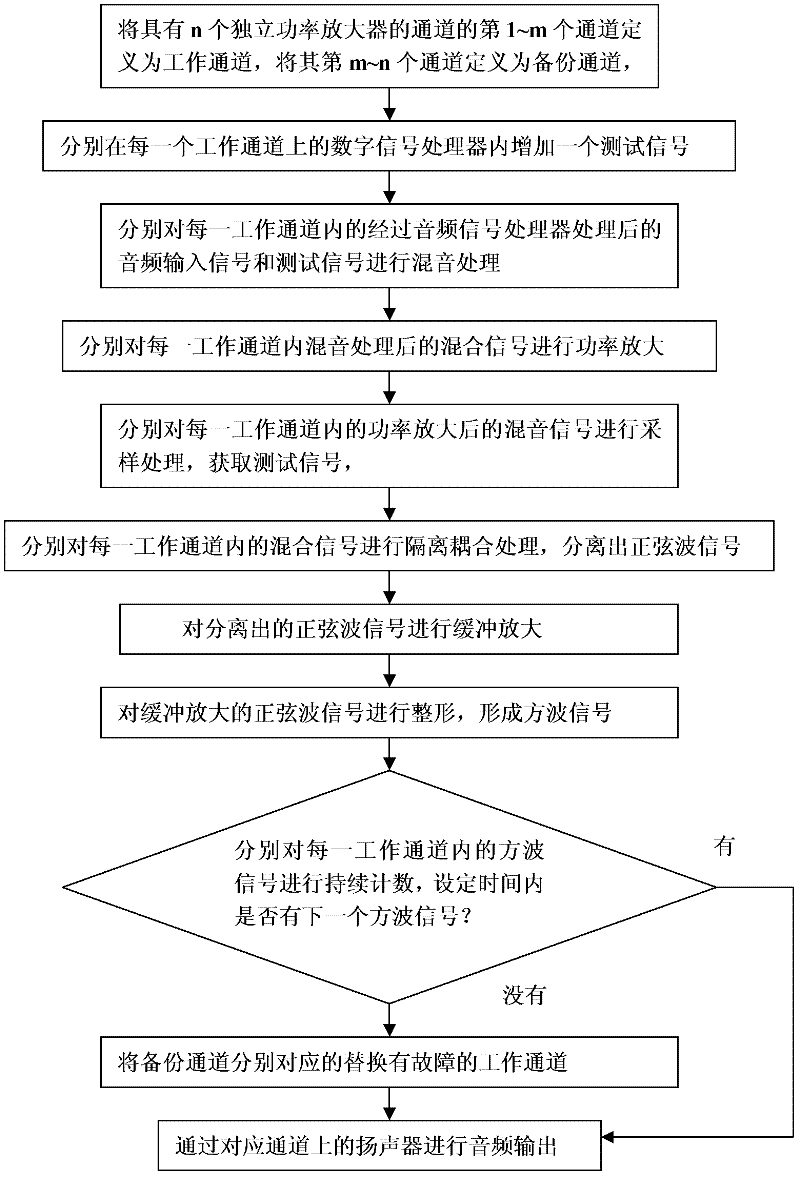

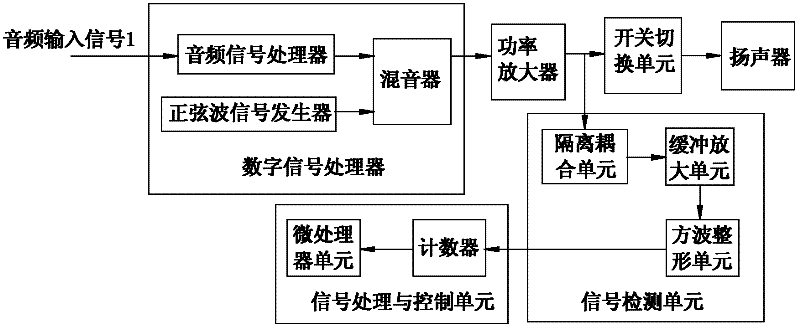

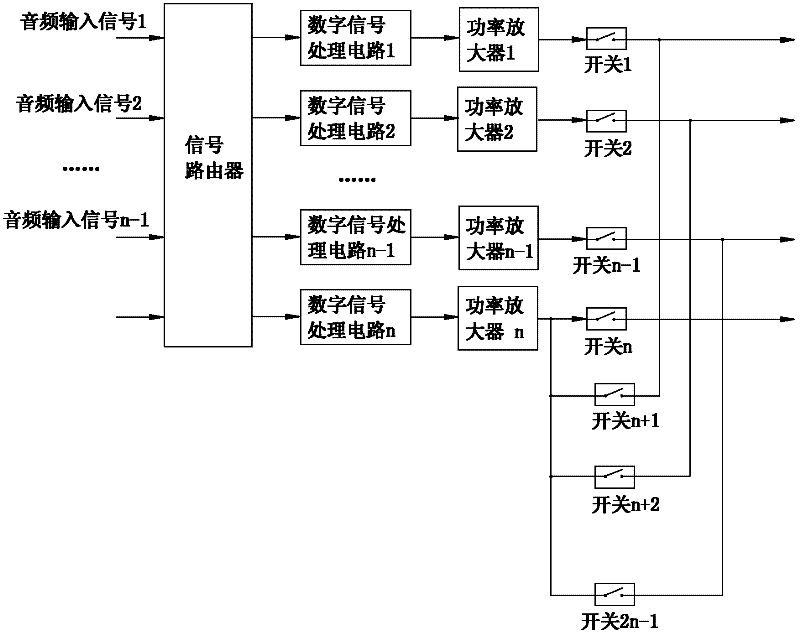

Hot backup method and hot backup device for multi-channel power amplifier

ActiveCN102231621AEffect does not affectProcessing will not affectAmplifier combinationsAmplifier protection circuit arrangementsManagement unitAudio power amplifier

The invention discloses a hot backup method and a hot backup device for a multi-channel power amplifier with an automatic failure detection function and an automatic failure backup function. A plurality of independent channels of the power amplifier are divided into working channels and backup channels; a test signal is added to the input end of each working channel; signal detection units monitor and sample the output end of the power amplifier on each working channel in real time; if the signal detection unit on each working channel can continuously detect the test signal, the power amplifier on the working channel is proved to work normally; and if the signal detection unit on a certain working channel cannot continuously detect a sampling signal, the power amplifier on the working channel is proved not to work normally, and a signal processing and control unit and a switching management unit correspondingly replaces the power amplifier on the failing working channel by the power amplifier on the backup channel to ensure a loudspeaker on the working channel still can work normally.

Owner:GUANGZHOU LEAFUN CULTURE SCI & TECH

Double glass curtain wall adopting main structure of antique shelf

The invention relates to a double glass curtain wall adopting a main structure of an antique shelf, which is used for solving the problems that the existing double glass curtain wall is poorer in permeability caused by an interlayer zone and single in the external facade modeling of the curtain wall, visual effect is affected and the like and comprises an outer-layer curtain wall and an inner-layer curtain wall. The technical point of the double glass curtain wall is that the main structure of the antique shelf is adopted to serve as a main support of the curtain wall; the inner-layer curtain wall is composed of an inner-layer panel with an opening fan and an inner-layer aluminium plate, and the outer-layer curtain wall is composed of an outer-layer panel and ribbed glass; a transfer assembly comprises a U-shaped transfer piece and an aluminum pressing plate; a hooking assembly comprises a toothed hooking piece, a clamping bolt assembly as well as a toothed anti-skid gasket and a clamp plate with a flexible pad which are respectively arranged on the tooth surfaces at the two sides of the toothed hooking piece; and a wind guiding shutter is arranged at the bottom between the inner-layer curtain wall and the outer-layer curtain wall. The double glass curtain wall is reasonable in structure, very convenient for operations such as manufacturing, installing, adjusting and the like and beneficial to adsorbing and regulating the deviation of curtain wall supporting members and has the advantages that the permeability and the aesthetic performance of integral structure are achieved, and the requirements of combining the external maintenance function and aesthetic feeling of the curtain wall are further met.

Owner:SHENYANG YUANDA ALUMINUM IND GROUP

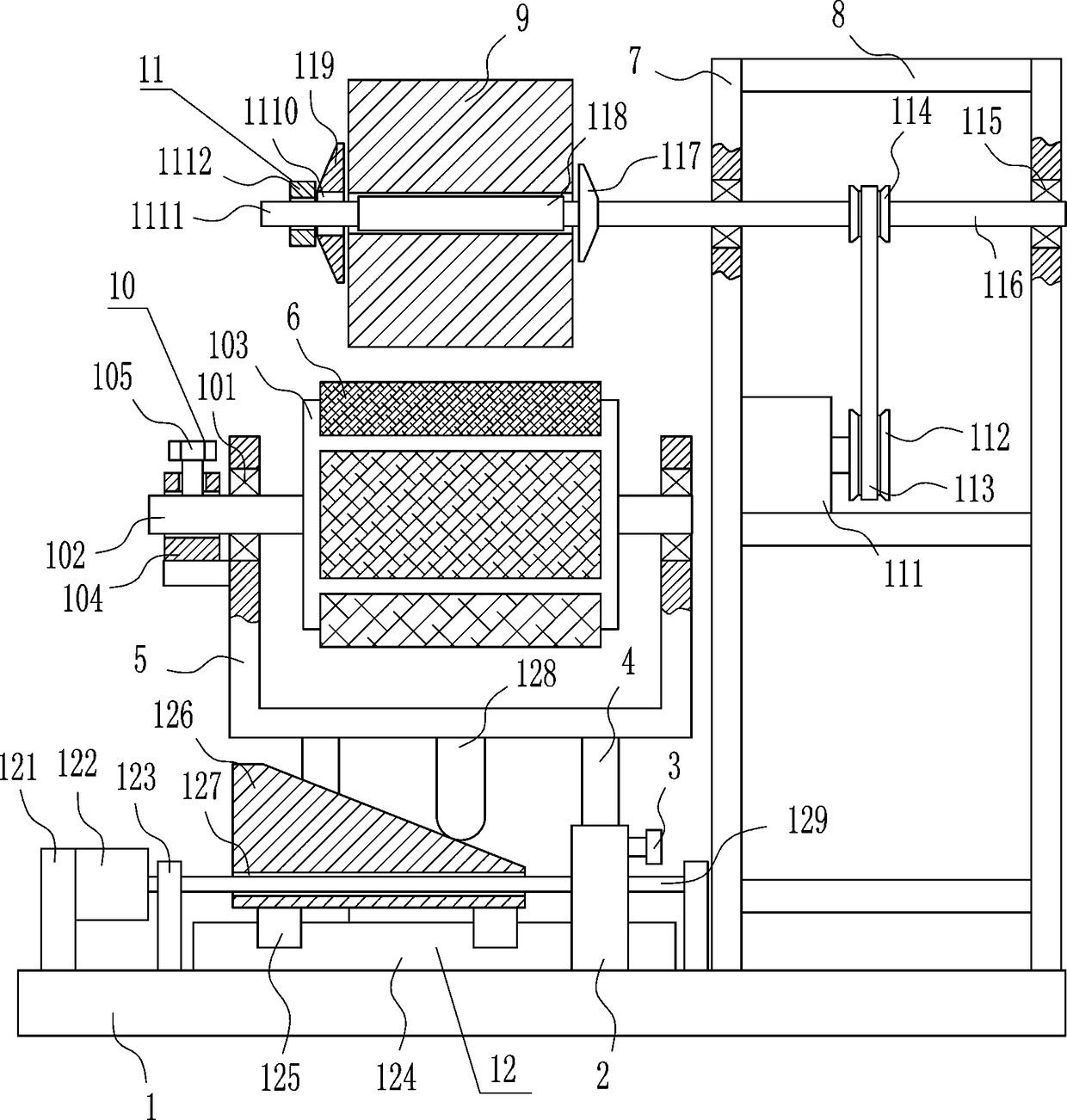

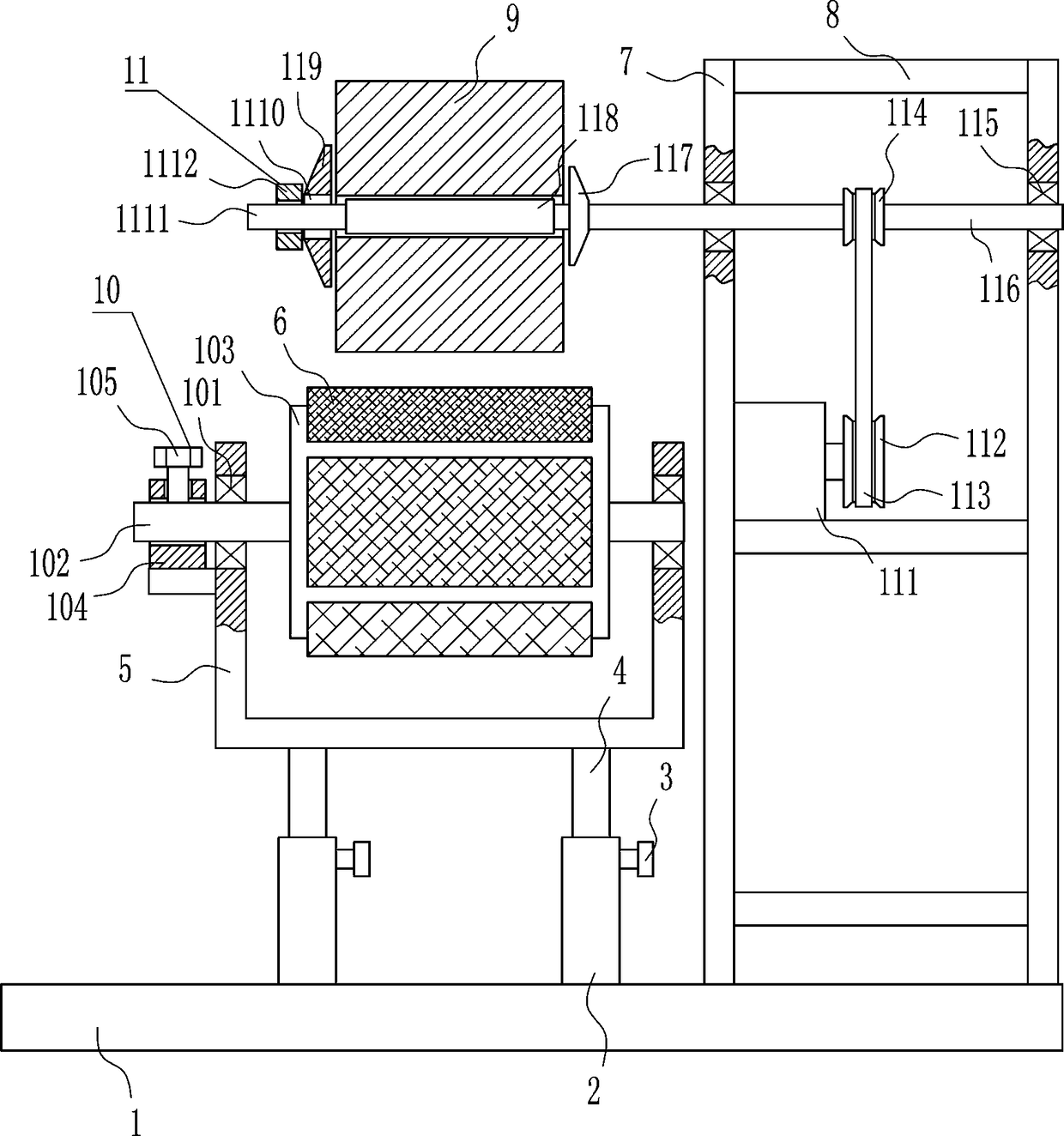

Device for testing wear resistance of rubber material

ActiveCN108303335AEffect does not affectThe test effect is goodInvestigating abrasion/wear resistanceRubber materialWear resistance

The invention relates to a test device, in particular, a device for testing the wear resistance of a rubber material. The invention aims to provide a test device, which is used to test the wear resistance of a rubber material, has the advantages of good testing effect and low labor strength, can absorb dusts during the testing process, and does not influence the surrounding environment. The invention provides a device for testing the wear resistance of a rubber material. The device comprises a bottom plate, sleeves, first fastening bolts, and movable rods. The left side and right side of the top of the bottom plate are both provided with a sleeve. A movable rod is arranged in each sleeve. The upper part of the right side of each sleeve is provided with a first fastening bolt. The first fastening bolts contact with the movable rods. A frame is arranged between the top end of the left movable rod and the top end of the right movable rod. By driving the device, people do not need to pullthe frame to contact a friction plate with a rubber material, time and labor are saved, the testing effect is good, the labor strength is low, during the testing process, the dusts can be absorbed, and surrounding environment is not influenced.

Owner:安徽创园体育科技有限公司

Label formed by two-dimensional code and variable information, generating method and generating system

InactiveCN105354606AEffect does not affectVariableCommerceRecord carriers used with machinesProgramming languageTrademark

The present invention provides a label formed by a two-dimensional code and variable information. The label comprises a two-dimensional code identification graph and at least one group of variable information identifications, wherein the two-dimensional code identification graph has a fixed pattern and has an association binding relationship with the variable information identifications; the variable information identifications surround the edge outside the two-dimensional code identification graph; the variable information identifications are formed by at least one or a combination of at least two of a trademark log, a single character, an ordered or unordered character sequence and same or different character sequences. The generating method for the label comprises: generating the vacant code type or non vacant code type two-dimensional code identification graph; generating the variable information identifications and setting positions between the variable information identifications and the two-dimensional code identification graph; and setting the association binding relationship between the variable information identifications and the two-dimensional code identification graph and uploading the association binding relationship to a label server. The generating system for the label comprises a two-dimensional code ID database, a two-dimensional code generating system, an encryption device, a variable information input device, a position regulating device, an association relationship binding device and the label server. According to the present invention, the generated label has variability and can be used for distinguishing the truth of a current product.

Owner:LEADER TECH KUNSHAN DIGITAL TECH

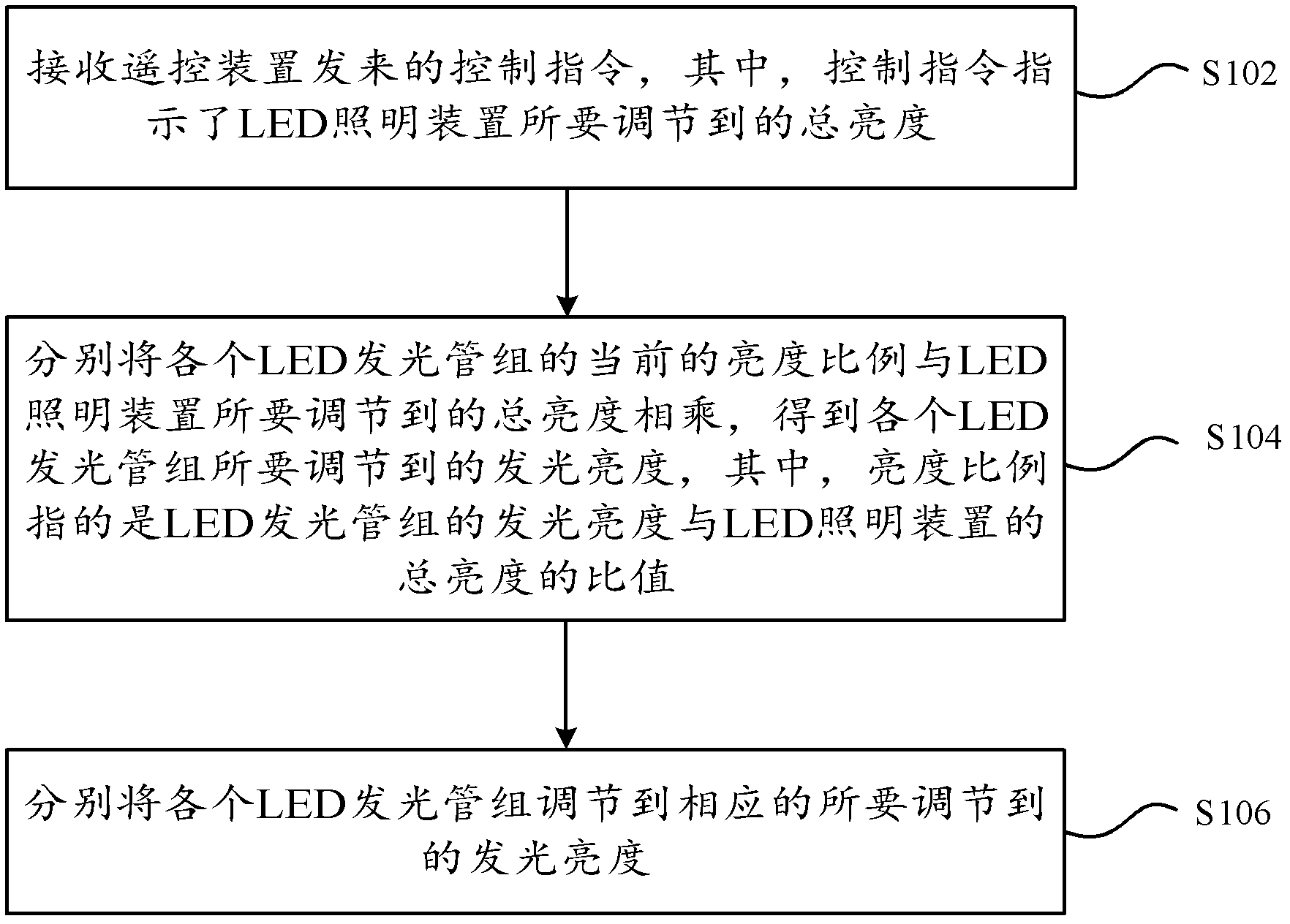

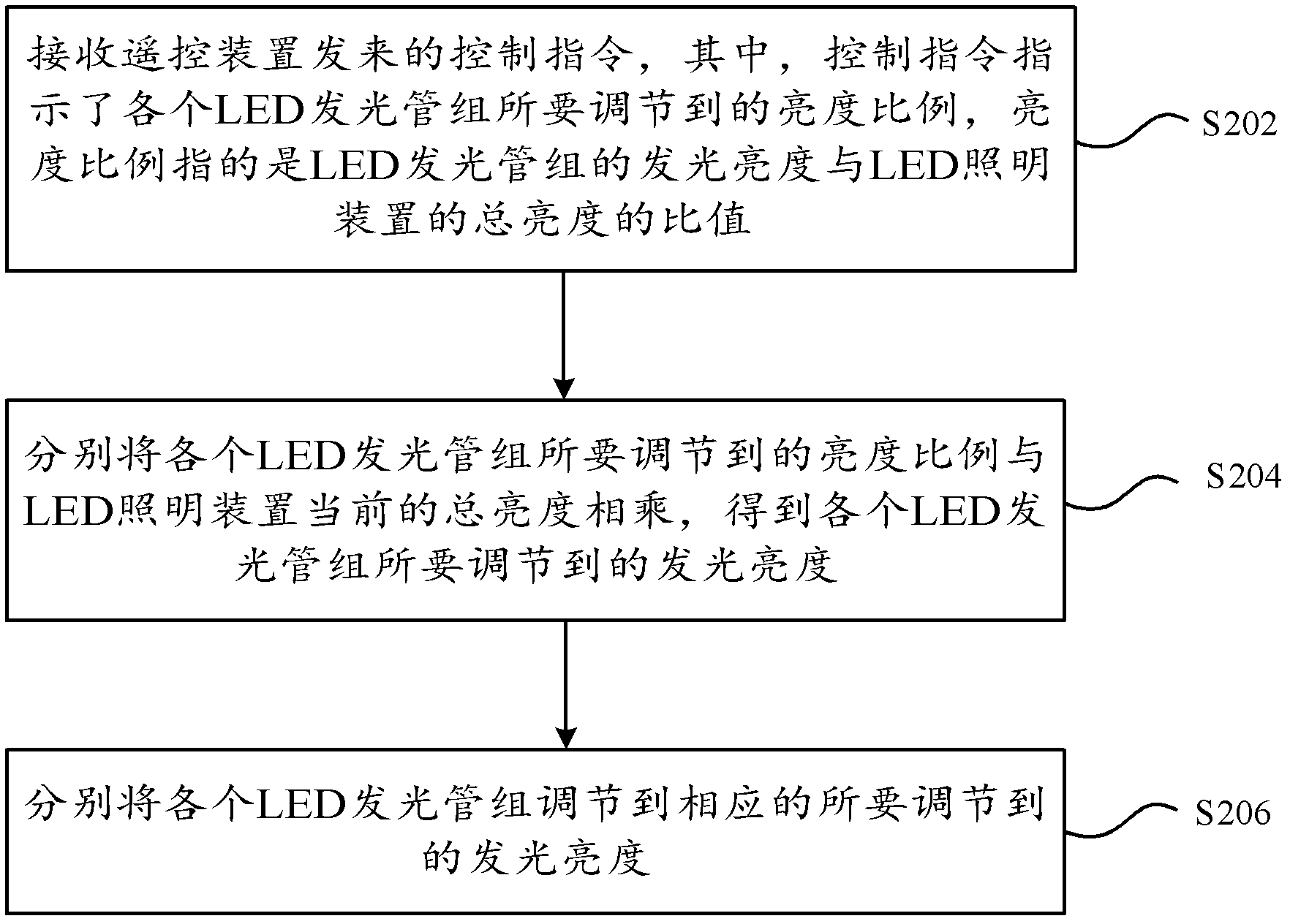

Light-emitting diode (LED) illuminating device and light regulation method thereof

ActiveCN103079305AThe brightness ratio does not changeEffect does not affectElectric light circuit arrangementRemote controlComputer science

The invention discloses a light-emitting diode (LED) illuminating device and a light regulation method thereof. The LED illuminating device comprises at least two LED luminotron sets inside. The light regulation method comprises the following steps of: receiving a control command sent by a remote control device, wherein the control command indicates total brightness to which the LED illuminating device needs to be adjusted; respectively multiplying current brightness ratios of all the LED luminotron sets and the total brightness to which the LED illuminating device needs to be adjusted to obtain brightness to which every LED luminotron set needs to be adjusted, wherein the brightness ratio refers to a specific value of the brightness of the LED luminotron sets to the total brightness of the LED illuminating device; and respectively regulating all the LED luminotron sets to the corresponding brightness to which the LED luminotron sets need to be adjusted. According to the LED illuminating device and the light regulation method thereof disclosed by the invention, an effect that colors cannot be influenced when the brightness of the LED illuminating device is adjusted is achieved, and the problem that the colors can be changed when the brightness of the LED illuminating device is adjusted in the prior art is solved.

Owner:BEIJING ITSYNC TECH

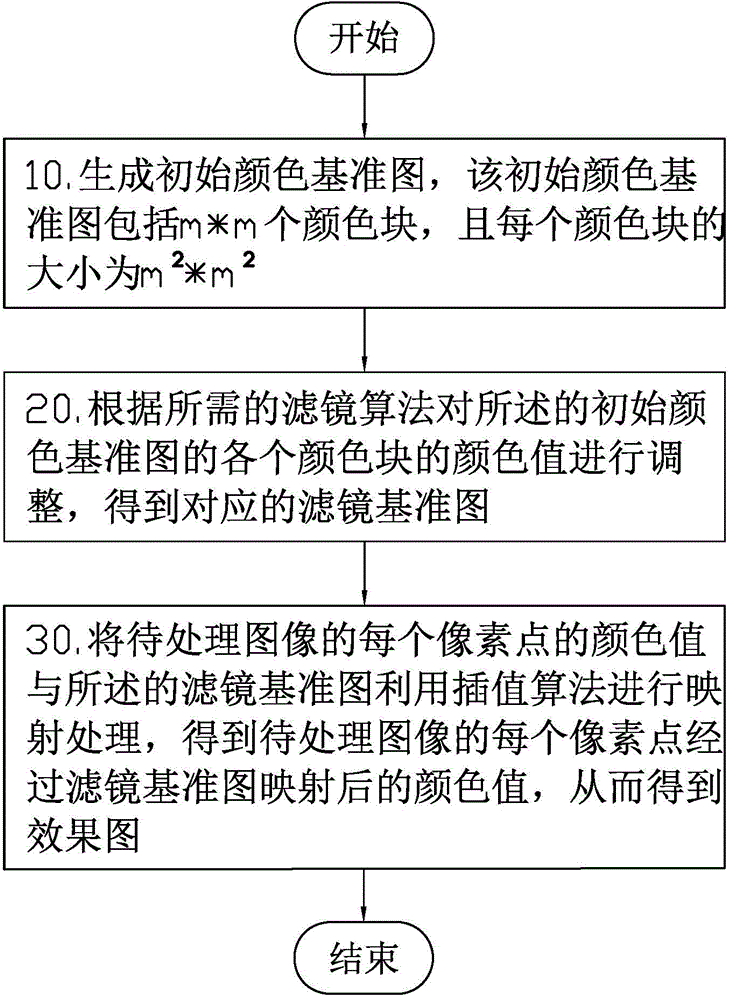

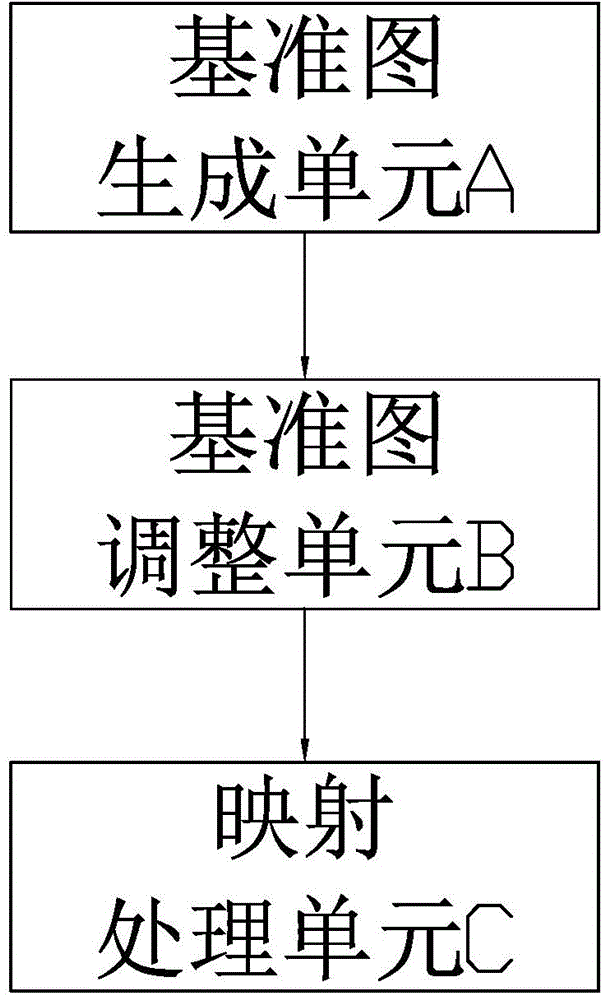

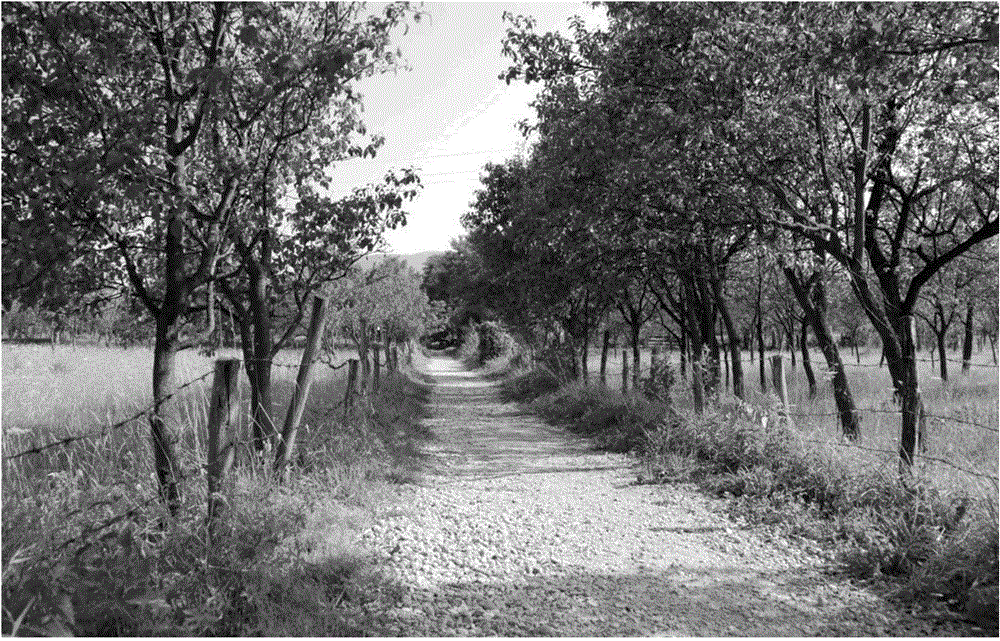

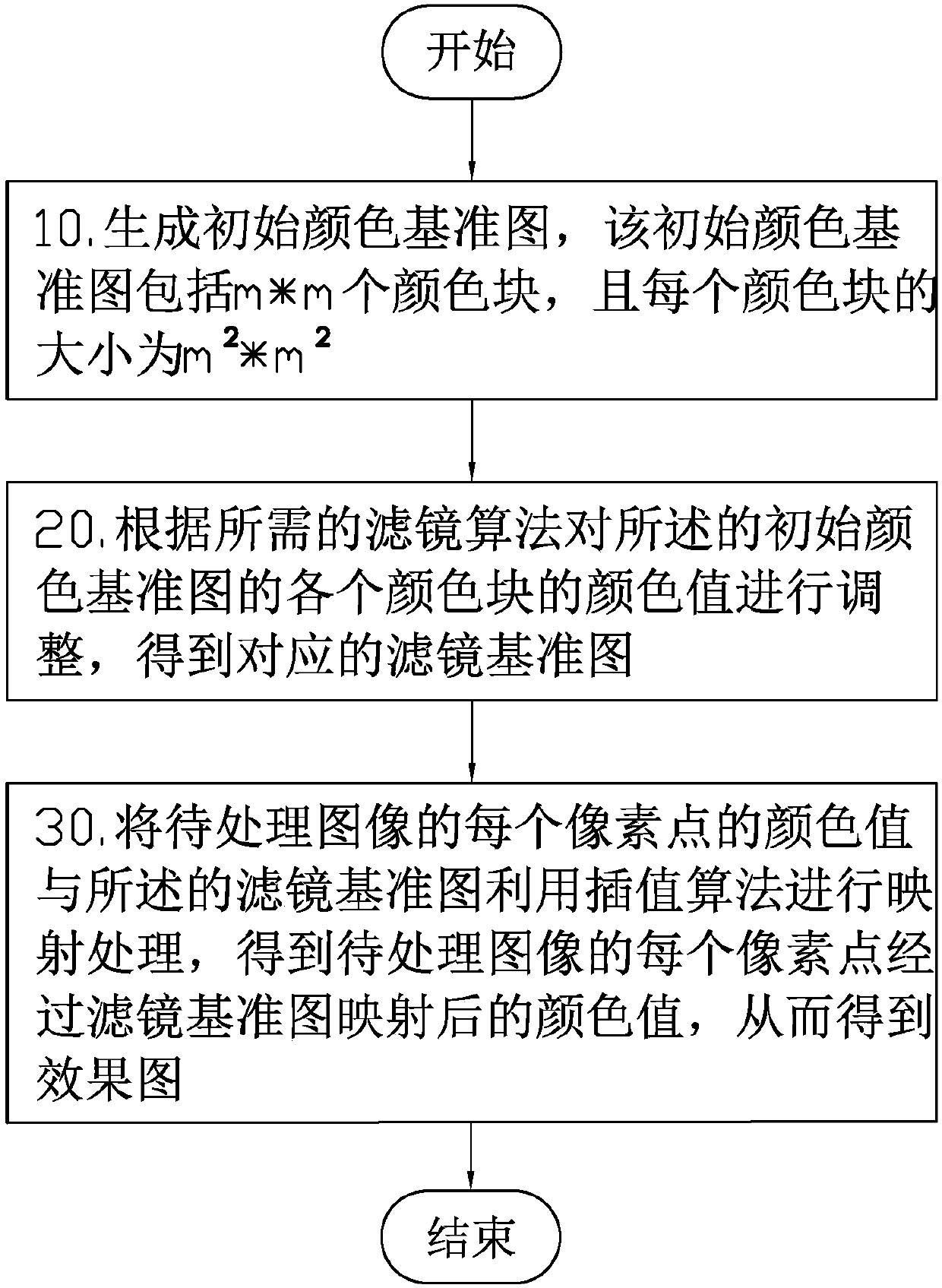

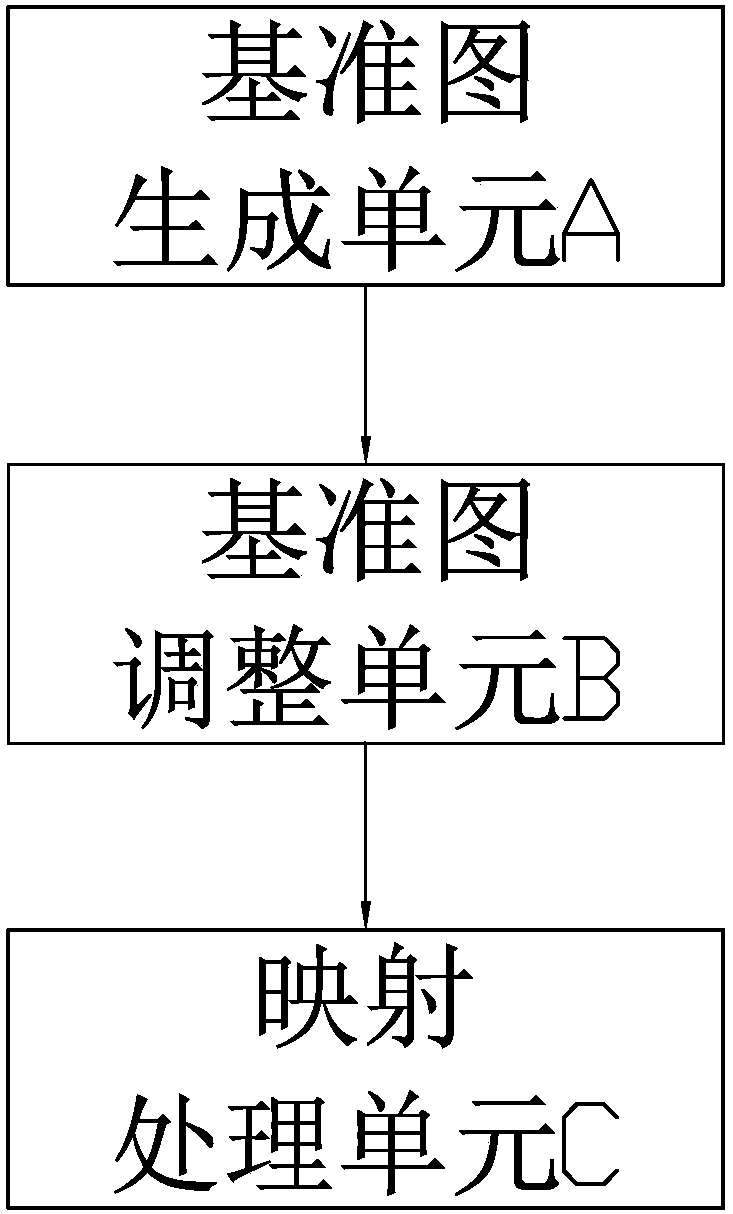

Image filtering processing method and device for quickly realizing multiple effects

The invention discloses an image filtering processing method and device for quickly realizing multiple effects. The method comprises the following steps: firstly, generating an initial color reference image which comprises m*m color blocks, and each color block is m<2>*m<2> in size, then regulating the color value of each color block of the initial color reference image according to a needed filtering algorithm to obtain a corresponding filtering reference image, and finally performing mapping treatment on the color valve of each pixel point of an image to be processed and the filtering reference image by utilizing an interpolation algorithm to obtain the color value of each pixel point of the image to be processed after mapping of the filtering reference image, so as to obtain an effect image. According to the image filtering processing method and device for quickly realizing multiple effects, the speed is high and the filtering effect is not affected; the performance improvement times is equal to the sum of algorithm steps of filtering, so that the processing time is shortened when multiple-step and big-batch processing is performed.

Owner:MEITU

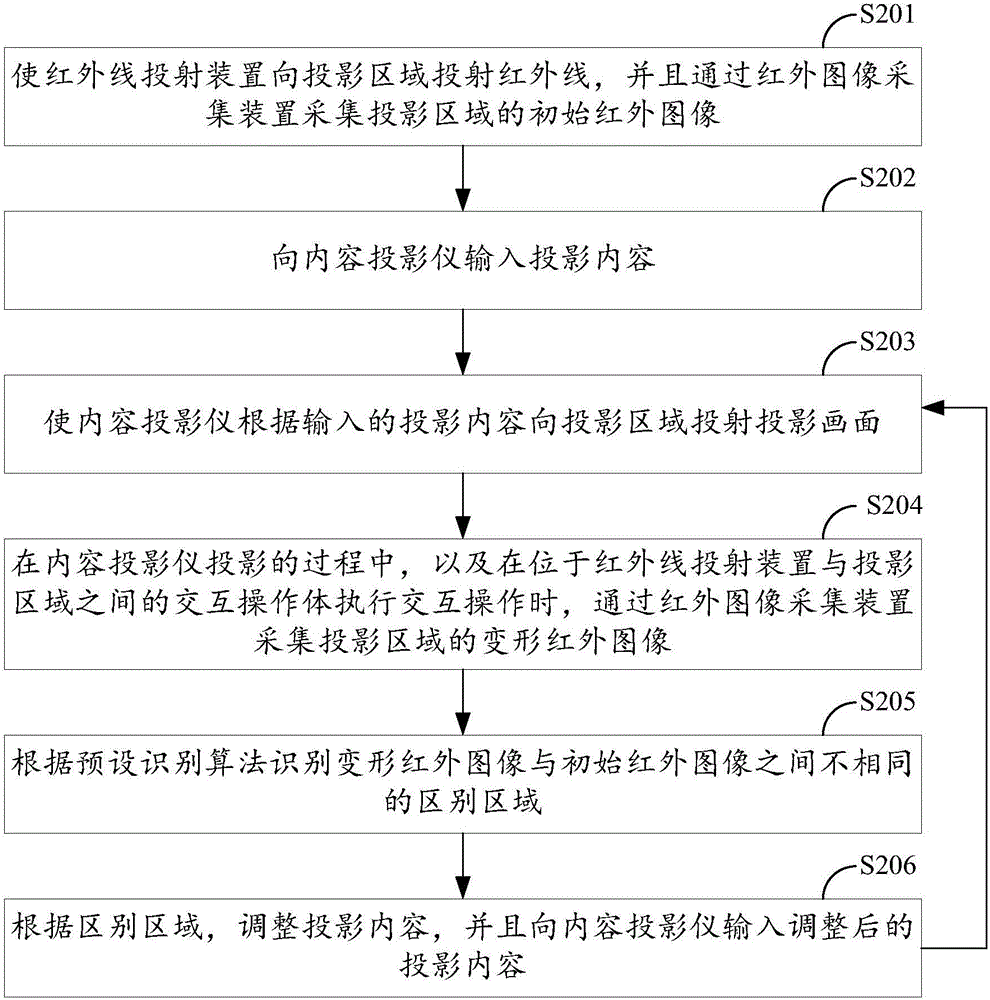

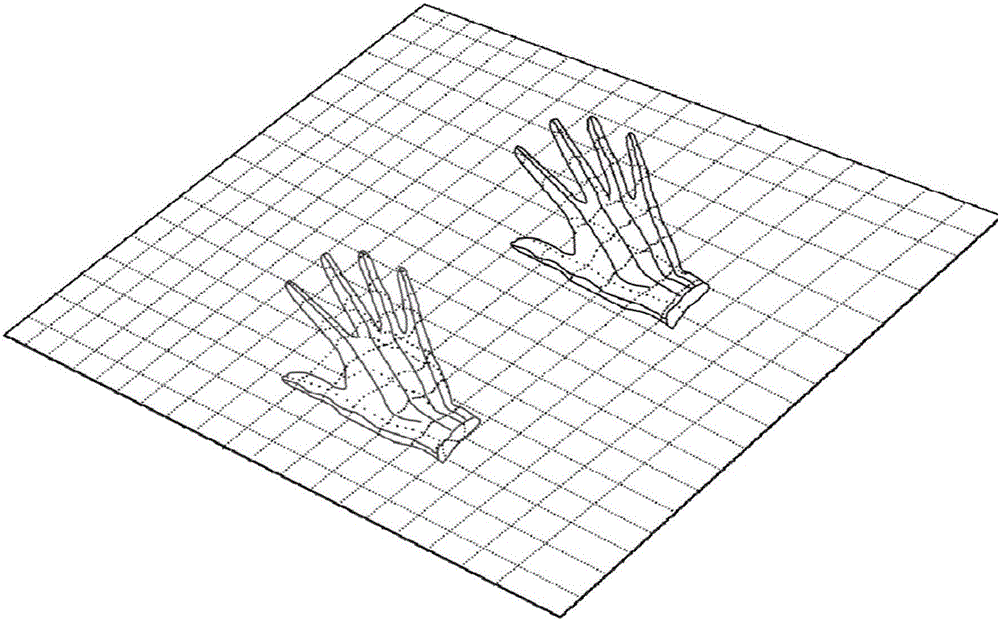

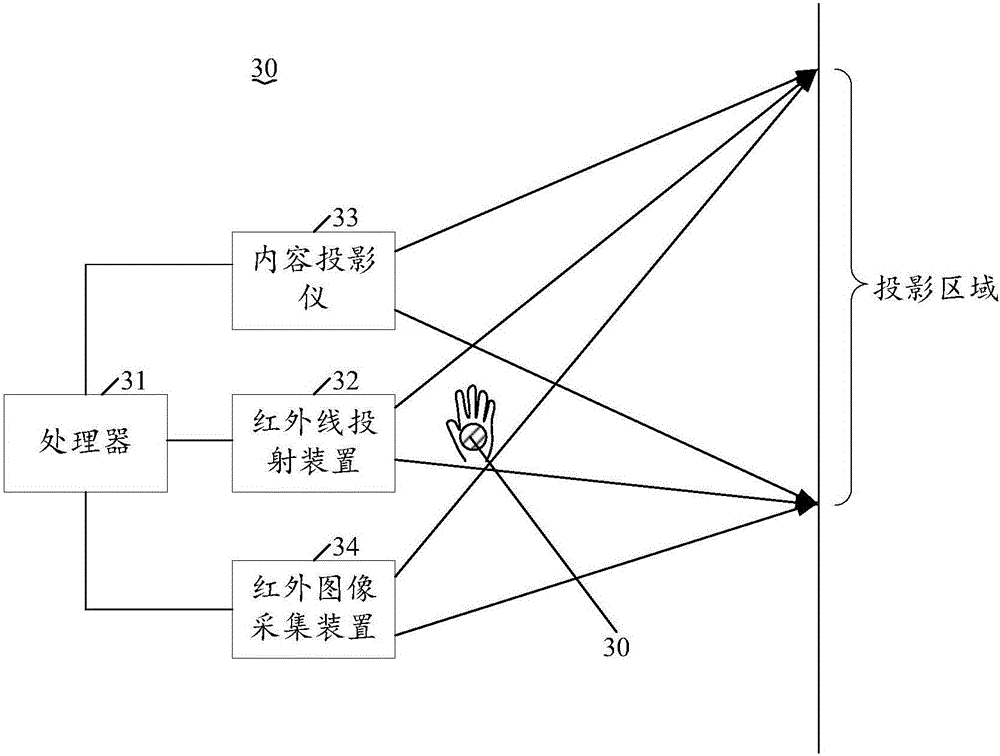

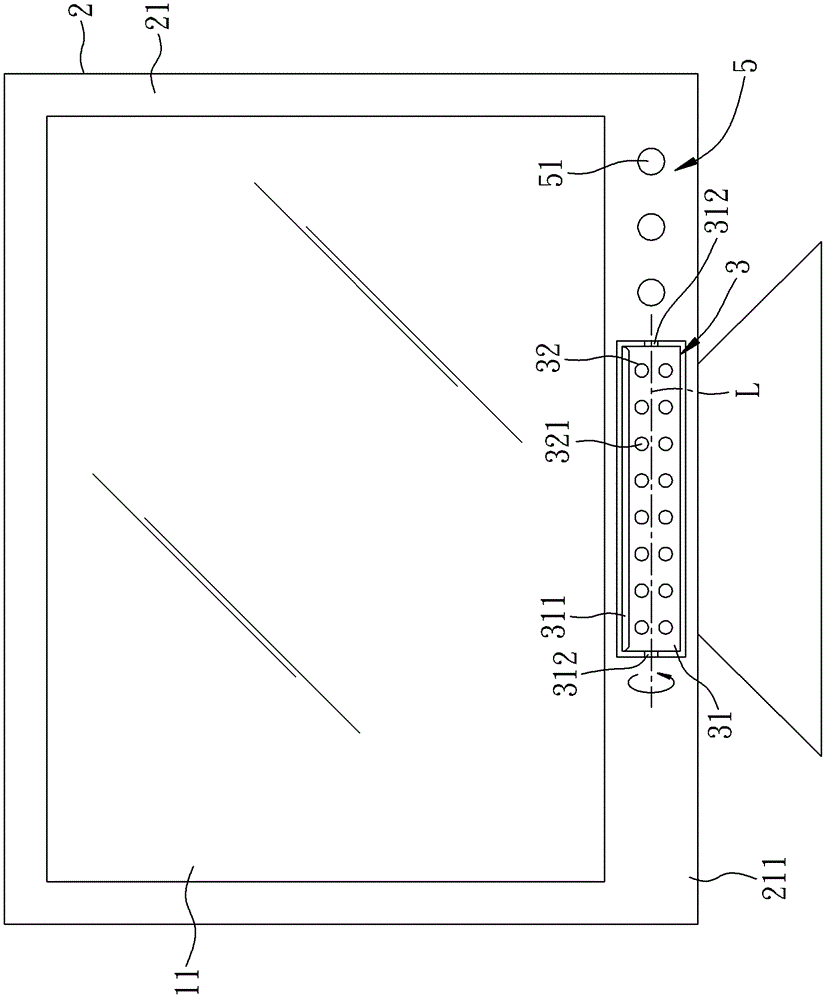

Interactive projection method and system

ActiveCN106095133AEffect does not affectImprove interoperabilityInput/output processes for data processingAcquisition apparatusProjection image

Embodiments of the invention disclose an interactive projection method and system. The method comprises the steps of enabling an infrared projection apparatus to project infrared rays to a projection region and acquiring an initial infrared image of the projection region through an infrared image acquisition apparatus; enabling a content projector to project a projection image to the projection region; acquiring a deformed infrared image of the projection region through the infrared image acquisition apparatus when an interactive operation body located between the infrared projection apparatus and the projection region performs interactive operation in the projection process of the content projector; identifying different distinguishing regions between the deformed infrared image and the initial infrared image; and adjusting projection content according to the distinguishing regions, and inputting the adjusted projection content in the content projector to enable the content projector to project the projection image to the projection region according to the input projection content. Through the embodiments of the interactive projection method and system, interactive projection can be realized, and the projection image is not shielded, so that the projection effect of the projection image is not influenced.

Owner:IVIEW DISPLAY SHENZHEN CO LTD

Waterborne copy paper and preparation method thereof

InactiveCN106087532AHigh static bending strengthReduce distortionPaper coatingPaper/cardboardFiberPolyvinyl alcohol

The invention discloses a piece of waterborne copy paper and a preparation method thereof. The waterborne copy paper is prepared from the following components in parts by weight: 20-55 parts of reed pulp, 4-9 parts of a vinylon binder, 33-66 parts of wood pulp, 1-10 parts of a dispersing agent, 10-18 parts of synthetic resin, 3-5 parts of phloem fibers, 5-25 parts of titanium dioxide, 1-7 parts of carbon black, 7-15 parts of polyvinyl alcohol, 10-13 parts of kaolin, 1-3 parts of resin glue, 1-3 parts of glycerine, 0.3-0.7 part of salinized sodium, 1-3 parts of polyvinyl acetate emulsion, 0.5-3 parts of white nano pigment pulp, 0.7-1.9 parts of a solidifying agent and 0.1-0.8 parts of a crosslinking agent. The waterborne copy paper adopts reed pulp, wood pulp and phloem fibers as main raw materials when being prepared, and the vinylon binder, titanium dioxide, the crosslinking agent and various dispersing agents are combined, so that the prepared waterborne copy paper has high bending strength, small deformation, good colour fastness and good colour saturation stability; and a protective layer is increased on a developing mixture of the paper, the copy paper can be repeatedly used for multiple times, and effect of the developing mixture cannot be influenced.

Owner:ZHEJIANG HUACHUAN IND GRP

Mixed weed killing agent with glyphosate and diguat dibromide

InactiveCN104542698AEffect does not affectPlay a synergistic roleBiocideAnimal repellantsGlyphosateToxicology

The invention relates to a mixed weed killing agent with glyphosate and diguat dibromide. The mixed weed killing agent is compounded by the following raw materials by weight percent: 1-99.99% of glyphosate and 0.01-99% of diguat dibromide. The mixed weed killing agent is compounded by screening the diguat dibromide and the glyphosate; the diguat dibromide has the contact-poisoning action, but the contact-poisoning action can not hinder the absorption of the glyphosate by leaves, not only is the effect of the glyphosate not influenced, but also the synergistic effect is achieved for the effect of the glyphosate, the weed killing time can be shortened for 3-10 days, and the cost of the pesticides is reduced by 10%, so that the mixed weed killing agent has the characteristics of economy and high efficiency.

Owner:JIANGXI NEW DRAGON BIOTECH

Preparation method of biodiesel composite additive

ActiveCN103642543ALower freezing temperatureGood fluidity at low temperatureLiquid carbonaceous fuelsBiodieselOil additive

The invention belongs to the field of fuel oil additives and in particular relates to a preparation method of a biodiesel composite additive. The preparation method of the biodiesel composite additive comprises the following steps: adding dodecyl methacrylate, steary methacrylate, isooctyl nitrate and dicthyl ortho-phthalate into a raw material mixing tank and stirring evenly; adding maleic anhydride and isooctanol and stirring evenly; and then adding tert-butylamine and double hexadecyl dimethyl ammonium chloride and stirring for 30-35 minutes; adding polyoxyethylene hexadecy phenolic ether and phenyl propargyl ether into a solution, heating to 45-50 DEG C, stirring for 20-30 minutes at 0.5-1.0MP, standing for 24 hours and filtering to remove sediment. The biodiesel composite additive prepared by the preparation method is good in cold filtering point reducing effect; and meanwhile, the problem of reversion of the cold filtering point can be avoided; the effects of other diesel additives are not influenced; and the biodiesel composite additive is efficient and stable in dispersion capability and good in oil solubility.

Owner:临沂星火知识产权服务有限公司

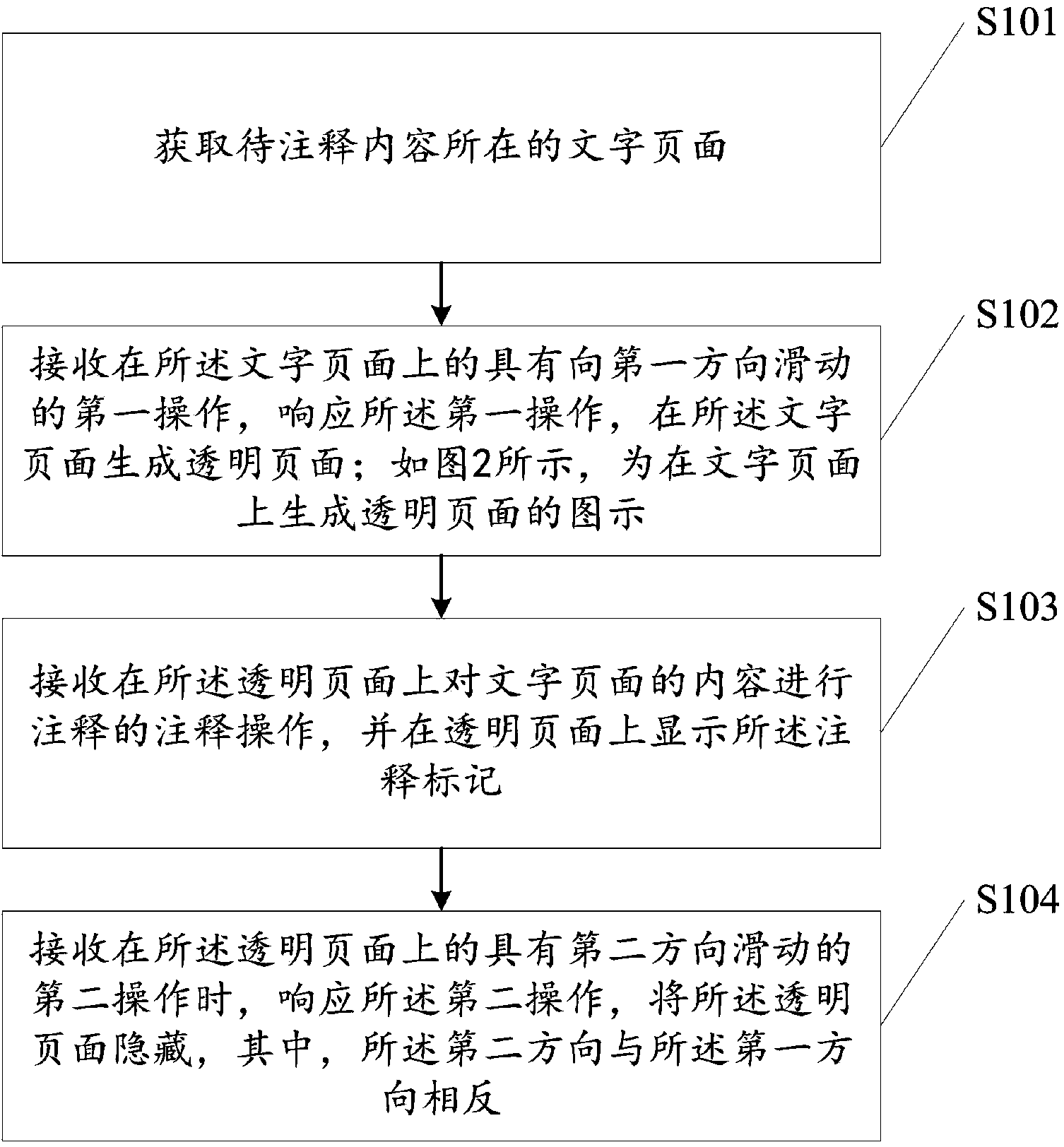

Method for annotating electronic book content

InactiveCN104391834AAnnotation effect influenceEffectSpecial data processing applicationsElectronic bookWorld Wide Web

The invention relates to the technical field of electronic book page design, in particular to a method for annotating electronic book content. The method comprises steps as follows: a text page where to-be-annotated content is located is acquired; first operation sliding in a first direction on the text page is received and responded, and a transparent page is generated on the text page; annotating operation for annotating content of the text page on the transparent page is received, and annotation marks are displayed on the transparent page; and when second operation sliding in a second direction on the transparent page is received, the second operation is responded, and the transparent page is hidden, wherein the second direction is opposite to the first direction. The technical problem that the reading effect when a user reads an electronic book is affected by the annotation effect provided by the electronic book in the prior art is solved, and the electronic book can be effectively annotated while the electronic book reading effect of the user is not influenced.

Owner:CHENGDU MINGRI XINGCHEN SCI & TECH CO LTD

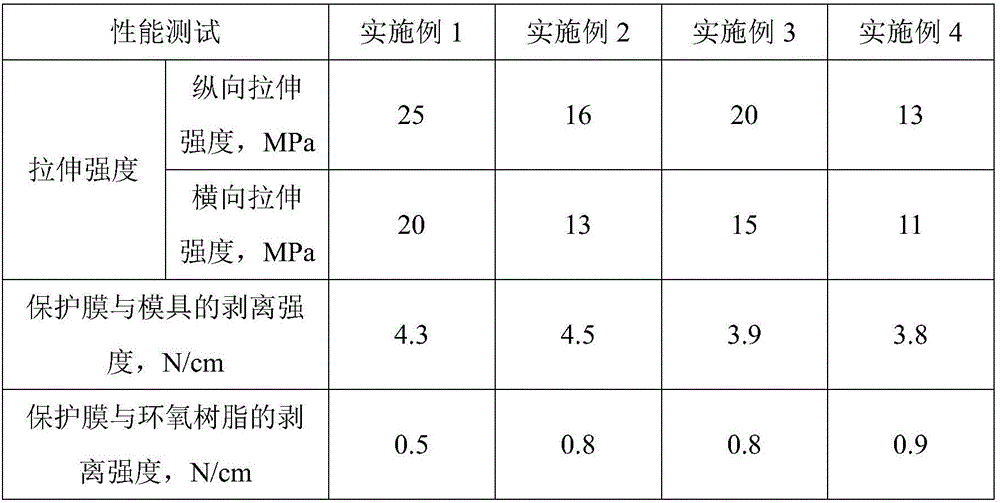

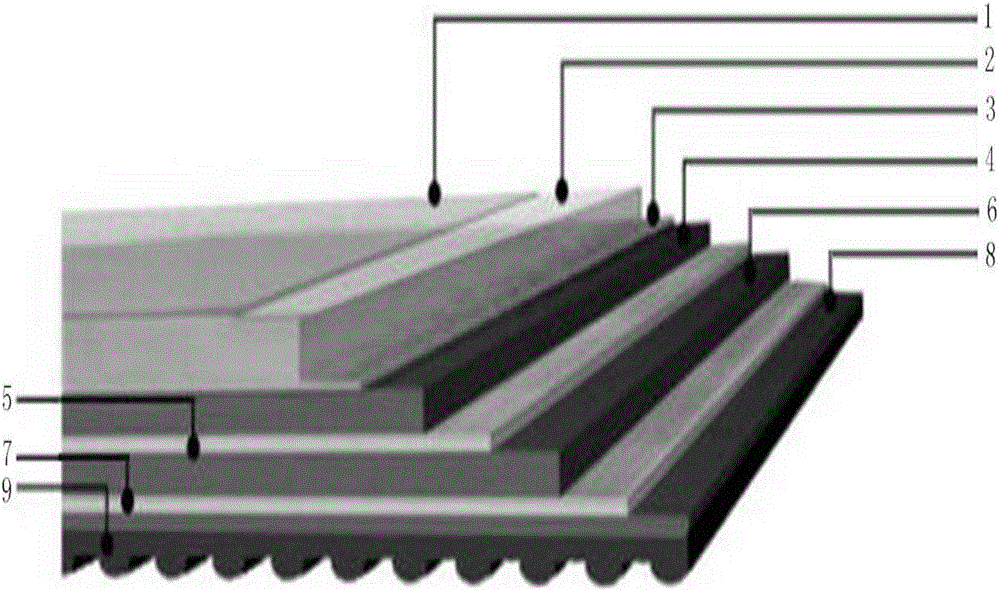

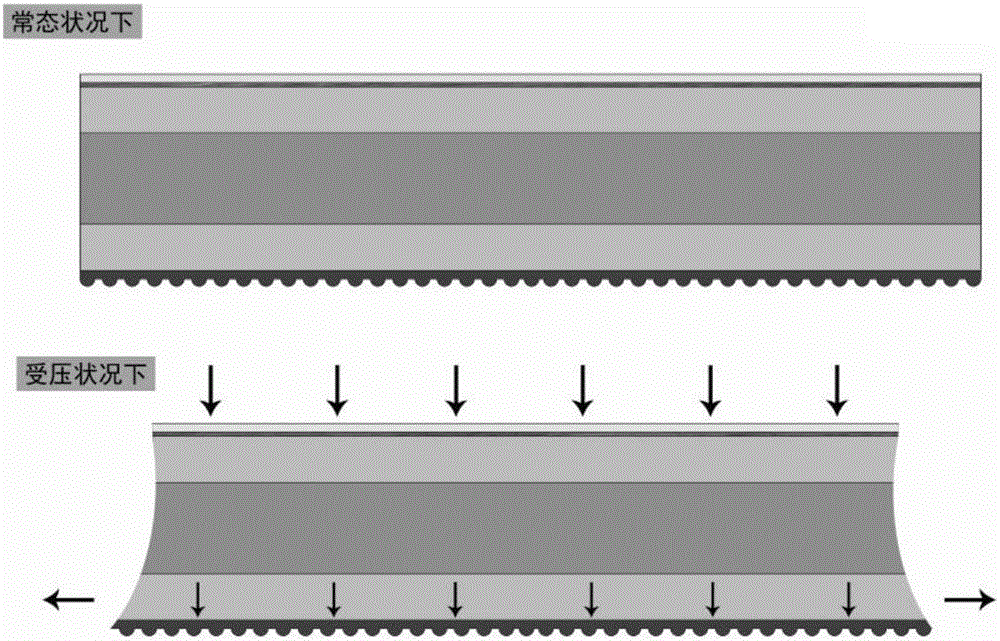

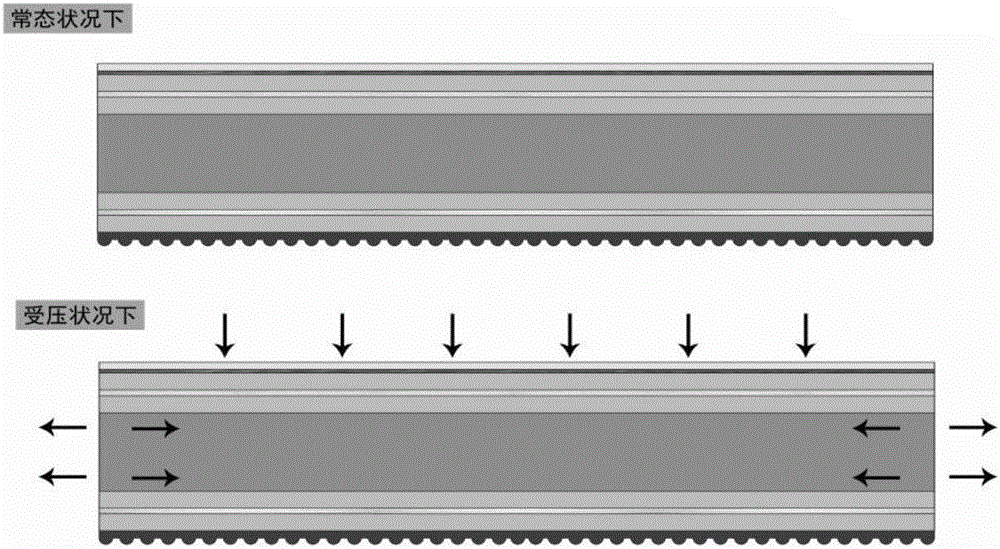

Large hook face die surface protection film

ActiveCN106515164AAvoid air pocketsImprove wear resistanceSynthetic resin layered productsLaminationPressure sensitiveMesh grid

The invention provides a large hook face die surface protection film. The large hook face die surface protection film sequentially comprises a gridding cloth air guiding layer, a pressure-sensitive adhesive self-adhesion layer and a macromolecule functional layer from the position closely attached to the surface of a die to the exterior. The macromolecule functional layer does not adhere to cured epoxy resin.

Owner:TECHSTORM MATERIAL TECH SHANGHAI CO LTD

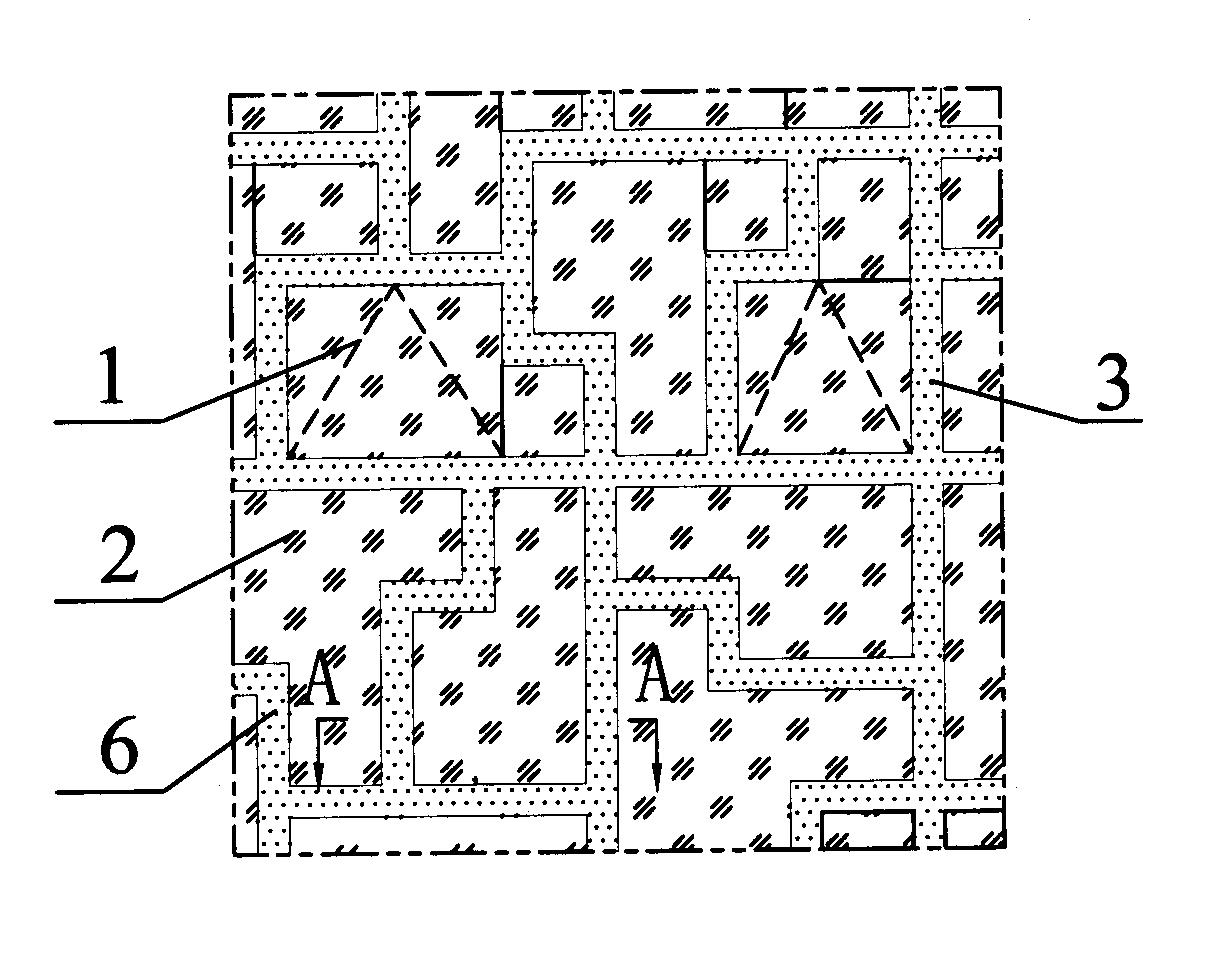

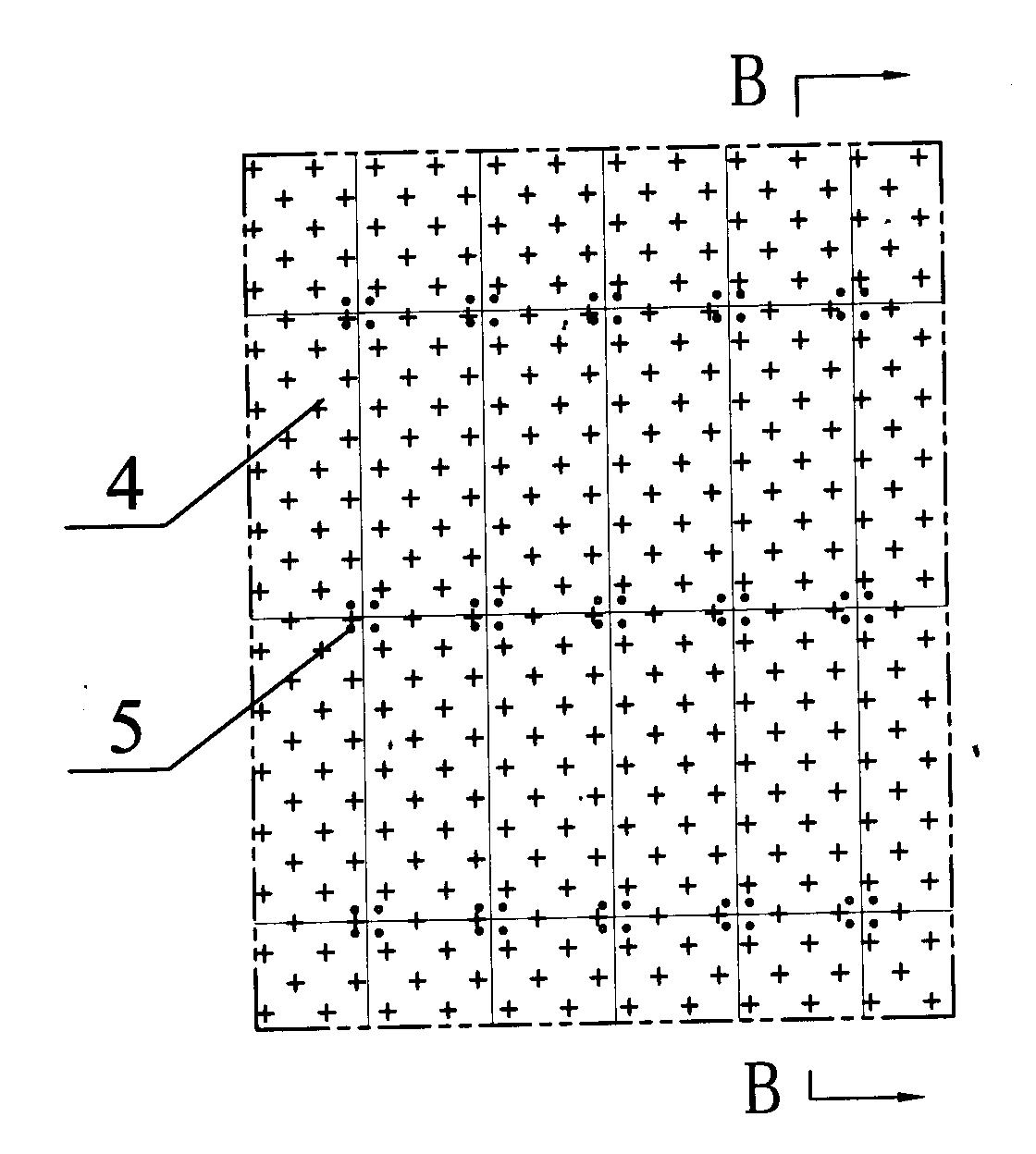

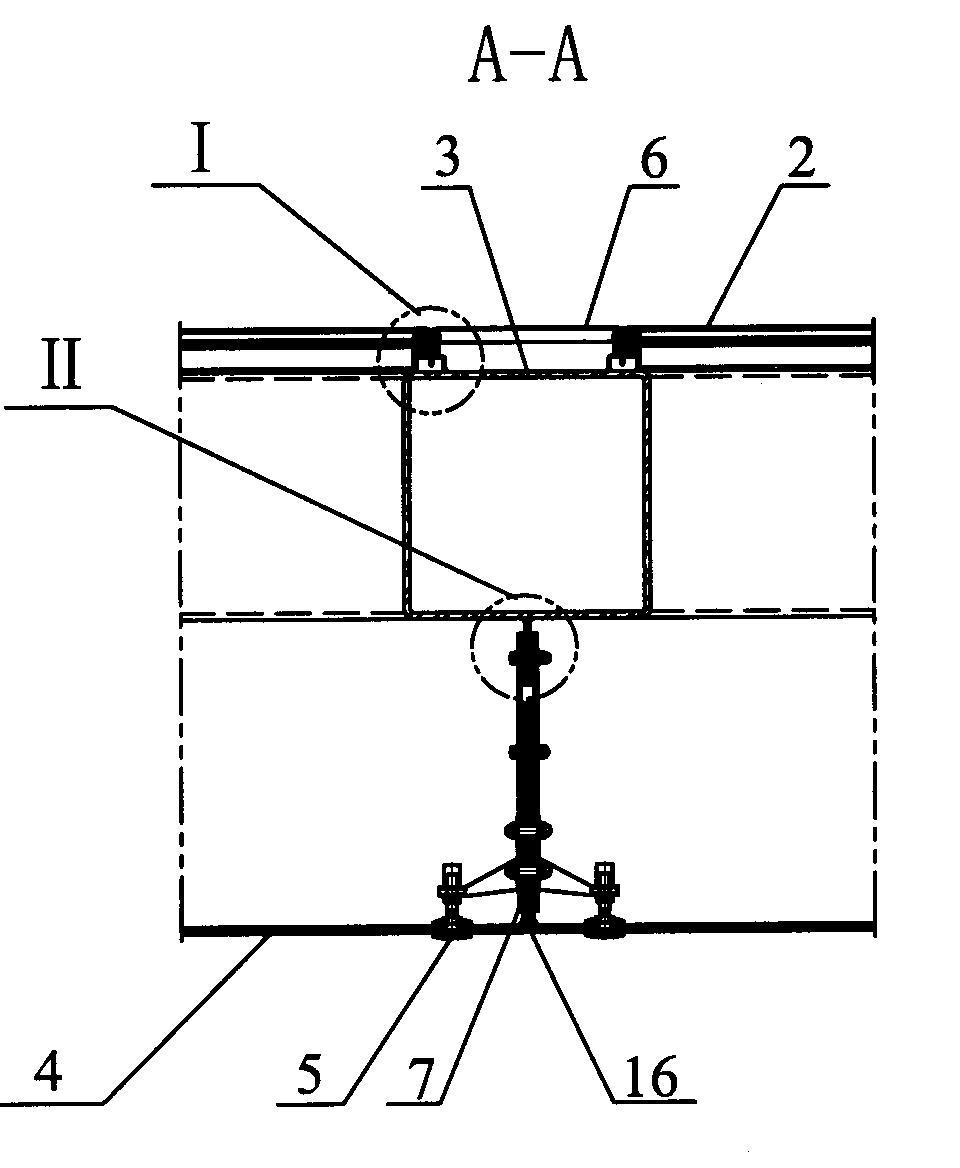

Structure-balancing movable environment-friendly floor and installation method thereof

InactiveCN106223570AEasy to installStructural balance and symmetrySynthetic resin layered productsConstructions elementsEngineeringMiddle line

The invention relates to the technical field of floor installation and in particular relates to a structure-balancing movable environment-friendly floor and an installation method thereof. The installation method comprises the following steps: after base course treatment, repair and polishing, drawing a cross position line with the center lines of the long sides of the site as the criterion, shifting the cross line according to the floor size and the single side length of the cross position line and computing the trimming size; snapping grid lines based on the shifted cross line and the material size, pasting a fixed sticker on each cross point or spreading the whole fixed sticker on the whole cross line and then beginning laying a first floor from the cross point of a cross center line, wherein the four sides of the floor cling to the right-angle sides of the grid lines; laying floors in sequence in contrast to the grid lines, wherein the floors have to cling to each other and lines on the floors have to be aligned; pasting double sided adhesive tapes close to the wall sides around a room for reinforcement; beginning trimming after laying is completed, wherein 1-2mm gaps are reserved between the trimmed floors and the walls; rolling the positions on which the adhesive tapes are pasted by using row rollers after floor laying is completed. The installation method has the effect that the installation and construction levels and work efficiency of raised floors can be greatly improved.

Owner:ARMSTRONG (CHINA) INVESTMENT CO LTD

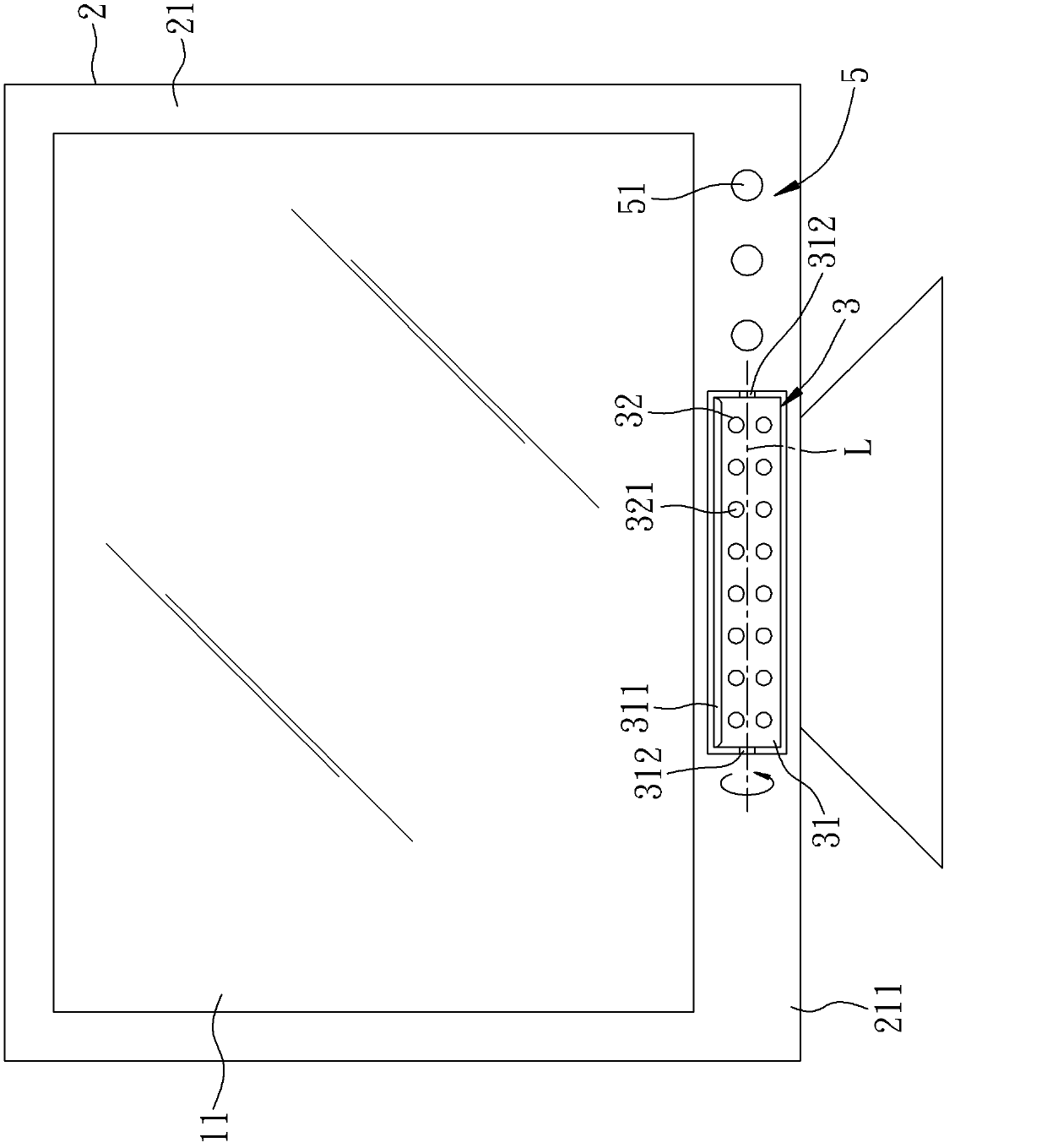

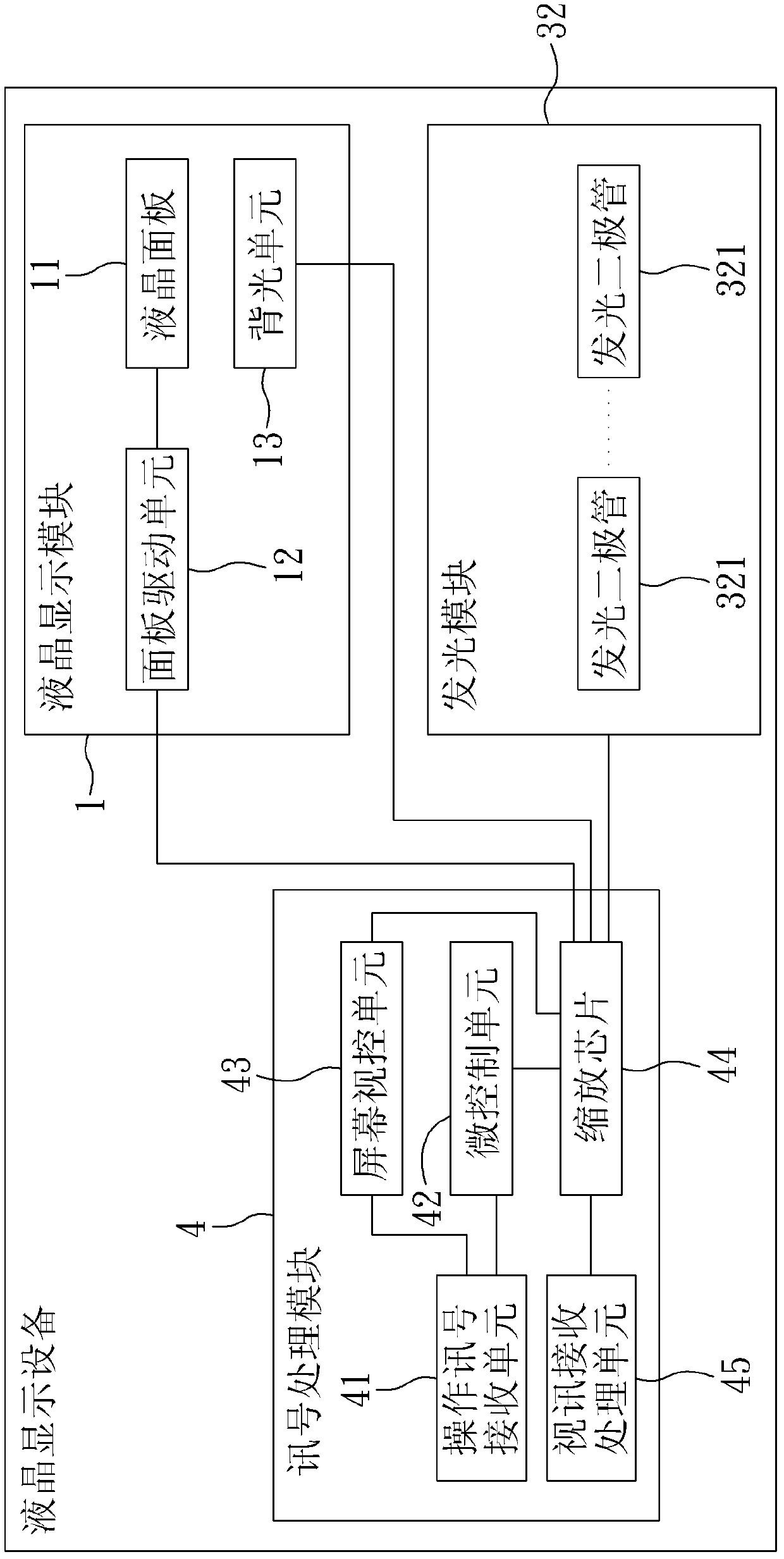

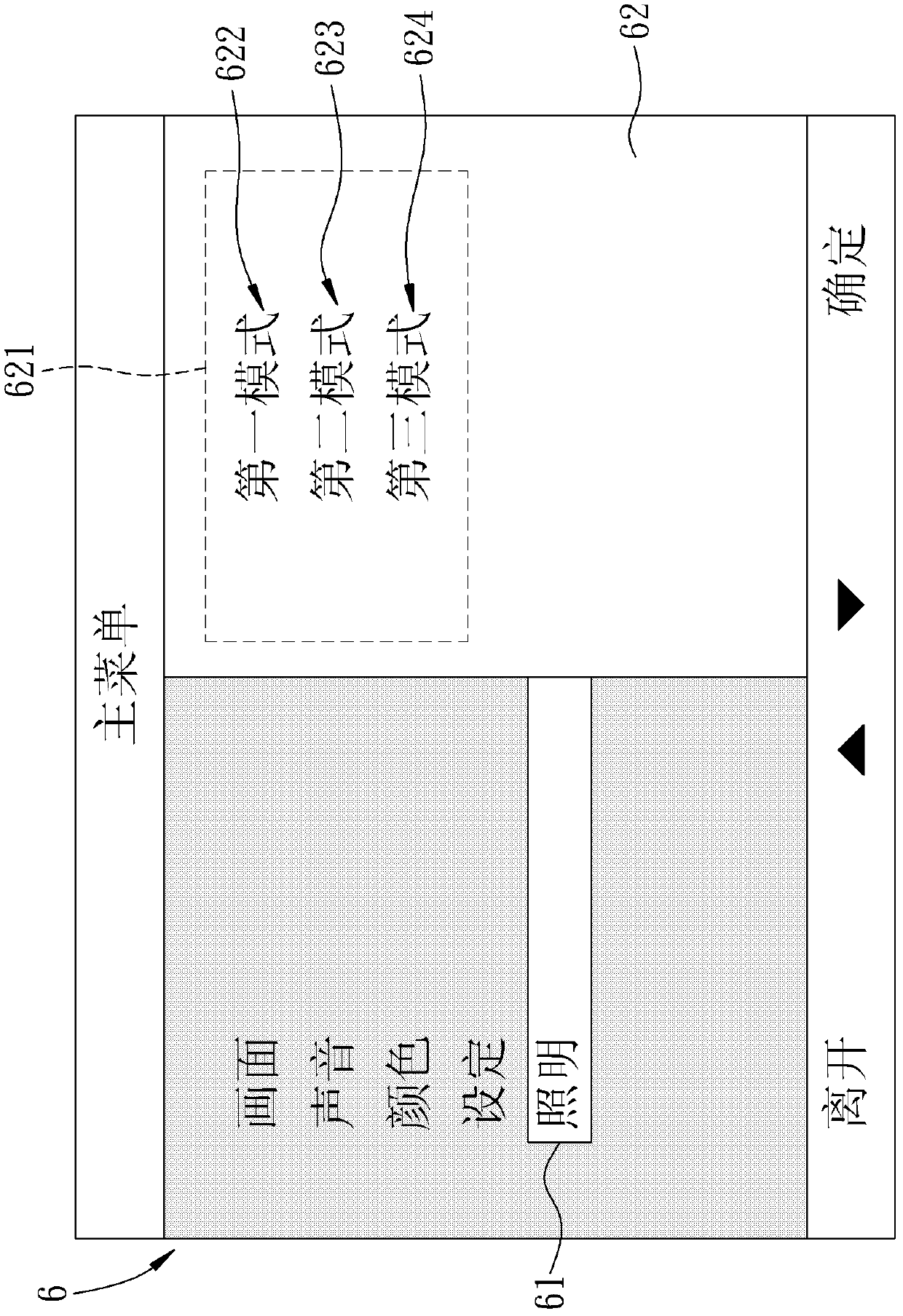

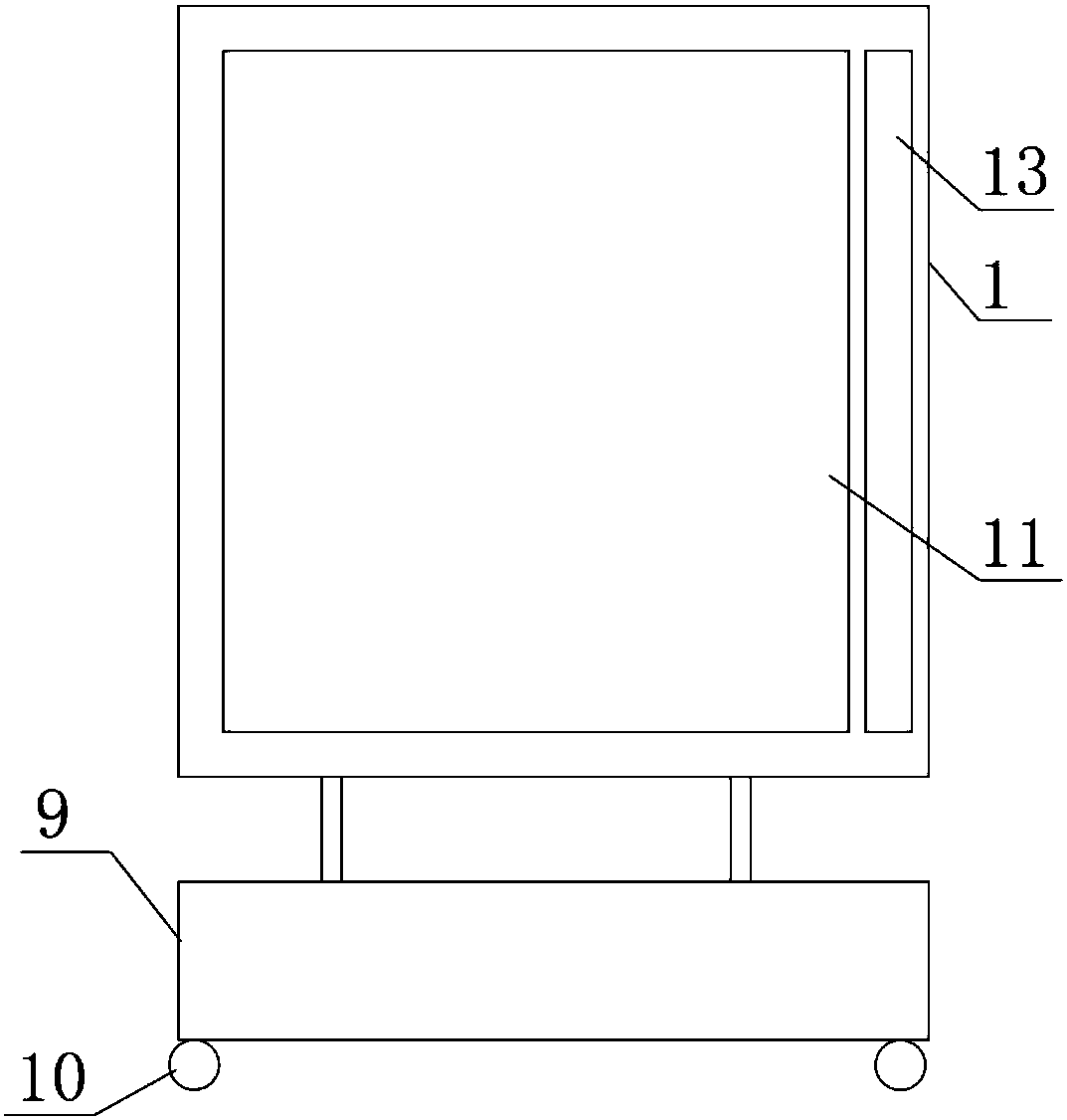

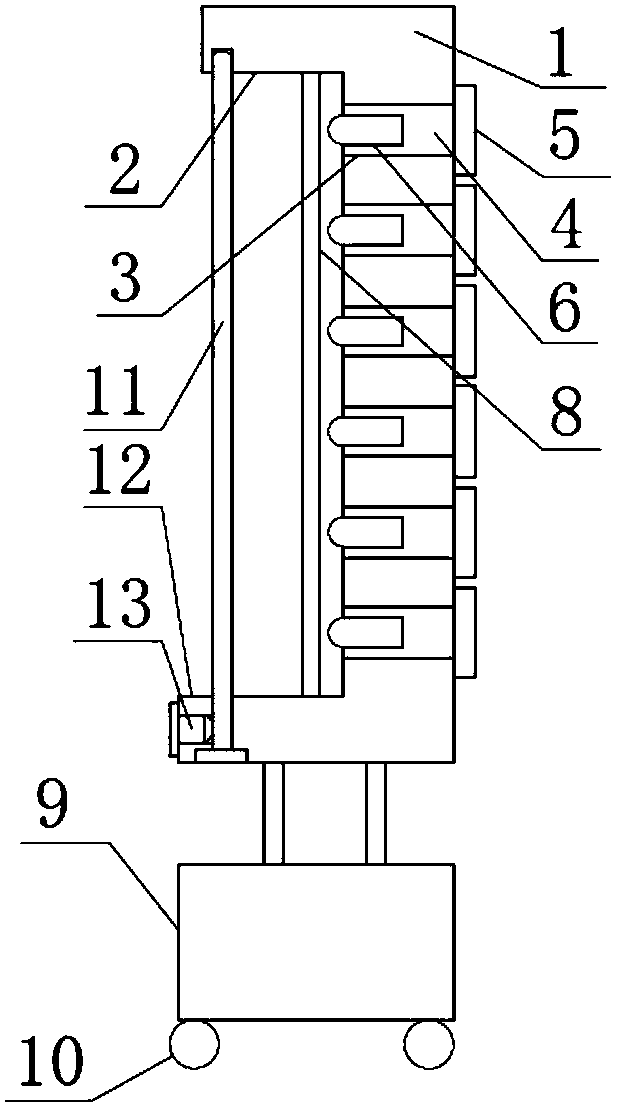

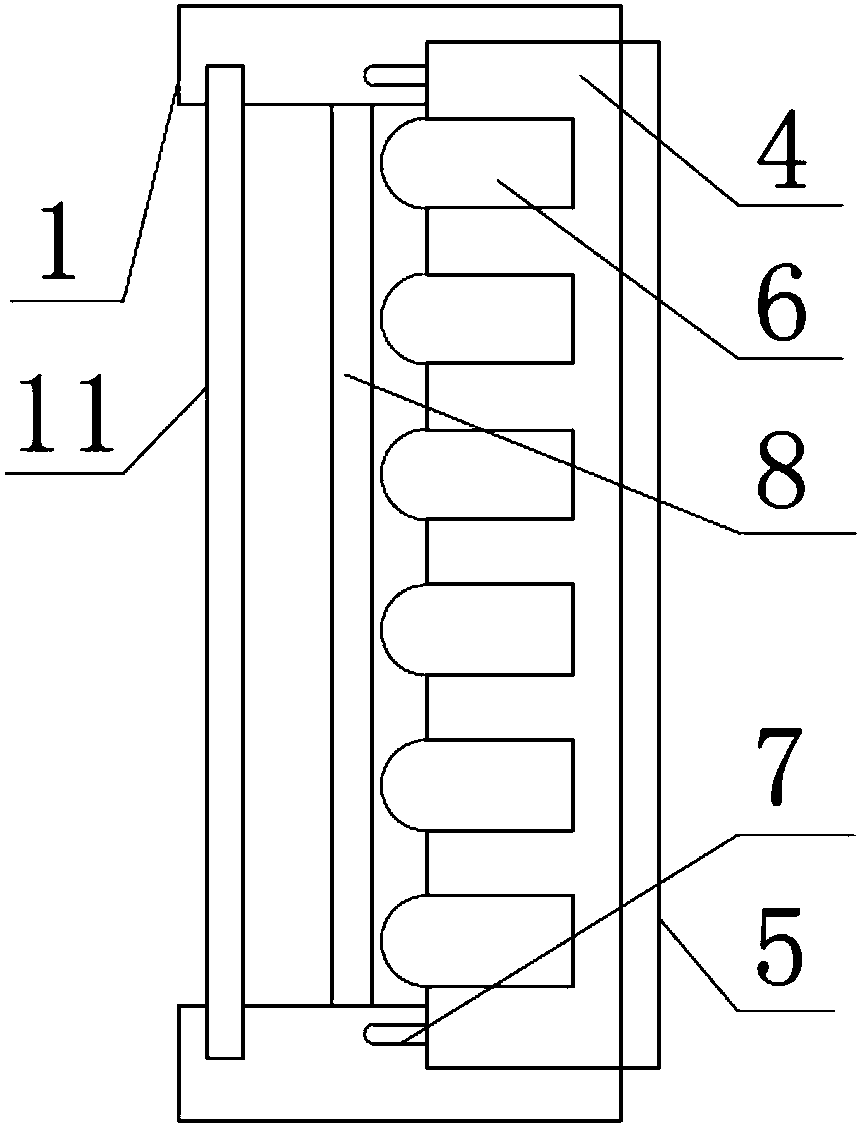

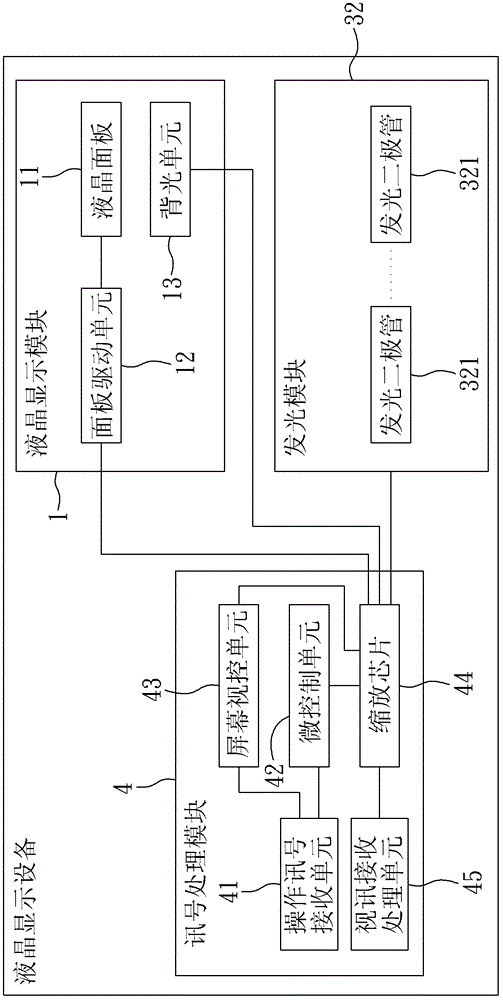

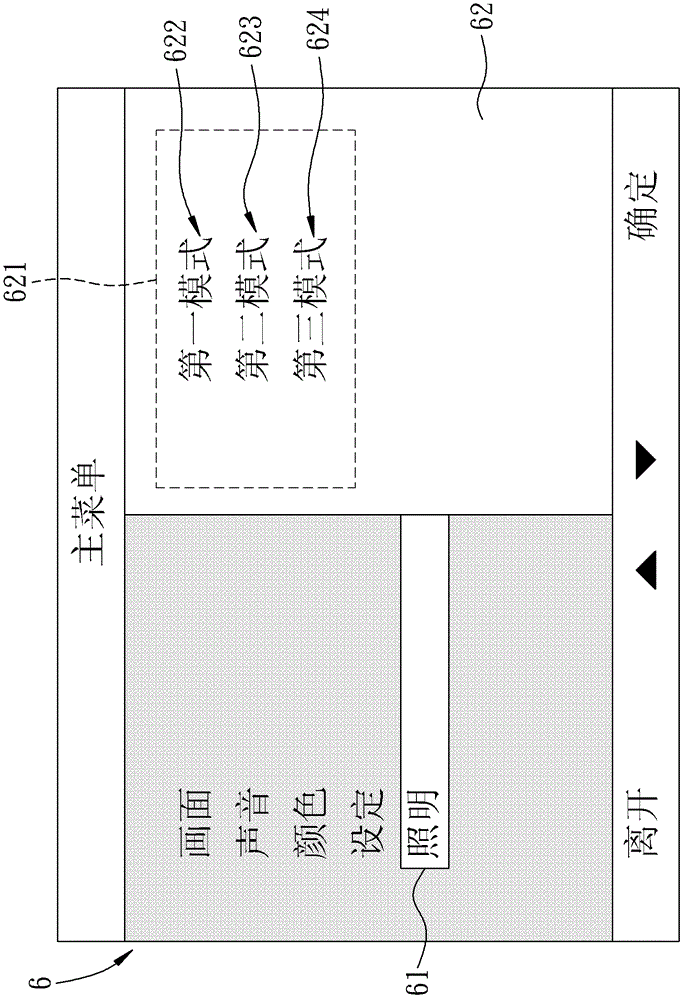

Liquid crystal display equipment with illuminating function

InactiveCN103309061AWith lighting functionAvoid spreadingPoint-like light sourceStatic indicating devicesLiquid-crystal displayControl signal

The invention discloses liquid crystal display equipment with an illuminating function. The liquid crystal display equipment comprises a liquid crystal display module, a body, an illuminating device and a signal processing module, wherein the liquid crystal display module comprises a liquid crystal panel and a backlight unit; the body comprises a border surrounding the liquid crystal panel; the border is provided with a lower frame part positioned below the liquid crystal panel; the illuminating device is arranged on the lower frame part, and comprises a lamp holder and a light-emitting module arranged on the lamp holder; the lamp holder is provided with a shielding unit positioned between the light-emitting module and the liquid crystal panel; the shielding unit is used for preventing light rays emitted by the light-emitting module from being transmitted towards the liquid crystal panel; and the signal processing module is used for transmitting a plurality of control signals to the backlight unit and the light-emitting module so as to control the backlight unit and the light-emitting module to emit light or not.

Owner:TOP VICTORY INVESTMENTS

Science and technology information display window

The invention discloses a science and technology information display window. The display window comprises a display window main body, an information releasing cavity is formed in the front surface ofthe display window main body, and grooves are formed in one side wall of the information releasing cavity. The sides, away from the information releasing cavity, of the grooves penetrate through the side wall of the display window main body. Openings of the sides, away from the information releasing cavity, of the grooves are formed in the back surface of the display window main body. Fixing columns are arranged in the grooves, back plates are arranged at one ends of the fixing columns and located on the back surface of the display window main body, and LED luminous bodies are arranged at theother ends of the fixing columns and located in the information releasing cavity. Through arrangement of the back plates on the display window main body and the LED luminous bodies parallelly arrangedon the back plates, the maintenance and replacement of the LED luminous bodies can be performed without affecting the information effect, so that the working time of the display window is saved, andthe working efficiency of the display window is improved.

Owner:大连率为环保科技有限公司

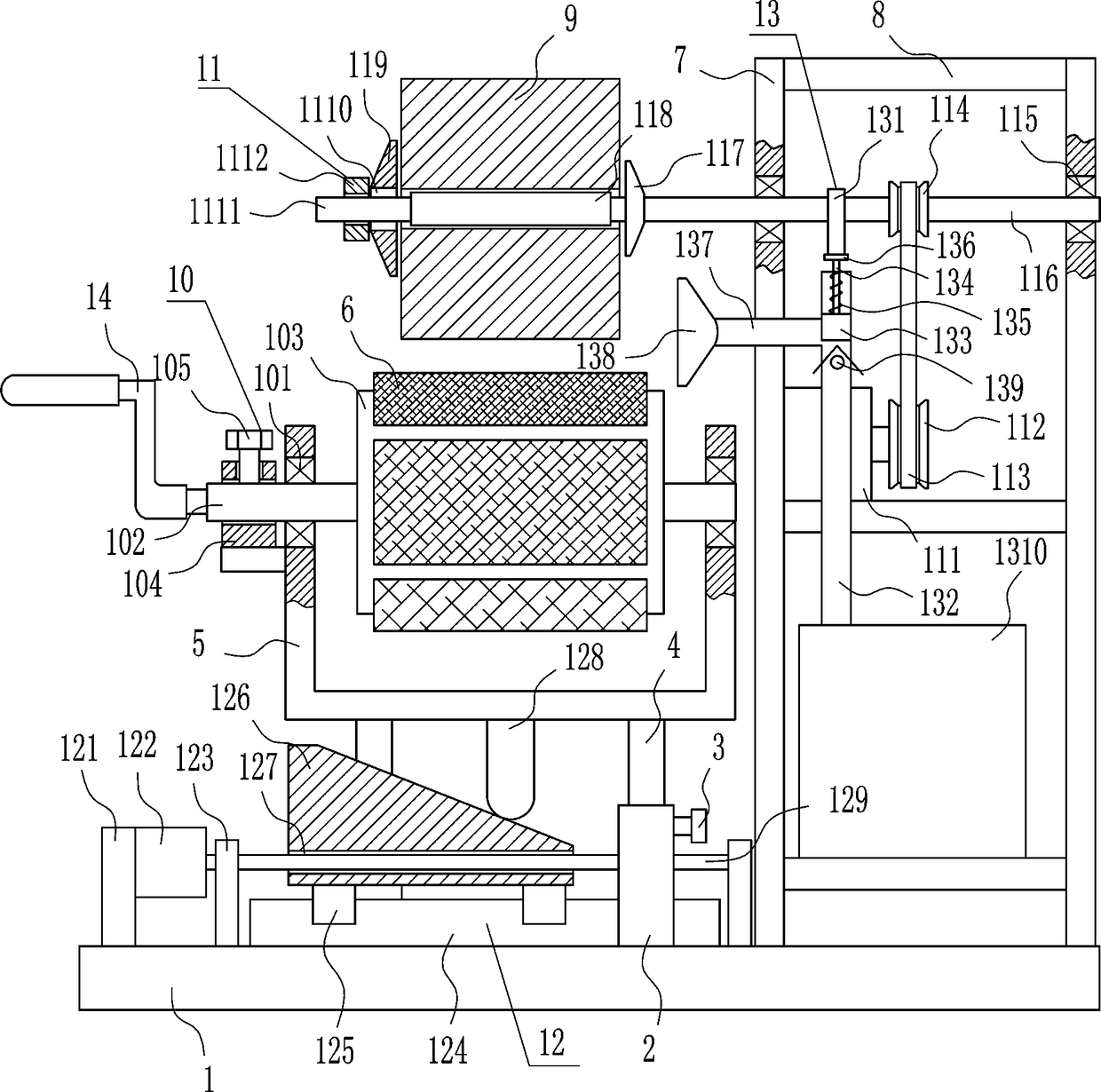

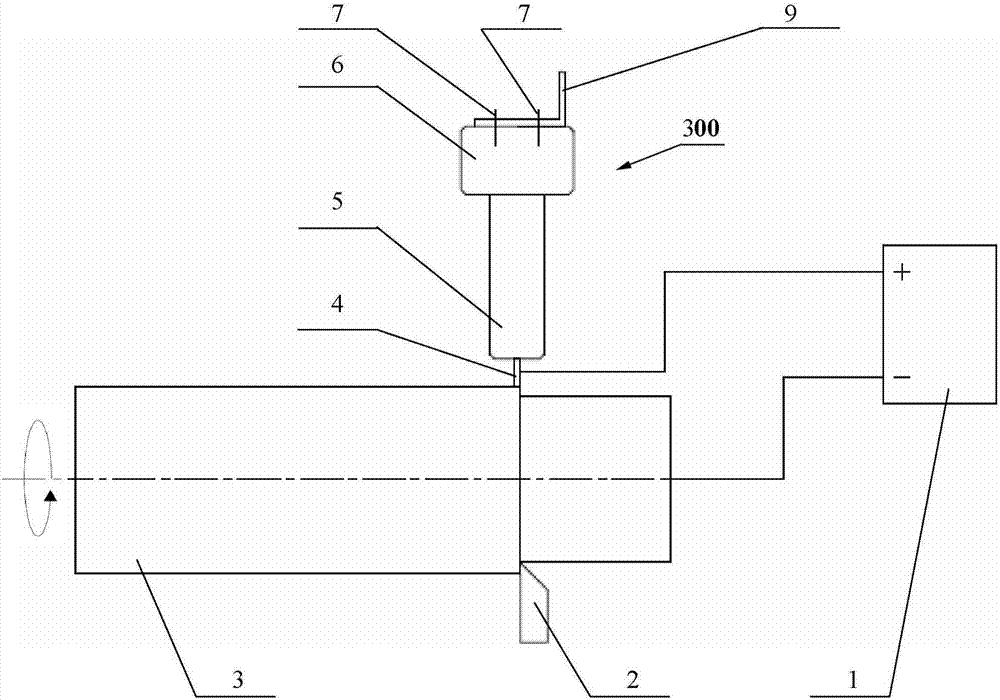

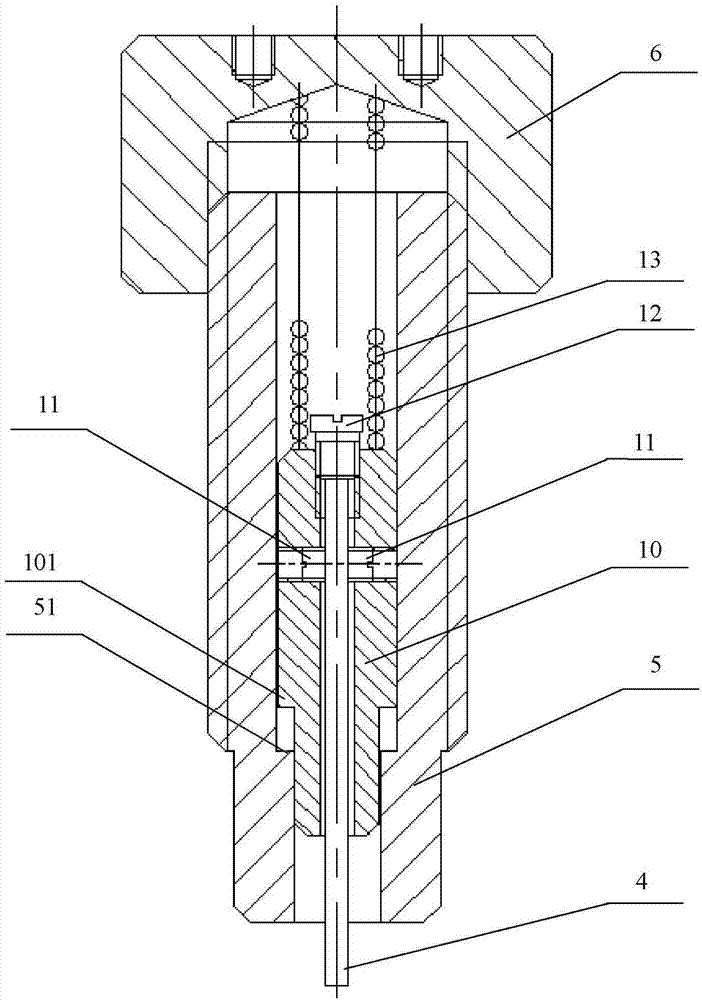

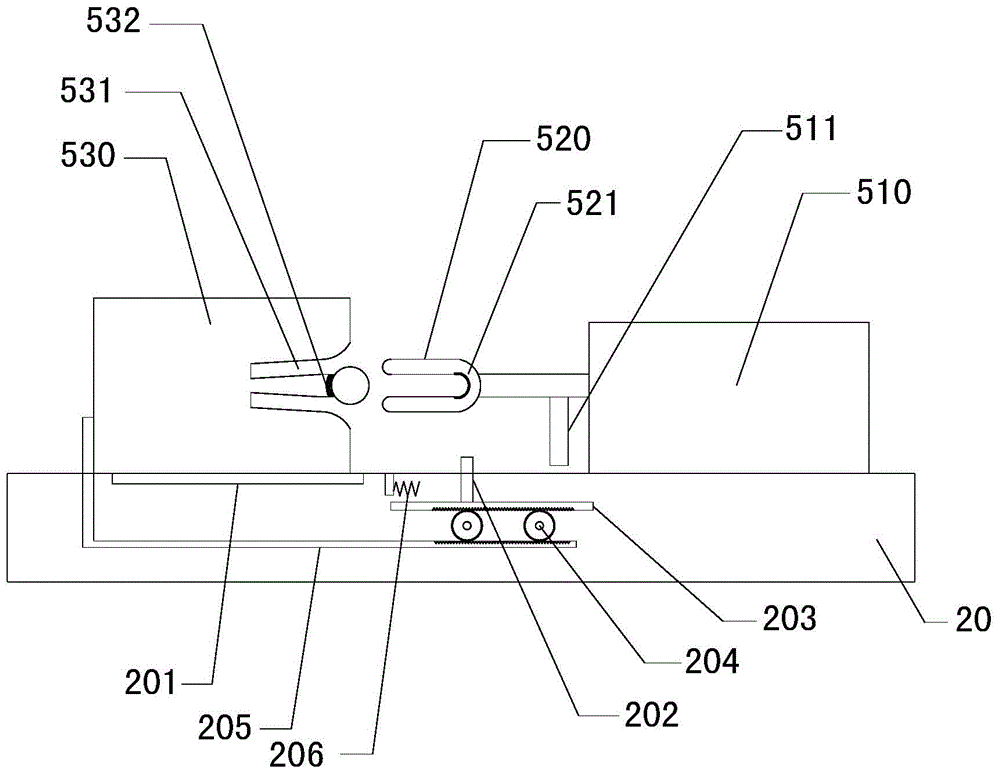

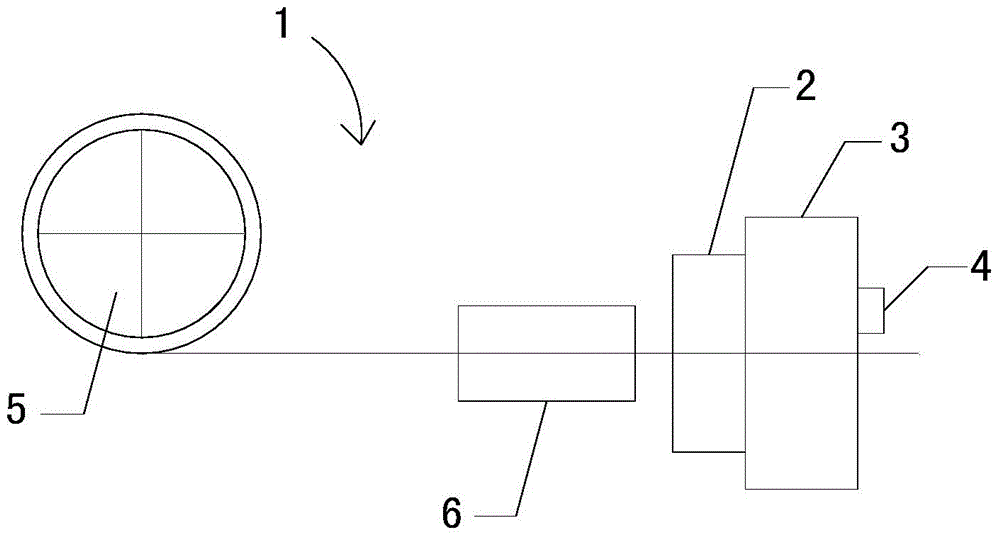

Turning machining device

ActiveCN107020427AImprove processing performanceReduce forceProcess efficiency improvementEngineeringPulse processing

The invention provides a turning machining device used for a machine tool. The turning machining device comprises an online electric pulse processing device used for performing electric pulse processing on a to-be-machined region of a workpiece to improve the machining performance of the to-be-machined region, the online electric pulse processing device comprises a pulse power supply and an electrode, the pulse power supply comprises a positive electrode and a negative electrode, one of the positive electrode and the negative electrode is electrically connected with the workpiece, and the electrode can make contact with the surface of the to-be-machined region of the workpiece and is electrically connected with the other of the positive electrode and the negative electrode. By employing the turning machining device, the acting force required by the turning can be reduced, the quality of the machining surface is improved, the tool loss is reduced, the structure is simple, and the machining cost is low.

Owner:THE HONG KONG POLYTECHNIC UNIV

Agricultural wood cutting equipment

InactiveCN108422494APrevents the effect of truncationReduce labor intensityBand sawsAgricultural engineeringEngineering

The invention relates to cutting equipment, and particularly relates to agricultural wood cutting equipment. The technical problem to be solved by the invention is to provide agricultural wood cuttingequipment which is low in labor intensity, high in cutting speed, and capable of collecting wood shavings occurring in a cutting process, without influence on the surrounding environment. The invention provides agricultural wood cutting equipment. The agricultural wood cutting equipment comprises a bottom plate and the like, wherein a vertical plate is installed at the right side of the top of the bottom plate; a top plate is installed on the upper part of the left side surface of the vertical plate; a drive device is arranged between the right side of the front side surface of the top plateand the upper part of the front side surface of the vertical plate; a cutting device is arranged at the bottom of the top plate; the cutting device is connected with the drive device; and a lifting device is arranged at the left side of the top of the bottom plate. According to the agricultural wood cutting equipment disclosed by the invention, collection treatment can be carried out on the falling wood shavings through the collection device, so that the wood shavings are prevented from influencing the surrounding environment; and wood is fixed through an arc-shaped plate, and can be preventedfrom moving to influence the cutting effect, so that the effects of being low in labor intensity, high in cutting speed, and capable of collecting wood shavings in a cutting process, without influence on the surrounding environment are achieved.

Owner:叶成雨

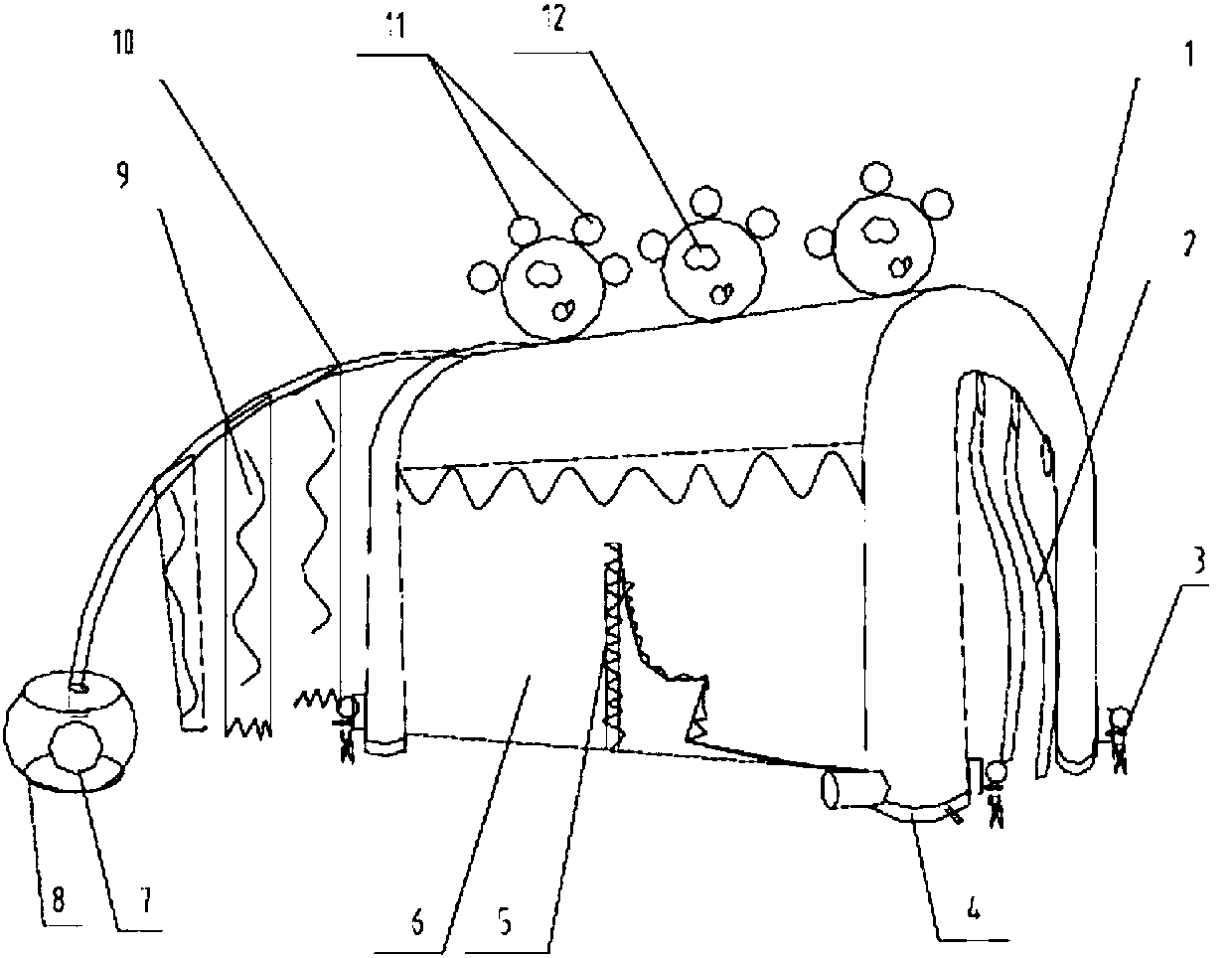

Marketing software advertising inflatable awning

The invention provides a marketing software advertising inflatable awning and mainly solves the problems that an existing dealer adopts a single inflatable arch which is monotonous in form and singlein fixing mode, and attractiveness and sales volume are affected in the prior art. The marketing software advertising inflatable awning is characterized in that the front of an awning body (1) is connected with an awning cloth (6), a zipper (5) is mounted in the middle of the awning cloth, sleeve rings are mounted on the outer sides of four bottom corners of the awning body, fixing pins (3) penetrate the sleeve rings, double-layer clamps (4) are arranged at the four bottom corners of the awning body, magnets are placed into the double-layer clamps, the top of a right side door of the awning body is connected with an advertising color strip (2) through a loop, the middle of a left side door of the awning body is connected outwards with an arc-shaped supporting rod (10), the other end of thesupporting rod is inserted into a circular pier (8) filled with a sponge, a balancing weight is placed at the inner bottom of the circular pier, and a plurality of advertising banners are hung on thesupporting rod. According to the marketing software advertising inflatable awning, product pictures and marketing information are displayed to consumers in various modes, and fixing modes are flexible.

Owner:CHANGSHA ZHIHONG CULTURAL MEDIA CO LTD

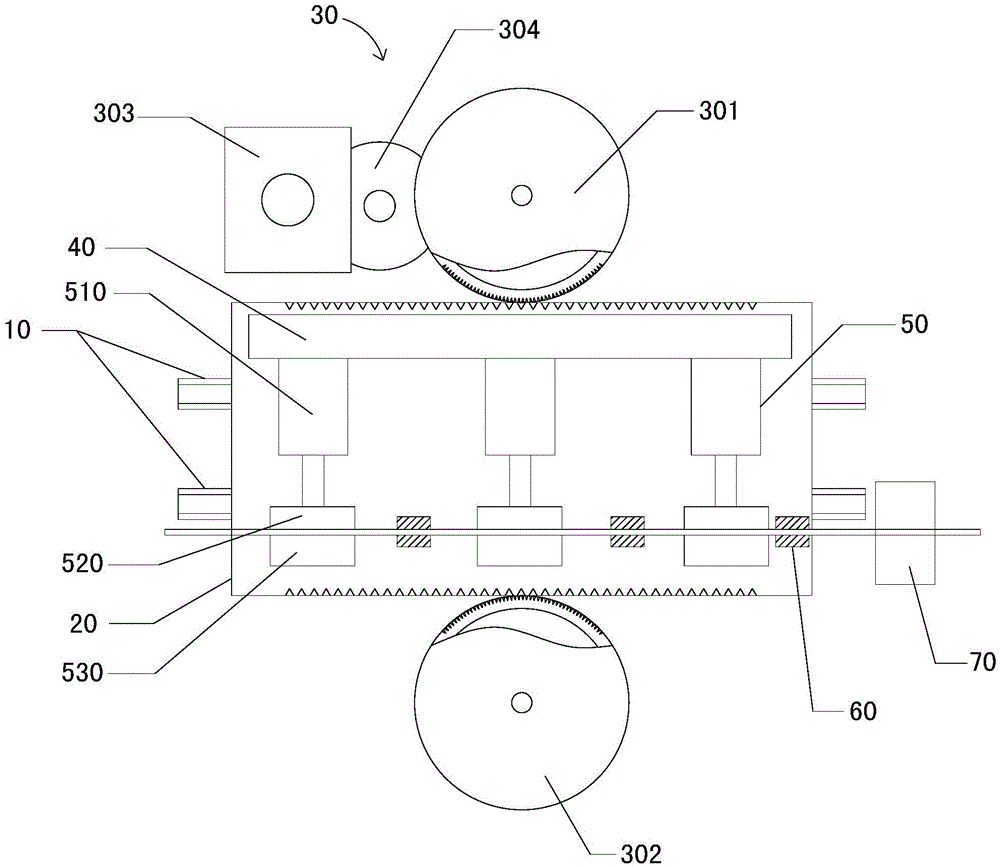

Multifunctional CNC spring forming machine

ActiveCN104607576AAvoid misalignmentRealize the wire feeding processWire springsPower unitMultiple function

The invention relates to spring forming devices, in particular to a multifunctional CNC spring forming machine. The multifunctional CNC spring forming machine comprises a wire feeding and transferring drive mechanism, a straightening mechanism, a curl forming mechanism and a cut-off mechanism. The wire feeding and transferring drive mechanism comprises a wire spool and a wire feeding device. The wire feeding device comprises guide rails, a sliding table, a power unit, a fixed base, clamping units, wire supporting tables and a wire guide table. The power unit controls the sliding table to slide relatively on the guide rails, and the fixed base is fixed on the sliding table. The number of the clamping units is at least three, the ends of the clamping units are fixed on the fixed base in parallel, and the wire supporting tables are respectively arranged between the clamping units. The wire guide table is arranged between the wire feeding device and the straightening mechanism. Each clamping unit comprises a hydraulic oil cylinder, a chuck and a clamping base, wherein the chuck is arranged at the output end of the hydraulic oil cylinder, and the clamping base is arranged on the other side, opposite to the chuck, of the sliding table and is matched with the chuck. The multifunctional CNC spring forming machine is high in clamping force to metal wires and accurate in wire feeding position.

Owner:SUZHOU ZHONGTAI POWER SPRING

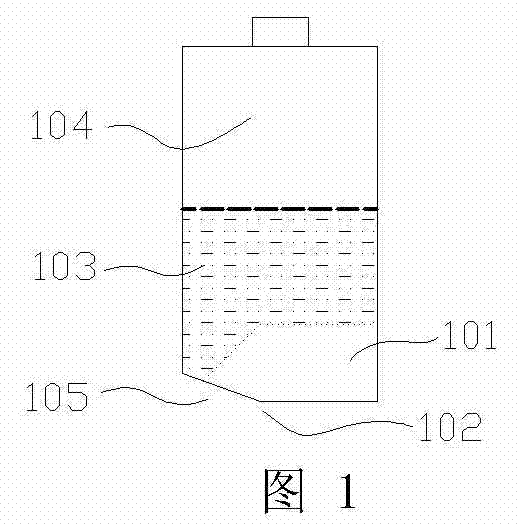

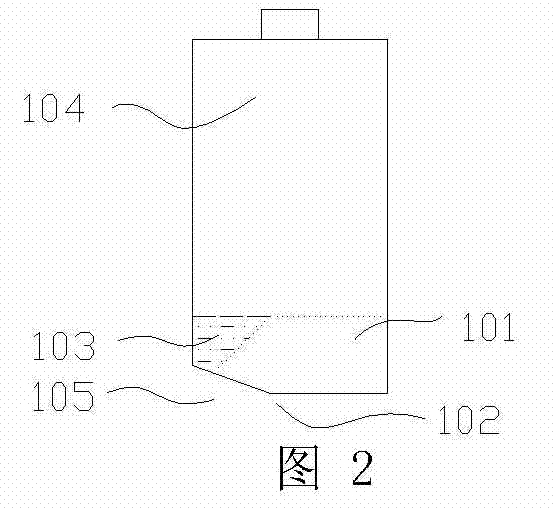

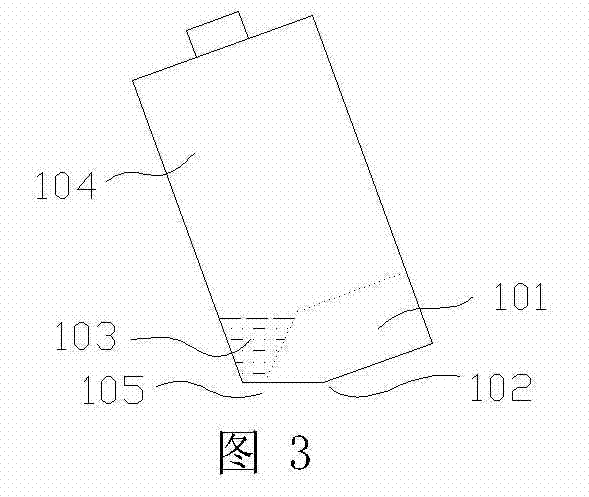

Container capable of prompting liquid surplus

InactiveCN102502040AReduce manufacturing costEffect does not affectRigid containersLiquid productStable state

The invention provides a container capable of prompting liquid surplus. The bottom part of the container is provided with a cavity; the cavity is smaller than the area of the bottom part and tends to one edge of the container; and the bottom part of the container, which is near the other edge, and the bottom part of the container form an inclined plane with a certain included angle. When liquid in the container is gradually reduced to be lower than the top face of the cavity, as the liquid only exists on the side of the inclined plane, according to the lever principle, the container can incline to the side of the inclined plane, and such the stable state is kept, thus, people can be reminded of changing for new liquid in time all the time. The container capable of prompting the liquid surplus has the obvious beneficial effects that the structure is novel and practical; the manufacturing cost is low; and for users often forgetting to change for new liquid products, not only is an effect not influenced but also an action of reminding all the time can be performed.

Owner:黄江

Synthesis method for phosphorus copolymerization flame retardant polyester

InactiveCN104513388AImprove flame retardant performanceImprove water resistancePolyesterDimethyl terephthalate

The invention discloses a synthesis method for phosphorus copolymerization flame retardant polyester. The method comprises the steps of: firstly subjecting dimethyl terephthalate, ethylene glycol, 9, 10-dihydro-9-oxo-10-phosphaphenanthrene, catalyst zinc acetate and antimony trioxide to ester exchange reaction at 150DEG C-230DEG C; and then raising the temperature to 275DEG C, reducing the pressure to 0.26kPa, and further carrying out reaction for 80min, thus obtaining the flame retardant polyester. The synthesis method for phosphorus copolymerization flame retardant polyester provided by the invention does not influence the catalyst effect during copolymerization, does not generate ether bond, and does not cause bridge stand effect, thus having no damage to the physical properties of original polyester. The obtained flame retardant polyester has good flame retardant performance and good water resistance.

Owner:QINGDAO SHOUSHENG IND

Process for preventing printing paper from curling

InactiveCN110593003ADoes not cause curlingEffect does not affectPaper/cardboardPulp material addition processesWater basedPulp and paper industry

The invention provides a process for preventing printing paper from curling. The problem that traditional printing paper is prone to bending is mainly solved. According to the process, after a pet film and the paper are compounded, the back surface of the paper is coated with water-based acrylic gloss oil before stripping the pet film, the water-based acrylic gloss oil is dried to 0.6 g and then cured, and the pet film is stripped after curing is completed, so that the function of preventing the paper from curling is achieved.

Owner:哈尔滨大东方新材料科技股份有限公司

Mixed weed killing agent with glufosinate ammonium and diguat dibromide

InactiveCN104542699AImprove weed control effectShorten weeding timeBiocideAnimal repellantsGlufosinate-ammoniumPotassium

The invention relates to a mixed weed killing agent with glufosinate ammonium and diguat dibromide. The mixed weed killing agent is compounded by the following raw materials by weight percent: 1-99.99% of glufosinate ammonium and 0.01-99% of diguat dibromide, wherein the glufosinate ammonium is from one or more in glufosinate-ammonium technical material, glufosinate-ammonium sodium salt, glufosinate-ammonium potassium salt, glufosinate-ammonium trimethyl sulfonium salt, glufosinate-ammonium ammonium salt and glufosinate-ammonium isopropylamine salt. The mixed weed killing agent is compounded by screening the diguat dibromide and the glufosinate ammonium; the diguat dibromide has the contact-poisoning action, and the contact-poisoning action can not hinder the absorption of the glufosinate ammonium by leaves, not only is the effect of the glufosinate ammonium not influenced, but also the synergistic effect is achieved for the effect of the glufosinate ammonium, the weed killing time can be shortened for 3-10 days, and the cost of the pesticides is reduced by 10%, so that the mixed weed killing agent has the characteristics of economy and high efficiency.

Owner:JIANGXI NEW DRAGON BIOTECH

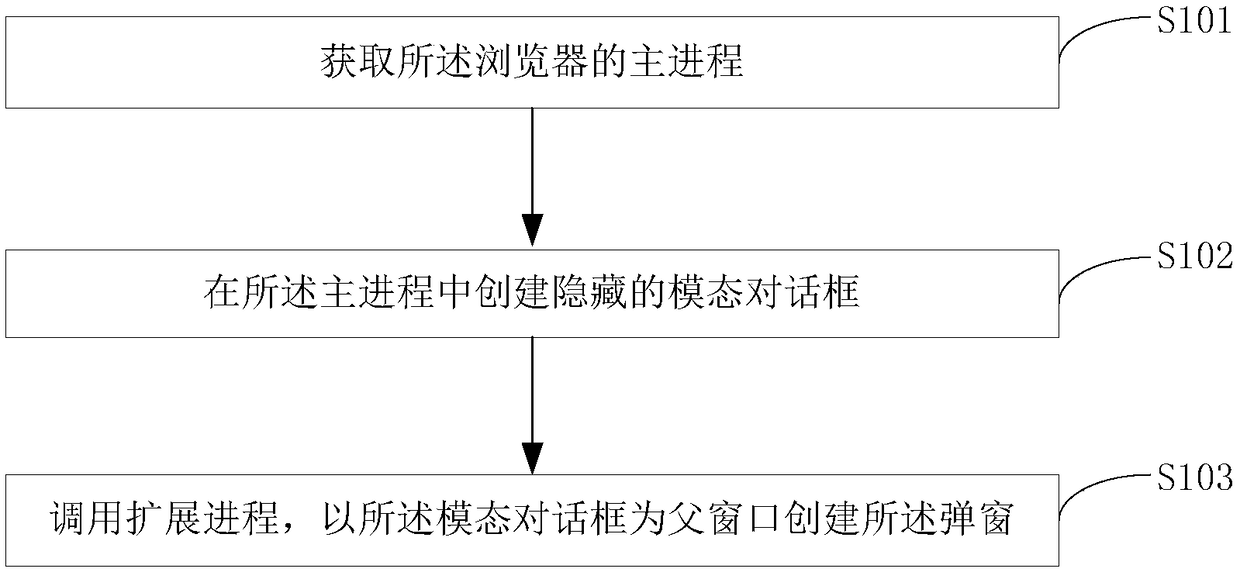

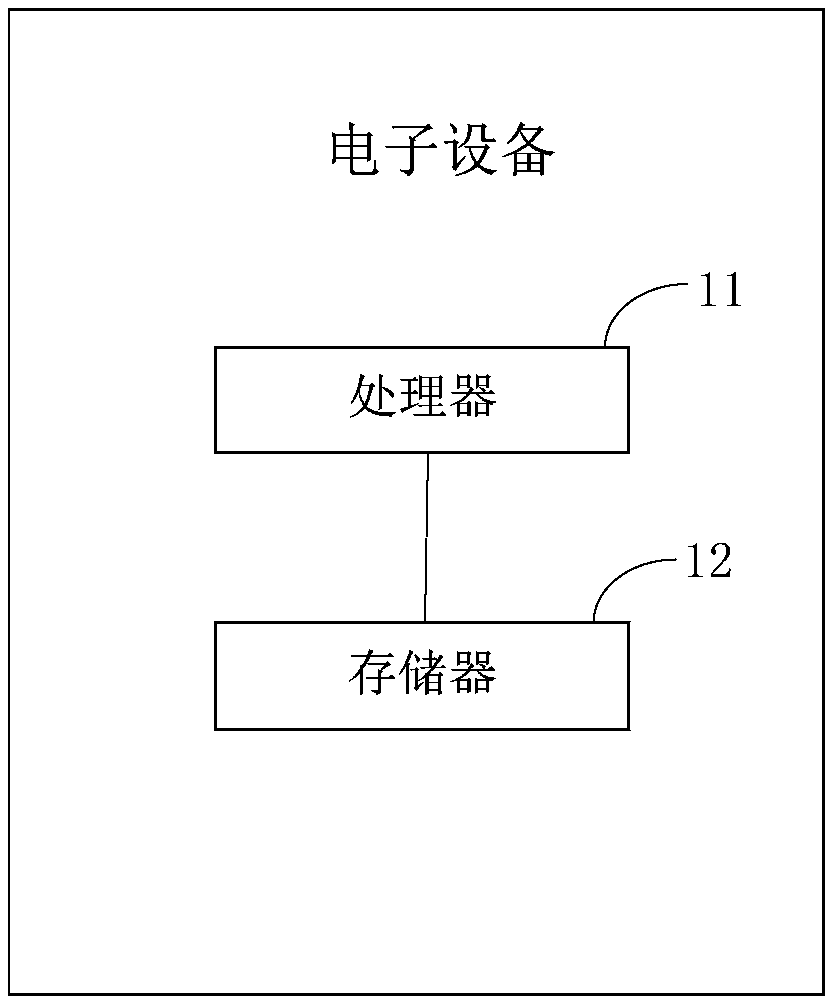

Browser pop-up window creation method, electronic device and storage medium

The invention discloses a browser pop-up window creation method, an electronic device and a storage medium. The method comprises: obtaining the main process of a browser; creating hidden modal dialogboxes in the main process; calling the extension process to create a pop-up window with the modal dialog box as the parent window. The browser pop-up window creation method, the electronic device andthe storage medium provided by the embodiment of the invention can obtain the main process of the browser, and create hidden modal dialog boxes in the main process, so that the browser can be blockedbecause the modal dialog boxes are in the same process as the browser. Then the extension process is called and a pop-up window is created with the modal dialog box as the parent window, so that the pop-up window blocks the browser without affecting other processes.

Owner:北京明华联盟科技有限公司

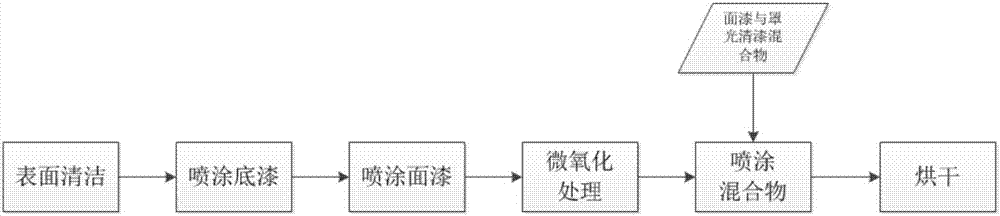

Process for coating of engine cylinder body

InactiveCN106853437AImprove antioxidant capacityEffective coverPretreated surfacesCoatingsEngineeringCylinder block

A process for coating of an engine cylinder body comprises the steps of first cleaning the surface of the engine cylinder body and then spraying primer and finish paint; performing microoxidation after the finish paint is sprayed; after the microoxidation, spraying a layer of mixture formed by evenly mixing the finish paint and finish varnish, wherein the finish paint in the mixture can eliminate defects on the surface of the finish paint sprayed in the preceding step; and performing drying after the drying. According to the process, a coating high in quality can be formed on the surface of the engine cylinder body, and the oxidation resistance of the coating can be improved by microoxidation of the finish paint; by spraying the mixture of the finish paint and the finish varnish, the defects on the surface of the finish paint are effectively covered, and an original effect of the finish paint layer is not affected. The one-time pass rate of spraying is greatly improved, and thus the coating cost is effectively reduced. The process further has the advantages of being simple, easy to operate and low in cost.

Owner:重庆樽明机械工业有限公司

Image filter processing method and device for quickly realizing multiple effects

ActiveCN104657946BEffect does not affectHigh speedImage enhancementPattern recognitionImaging processing

Owner:MEITU

Liquid crystal display device with lighting function

InactiveCN103309061BWith lighting functionAvoid spreadingPoint-like light sourceStatic indicating devicesLiquid-crystal displayControl signal

The invention discloses liquid crystal display equipment with an illuminating function. The liquid crystal display equipment comprises a liquid crystal display module, a body, an illuminating device and a signal processing module, wherein the liquid crystal display module comprises a liquid crystal panel and a backlight unit; the body comprises a border surrounding the liquid crystal panel; the border is provided with a lower frame part positioned below the liquid crystal panel; the illuminating device is arranged on the lower frame part, and comprises a lamp holder and a light-emitting module arranged on the lamp holder; the lamp holder is provided with a shielding unit positioned between the light-emitting module and the liquid crystal panel; the shielding unit is used for preventing light rays emitted by the light-emitting module from being transmitted towards the liquid crystal panel; and the signal processing module is used for transmitting a plurality of control signals to the backlight unit and the light-emitting module so as to control the backlight unit and the light-emitting module to emit light or not.

Owner:TOP VICTORY INVESTMENTS

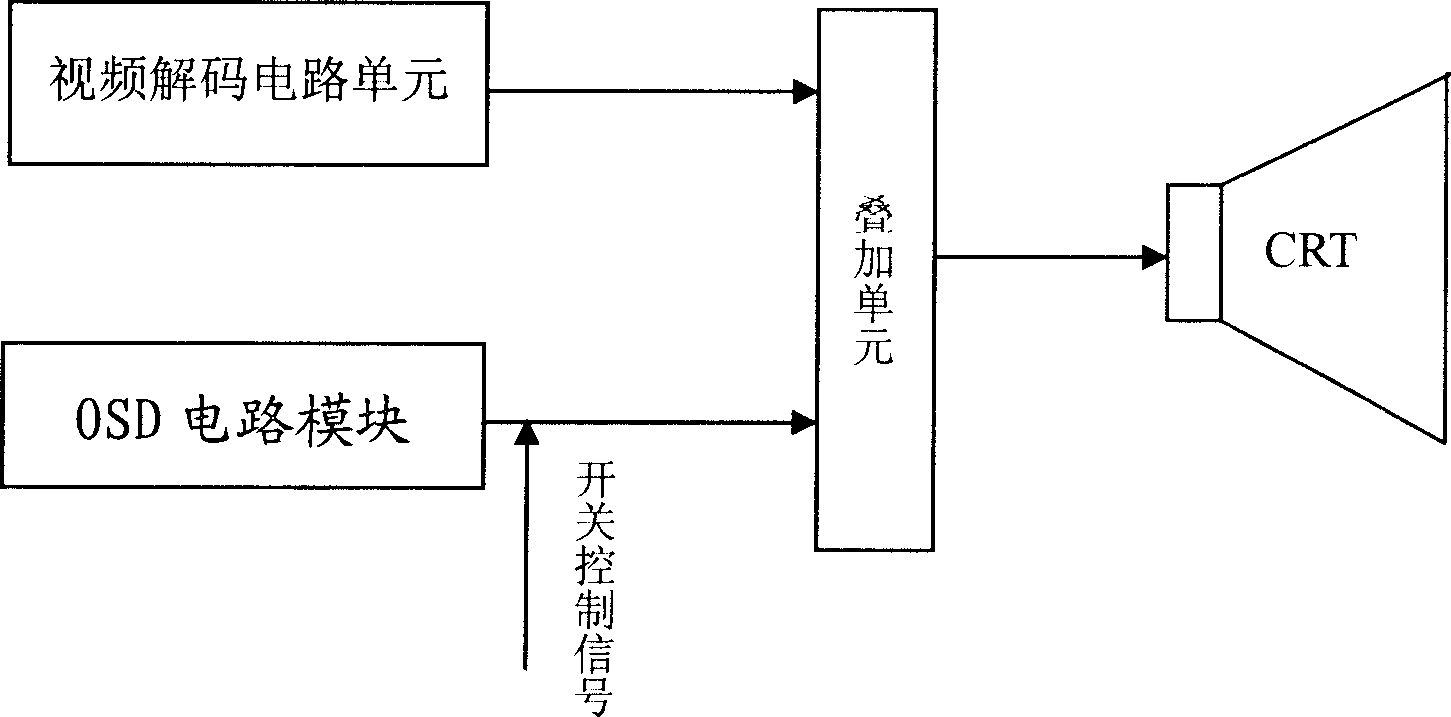

Method for preventing CRI fron heat injury caused by still picture

InactiveCN1281068CEffect does not affectBrightness does not affectTelevision system detailsPicture reproducers using cathode ray tubesStart timeSignal on

The invention discloses a method for preventing still images from burning a CRT, comprising the following steps: using an OSD circuit module to generate red, green and blue primary color OSD signals for forming a low-brightness area on a fluorescent screen; setting the OSD switch control signal The high level of the above-mentioned low-brightness three-primary-color OSD signal is formed into a translucent low-brightness three-primary-color OSD signal; the scanning start time of the signal generated by the control OSD circuit module; the translucent low-brightness three-primary-color OSD signal and The signal generated by the video decoding circuit unit to form a normal TV picture is superimposed by the superimposing unit; the superimposed signal is used to control the imaging circuit of the CRT. In this way, the brightness of the still image is reduced, and it is not easy to leave burn marks on the fluorescent screen of the CRT, which protects the CRT and prolongs the service life of the TV set.

Owner:SHENZHEN SKYWORTH RGB ELECTRONICS CO LTD

An Internet of Things security access control

The invention relates to the technical field of access control equipment, and discloses an internet-of-things safety access control. The internet-of-things safety access control comprises a door framefixed on a wall body and a door plate, an iron plate is fixedly connected to the top of the inner wall of the door frame; the side, close to the door frame, of the door plate is fixedly connected with double-layer sealing rubber rings, a fingerprint lock is fixedly mounted on one side, away from the door frame, of the door plate, a square hole is formed in the position, corresponding to the ironplate, of the door plate, a fixing box is fixedly connected into the square hole, a positioning plate is fixedly connected into the fixing box, a hole is formed in the positioning plate, a cylinder isfixedly connected into the hole, a square hole is formed in the fixing box, and a magnetic lock is fixedly connected into the square hole. According to the internet-of-things safety access control, the double-layer sealing rubber rings are matched with a square iron sheet, so that supporting points of the door frame to the door plate are increased, and the door is prevented from being forcibly broken by people from the side edge of the door; and the stress at hinges is reduced, damage caused by excessive stress at a certain position is avoided, and the effect of an air interchanger in a physical evidence room cannot be affected by external air.

Owner:NINGBO FUMATE METAL PROD IND

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com