Egg tart crust automatic-moulding machine

An automatic forming machine and egg tart skin technology, which is applied in the fields of dough forming machinery or equipment, baking, food science, etc., can solve the problems of low production efficiency, achieve low cost, simple structure, and reduce labor costs

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0016] The purpose of the invention of the present invention will be described in further detail below in conjunction with the accompanying drawings and specific embodiments, and the embodiments cannot be repeated here one by one, but the implementation of the present invention is not therefore limited to the following embodiments.

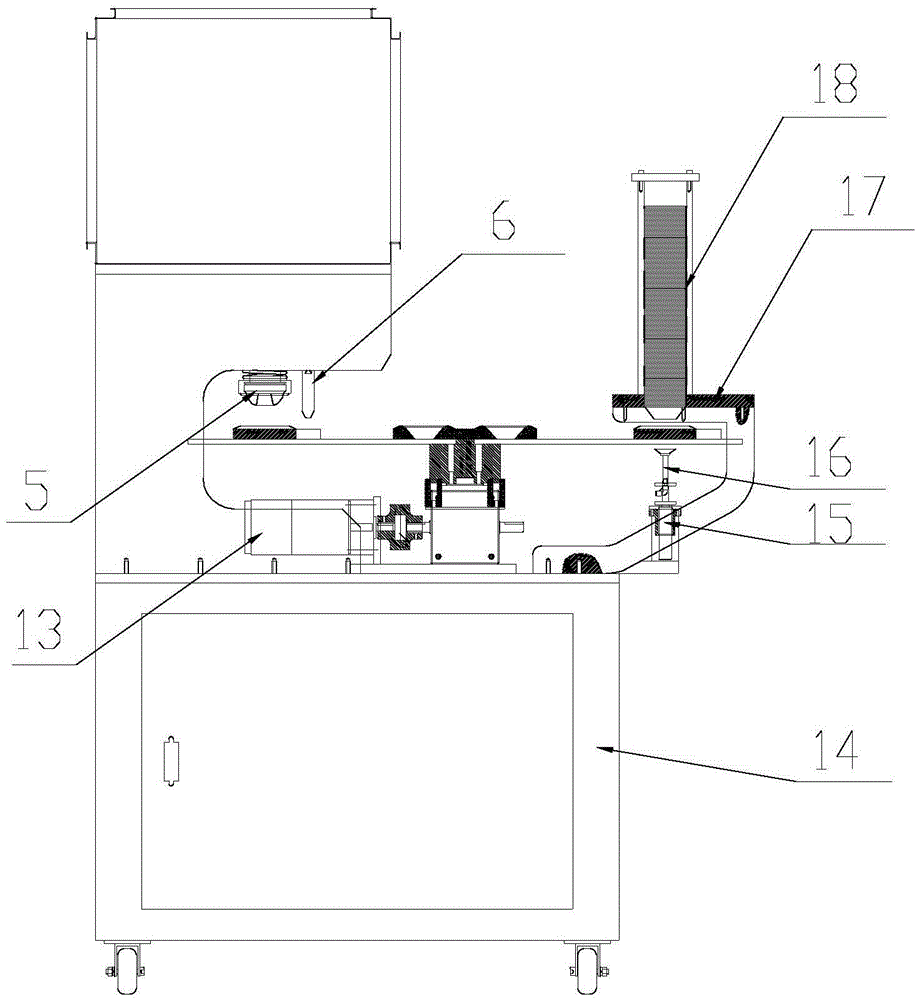

[0017] like Figure 1 to Figure 3 Shown, a kind of egg tart shell automatic molding machine comprises frame 14, is arranged on the electric control box 12 on frame 14, also comprises the cam divider 9 and motor 13 that are fixed on frame 14, and described motor 13 passes through The coupling is connected to the input end of the cam divider 9, and the output end of the cam divider 9 is connected to a horizontally rotating turntable 8, and the turntable 8 is evenly provided with double rows of forming dies 7 along the concentric circles of its rotation center, The bottom of each forming groove of the double-row forming die 7 is provided with a throu...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com