Capacitor flexible conductor automatic welding machine

An automatic welding machine and flexible wire technology, applied in the direction of circuits, connections, electrical components, etc., can solve problems such as high labor costs, troublesome management and production, and incoherent welding processes, so as to improve automatic processing, facilitate management and production, Effect of improving processing efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

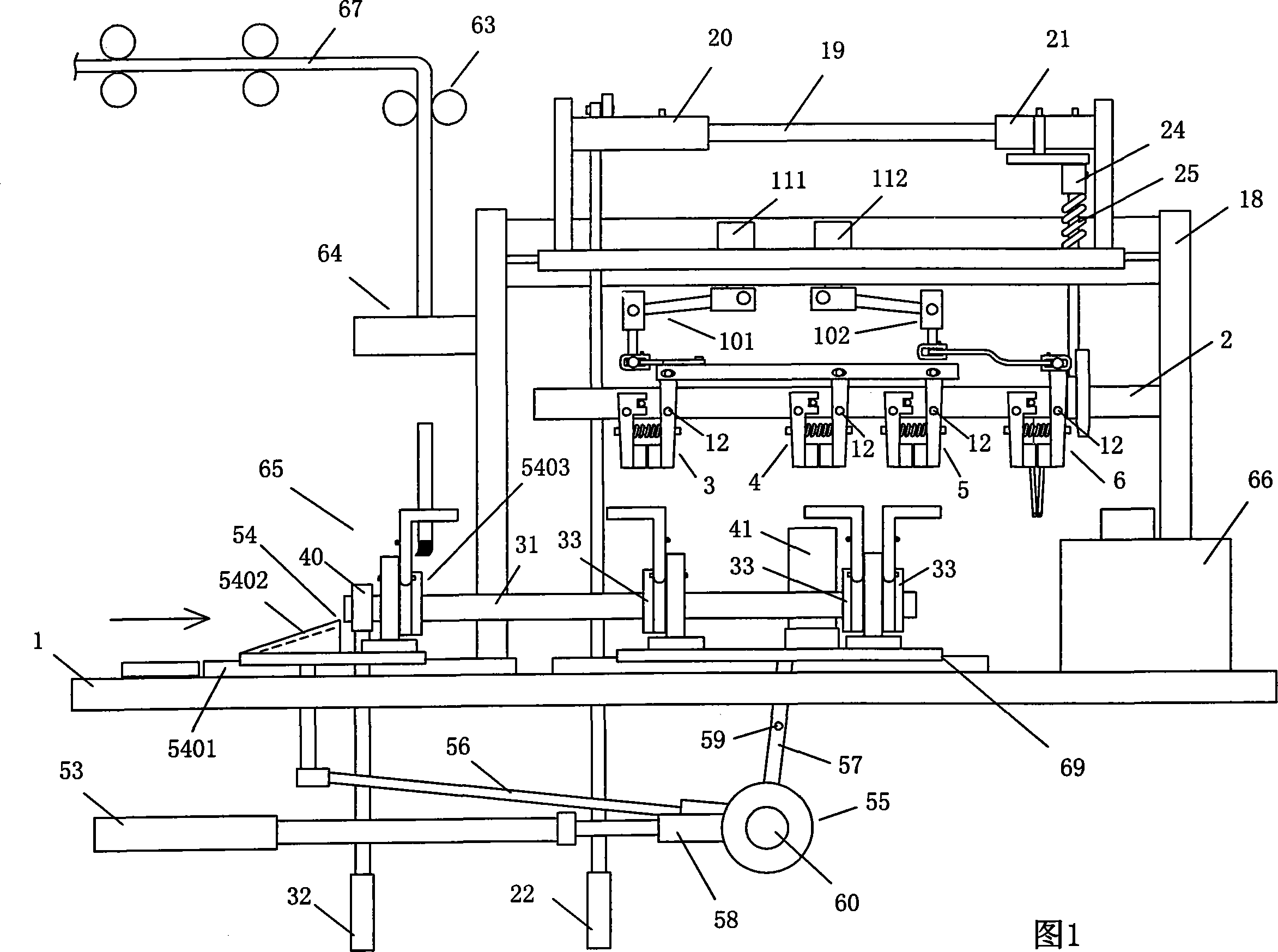

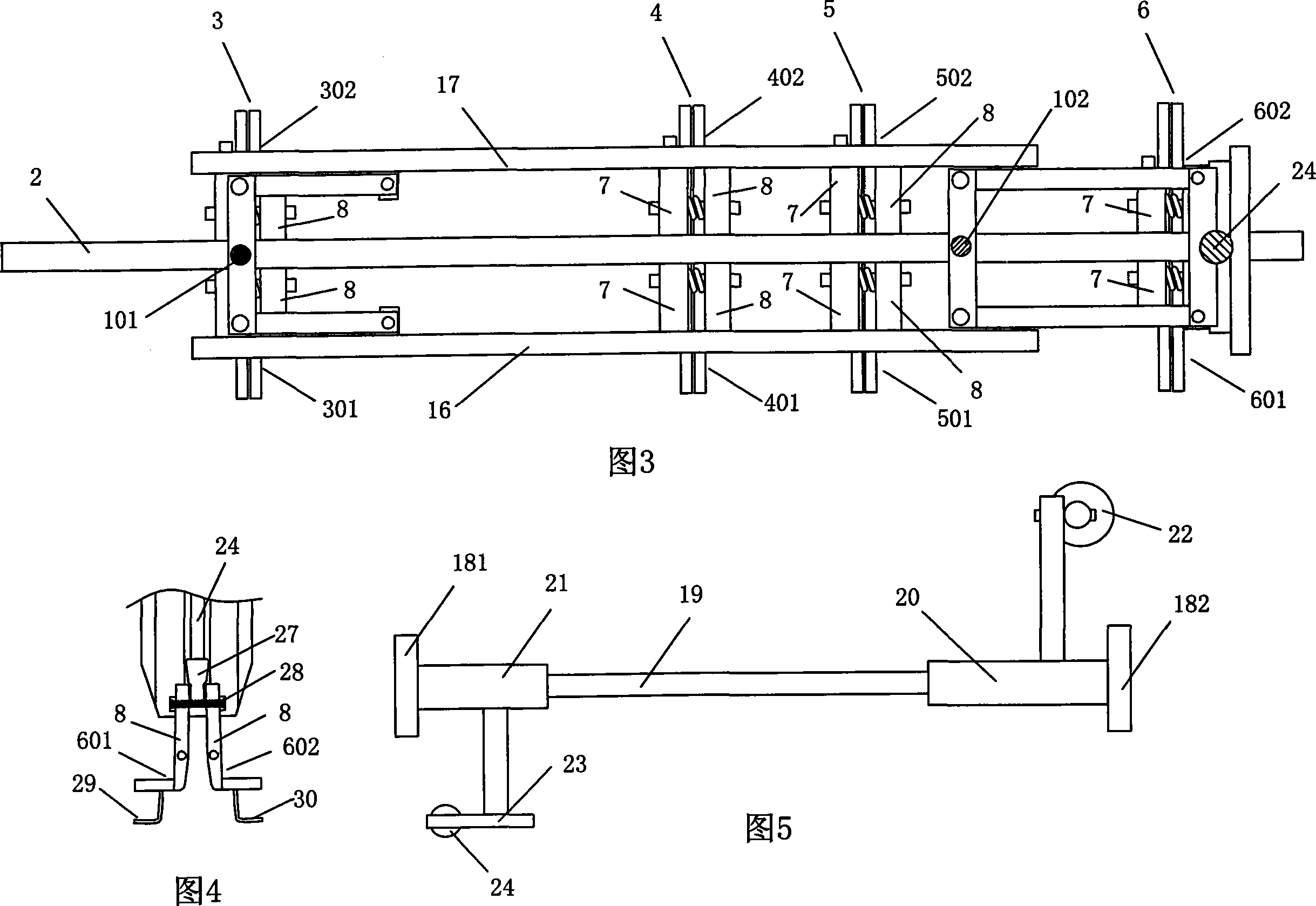

[0033] As shown in Figures 1 to 5, an automatic welding machine for flexible capacitor wires includes a frame 1 on which a wire straightening device 63, a wire stripping device 64, a wire transfer device 65, and a welding device 66 are arranged. 1, between the wire transfer device 65 and the welding device 66, upper and lower clamping devices 68, 69 of the wires are also provided. The upper clamping device 68 is equipped with a mounting plate 2 on the frame, and the mounting plate 2 At least two pairs of upper clamp arm assemblies 3, 4, 5, 6 are provided, and each pair of upper clamp arm assemblies 3, 4, 5, 6 consists of two adjacent left and right upper clamp arm assemblies 301, 302; 401, 402; 501, 502; 601, 602, each of the upper clamp arm assemblies 301, 302, 401, 402, 501, 502, 601, 602 includes front and rear arm bars 7, 8, front and rear arm bars The lower ends of 7 and 8 form an upper clamping opening 9, and each upper clamping arm assembly 301, 302, 401, 402, 501, 502,...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com