Automatic terminal processing equipment and method

A technology for processing equipment and terminals, which is applied in the field of automated terminal processing equipment, can solve problems such as reducing product defect rate, affecting production efficiency, and terminal defects, and achieve the effects of reasonable and ingenious structural design, reducing product defect rate, and avoiding bad features

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

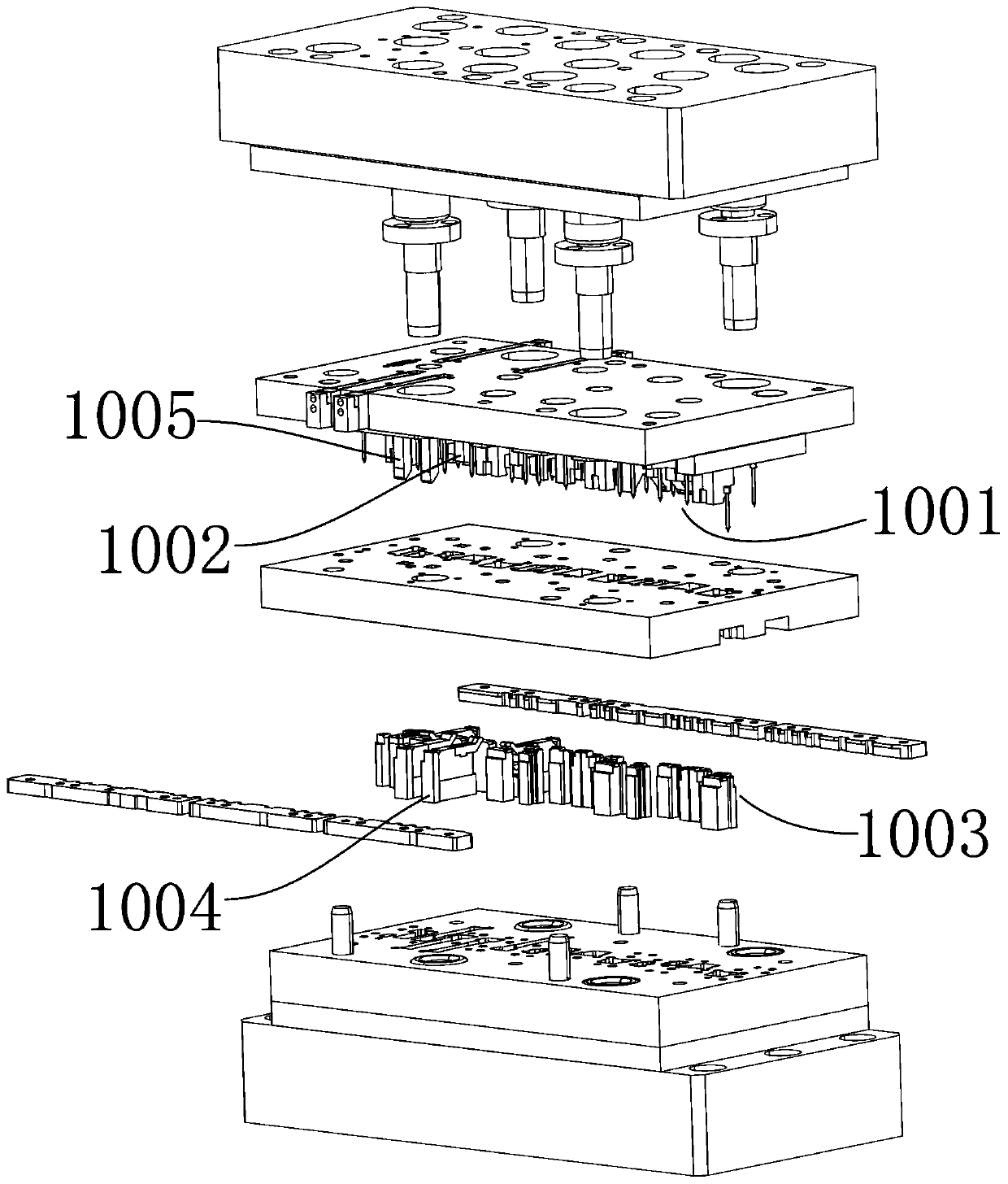

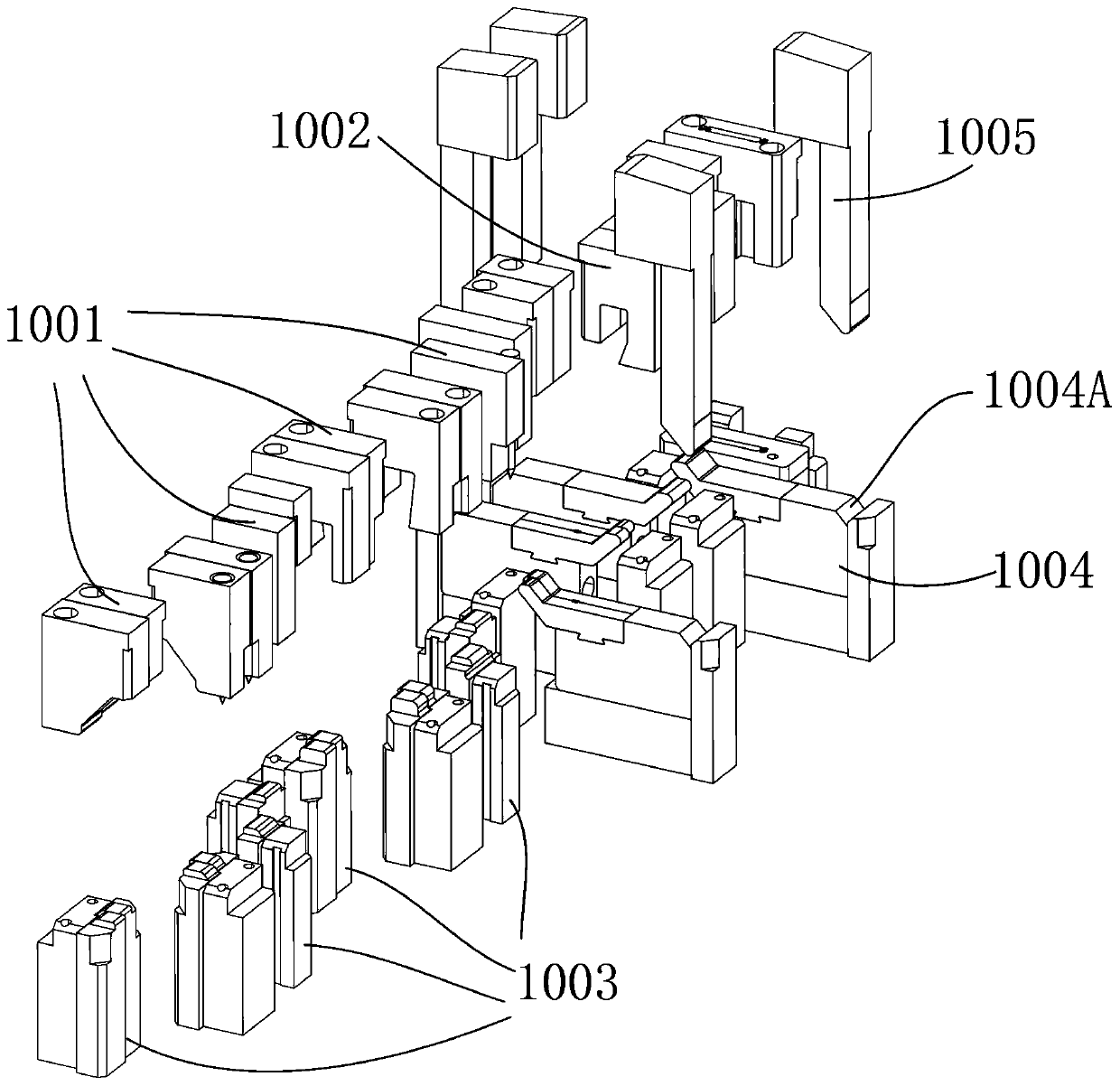

[0040] Examples, see Figure 1 to Figure 16An automatic terminal processing equipment provided in this embodiment includes: a terminal bending and cutting device 1, a terminal tail tape and nozzle cutting device 2, and a terminal pin insertion device 3 arranged in sequence according to the terminal processing direction; corresponding to the terminal bending The cutting device 1, the terminal tail tape and nozzle cutting device 2 are equipped with a feeding manipulator 4; corresponding to the terminal tail tape and nozzle cutting device 2, the terminal pin insertion device 3 is provided with a handling mechanism 5; On one side of the output end of the device 3 is provided a detection positioning seat 61 for the terminal to be nested and placed, and corresponding to the detection positioning seat 61 is provided a metal detection head 62 for detecting terminal pins.

[0041] Specifically, the detection positioning seat 61 is provided with a terminal placement groove 611 . The te...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com