Patents

Literature

Hiro is an intelligent assistant for R&D personnel, combined with Patent DNA, to facilitate innovative research.

831 results about "Pneumatic tool" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

A pneumatic tool, air tool, air-powered tool or pneumatic-powered tool is a type of power tool, driven by compressed air supplied by an air compressor. Pneumatic tools can also be driven by compressed carbon dioxide (CO2) stored in small cylinders allowing for portability.

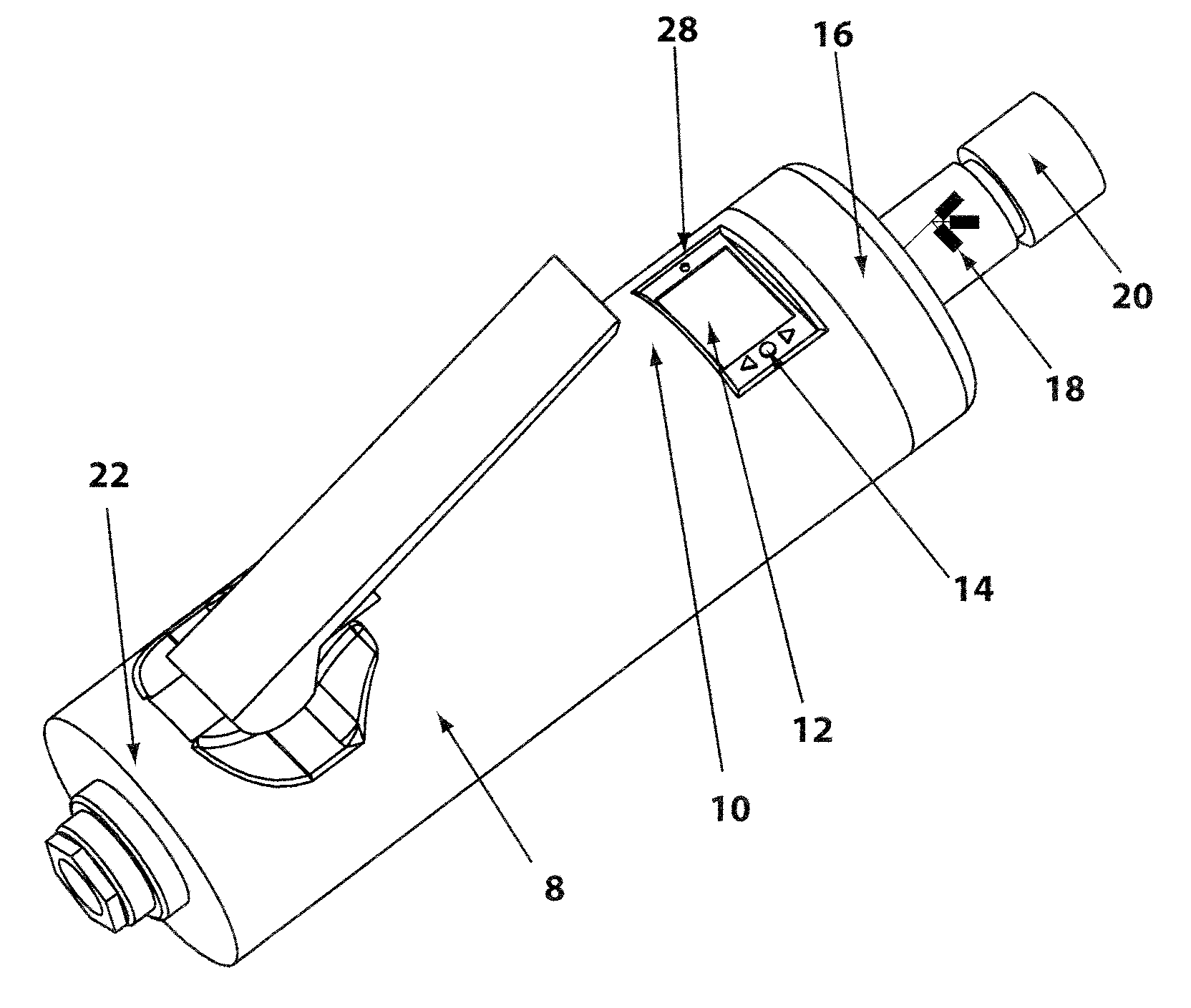

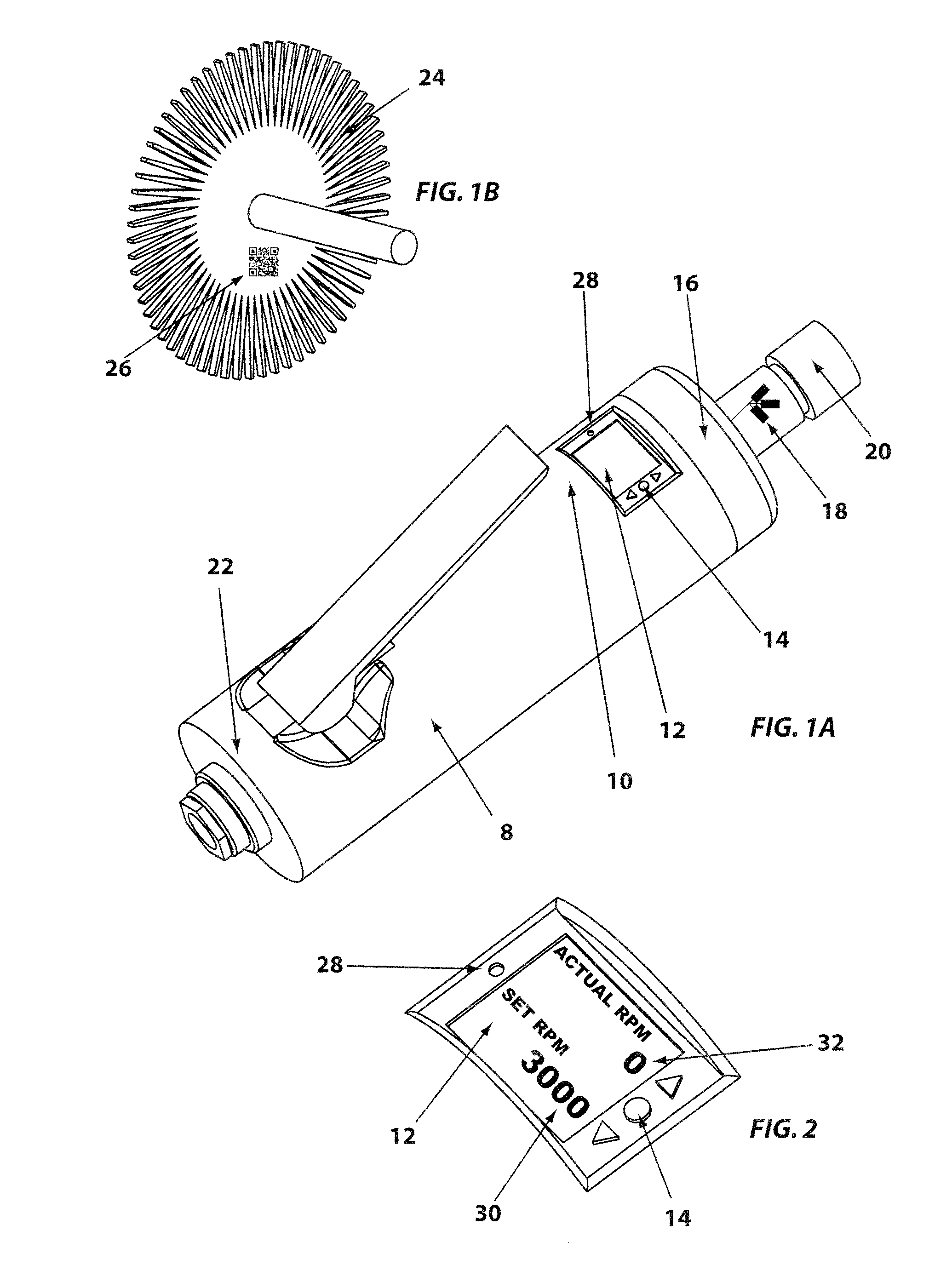

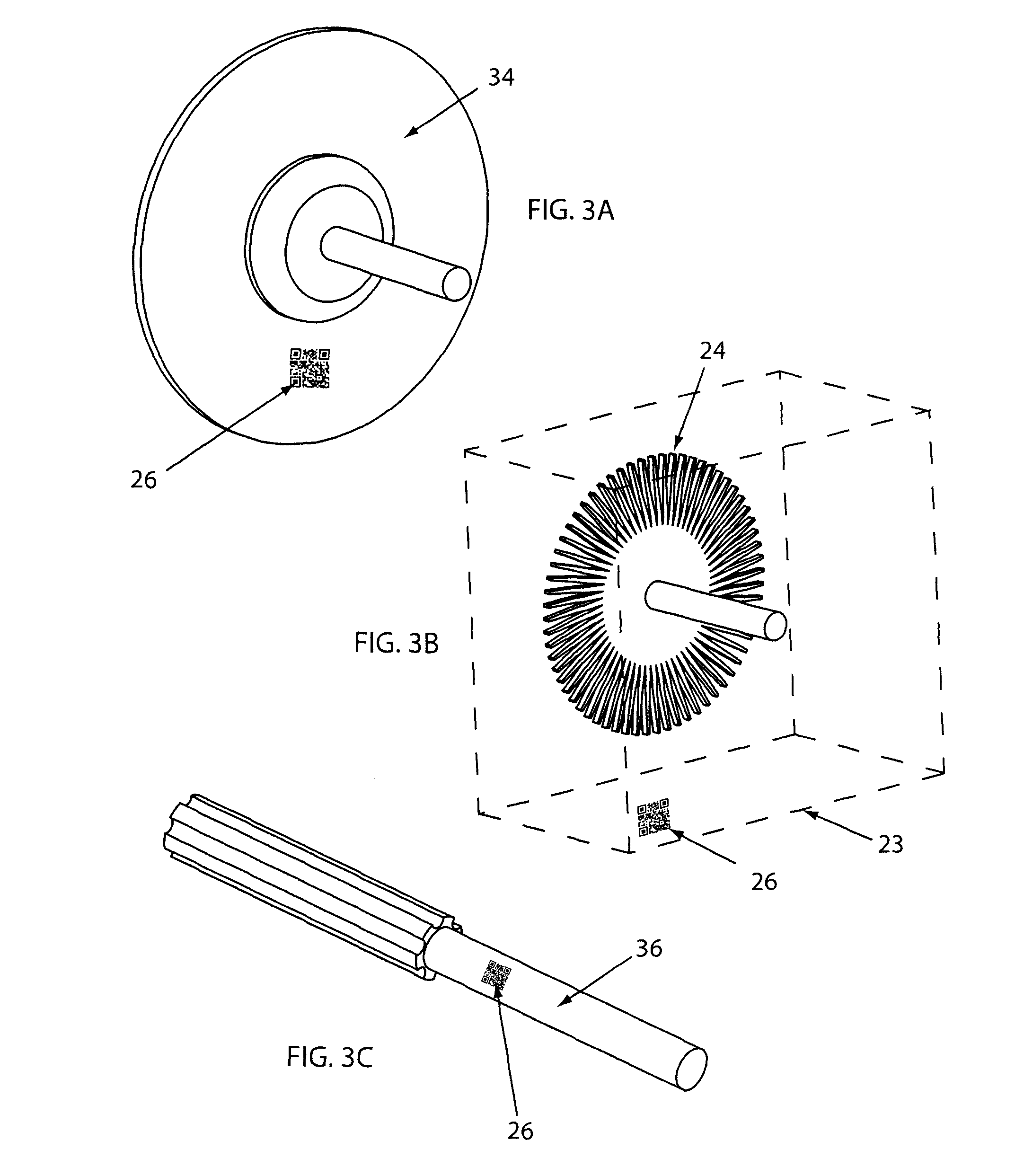

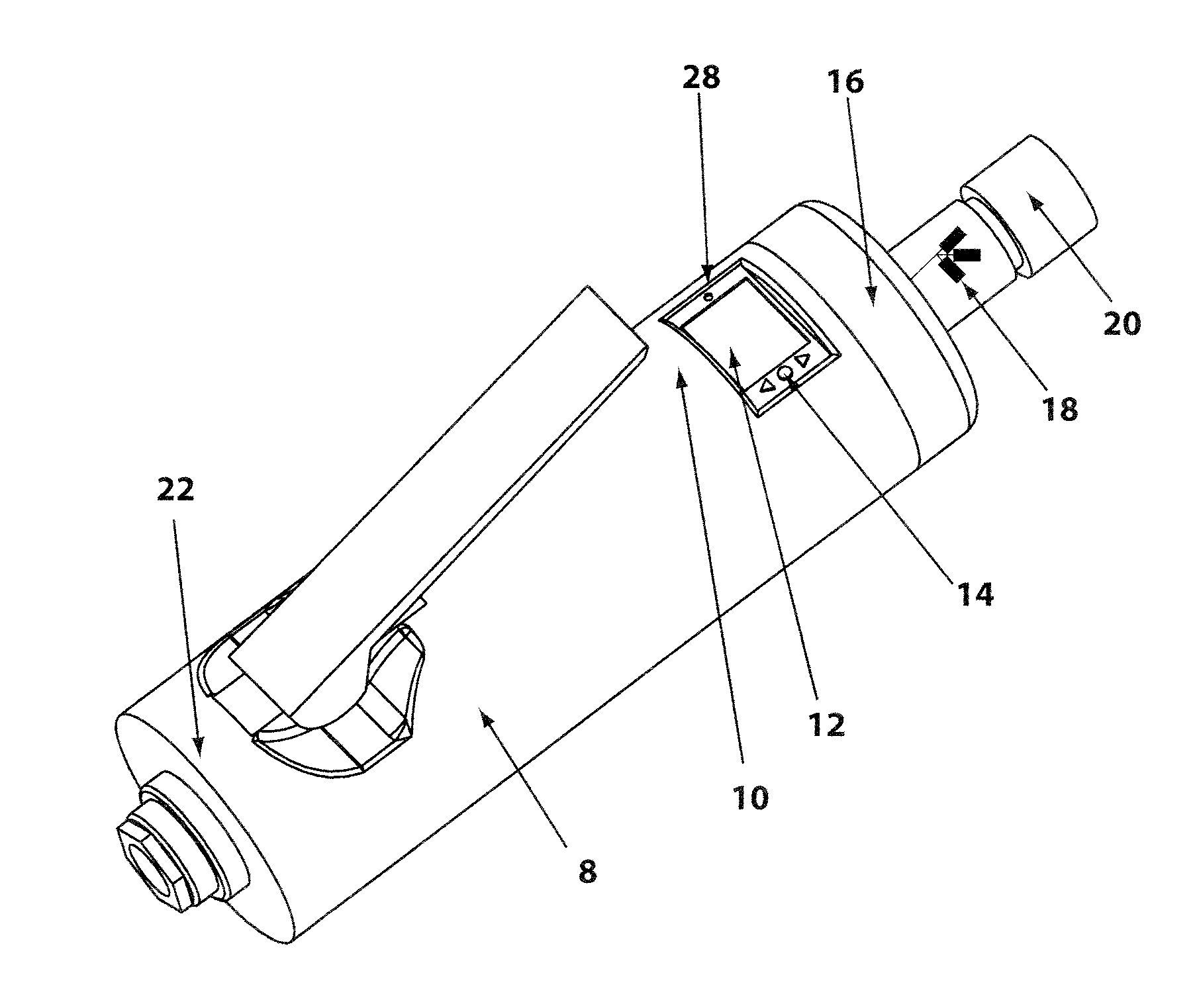

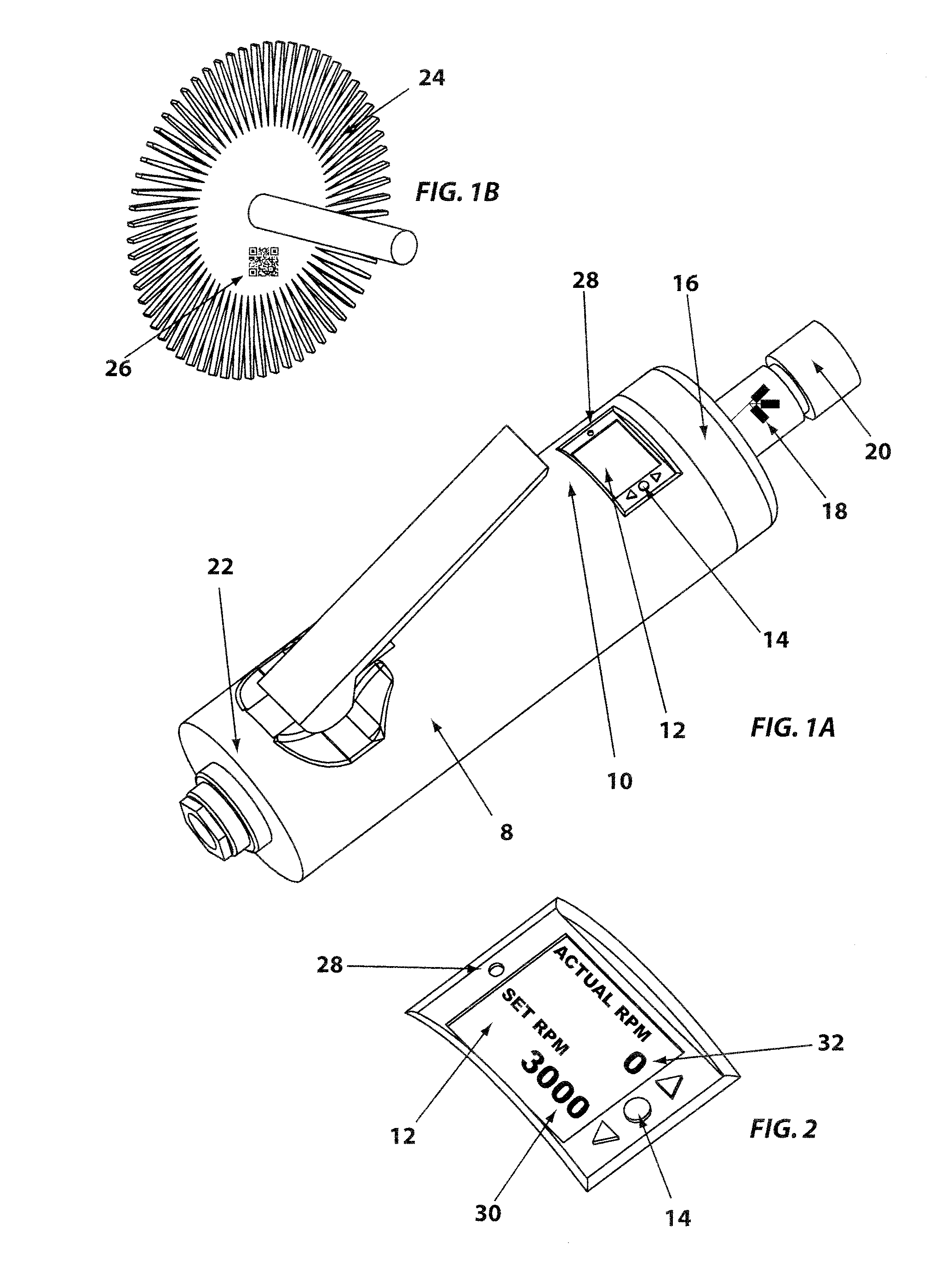

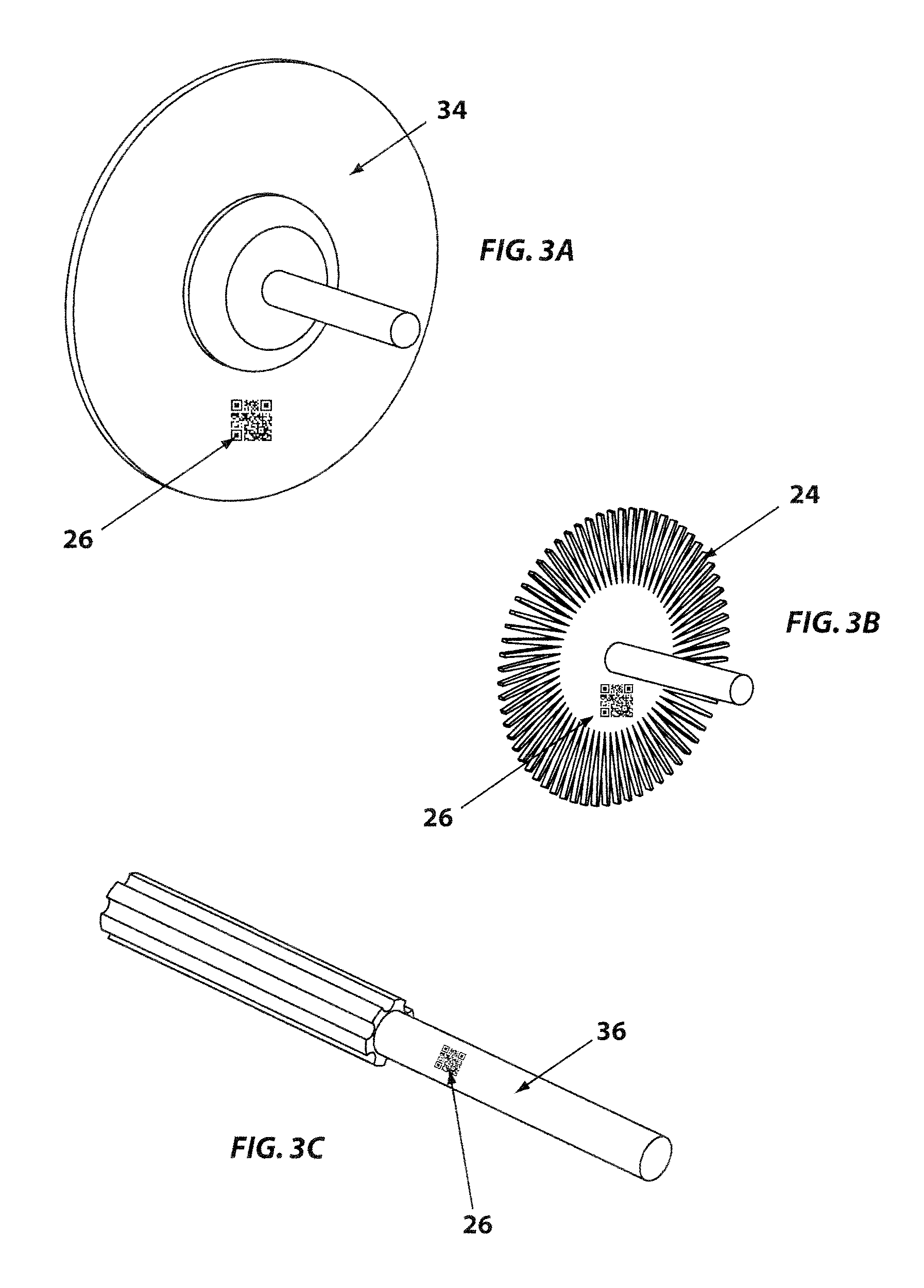

Controlled electro-pneumatic power tools and interactive consumable

Owner:FORGUES SYLVAIN +1

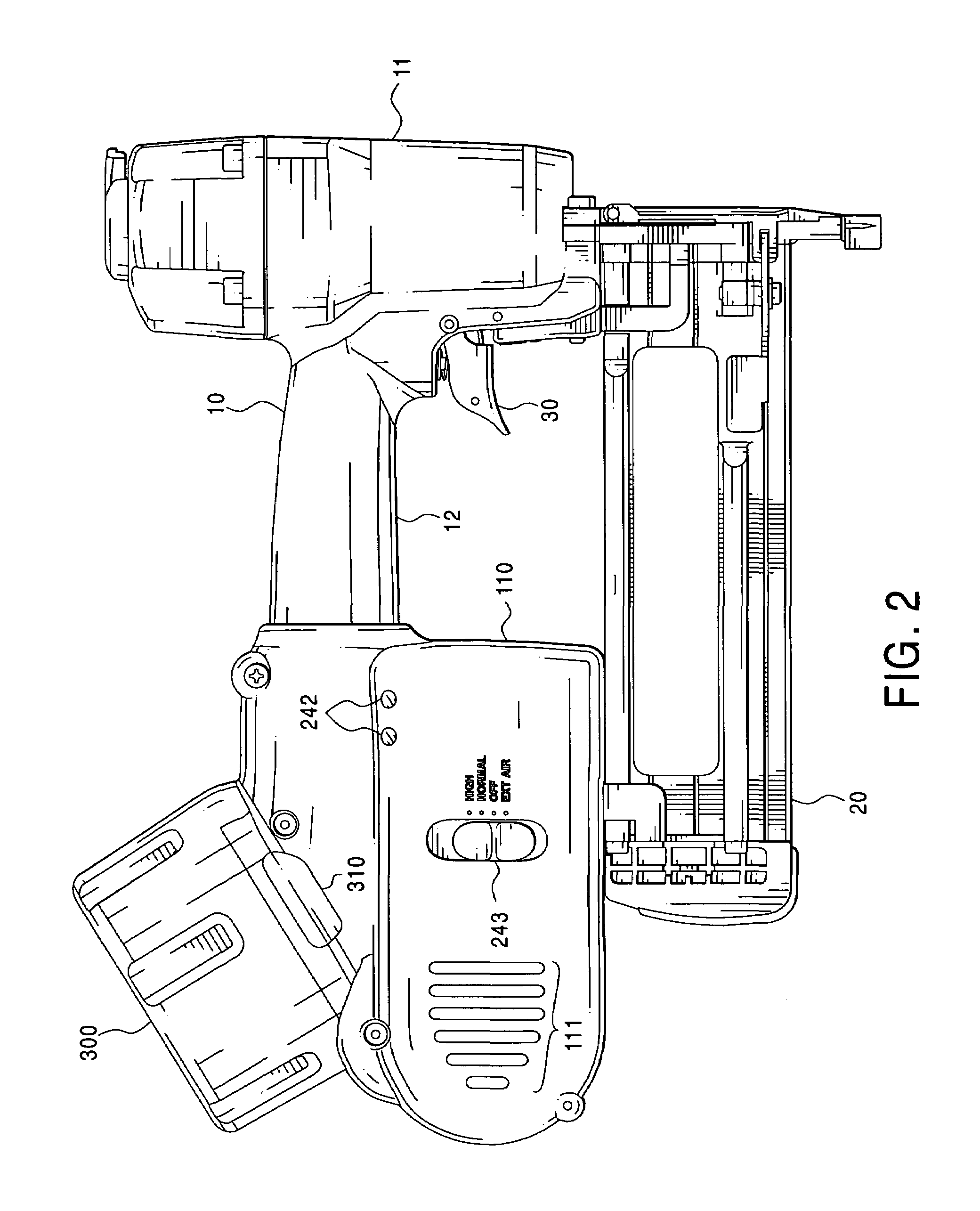

Portable, battery-powered air compressor for a pneumatic tool system

Owner:BLACK & DECKER INC +1

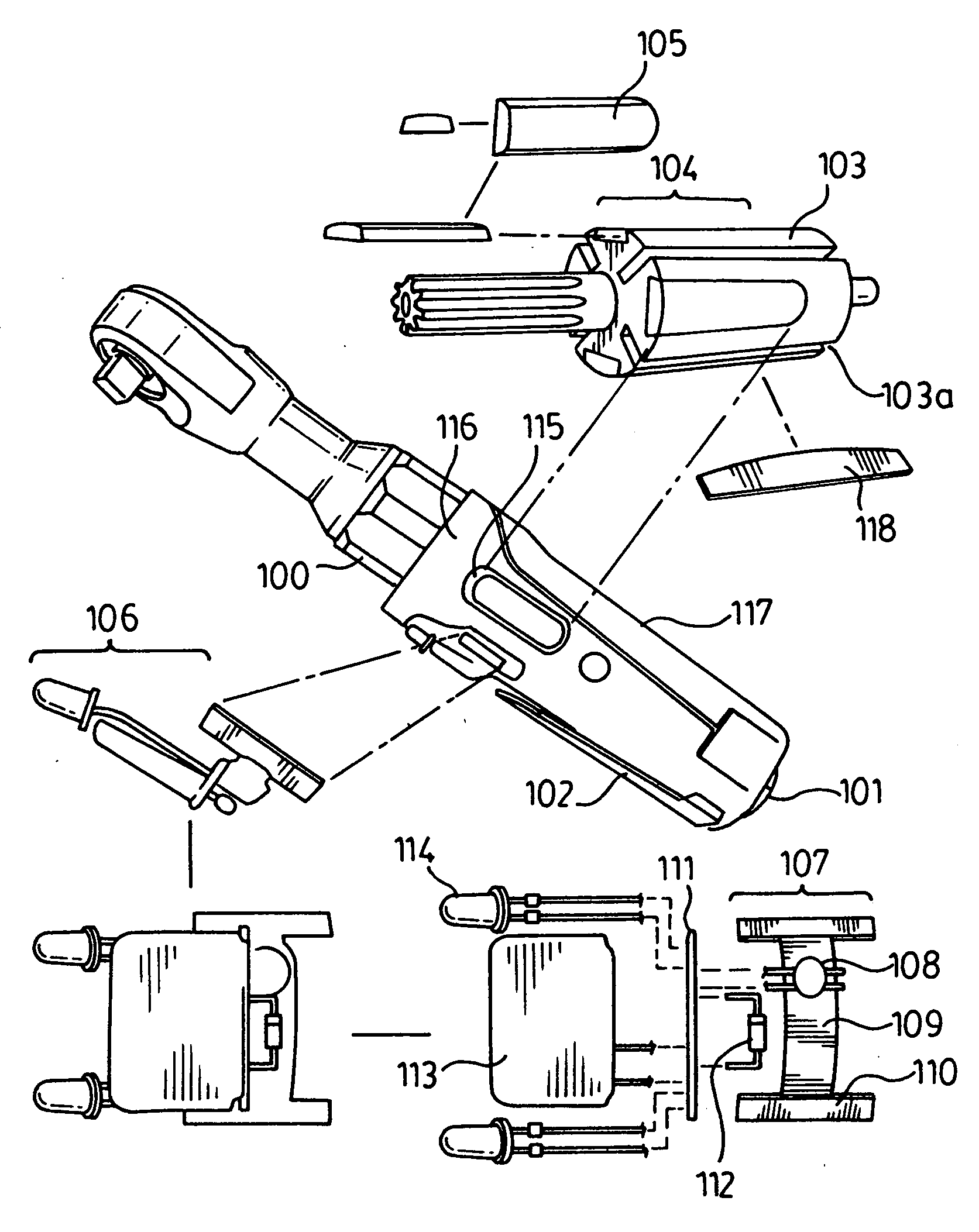

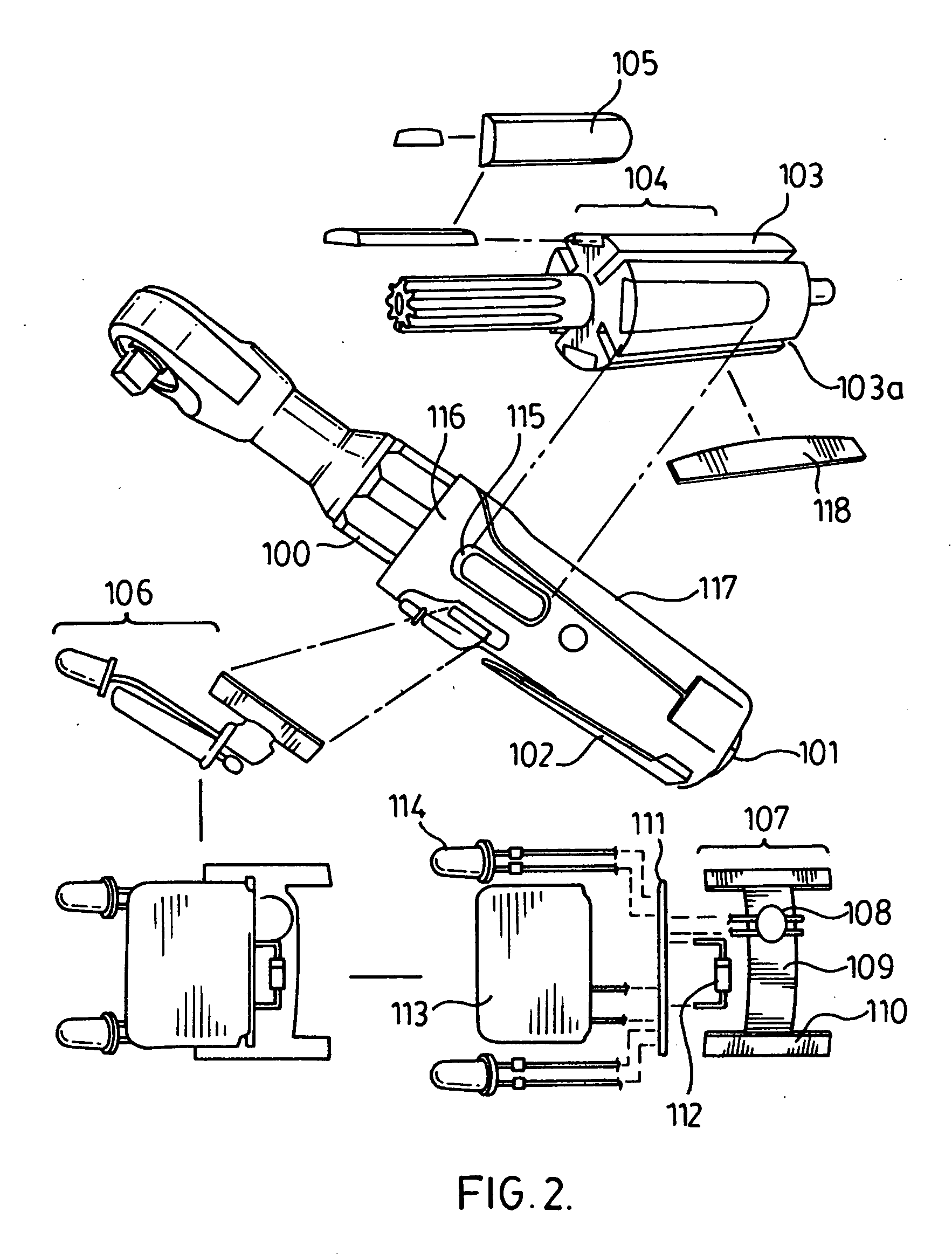

Controlled electro-pneumatic power tools and interactive consumable

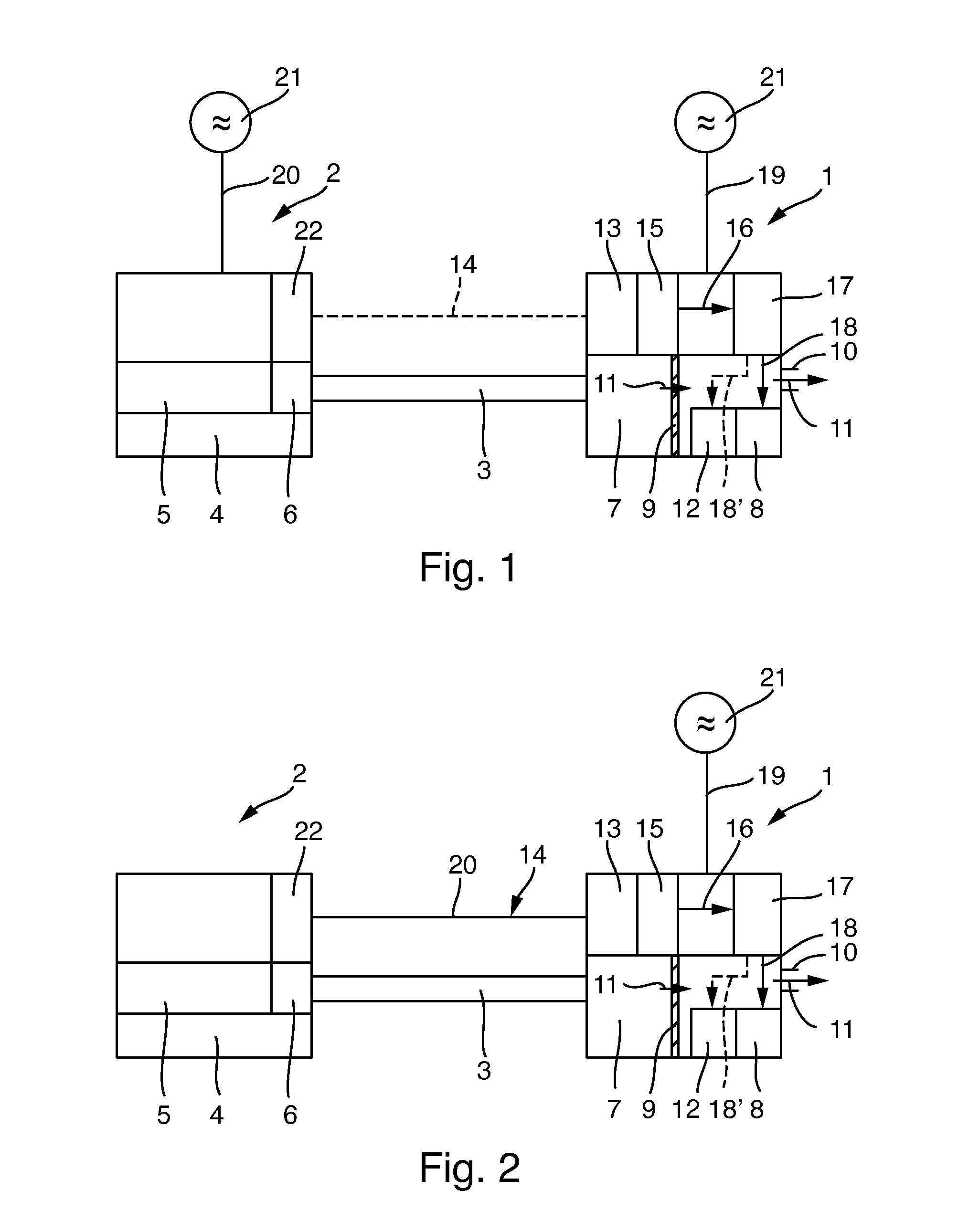

ActiveUS20120007748A1Electric signal transmission systemsTelemetry/telecontrol selection arrangementsMicrocontrollerElectrical battery

A controlled electro-pneumatic power tool includes an electro-mechanical adjustable valve, a pneumatic motor and a rotational speed sensor connected to a microcontroller for the selection, monitoring and adjustement of the rotational speed in real time. The electro-pneumatic power tool may include input buttons, data ports to save data and a communication port to read / write data from an interactive consumable. The electo-pneumatic power tool may also include a battery and a generator as well as a variable speed transmission with flexible shaft and lightweight handpiece. Using the communication port, important data for the consumable, such as optimum rotation speed, optimum applied pressure and average usage time, can be transmitted to the controlled electro-pneumatic power tool. The controlled electro-pneumatic power tool can read and utilise the transmitted data to select, adjust and maintain the optimum process parameters for the consumable without any input from the operator person. Furthermore, the communicated data can be used to warn the operator person that the tool used is inadequate for the selected consumable, to caution the operator person if he is using the consumable inadequately and to advise him when the consumable should be replaced for safe operation. This will increase the safety of the operator person, improve the quality of the work performed with pneumatic power tools and limit potential damages to the parts being treated.

Owner:FORGUES SYLVAIN +1

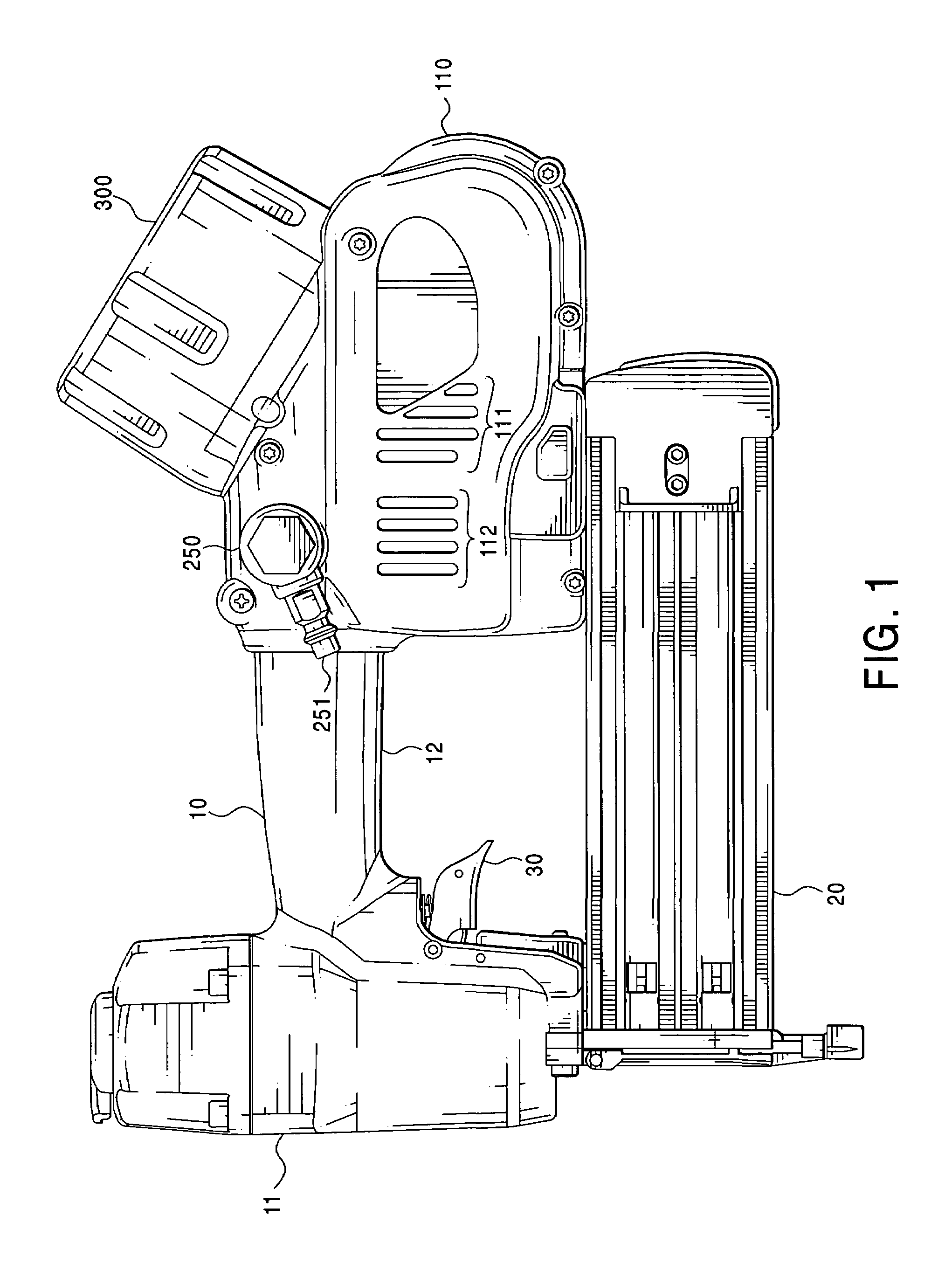

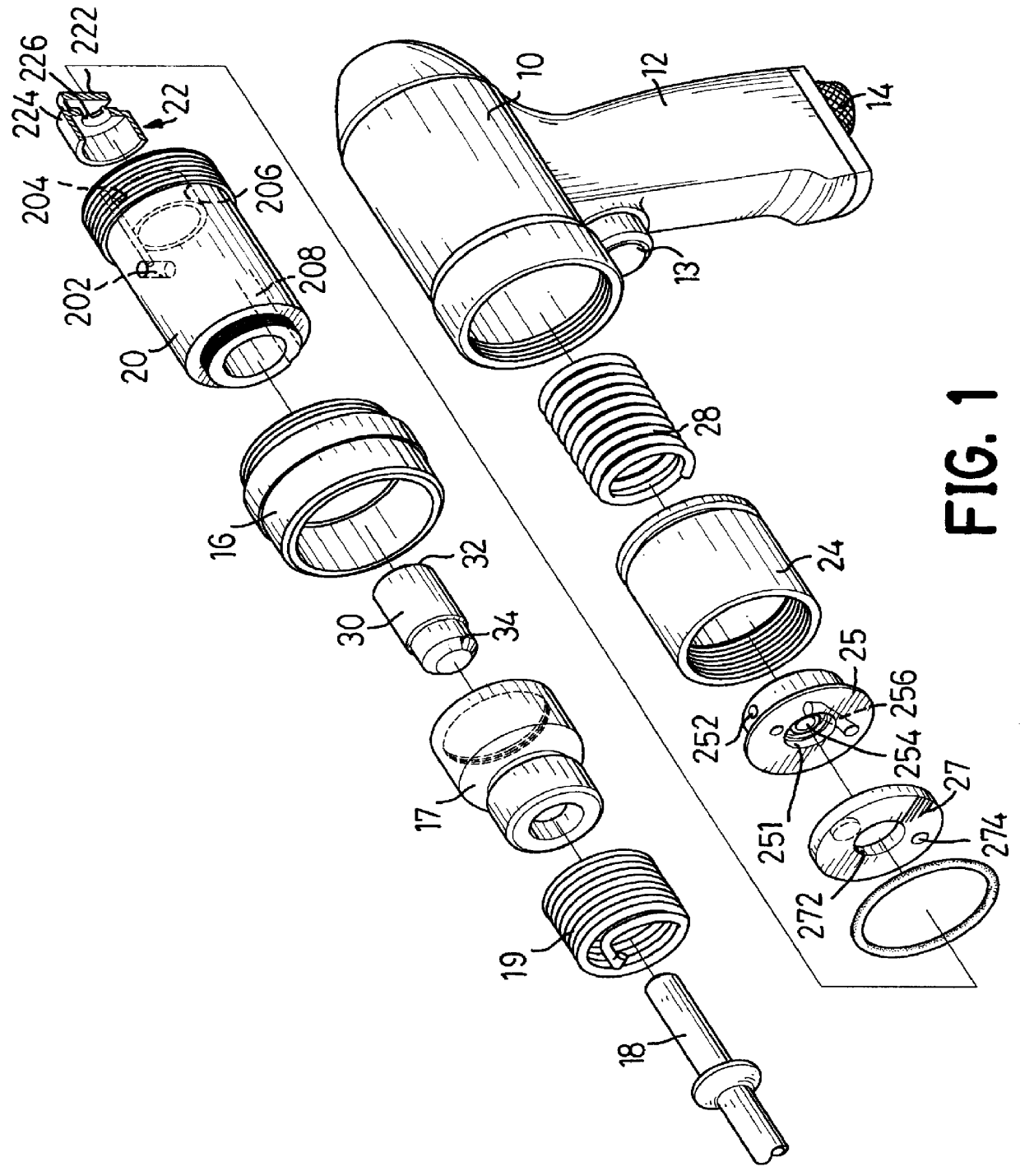

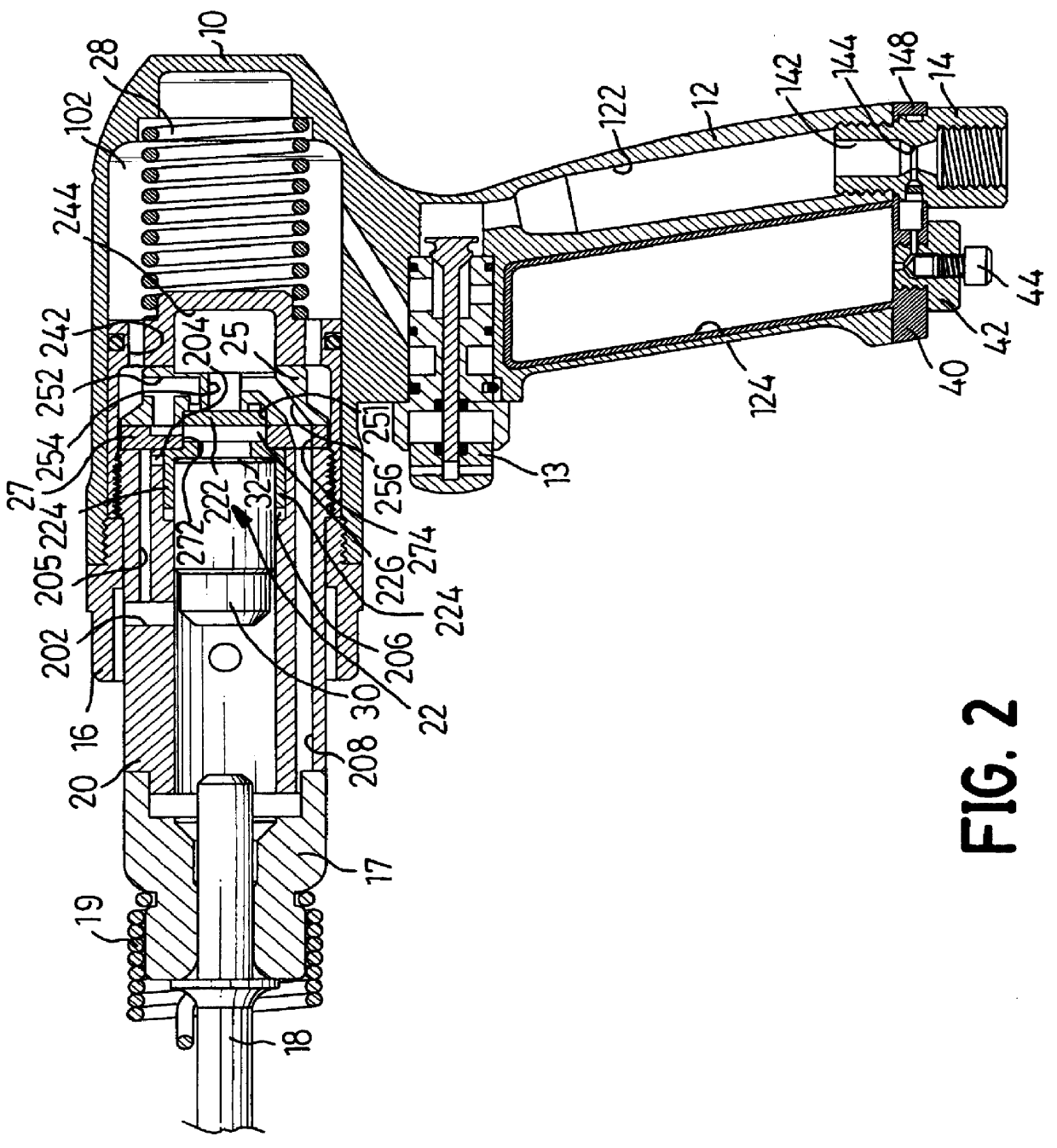

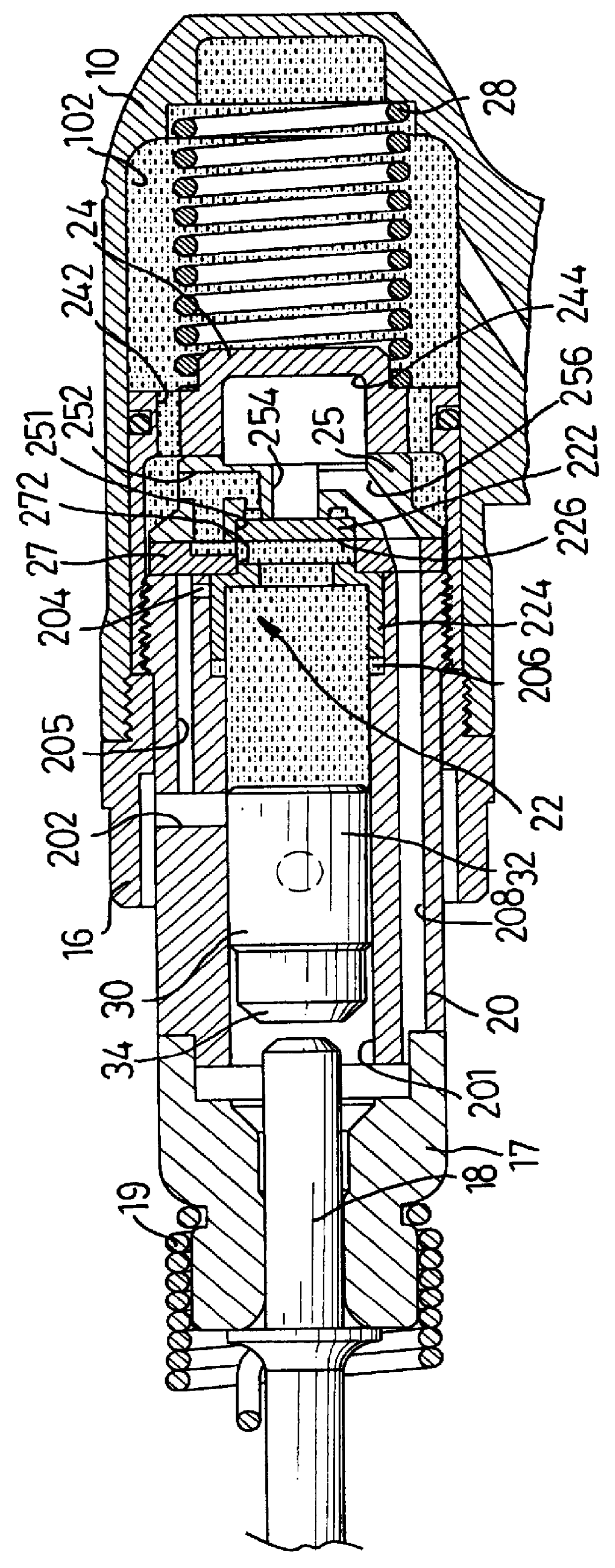

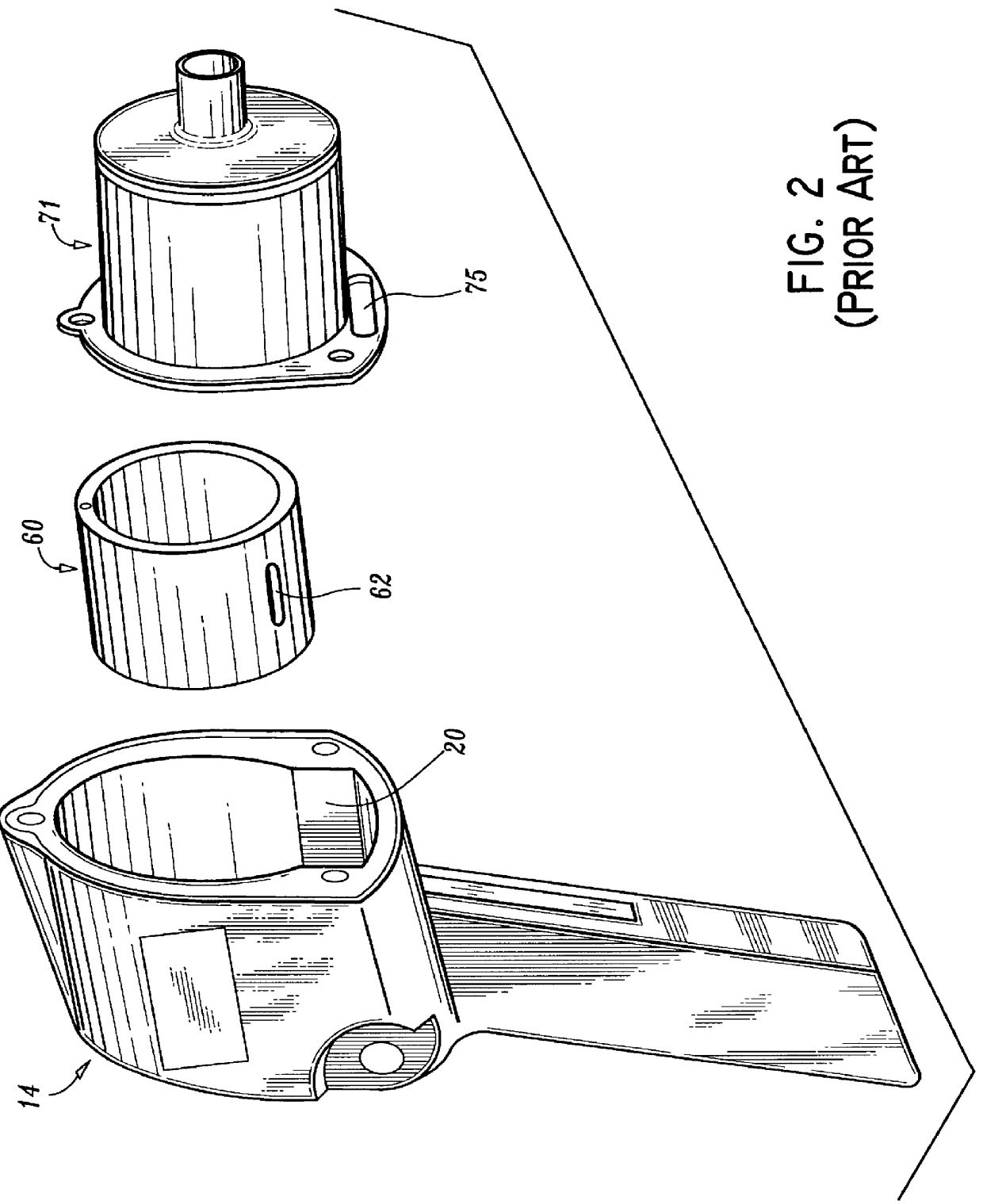

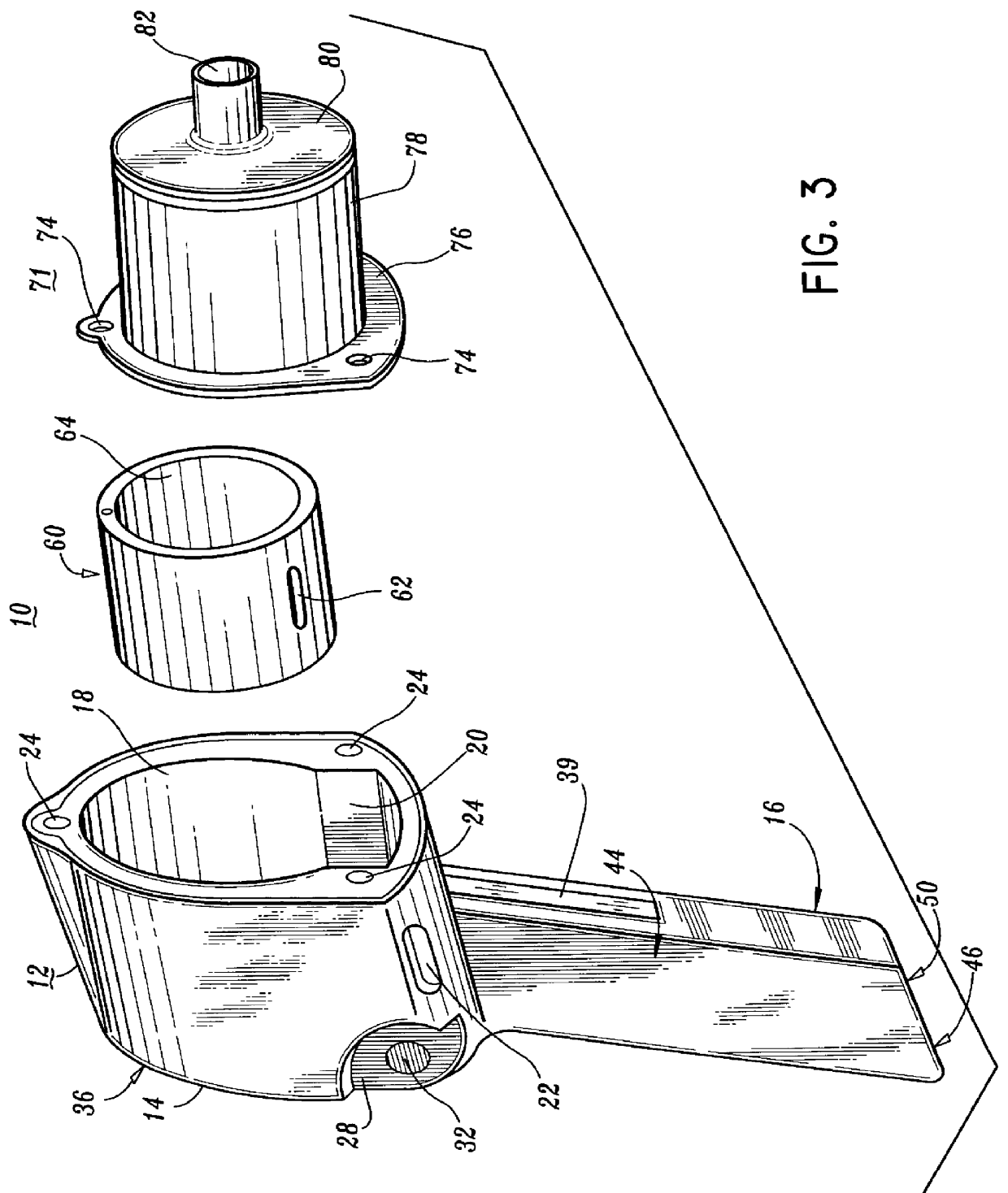

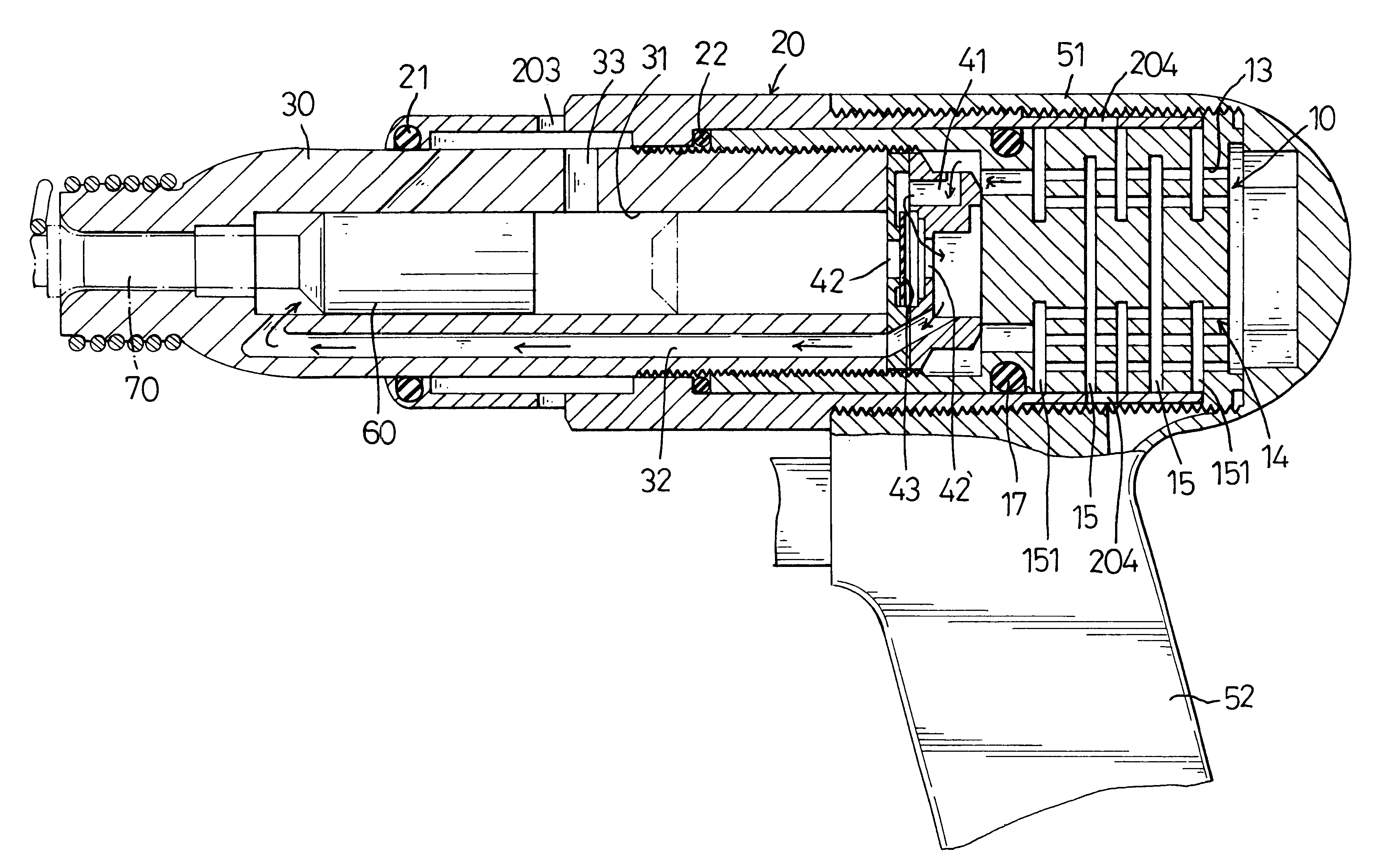

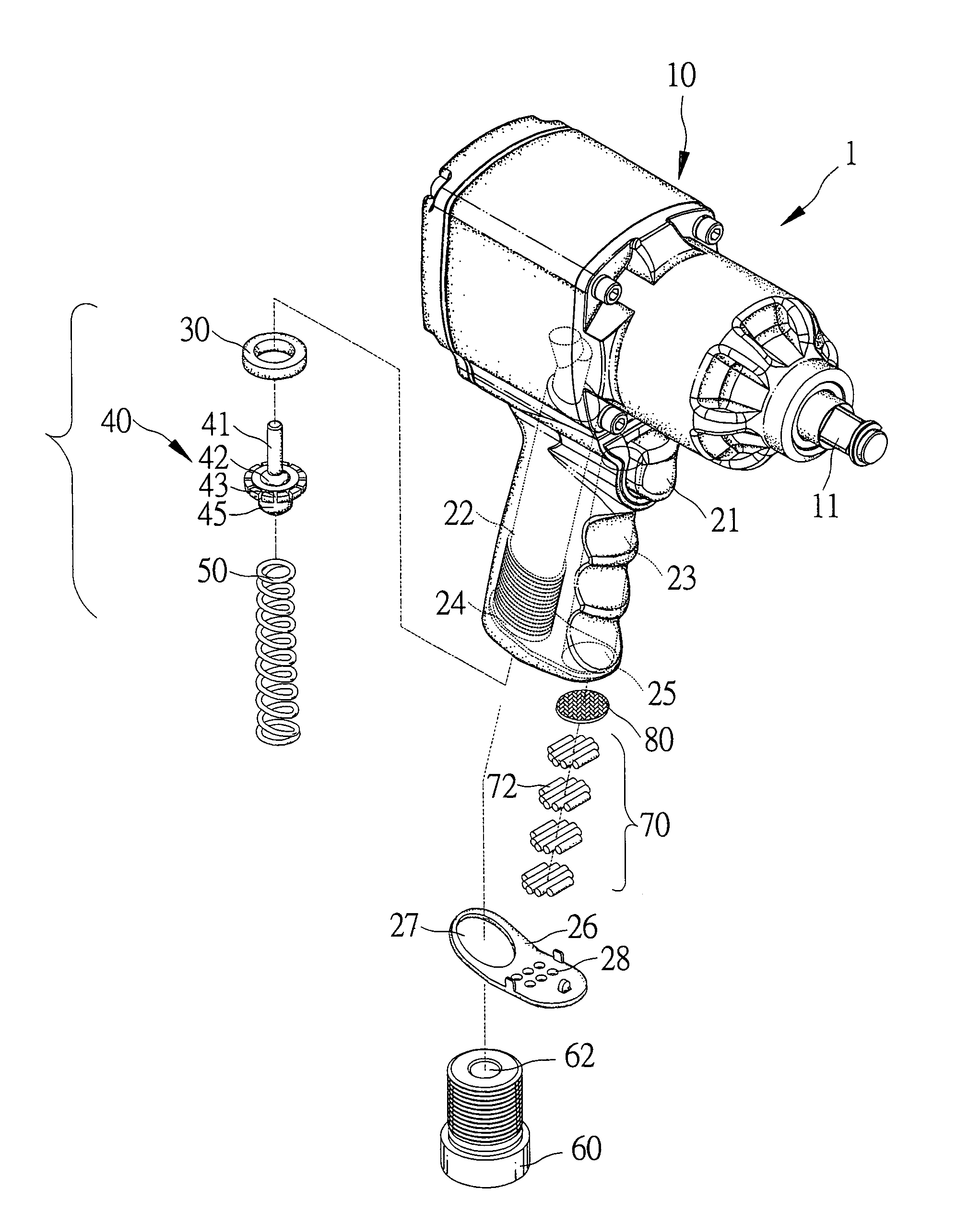

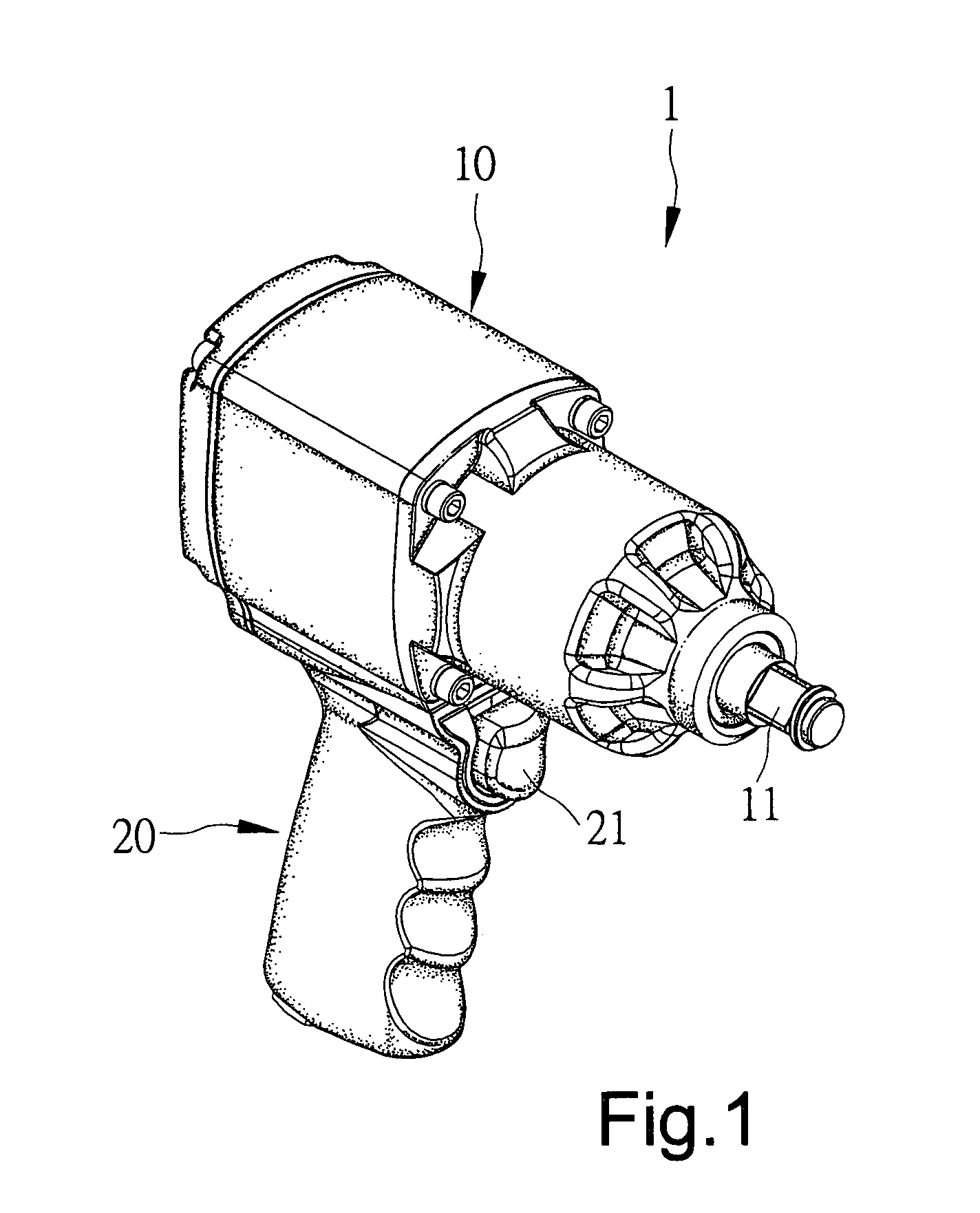

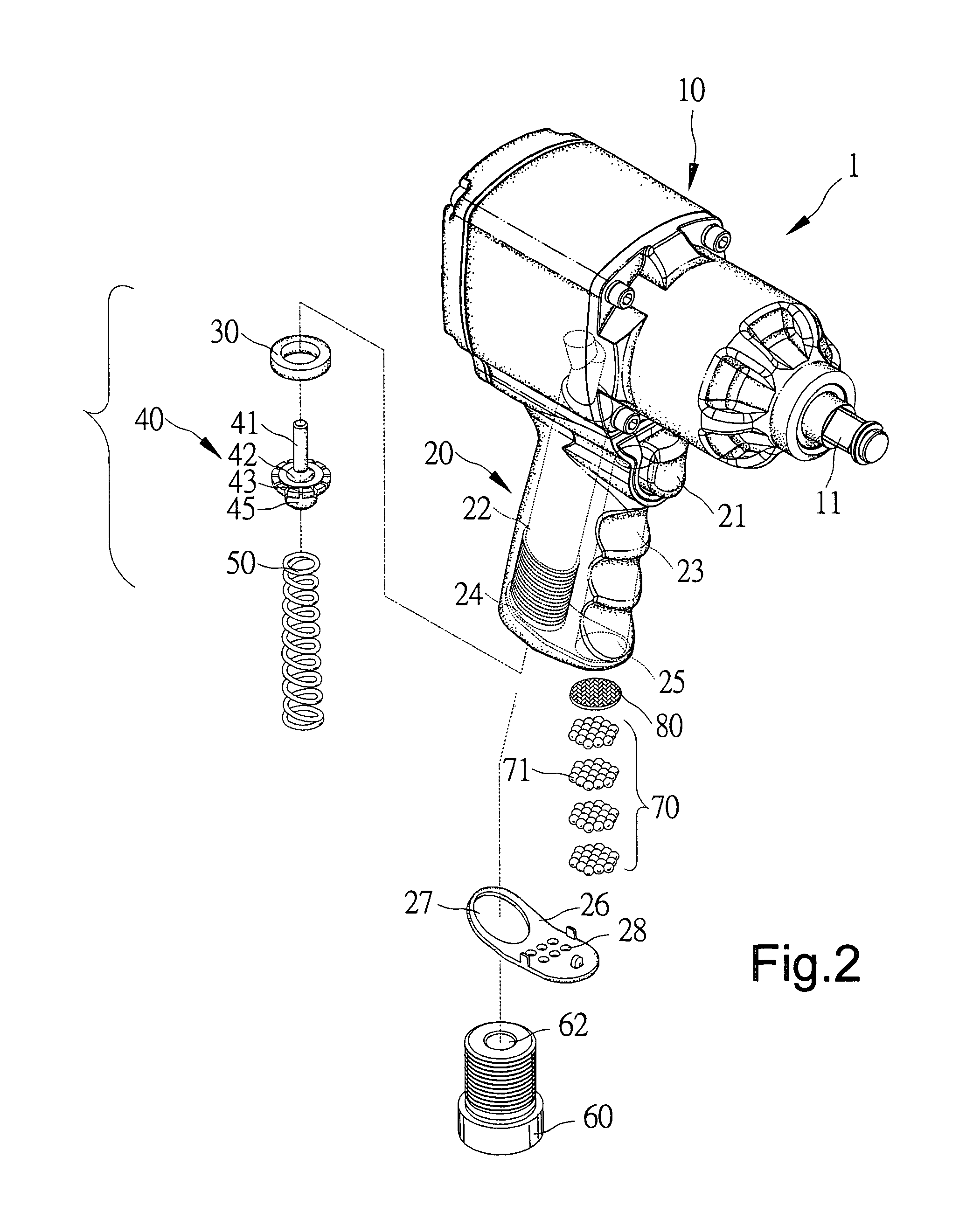

Pneumatic tool

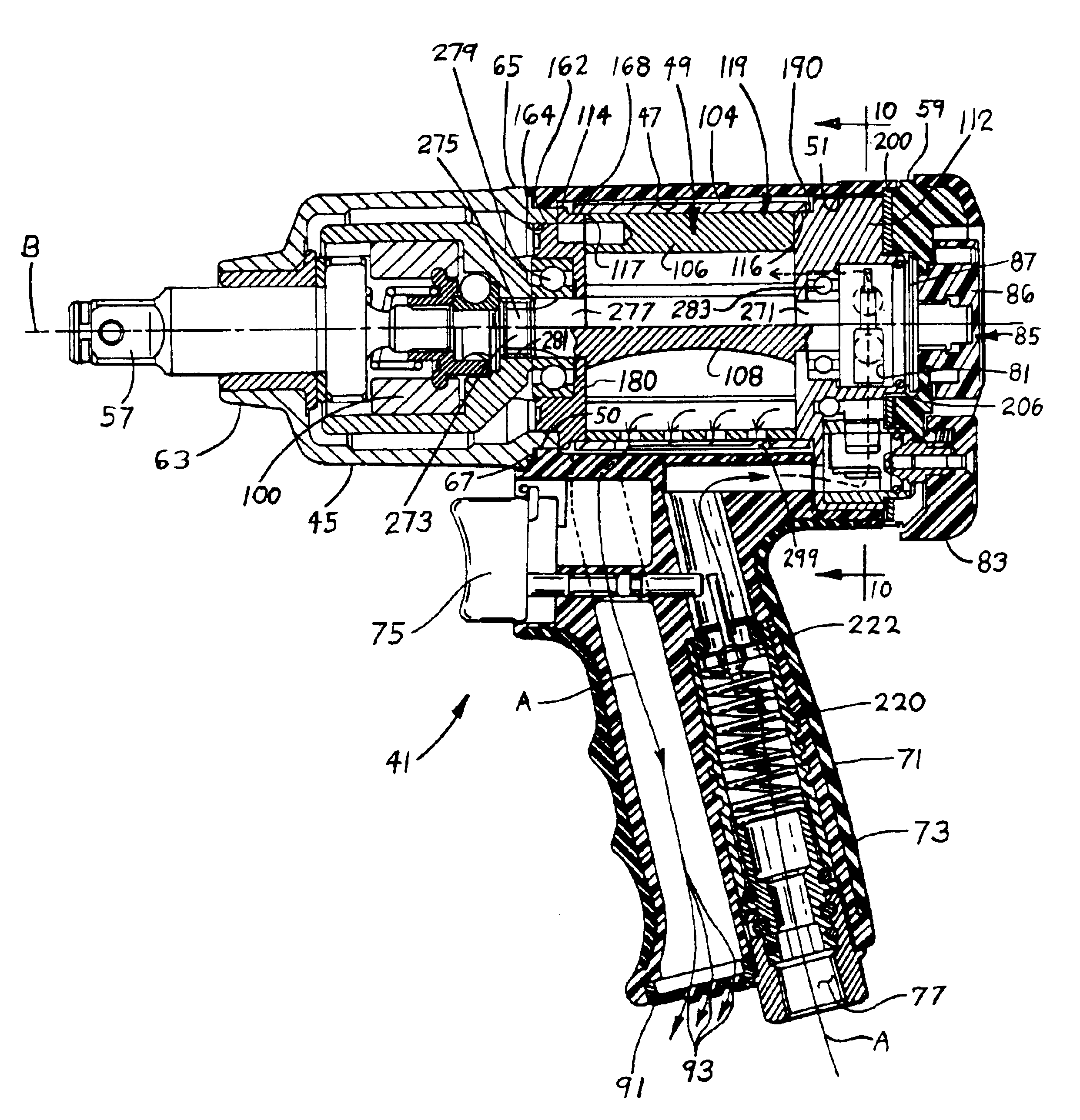

InactiveUS6161628AConstructionsReciprocating drilling machinesOperational effectivenessPneumatic tool

A pneumatic tool is disclosed. The pneumatic tool has a hollow housing with a handle extending therefrom, the handle having a chamber defined therein and an air passage communicating with the housing, an actuating mechanism mounted in the housing to actuate a tool shank and a cap securely attached to said handle to cover the chamber so as to form an oil reservoir in the handle. The pneumatic tool further has a control member mounted in the actuating mechanism to control the opening and closing of a discharge passage formed in the actuating mechanism. The disclosed pneumatic tool can limit the size of the pneumatic tool and let the air completely flow out so as to improve the convenience and operational effectiveness of the pneumatic tool.

Owner:Q C WITNESS INT

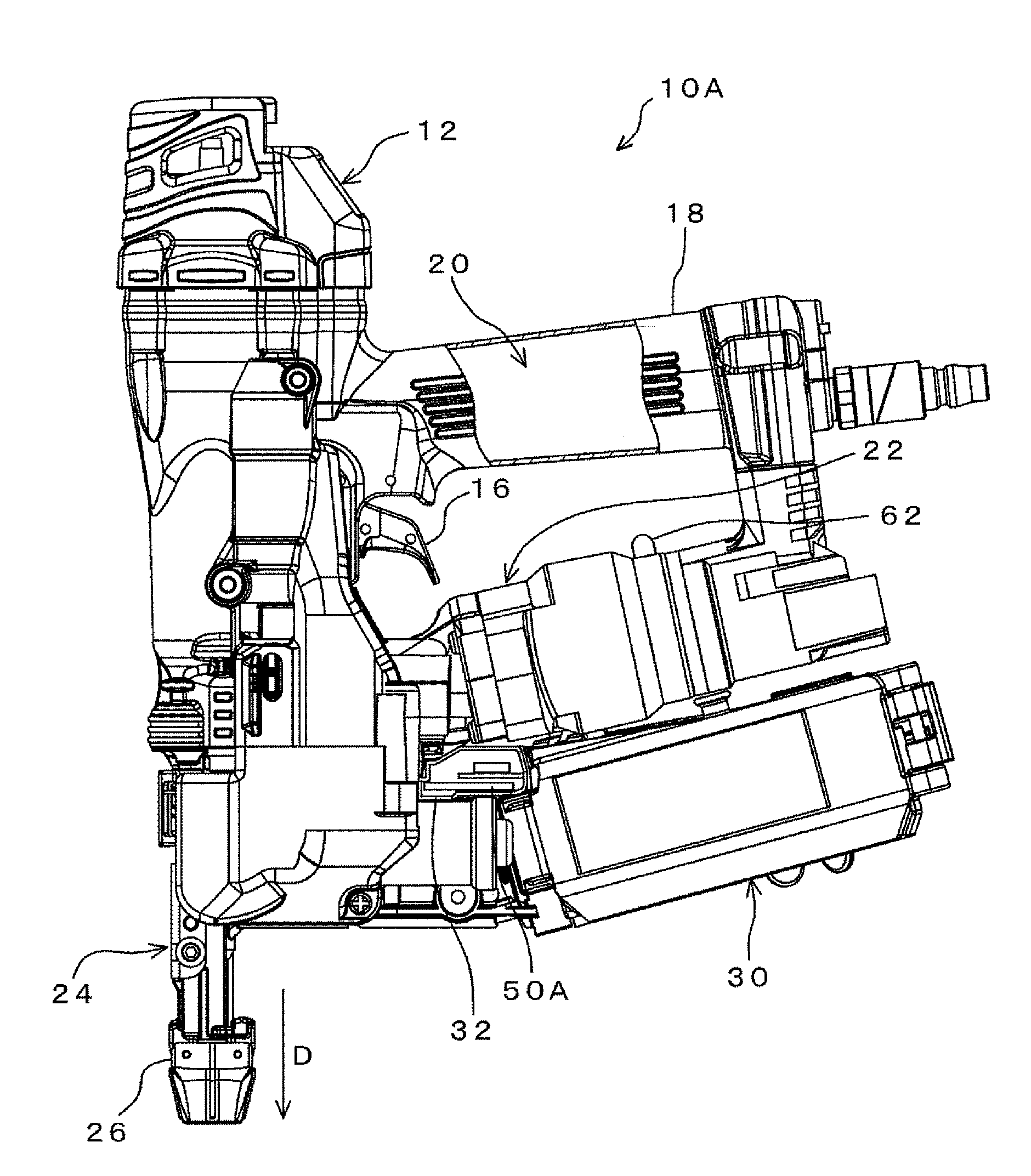

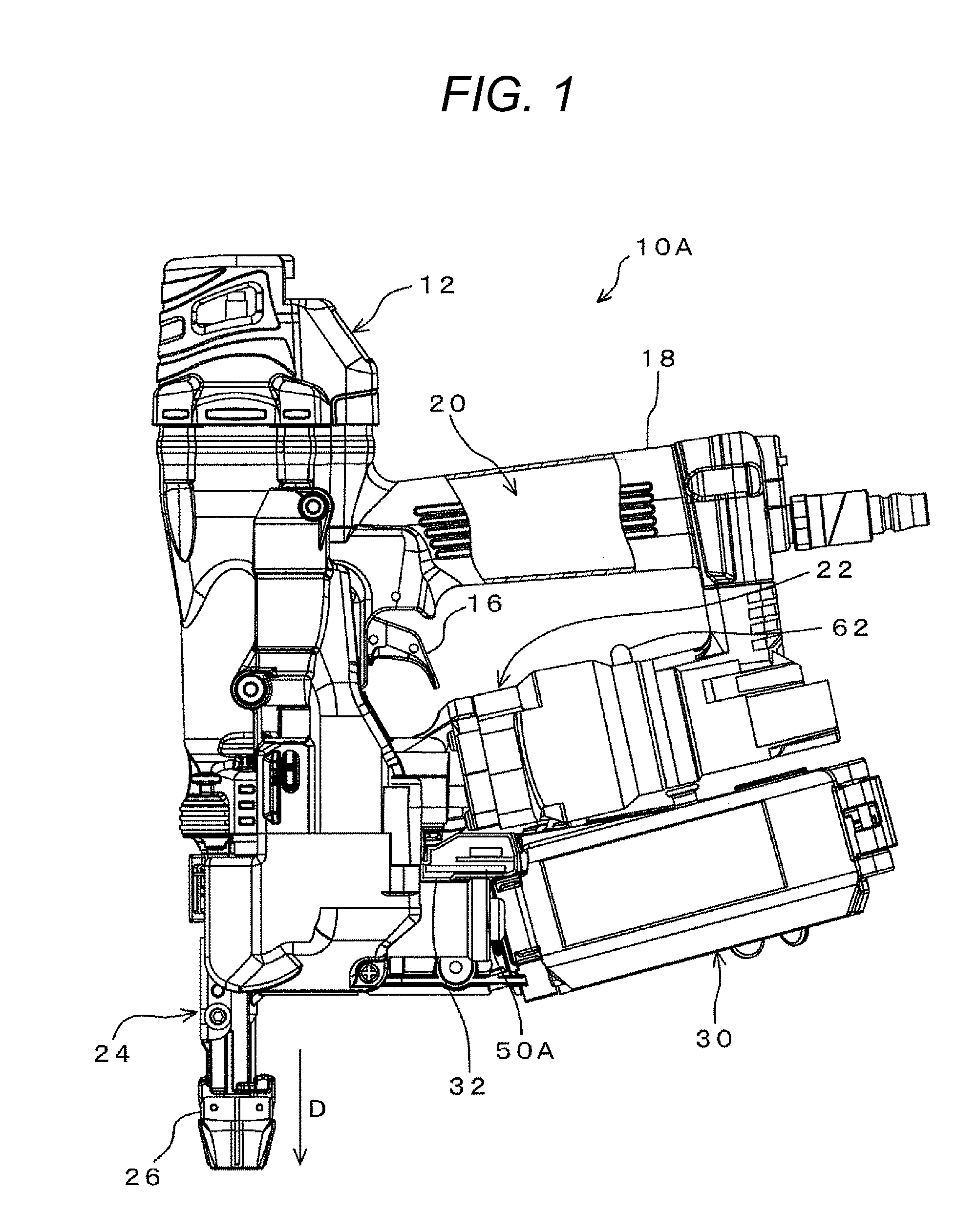

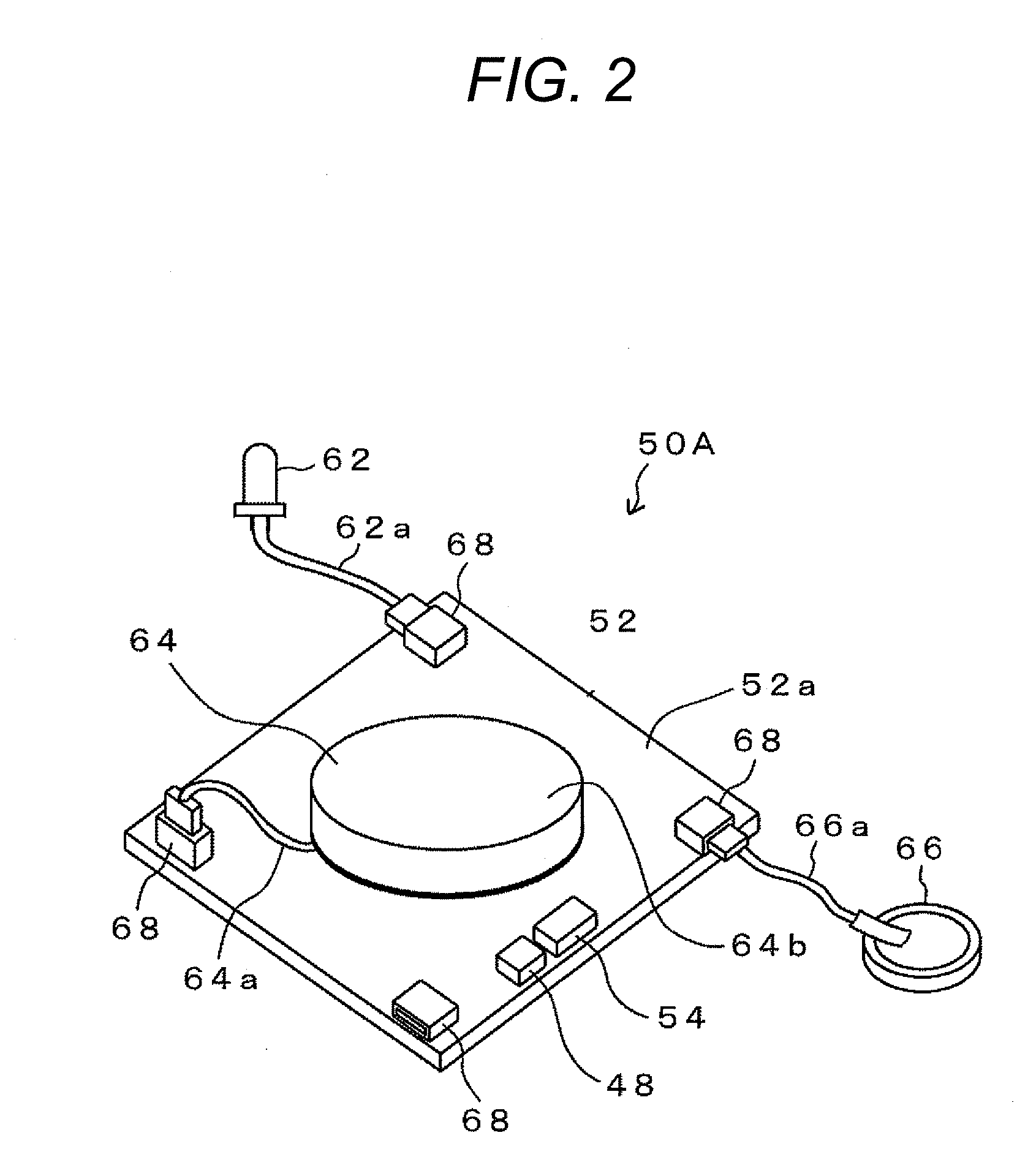

Tool, information processing unit, terminal unit, and management system

A sensor part detects an actual driving signal in the driving time by a pneumatic tool. A control part, based on the detected actual driving signal, makes an addition to the actual driving number which has already stored in a memory part to updates the actual driving number, and compares the updated accumulative actual driving number with the previously set basic maintenance number. As a result of the comparison, in case the accumulative actual driving number exceeds the basic maintenance number, it is determined that maintenance is necessary for the pneumatic tool. A light emitting part emits the light and blinks by an instruction from the control part, thereby to warn a user that the pneumatic tool is into the maintenance time. Hereby, the user can grasp the maintenance time of the tool surely and exactly.

Owner:MAX CO LTD

Pneumatic rotary tool

InactiveUS6880645B2Low costEasy to useConstructionsReciprocating drilling machinesPlastic materialsPneumatic tool

Owner:S P AIR

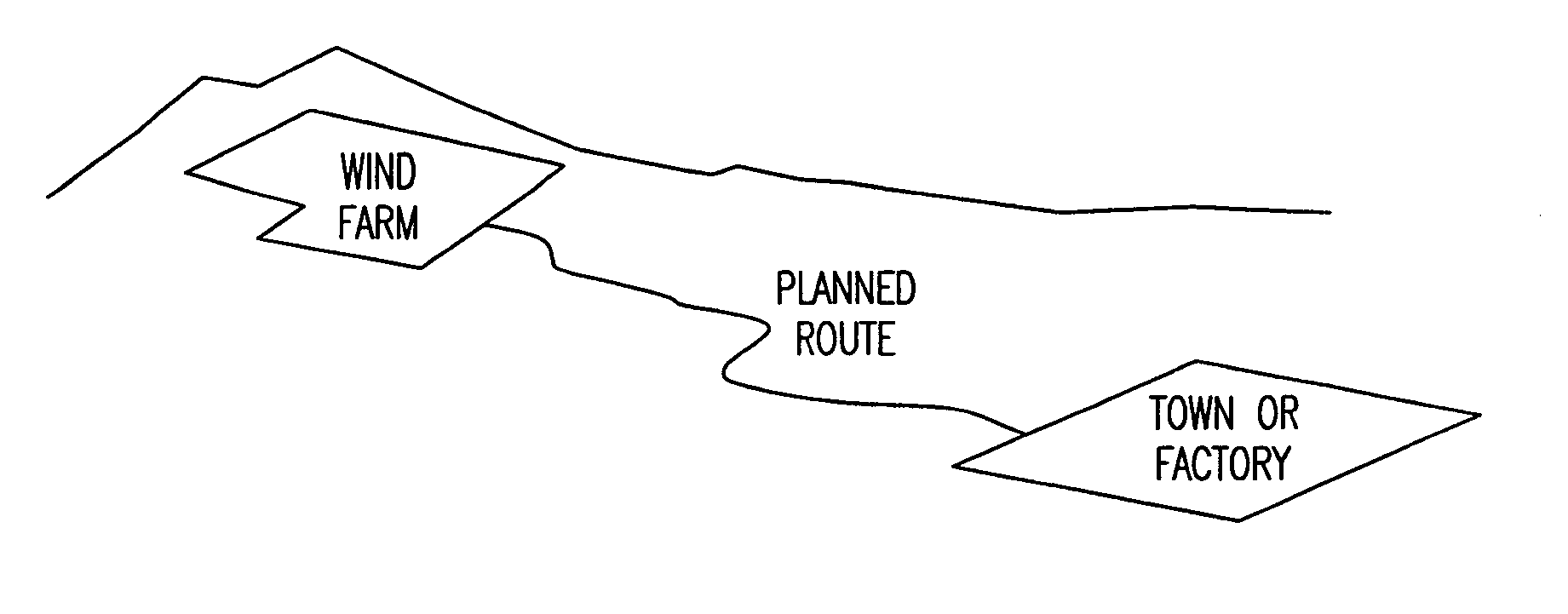

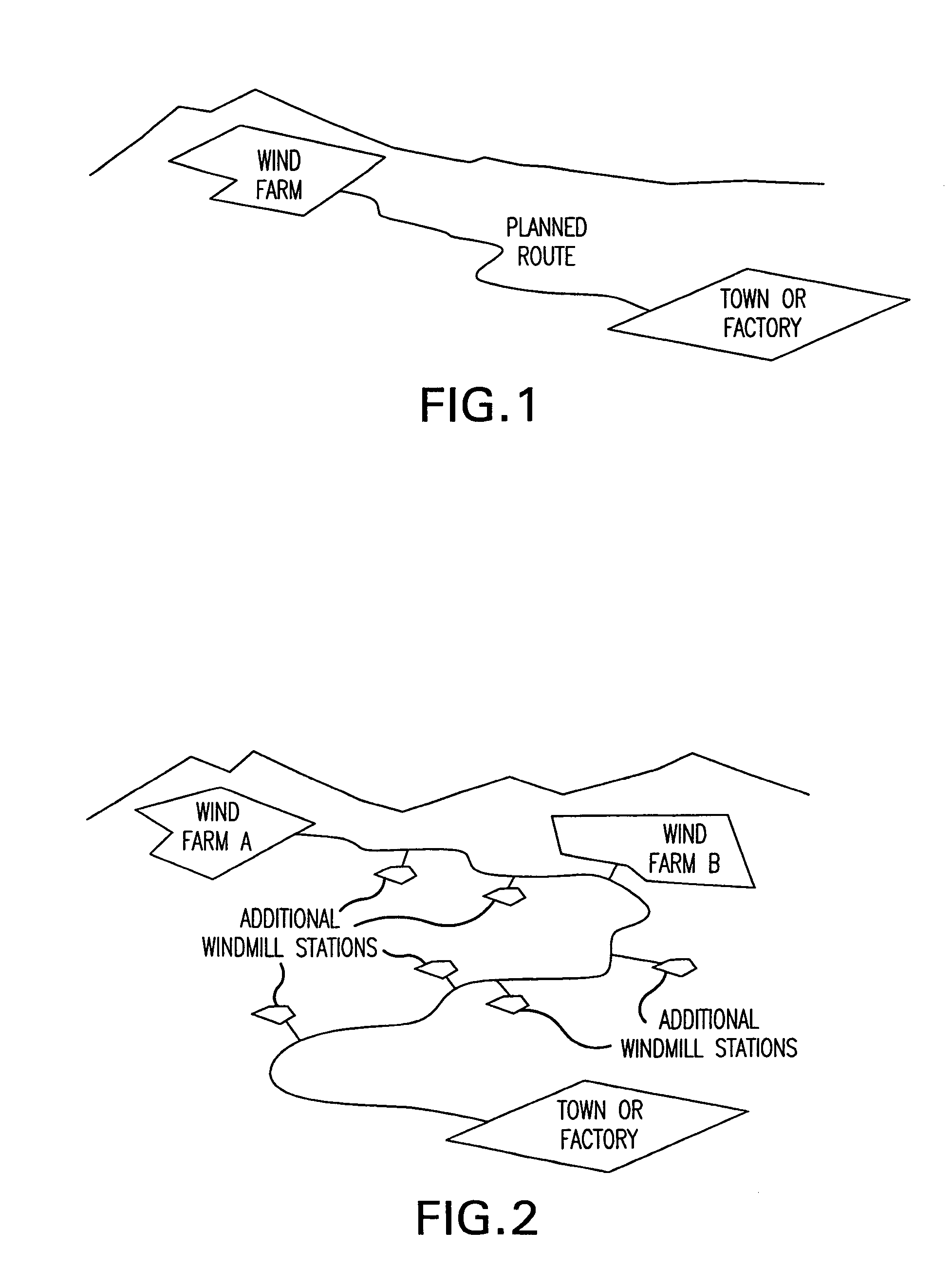

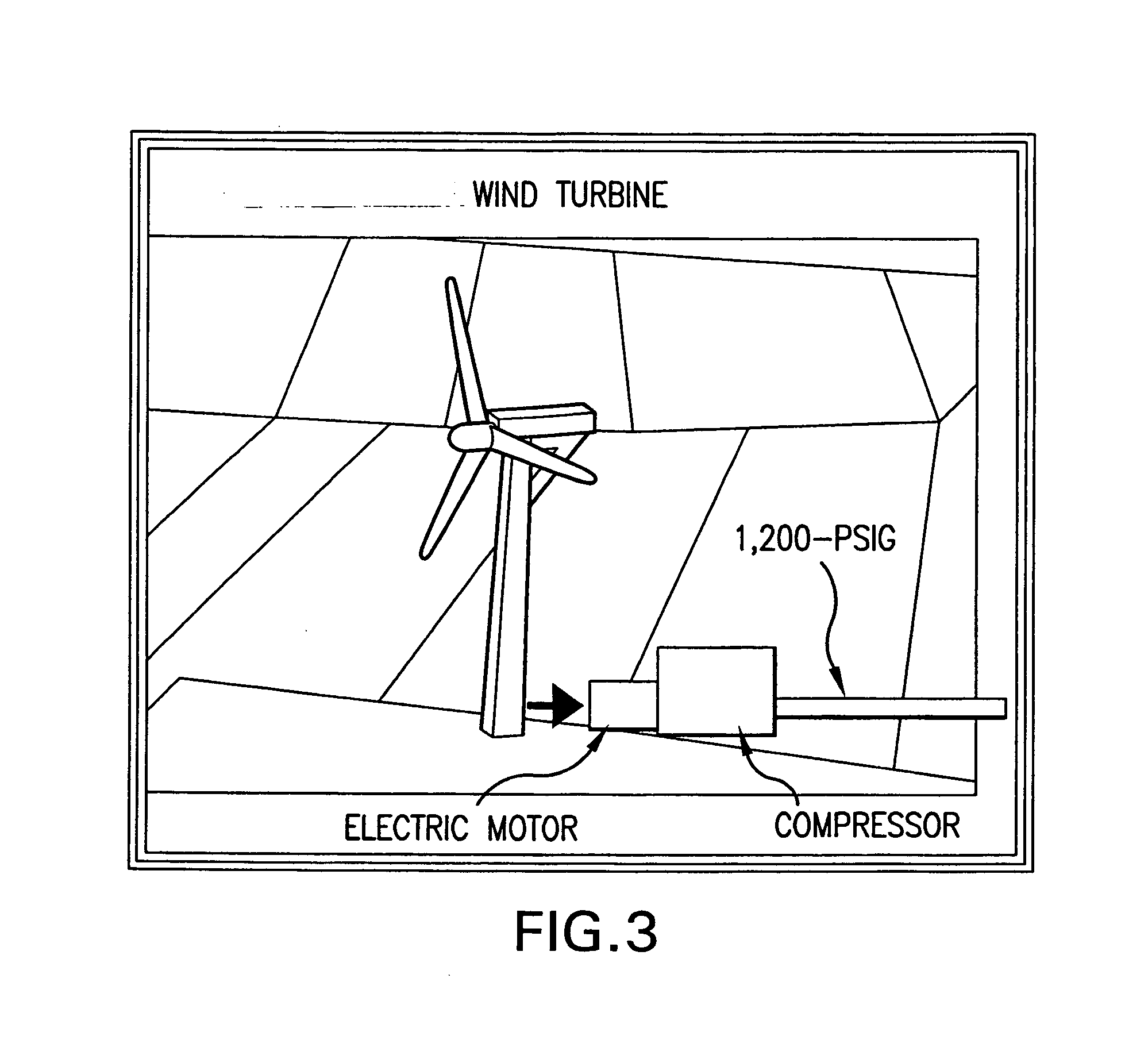

Method of transporting and storing wind generated energy using a pipeline

ActiveUS20070182160A1Low costAvailable energyGeneral water supply conservationWind energy with garvitational potential energyLow demandPneumatic tool

The invention relates to a method of storing and transporting wind generated power in the form of compressed air energy, via a pipeline, from a location where wind conditions are ideal, to a facility or community where energy is needed. The method preferably comprises using at least one wind turbine to drive a compressor to compress air into storage, wherein the size and length of the pipeline can be adapted to reduce the pressure losses that are experienced along the length of the pipeline. The pipeline can be located on railroad ties, or on the desert floor, or can be extended along paths where existing right of ways are provided. The facility or community using the energy can use energy in the form of electricity, or to drive pneumatic tools or equipment, or to generate chilled air as a by-product, which can be used for refrigeration, air conditioning or desalination. A utility or grid can be provided to generate compressed air energy when the wind is not blowing, wherein compressed air energy can be produced and stored during low demand periods, and used during high demand periods.

Owner:ENIS BEN M +1

Pneumatic tool with side exhaust

The present invention relates to a pneumatic tool having a housing including a motor housing portion which is pneumatically and securely connected to a handle housing portion. The motor housing portion has a motor housing exhaust opening with a motor housing exhaust opening port therethrough. The motor housing exhaust opening port functions to direct pressurized air from a forward direction to a sideways direction.

Owner:BRUNNHOELZL RACING

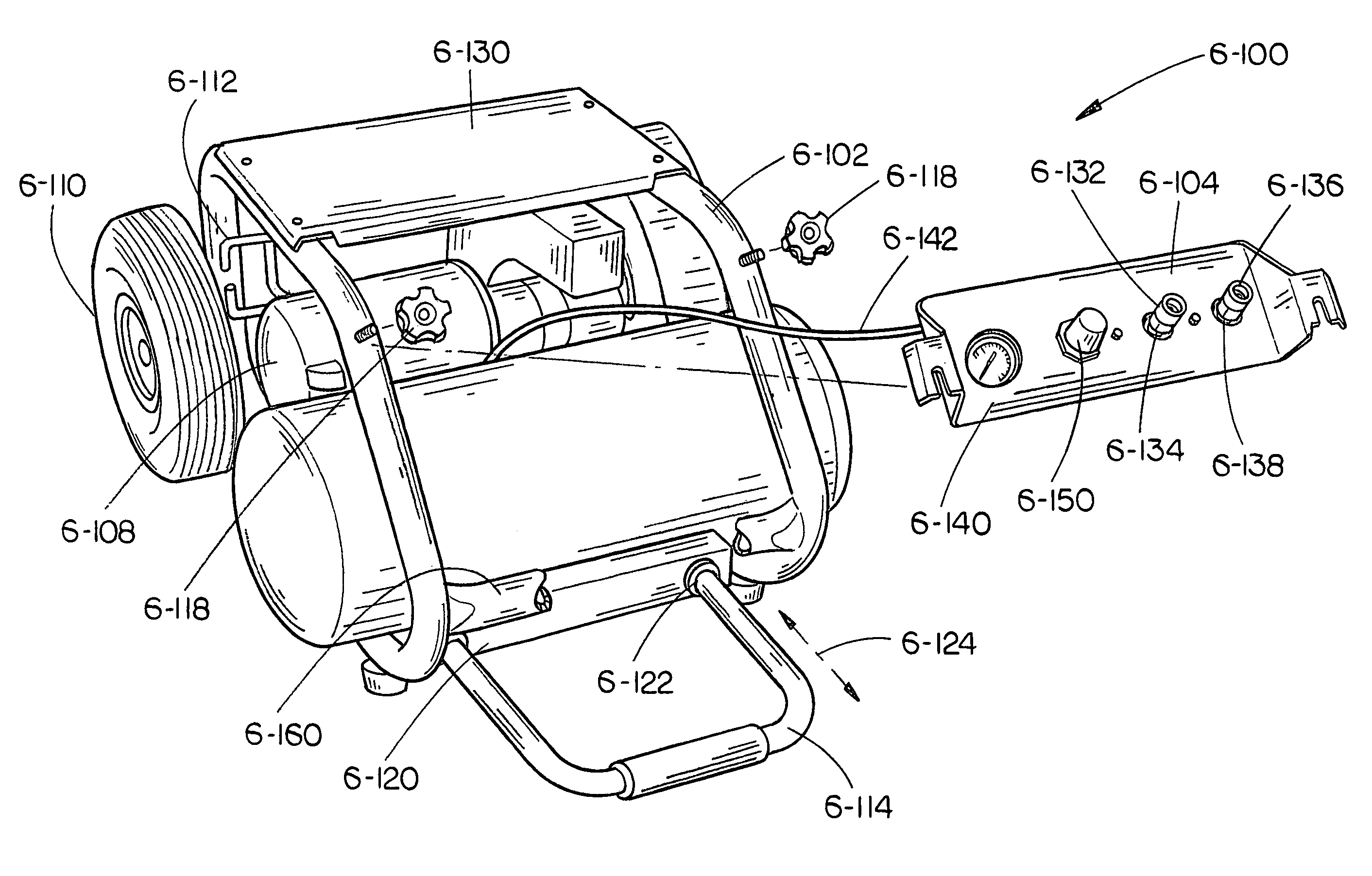

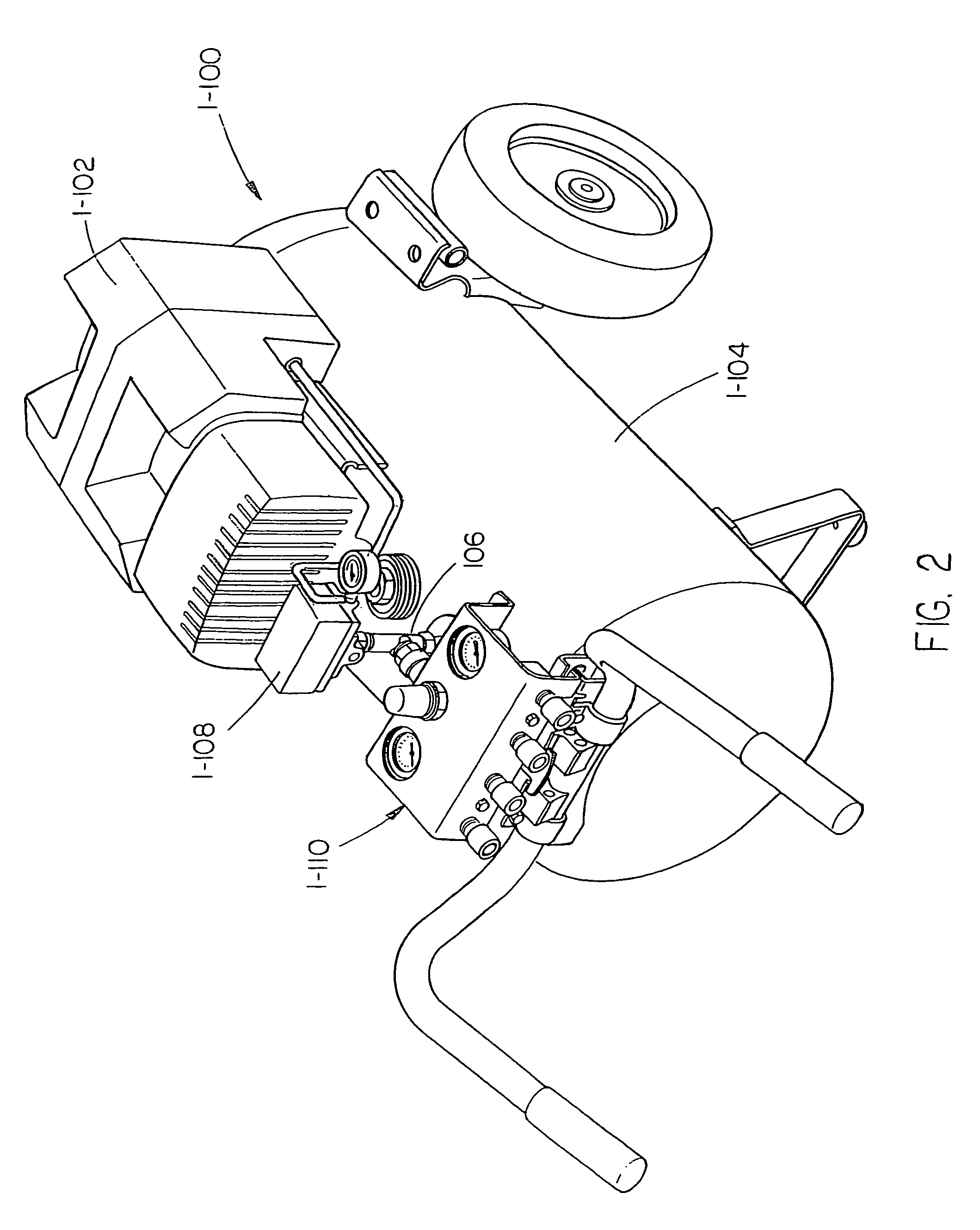

Air compressor with extensible handle bar assembly

InactiveUS6923627B1Damage to contactPrevent removalValve arrangementsPipeline systemsGas compressorPneumatic tool

An air compressor assembly with one or more of the following features: a removable manifold assembly capable of being remotely located from the air compressor assembly for controlling and distributing compressed air from the air compressor assembly to one or more air powered tools, a lifting handle, a handle capable of assuming a plurality of positions, condensate removal devices, and a stable base and tie-down points.

Owner:BLACK & DECKER INC

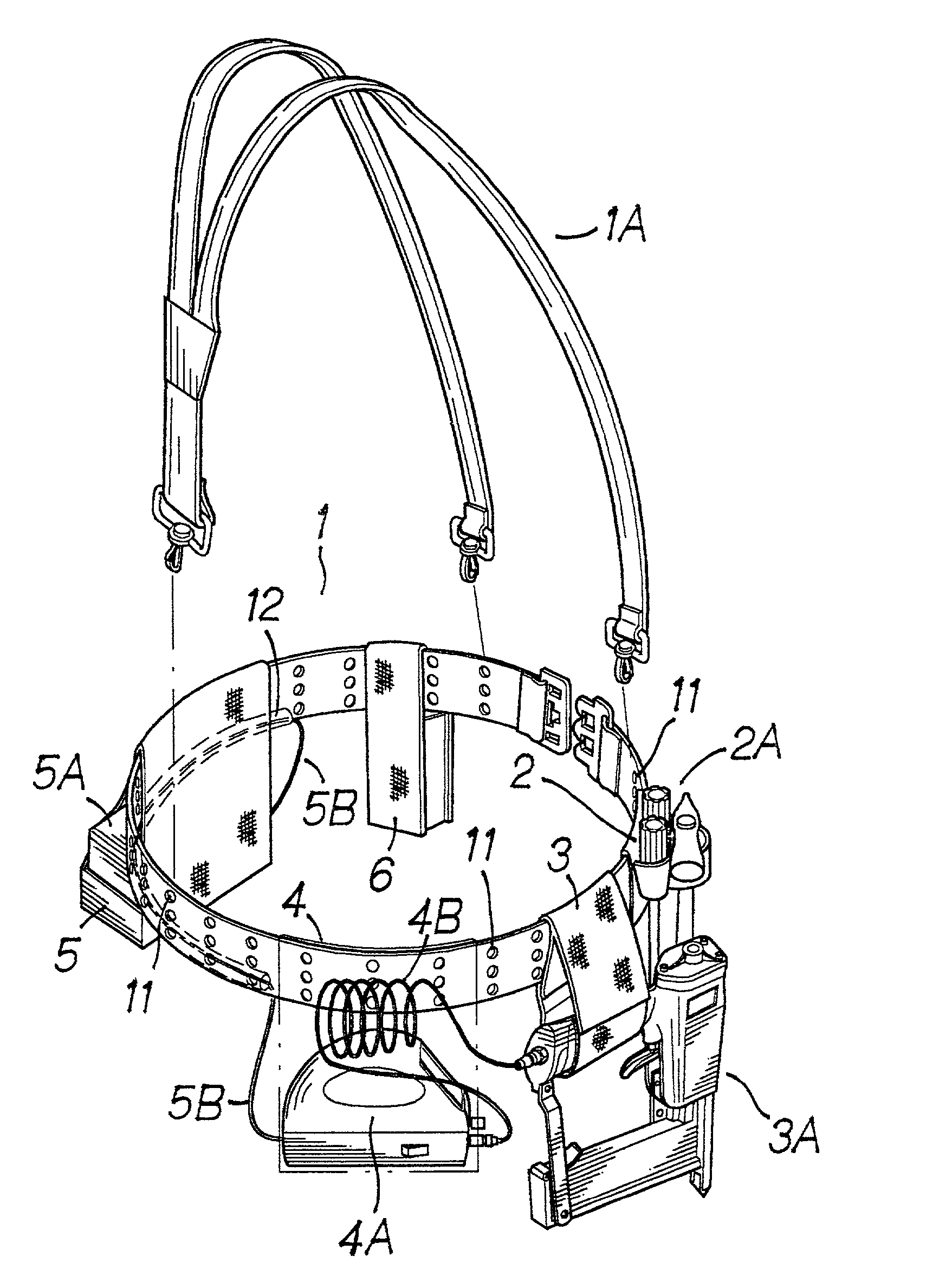

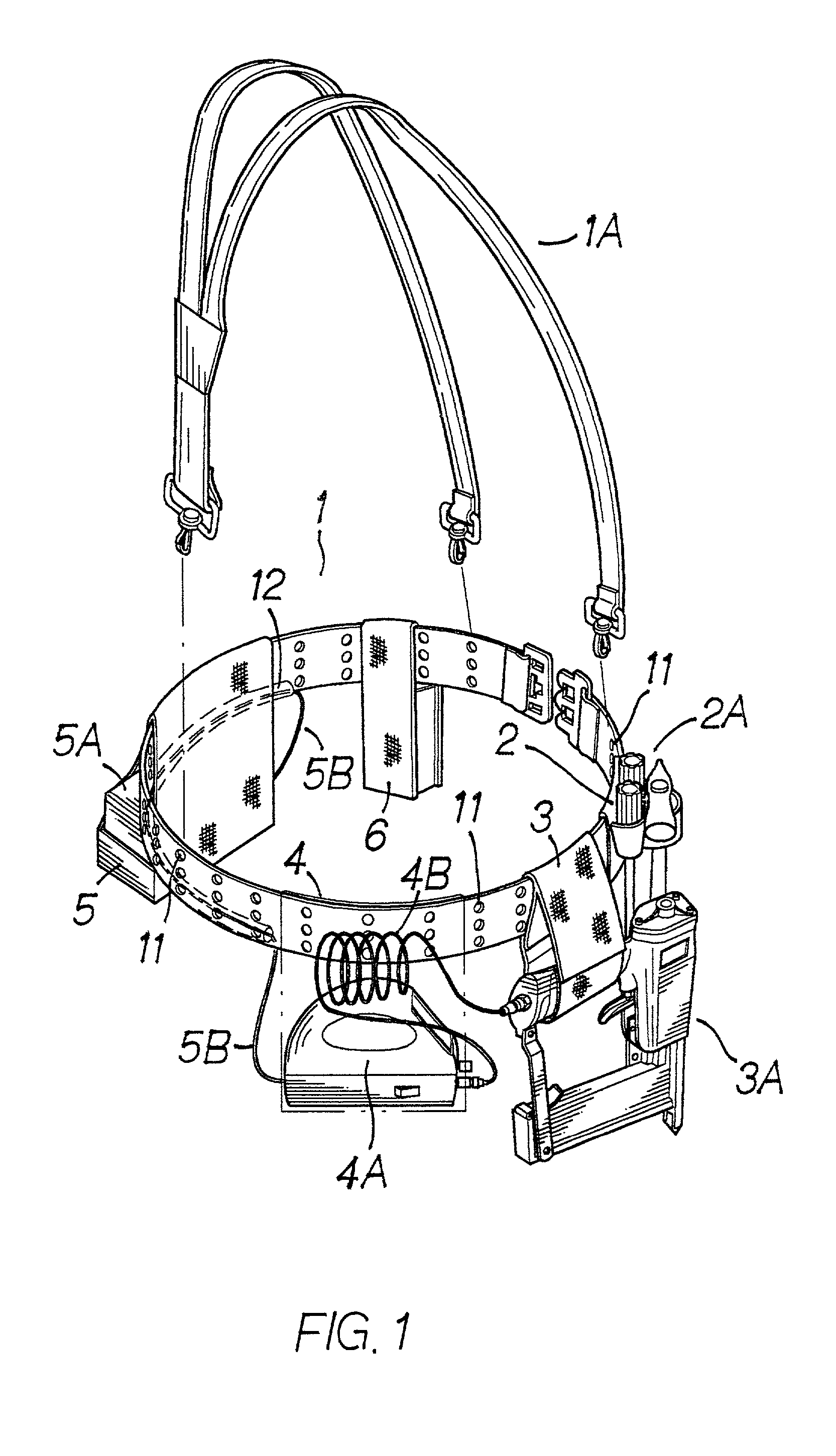

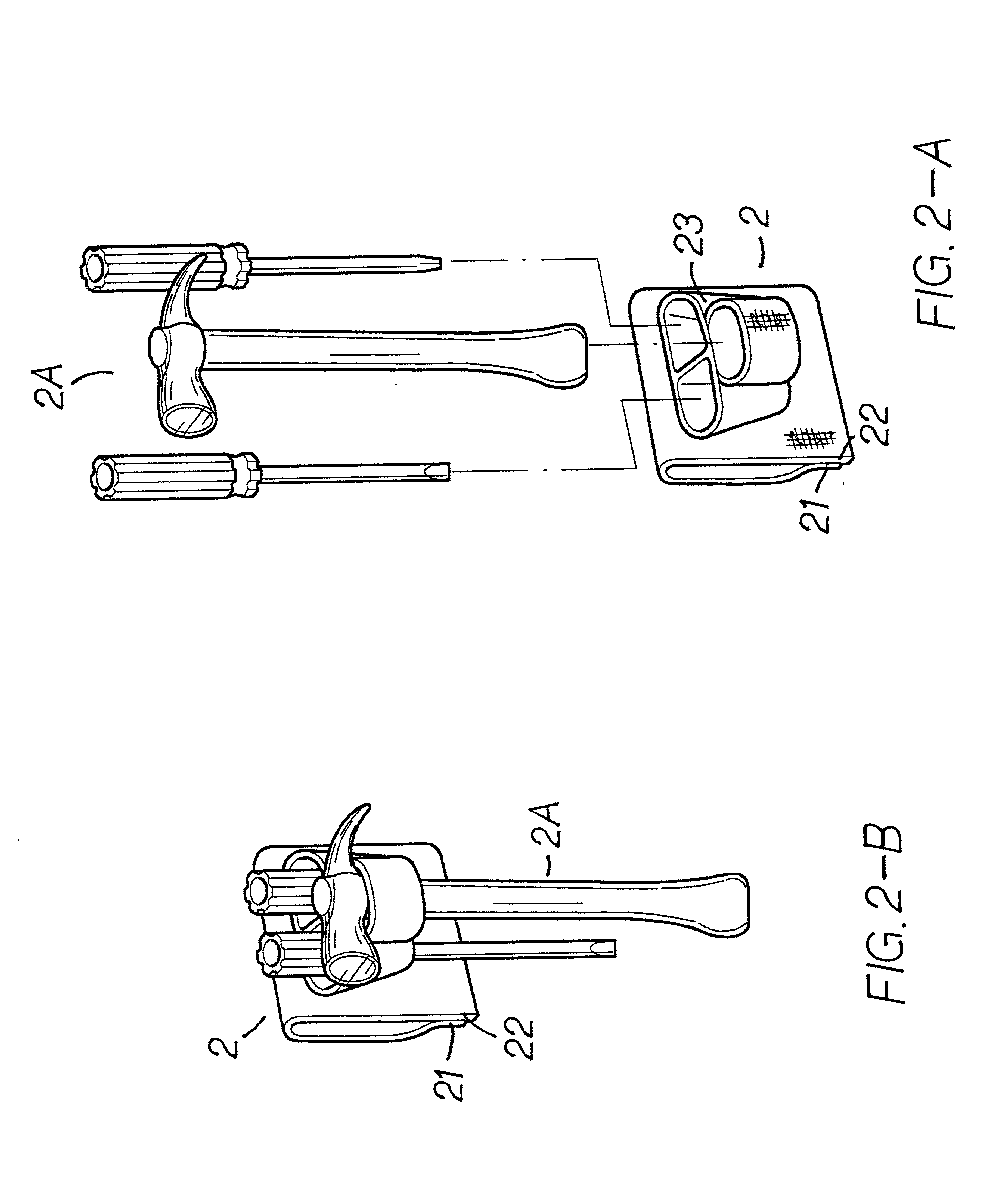

Pneumatic tool system operation and carrier belt

A pneumatic tool system operation and carrier belt comprised of a band worn around the waist of the user and from which is suspended a plurality of cinctures that respectively hold a set of hand tools, a pneumatic tool, a mini compressor, a small battery, and goggles, wherein the pneumatic tool, the mini compressor, and the small battery are interconnected. As such, the user goes to the work site only wearing the carrier belt holding the entire pneumatic tool system and operates the pneumatic tools directly from the belt because the power supply and compressed air source are built in, which improves upon the conventional need to connect a confusing array of equipment cables and hoses. Furthermore, the present invention does not hinder work and prevents accidental injury and other hazardous situations, and thereby provides a carrier belt that facilitates construction and manual dexterity.

Owner:VIVA ENTERPRISE

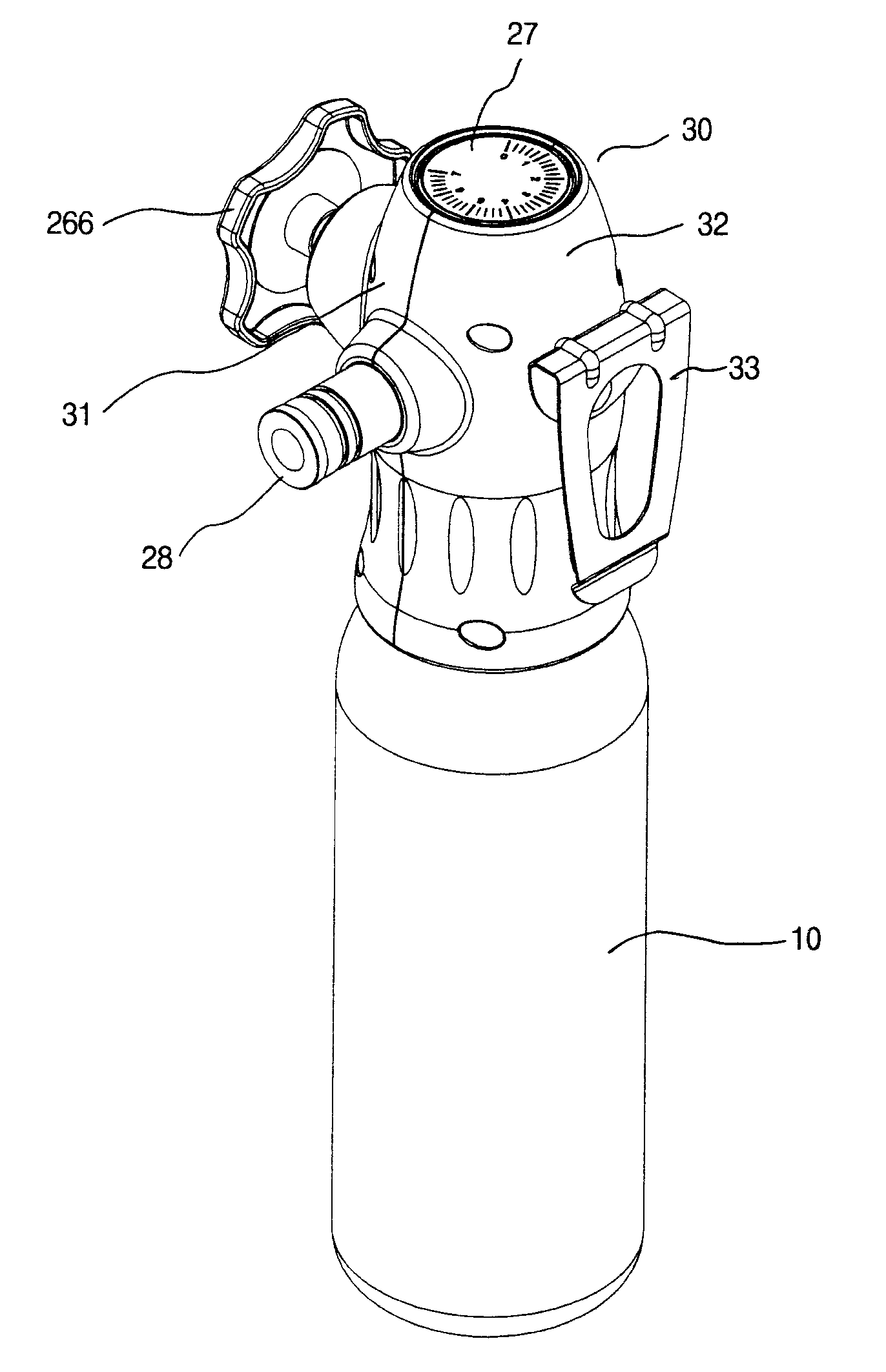

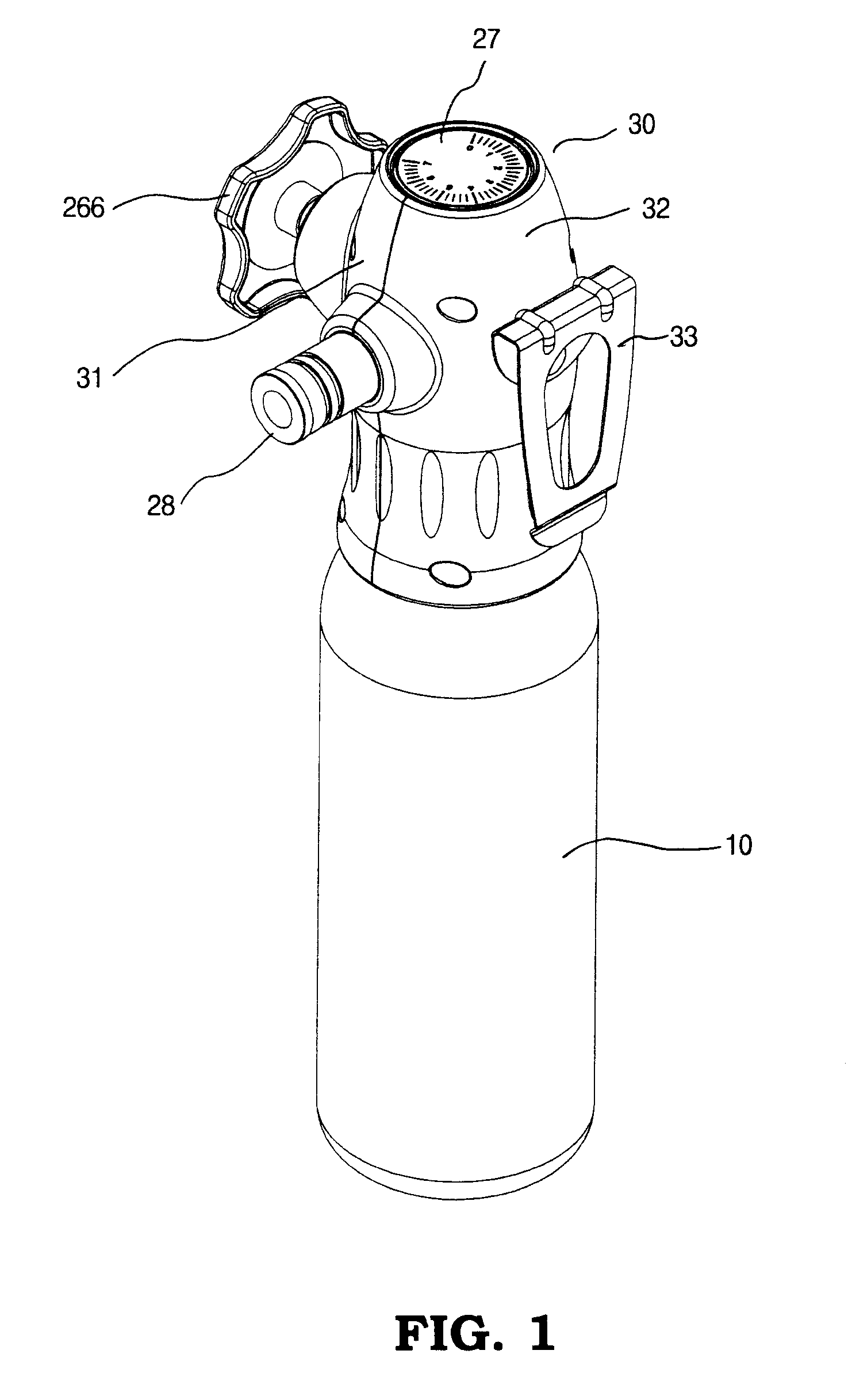

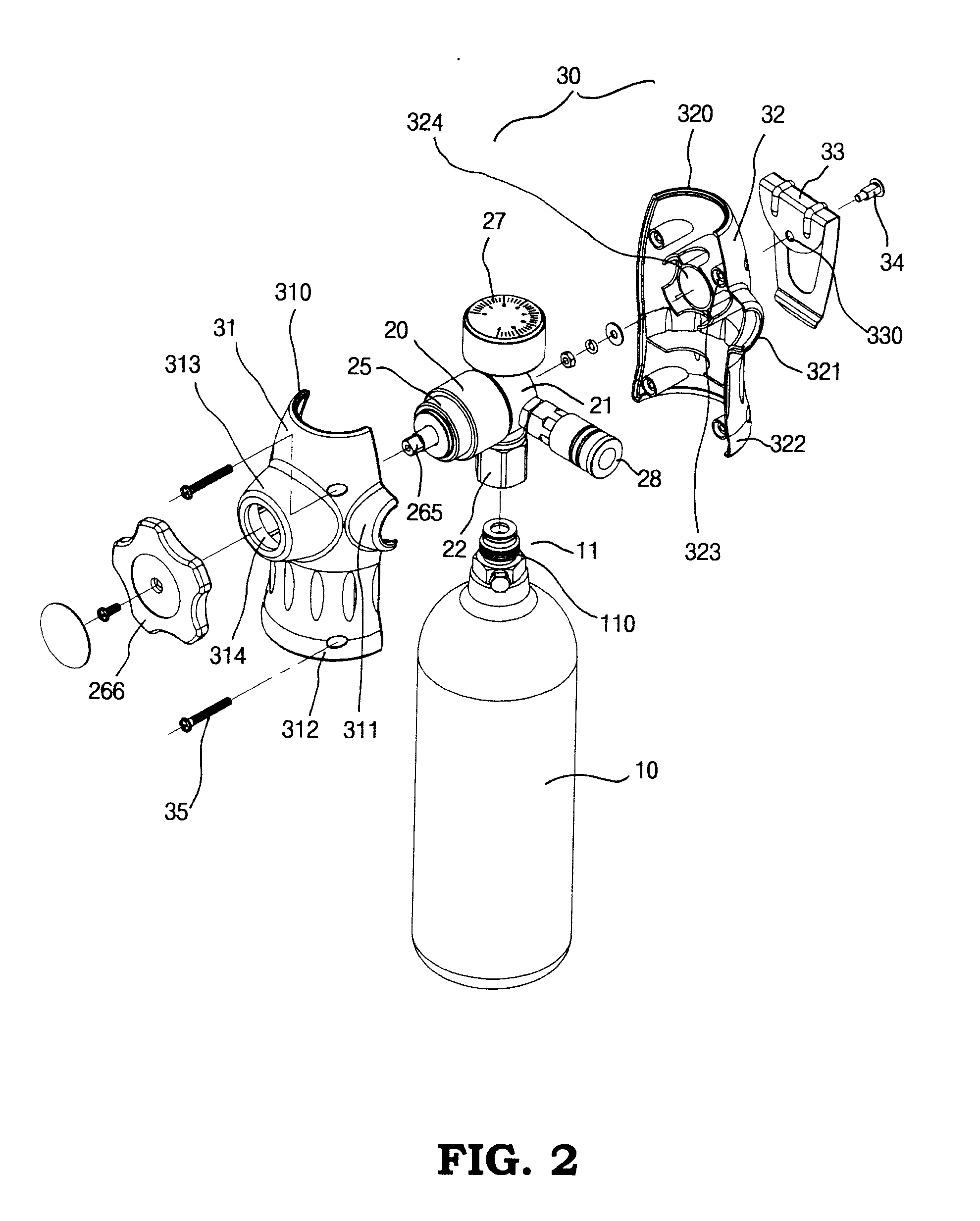

Portable device for supplying compressed CO2 from a pressure vessel to a pneumatic tool

A device includes a pressure regulator comprising a body including a control chamber adapted to connect to a portable pressure vessel filled with compressed CO2 via an inlet coupling, the control chamber having a threaded stepped diameter passageway, a relief valve, and a pressure gauge, a valve, a cap including a hand wheel, and a pressure adjustment assembly including a resilient sealing disk, a disc, a thumbtack member, a fastener for securing the thumbtack member and the sealing disk together, and a spring biased between the sealing disk and the disc; a housing for partially enclosing the pressure regulator with the hand wheel, the pressure gauge, and an outlet coupling being exposed; and a hanging member pivotably secured onto the housing.

Owner:FEVER INDAL

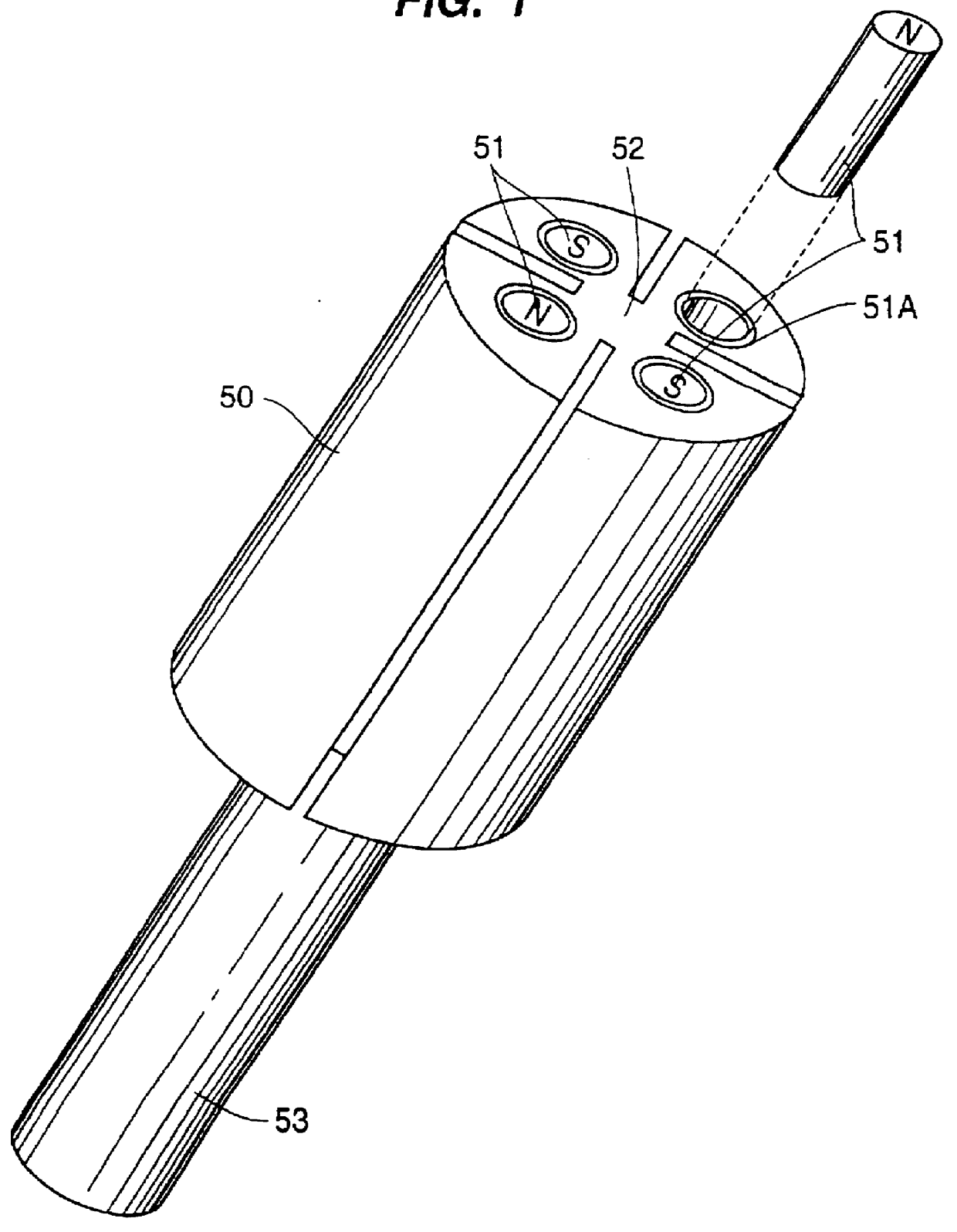

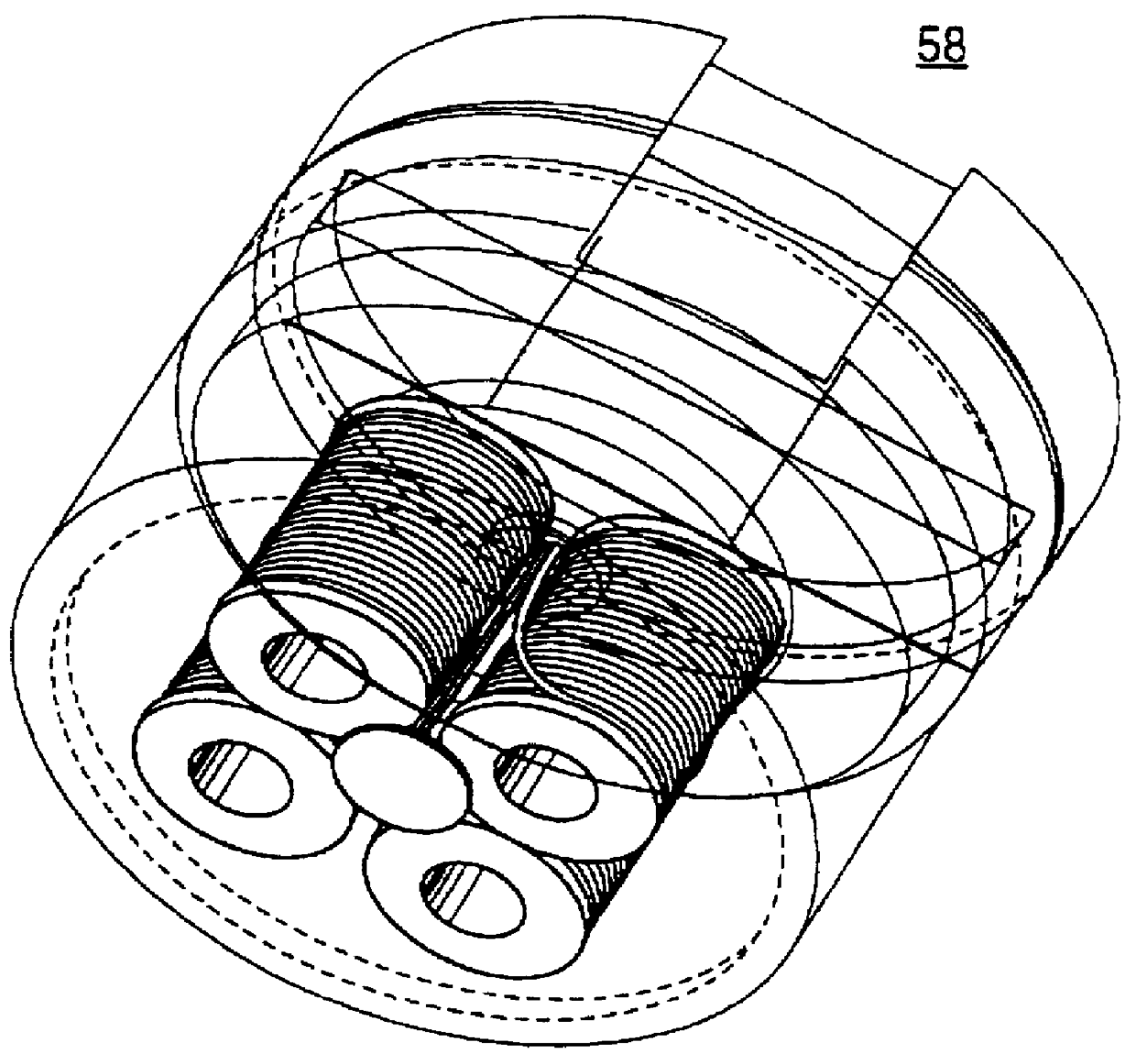

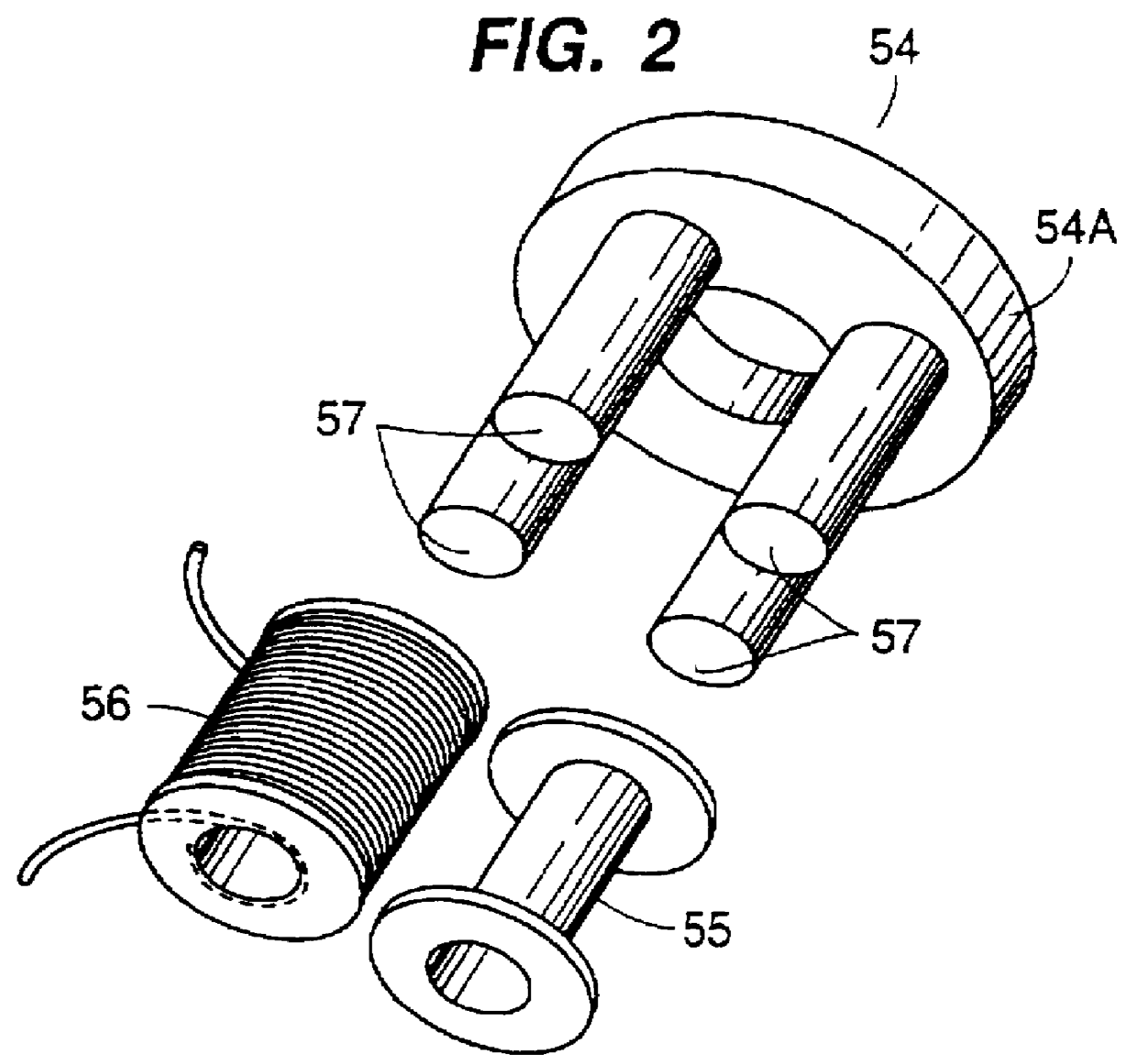

Pneumatic tool having integrated electricity generator with external stator

ActiveUS20080122302A1Easy to operateReduce resistanceManufacturing dynamo-electric machinesMachines/enginesElectricityPneumatic tool

A pneumatic tool includes a nonmagnetic tool housing; a cylindrical rotor inside the tool housing and rotatable in response to a flow of pressurized fluid through the tool housing; magnets mounted in the rotor; and a stator external to the tool housing. The stator is dimensioned to cooperate with the magnets to, upon rotation of the rotor, generate electrical current for supply to a load.

Owner:1543803 ONTARIO LTD +1

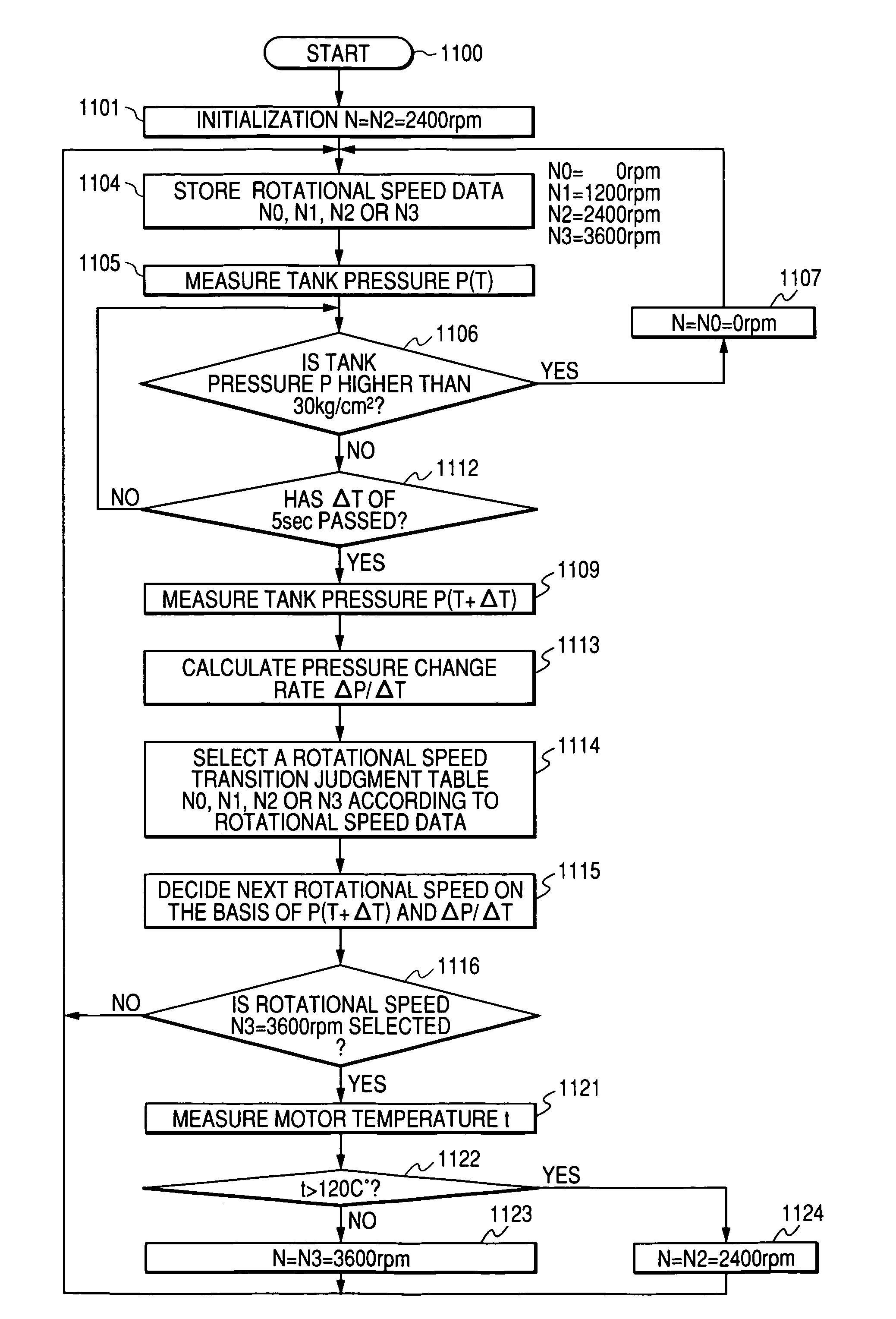

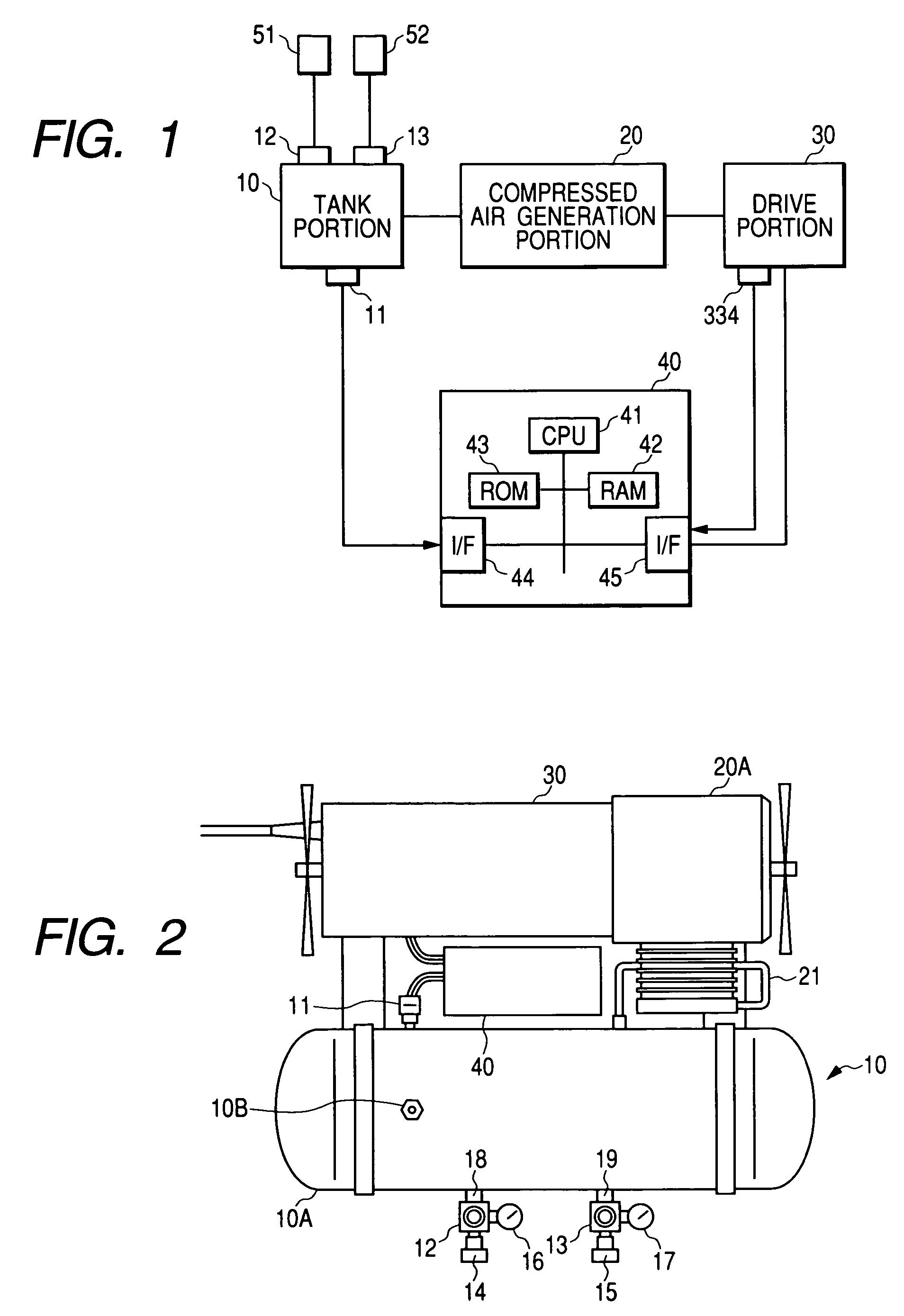

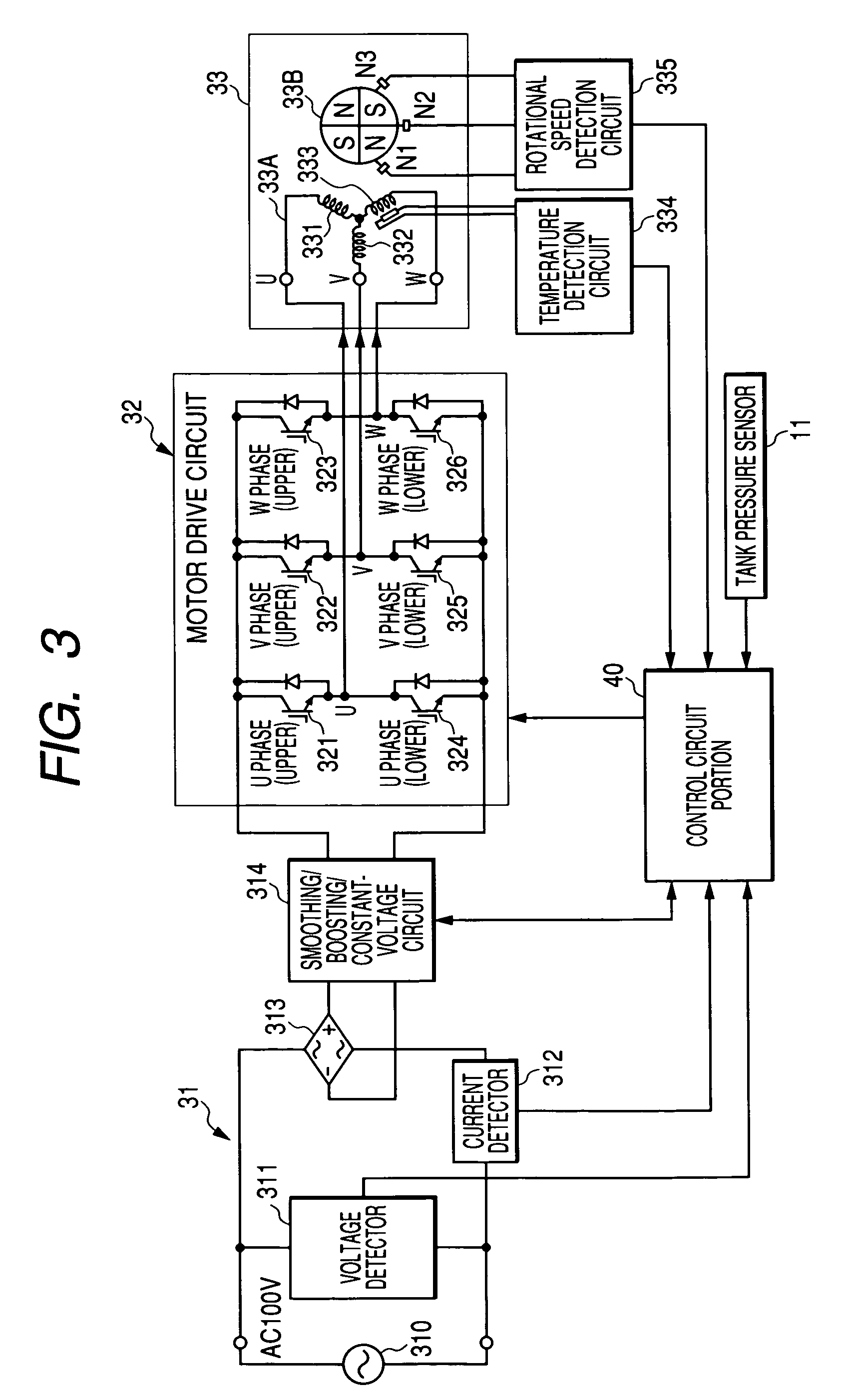

Air compressor and method for controlling the same

ActiveUS7704052B2Compressed air can be generated efficientlyAvoid power shortageMotor parameterPump controlGas compressorPneumatic tool

An air compressor includes: a tank portion for reserving compressed air used in a pneumatic tool; a compressed air generation portion for generating compressed air and supplying the compressed air to the tank portion; a drive portion including a motor for driving the compressed air generation portion; a control circuit portion for controlling the drive portion; and a pressure sensor for detecting pressure of the compressed air reserved in the tank portion. The control circuit portion includes a unit for controlling the rotational speed of the motor multistageously on the basis of a detection signal output from the pressure sensor.

Owner:KOKI HLDG CO LTD

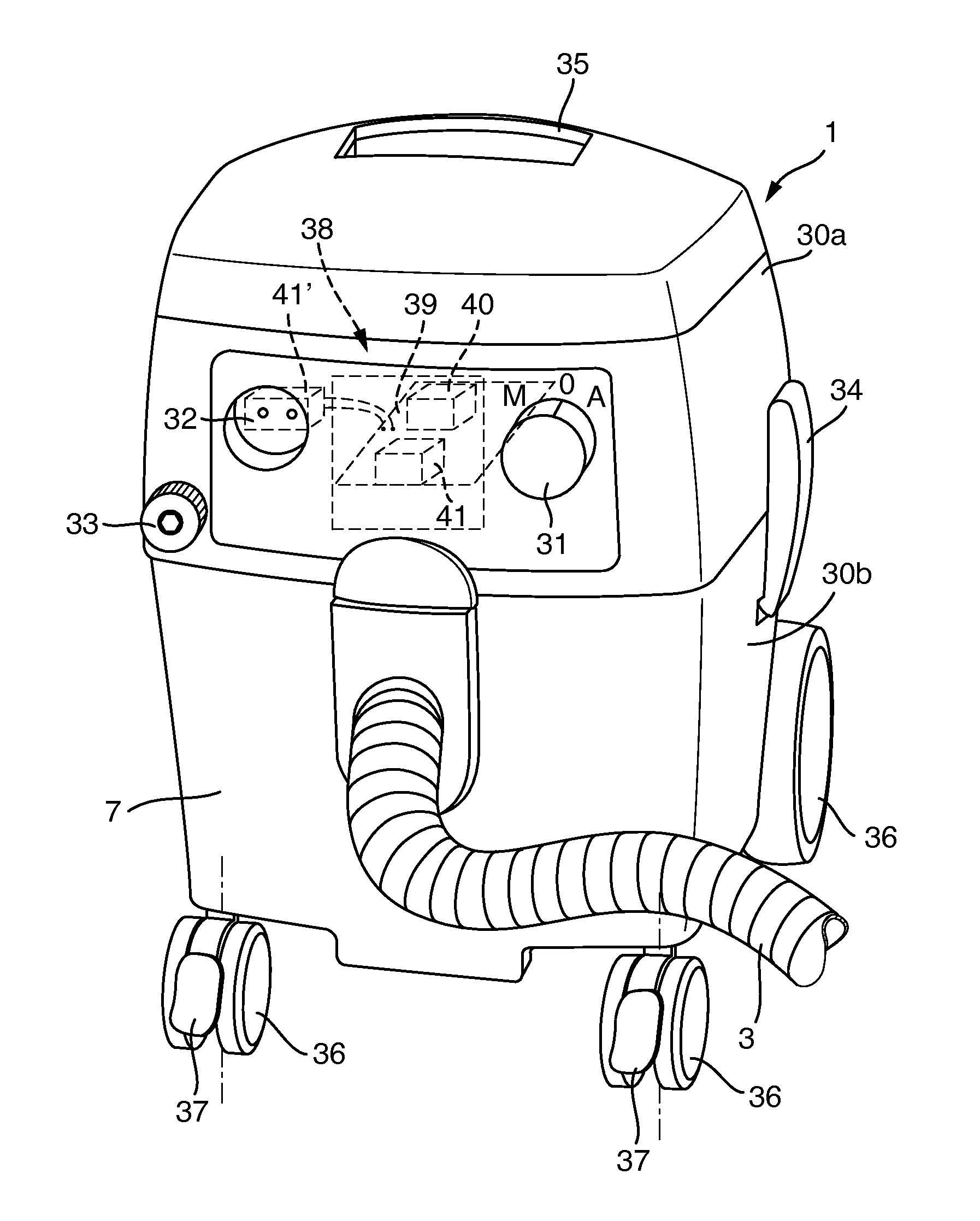

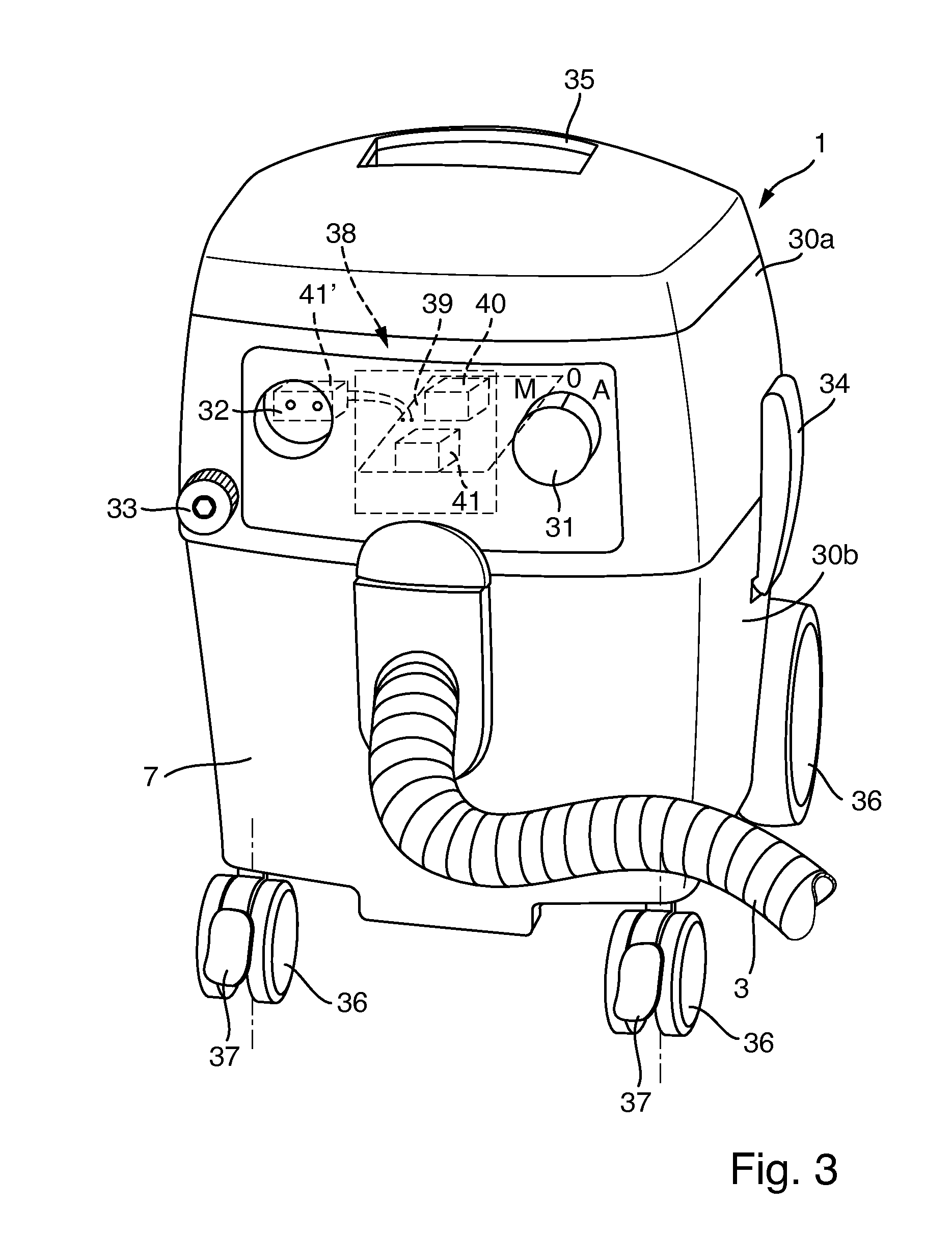

Vacuum cleaner pneumatically connected to a power tool, method for controlling operation parameters of such a vacuum cleaner and power tool for pneumatic connection to such a vacuum cleaner

InactiveUS20160100724A1Impede proper functioningNegative health effectCleaning filter meansTransmission systemsEngineeringPneumatic tool

The present invention refers to a vacuum cleaner adapted for pneumatic connection to a power tool generating dust during its operation, in order to draw at least part of the dust away from the tool into the vacuum cleaner, the vacuum cleaner operating under certain operation parameters when it is turned on. In order to optimize operation of the vacuum cleaner based on the characteristics of the tool and / or its current use, the vacuum cleaner includes a reception mechanism for receiving information regarding characteristics of the tool and / or its current use, a processing and calculation mechanism for processing the received information and for calculating a correction signal for at least one of the vacuum cleaner's operation parameters based on the received information, and an adjustment mechanism for adjusting the at least one operation parameter based on the calculated correction signal.

Owner:VALENTINI GUIDO

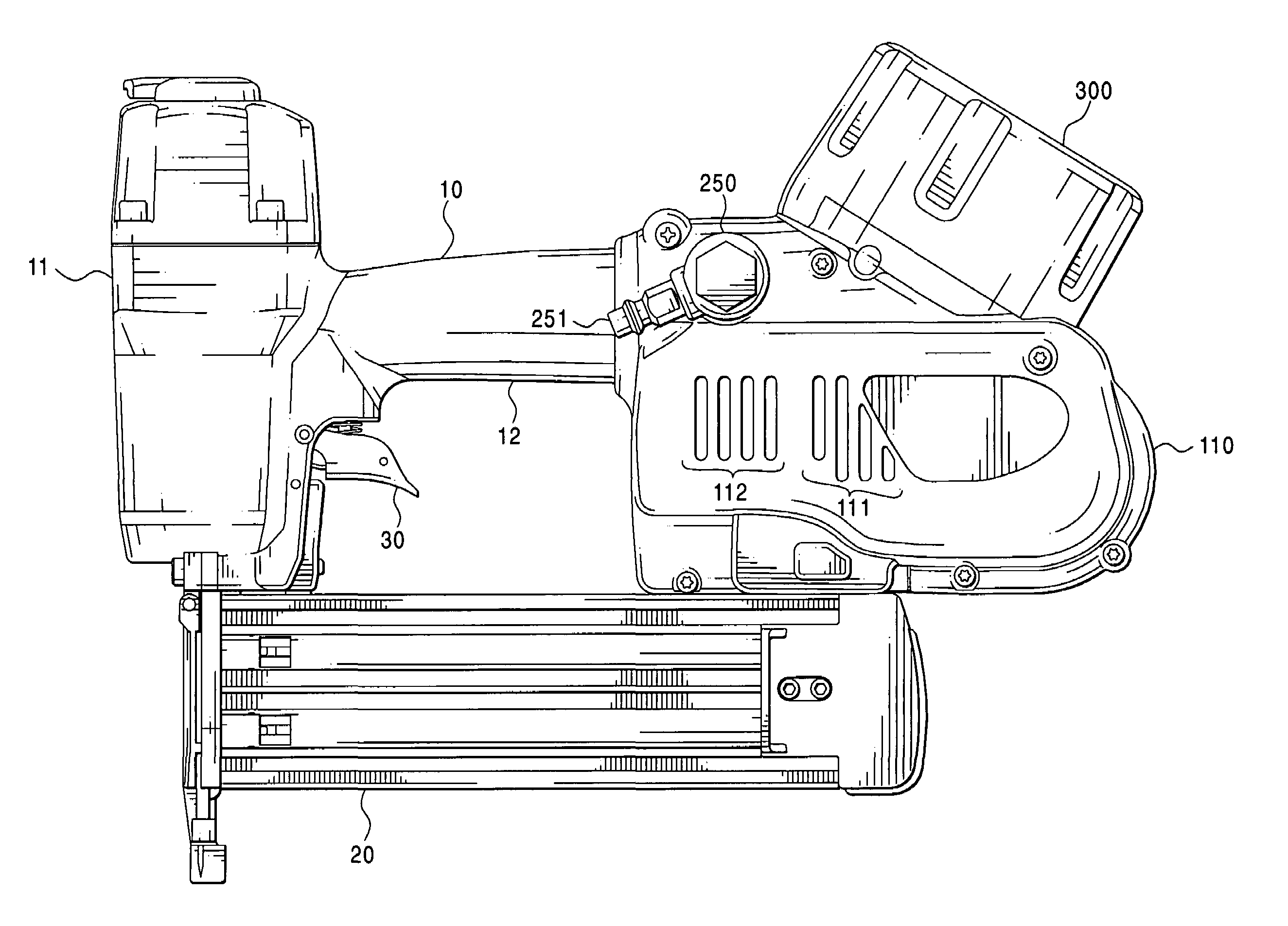

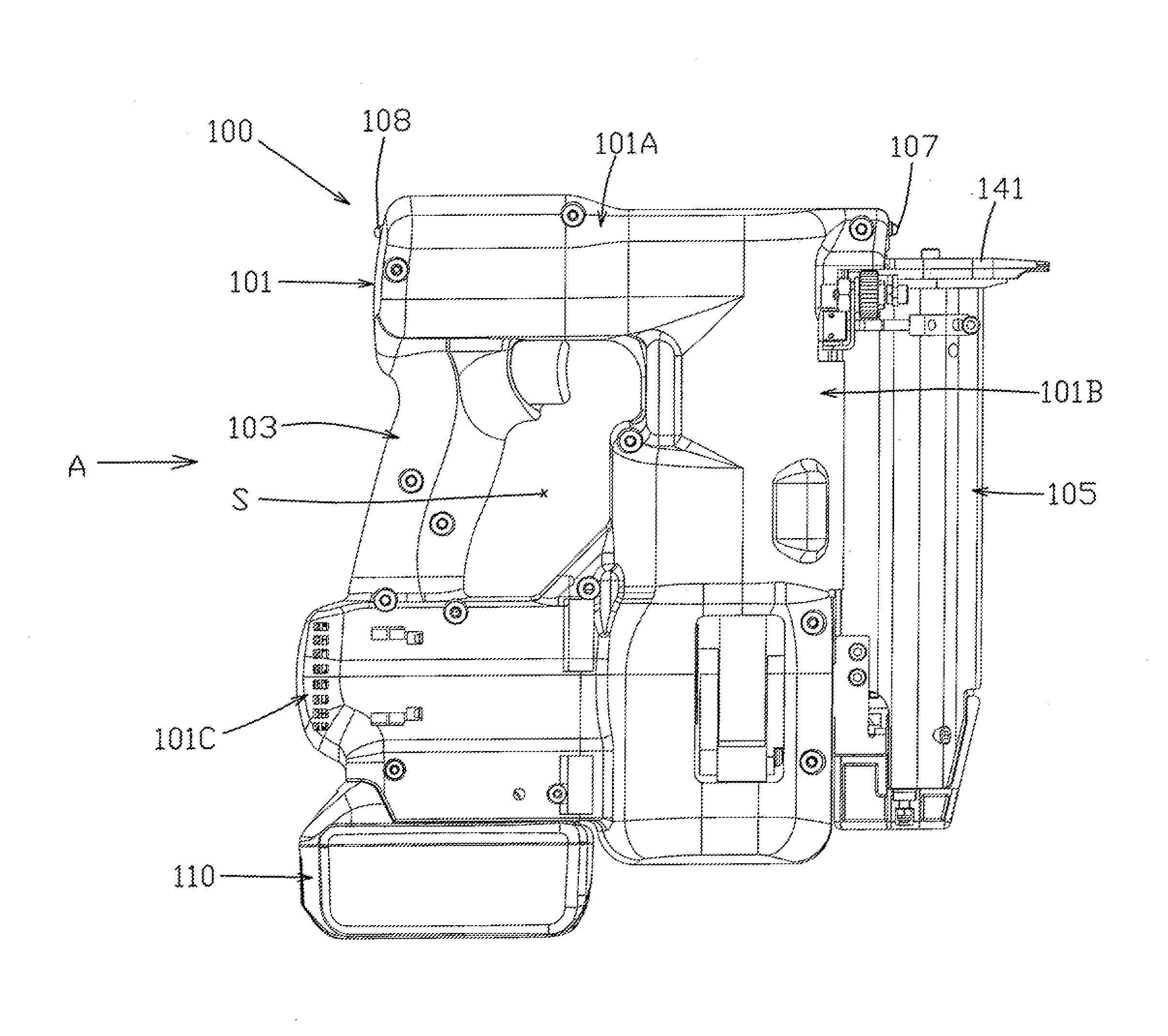

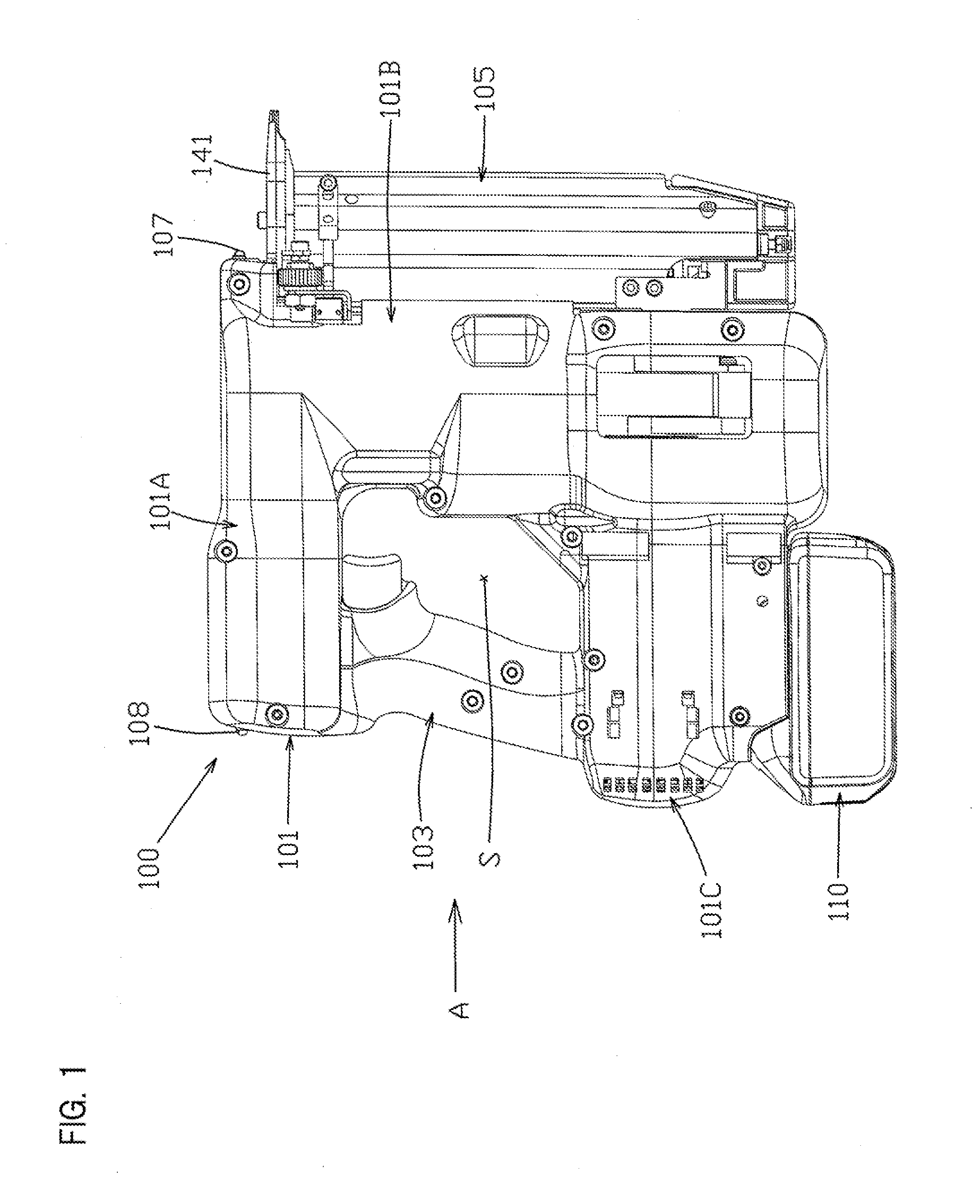

Driving tool

ActiveUS20150158160A1Smoothly and reliably performedAccurate and reliable processServomotor componentsServomotorsTop dead centerPneumatic tool

An electro-pneumatic tool drives a fastener into a workpiece by energizing an electric motor to drive a first piston and generate compressed air in a first cylinder. The compressed air is then supplied to a second cylinder and causes a second piston to move and drive the fastener into the workpiece. After the first piston has passed through its top dead center, braking is applied to the first piston according to one or more braking parameters. Then, if a control unit determines that the first piston has come to a stop at a position that is outside a predetermined range about the bottom dead center of the first piston, one or more of the braking parameters is changed in a subsequent fastener driving cycle to cause the first piston to stop closer to its bottom dead center after conclusion of the subsequent fastener driving cycle.

Owner:MAKITA CORP

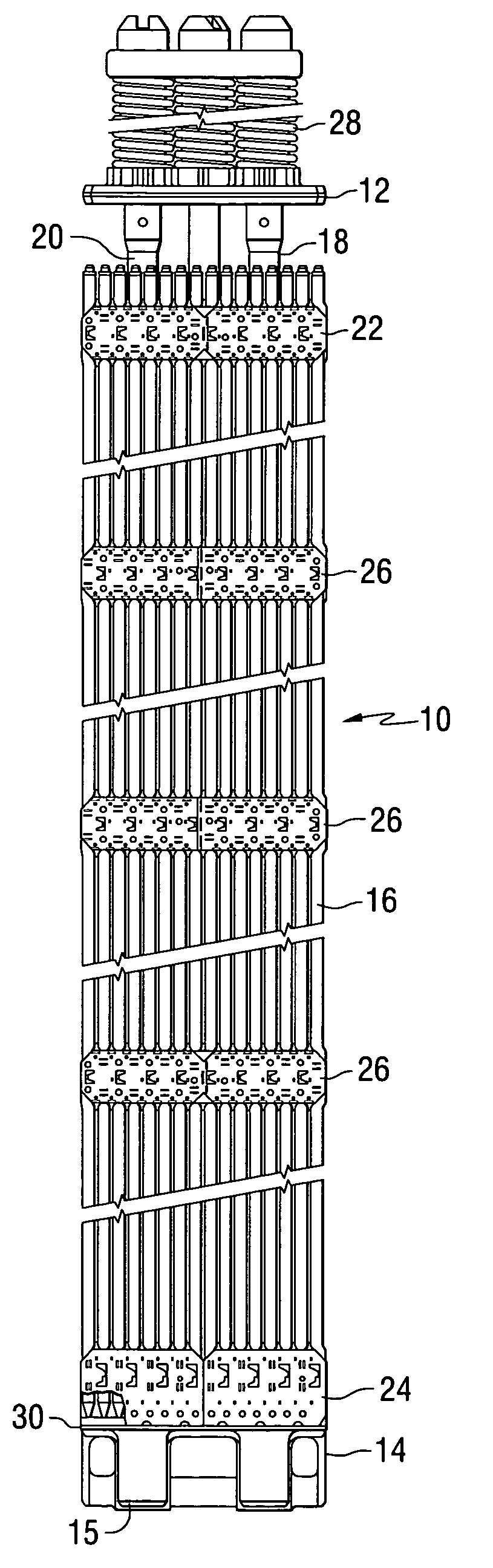

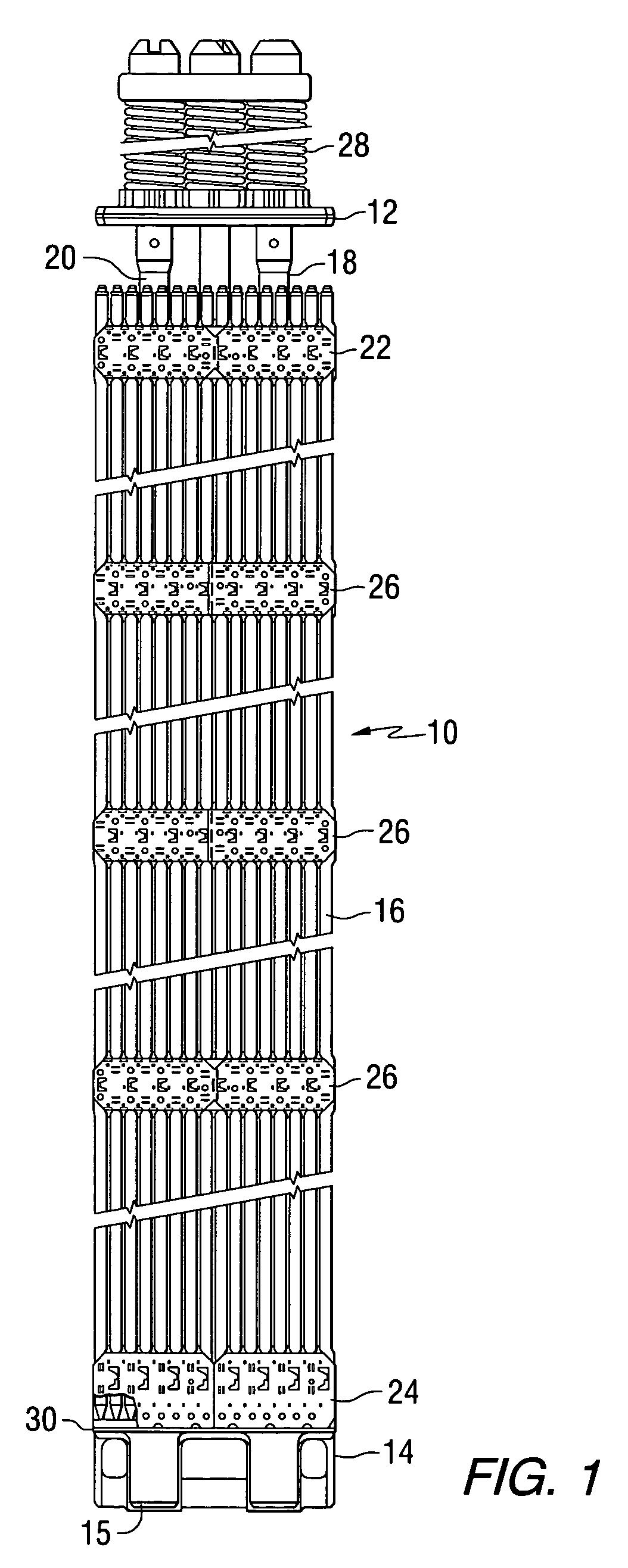

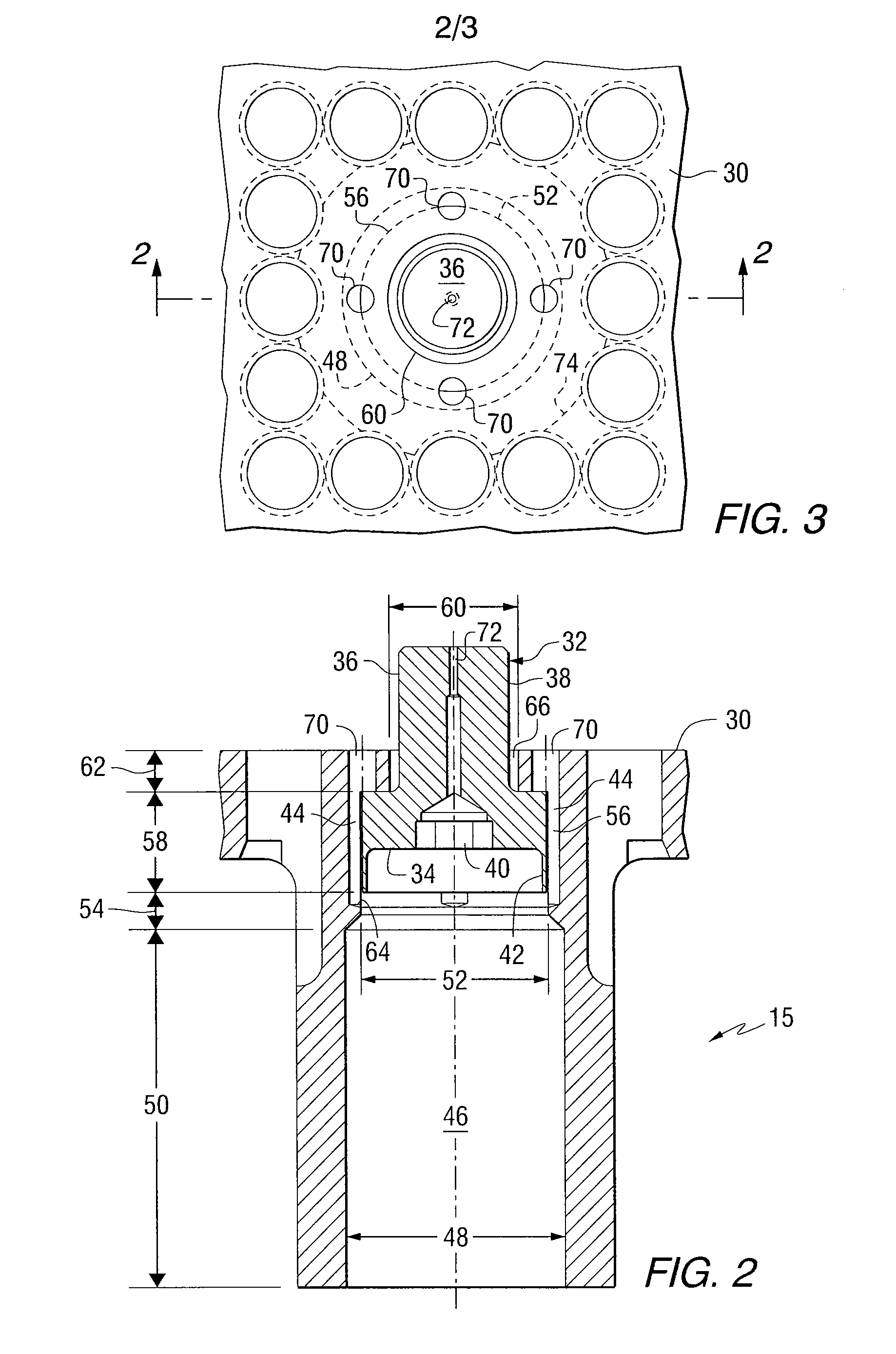

Nuclear fuel assembly control rod drive thimble to bottom nozzle connector

ActiveUS7453972B2Easy to implement and re-work and inspectLess componentsNuclear energy generationFuel element assembliesEngineeringPneumatic tool

A secure connection between the bottom nozzle of a nuclear fuel assembly and the control rod guide thimbles having two or four crimped pockets in the side wall of a bottom nozzle leg counterbore which are formed by drilling two or four blind holes through the top surface of the bottom nozzle. After attaching the bottom nozzle to the fuel assembly with a crimp bolt a pneumatic tool is then inserted into a flanged cup feature on the crimp bolt head and the flanged portion of the cup feature of the crimp bolt is deformed into the crimp pockets. The crimp pockets are contained within the leg counterbore and prevent the screw from rotating or falling out of the assembly in the event of preload loss or screw fracture.

Owner:WESTINGHOUSE ELECTRIC CORP

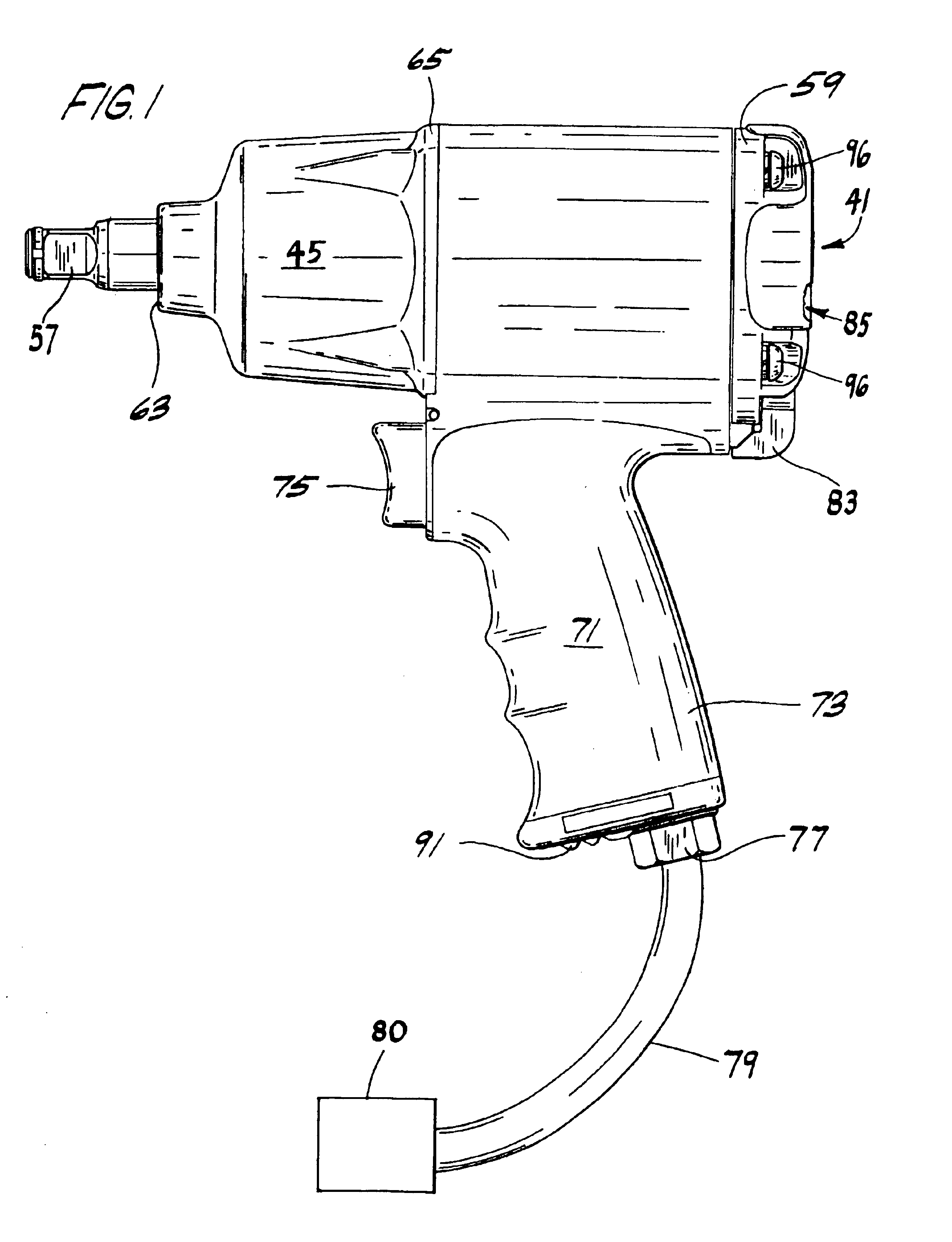

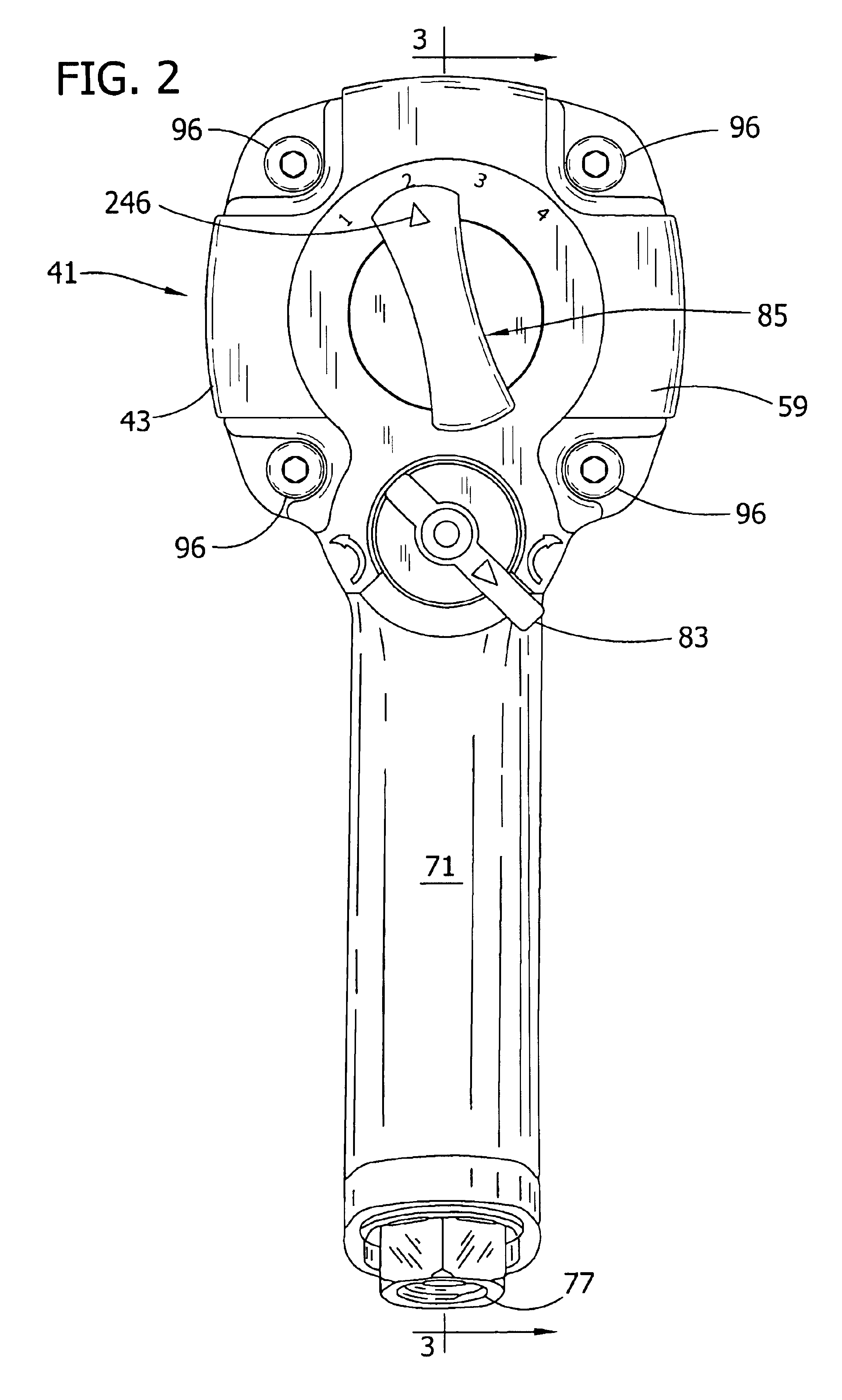

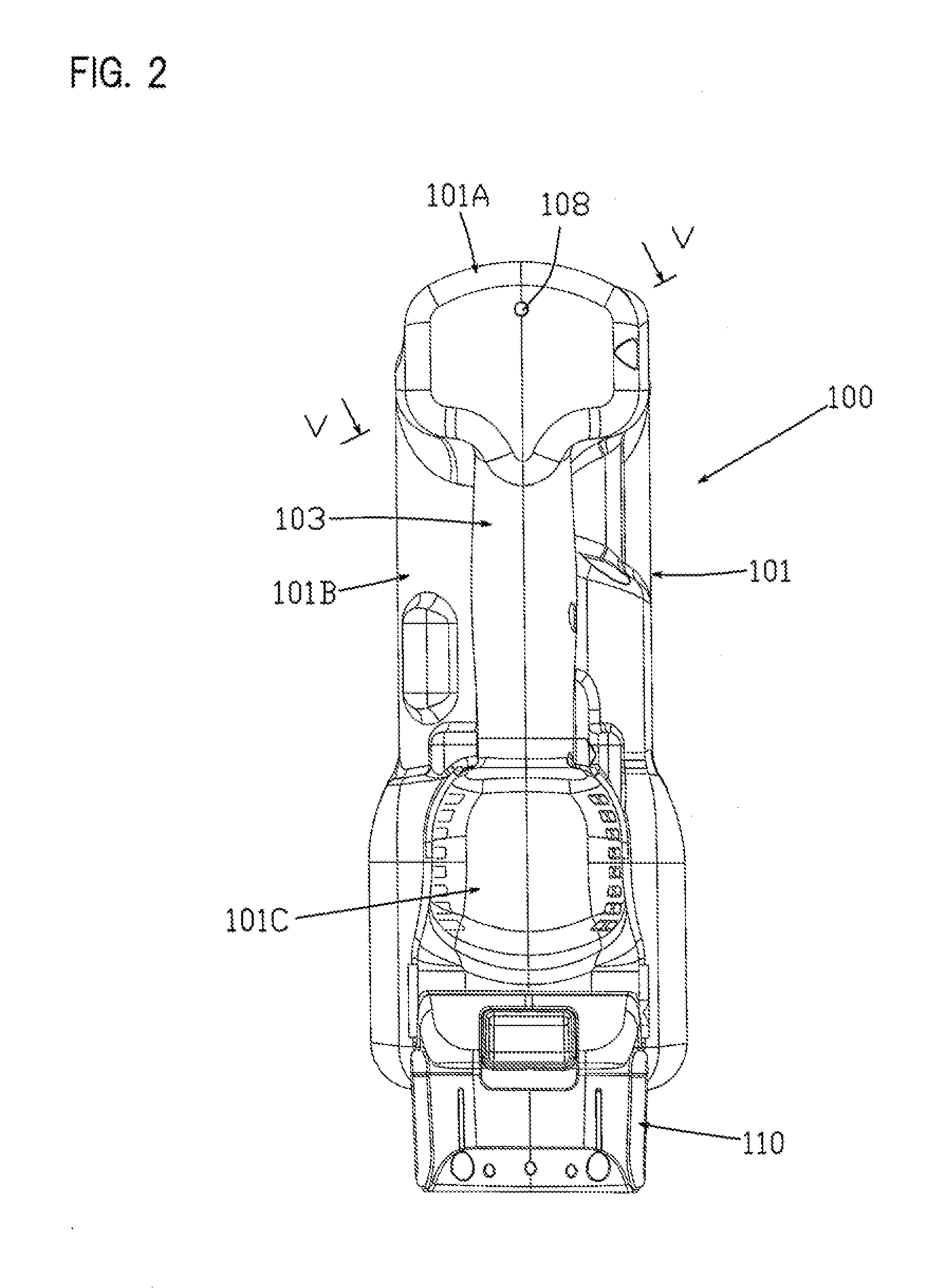

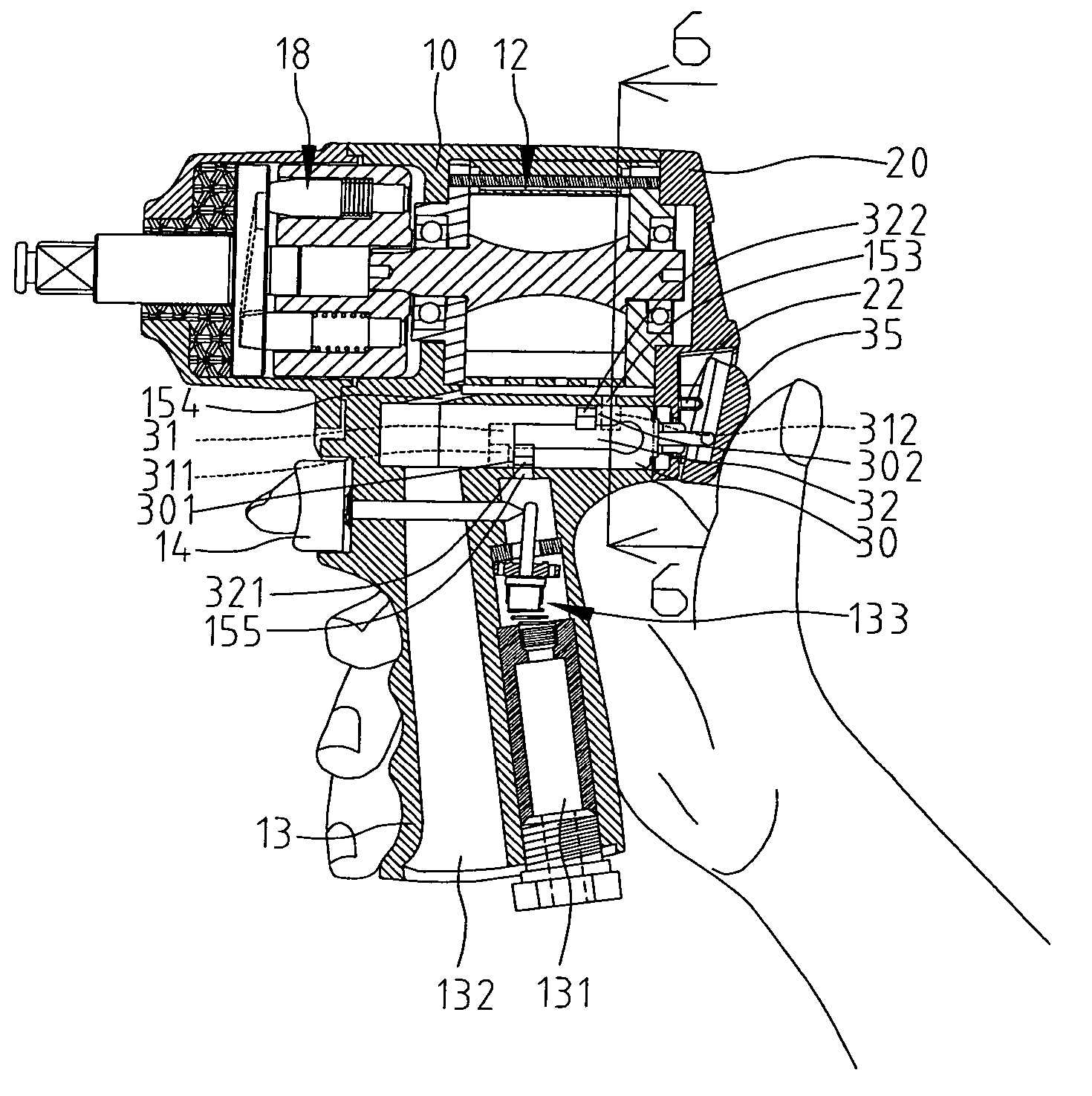

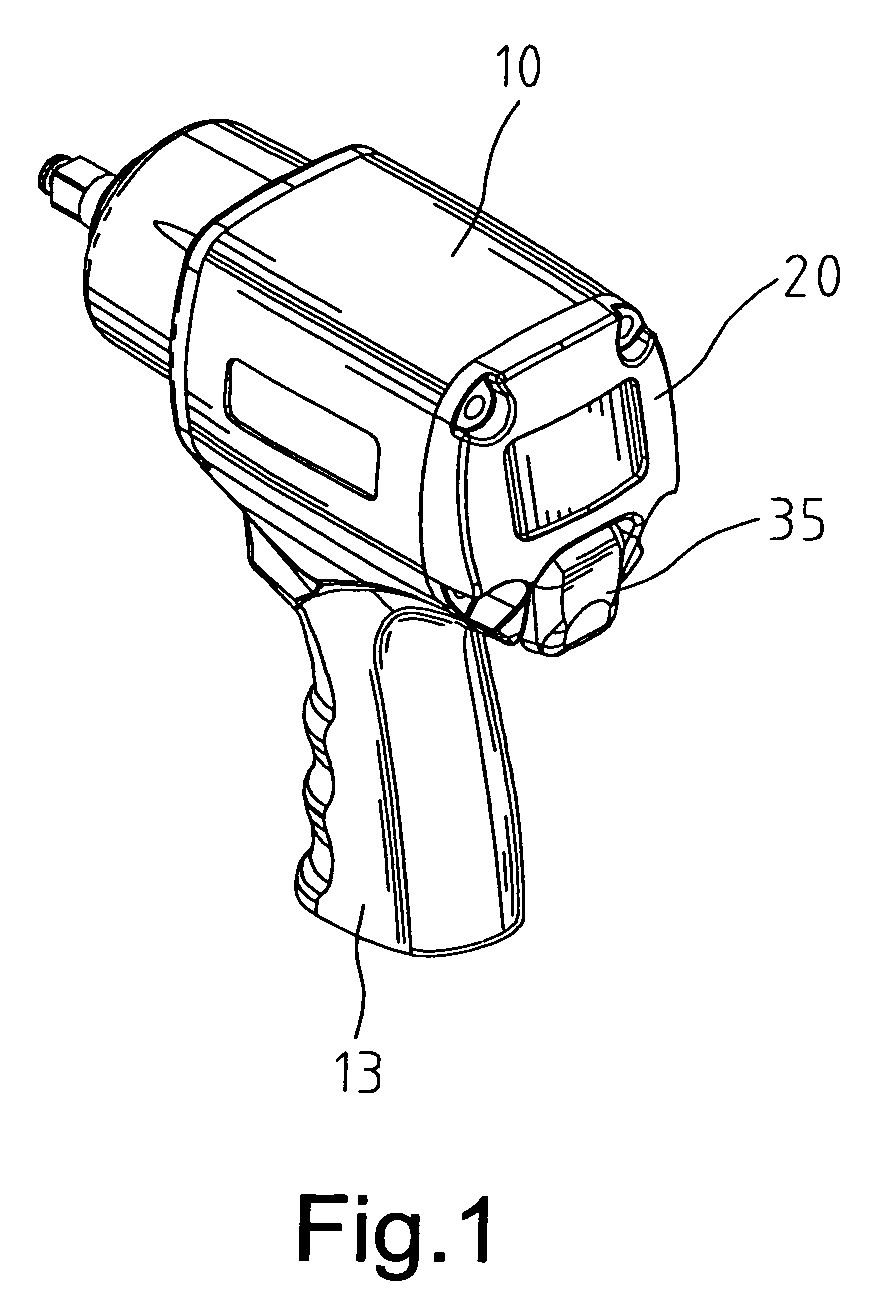

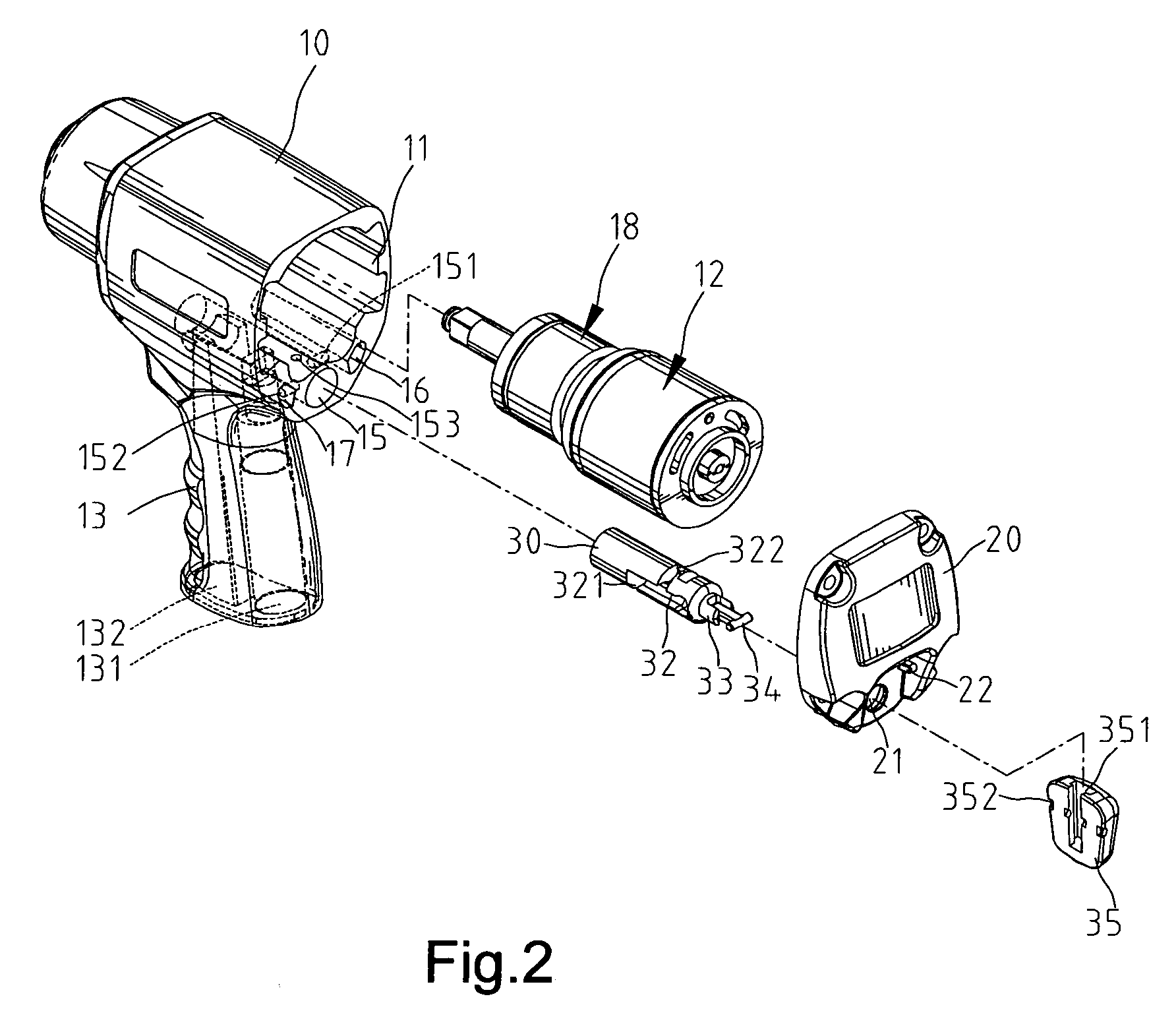

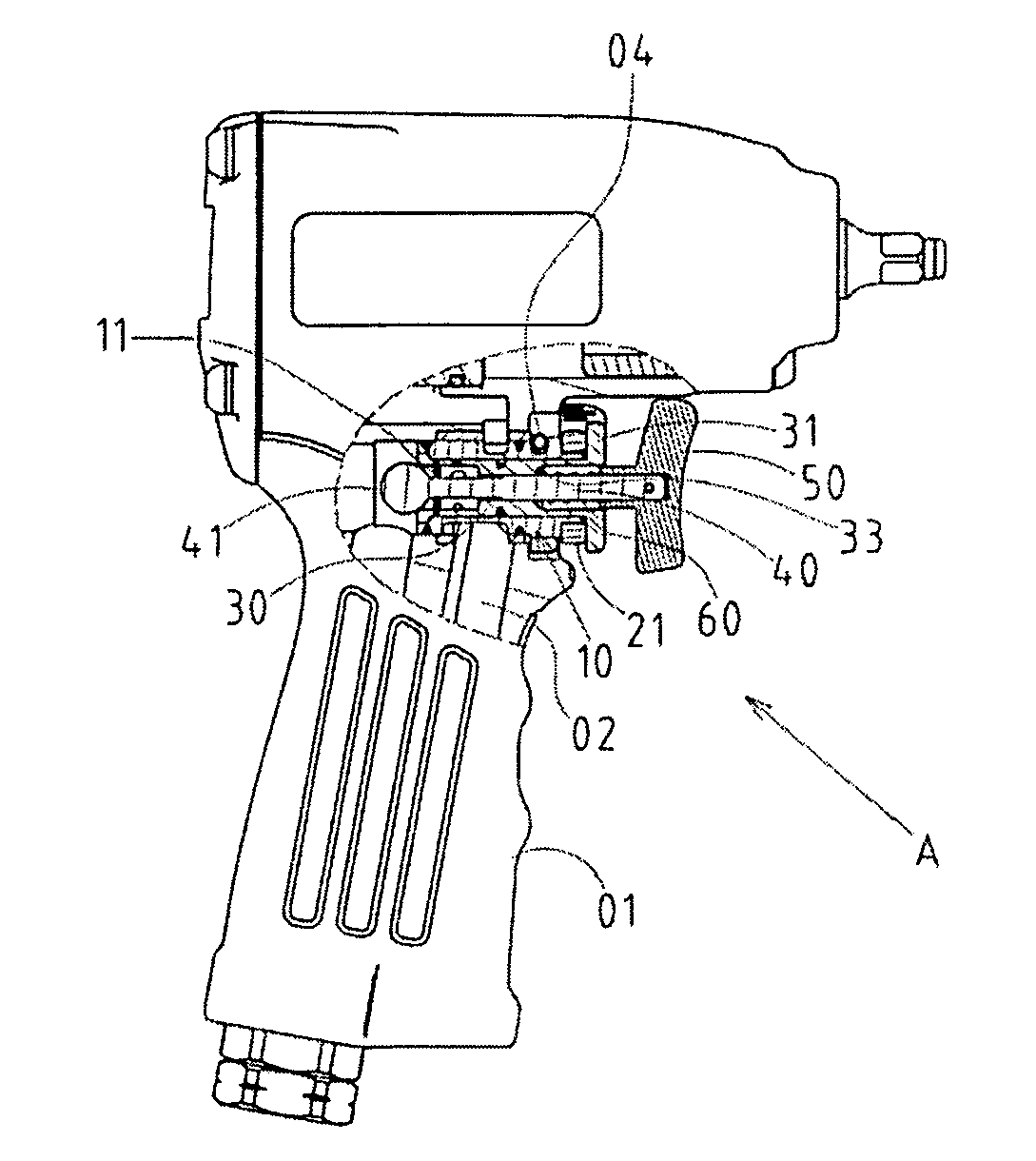

Pneumatic tool with direction switch operable with single hand

A pneumatic tool is operable with a single hand. The pneumatic tool includes a shell defining a first chamber and a second chamber. The second chamber includes intake and outlet apertures in communication with the first chamber. A cylinder is in the first chamber. A controller is movable in the second chamber between a first position and a second position. The controller includes a first groove and a second groove. In the first position, the first groove communicates with the intake aperture for directing pressurized air to drive the cylinder in a first direction. In the second position, the second groove communicates with the intake aperture for directing pressurized air to drive the cylinder in a second direction. A cover seals the first chamber and the second chamber. The cover defines an opening through which the controller extends from the second chamber so that the controller can be moved.

Owner:PNEUTECH MFG

Damping apparatus for reciprocating pneumatic tools

InactiveUS6668942B1Operator-supported drilling machinesPortable percussive toolsPneumatic toolEngineering

A damping apparatus for a reciprocating pneumatic tool mainly includes a cylindrical damper. The damper has a front opening and an enlarged rear end. The front opening is attached to a cylinder of the reciprocating pneumatic tool. A damping segment is formed between the front opening and the enlarged rear end of the damper. A spiral slot is defined longitudinally through the enlarged rear end of the damper. Several slots are defined parallel and transversely in the damping segment of the damper and communicate with the spiral slot. The damping segment has gaps arranged longitudinally by the slots such that the structure has high internal damping to attenuate shock that is caused by return movement of a piston in the cylinder. Consequently, a user holding the pneumatic tool can feel comfortable.

Owner:LIN CHING TIEN

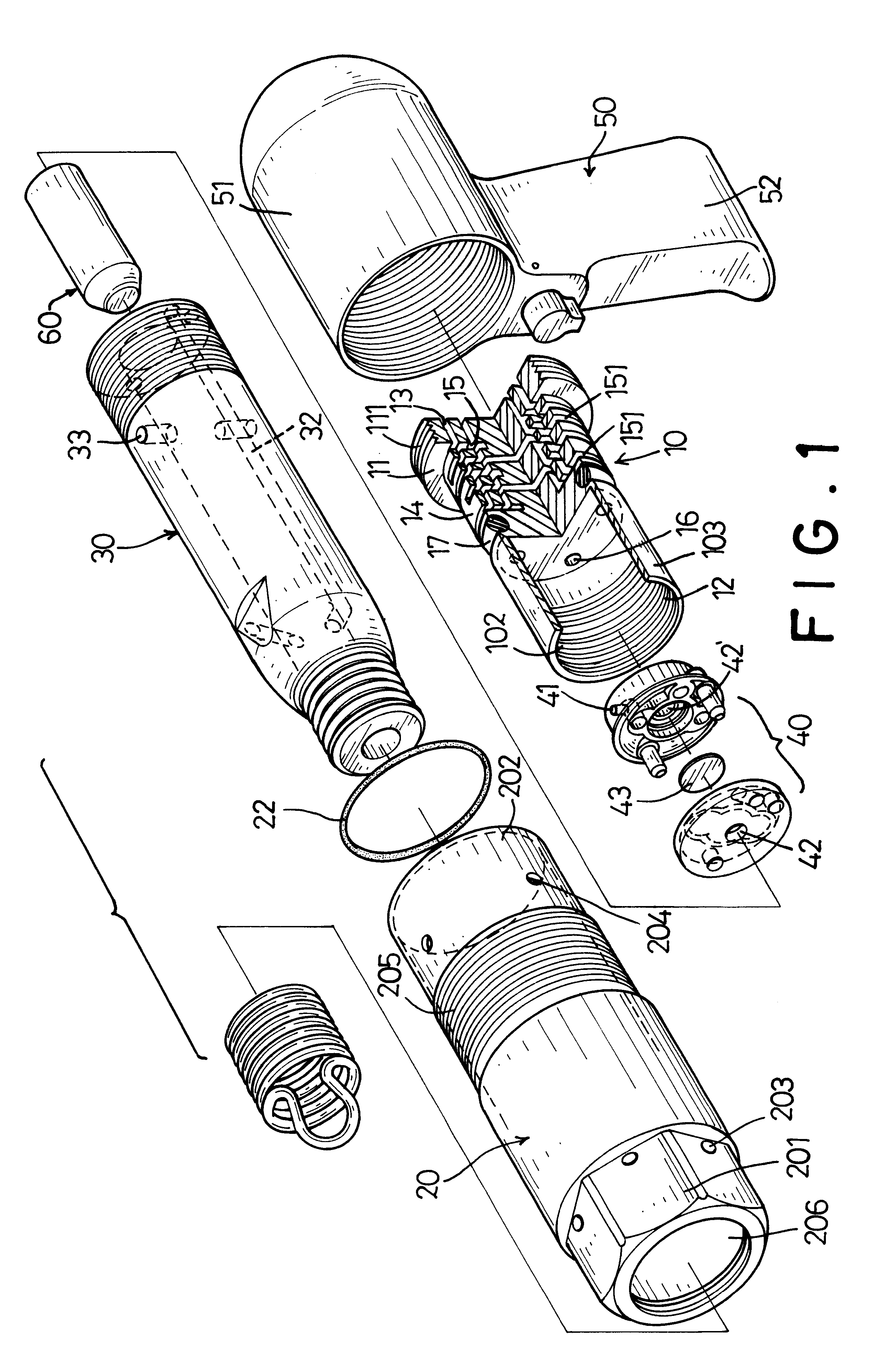

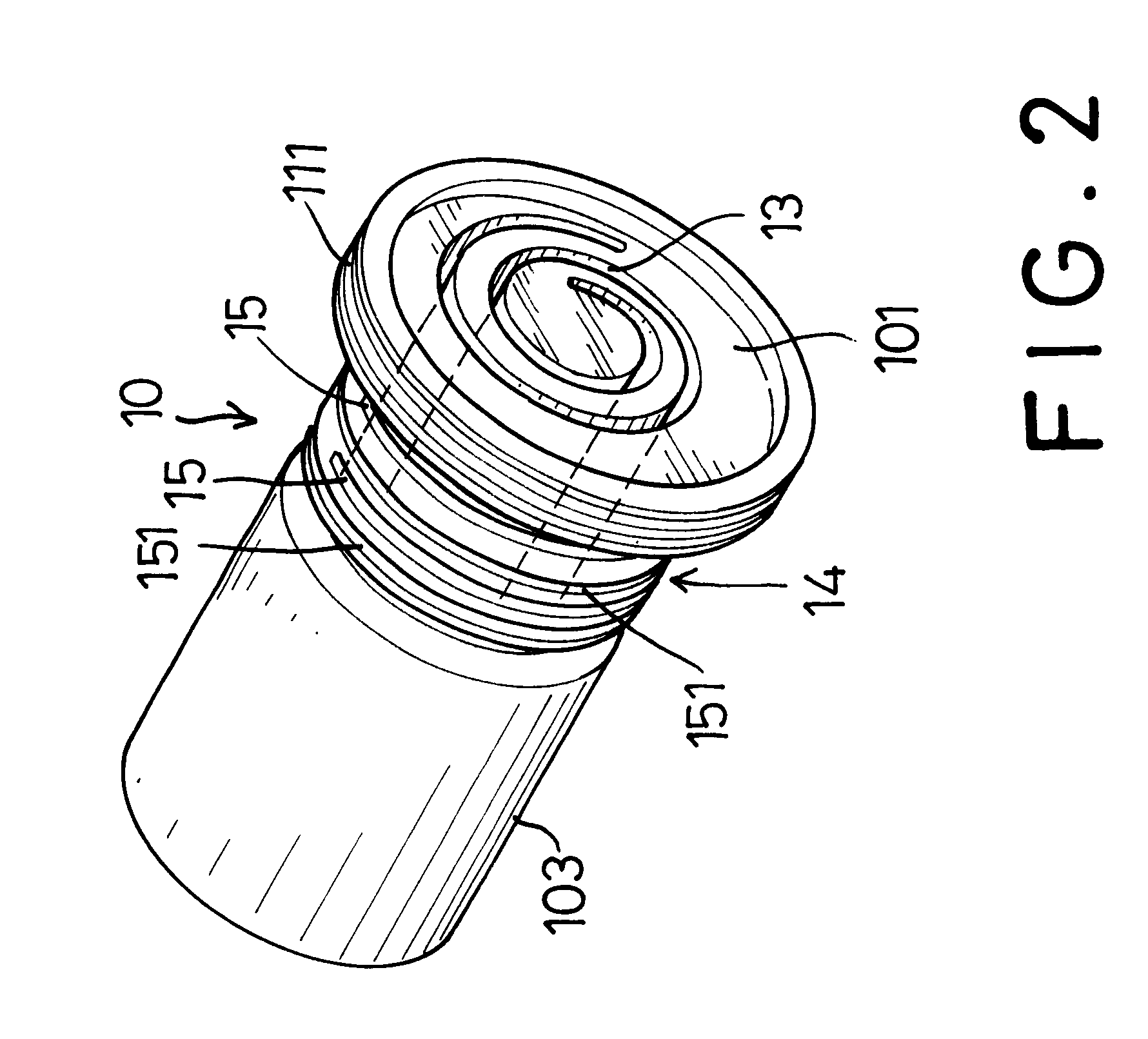

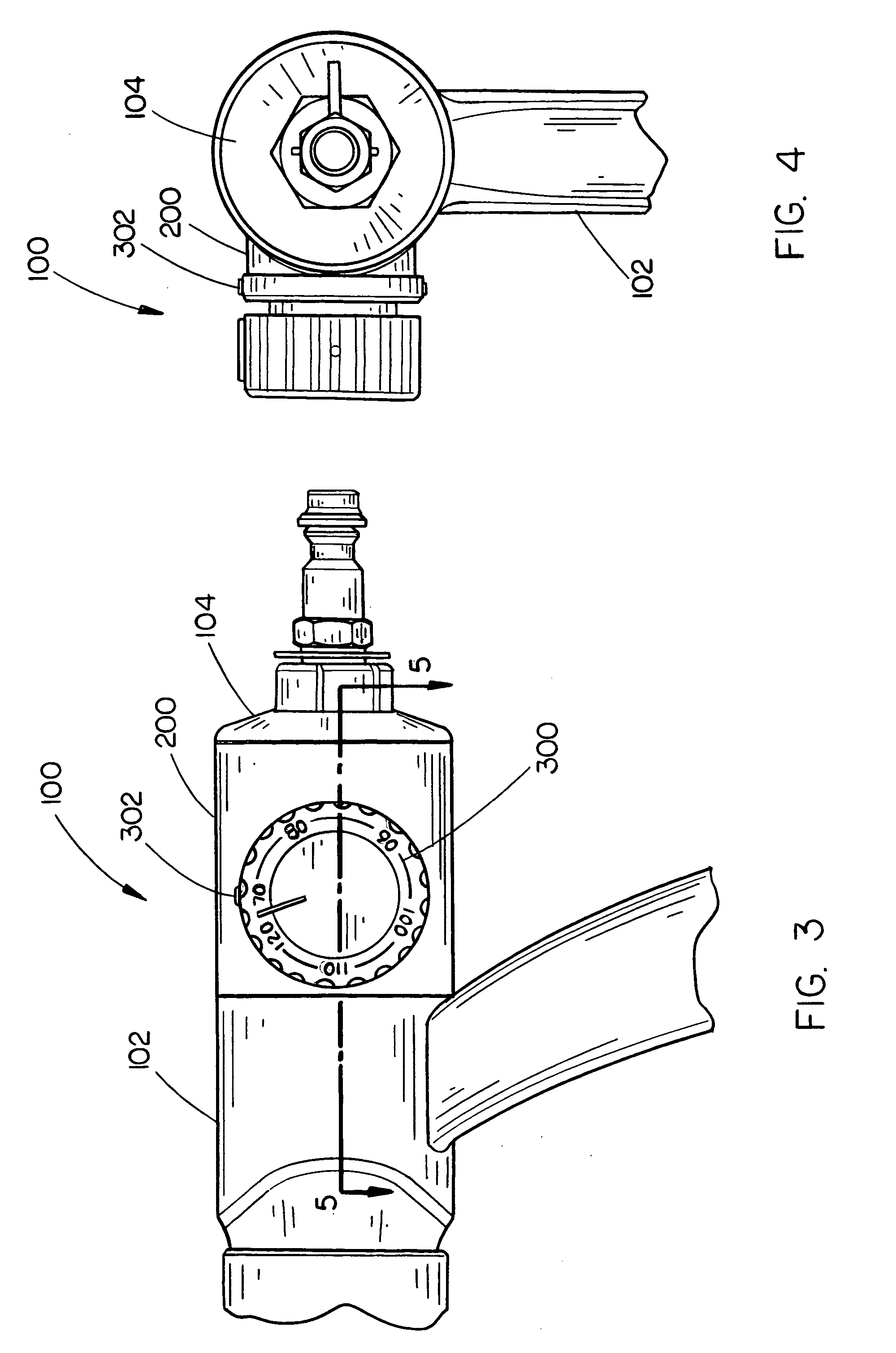

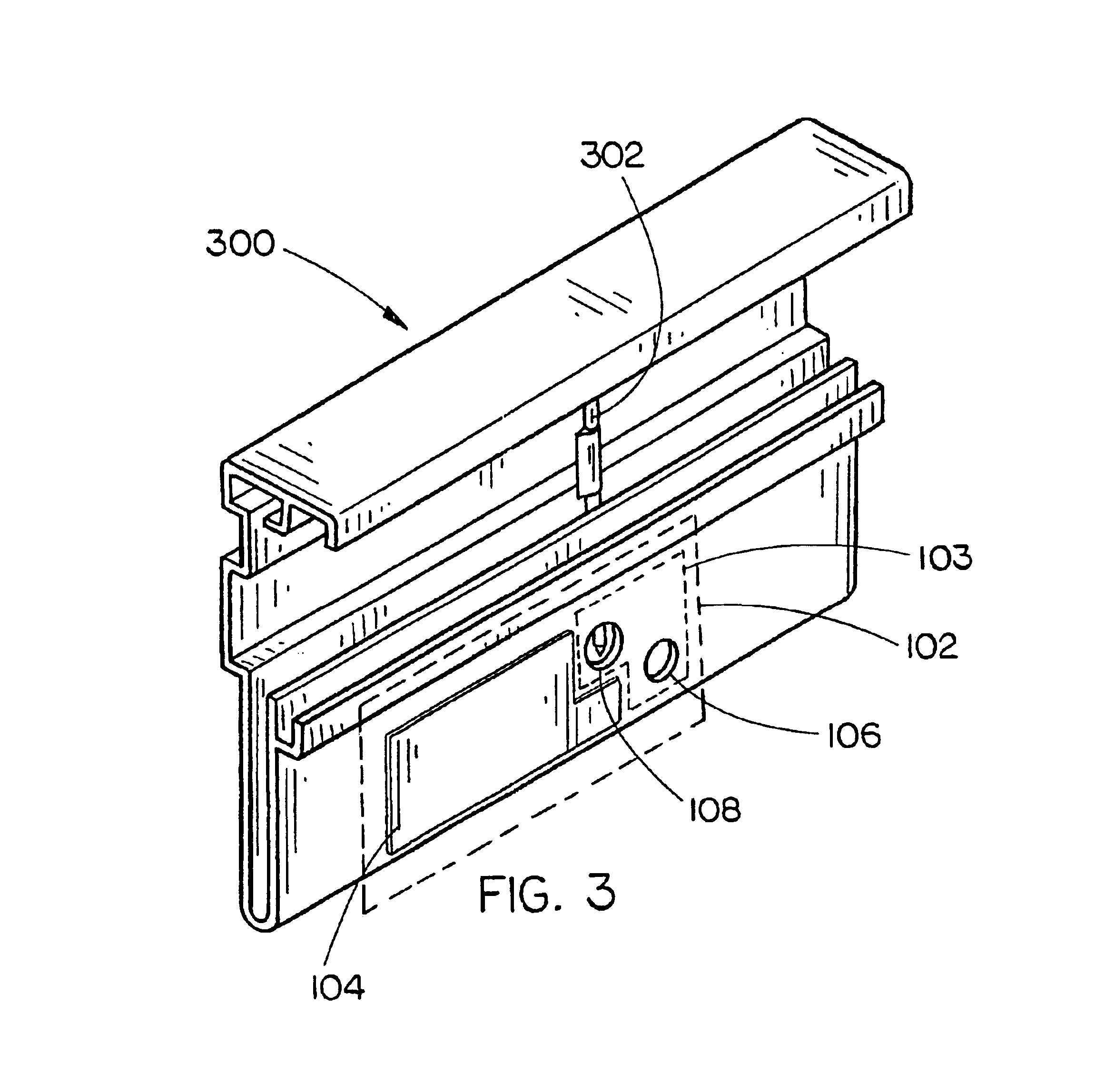

Integrated air tool and pressure regulator

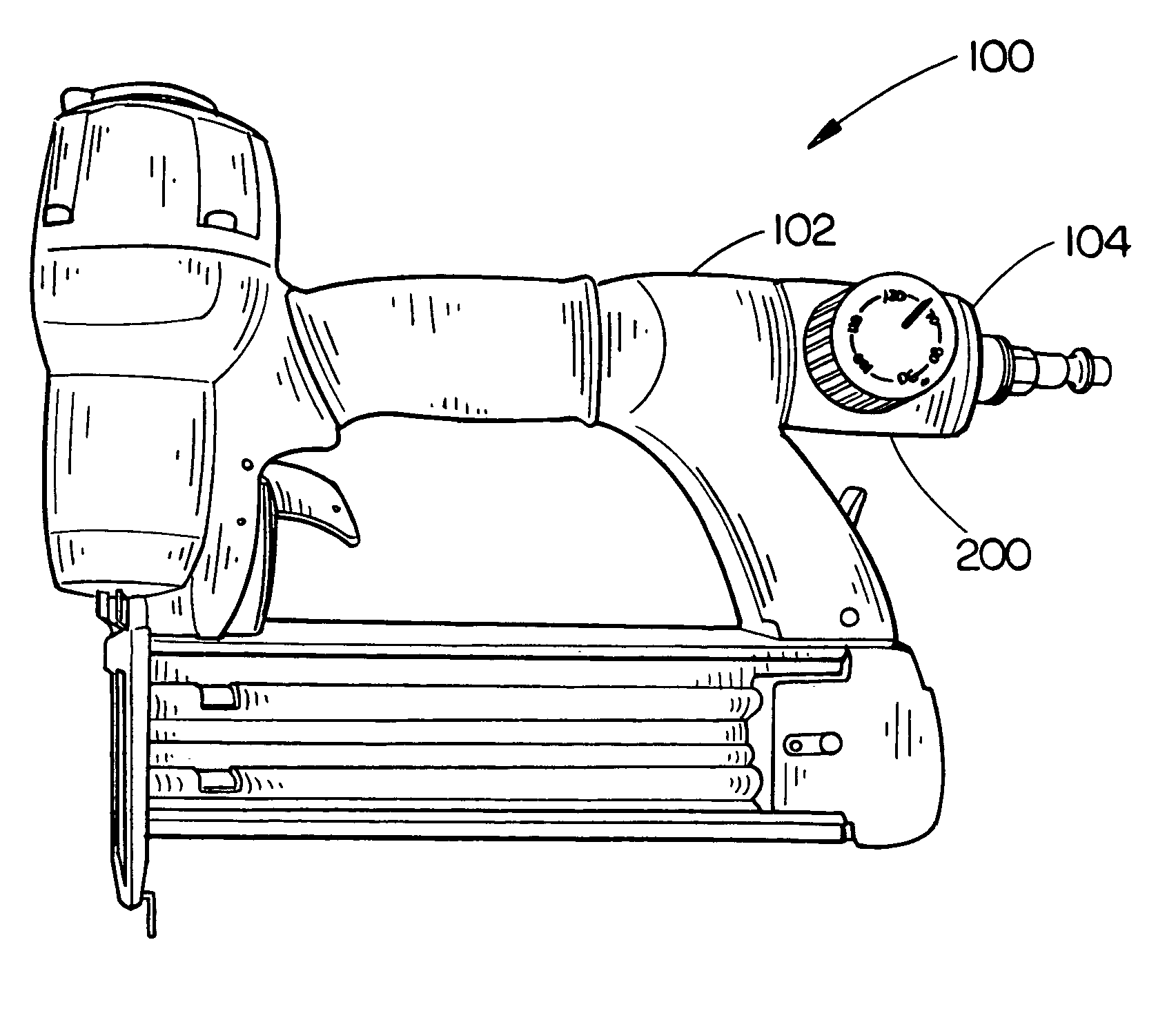

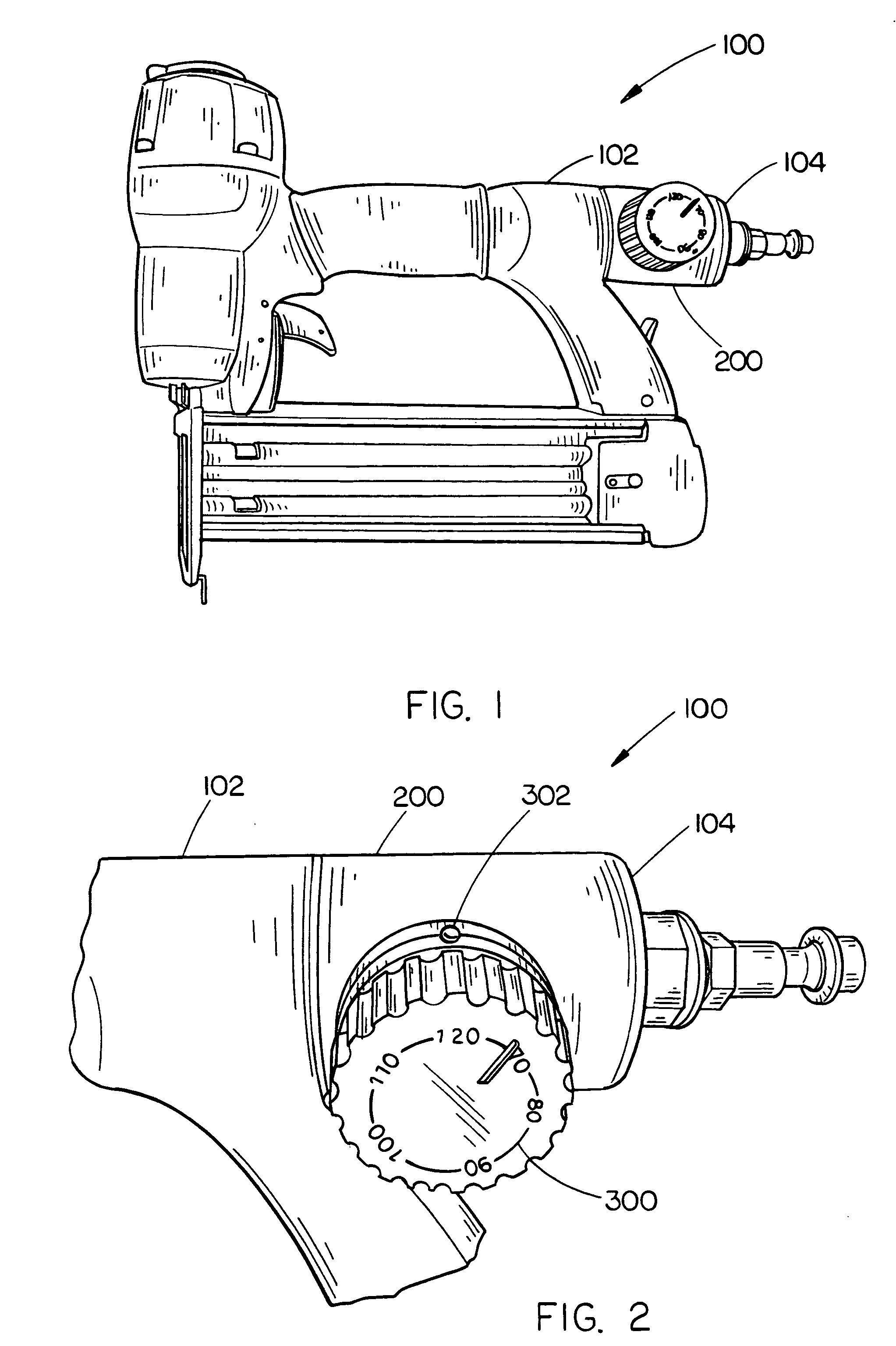

InactiveUS20050247750A1Less pressure lossImprove transportation efficiencyStapling toolsOperator-supported drilling machinesDistribution systemPneumatic tool

The integrated air tool and pressure regulator assembly allows several air tools to operate from a single air compressor, using a simplified air hose distribution system. An operator may independently adjust the regulated pressure of the integrated air tool and pressure regulator assembly to compensate for varying working conditions. A greater air hose supply pressure may be used, as regulation of air pressure is accomplished at the integrated air tool and pressure regulator assembly. The increased air transport efficiency allowed by the integrated air tool and pressure regulator assembly of the present invention may provide for the use of smaller diameter hose, which may be lighter, more flexible, less costly, and the like.

Owner:BLACK & DECKER INC

Air tool

InactiveUSRE36917E1Solve excessive vibrationSmall sizeMachines/enginesWrenchesPower capabilityBattery charge

An improved air tool includes an integrated air motor and electrical generator wherein the stator is positioned on a side of the rotor body opposite the working end of the tool to reduce vibrations transmitted to the stator. The stator is also positioned between the compressed air inlet and the rotor body such that compressed air flows across the stator to prevent overheating of the stator. The air tool includes an indicating circuit connected to the battery charging circuit for indicating a battery charge condition, a battery discharge condition, and a low lubrication condition of the air vanes. A light ring assembly is attached to the working end of the tool housing to provide light at the working end of the tool. Materials chosen for the magnets and the poles of the stator increase the power capability of the electrical generator. An illuminating apparatus for a conventional air tool includes a light ring with integral generator.

Owner:VOLT AIRE CORP

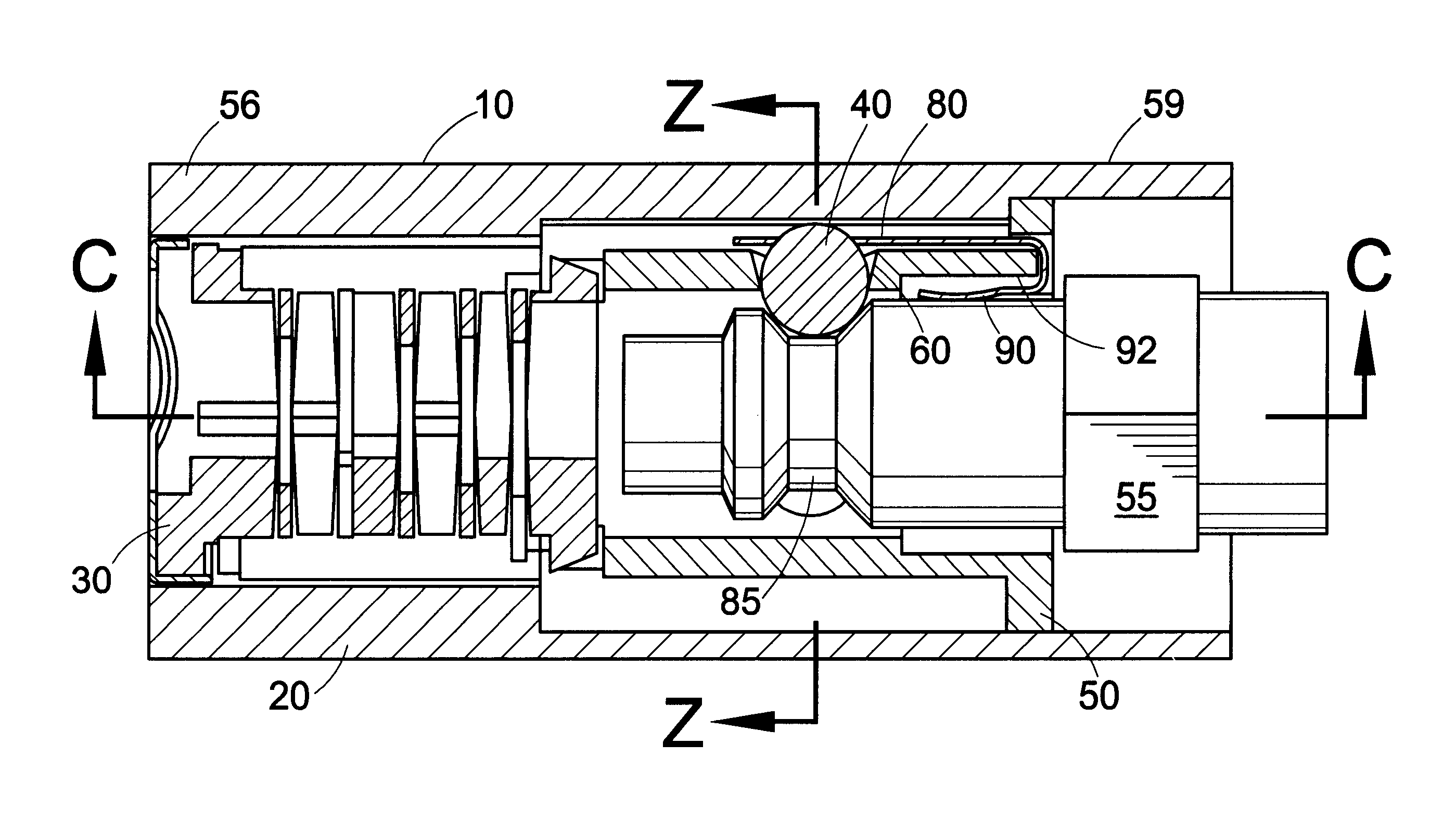

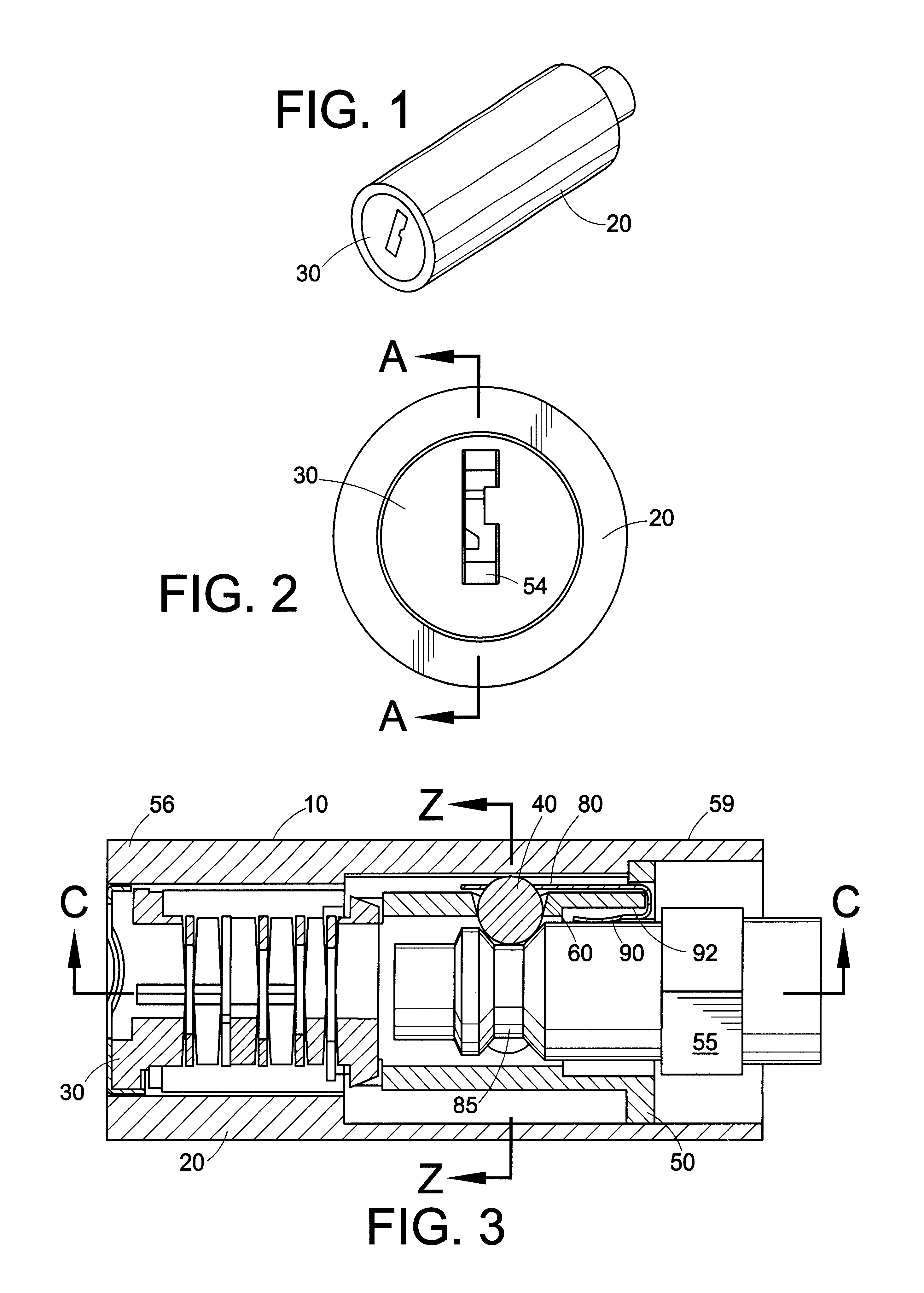

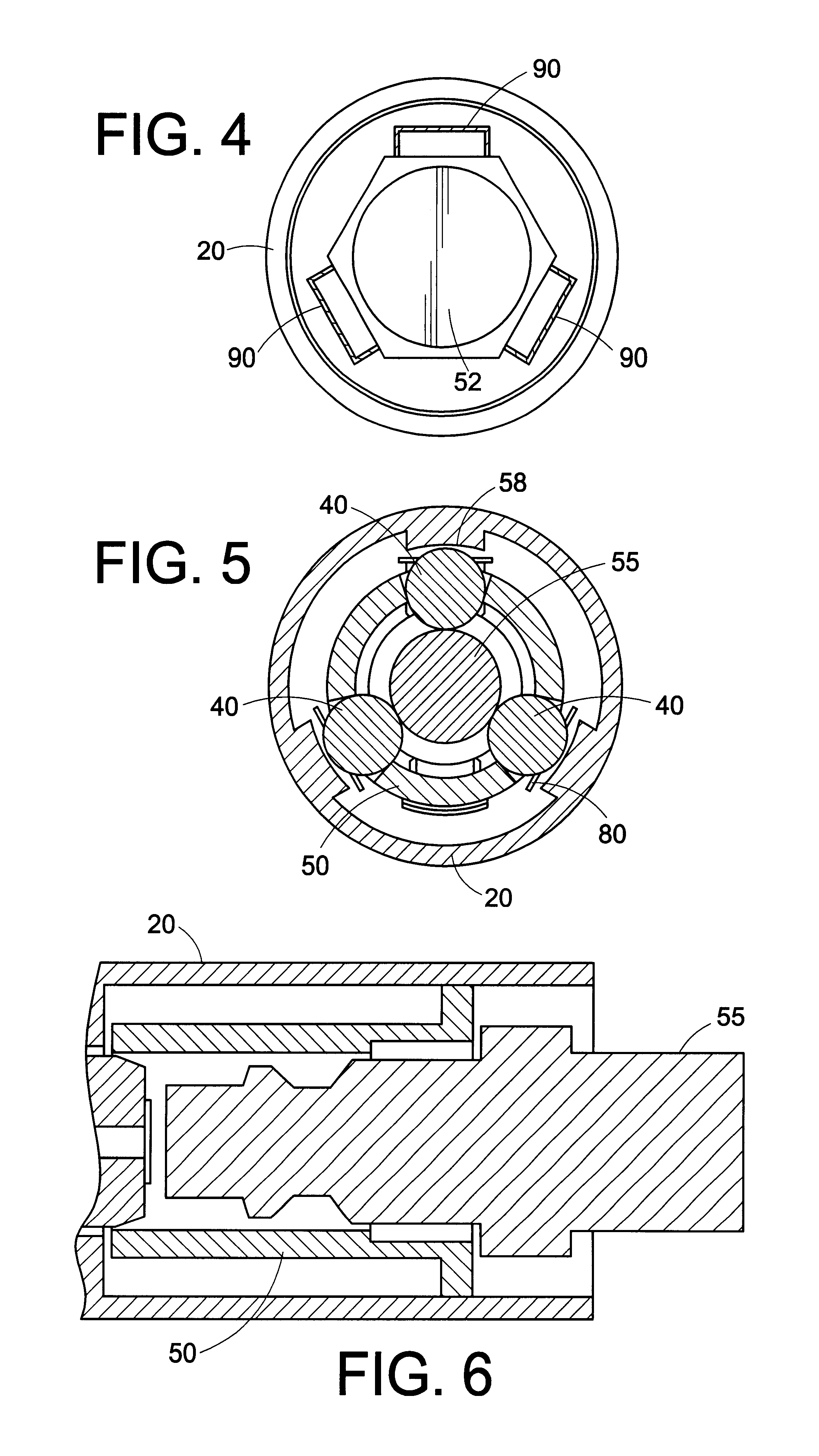

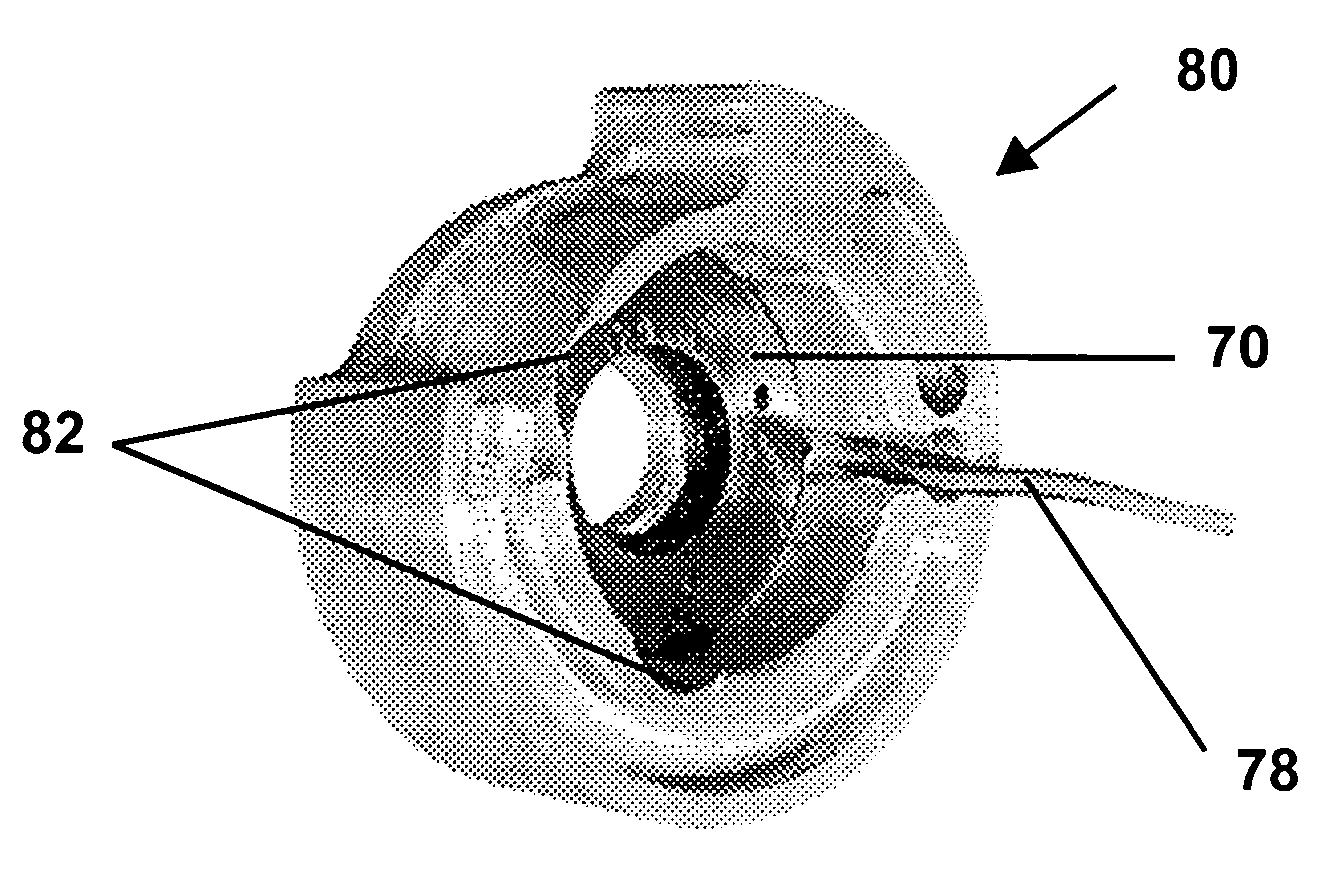

Pneumatic tool lock

A tool lock, especially useful in preventing theft or unauthorized use of a tool. The tool lock has a housing in which a lock cylinder assembly and locking balls are disposed. The tool lock housing has an opening at one end in which a portion of a tool, such as a pneumatic fitting on a pneumatic tool, may be inserted and secured by the engagement of the locking balls. The tool lock housing may further include a shackle portion which can be used in conjunction with a cable, either integral or separate, padlock, or chain to secure the tool lock to another object.

Owner:MASTER LOCK COMANY LLC

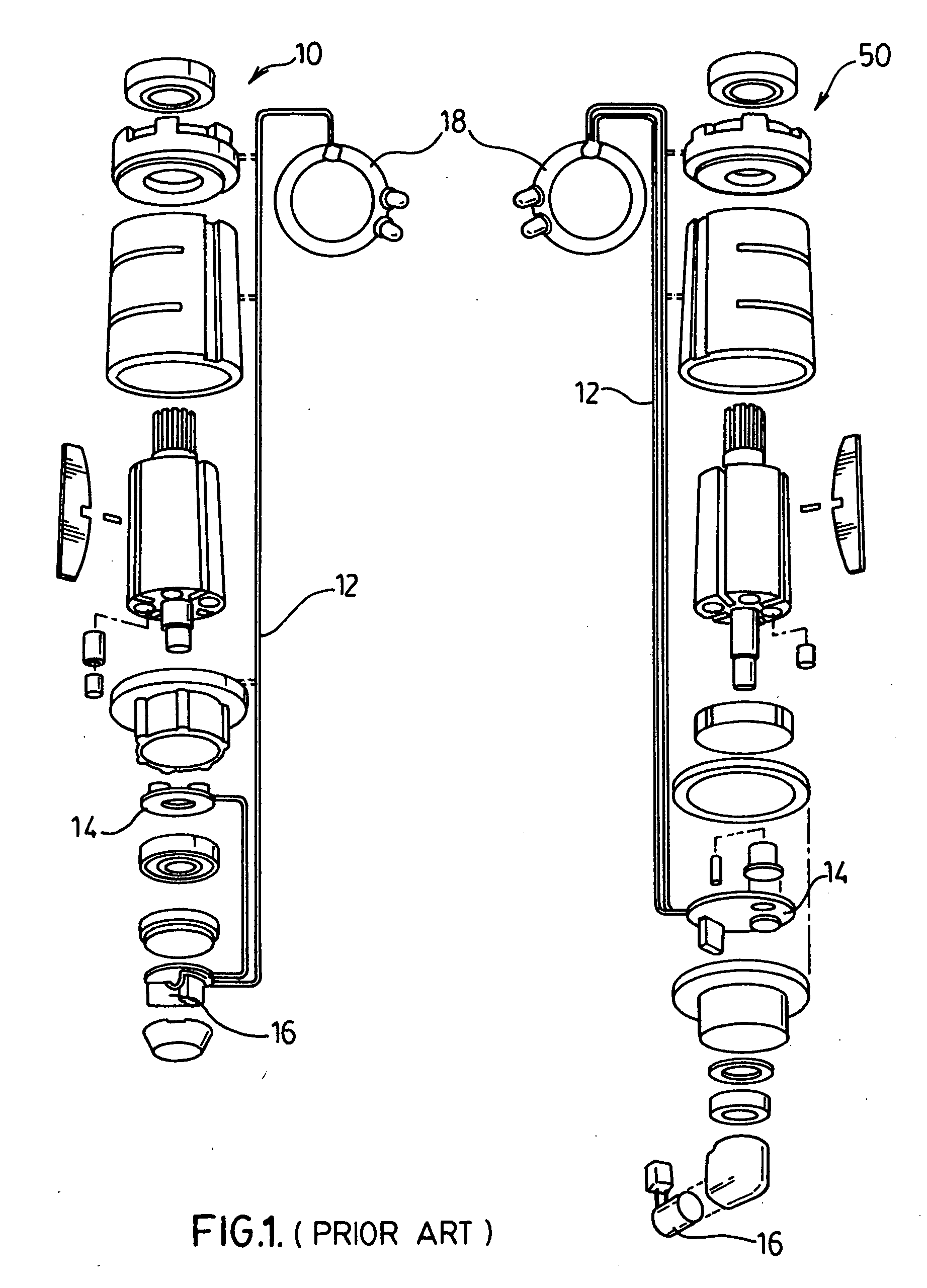

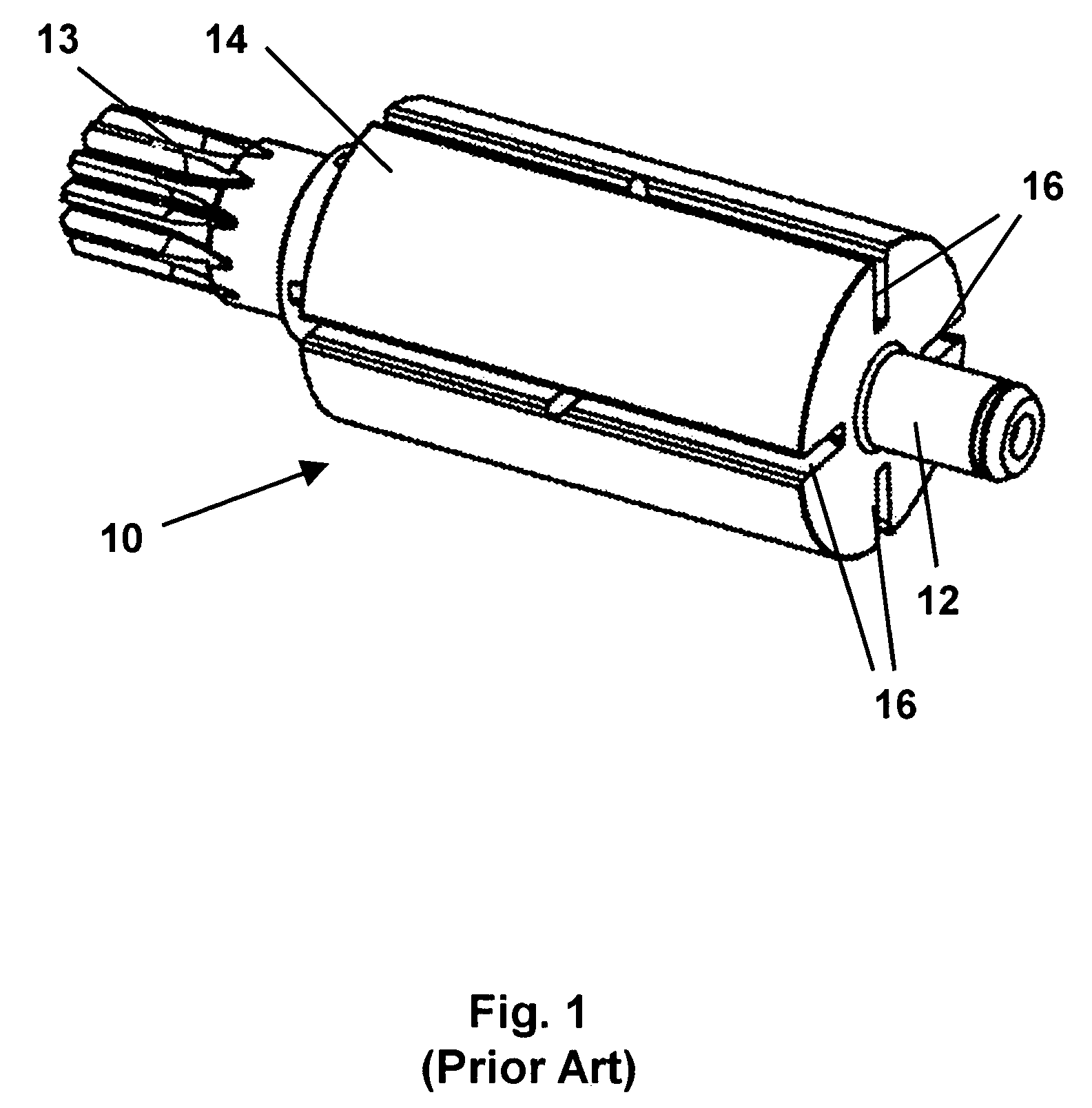

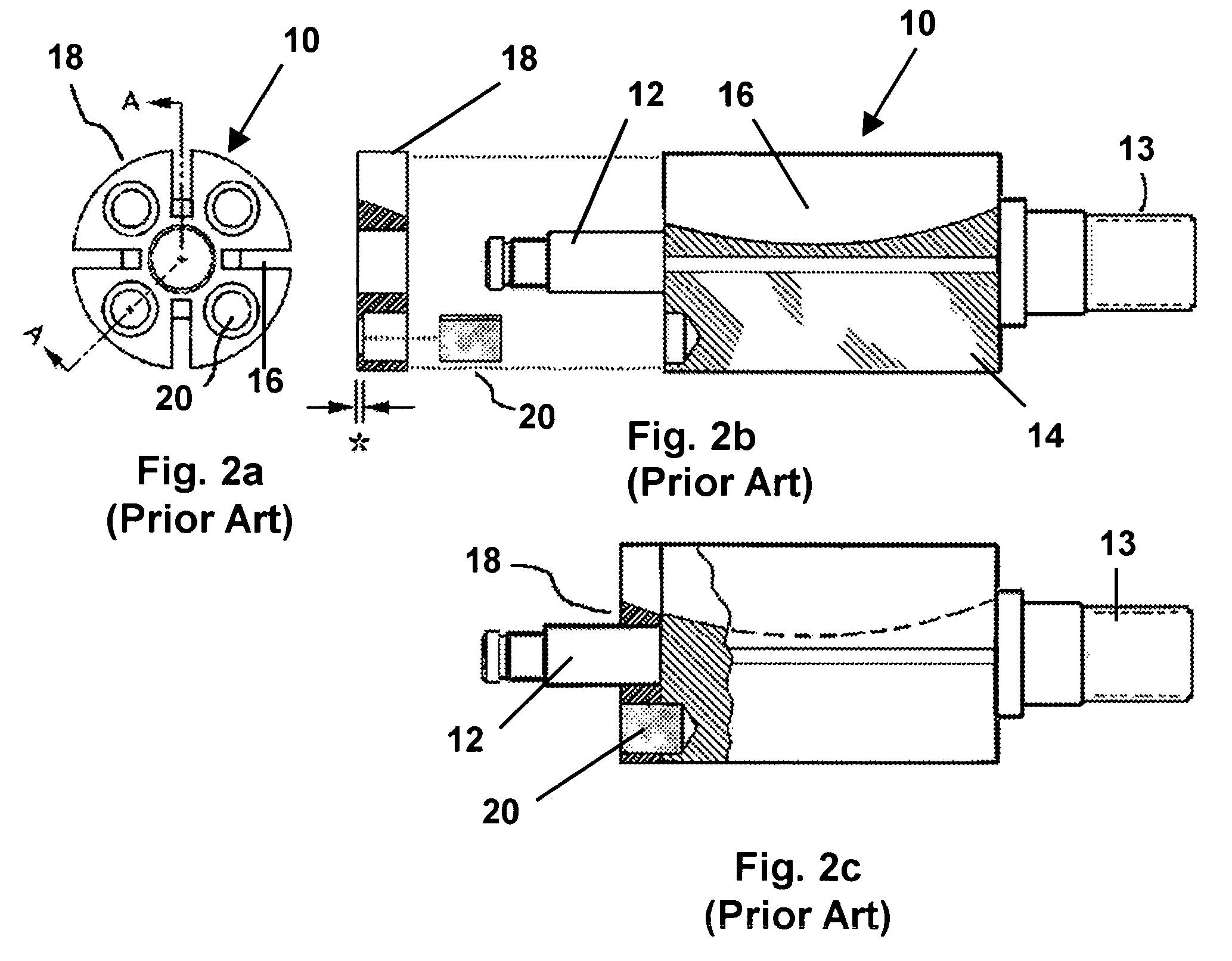

Pneumatic tool with integrated electricity generator

ActiveUS7095142B2Well formedLess costlyMachines/enginesPortable power-driven toolsElectricityPneumatic tool

A rotor for a pneumatic tool having electricity-generating capabilities includes a shaft and an integral rotor body. The rotor body includes recesses dimensioned to receive an insulated subassembly having a magnet received within a nonmagnetic insulator to allow flux to be concentrated against stator windings. The rotor can be used in a conventional pneumatic tool, but can also be fitted with the insulated subassemblies in order to cooperate with a stator in the tool to generate electricity upon rotation of the rotor when pressurized fluid is applied to the vanes. A ring stator is connected to a supporting circuit by a connector and is supportable by a nonmagnetic end plate of the pneumatic tool and is disposed between the rotor and the rotor bearing.

Owner:VOLT AIRE CORP +1

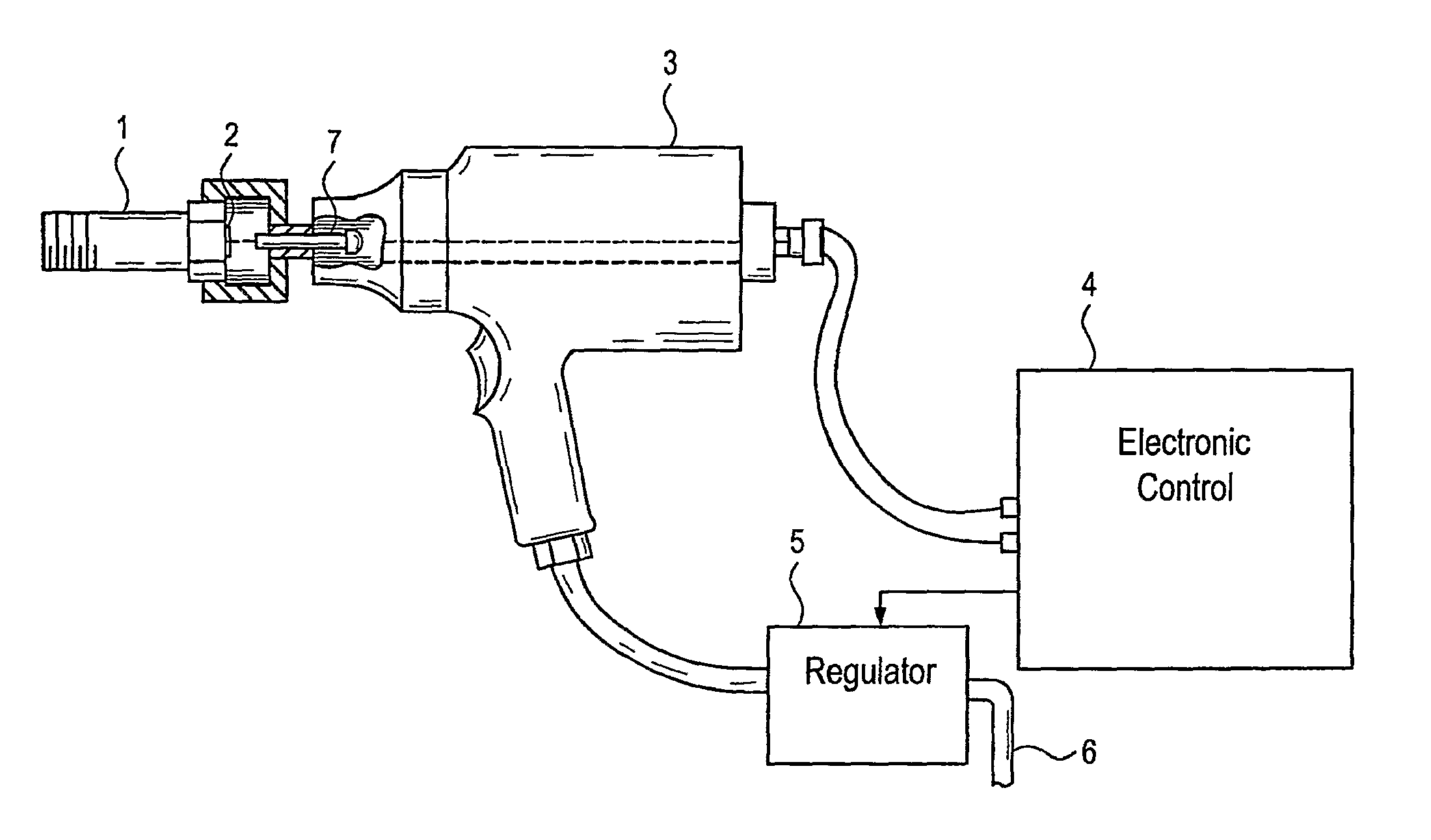

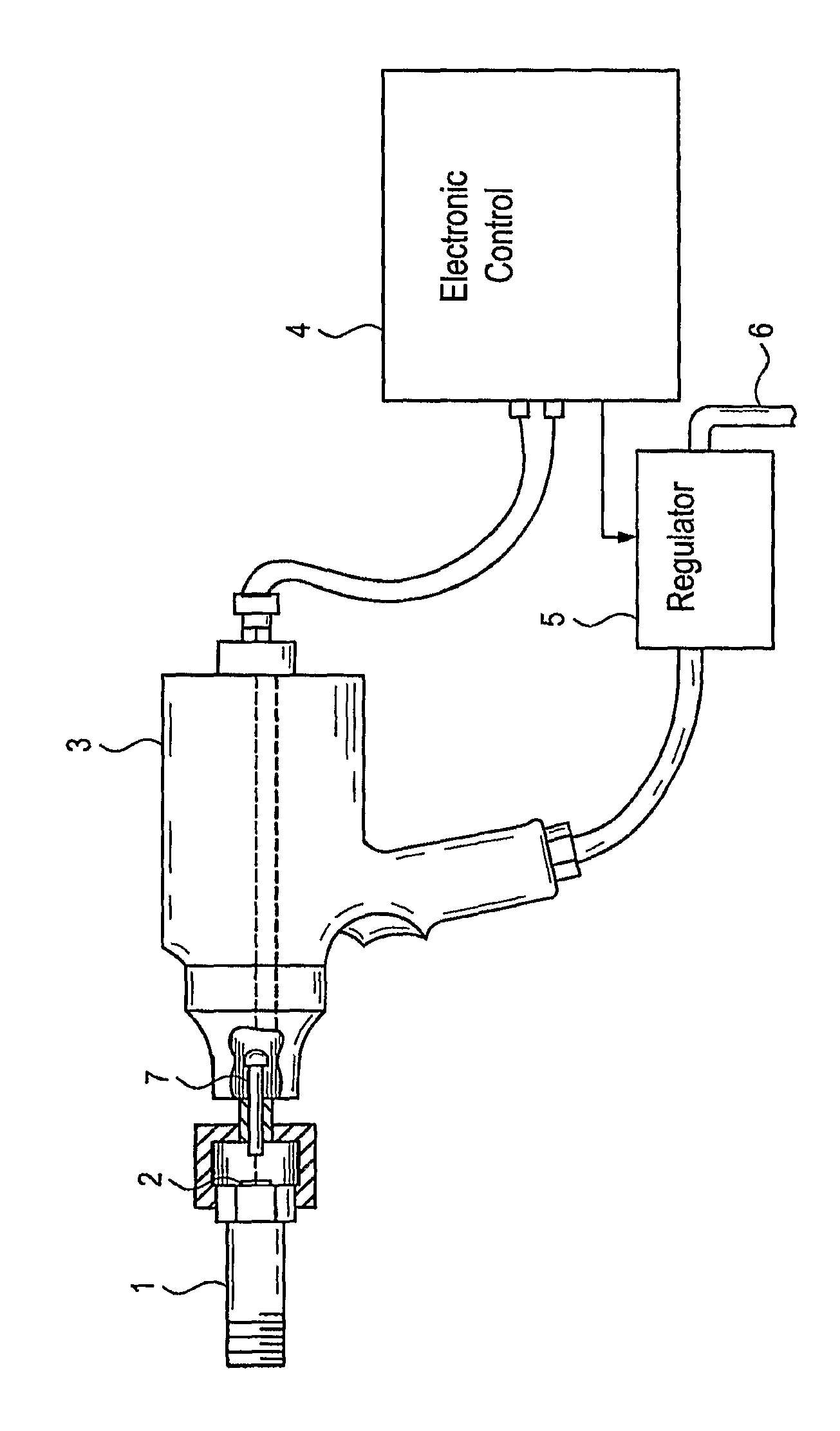

System for dynamically controlling the torque output of a pneumatic tool

ActiveUS7823458B2Reduce probabilityStop preciseDerricks/mastsTemperatue controlRotation velocityHeating effect

Pneumatic tightening tools can be used for high speed assembly of critical bolts to precise loads by dynamically controlling the output power of the pneumatic tool during a tightening cycle using an electronically controlled air pressure regulator to reduce the tightening rate, or the load increase per impact for impact or impulse tools, to enable the tool to be stopped precisely at a specified stopping load or torque. For prevailing torque fasteners, the output power of the pneumatic tool is dynamically controlled to minimize the speed of rotation during rundown, to minimize the heating effects associated with such torque fasteners, and to then increase the power from the tool, as required, to provide the torque to reach the specified stopping load or torque. The maximum air pressure supplied to the pneumatic tool can be limited, depending on the expected torque required to tighten the fastener to the specified load or torque.

Owner:INNOVATION PLUS LLC

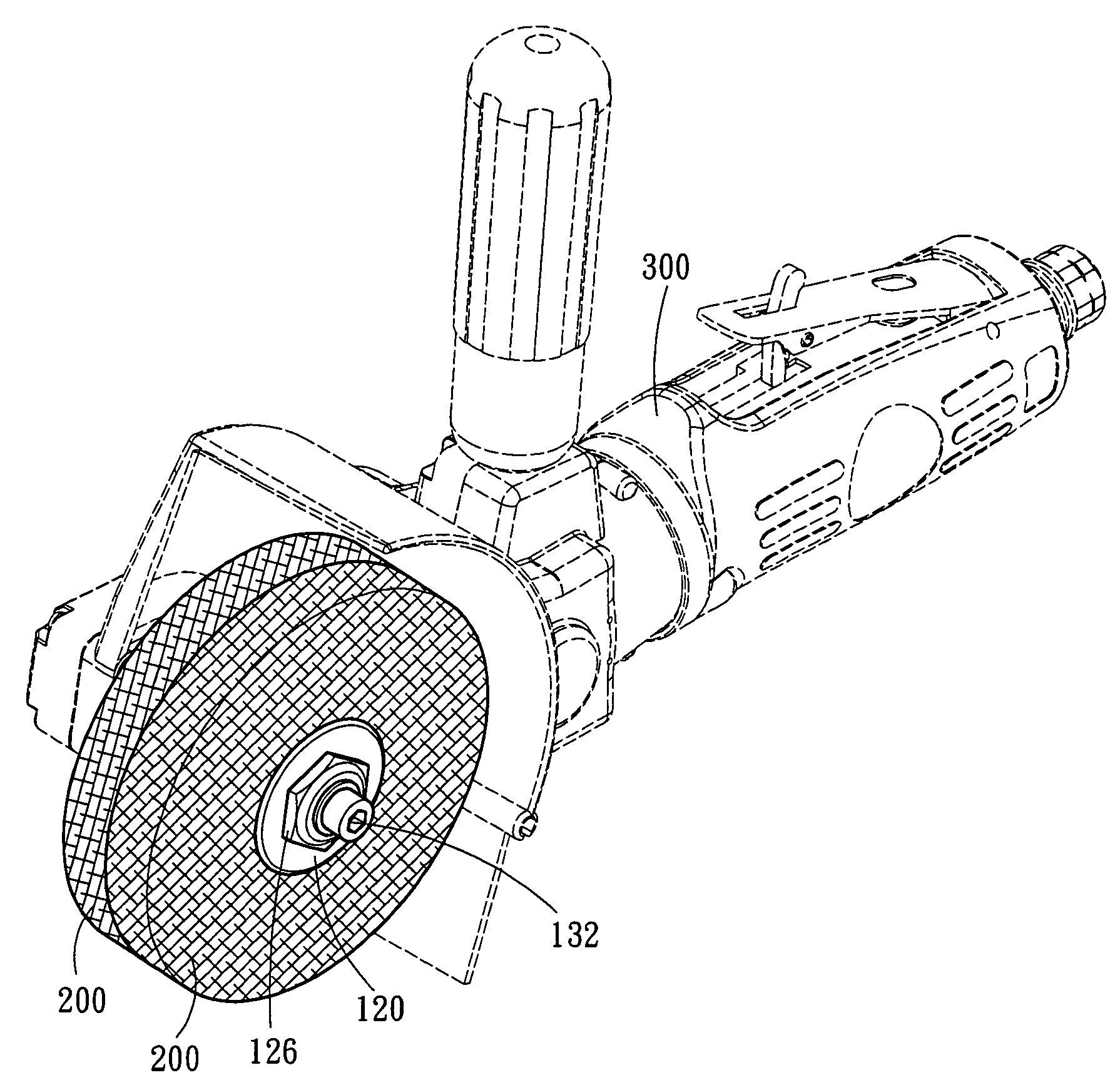

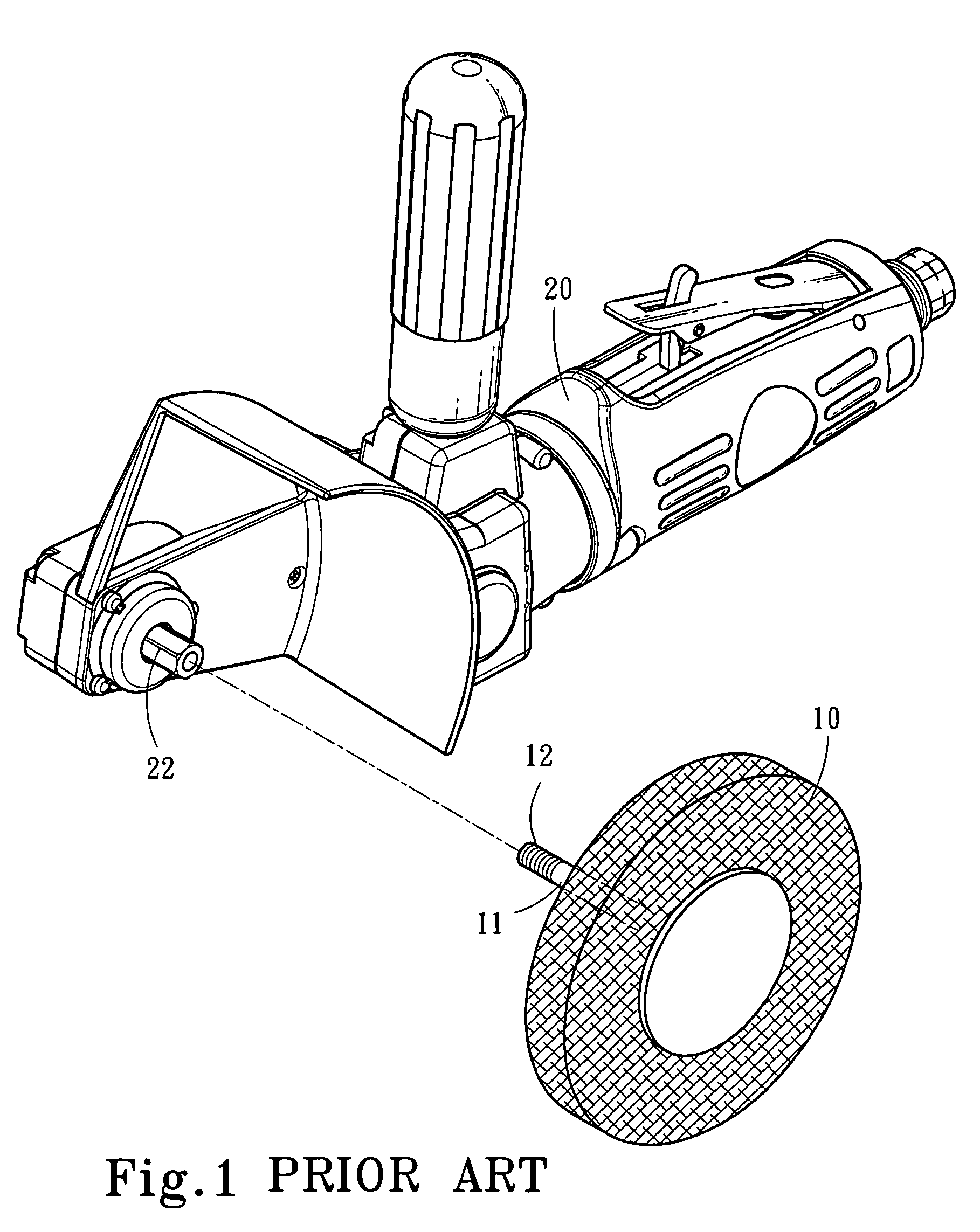

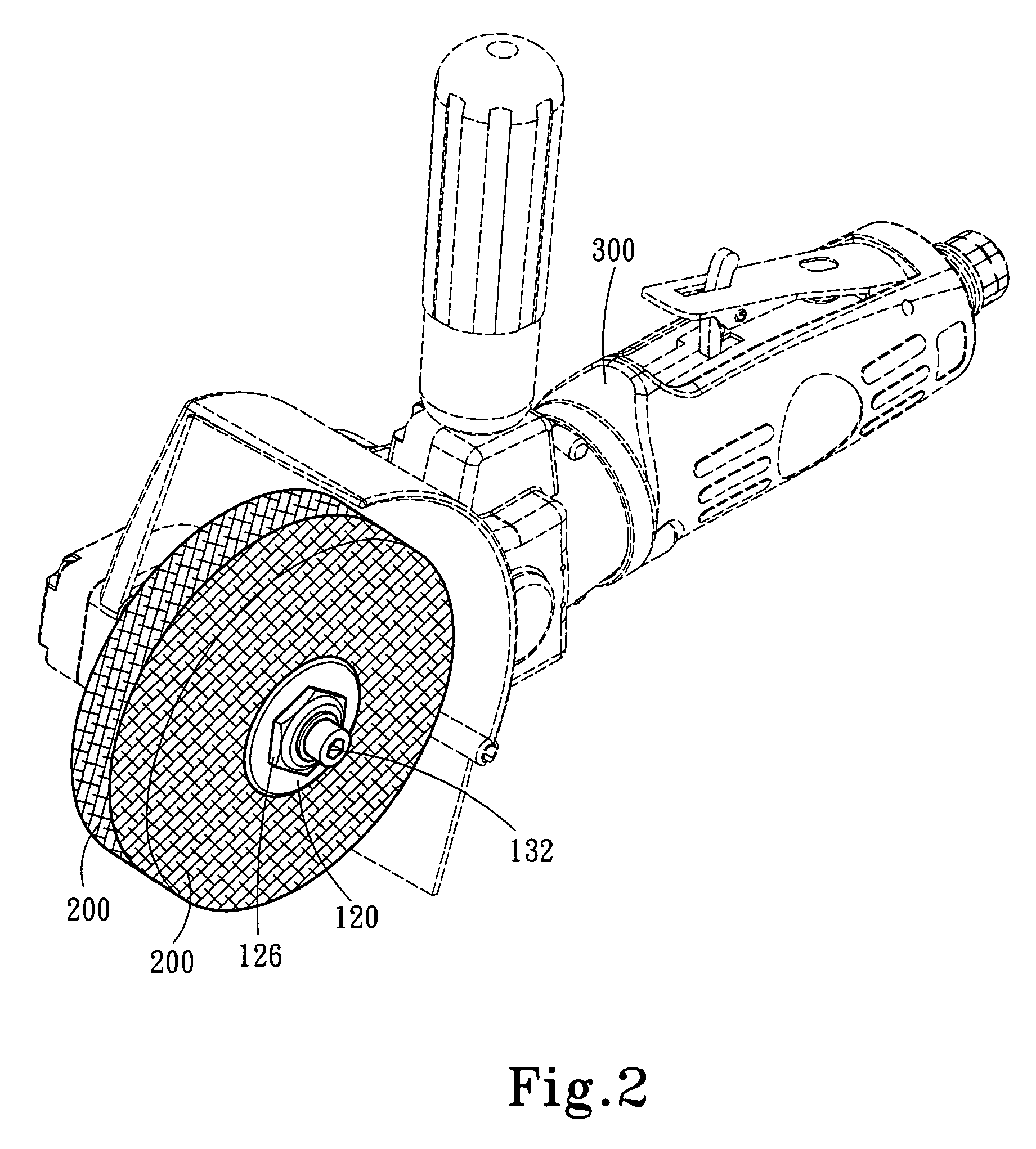

Coupling structure for grinding members

InactiveUS7115028B1Simple structureLow costGrinding machine componentsRevolution surface grinding machinesCouplingEngineering

Owner:SUNMATCH INDAL

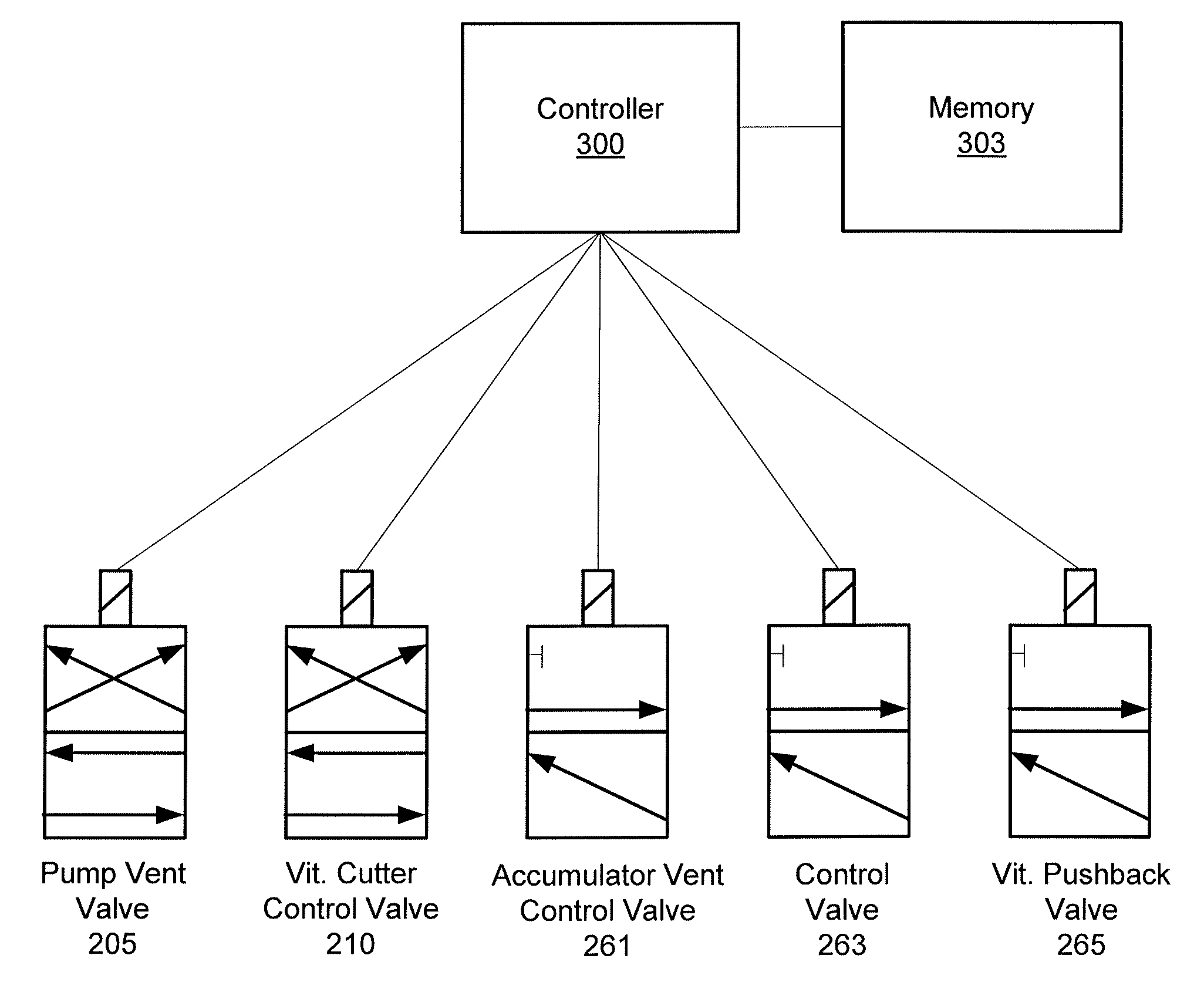

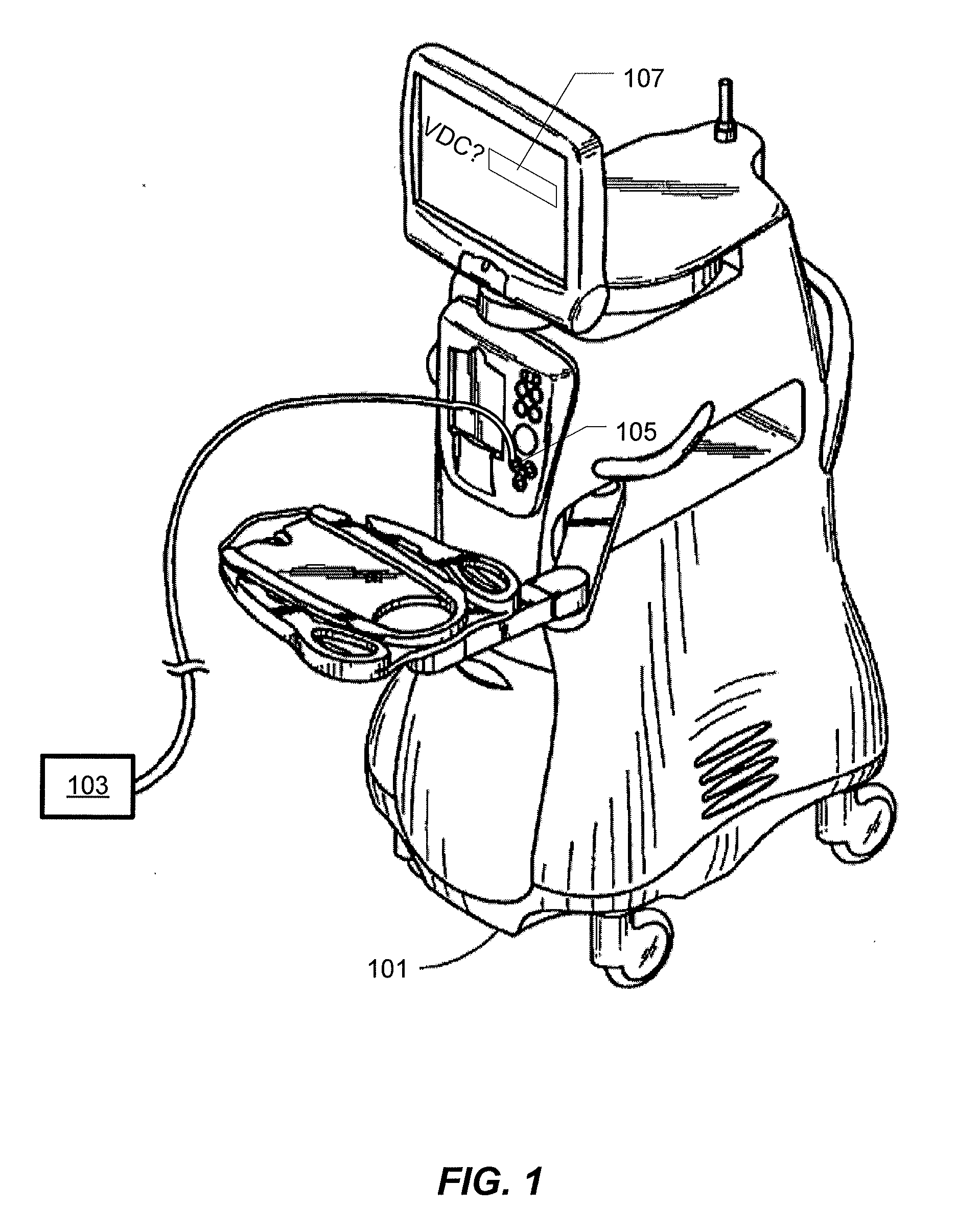

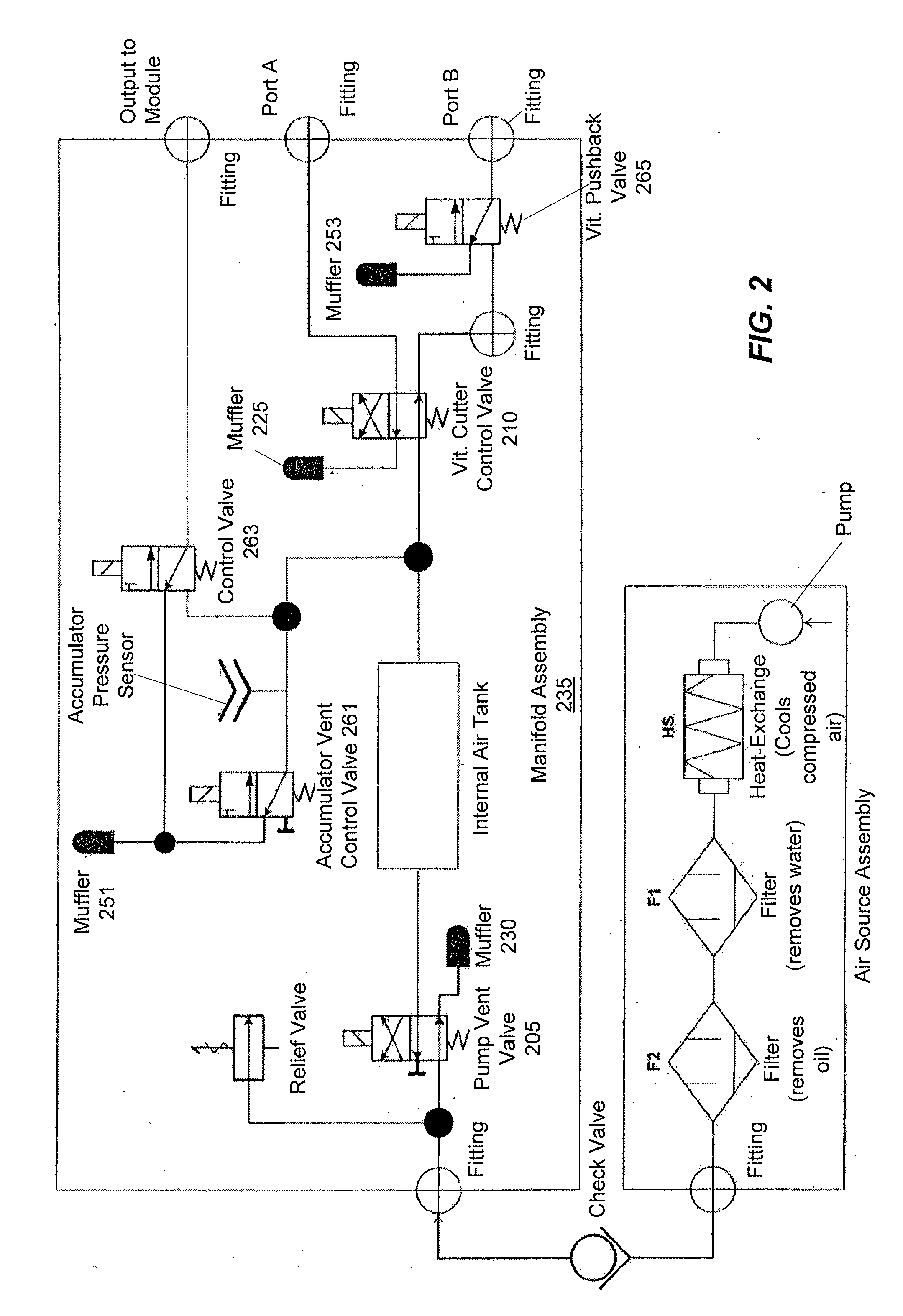

Pneumatic Pressure Output Control by Drive Valve Duty Cycle Calibration

In various embodiments, a surgical console may include a pneumatic valve to drive a pneumatic tool coupled to the surgical console. The console may further include a controller operable to control and adjust the valve open / close cycle times according to a valve duty cycle. The valve may switch between ports (valve open time for a first port and valve close time for a second port) such that a total valve time may approximately equal the valve open time plus the valve close time. The valve duty cycle may indicate a percentage of the total valve time for the controller to signal the valve to open and may include an adjustment that corresponds to a signal timing of the open and / or closed valve positions that will result in open and closed operating pressures above a predetermined threshold.

Owner:ALCON INC

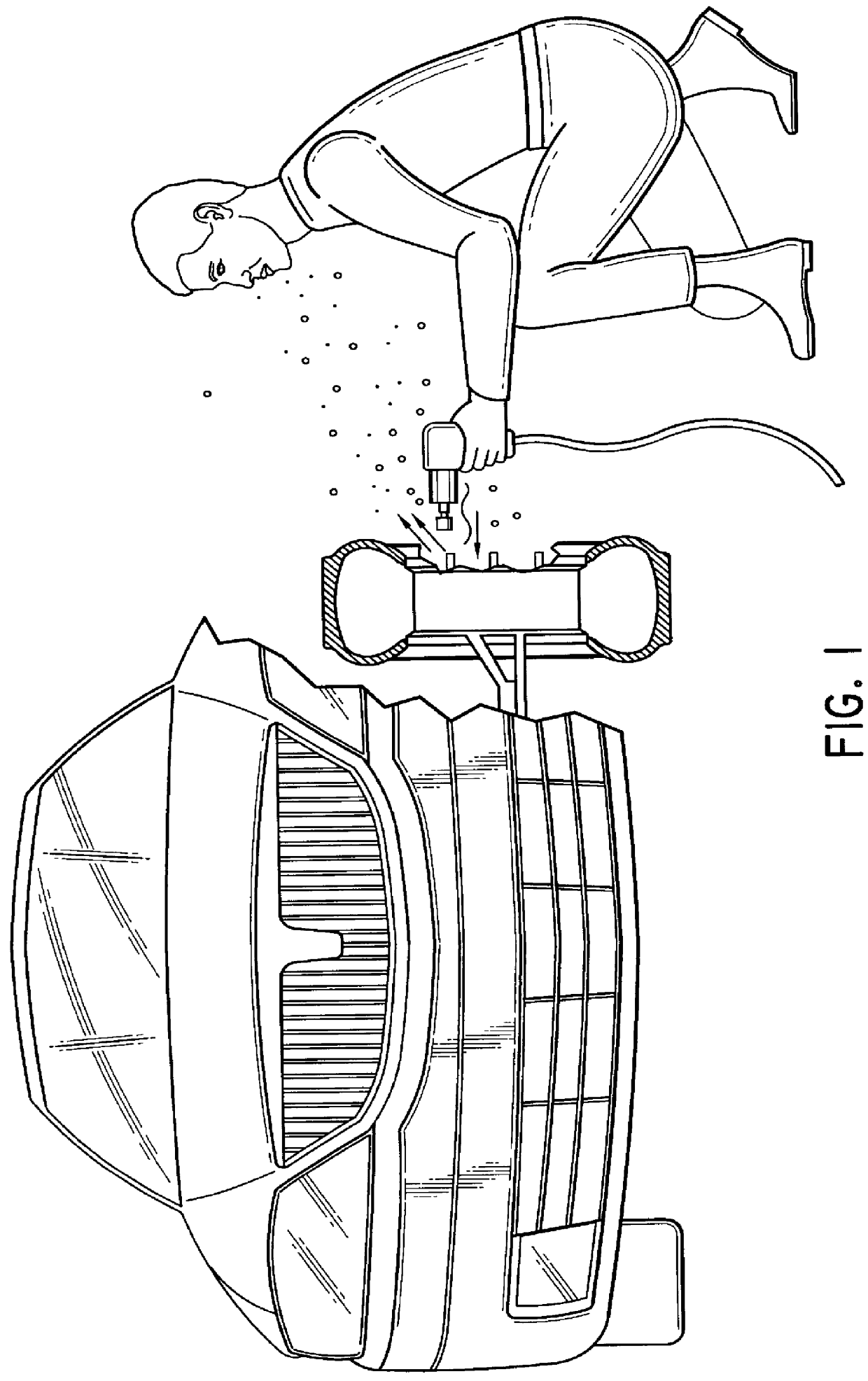

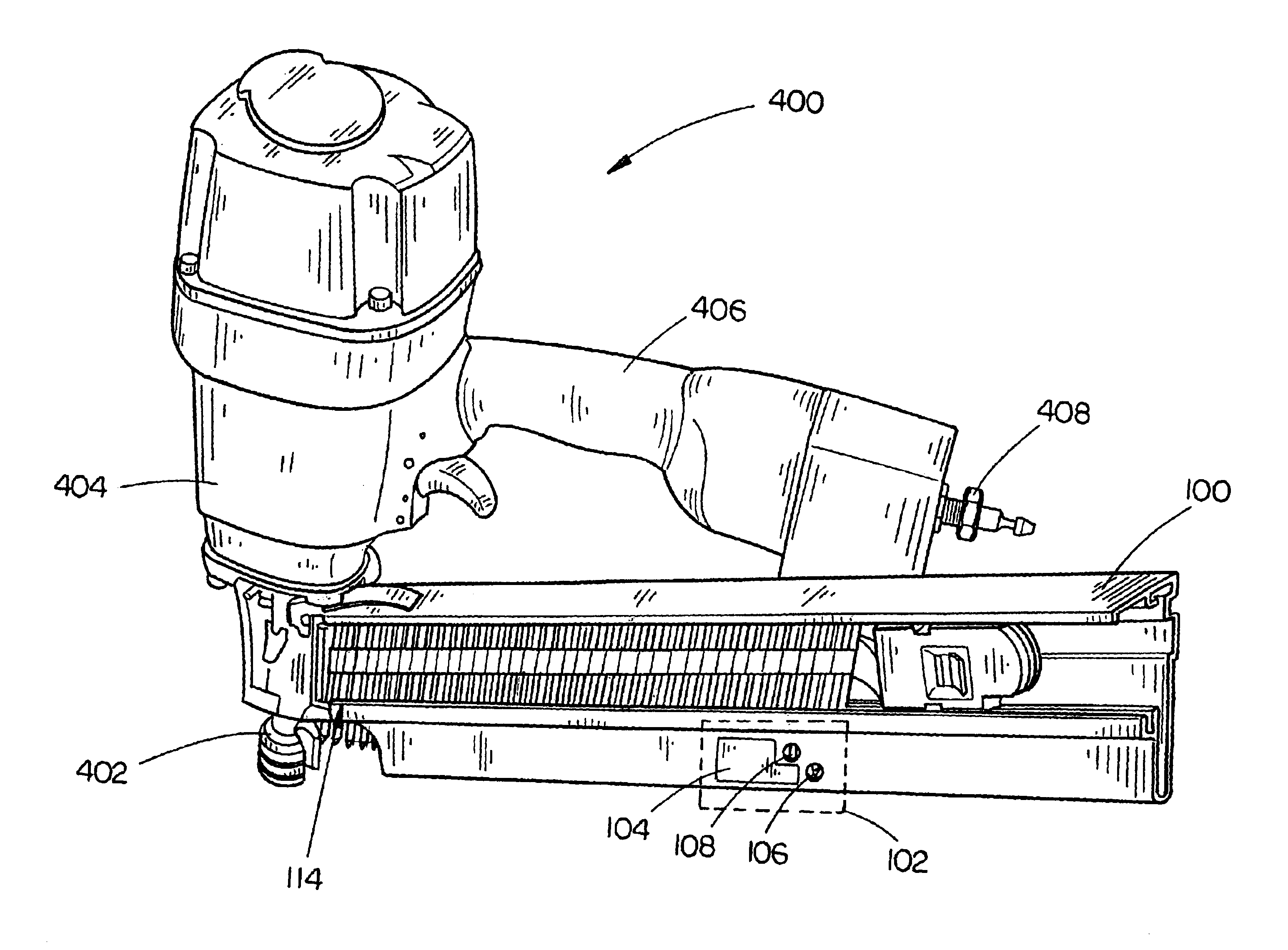

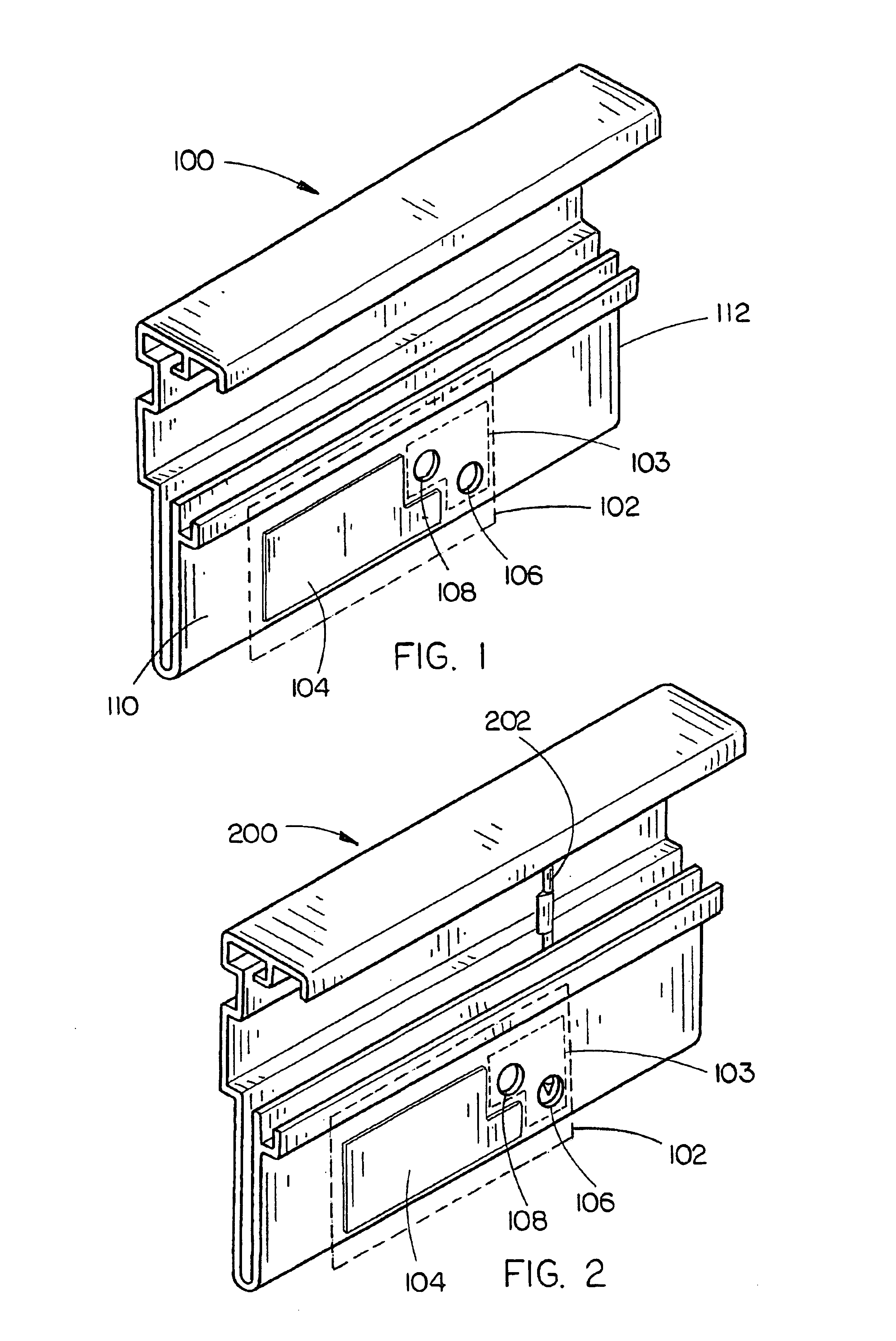

Apparatus and method to indicate required compressor pressure for use with pneumatic tool device

Owner:BLACK & DECKER INC

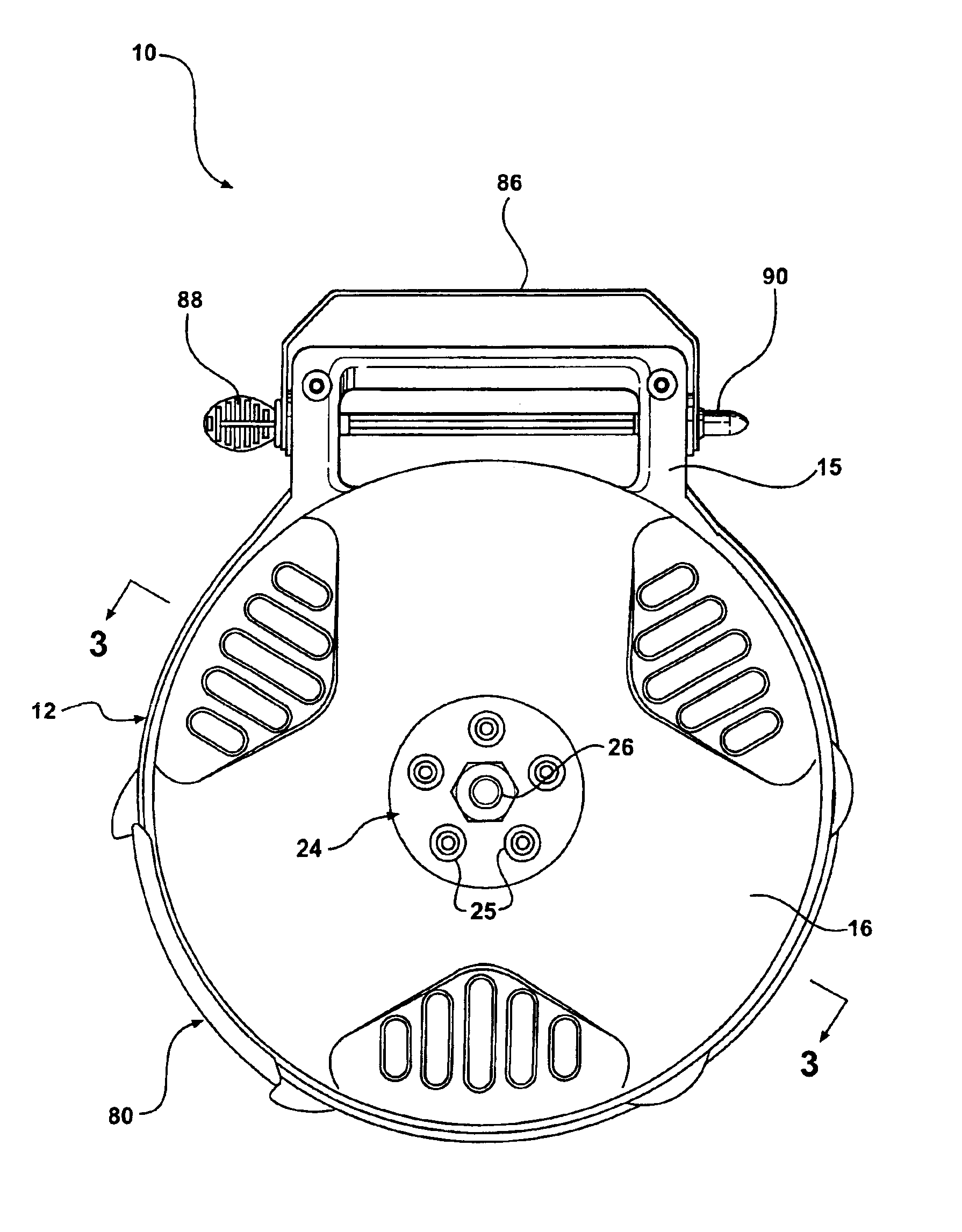

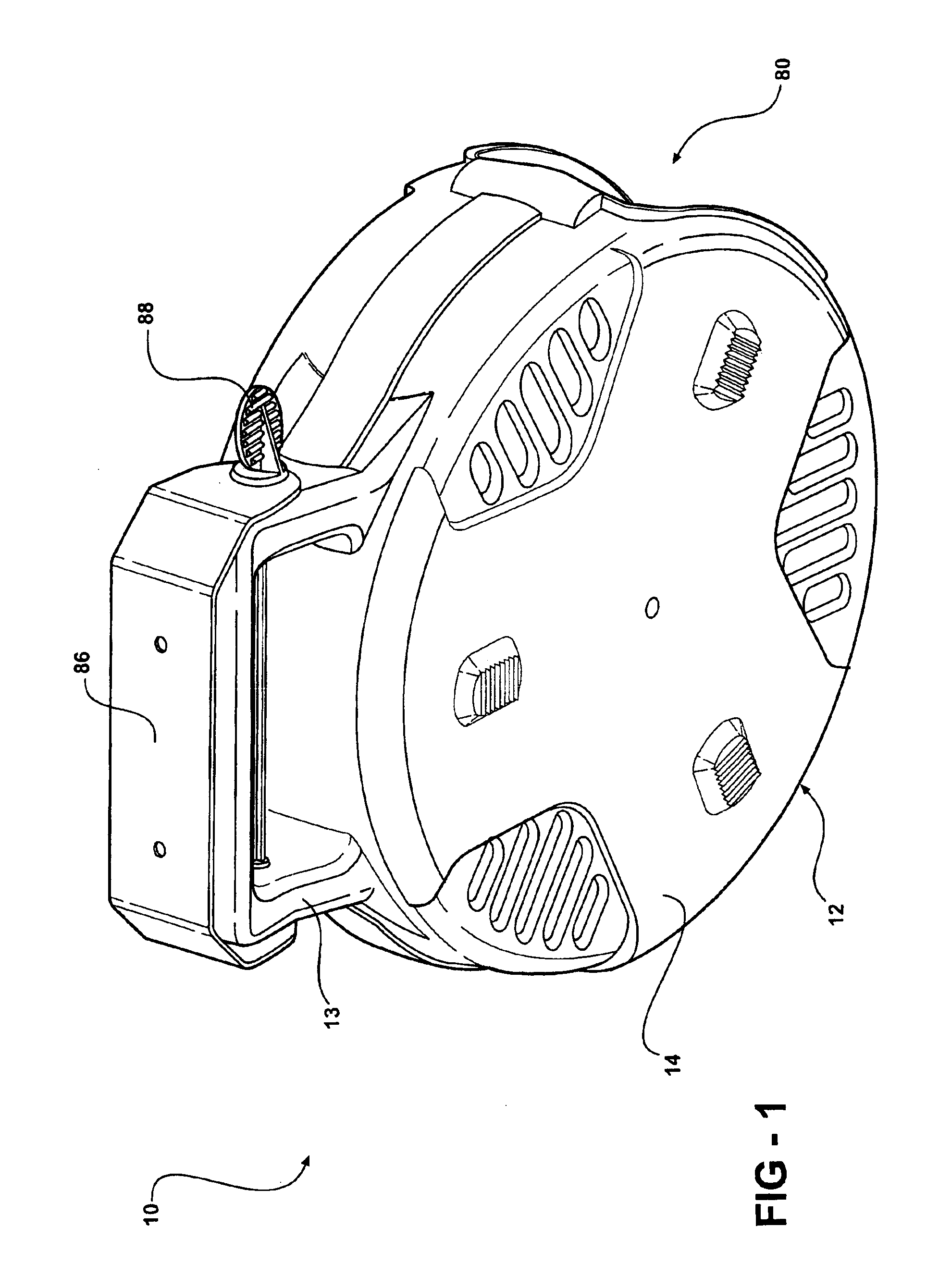

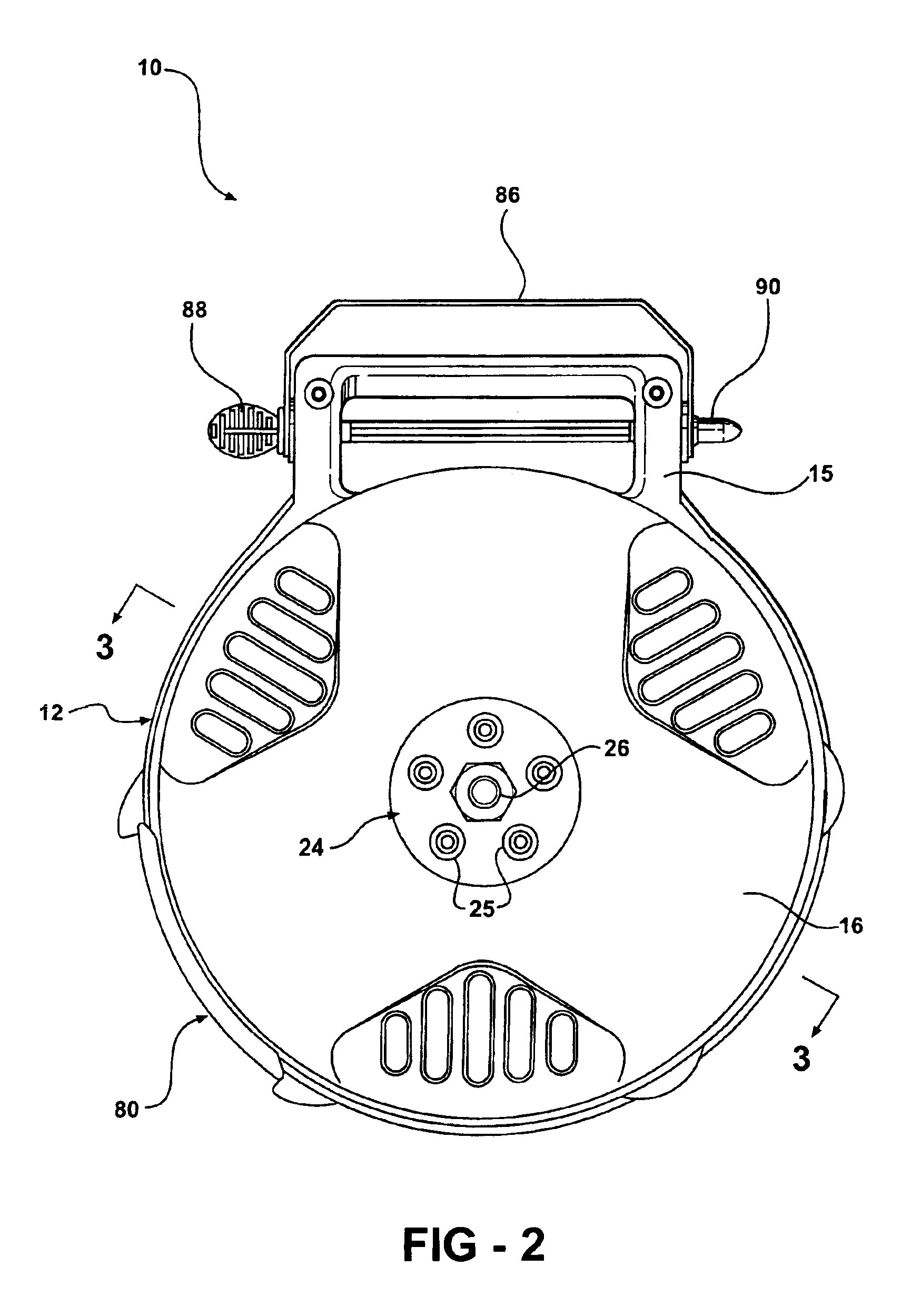

Air hose reel

A reel for storing an air hose includes a hollow housing having a spring biased pulley rotatably mounted therein. A pressured air inlet extends through the housing along the pulley axis of rotation and is sealed to a nozzle rotating with the pulley. The pulley stores an air hose having one end connected to the nozzle and an opposite end extending through an opening in the housing for attachment to a pneumatic tool.

Owner:ALERT STAMPING & MFG

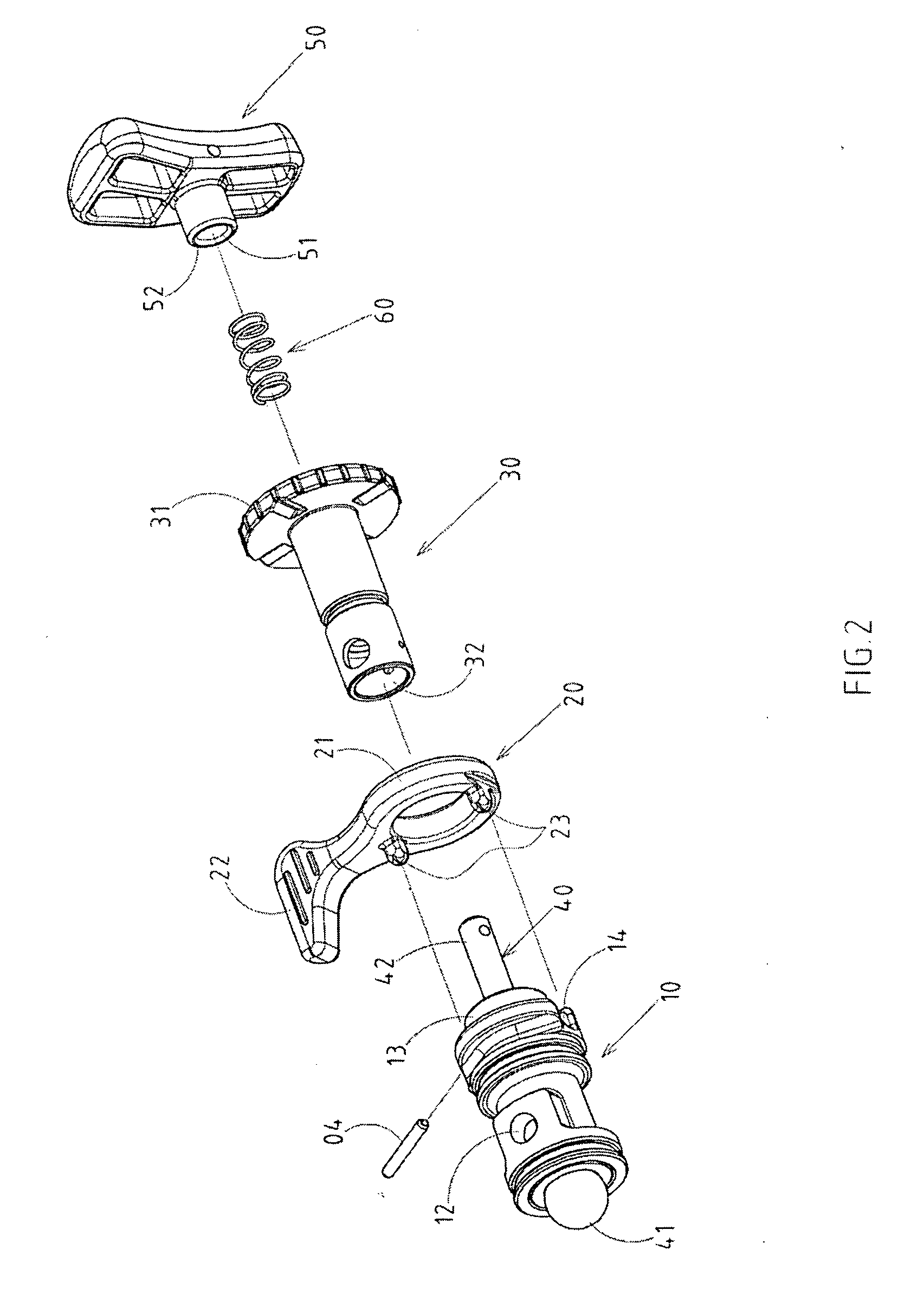

Switchover mechanism for a reversible control valve of a pneumatic tool

ActiveUS20070011884A1The process is simple and fastPractical and convenientDrilling rodsConstructionsElastic componentToggle switch

The switch mechanism for the reversible control valve of the pneumatic tool focuses on the switchover bar because of the users' right handed and left-handed issues. The primary feature is to make the switchover bar of the reversible control valve and the speed-adjusting valve to roll in the axial direction, and use the combination of the elastic component to make the combination and position section of the connecting section to position with the valve bar positioning section of the reversible control valve. When force of the connecting section of the switchover bar is pulled toward external trigger, it can release the combination and position section and the toggle switch of the switchover bar can achieve switching. When the toggle switch is adjusted, the repositioning may be restored by using the combination and position section and valve bar positioning section without having to take the parts apart.

Owner:BASSO IND CORP

Pneumatic tool

InactiveUS6991043B1Smooth exhaustEfficient reductionExhaust apparatusSilencing apparatusPneumatic toolEngineering

A pneumatic tool includes a shell with a chamber defined therein, a first passage communicated with the chamber and a second passage communicated with the chamber. A rotor is installed in the chamber for rotation when driven by pressurized air flowing into the chamber through the first passage. A shaft extends to the exterior of the shell from the rotor. A trigger is installed on the shell. A control device is put in the first passage and connected with the trigger for controlling the first passage. A muffler is put in the second passage. The muffler includes a plurality of balls.

Owner:HYPHONE MASCH IND CO LTD

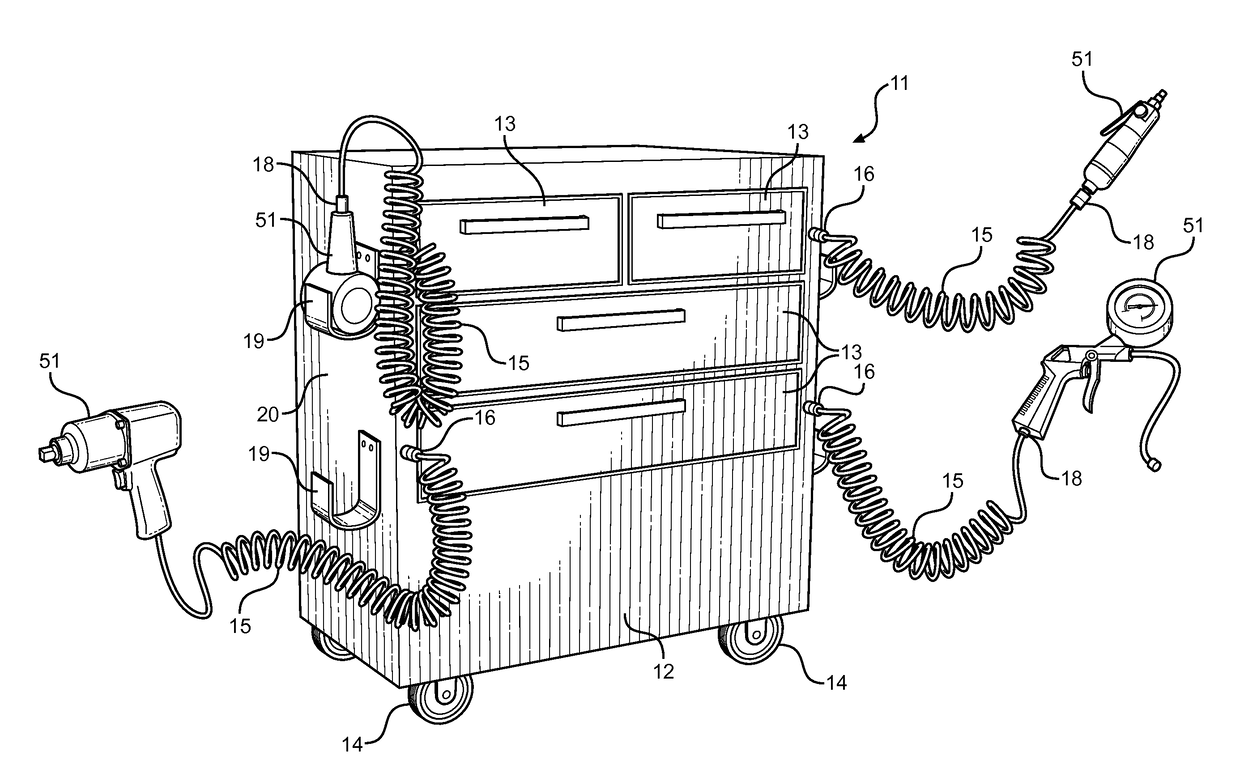

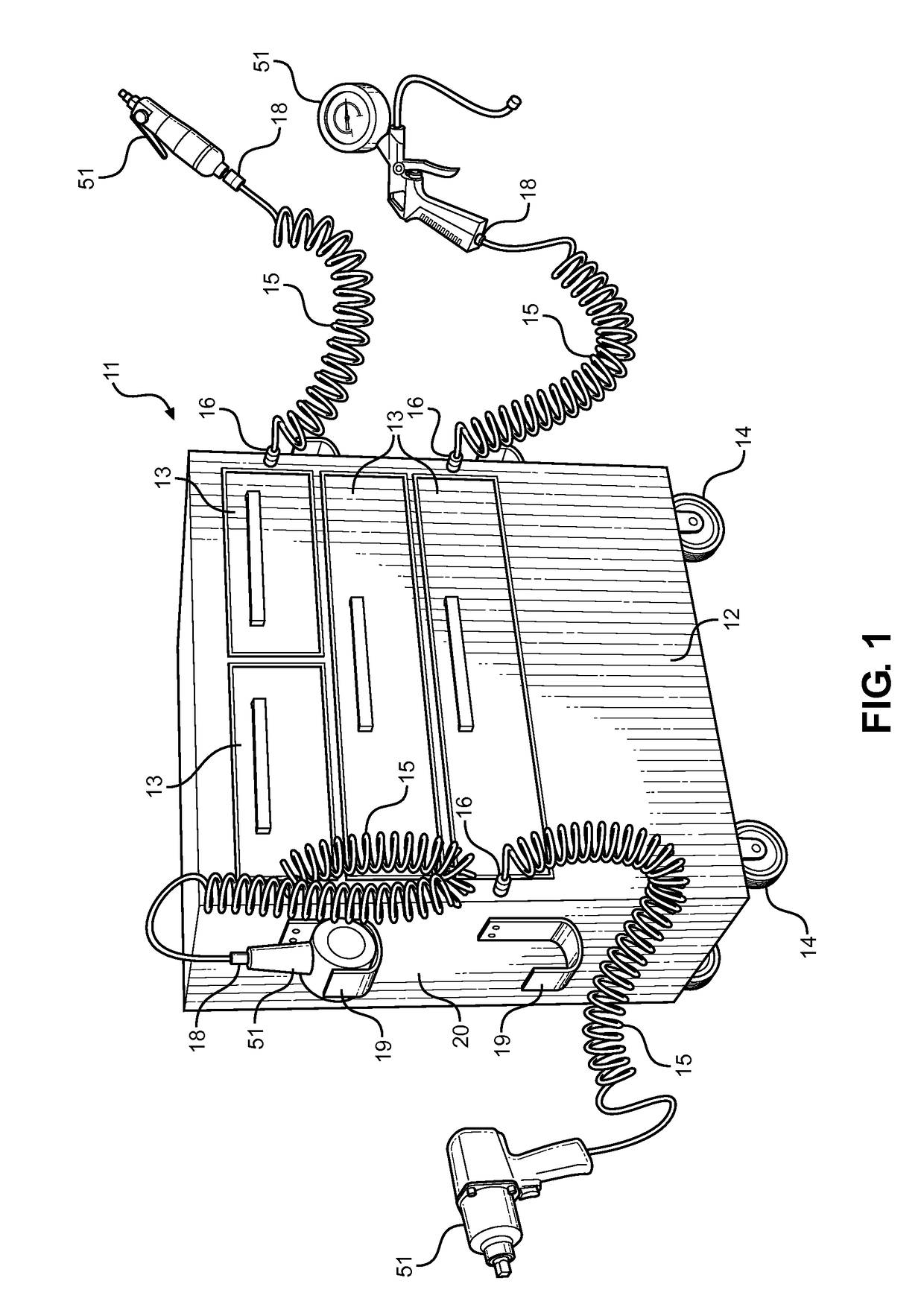

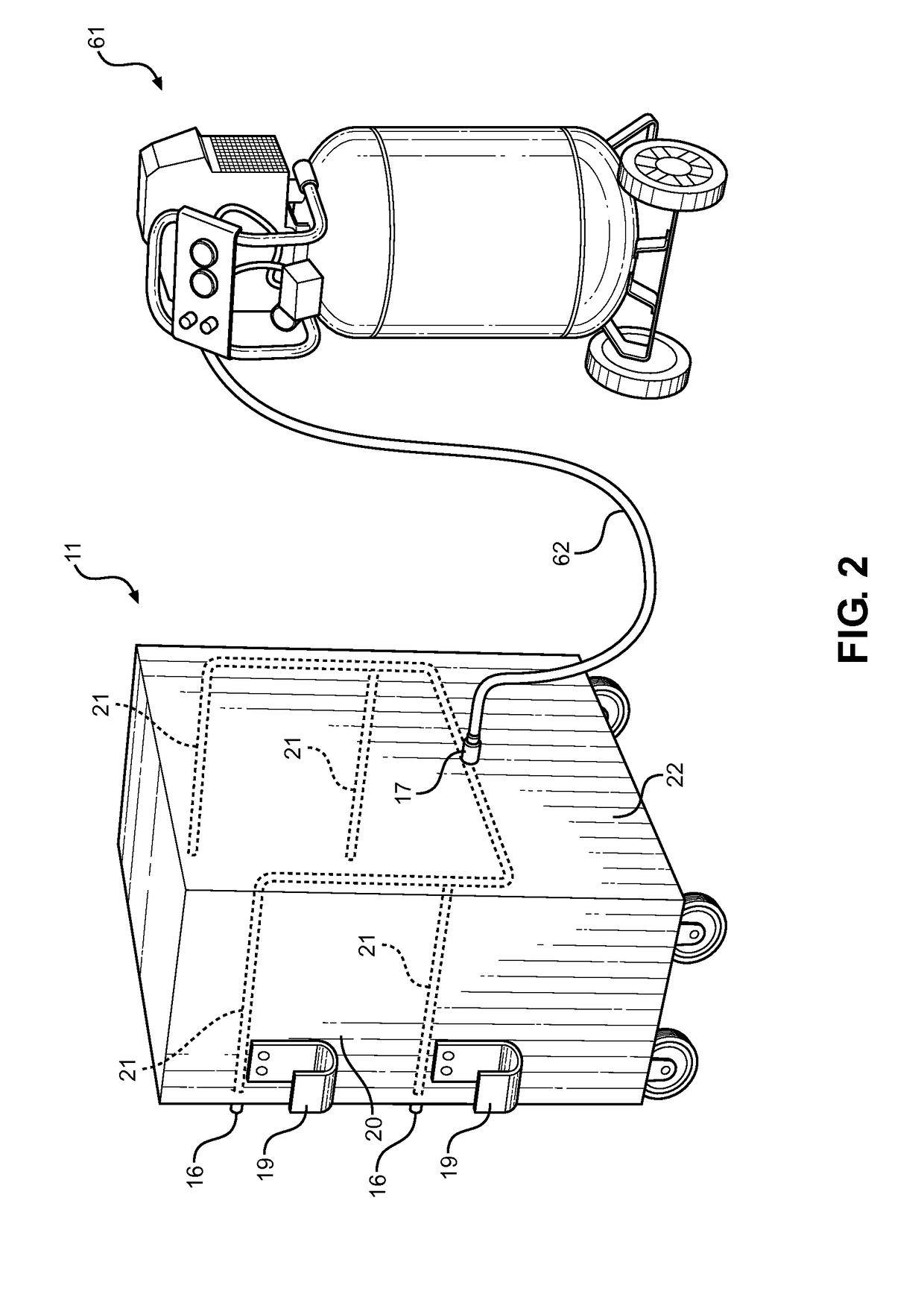

Tool cabinet having integral air lines

InactiveUS9895797B2Quantity minimizationEasy to makeCheck valvesWork benchesInlet valvePneumatic tool

A tool cabinet having integral pneumatic air lines. The present invention is a tool cabinet having an inlet valve, which is adapted to have an air compressor attached thereto, and a plurality of outlet valves, which are adapted to have a variety of different pneumatic tools connected thereto. The present invention also has a plurality of holders disposed on the exterior surface of the tool cabinet to hold the pneumatic tools. The present invention is otherwise designed to function as a traditional tool cabinet, including having a plurality of drawers, hooks, slots, or other such structures adapted to hold and organize tools.

Owner:SMITH SHAWN

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com