Patents

Literature

Hiro is an intelligent assistant for R&D personnel, combined with Patent DNA, to facilitate innovative research.

877results about How to "Realize automatic processing" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

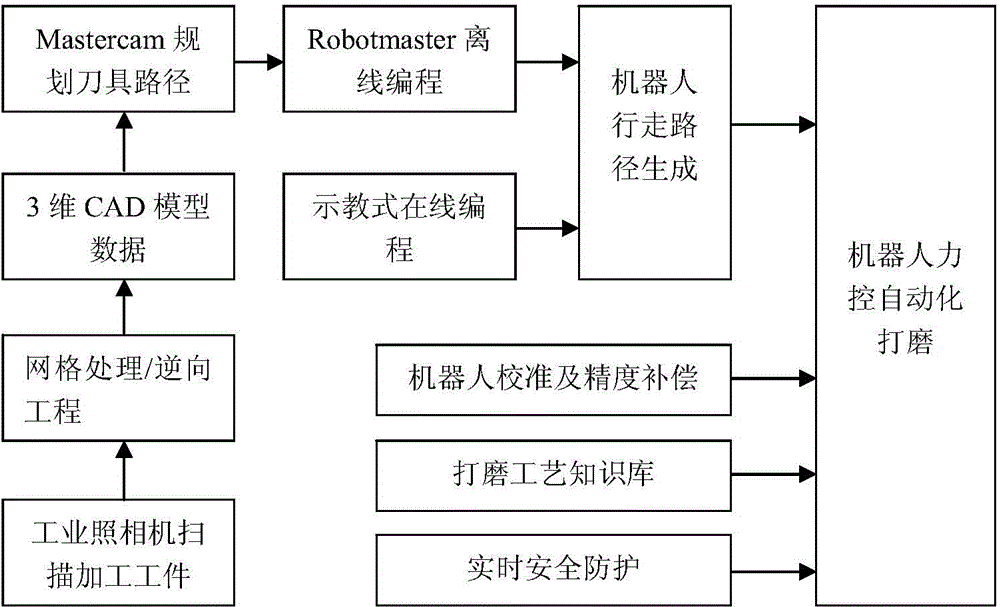

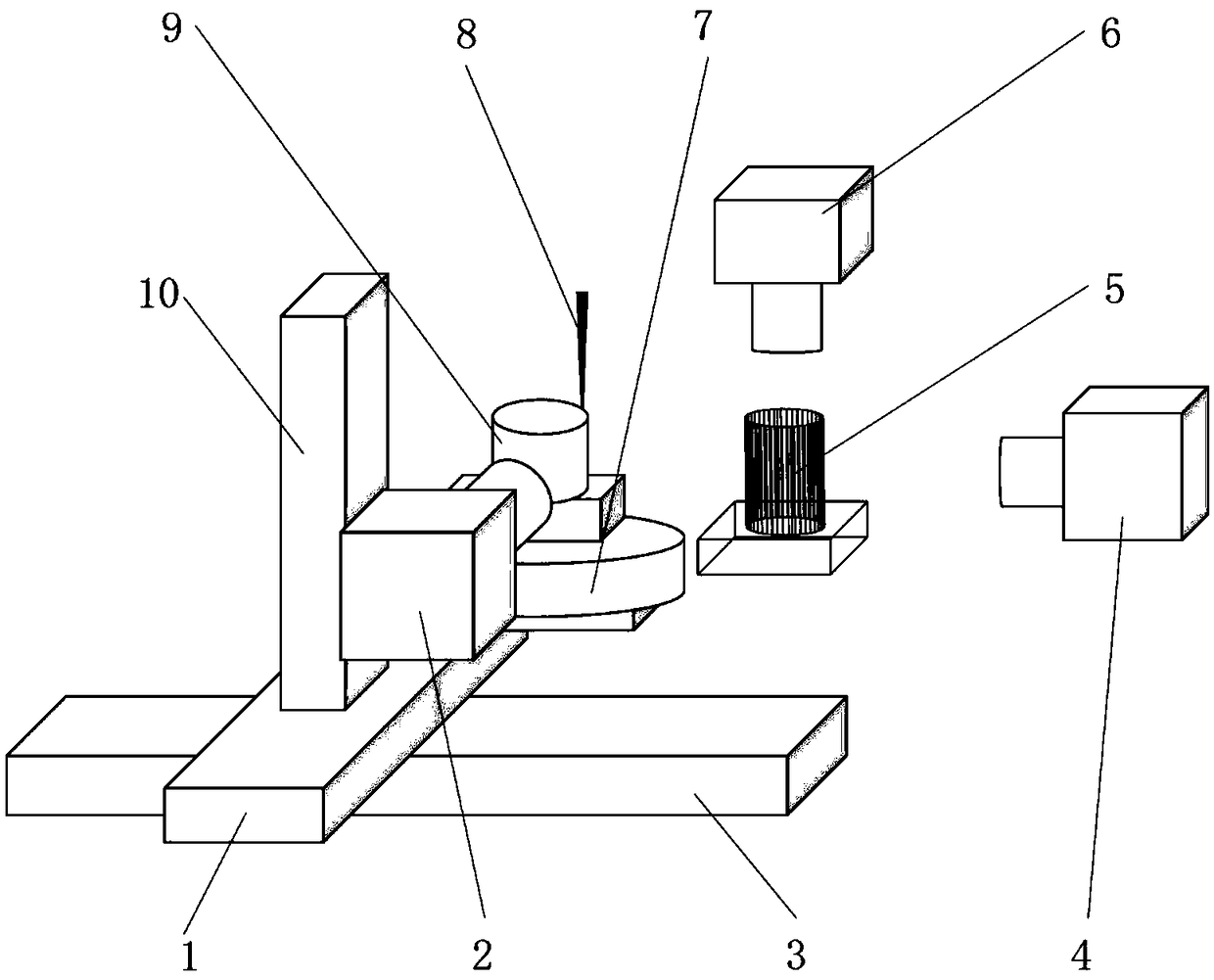

Intelligent force control robot grinding system and method

ActiveCN104972362ARealize automatic processingImprove machining accuracyAutomatic grinding controlSurface finishControl theory

The invention relates to an intelligent force control robot grinding system. The intelligent force control robot grinding system comprises a computer, an industrial camera, a robot, a robot controller, a calibration and compensation system, a safety protection unit, a force sensor and an automatic knife changing system. The computer is connected with the industrial camera. The robot controller is connected with the computer, the robot, the calibration and compensation system, the safety protection unit, the force sensor and the automatic knife changing system. A method comprises the steps that the computer receives workpiece scanning data collected by the industrial camera, generates a knife path and converts the knife path into the robot posture and the tail end path; calibration and compensation are carried out; the robot controller controls all joints to move while the robot posture and the tail end path are adjusted. Hardware of a high-precision force control grinding system is achieved, the path self-calibration and online compensation technology is adopted, and the machining of a complex hook face with the high requirements for machining precision and surface smoothness can be finished.

Owner:宏阔(南通)智能装备有限公司

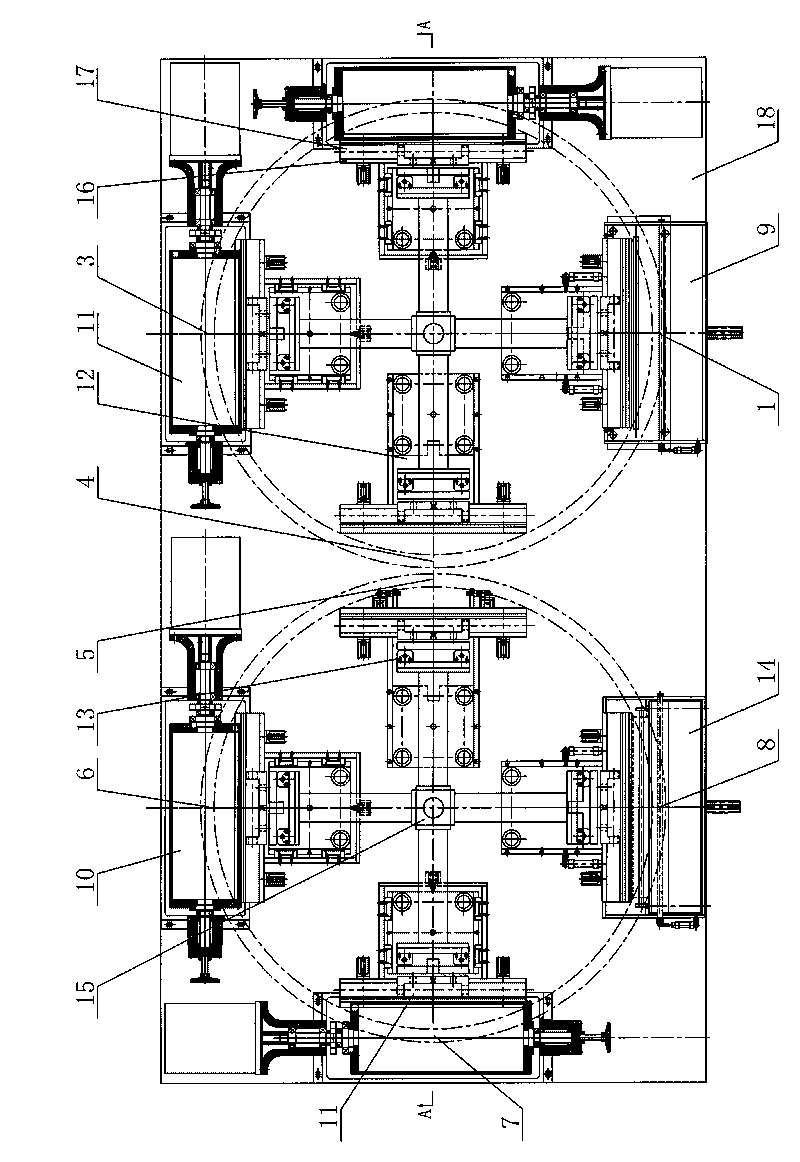

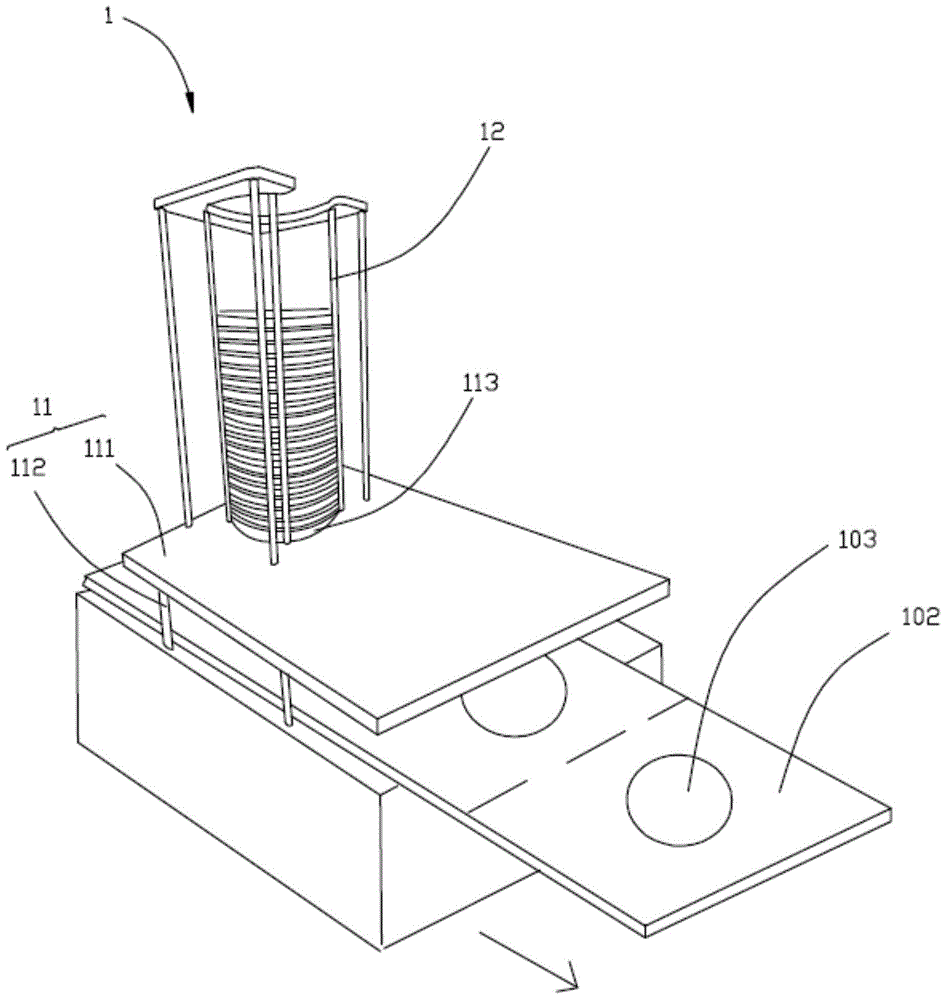

Full-automatic water-drill grinding and polishing machine

InactiveCN101758433AImprove work efficiencyFixture positioning is accurateEdge grinding machinesManipulatorEngineering

The invention disclosed a full-automatic water-drill grinding and polishing machine which comprises a fixture, a fixture seat and a mechanical hand. The full-automatic water-drill grinding and polishing machine is characterized in that: the machine includes a left grinding and polishing part and a right grinding and polishing part, wherein the right grinding and polishing part includes a bead loading station, a right grinding station, a right polishing station and a right butting station; the left grinding and polishing part includes a left butting station, a left grinding station, a left polishing station and a bead unloading station; the left butting station and the right butting station are arranged correspondingly; the fixture and the fixture seat are arranged independently; the fixture can act along with the mechanical hand; and the fixture seat is arranged correspondingly to the bead loading mechanism, the grinding mechanism, the polishing mechanism, the left butting mechanism, the right butting mechanism and the bead unloading mechanism. With accurate fixture positioning and high grinding as well as polishing precision, the grinding and polishing machine can realize automatic grinding and polishing of a water drill and can automatically correct processing dimension errors caused by abrasion of abrasive wheels.

Owner:瑞安市天成包装机械有限公司

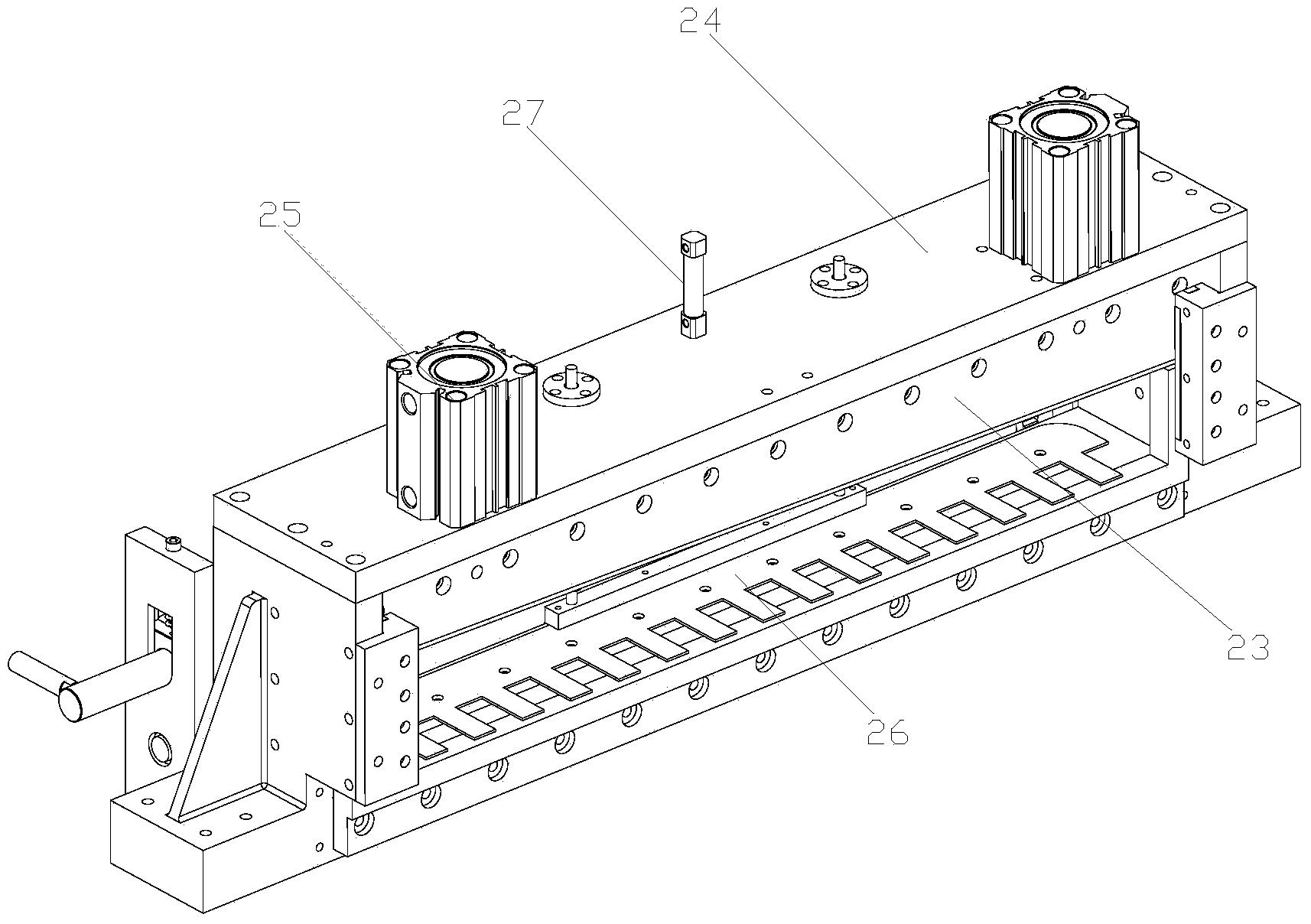

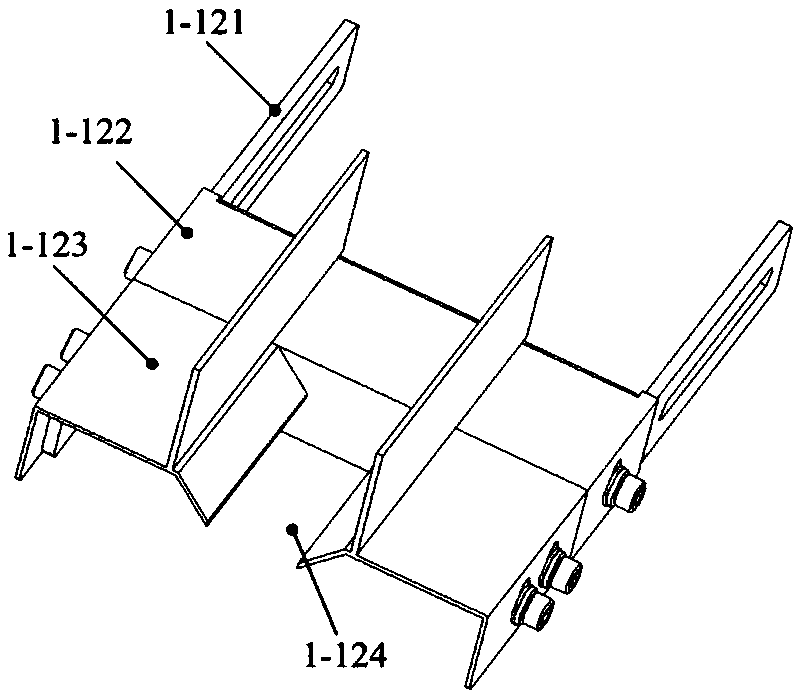

Multifunctional wiring-duct machining device and machining method thereof

InactiveCN105251878APerfect shapeConsistent processing shapeShaping toolsPerforating toolsEngineeringMachining

The invention relates to a multifunctional wiring-duct machining device and a machining method thereof. The machining device comprises a C-shaped base, an upper die rotary plate, a plurality of upper dies, a downward pressing device and a lower die. The upper die rotary plate is rotationally mounted at the upper end of the inner side of the C-shaped base, and the upper dies are mounted at the lower end of the upper die rotary plate in the radial direction. The downward pressing device is vertically mounted on the top of the C-shaped base and located on one side of the radial direction of the rotary plate. The lower die is fixedly mounted in the position, below the downward pressing device, of the upper end of the bottom of the C-shaped base. According to the multifunctional wiring-duct machining device and the machining method thereof, the problem that dies are frequently replaced during wiring-duct machining is solved; after integration, operation is convenient, batch machining can be achieved, work hours are shortened, and the manual labor intensity is relieved; in addition, after program control is added, automatic machining can be achieved, and the automation degree is increased.

Owner:TIANJIN RES INST OF ELECTRIC SCI

Reflecting type whole solid paper loading electrochromism device and preparation method thereof

The invention relates to reflecting type whole solid state electrochromism device with paper carrier material and the manufacturing method. The device includes paper carried electrochromism layer, ion conductor layer, ion storing layer, current-carrying electrode layer, and transparent glass base layer. It uses the paper carried electrochromism as main display thin film. Its two sides are tightly pressed with the ion conductor layer of which two sides are respectively set current carrying electrode layer and the transparent glass base layer. Each layer side is hermetically packaged and connected with electrode. The device can greatly increase device contrast, overcome 'cross talk', 'pixel dispersion', leakage, image blur etc, gain the electrochromic display with low cost, and lay stable foundation for merchandizing and popularity of the electrochromism type electronic ink and paper, color electrochromic display.

Owner:SOUTHWEST UNIVERSITY

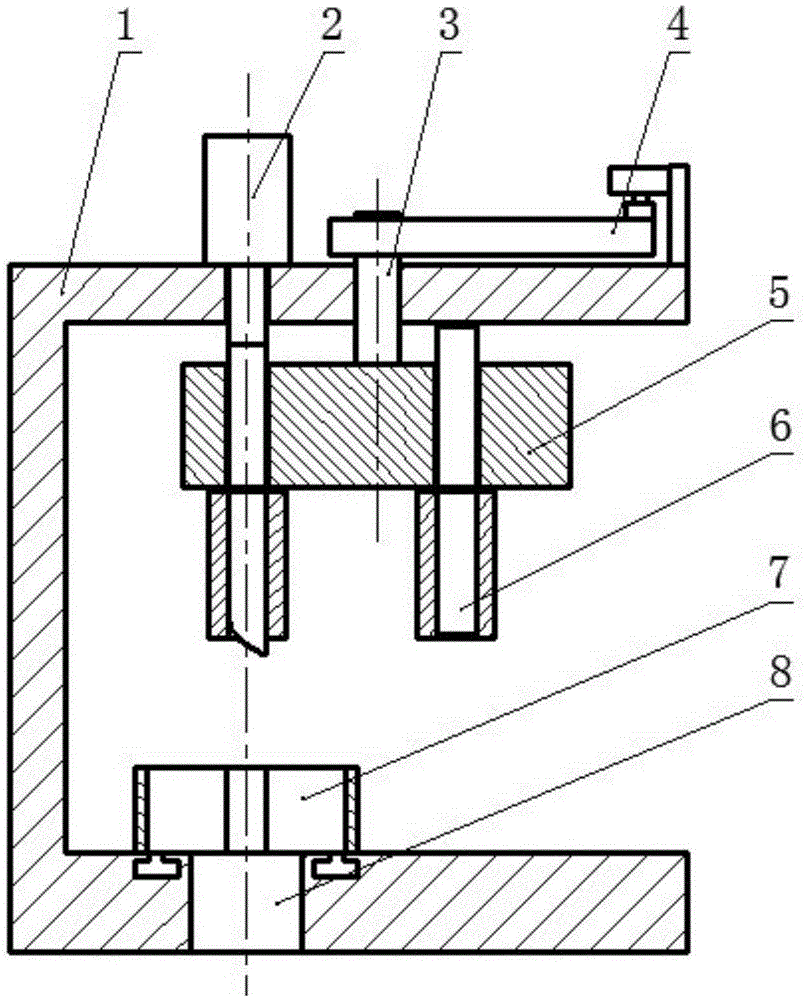

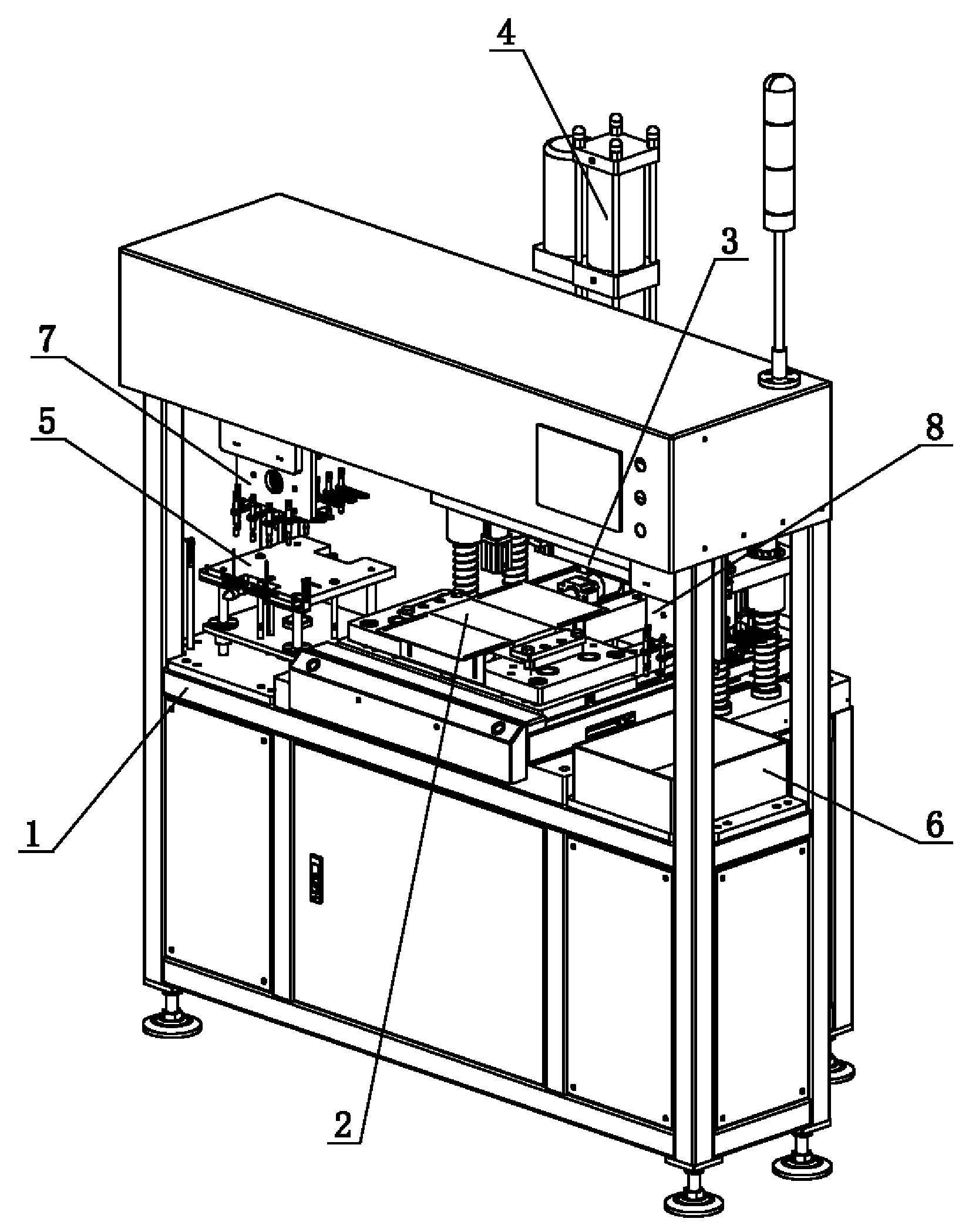

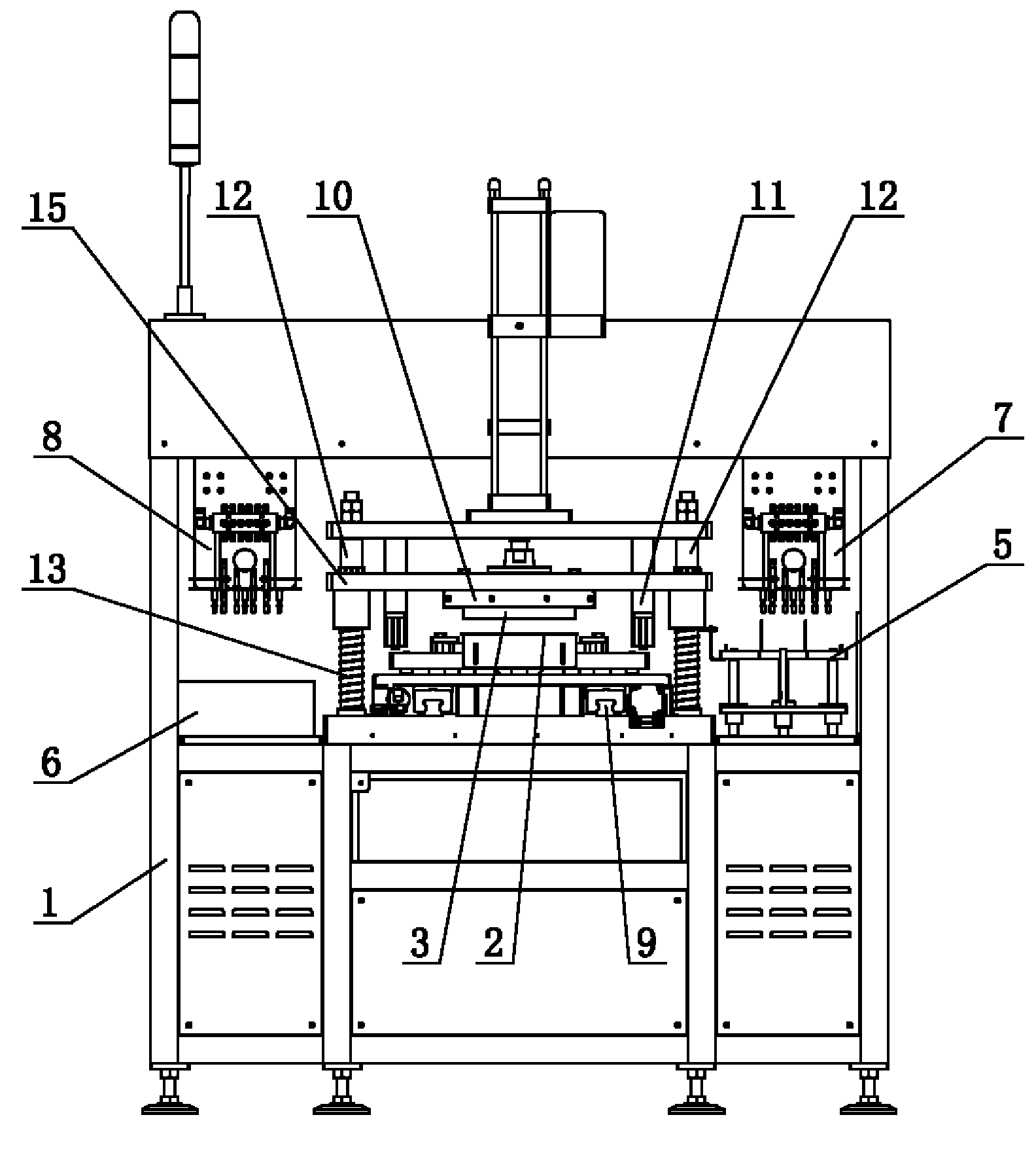

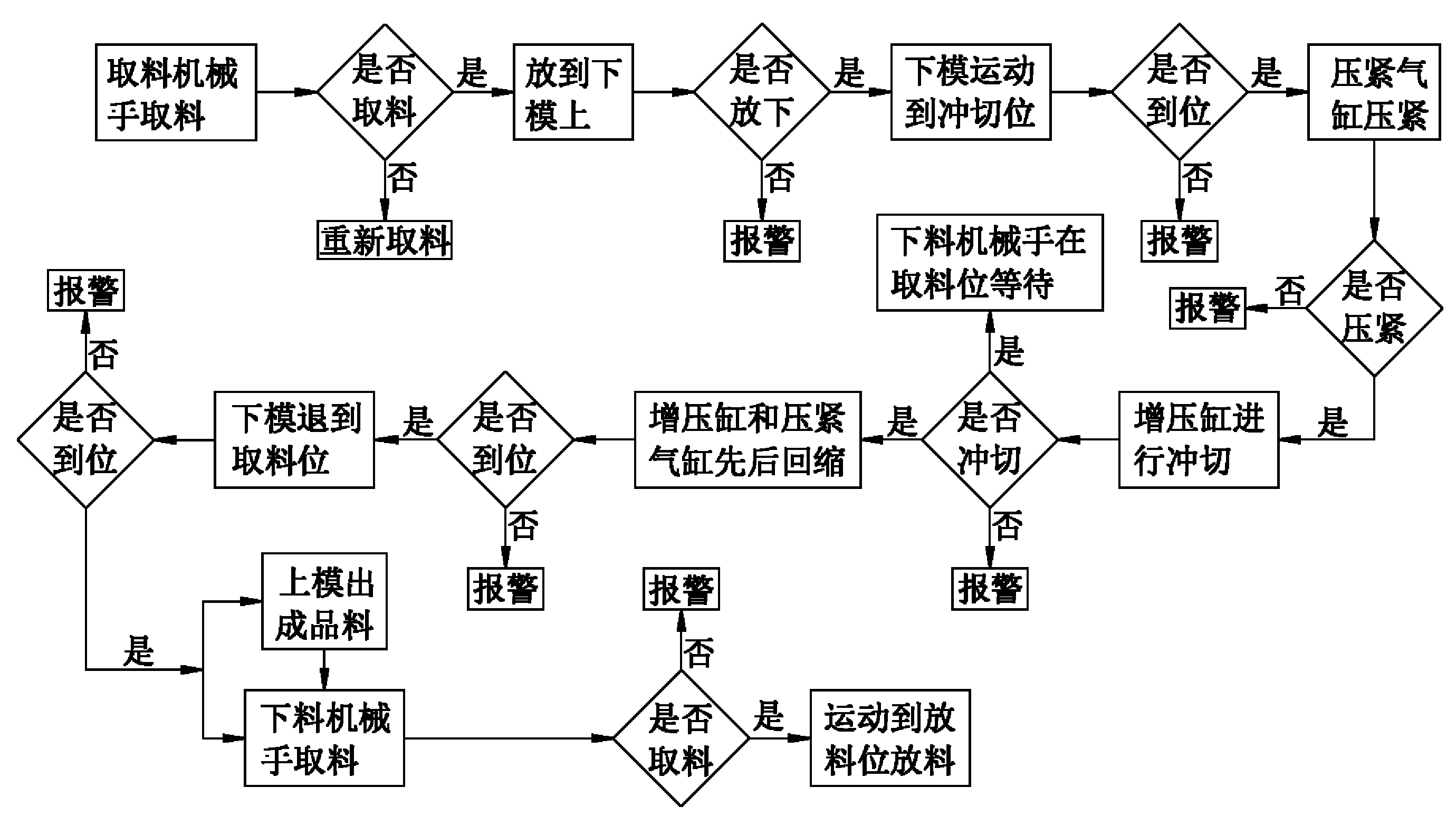

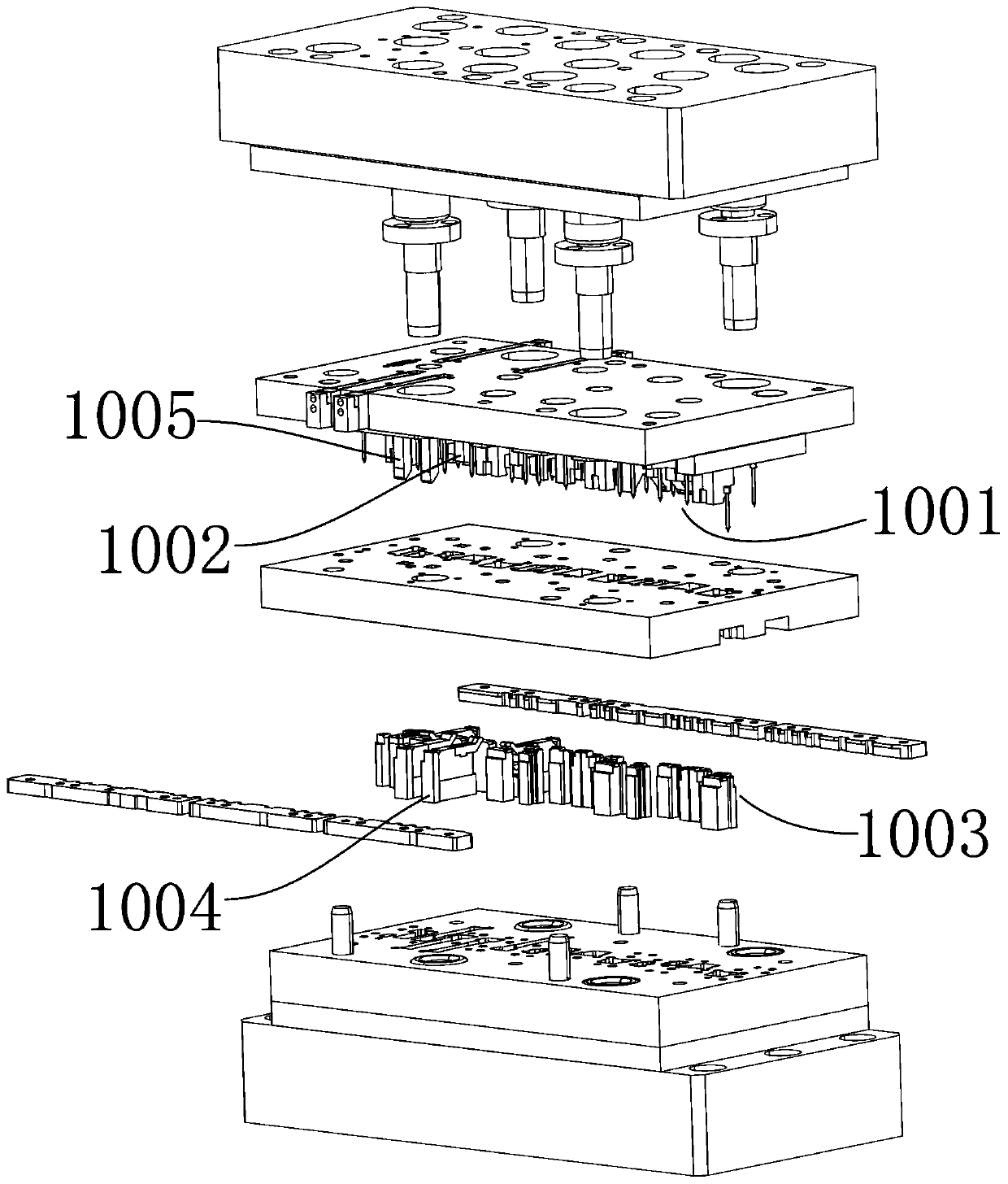

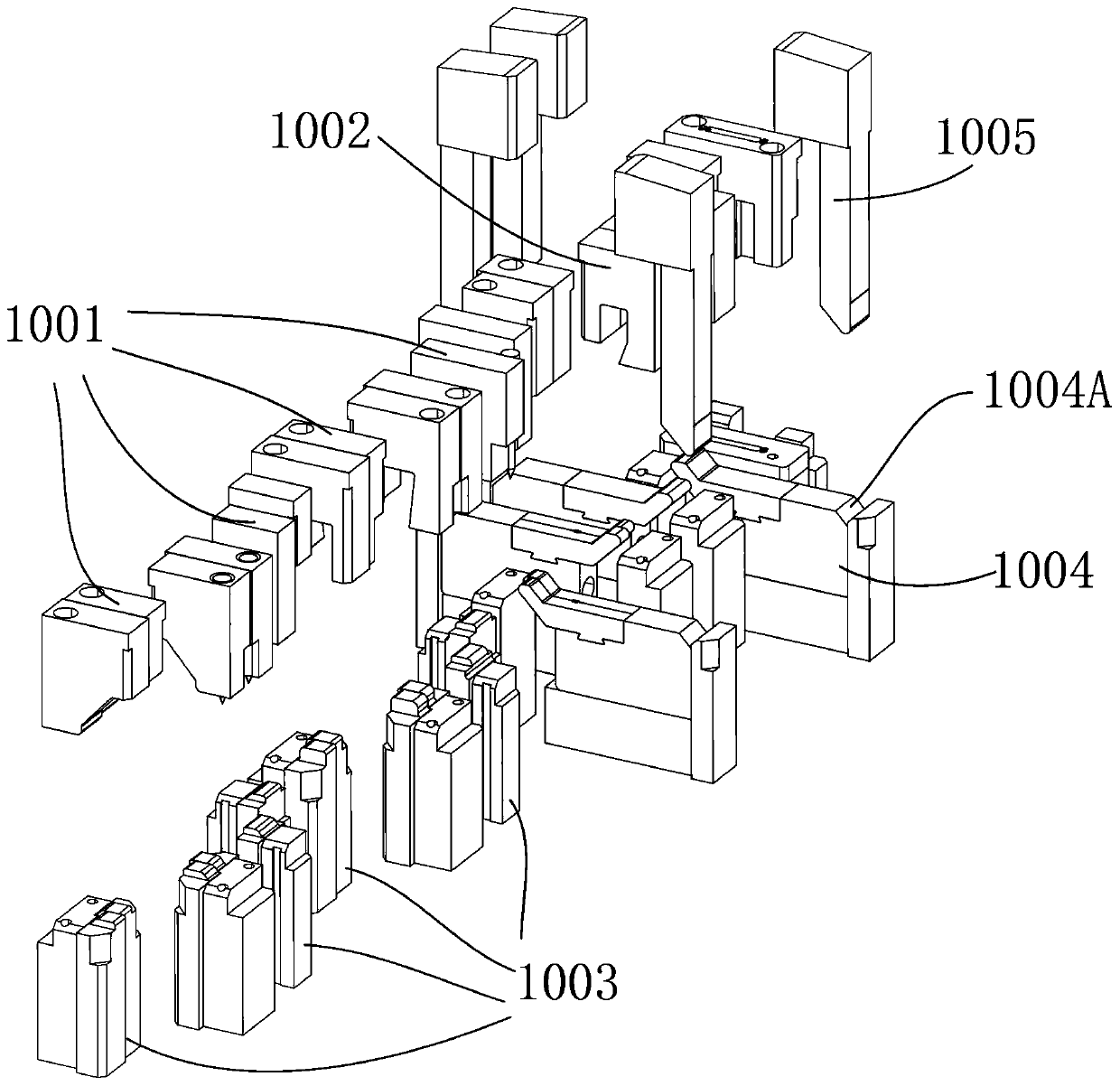

Automatic punch equipment and processing method thereof

ActiveCN104227781AImprove processing qualityRealize automatic processingMetal working apparatusConveyor partsAutomatic test equipmentPunch press

The invention relates to the technical field of FPC (flexible printed circuit) processing equipment, in particular to automatic punch equipment. The automatic punch equipment comprises a lower die, an upper die and a pressure cylinder, wherein the lower die is arranged on a rack, the upper die is located right above the lower die, and the pressure cylinder is used for driving the upper die to vertically move; the pressure cylinder is fixedly arranged on the rack; the rack is also provided with a feeding tray and a discharging tray; a feeding manipulator is arranged above the feeding tray; a discharging manipulator is arranged above the discharging tray; the processing method for the automatic punch equipment comprises the following steps: clamping an FPC material from the feeding tray by the feeding manipulator and transferring the FPC material to the lower die, and backwards moving the lower die to a punching position from a material fetching position; downwards moving the upper die to perform punching processing and then, returning to an original position; forwards moving the lower die to return to the material fetching position; transferring an FPC finished product into the discharging tray from the material fetching position by the discharging manipulator. Automatic processing of FPC punching is realized; manual feeding and discharging actions are not needed; a feeding position and a discharging position are more accurate; the processing quality of the punch equipment is greatly improved.

Owner:GUANGDONG HUAHENG INTELLIGENT TECH CO LTD

Egg tart crust automatic-moulding machine

The invention discloses an egg tart crust automatic-moulding machine which includes: a rack; an electric-control box arranged on the rack; and a cam cutting device and a motor fixed on the rack. The motor is connected to an input end of the cam cutting device through a coupling joint. A rotating disk rotating horizontally is connected to an output end of the cam cutting device. A double-row moulding concave die is uniformly arranged on the rotating disk along the circles concentrically to a rotation center of the disk, wherein the bottom of each moulding groove of the double-row moulding concave die is provided with a through hole. An egg tart crust stamping apparatus is arranged over the rotating disk. The rack is provided with an automatic cup-falling device and is also provided with a push-out mechanism used for pushing-up and pushing-out an egg tart crust from the double-row moulding concave die and an automatic output apparatus. By means of arrangement of a pneumatic system, the egg tart crust stamping apparatus and the automatic loading / unloading apparatus, automatic processing of the egg tart crust is achieved, so that the automatic-moulding machine can greatly increase production efficiency and reduce labor cost, is simple in structure and low in cost, and is good in reliability.

Owner:SOUTH CHINA UNIV OF TECH

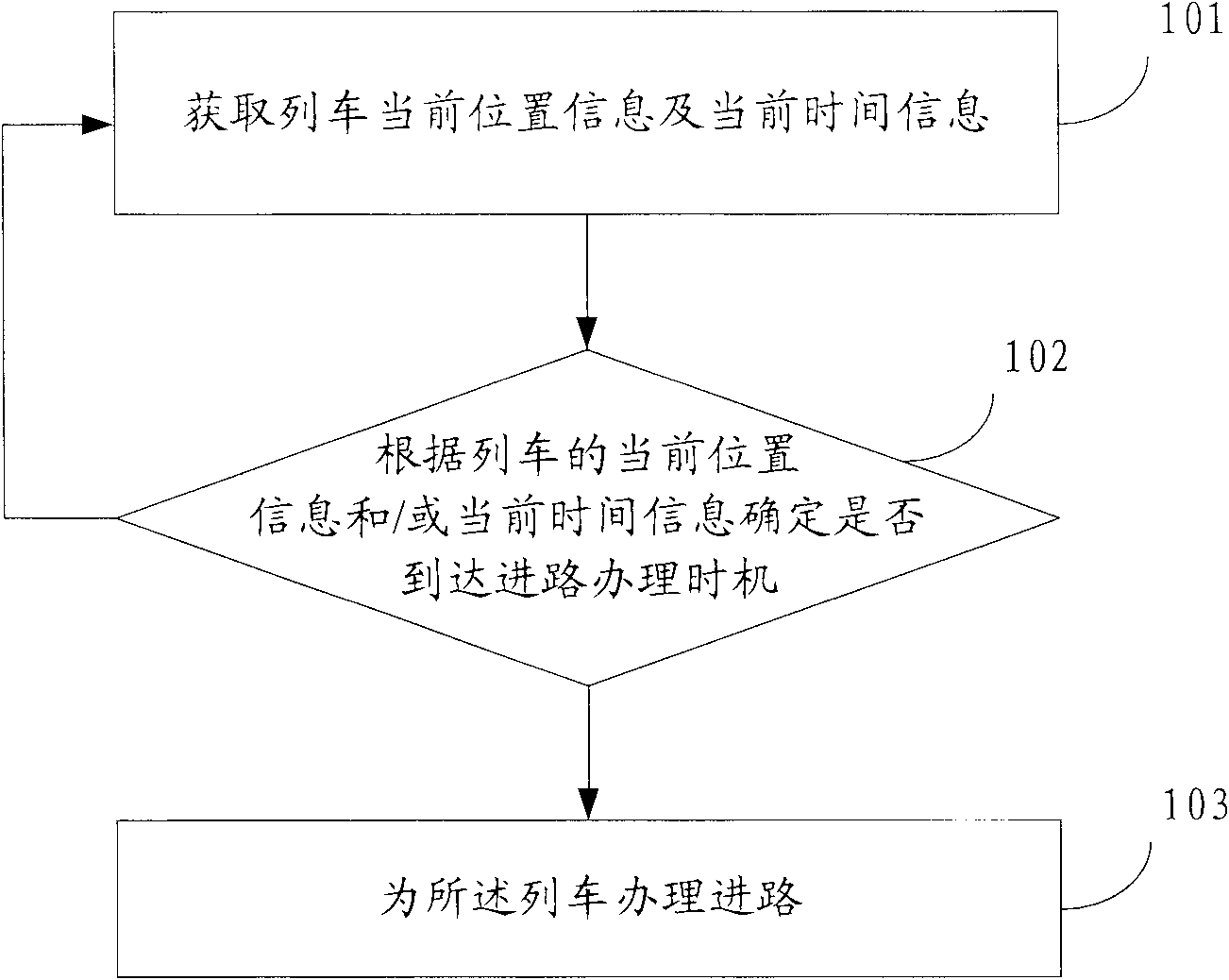

Method and system for controlling train route

ActiveCN101898569ARealize automatic processingIncrease profitRailway traffic control systemsTime informationUtilization rate

The invention relates to the technical field of train operation control and discloses a method and a system for controlling a train route. The method comprises the following steps of: acquiring the present position information and the present time information of a train; determining whether a route setting time approaches or not according to the present position information and / or the present time information of the train; and if so, setting route for the train. The method and the system of the invention can reasonably determine the route setting time of the train, realize automatic setting of train route and improve utilization rate of a station.

Owner:CRSC RESEARCH & DESIGN INSTITUTE GROUP CO LTD

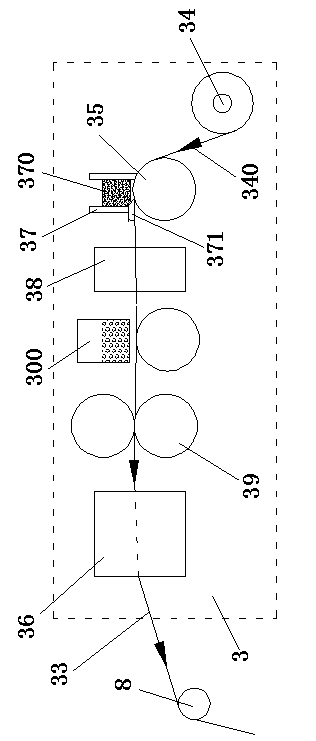

Production system of nonel detonator

The invention discloses a production system of nonel detonators. The production system includes a material feeding mechanism, a material taking mechanism, a waist clamp mechanism, a carrier, a driving mechanism, a transmission mechanism, a rubber plug assembling mechanism, a mouth clamp mechanism, a guidance mechanism and a nonel processing mechanism. A basic detonator of the nonel detonator is arranged on the material feeding mechanism. The material taking mechanism is disposed on the material feeding mechanism and is disposed slidingly between the material feeding mechanism and the waist clamp mechanism. The carrier is arranged at an output end of the waist clamp mechanism. The rubber plug assembling mechanism and the mouth clamp mechanism are respectively arranged at one side of the transmission mechanism. The driving mechanism is arranged on the transmission mechanism. The guidance mechanism is arranged at one side, which is far away from the transmission mechanism, of the mouth clamp mechanism. The nonel processing mechanism is disposed at one side, which is far away from the mouth clamp mechanism, of the guidance mechanism. The production system can automatically process and assemble the nonel detonators, and not only is high in production efficiency but also can reduces operators and production cost.

Owner:DONGGUAN CHUANGZHE AUTOMATION TECH CO LTD

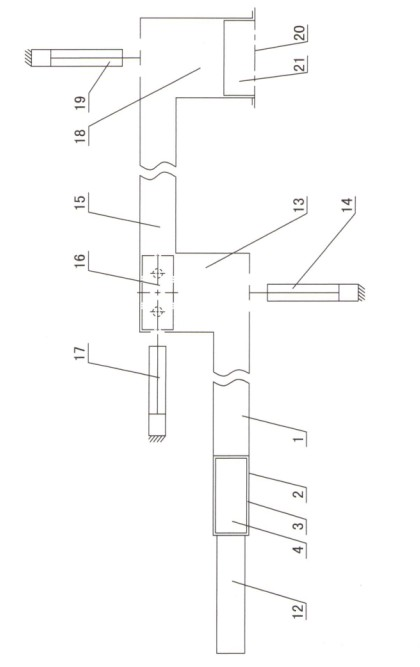

Digital controlled ceramic constructing forming machine

InactiveCN101143457AWide range of sizesImprove machining accuracyCeramic shaping apparatusManipulatorEngineering

A numerical control ceramic pile forming machine is automatic production equipment which integrates a plurality of functions of ceramic forming, basing and engraving. Three linear axles of X, Y and Z and two revolving axles of A (worktable revolving) and B (rolling manipulator and engraving joint swinging shaft) are movably composed. Five axles in all are composed and five-axle linkage is realized. Plugs are extruded out of a vacuum extruder (20). The machine can pile the pugs layer by layer for forming in any shape through a soft pipe (7) by the rolling manipulator (6) on the worktable (4) to replace a manual billet tension process. The pentahedron basing and the engraving process are implemented on the billets after being dried. Therefore, the automatic production of ceramic forming, basing and engraving is realized.

Owner:徐晗

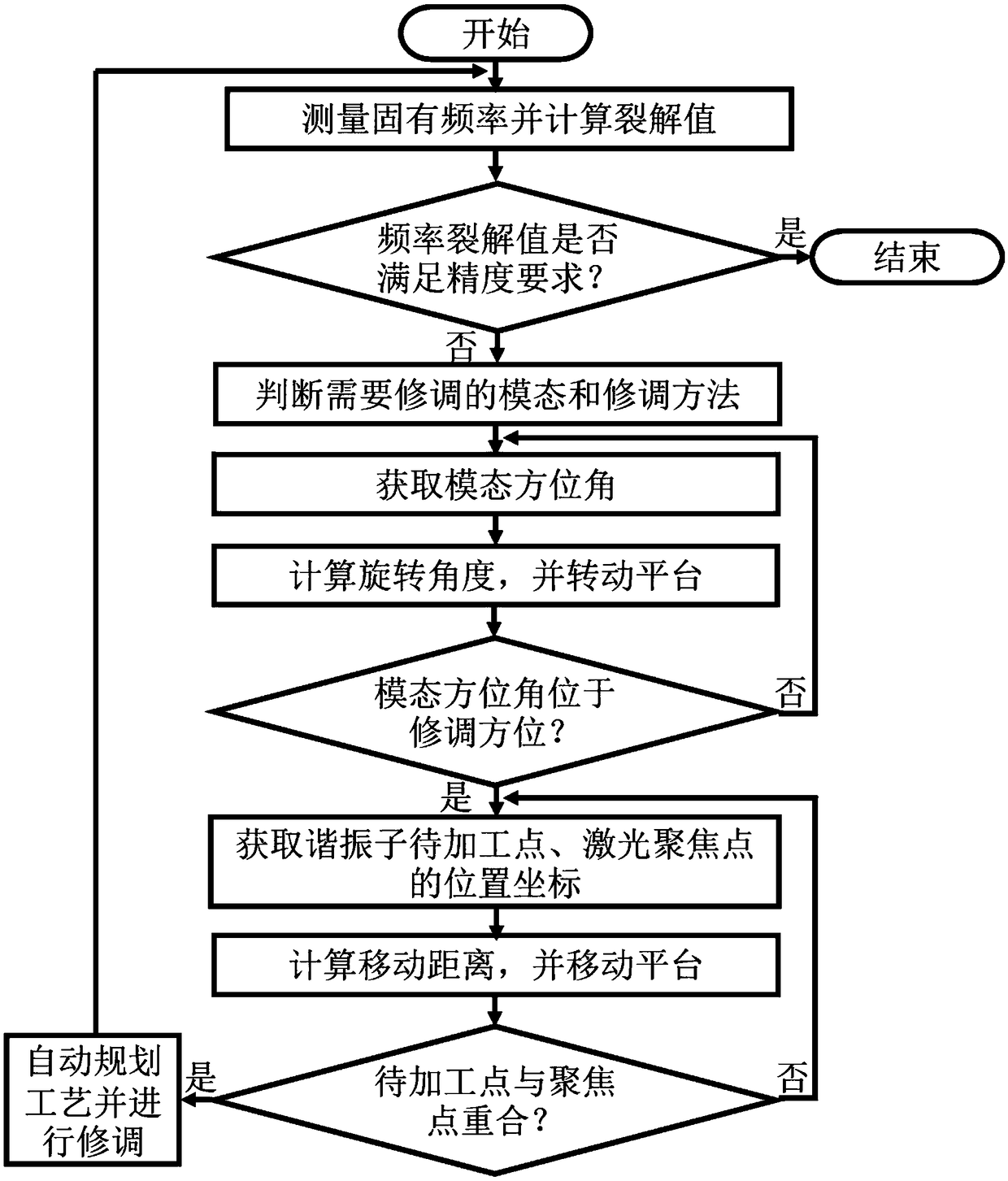

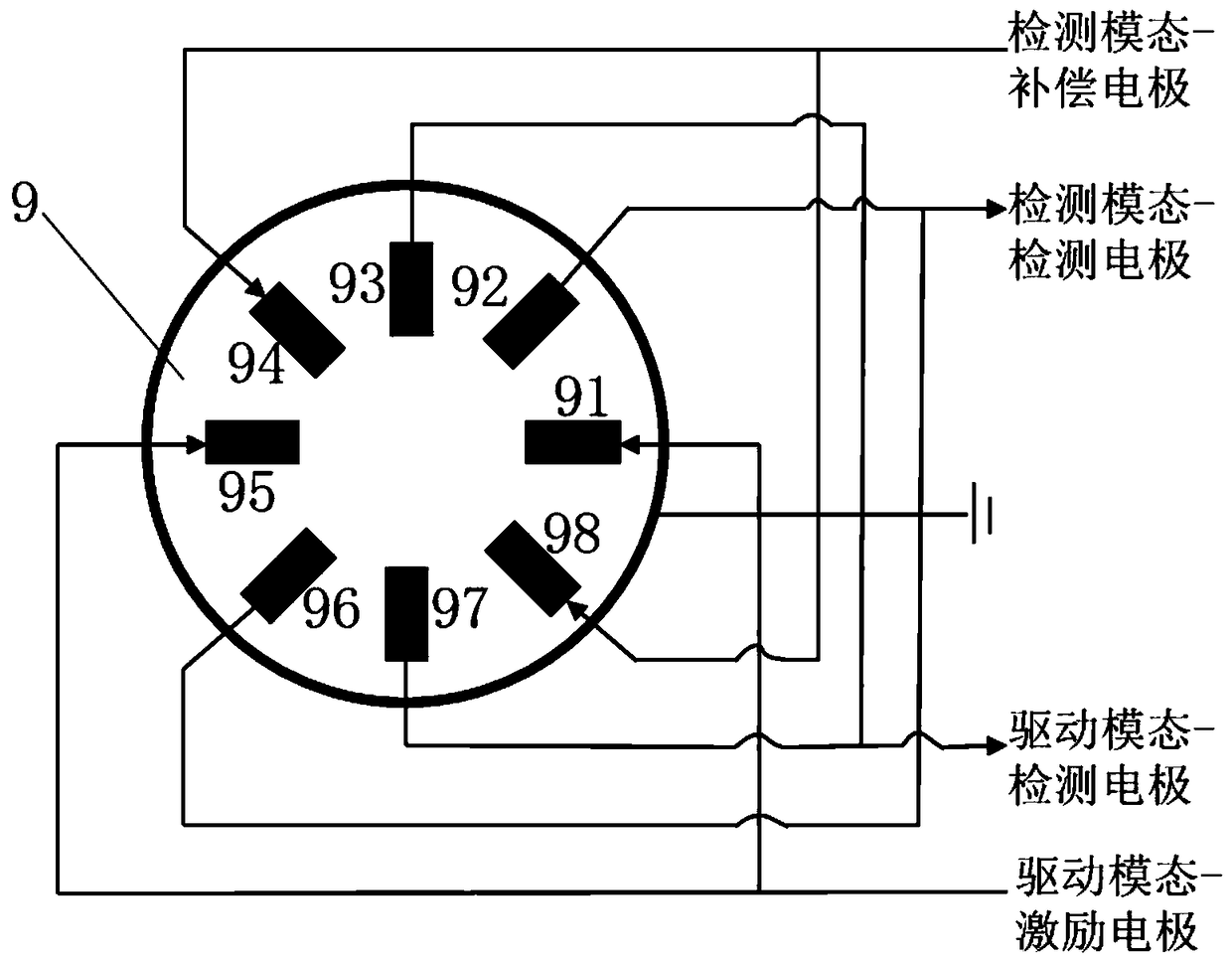

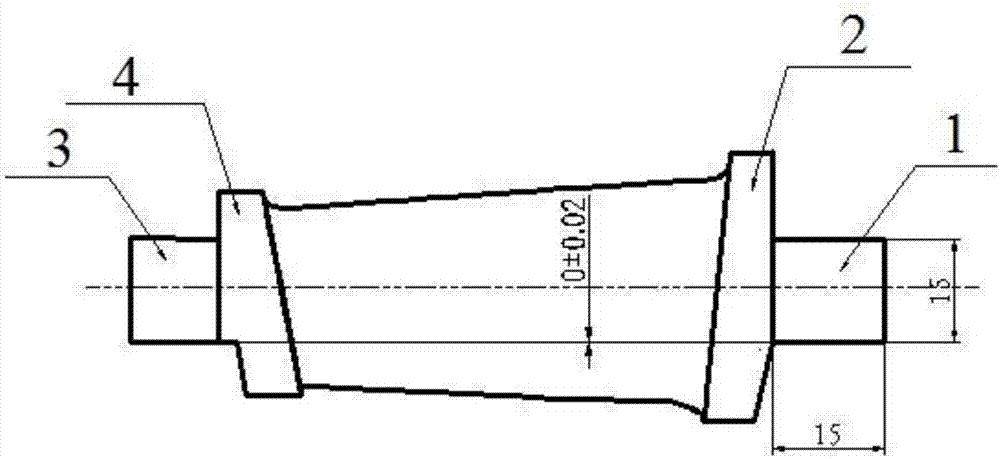

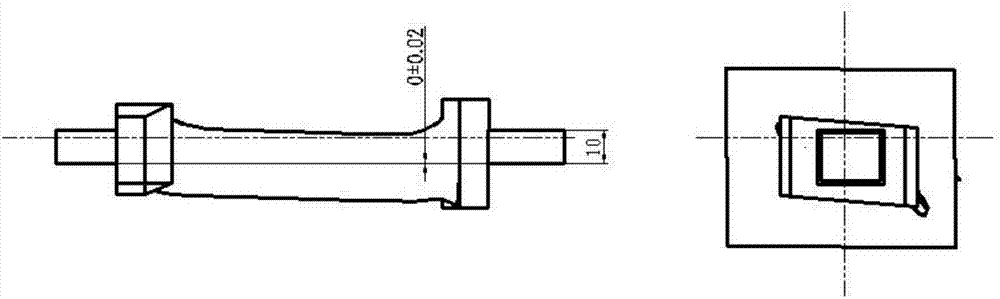

Automatic vibrating gyroscope trimming method

The invention belongs to the field of sensors, and discloses an automatic vibrating gyroscope trimming method. The automatic vibrating gyroscope trimming method comprises the following steps: (1), automatically measuring the intrinsic frequencies of a harmonic vibrator of a vibrating gyroscope in two working modes, and calculating ta frequency cracking value according to the intrinsic frequencies;(2), if the frequency cracking value does not meet an accuracy requirement, comparing the two intrinsic frequencies to automatically determine a trimming mode and a corresponding trimming method; (3), controlling the gyroscope to move to an expected machining position by automatically positioning the relevant physical position of the gyroscope and the physical position of a trimming mechanism ofmachining equipment; (4), automatically planning a machining technology according to a relationship between the required removed mass and machining technological parameters, automatically trimming thegyroscope according to the planned machining technology, and returning to the step (1) after completion of trimming. By the method, the degree of automation is high and the trimming accuracy and thetrimming efficiency are improved.

Owner:CENT SOUTH UNIV

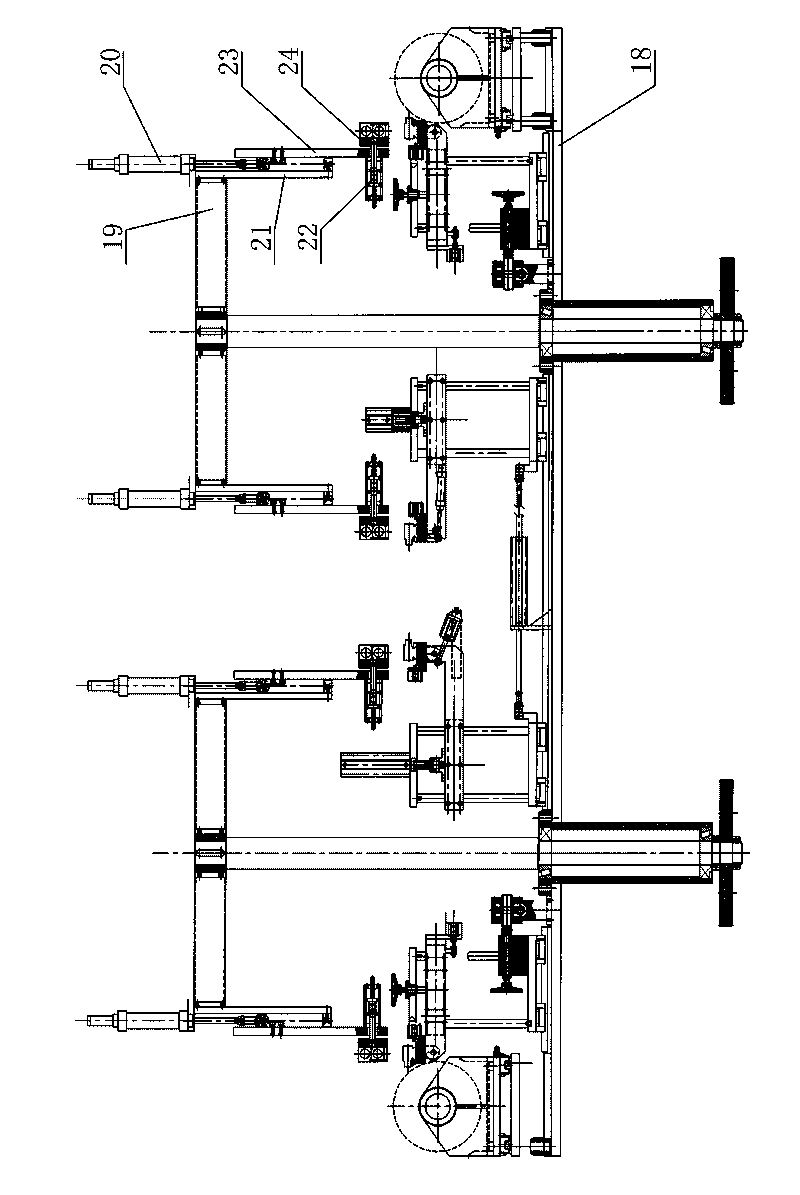

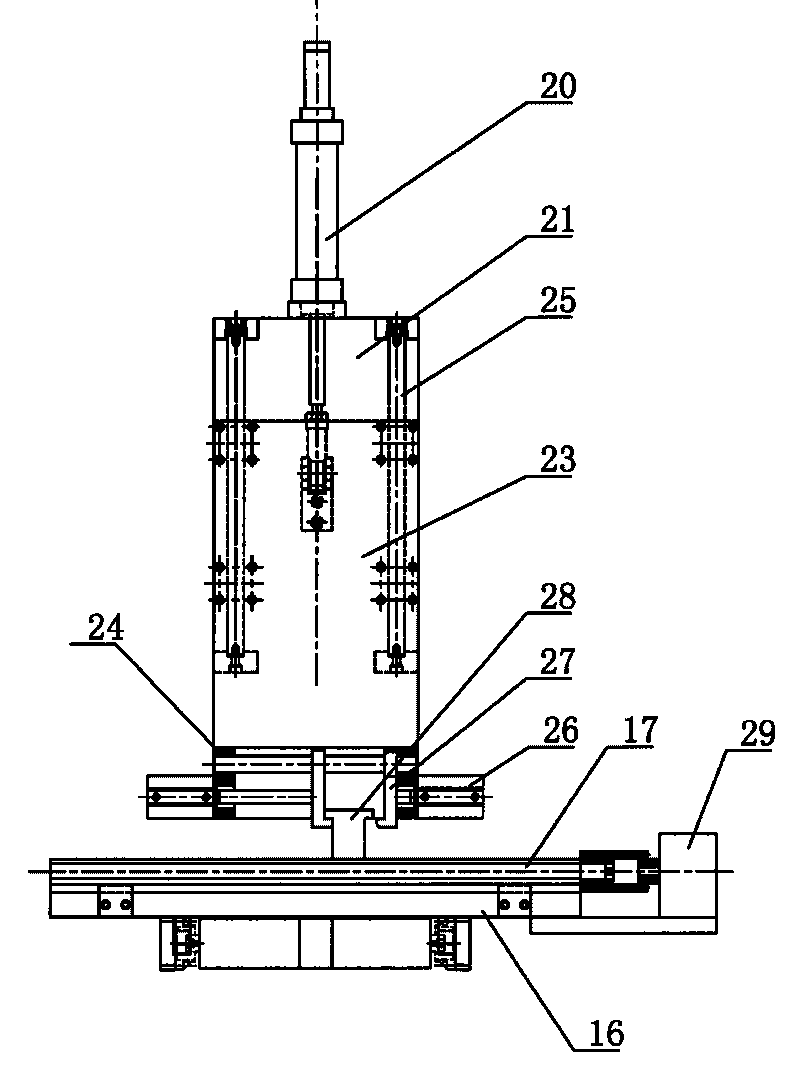

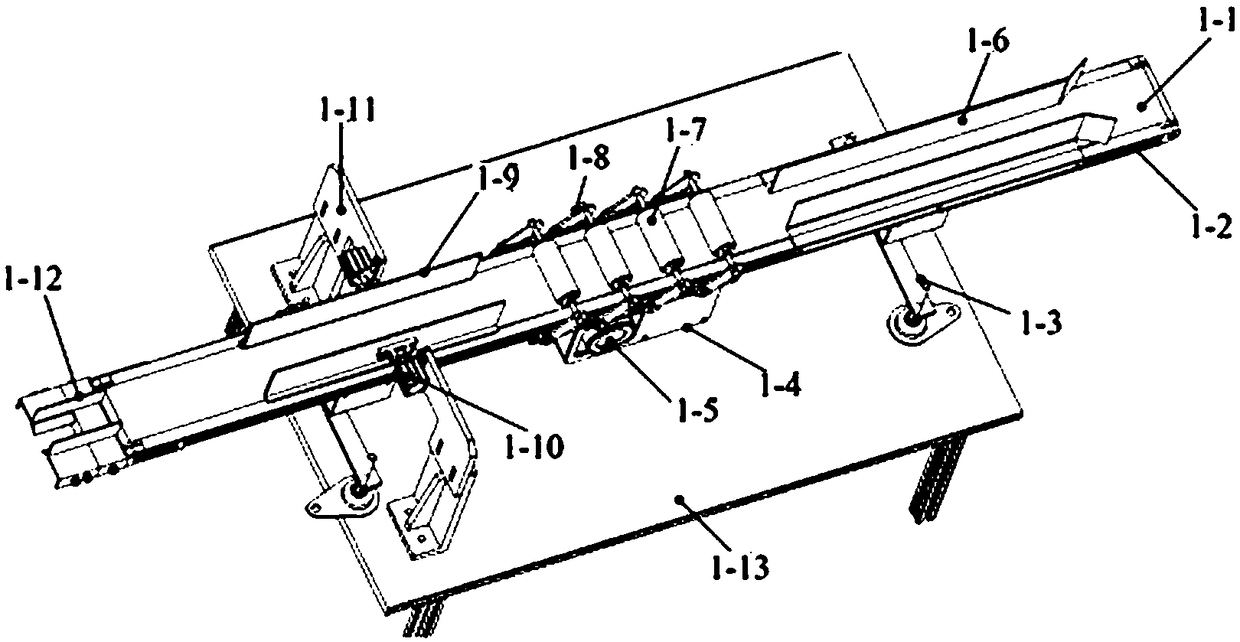

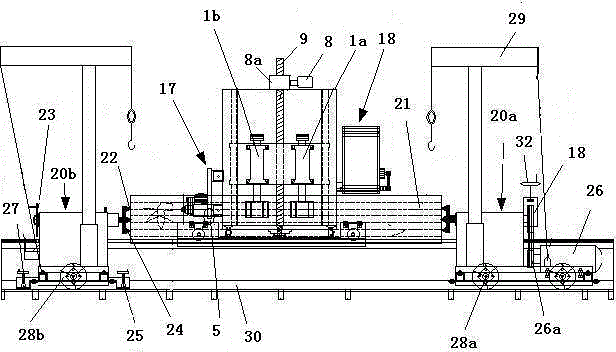

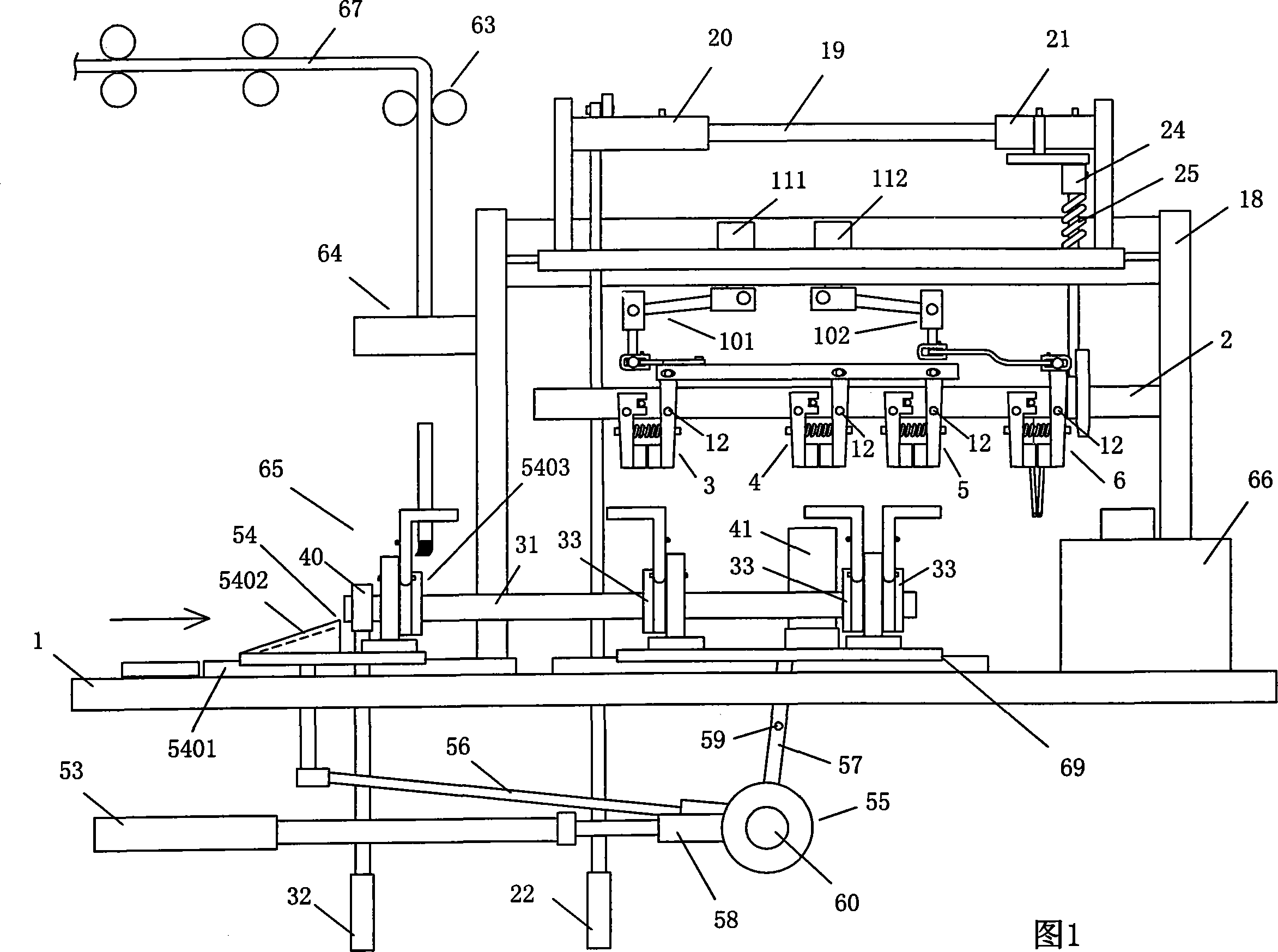

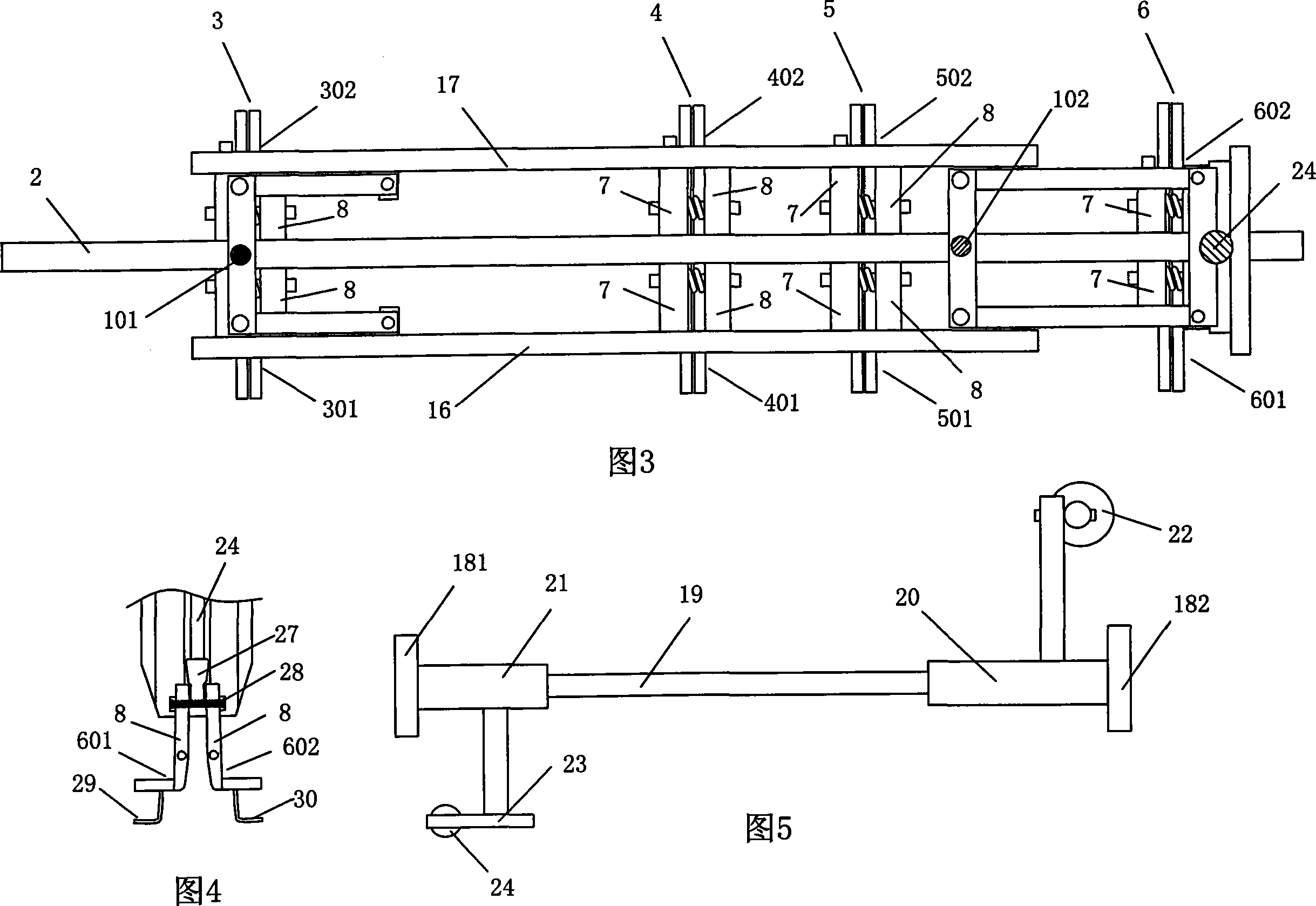

Automatic automobile shifting fork machining machine tool

InactiveCN103920918ARealize automatic processingMeet the needs of mass productionMilling equipment detailsMetal working apparatusBatch productionEngineering

The invention relates to an automatic automobile shifting fork machining machine tool which mainly solves the problems that conventional automobile shifting fork machining equipment is low in production efficiency, the product quality is difficultly controlled, the machining cost is high and automation is difficultly realized. The automatic automobile shifting fork machining machine tool is characterized in that a numerical control sliding table (2) which slides along a machine tool body (1) is arranged on the machine tool body (1); a first milling power head (3), a second milling power head (4) and a third milling power head (5) are arranged on one side of the machine tool body (1); a pneumatic tool (36) is arranged on the numerical control sliding table (2); a workpiece conveying slideway (18), a pneumatic mechanical hand (19) and a sliding rack (20) are arranged on one side of the numerical control sliding table (2); the pneumatic mechanical hand (19) can lift up and down and move horizontally. By adoption of an automatic clamping tooling, the pneumatic mechanical hand and the numerical control sliding table, automatic production is realized, the production efficiency and product quality are improved, the machining cost is reduced, and the requirement of batch production of automobile shifting forks is met.

Owner:珠海市金蓝五金机电设备有限公司

Overlock processing equipment

InactiveCN104250892ARealize automatic processingIncrease productivityWork-feeding meansEngineeringAutomatic processing

The invention relates to overlock processing equipment comprising a bench, a belt conveying mechanism, a synchronous roller, a cutoff mechanism, a clamping mechanism, a label bending and feeding mechanism and a two-needle machine. The belt conveying mechanism, the synchronous roller, the cutoff mechanism, the clamping mechanism, the label bending and feeding mechanism and the two-needle machine are fixed on the bench. The synchronous roller is arranged on one side of a conveying direction of the belt conveying mechanism. The cutoff mechanism is fixed between the synchronous roller and the belt conveying mechanism. The clamping mechanism is fixedly suspended over the belt conveying mechanism. The clamping mechanism is used for holding and placing cloth on the belt conveying mechanism. The two-needle machine is fixed at a feed exit of the belt conveying mechanism. The label bending and feeding mechanism is fixed on one side of the belt conveying mechanism between the synchronous roller and the two-needle machine. In this way, the overlock processing equipment has the advantages that unidirectional feeding is achieved via the synchronous roller, material is unified by the steps of clamping, cutoff and the like, the material is fed into the two-needle machine for overlock processing by the belt conveying mechanism arranged in the opposite direction, especially the cloth is subjected to label sewing prior to entering the two-needle machine, full-automatic processing is thoroughly completed, production efficiency is high, and processing quality is high.

Owner:SUZHOU JUKANG SEWING ROBOT

Automatic wool planting system of paint brush

InactiveCN108903229AReduce labor intensityImprove the quality of hair transplantBrush bodiesCardboardBristle

The invention discloses an automatic wool implantation system of a paint brush. The system comprises a bristle separating component, a cardboard implanting component, an iron shell conveying component, a bristle trimming component and a pneumatic control device, wherein the bristle separating component further comprises a wool screening device and a wool separating and implanting device; the cardboard implanting component further comprises a cardboard feeding device and a cardboard cutting device; the pneumatic control device comprises a pneumatic mechanism and a control system; wherein, the iron shell conveying component, the wool separating and implanting device, the cardboard cutting device and the bristle trimming component are centrally mounted on a fixing platform; the wool screeningdevice is located on the front side of the fixing platform; the cardboard feeding device is located on one side of the fixing platform, and is matched with the cardboard cutting device; and the bristle separating component, the cardboard implanting component, the iron shell conveying component and the bristle trimming component are all connected with the pneumatic control device. The automatic wool implantation system of the paint brush can be applicable to the wool implantation of different types and specifications of the paint brushes, is high in degree of automation, simple in operation and convenient to operate, saves manpower, and reduces production cost.

Owner:XUZHOU NORMAL UNIVERSITY

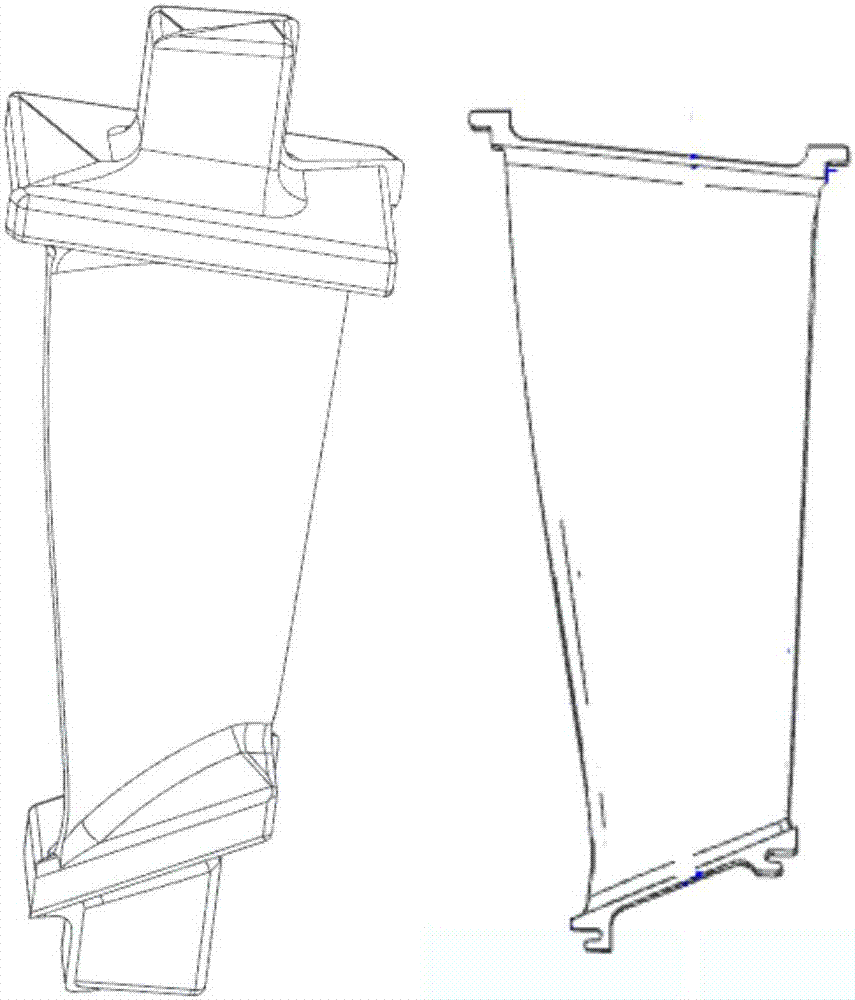

Method for quickly preparing double-mounting plate blade

The invention provides a method for quickly preparing a double-mounting plate blade. The method comprises the specific technological processes of (1) processing upper and lower technological tables: one technological table is processed at each of the upper and lower ends of a blade blank, the upper technological table is connected to a blade tenon or the outer side surface of an upper mounting plate, and the lower technological table is connected with the outer side surface of a lower mounting plate of the blade; (2) designing a clamping structure with the upper and lower technological tablesadopted as a datum; (3) carrying out rough / finish milling on the mounting plates and a blade body profile with the upper and lower technological tables adopted as the datum; (4) polishing the blade body profile; and (5) removing the upper and lower technological tables of the blade. According to the method, the problems that during conventional machining for complex-structure blades of an air compressor, the technology is complex, clamping is difficult, precision is hard to guarantee, procedures are long, quality efficiency is low, and the like, are solved.

Owner:SHENYANG LIMING AERO-ENGINE GROUP CORPORATION

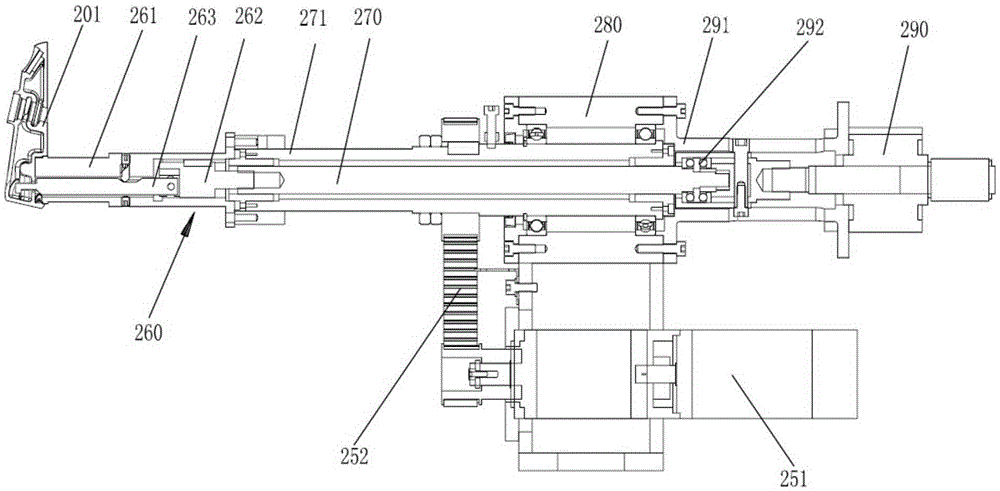

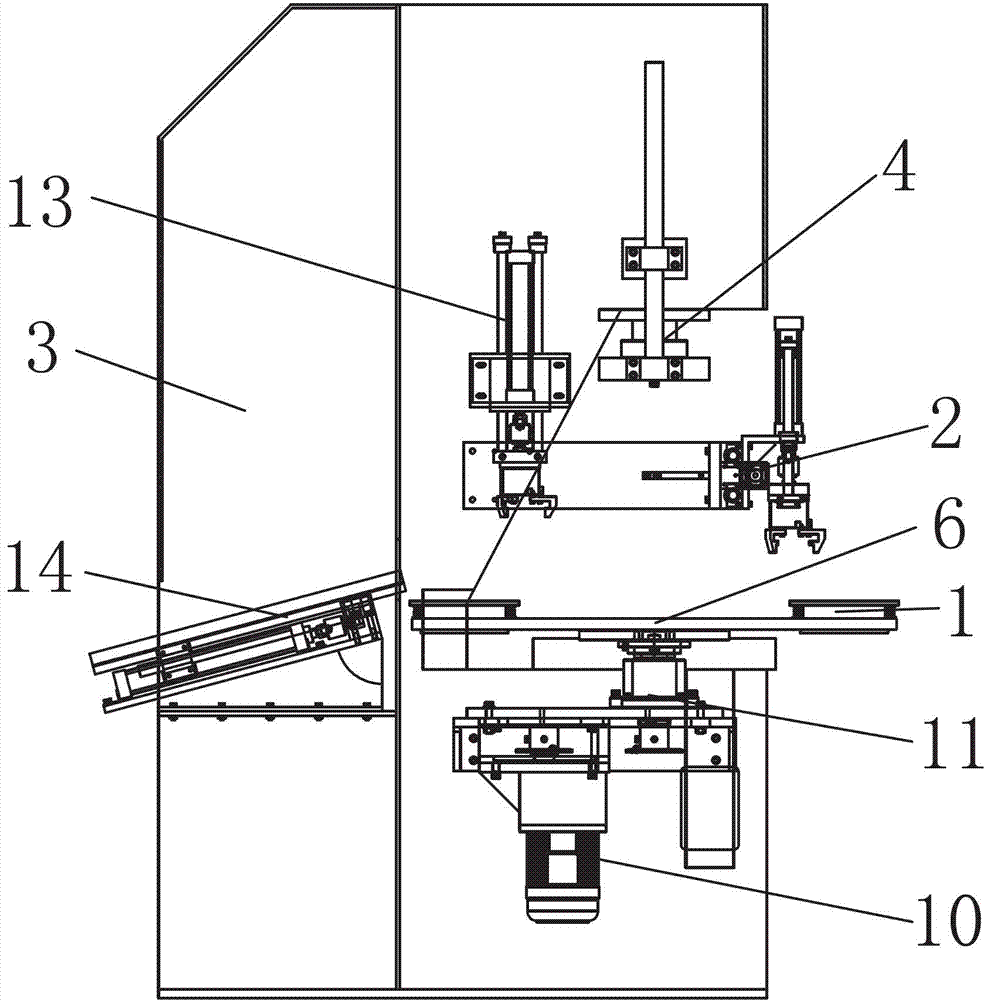

Automatic terminal processing equipment and method

PendingCN110380315ARealize automatic processingImprove yield rateContact member manufacturingContact member assembly/disassemblyManipulatorProduct defect

The invention discloses automatic terminal processing equipment. The automatic terminal processing equipment and method includes a terminal bending and cutting device, a terminal tail belt and water gap cutting device and a terminal plugging device according to the terminal processing sequence, wherein correspondingly, the terminal bending and cutting device and the terminal tail belt and water gap cutting device are provided with a conveying robot, correspondingly, the terminal tail belt and water gap cutting device and the terminal plugging device are provided with a conveying mechanism, oneside of an output end of the terminal plugging device is provided with a detection positioning seat for disposing terminals, and the detection positioning seat is correspondingly provided with a metal probe used for detecting terminal plugging. The automatic terminal processing equipment is advantaged in that structural design is reasonable and ingenious, automatic processing of the terminals isachieved, terminal plugging and length of wiring terminals are detected, cost is saved, common bad properties in market can be avoided, the yield of output products is effectively improved, moreover,break of the terminals is avoided through continuous dies for terminal bending, and the product defect rate is reduced.

Owner:东莞诚信电子塑胶有限公司

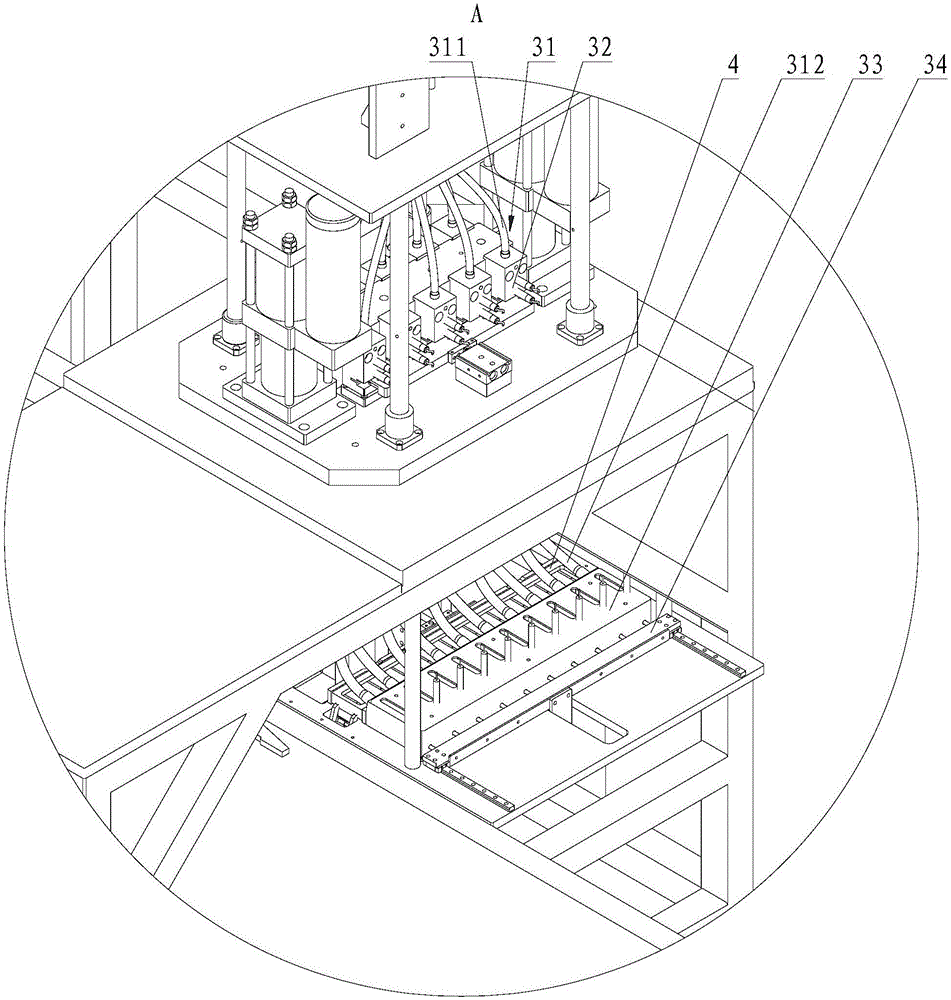

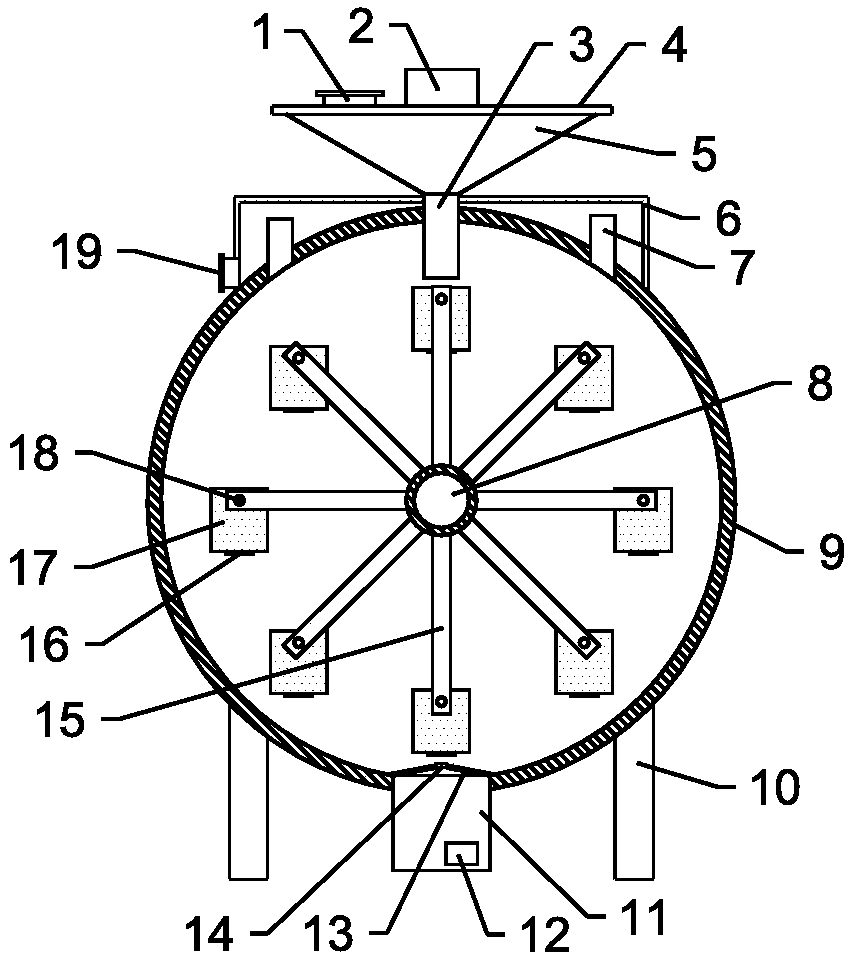

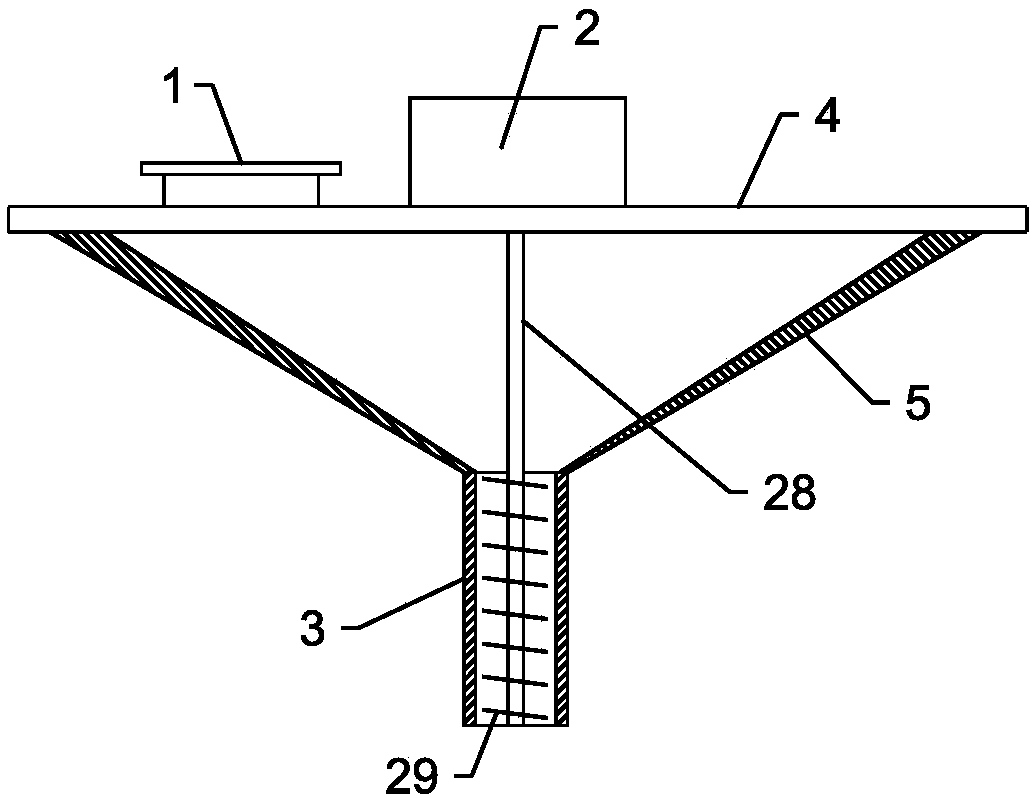

Grinding wheel polishing system and polishing control method thereof

ActiveCN105234781ARealize automatic processingEasy to controlGrinding carriagesGrinding drivesProduction lineControl system

Disclosed is a polishing system. The polishing system comprises polishing equipment and a control system; the polishing equipment comprises a polishing platform and N grinding seats uniformly distributed on the periphery of the polishing platform, and N is an integer lager than or equal to 2; the polishing platform and the N grinding seats are connected with the control system through a bus cable / bus optical cable respectively; the polishing platform comprises a base, a rotary plate arranged on the base and a first driving device; the first driving device drives the rotary plate to rotate around the center of the rotary plate; the M workpiece driving seats are uniformly distributed on the rotary plate, and M is an even number larger than N; the first driving device comprises a first motor and an intermittent separator; the first motor is in driving connection with the intermittent separator, and the intermittent separator is in driving connection with the rotary plate so as to drive the rotary plate to intermittently rotate; a communication sliding ring is arranged in the center of the rotary plate, and the workpiece driving seats are connected with the control system through the communication sliding ring. During machining, a production line is adopted for high-efficiency polishing and grinding.

Owner:广东遂联智能装备制造有限公司

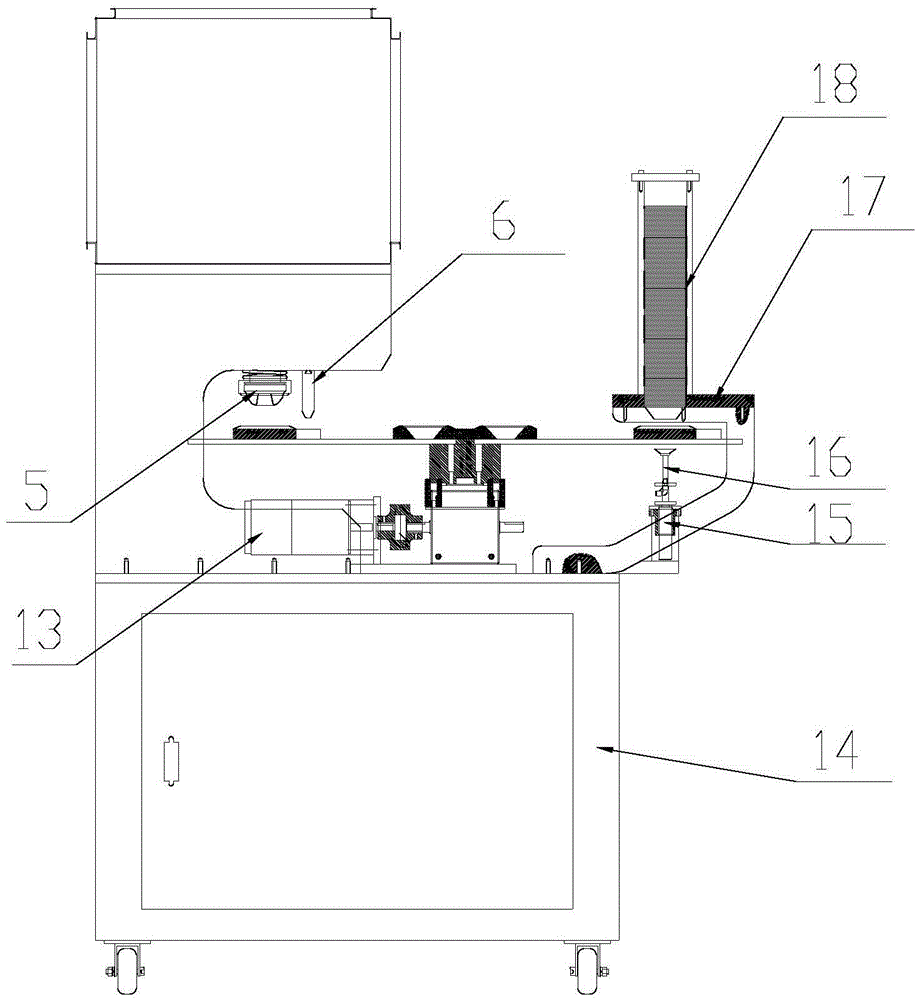

Full-automatic rotor aluminum-casting machine

The invention discloses a full-automatic rotor aluminum-casting machine which comprises a rack, a hydraulic press and a die plate, wherein the hydraulic press is fixed on the upper part of the rack, and the die plate is arranged below the hydraulic press; the lower part of the rack is provided with a rotary plate drive mechanism which can rotate automatically, and the rotary plate drive mechanism is provided with a material plate; an automatic feeding mechanism and an automatic discharging mechanism are arranged at a position, which corresponds to the material plate, on the rack; a belt conveyor is arranged at a position, which corresponds to automatic feeding mechanism is parallel to the material plate; a an automatic material receiving plate is arranged at a position which is located on the rack and provided with the automatic discharging mechanism; a waste treatment mechanism is arranged at a position which is located on the rack and corresponds to the die plate; and the rack is also provided with a ventilating luffer board. Through the way, the machine can realize the automated operation of feeding, aluminum-casting, discharging and waste treatment processes, so that the labor cost is reduced, the production efficiency is high, the operation is stable and reliable, and therefore, the machine is applicable to the mass production of aluminum products.

Owner:NIDE MECHANICAL EQUIP

Full-automatic LED package machine

ActiveCN107910287AConvenient order placementEasy to moveSemiconductor/solid-state device manufacturingConveyor partsEngineeringAutomatic processing

The invention discloses a full-automatic LED package machine. The full-automatic LED package machine comprises a hollow-structure shell and also comprises a feeding mechanism, a package mechanism, a transmission mechanism and an adjustment mechanism, wherein the feeding mechanism is arranged at one side of the top of the shell, the package mechanism is arranged on an inner wall of the other side of the top of the shell, the adjustment mechanism moves with the transmission mechanism, the transmission mechanism comprises a support rack, a transmission shaft, a conveying belt and a third drivingdevice, the transmission shaft is rotatably connected to the top of the support rack, the conveying belt sleeves the transmission shaft, the third driving device drives the transmission shaft to rotate, the adjustment mechanism comprises a hollow fixed seat, the hollow fixed seat is fixedly arranged at the top of the transmission shaft, a positioning rod and a fourth driving device are arranged onan inner wall of the bottom of the hollow fixed seat, a first gear is arranged on an output shaft of the top of the fourth driving device, a fixed block is welded at a middle position of the positioning rod and is perpendicular to the positioning rod, and a rotation rod is rotatably connected with one side of the fixed block and is parallel to the positioning rod. The full-automatic LED package machine is reasonable in design and low in manual operation cost, full-automatic processing is achieved, the LED package efficiency and package accuracy are improved, and mass production is facilitated.

Owner:ZHONGSHAN MULINSEN ELECTRONICS CO LTD

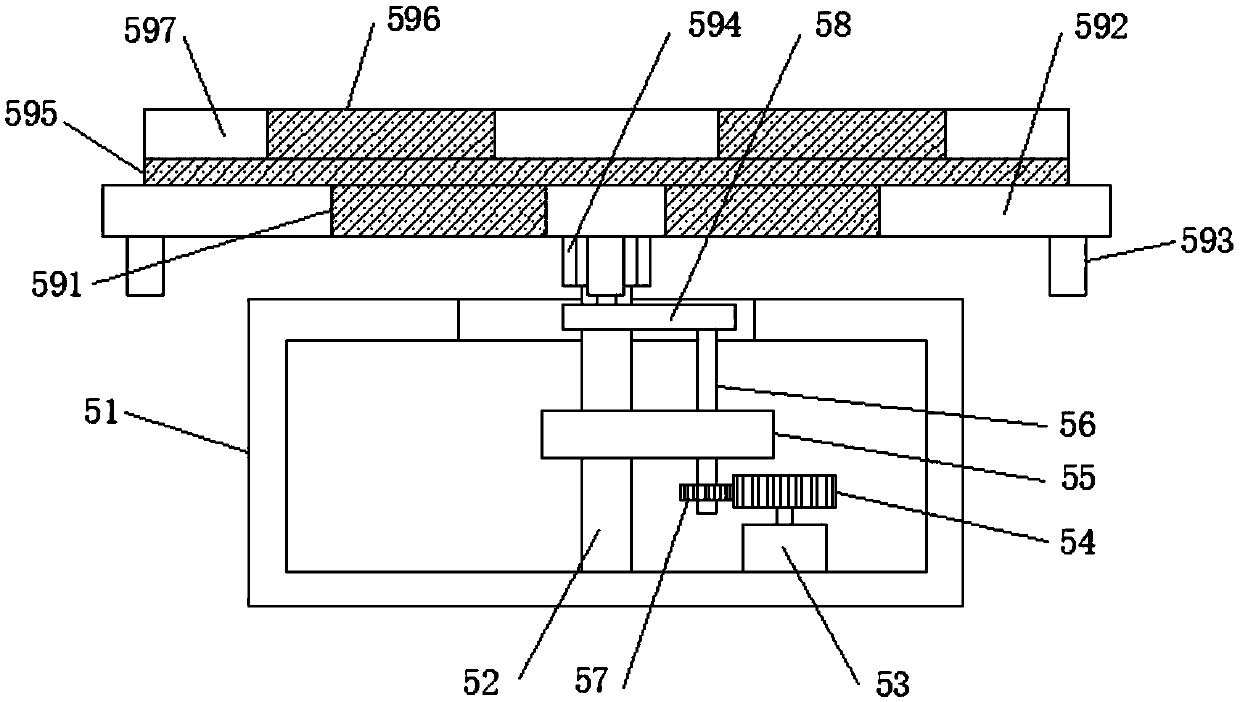

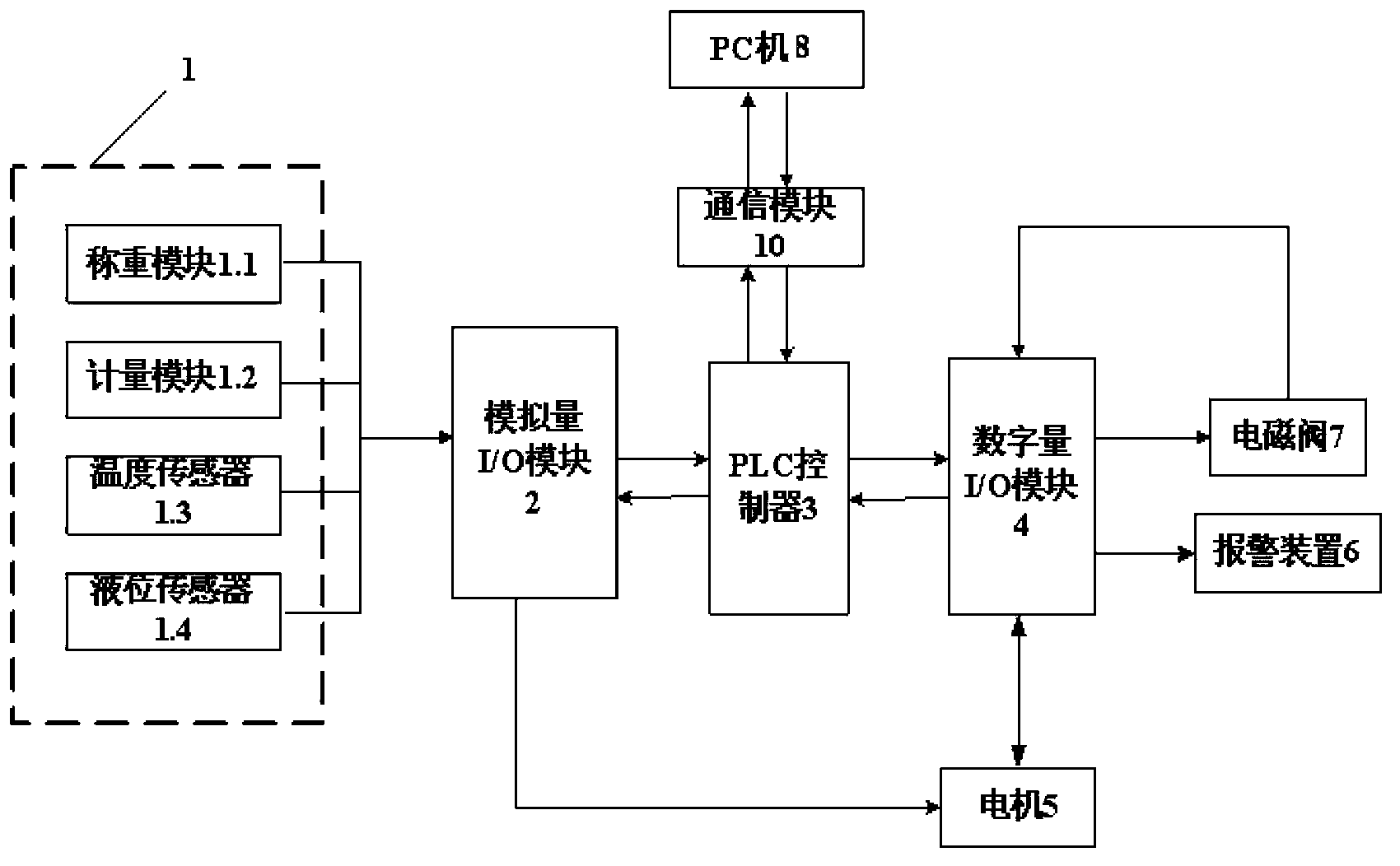

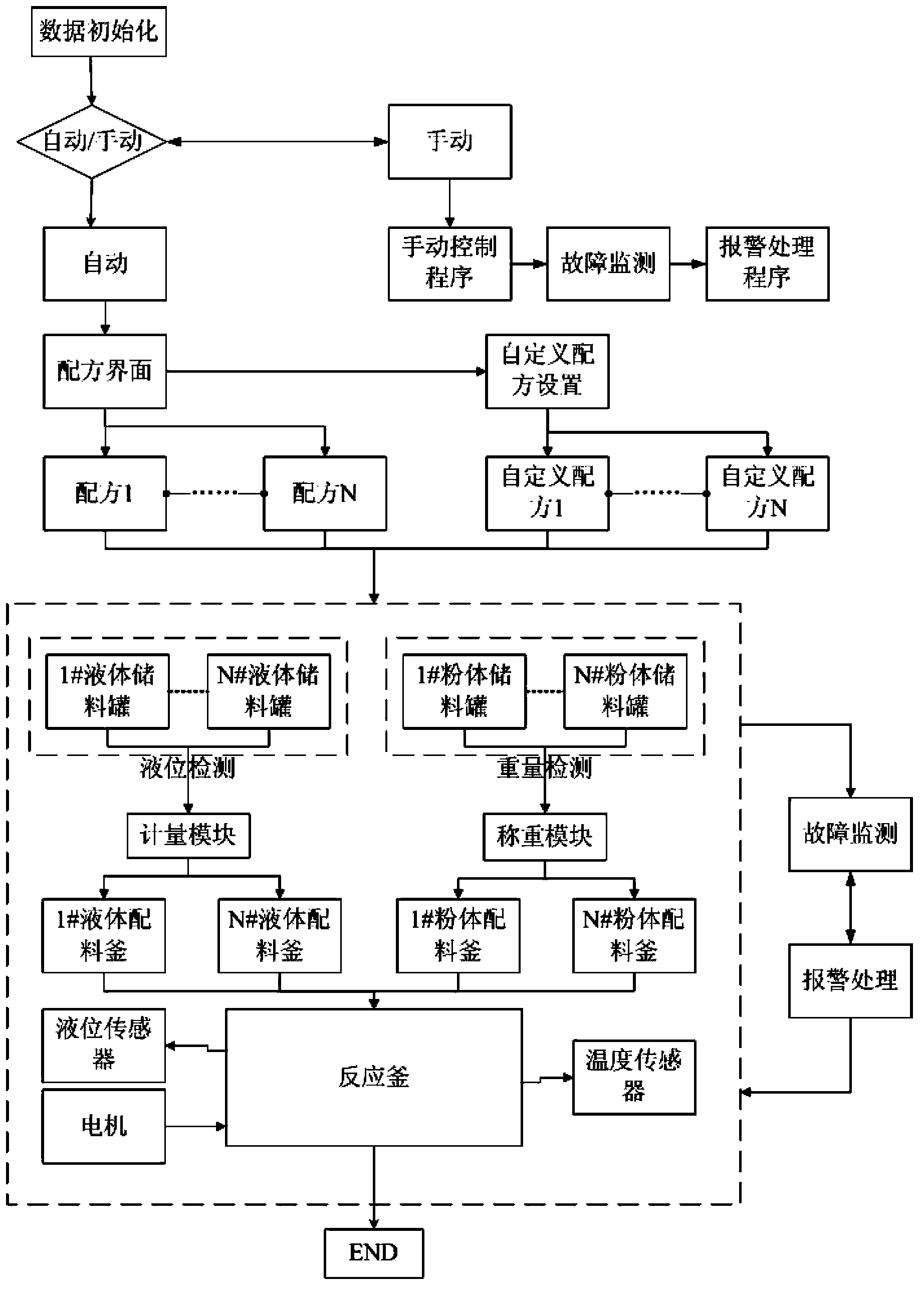

DCS control system for material processing

InactiveCN103823416AReduce operating intensity and number of peopleReduce manufacturing costTotal factory controlProgramme total factory controlAutomatic processingProgrammable logic controller

The invention provides a DCS control system for material processing. The system comprises a diaphragm pump arranged on a material storage tank and a motor used for starting material processing, an electromagnetic valve is arranged on the diaphragm pump, and a detection module is arranged inside the material storage tank. The detection module is in interactive connection with a PLC via an analog I / O module, the programmable logic controller is in interactive connection with a digital I / O module, the digital I / O module controls operation of the diaphragm pump through the electromagnetic valve, the output end of the electromagnetic valve is connected with the input end of the digital I / O module, and the output ends of the analog I / O module and the digital I / O module are both connected with the motor. According to the DCS control system for material processing provided by the invention, material weighing, material feeding, and the temperature, liquid level and the like inside the material storage tank in the process of material stirring, dispersing or grinding can be automatically and remotely controlled, a processing device can be automatically started or stopped, the purpose of automatic processing is achieved, the cost is saved, and the product quality is improved.

Owner:ANHUI LAND GRP

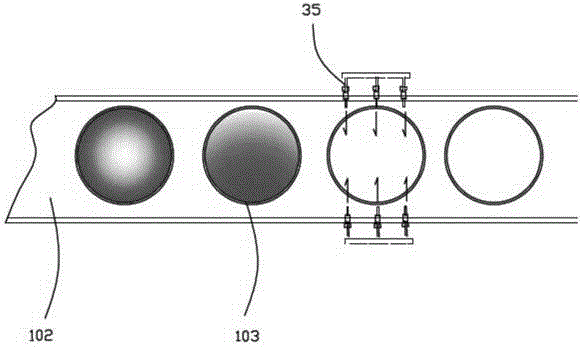

Production process of reflective thermal attachment film and special production line thereof

ActiveCN103529504ASimple processing technologyReduce processing costsLayered productsReflex reflectorsMachining processAdhesive

The invention relates to a production process of a reflective thermal attachment film. The production process comprises the following steps: firstly coating a composite adhesive on an anti-adhesion film through a composite adhesive coating mechanism and then feeding into a drying tunnel for drying; performing first compounding with a bead implanted film through a rubber roll and a steel roll; performing second compounding on the composite bead implanted film and the adhesive film through a rubber roll and a steel roll; coiling after the two compounding steps to obtain a finished product. According to the production line, automatic feeding of the anti-adhesion film, the composite bead implanted film and the like is realized by using mechanisms such as each bottom roll and guide roll, and continuous automatic machining is realized on the same production line. By using the production process and the production line of the reflective thermal attachment film, firstly the machining process is simplified and the machining cost is effectively reduced, secondly the machining efficiency and the machining quality are also effectively improved while automatic machining is realized and a large amount of cost such as labor cost is saved, and thirdly automatic stripping and recovery of the anti-adhesion film are realized, the recycling is facilitated, a large amount of material cost is saved, and considerable economic profit is brought to manufacturers.

Owner:HANGZHOU CHINASTARS REFLECTIVE MATERIAL

Core insertion machine for earpieces

InactiveCN105834714ARealize automatic processingIncrease productivityMetal working apparatusEngineeringAutomatic processing

The invention discloses a core insertion machine for earpieces. A machine frame is provided with a closed conveying rail, the conveying rail is provided with a plurality of clamping devices for clamping the earpieces, and the clamping devices are distributed on the conveying rail at intervals and correspond to an earpiece feed mechanism, an insertion pin feed mechanism, a waste removal mechanism, a press-polishing mechanism, a glue covering mechanism and a discharge mechanism in a one-to-one mode; the machine frame is further provided with conveying drive devices driving the clamping devices to slide along the conveying rail; two opening assemblies used for opening the clamping devices are arranged on one side of the conveying rail, one opening assembly is arranged on the earpiece feed mechanism and is used for clamping the earpieces on the clamping devices, the other opening assembly is arranged on the discharge mechanism and is used for taking out the earpieces from the clamping devices, and therefore automatic processing is realized, and the production efficiency is improved; the conveying rail is provided with the multiple clamping devices, and therefore the utilization rate of equipment can be effectively increased, and the production efficiency can be improved.

Owner:温州创宇智能设备有限公司

Method and apparatus of continuous collision reinforcement by laser

InactiveCN1928127AEasy to realize industrial applicationRealize automatic processingManufacturing technologySystems design

The present invention relates to special machining and manufacture technology, and is especially continuous impacting high energy short pulse laser apparatus and process for reinforcing metal material. The apparatus is provided with sliding block, flexible working film, cushion block, liquid exhausting piston and other parts to form a flowing constraint liquid medium layer capable of being replaced automatically through liquid inflow in the liquid inlet and the liquid outflow in the liquid outlet. The present invention has properly designed system to integrate the constraint liquid medium essential for laser impacting and the coating skillfully, so as to realize continuous laser impact reinforcing treatment without needing constraint layer fixing and coating. The present invention can also realize online assembling or repairing impact reinforcement.

Owner:JIANGSU UNIV

Automated fruit filling packaging production line and packaging method thereof

ActiveCN104670526AIncrease productivityRealize automatic processingSolid materialEngineeringPacking method

The invention provides an automated fruit filling packaging production line which comprises a first conveying belt structure, a second conveying belt structure, a box feeding device, a material injecting device, a film sealing device, a cover mounting device, a cover pressing device, a line changing device, a weight measuring mechanism and a labeling mechanism. A load-bearing hole is formed in a conveying belt of the first conveying belt structure to bear a material containing box used for containing fruit filling, the box feeding device, the material injecting device, the film sealing device, the cover mounting device and the cover pressing device are sequentially arranged on the first conveying belt structure, the weight measuring mechanism and the labeling mechanism are sequentially arranged on the second conveying belt structure, the line changing device is arranged at a position where the first conveying belt structure is connected with the second conveying belt structure to transfer the material containing box born in the load-bearing hole of the conveying belt of the first conveying belt structure onto the surface of the conveying belt of the second conveying belt structure. The automated fruit filling packaging production line is high in automation level, and production efficiency in fruit filling packaging can be improved greatly.

Owner:ZENGCHENG LEGO FOODS CO LTD

Automatic stamping and conveying mechanism of duplex-glue black box threading hole

ActiveCN102179836AReduce labor intensityReduce manufacturing costMetal working apparatusEngineeringAutomatic testing

The invention relates to an automatic stamping and conveying mechanism of a duplex-glue black box threading hole, comprising a stamped bottom surface conveying device, a stamped long plate conveying device and a stamped short plate conveying device, wherein the stamped bottom surface conveying device is used for conveying a duplex-glue black box into a stamped bottom hole die; the duplex-glue black box passes through a stamped bottom hole of the stamped bottom hole die and is then conveyed into a stamped long plate die through the stamped long plate conveying device; after two sides of the duplex-glue black box are stamped, the duplex-glue black box is conveyed into a stamped short plate die by using the stamped long plate conveying device; and after short plates at two ends are stamped, the duplex-glue black box is pushed to a collection box through a stamped short plate jacking cylinder. According to the automatic stamping and conveying mechanism, the duplex-glue black box threading hole is automatically stamped by adopting the conveying mechanisms to realize automatic machining, and therefore, the production efficiency and the machining precision are improved, the labor intensity is lightened, and the production cost is reduced.

Owner:YONGGAO CO LTD

Multifunctional wood machining equipment

ActiveCN104890063AMove fastReduce resistance to movementMulti-purpose machinesBark-zones/chip/dust/waste removalWood machiningEngineering

The invention discloses multifunctional wood machining equipment and belongs to the field of wood machining equipment. A running vehicle comprises a movement and driving devices moving along X-axis direction, Y-axis direction and Z-axis direction, at least two rotating spindles taking vertical direction as axis are arranged at the front end of the movement, a knife is arranged at the lower end of each spindle, and multiple rows of blades are arranged around each knife, distances between the blades on different spindles and cut wood are difference, the spindles are rotatably connected with a motor respectively, multiple top discs different in diameter are arranged on a top tip seat and a top tip of a tail seat, a rolling device along the X-axis direction is arranged on the lower portion of the tail seat, and a control panel is arranged on the multifunctional wood machining equipment. By the multifunctional wood machining equipment, production efficiency can be improved, labor intensity of operating personnel can be lowered, machining diameter can be expanded, machining variety can be increased, and sales market can be expanded.

Owner:安阳市涵缘机械设备有限公司

Special machine tool for machining pattern roller lentil-shaped groove

InactiveCN106001723ARealize processingClamp firmlyMilling machinesMilling equipment detailsHydraulic cylinderElectrical control

The invention discloses a special machine tool for machining a pattern roller lentil-shaped groove, and aims to provide a special machine tool in the field of metallurgical machining. The machine tool is provided with a frame module, a positioning and clamping device, a power head milling device and a feed indexing device; and the positioning and clamping device, the power head milling device and the feed indexing device are all arranged on the frame module. The whole structure of the machine tool adopts a gantry vertical milling machine layout; the rigidity of a machining process system is good; the workpiece positioning and clamping are realized by using a support roller and V-shaped block combined effect; a roller is fast in rotation and reliable in clamping; the workpiece maneuvering clamping and loosening are realized by using a hydraulic cylinder to achieve the effects of labor saving and fastness; a servo motor is adopted to provide power for peripheral indexing of the roller and positioning of a multi-station feeding position; the indexing and positioning precision is high; the automatic workpiece machining can be realized through electric control; and the machine tool is used for machining workpieces, low in vibration, few in surface vibration patterns, high in machining quality, simple in structure, convenient for maintenance and low in equipment investment.

Owner:KUNMING UNIV

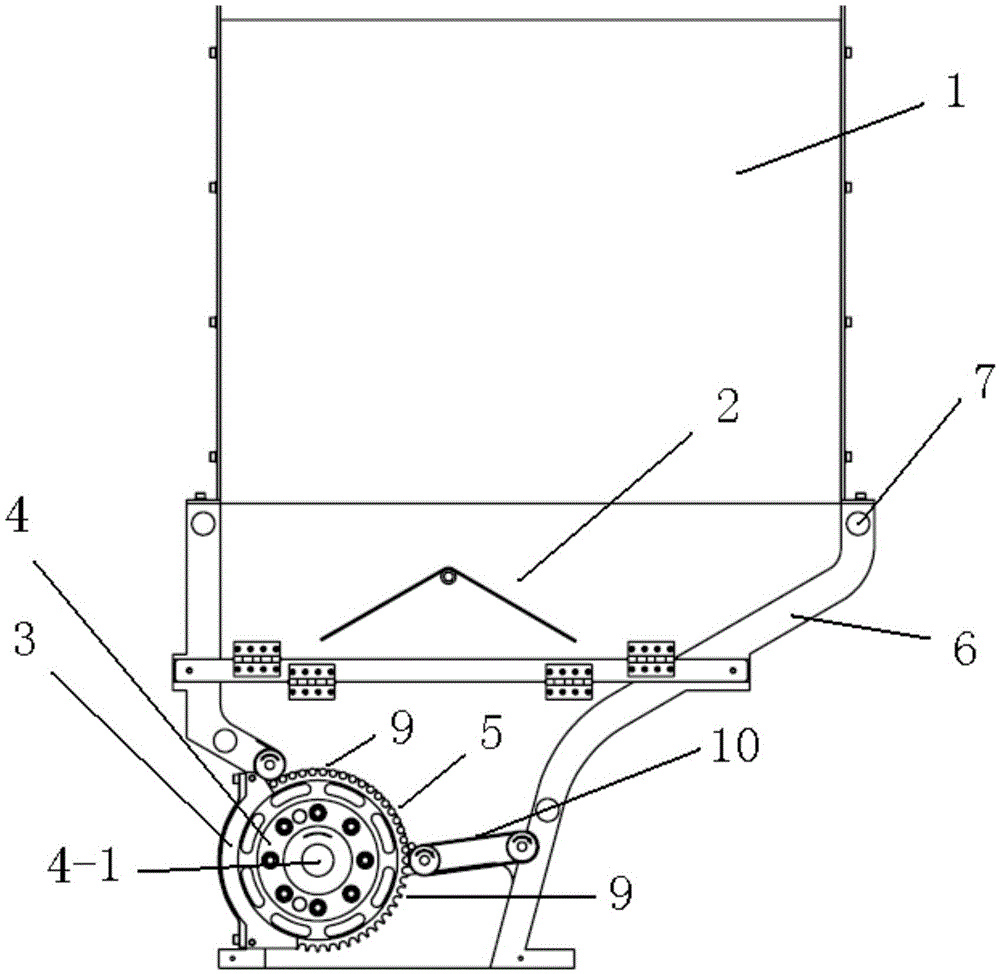

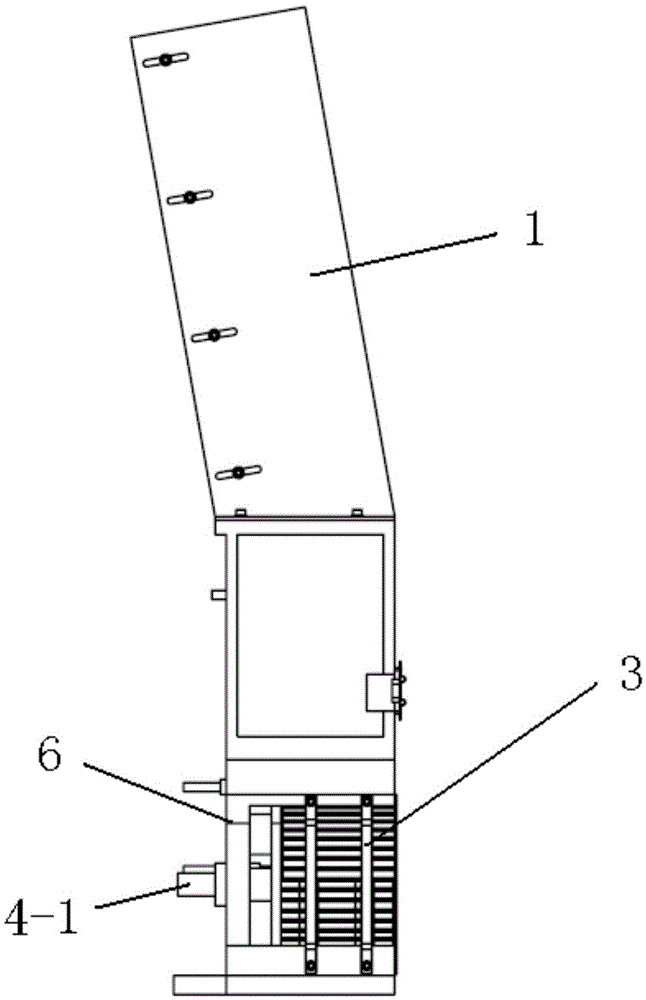

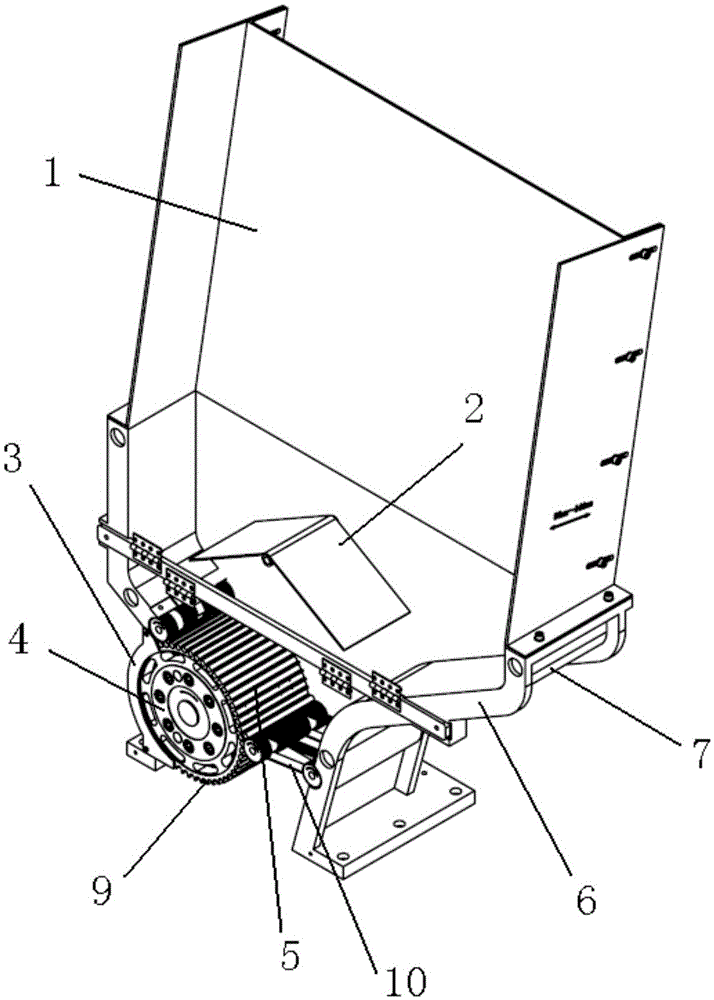

Automatic rotatable filter stick machining device

ActiveCN105533801AGood lookingHigh hardnessTobacco smoke filtersMetal working apparatusVertical planeAnnular cutter

The invention relates to an automatic rotatable filter stick machining device which comprises a machine frame (6), a drum (4) and a filter stick annular cutter (8). The machine frame (6) is provided with a conveying belt (10) for conveying filter sticks. The drum (4) is arranged on the machine frame (6) and can rotate around a horizontal rotating shaft (4-1) in the vertical plane, a plurality of grooves (9) which are parallel to one another are formed in the periphery of the drum or an annular groove belt (5) on the periphery of the drum, each groove is used for containing one filter stick, the bottom of each groove is provided with an air sucking opening, a pair of arc-shaped fixed stop pieces (3) are arranged on the circumference of the side face of the drum (4), an air sucking device communicated with an arc-shaped air flow section between the starting ends of the arc-shaped fixed stop pieces and the discharge point of the conveying belt is arranged in the drum (4), the filter stick annular cutter (8) is provided with a rotating shaft (8-1) parallel to the horizontal rotating shaft (4-1) of the drum (4) and can be driven by an annular cutting motor (8-2) to rotate, and the rotating shaft is provided with at least one annular blade (8-3).

Owner:CHINA TOBACCO YUNNAN IND

Capacitor flexible conductor automatic welding machine

InactiveCN101083377ARealize automatic processingAvoid manual interventionLine/current collector detailsElectric capacityEngineering

The invention publishes an automatic welding apparatus of electric capacity soft wire, on the rack has establishes the wire straighten installment, the wire peeling installment, the wire transfer device and the welding plant, on the rack also establishes the wire top and bottom holding device between the wire transfer device and the welding plant, the top holding device is equipped with the mounting panel on the rack, on the mounting panel has establishes at least two pairs of top clamp arm module, the each pair of the top clamp arm module is composed of the left and right two top clamp arm module, the each top clamp arm module includes the former, back arm perch, the below end of the former, back arm perch forms the up clamp hold mouth, each up clamp arm module also includes the movable former arm perch or back arm perch, the one end of the pull organization which opens the up clamp hold mouth connects to the gas jar, the former, back arm perch which connects the another end of the pull organization has the fulcrum, between the former and back arm perch has equipped with the reposition lug reed. The invention has saved the labor cost, raised the production efficiency effectively, and realized the automated production.

Owner:孔星

Separation-slot rotary peanut baking device

InactiveCN108185472AImprove drying effectImprove cleanlinessFood treatmentCooking & bakingSpiral blade

The invention discloses a separation-slot rotary peanut baking device. The separation-slot rotary peanut baking device comprises a machine body, wherein a central pipe is arranged at the middle of theinner side of the machine body; a baking oven is arranged at the opening end of the central pipe in a covering manner; an air blower is mounted on the baking oven; a second driving motor is mounted at the closed end of the central pipe; a plurality of groups of baking mechanisms are peripherally mounted on the central pipe on the inner side of the machine body; a feed pipe is mounted at the middle of the top of the machine body; a raw material box is mounted at the upper end of the feed pipe; a box cover is mounted at the top of the raw material box; a material conveying shaft is arranged atthe middle of the inner side of the feed pipe; spiral blades are mounted on the material conveying shaft on the inner side of the feed pipe; a first driving motor connected with the material conveyingshaft is also arranged at the upper end of the material conveying shaft; a material storage box is mounted at the middle of the bottom of the machine body; and an electromagnet is fixedly connected to the top of the material storage box through a plurality of supporting rods. The separation-slot rotary peanut baking device disclosed by the invention is novel in structure, reasonable in design, and good in peanut baking effect, and automatic processing is realized.

Owner:SHENZHEN RUNFENG INVESTMENT CONSULTATION CO LTD

Numerical control milling and drilling device for roof of train

ActiveCN102873537ARealize automatic processingPrecise positioningFeeding apparatusOther manufacturing equipments/toolsNumerical controlSemi automatic

The invention relates to a numerical control milling and drilling device for the roof of a train, which comprises a base, a base positioning mechanism, a base fastening mechanism, an X-axis movement mechanism, a Y-axis movement mechanism, a Z-axis movement mechanism and at least one working end. The base positioning mechanism and the base fastening mechanism are arranged on the base. The X-axis movement mechanism is arranged on and connected with the base. The Y-axis movement mechanism is arranged on and connected with the X-axis movement mechanism. The Z-axis movement mechanism is arranged on and connected with the Y-axis movement mechanism. The working end is arranged on the Z-axis movement mechanism. The numerical control milling and drilling device for the roof of the train can automatically perform face milling, hole drilling and tapping in the stroke range after being primarily positioned and stabilized. Compared with machining by manually climbing the roof and machining of a semi-automatic device of Siemens, the numerical control milling and drilling device at the roof of the train is more accurate to position, higher in machining precision and stable, and the machining quality is ensured, the work efficiency is improved exponentially and the numerical control milling and drilling device for the roof of the train is safe and reliable.

Owner:深圳市威远精密技术有限公司

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com