Patents

Literature

Hiro is an intelligent assistant for R&D personnel, combined with Patent DNA, to facilitate innovative research.

549results about "Operator-supported drilling machines" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

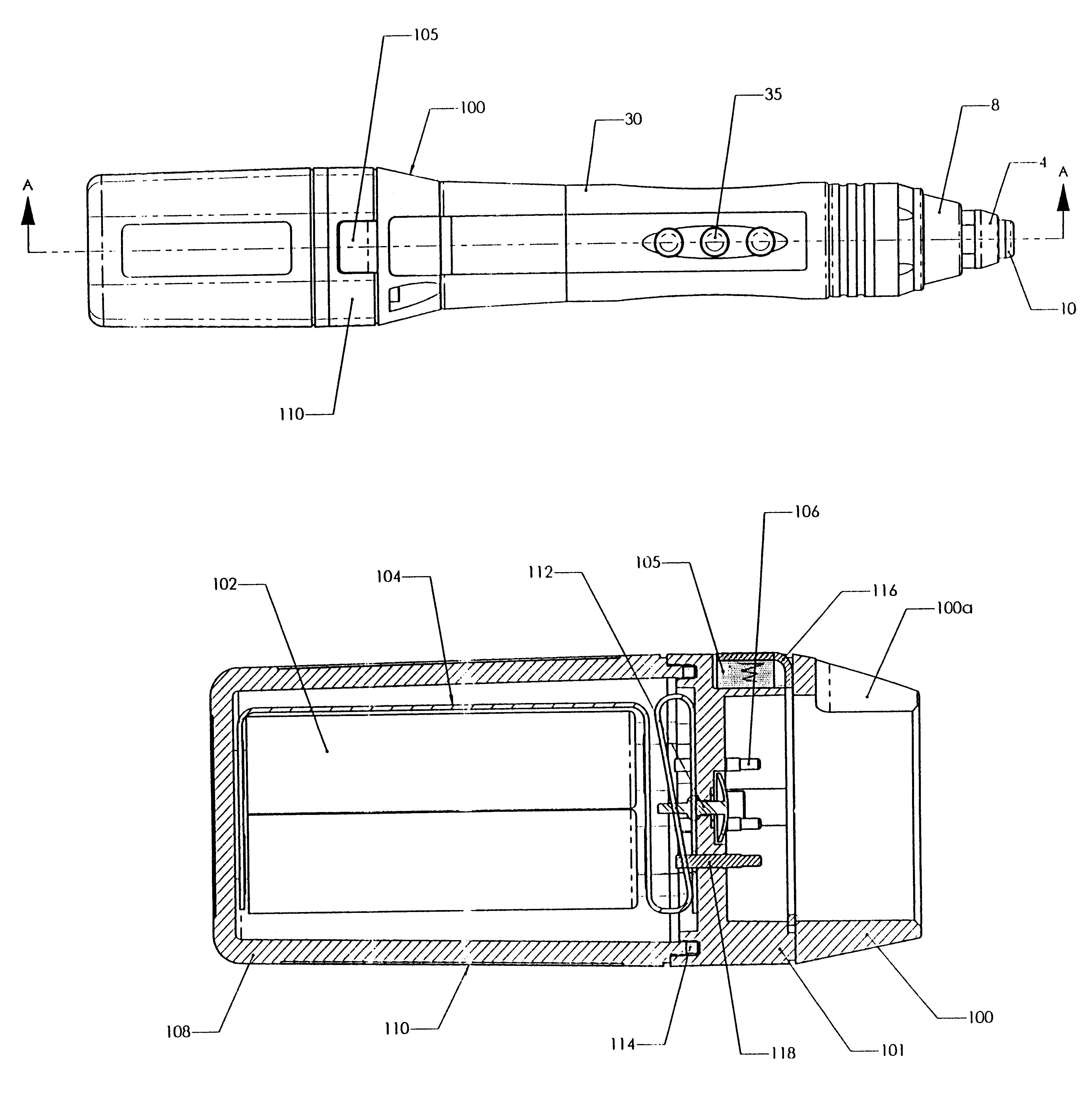

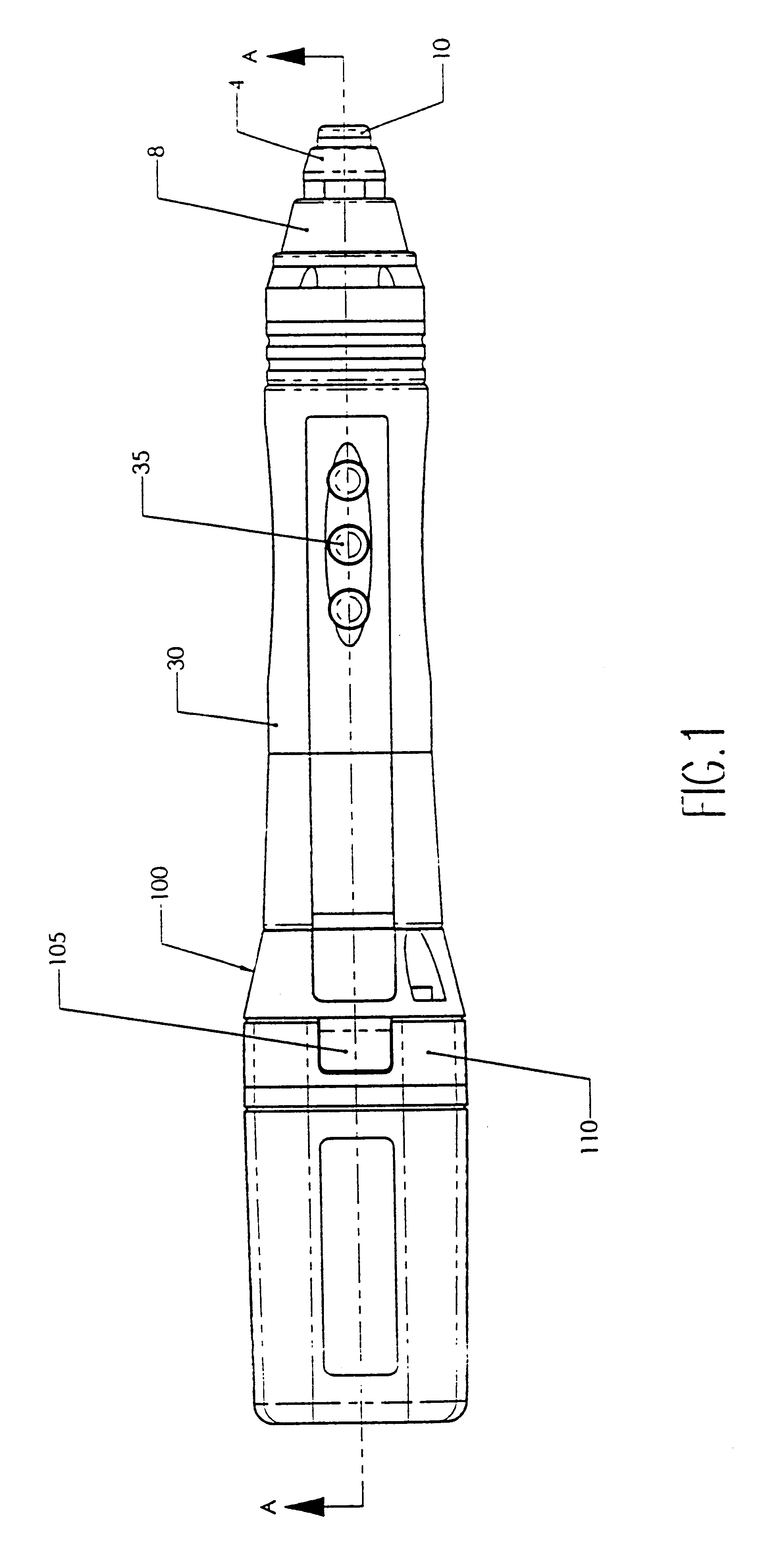

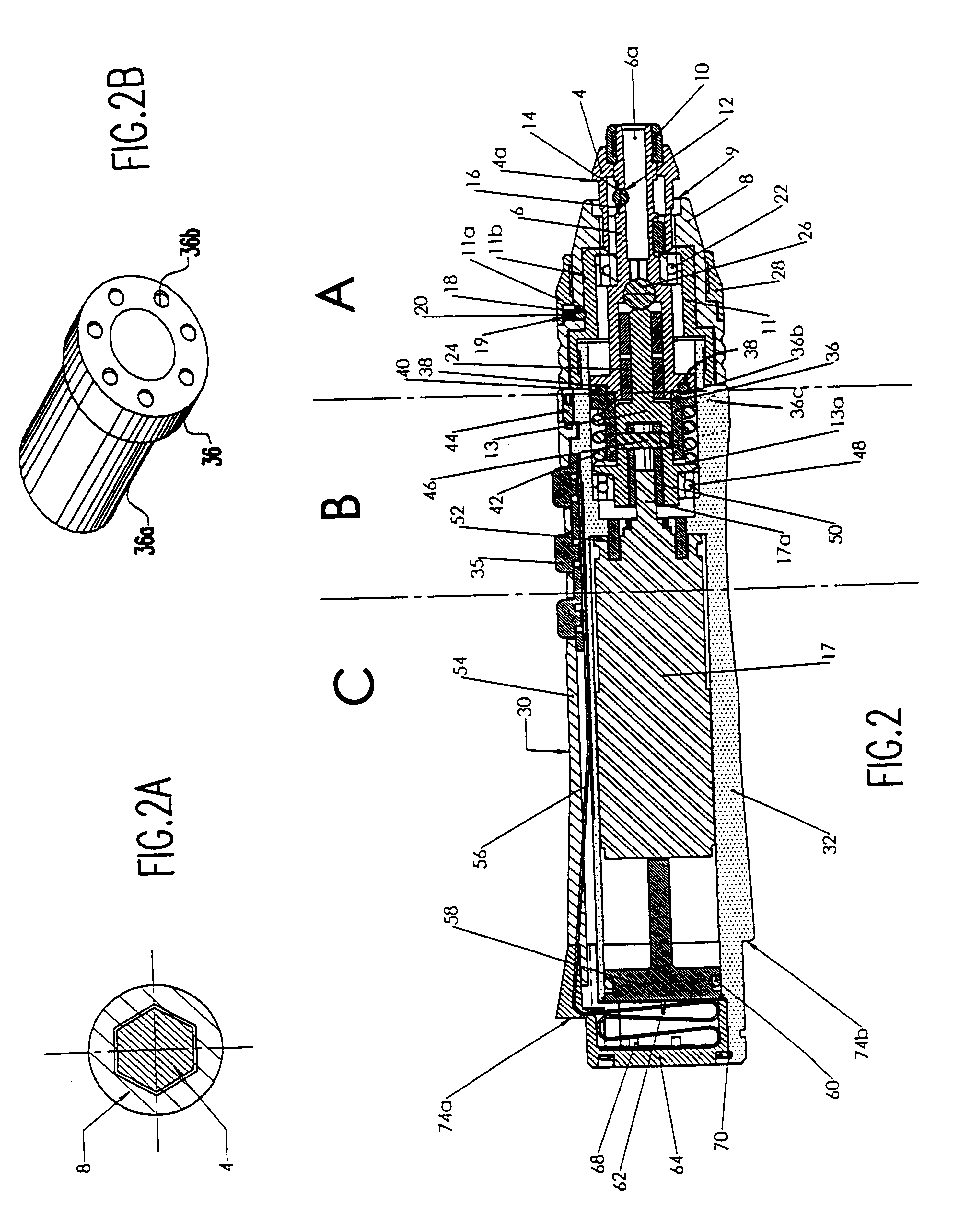

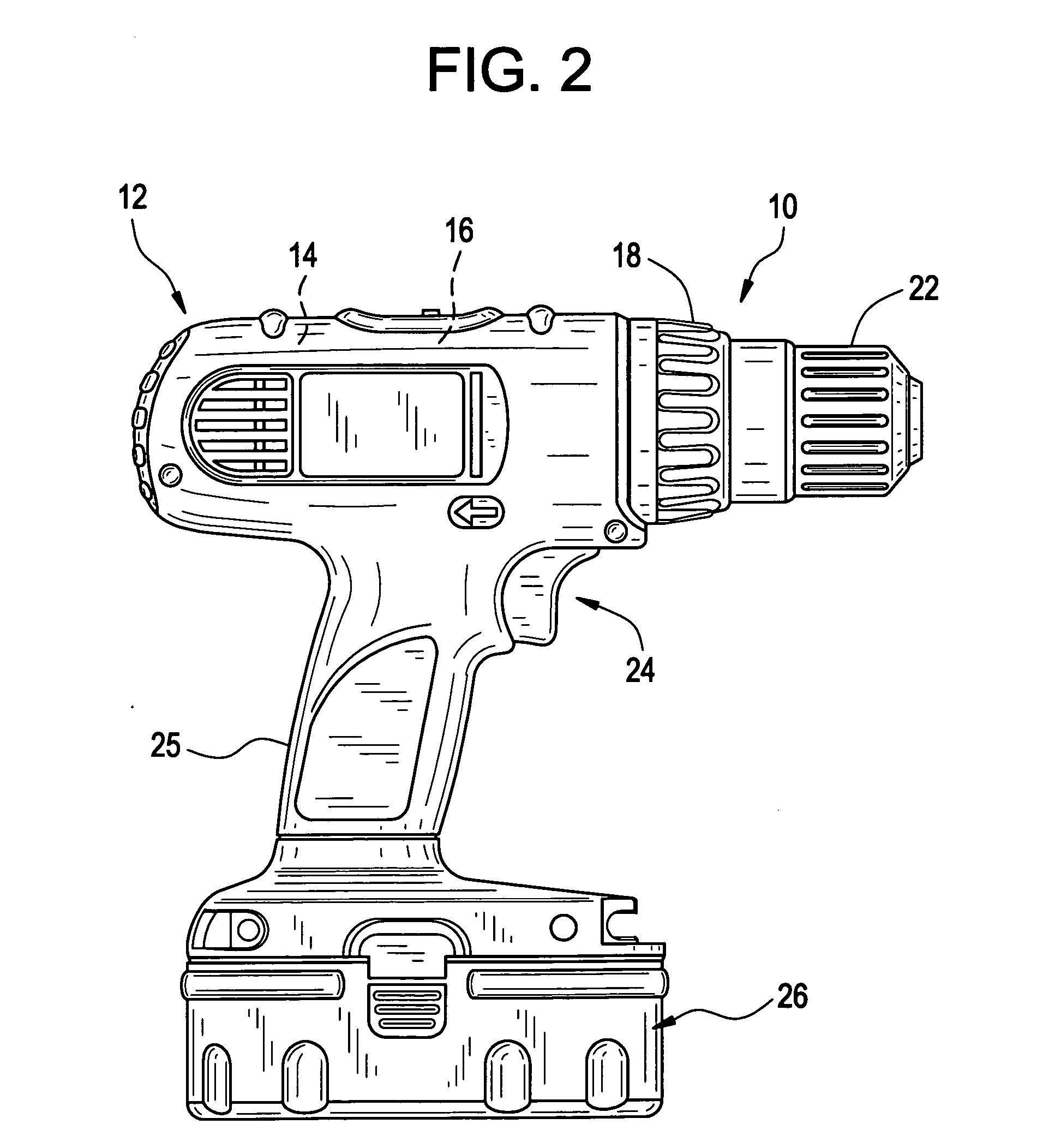

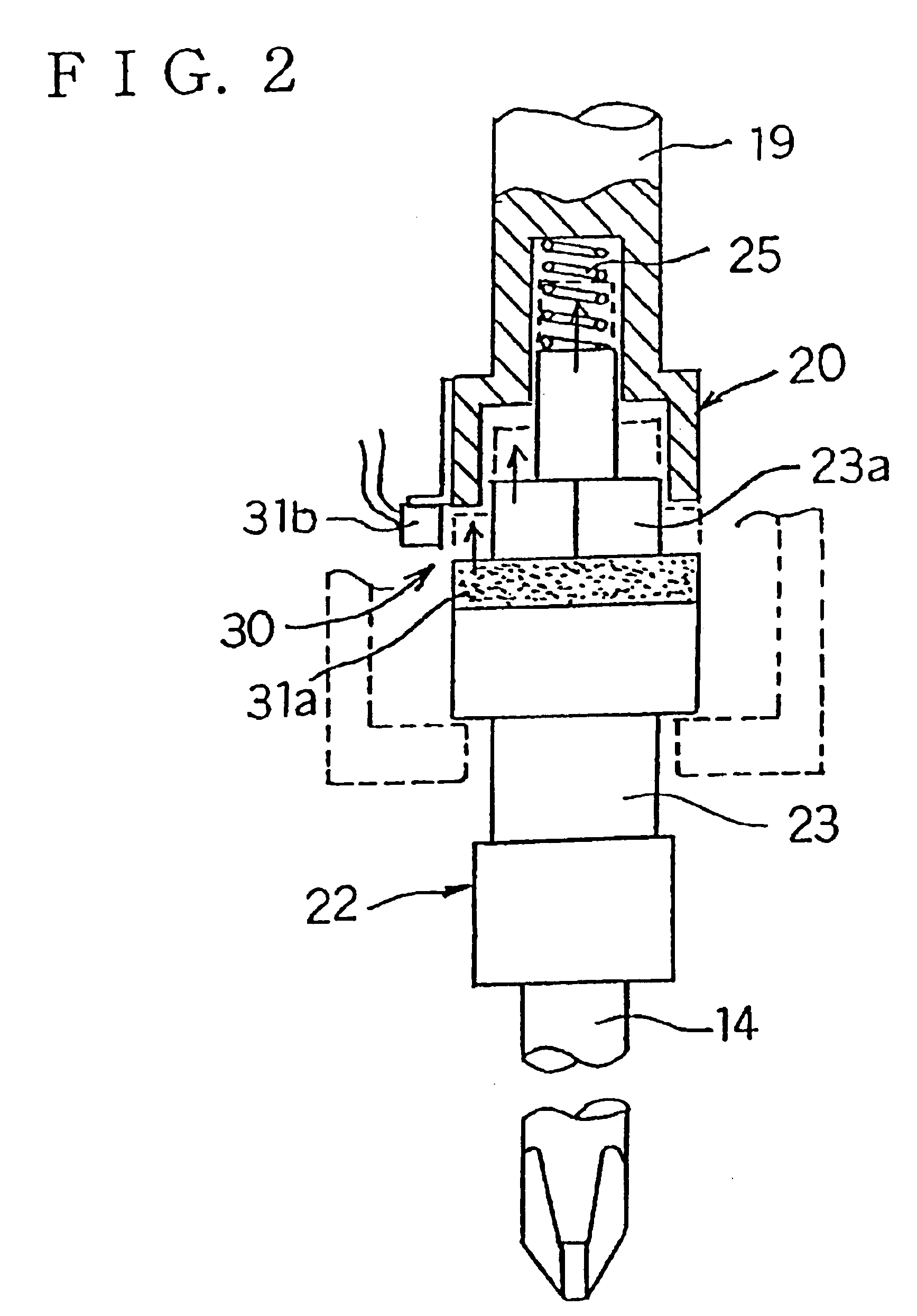

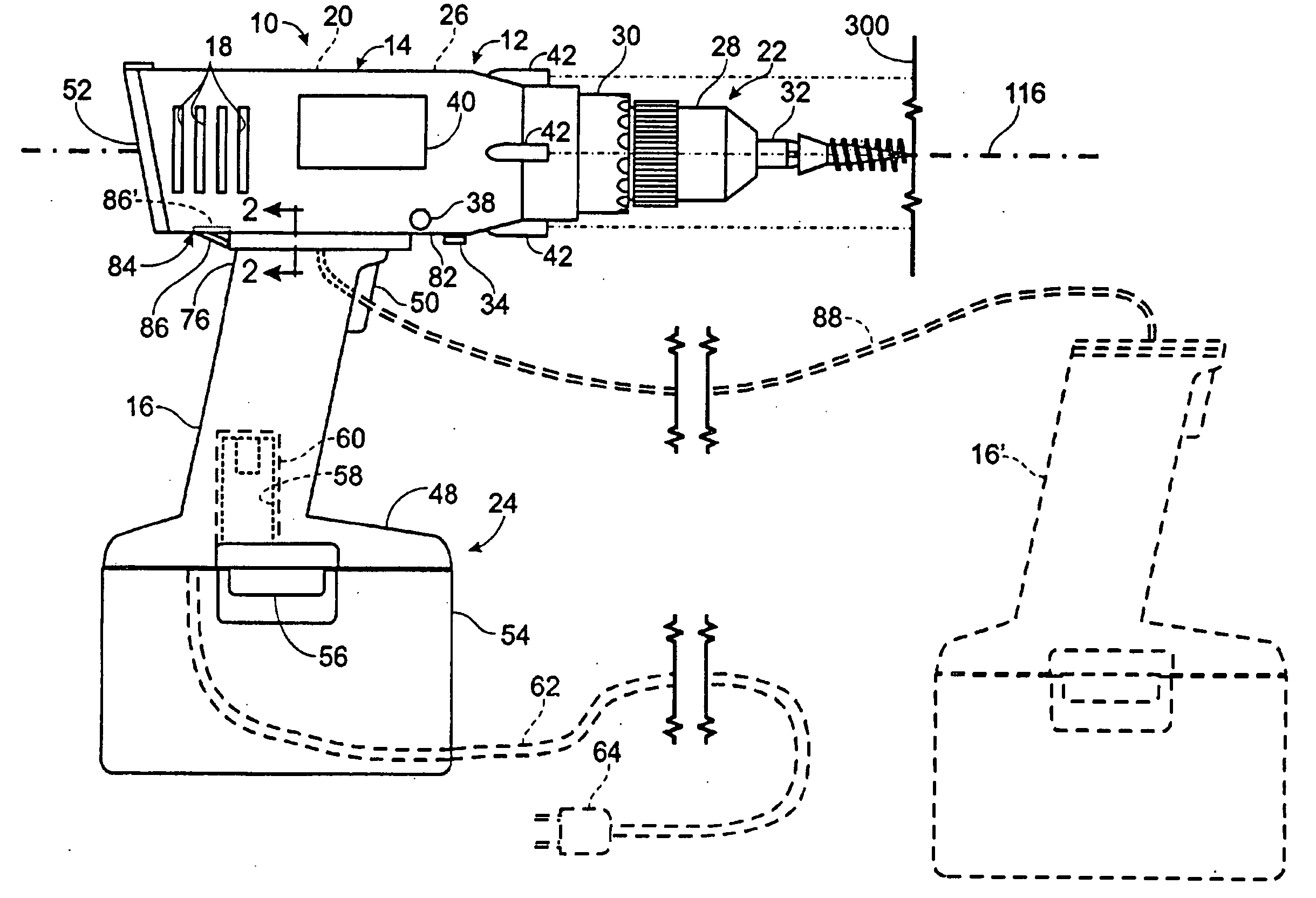

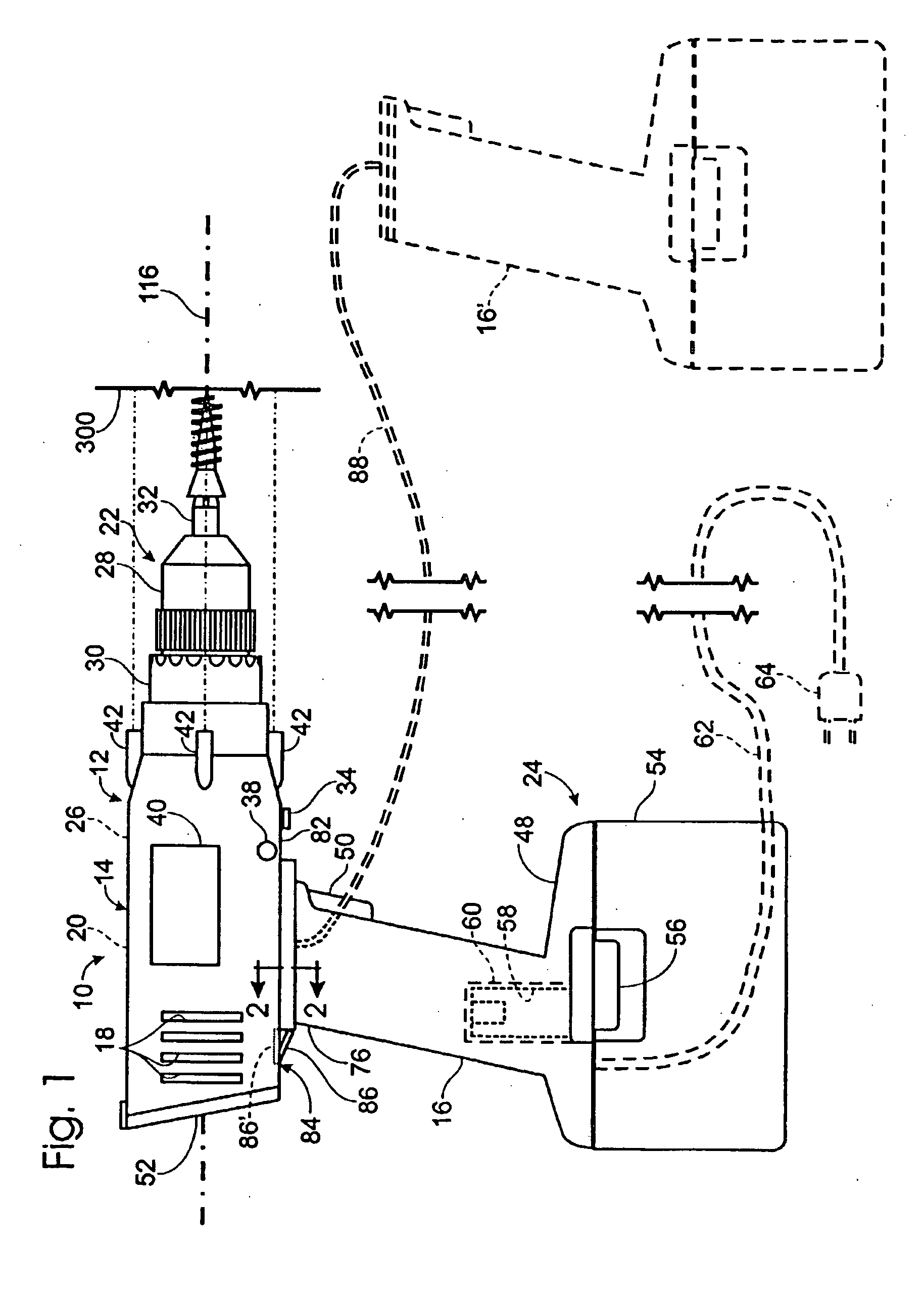

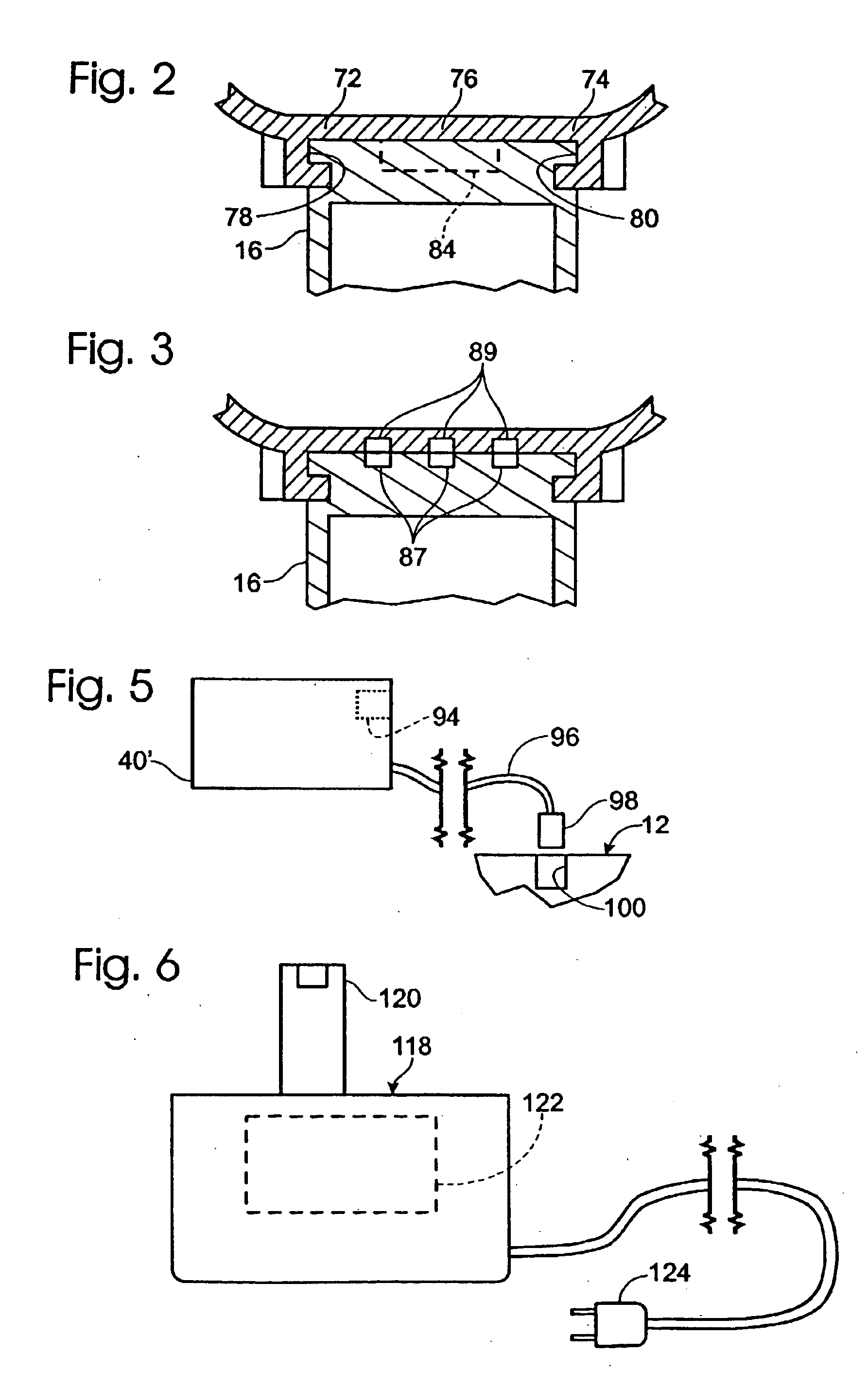

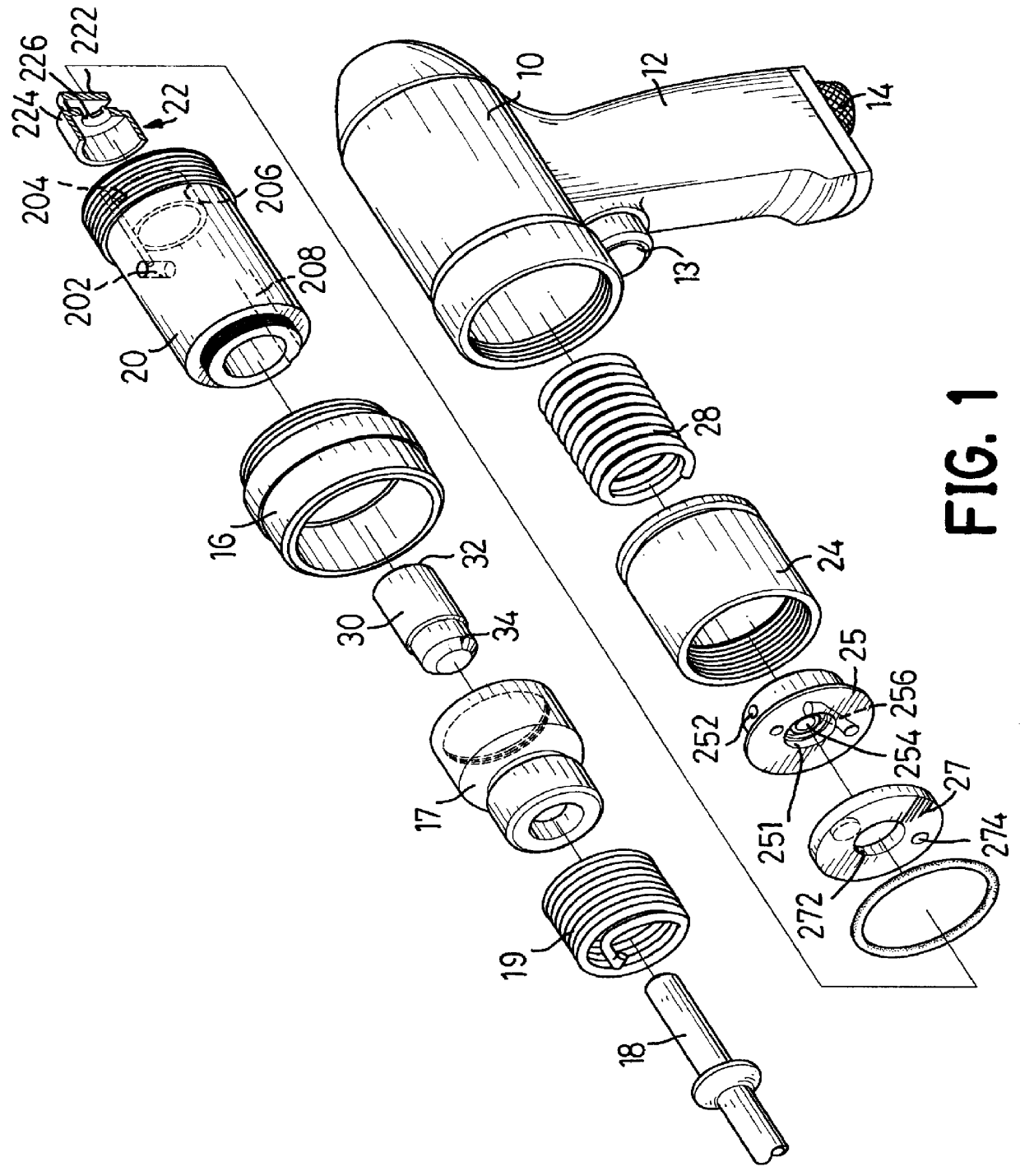

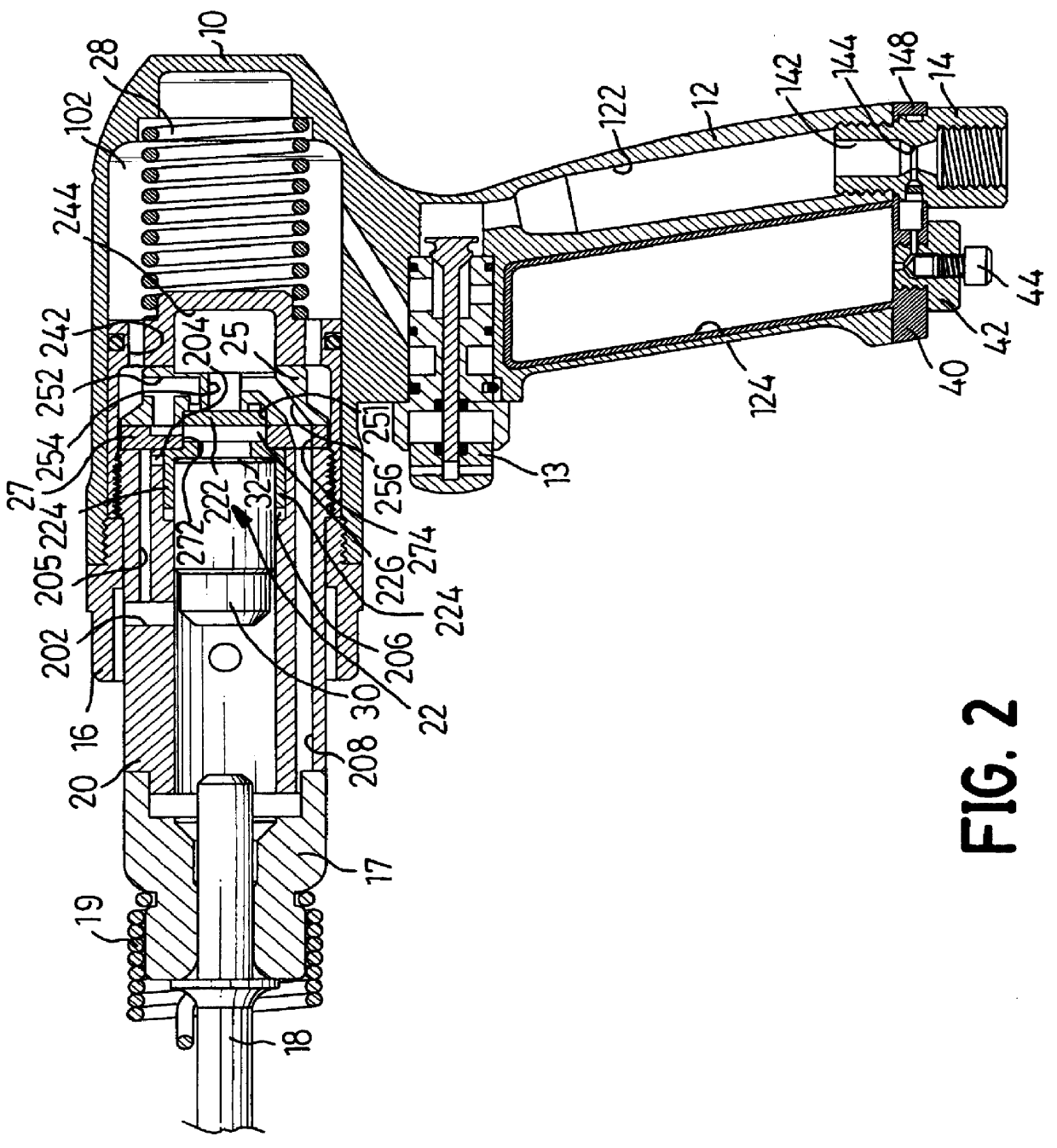

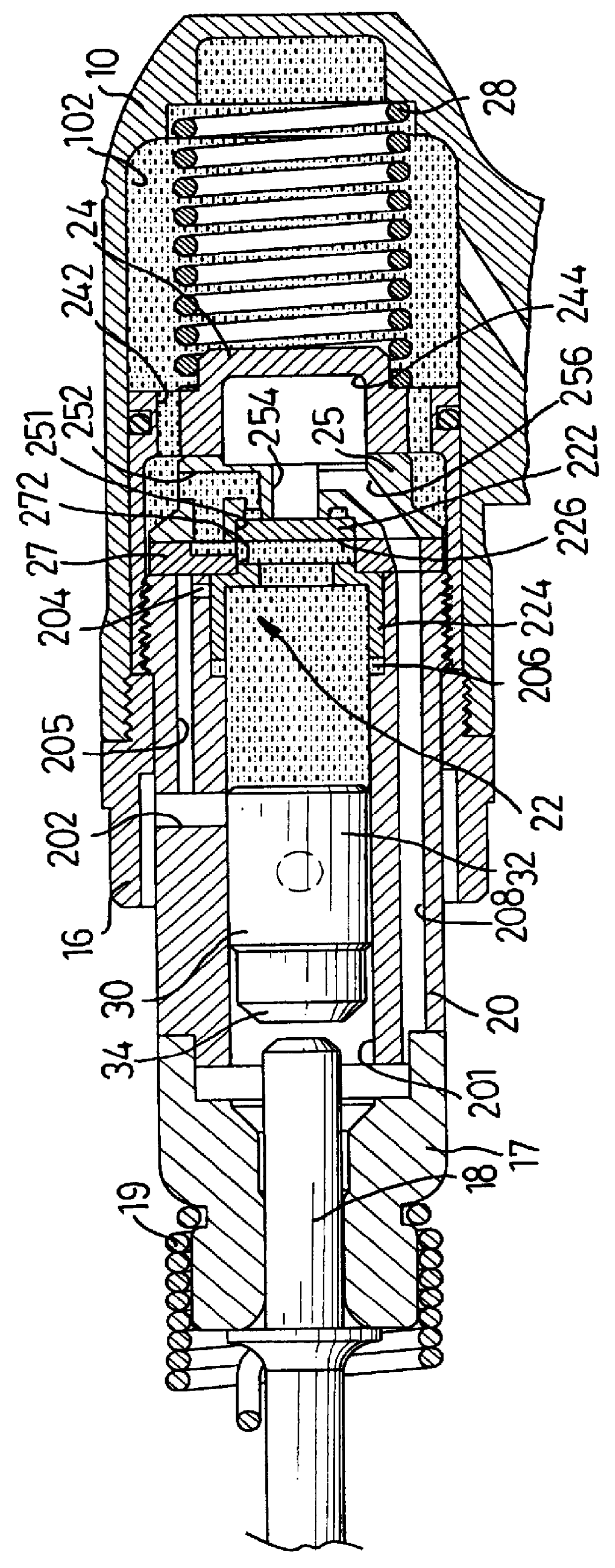

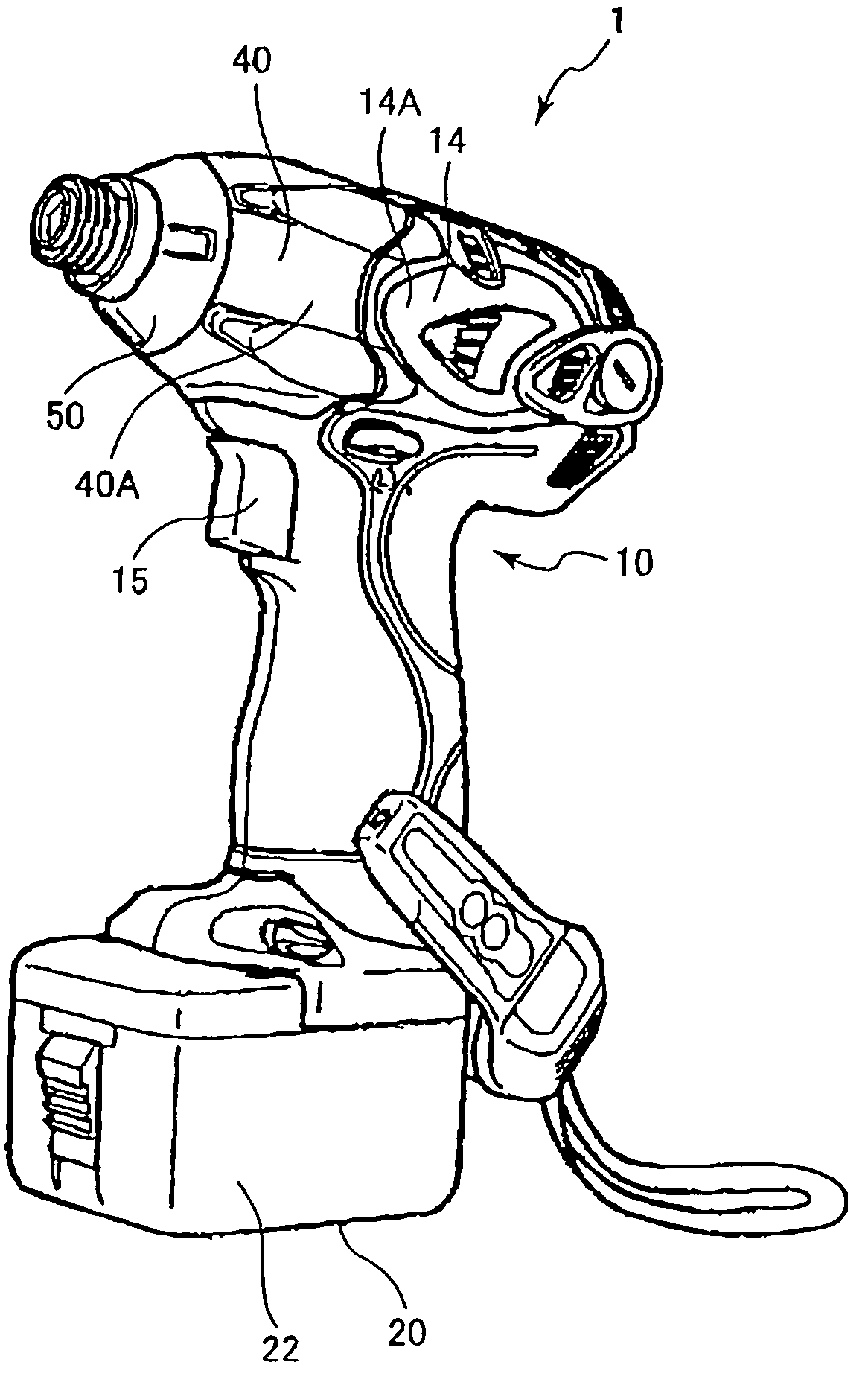

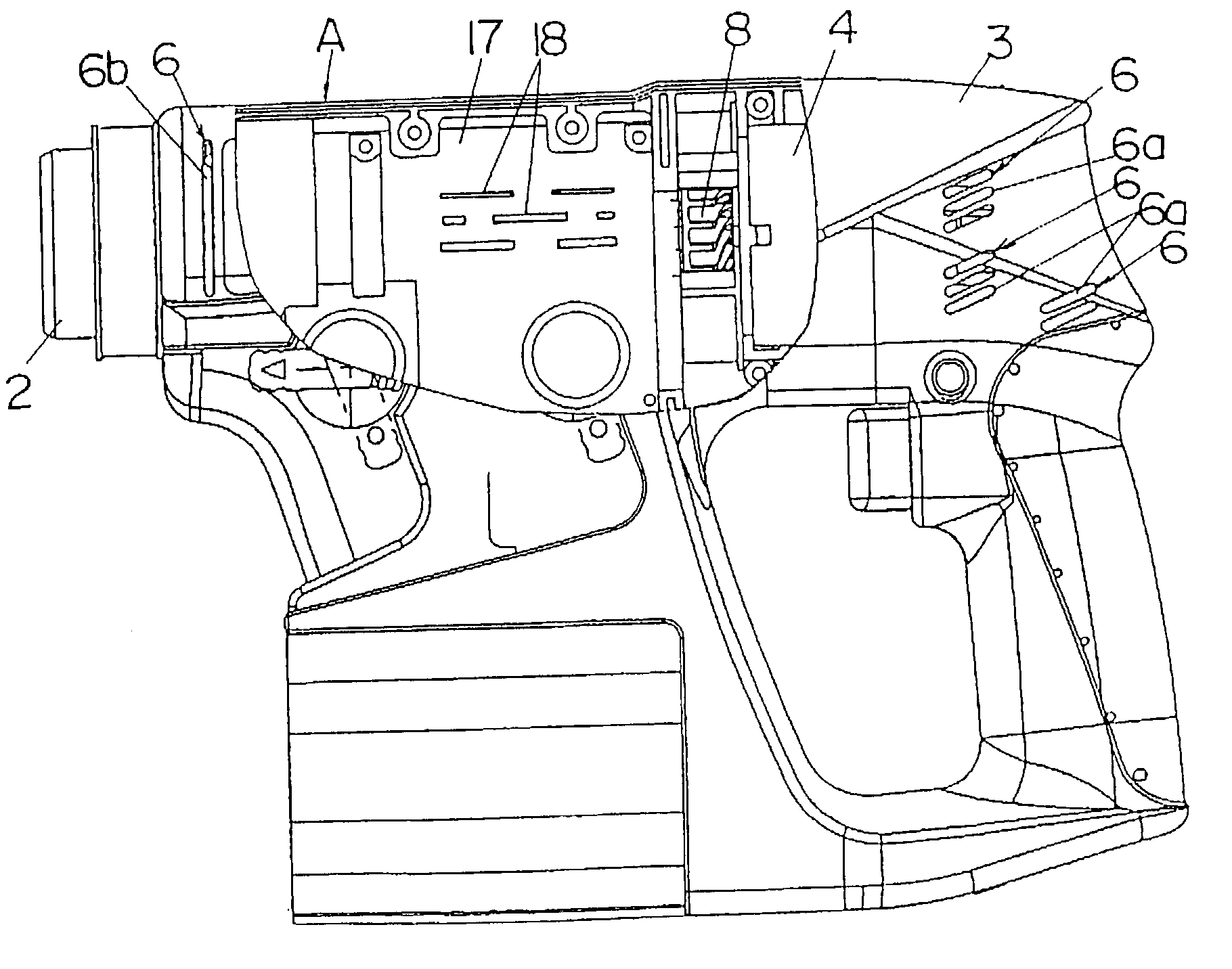

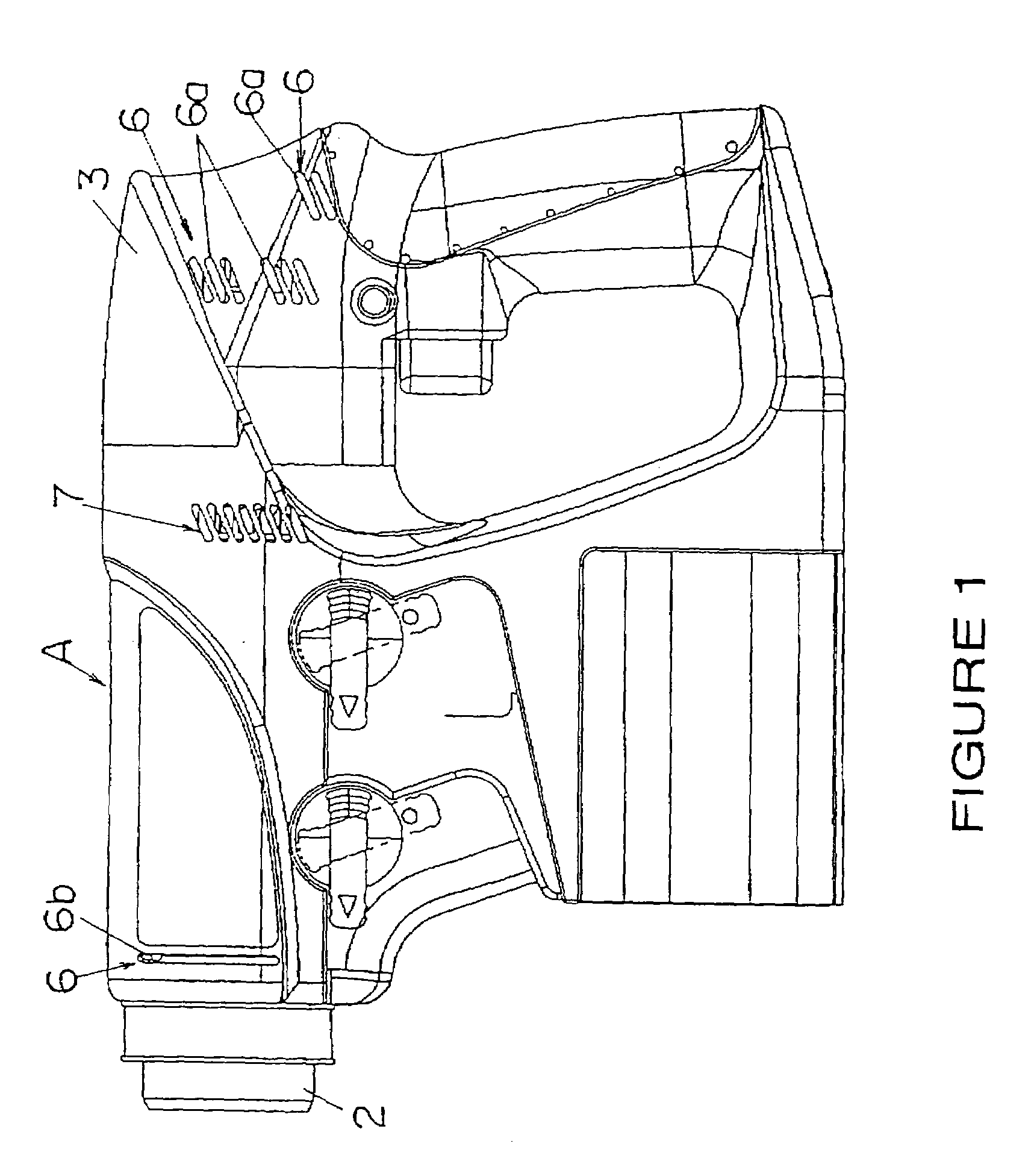

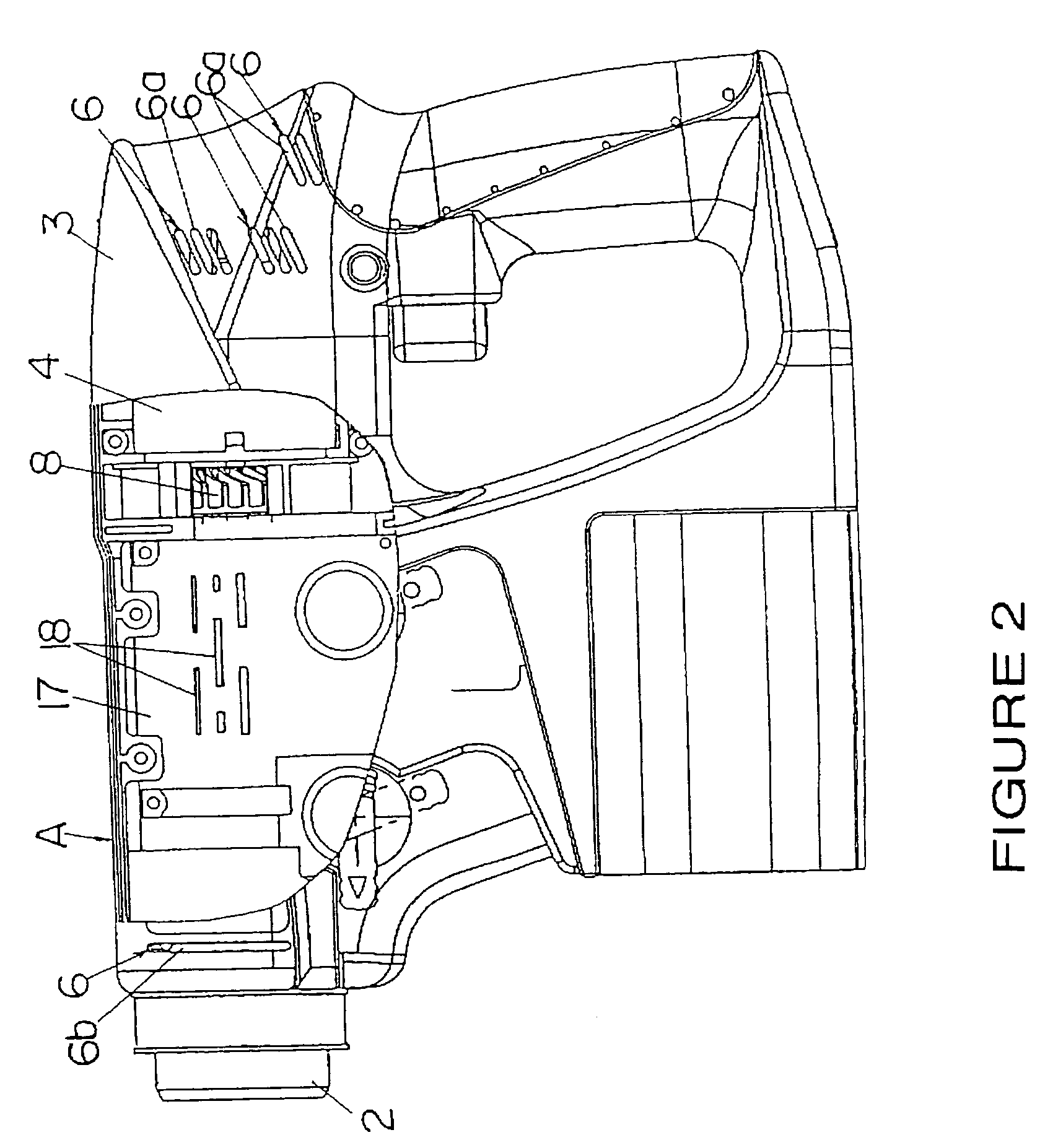

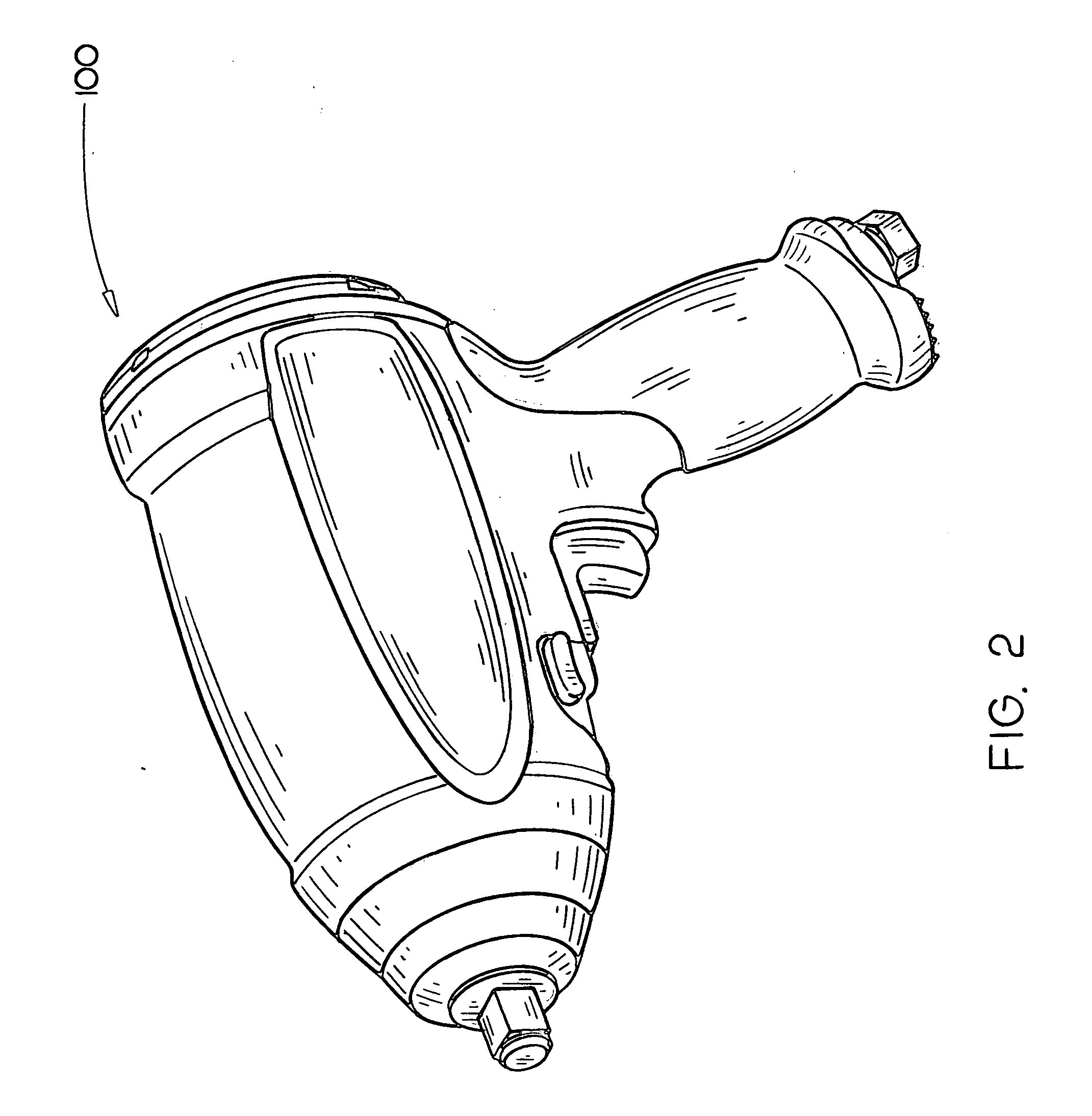

Powered surgical instrument having locking systems and a clutch mechanism

InactiveUS6220368B1Easy to mountEasy to removeDrilling rodsConstructionsLocking mechanismDrive shaft

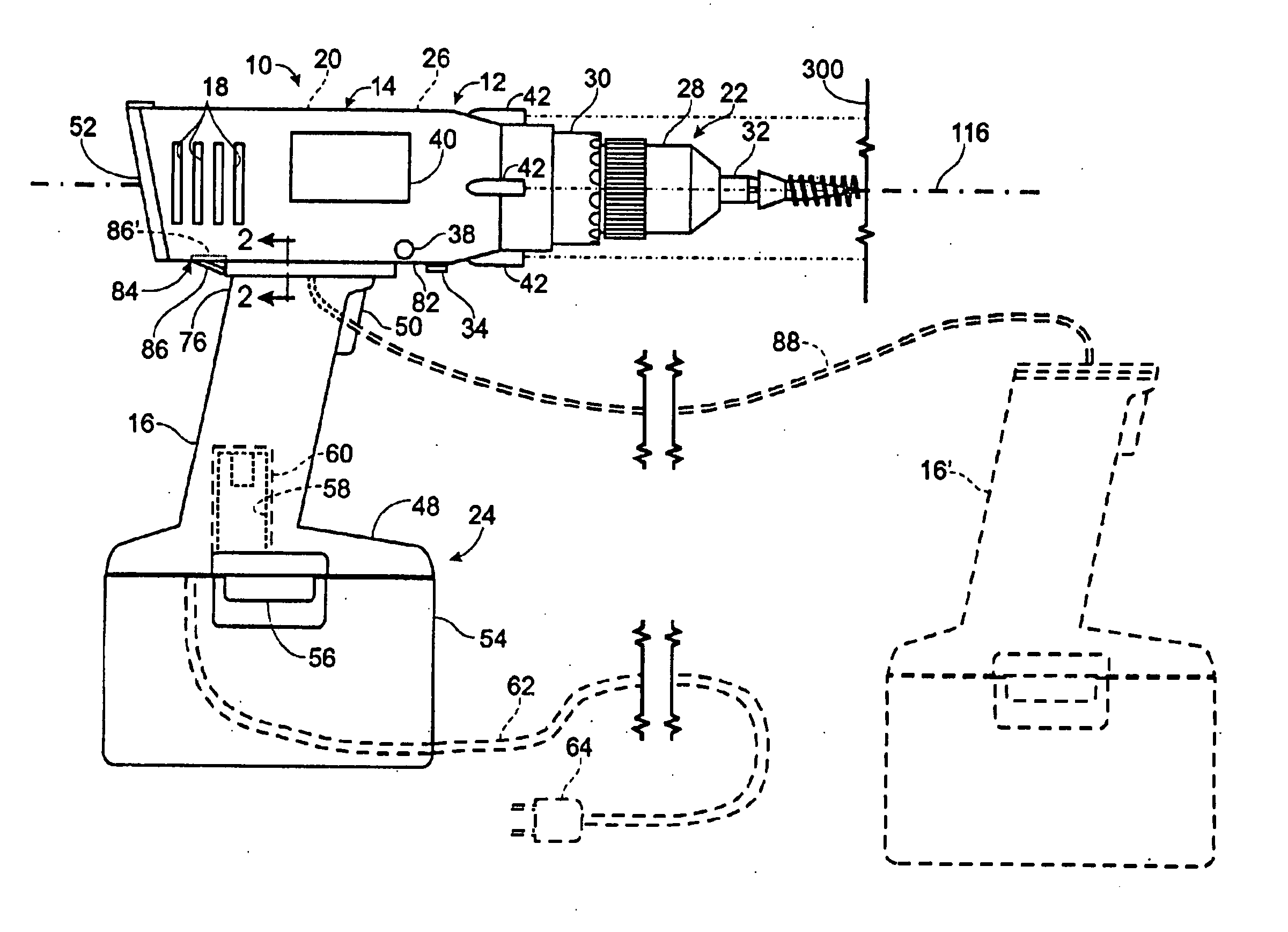

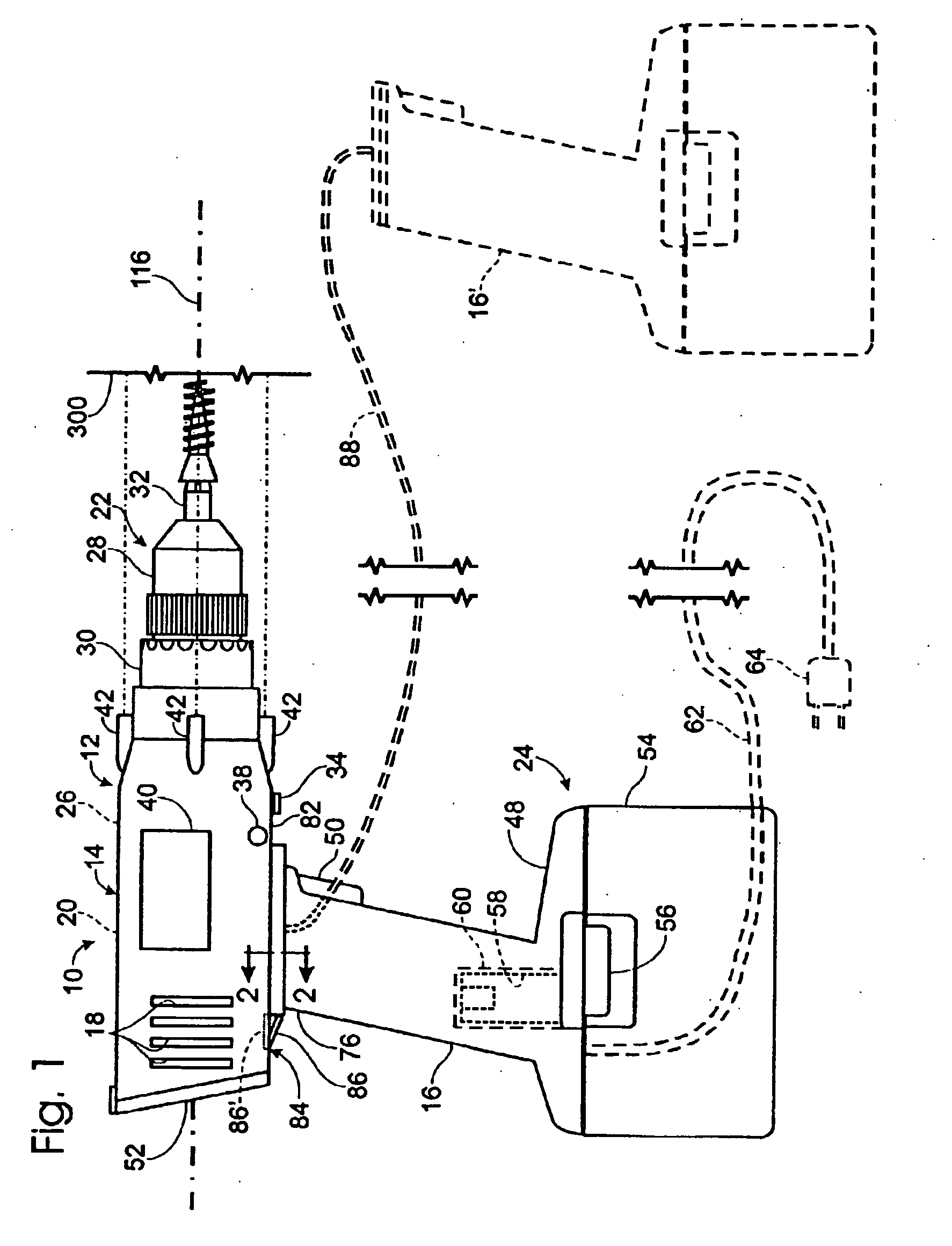

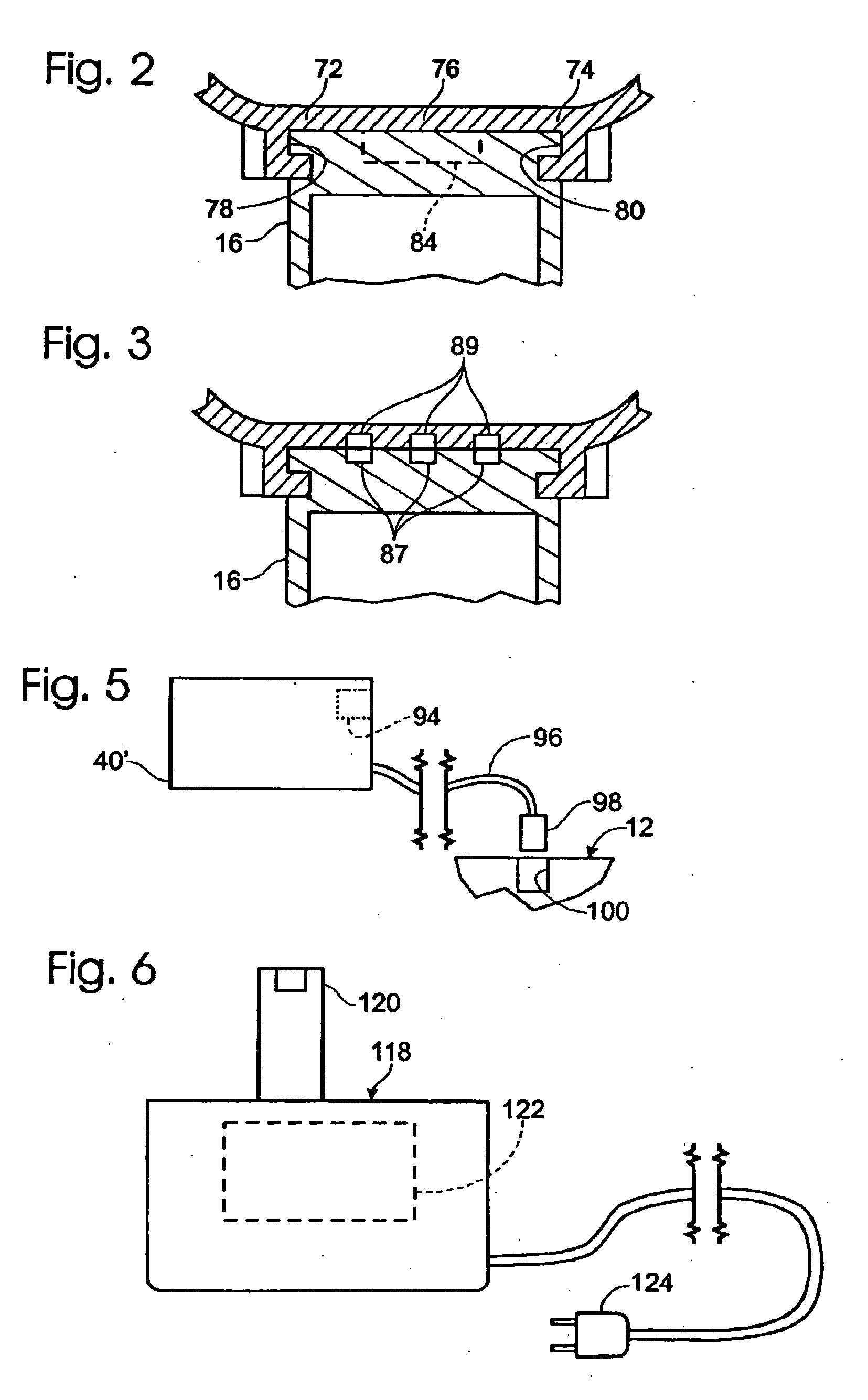

A surgical instrument having a locking mechanism for preventing an output shaft of the surgical instrument from rotating and a further locking mechanism for mounting a battery pack to a distal end of a housing of the surgical instrument. The surgical instrument further includes a clutch mechanism for limiting the torque of a drive shaft of the surgical instrument. The locking mechanism for preventing the output shaft from rotating includes a locking switch which mates with a locking cap disposed on the output shaft. The locking mechanism for mounting the battery pack to the housing includes a groove at the distal end of the housing and a retaining ring which engages the groove when the battery pack is mounted on the housing. The clutch mechanism includes a clutch plate that interfaces with both the output shaft and the drive shaft and prevents failure of the motor shaft.

Owner:MICROAIRE SURGICAL INSTR

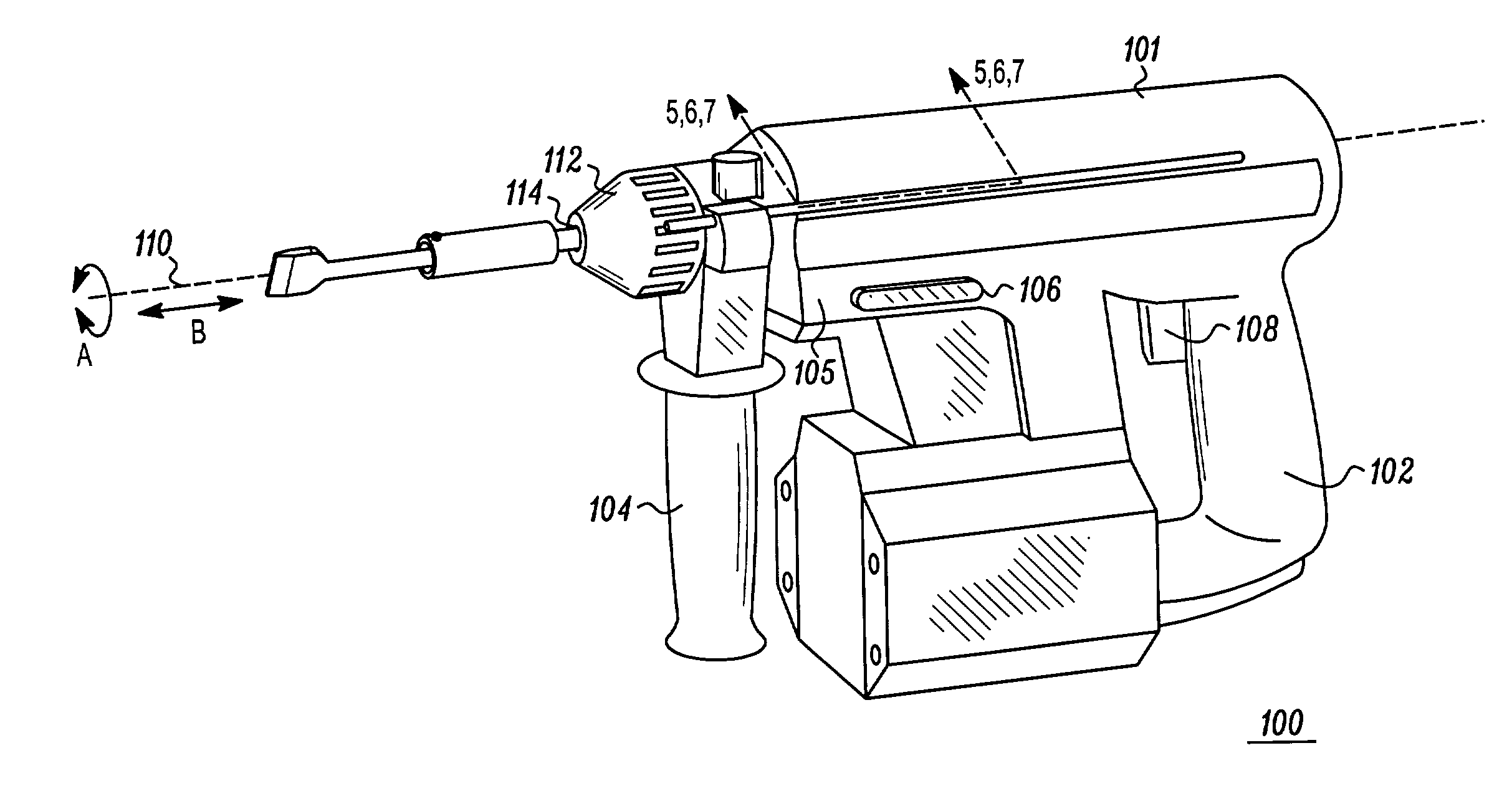

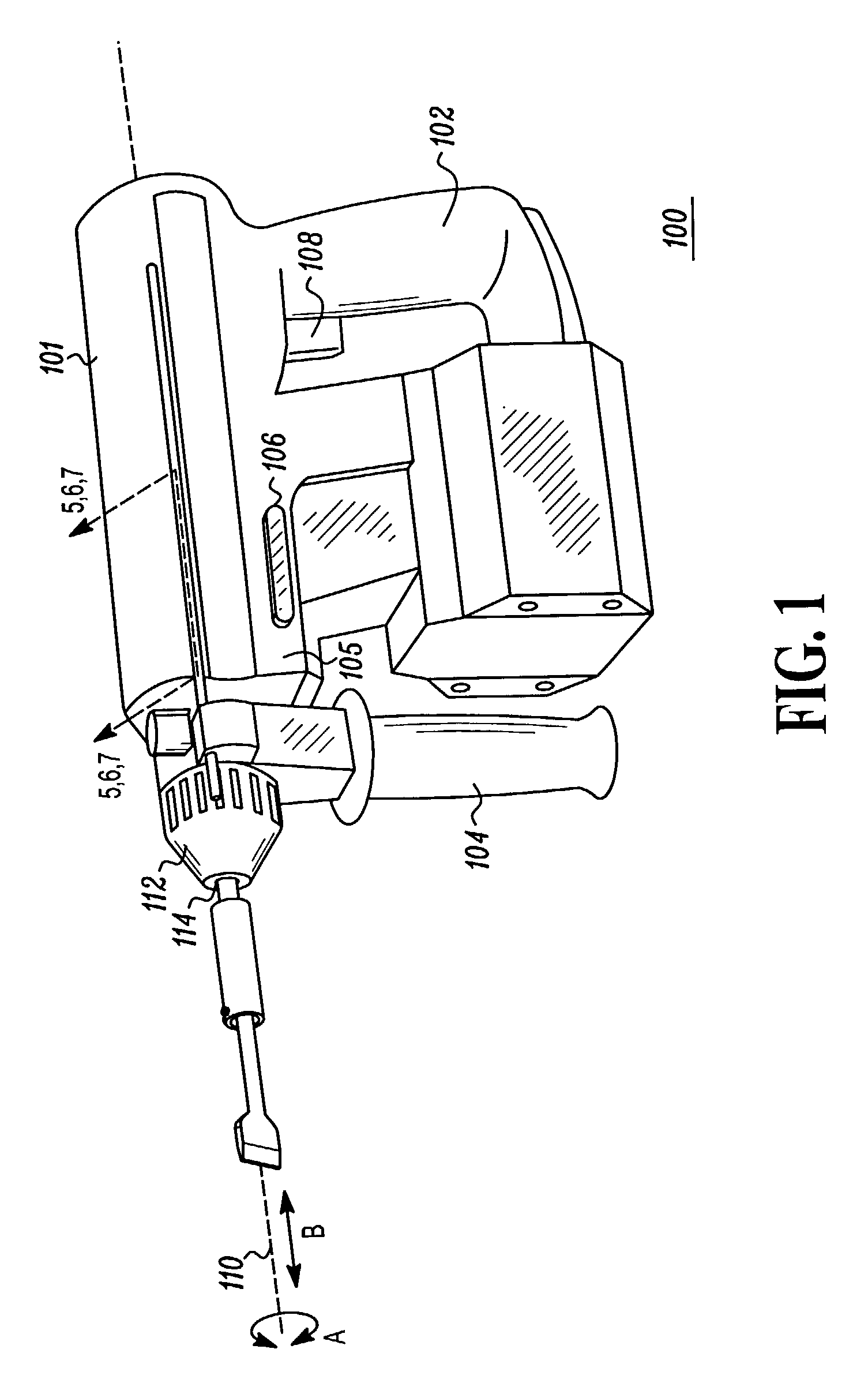

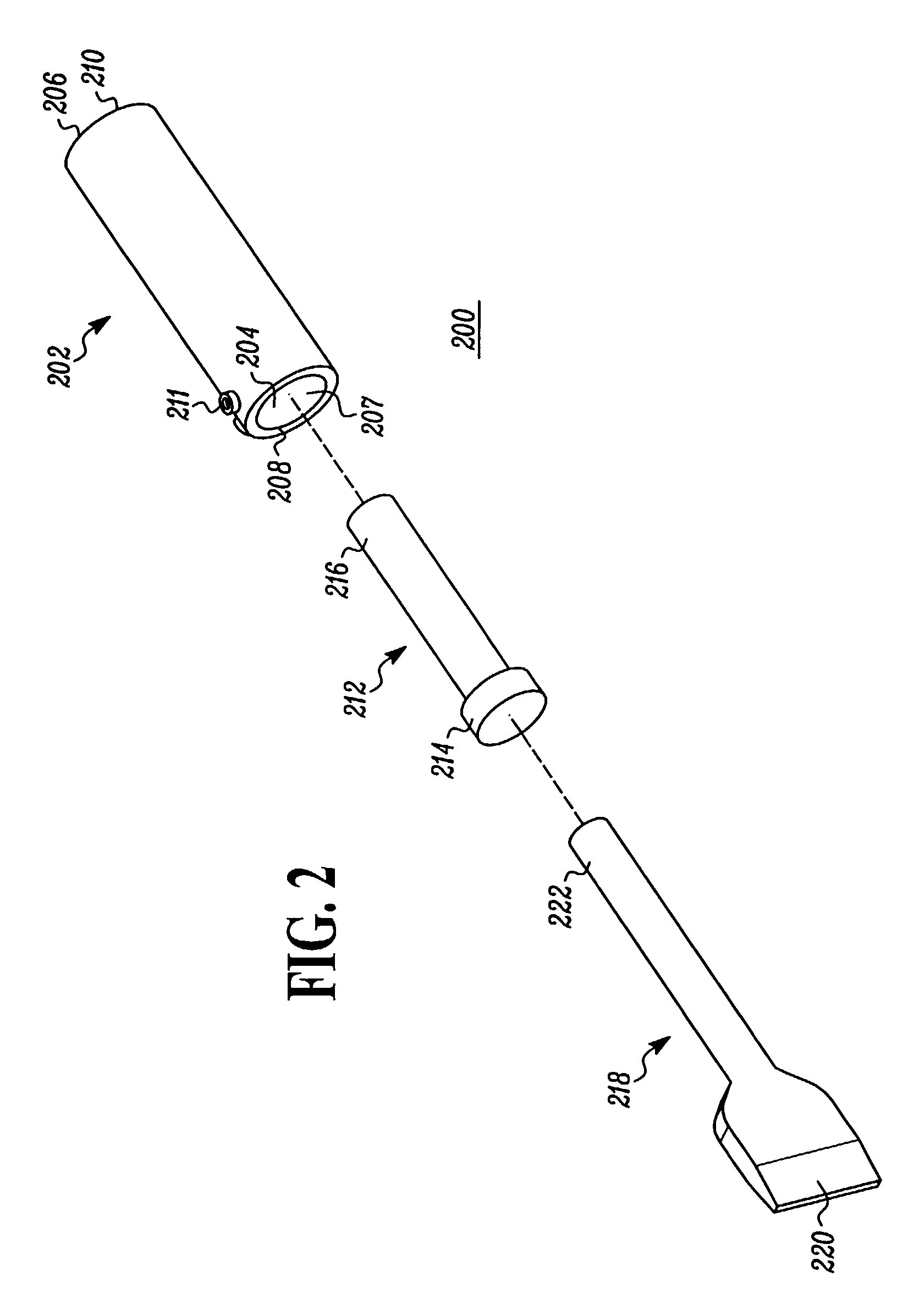

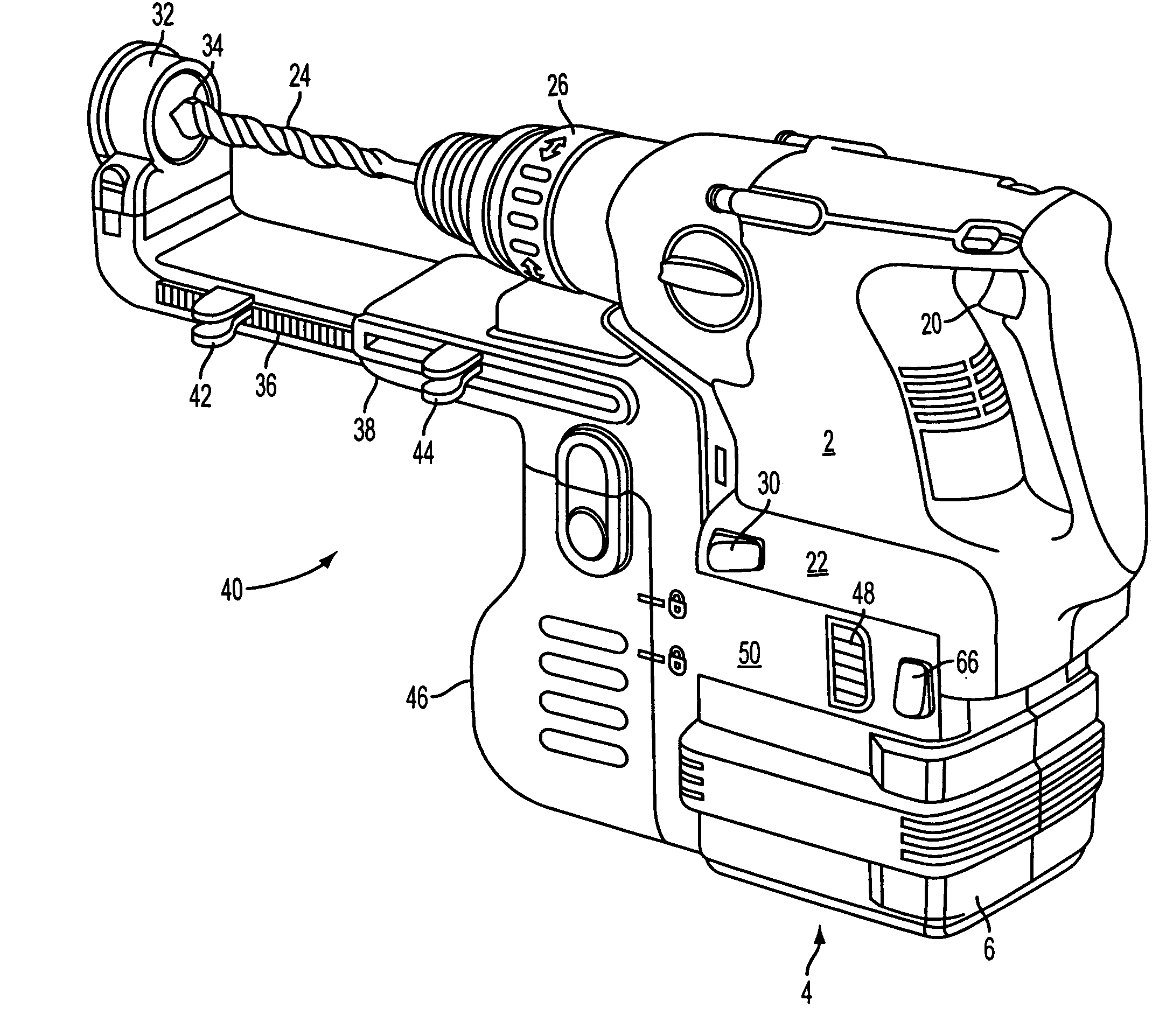

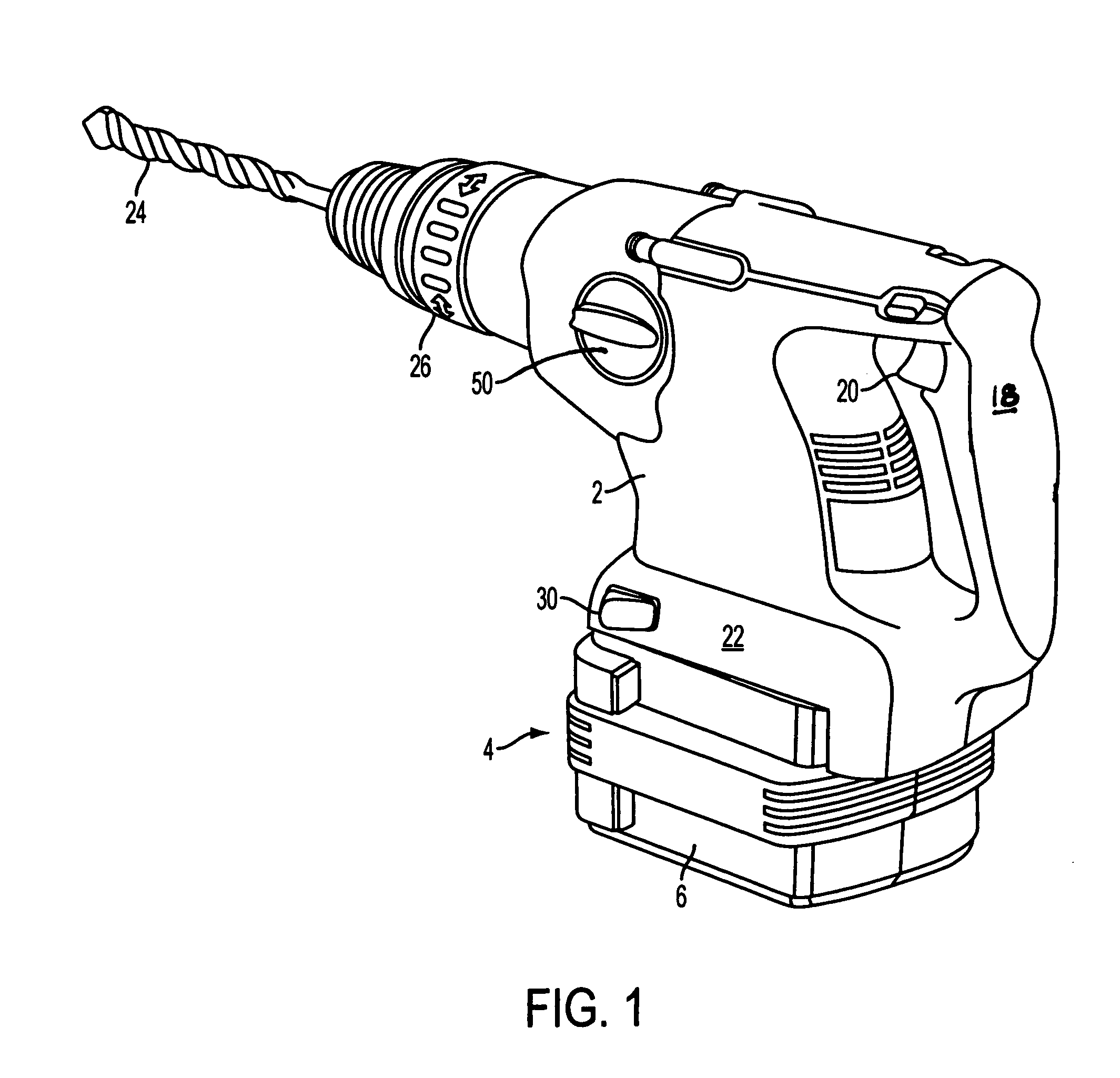

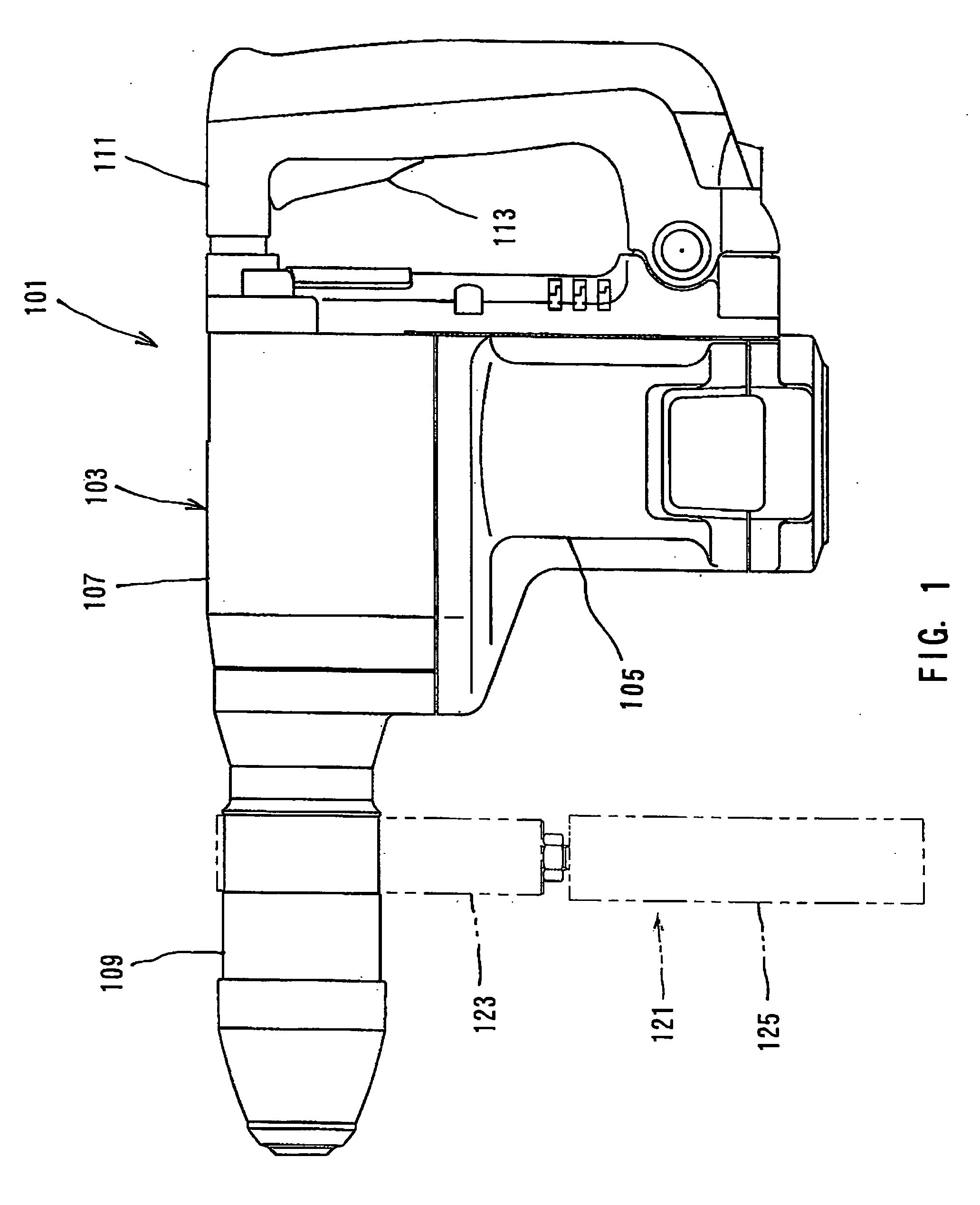

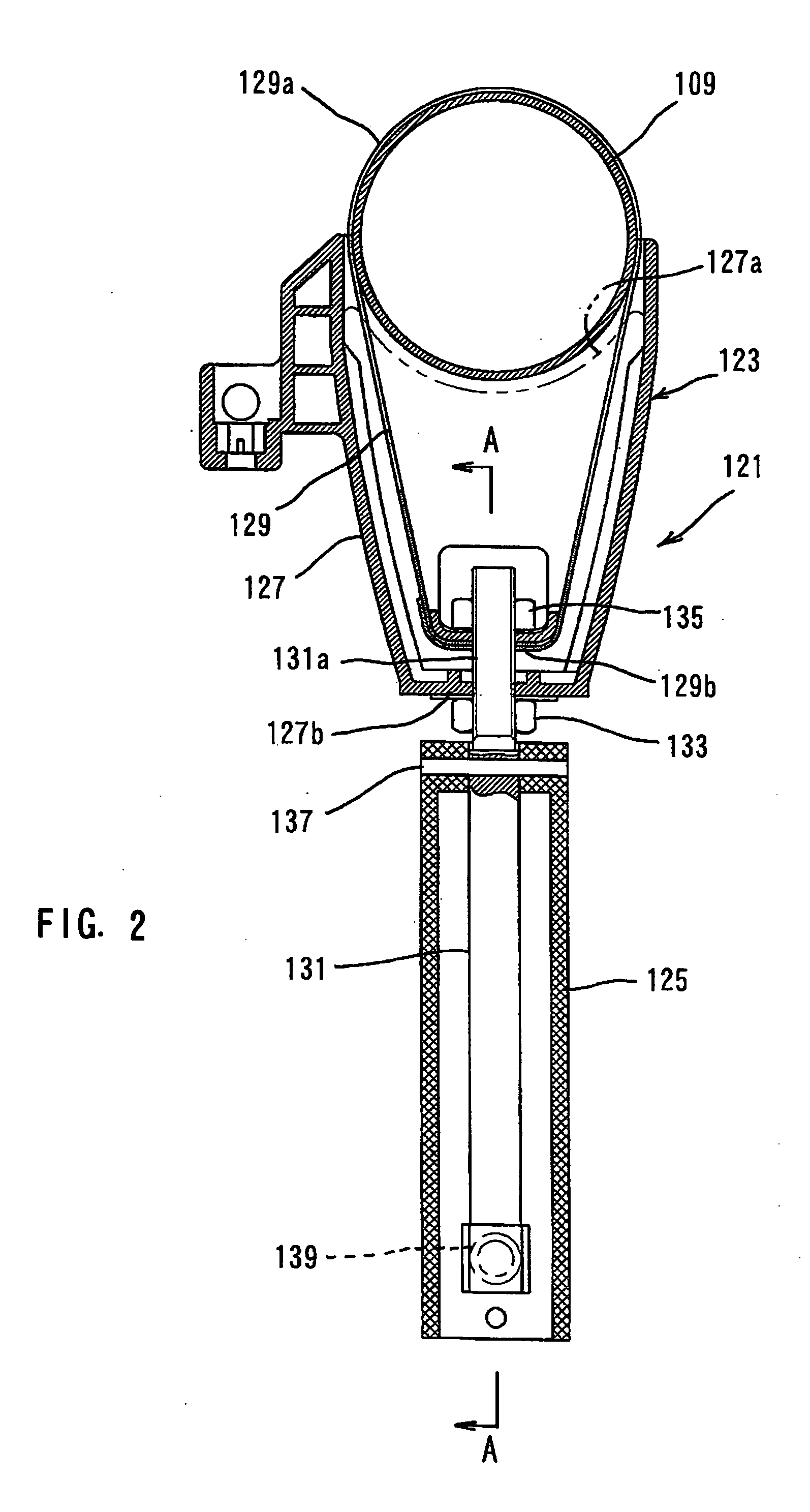

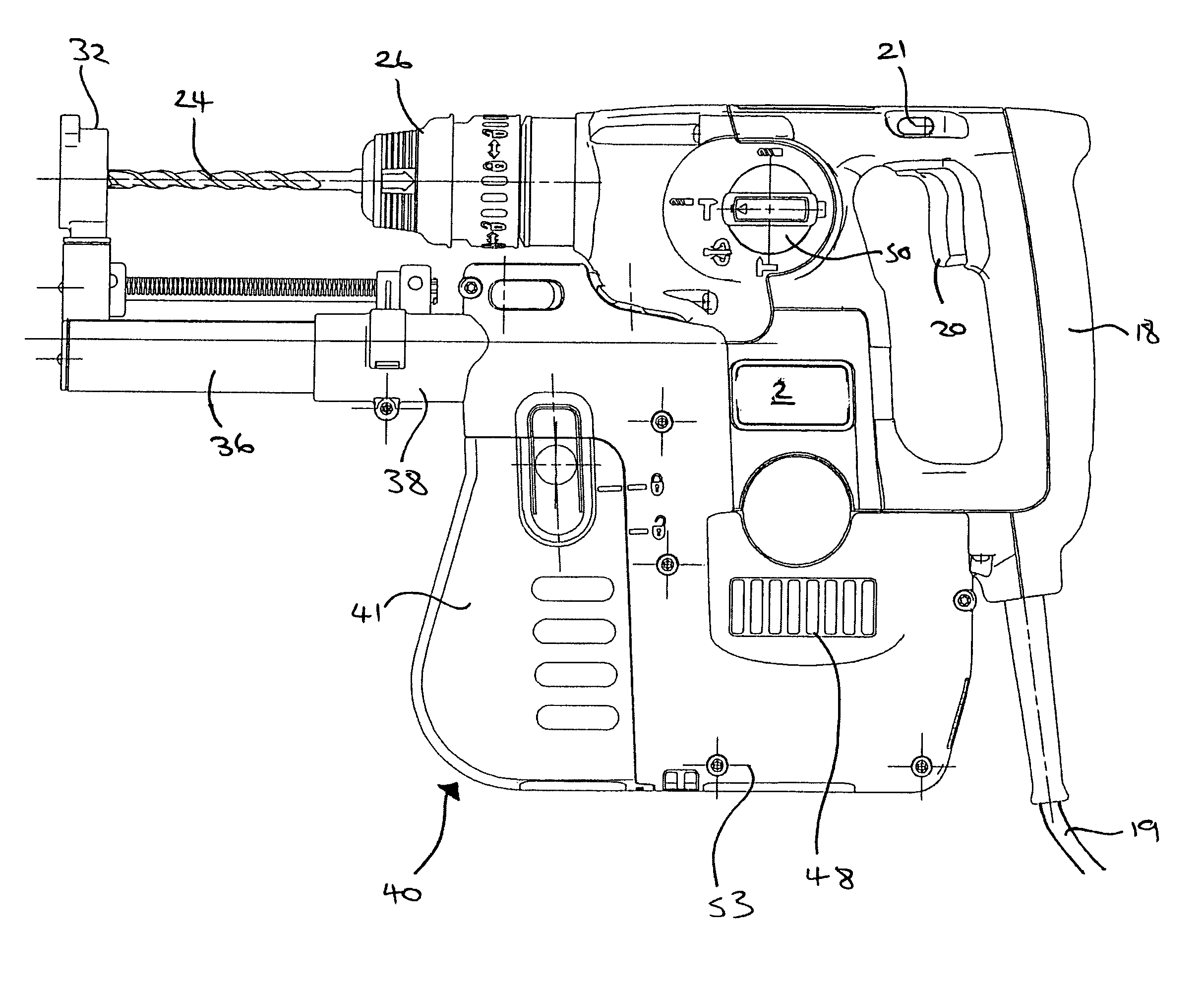

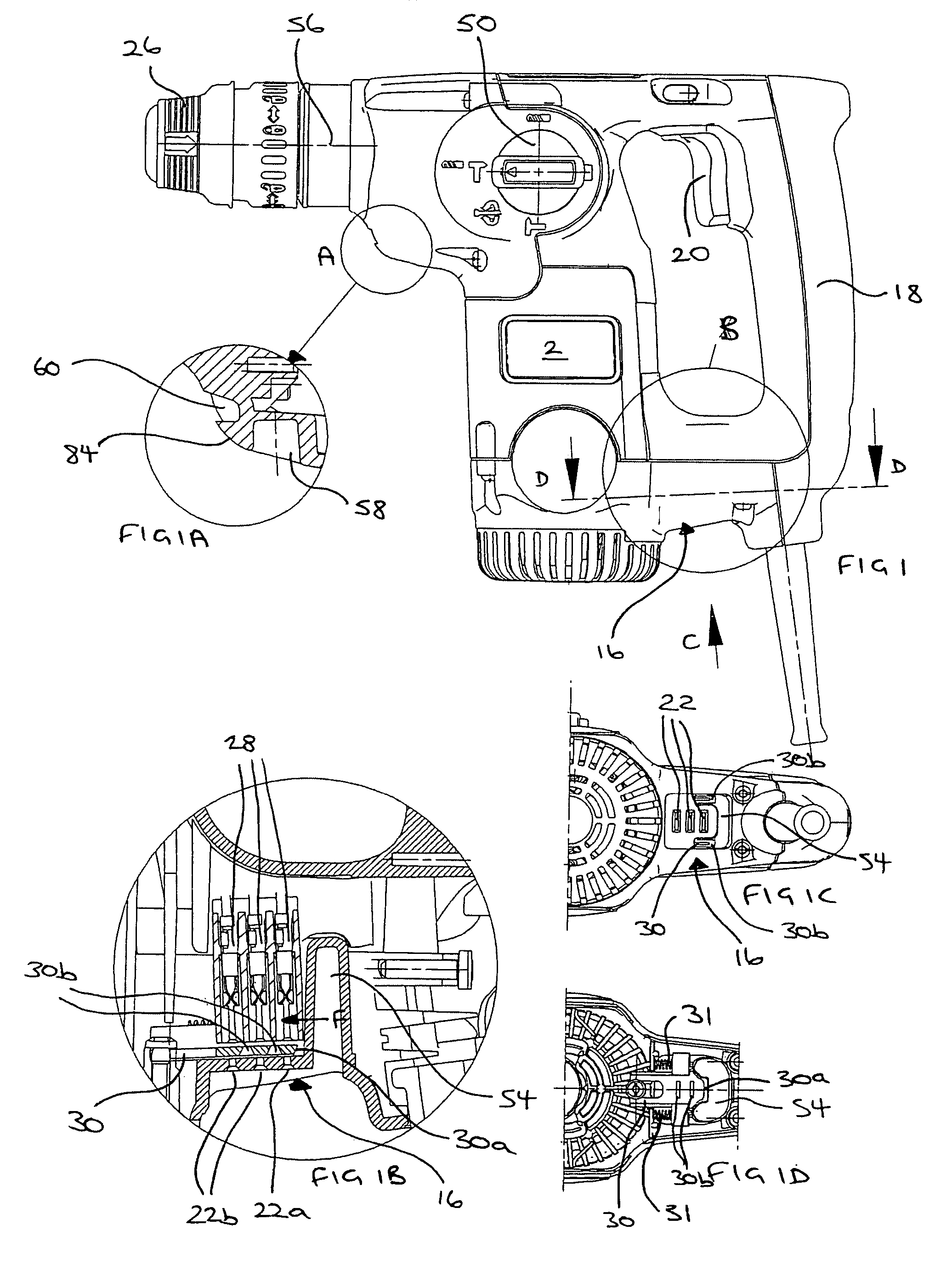

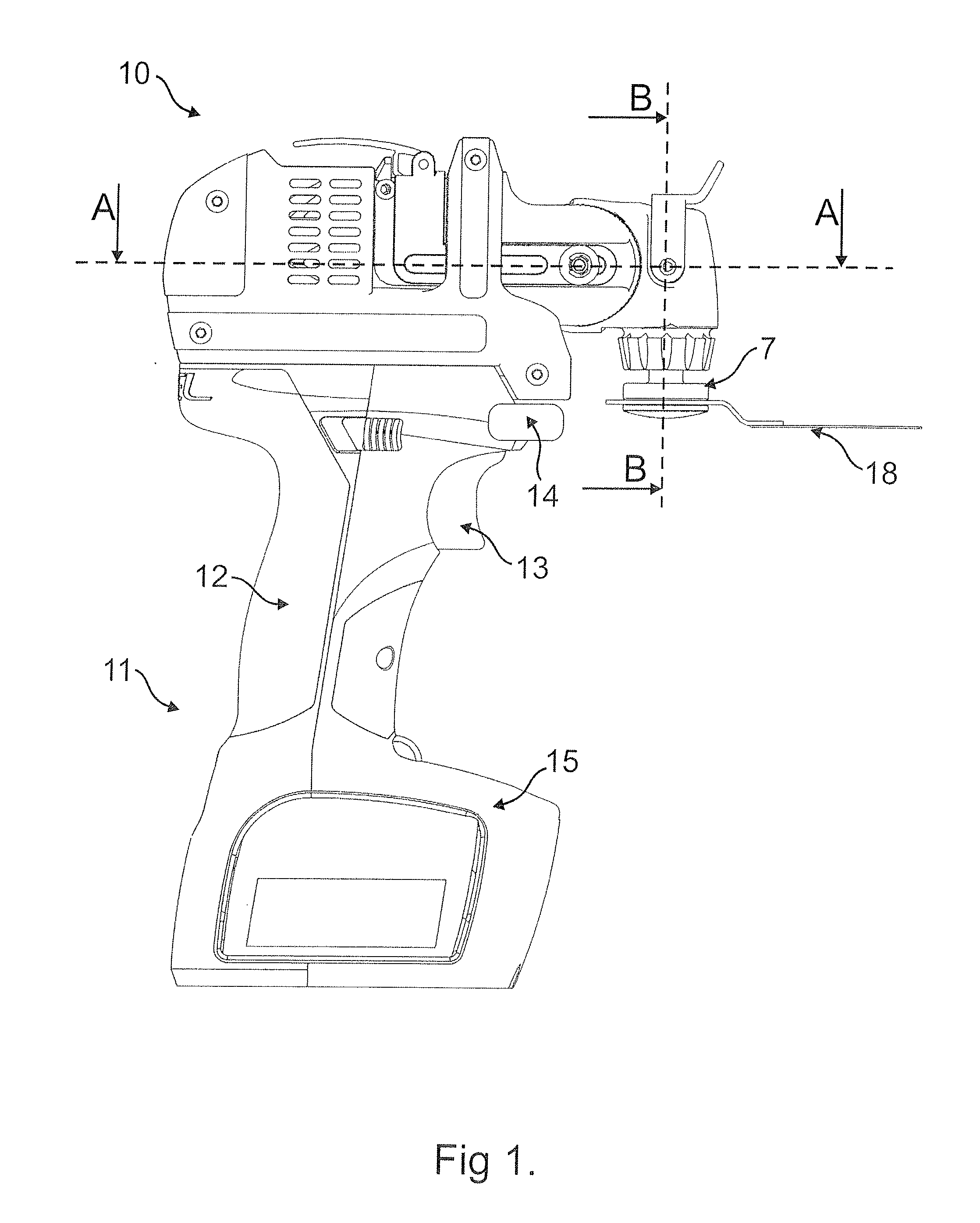

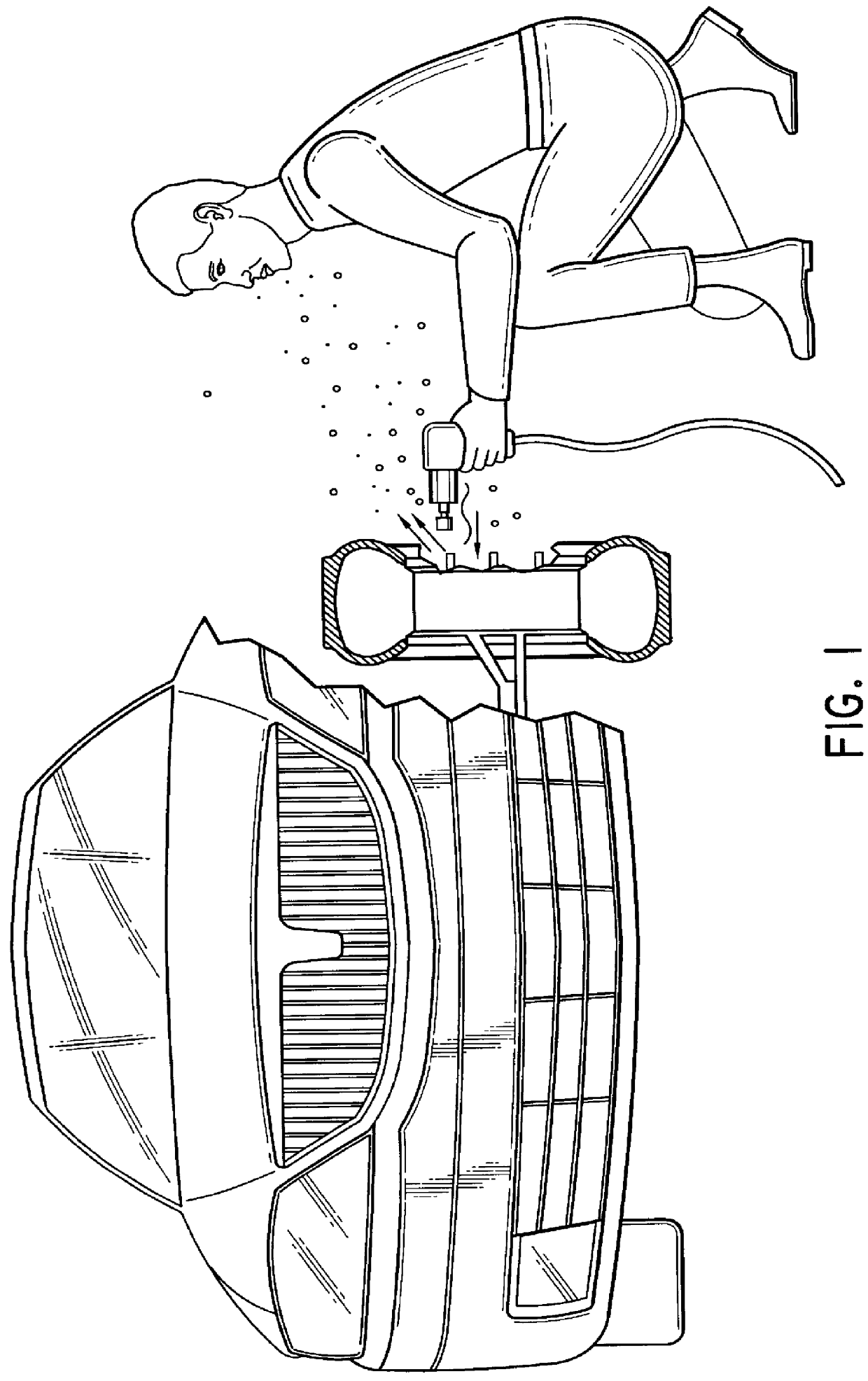

Hammer drill attachment

Power tools of the type under consideration include hammer drills, for example, which are electric or battery powered and includes two modes of operation: a rotation mode and a rotation-hammer mode. A manually operable selector lever enables the hammer drill to be selectively operated in one of the two modes by disengaging and engaging a hammer mechanism. In rotation-hammer mode, the drive shaft of the hammer drill rotates a tool element about a rotational axis and oscillates the tool element along a rotational axis. An attachment mountable within the chuck of a hammer drill prevents a tool element from rotating when the hammer drill is operating in rotation-hammer mode. The hammer drill attachment transfers hammer action, but not rotation, to the tool element. The hammer drill attachment enables dual function power tools to be operated in a hammer only mode to perform a function, for example, chiseling.

Owner:OROZCO JR EFREM

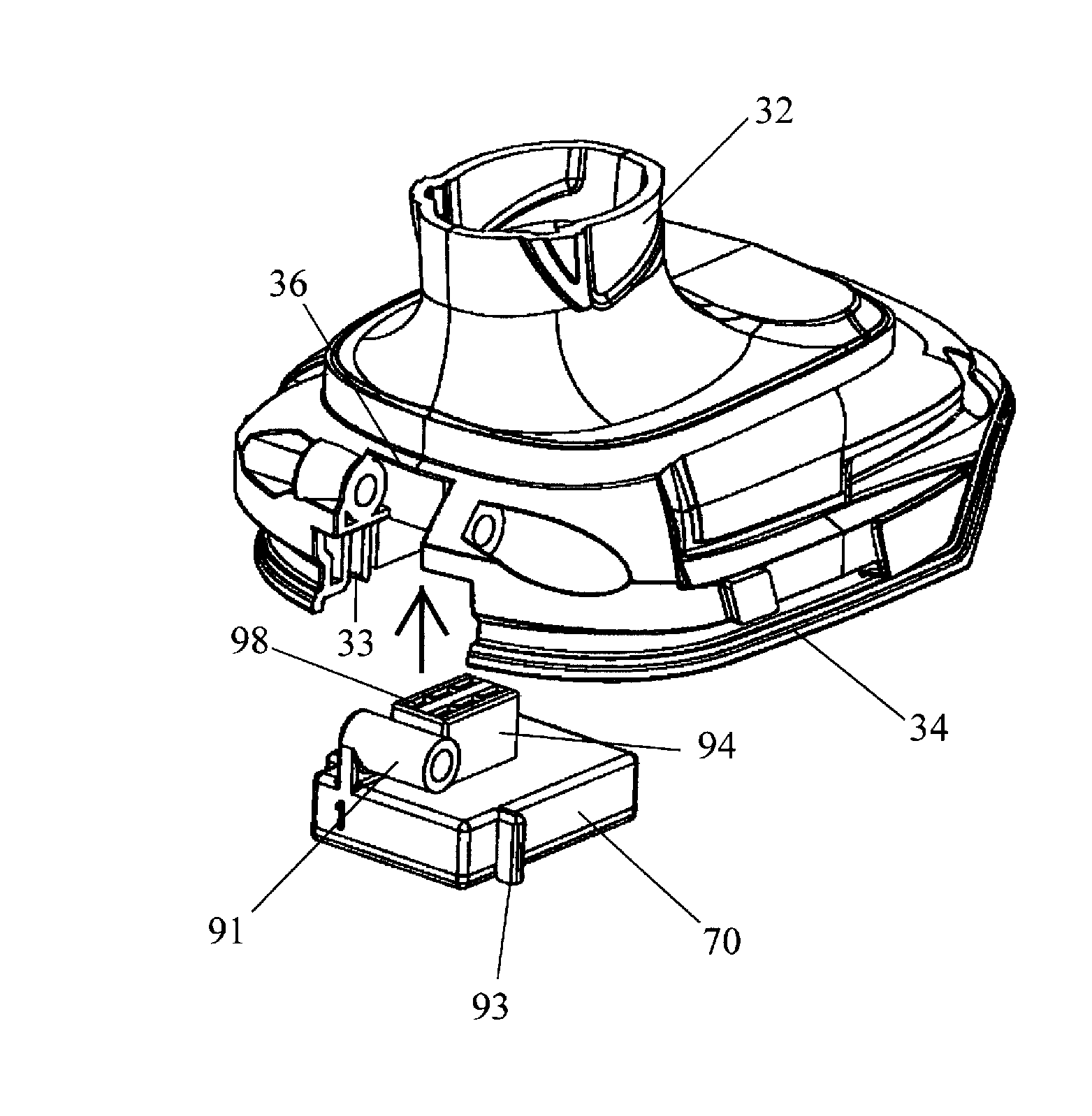

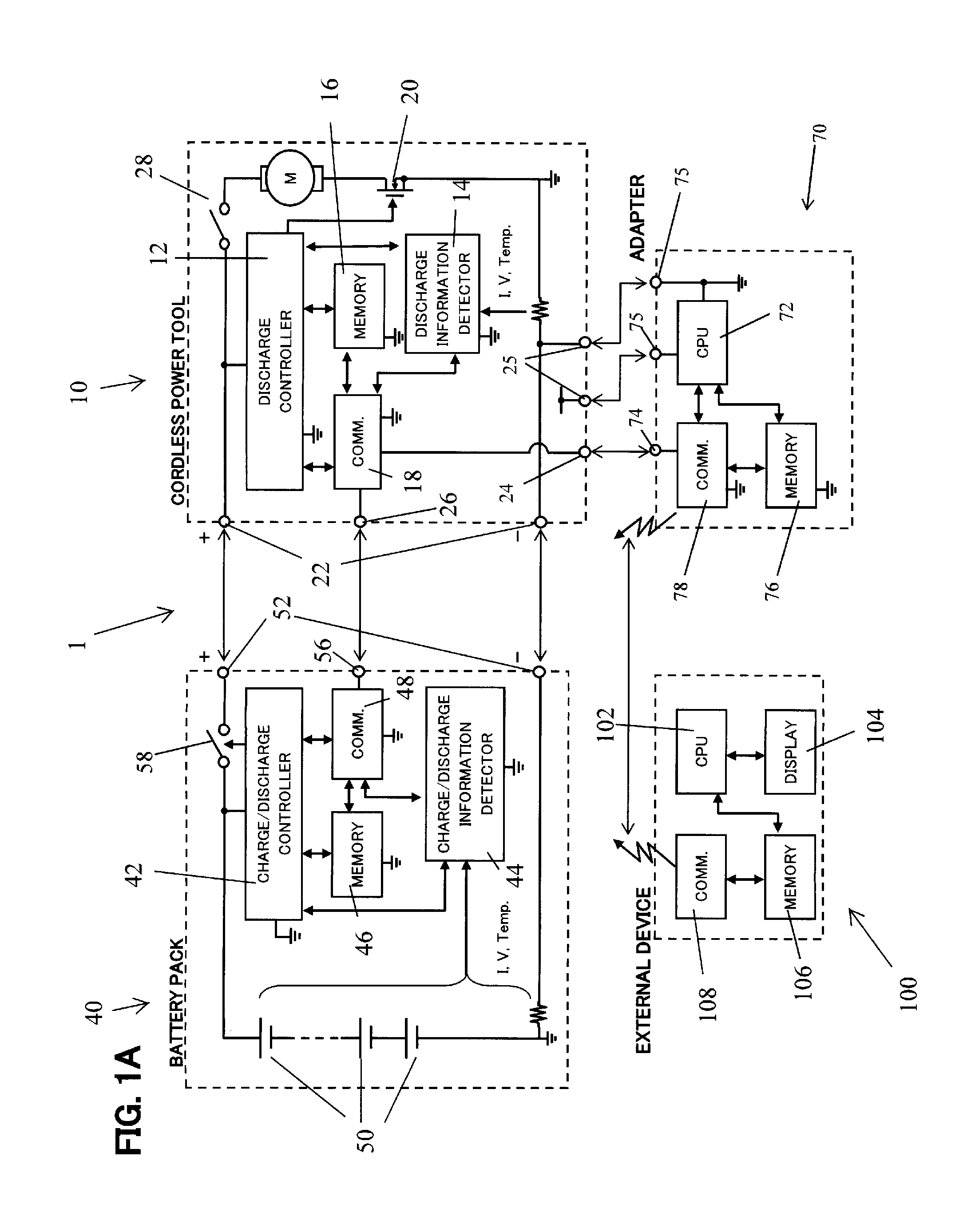

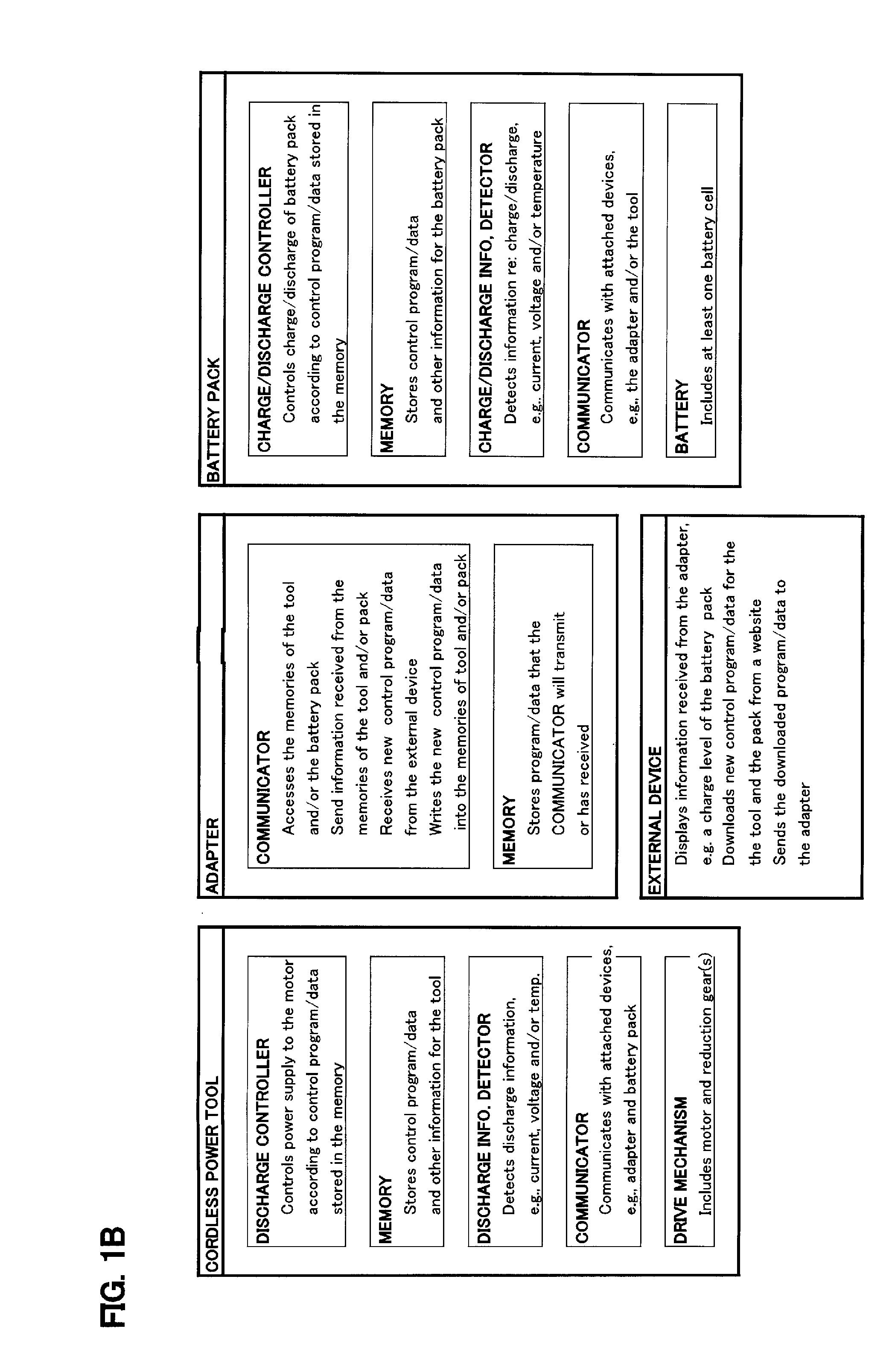

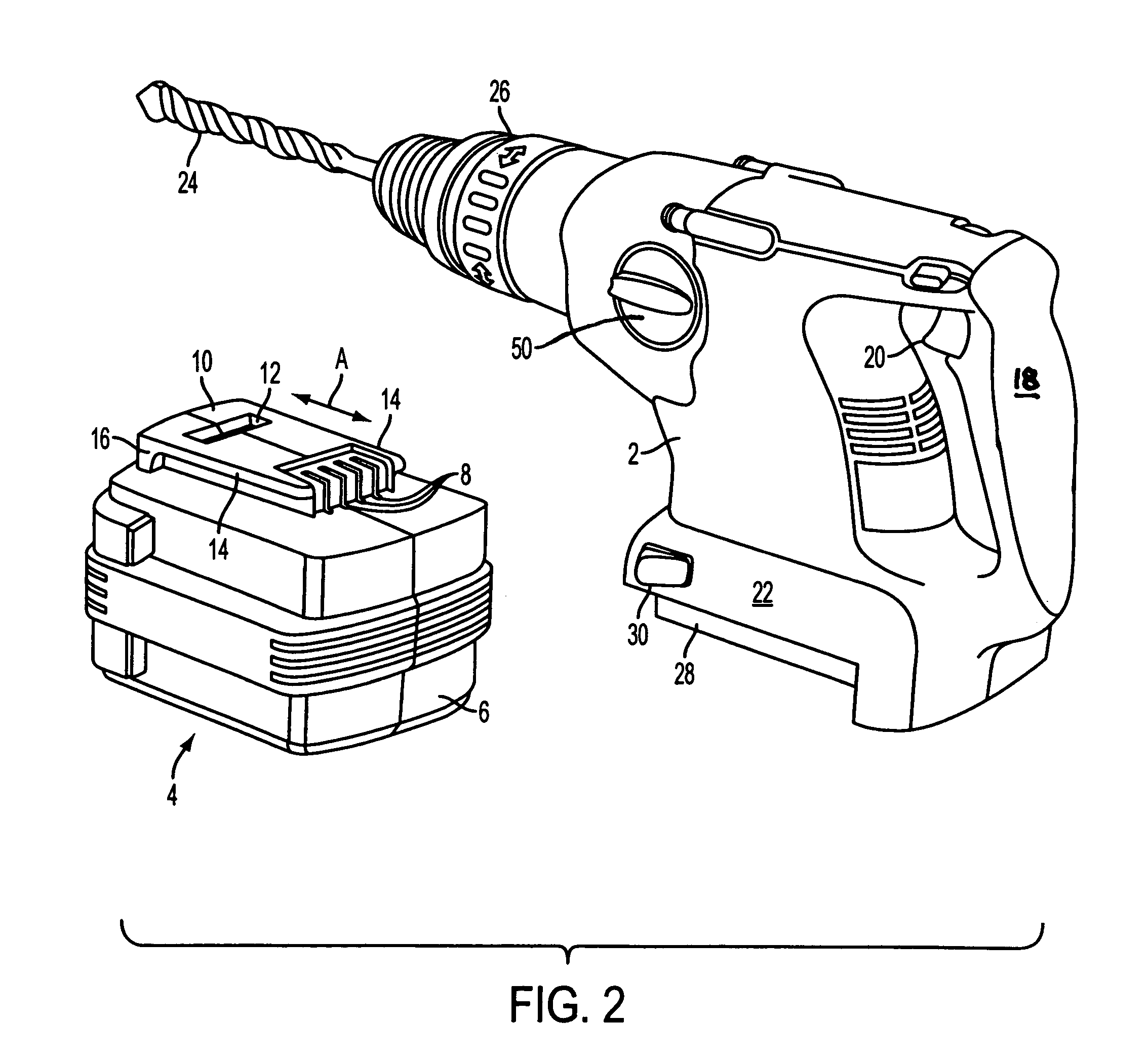

Power tool system and adapter therefor

InactiveUS20140151079A1Stable structureReadily dislodged from the power tool during operationBatteries circuit arrangementsTransmission systemsElectricityEngineering

A power tool system includes a hand-held power tool having a housing with a battery pack interface, an electrically-driven device and a first connector. A battery pack is detachably attached to the battery pack interface and supplies current to the electrically-driven device. An adapter has a second connector physically and electrically connected with the first connector in a detachable manner. The adapter receives power from the battery pack via the hand-held power tool and provides at least one additional electrical function to the hand-held power tool or performs at least one additional electrical function that the hand-held power tool is not otherwise capable of performing. Further, the adapter is at least partially disposed in a space defined in part by the housing and in part by the battery pack when the housing and battery pack are attached to each other.

Owner:MAKITA CORP

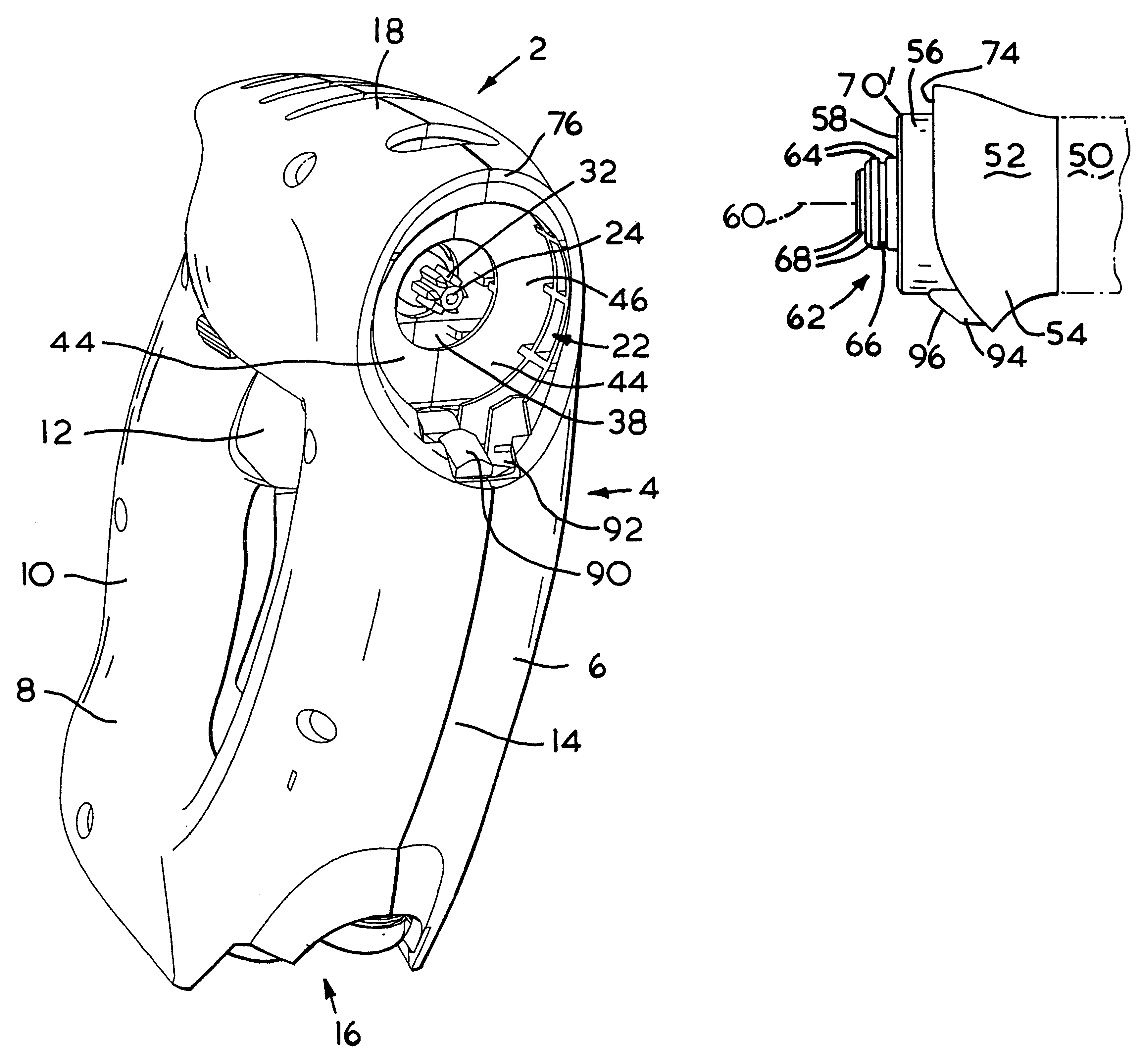

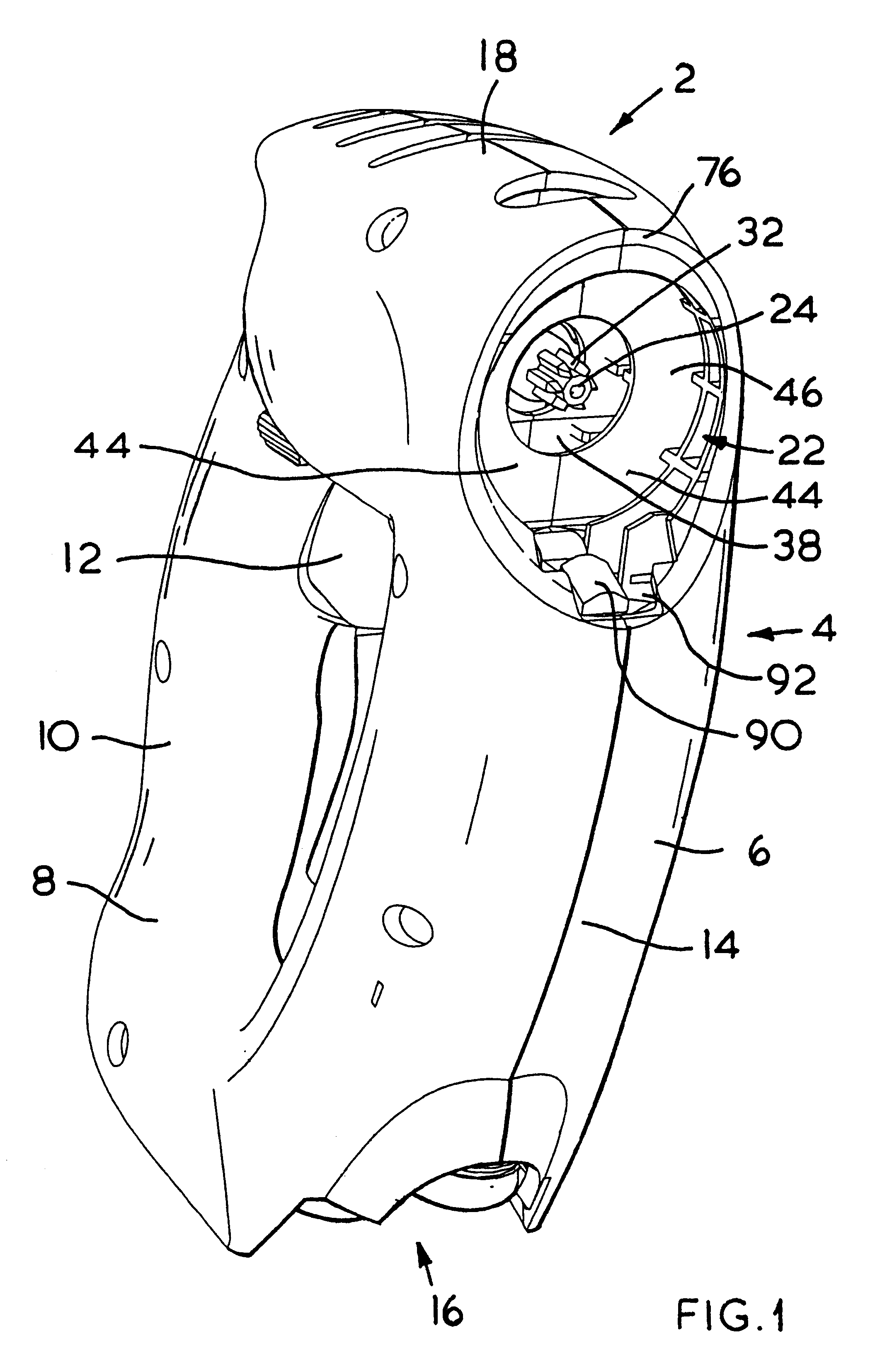

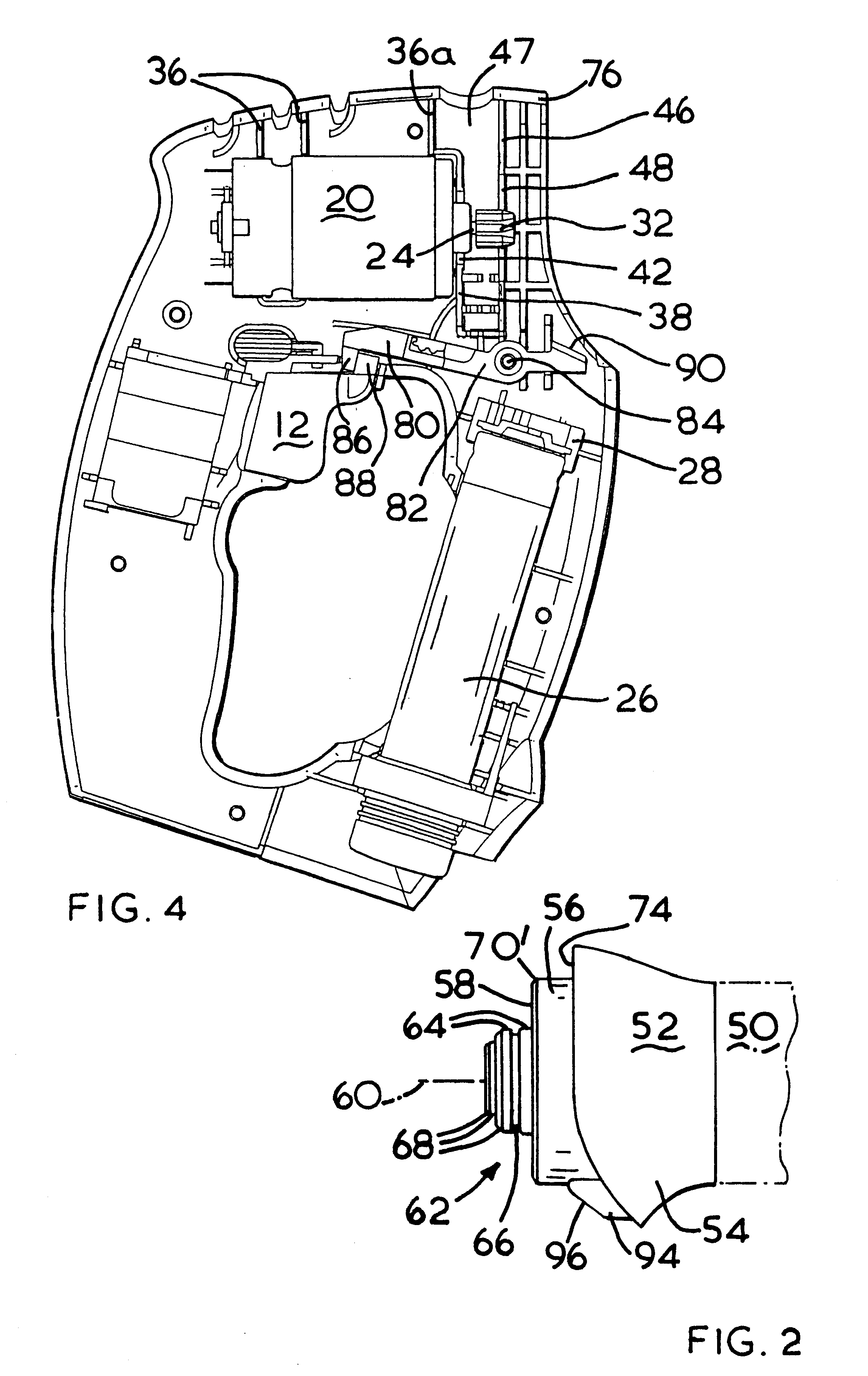

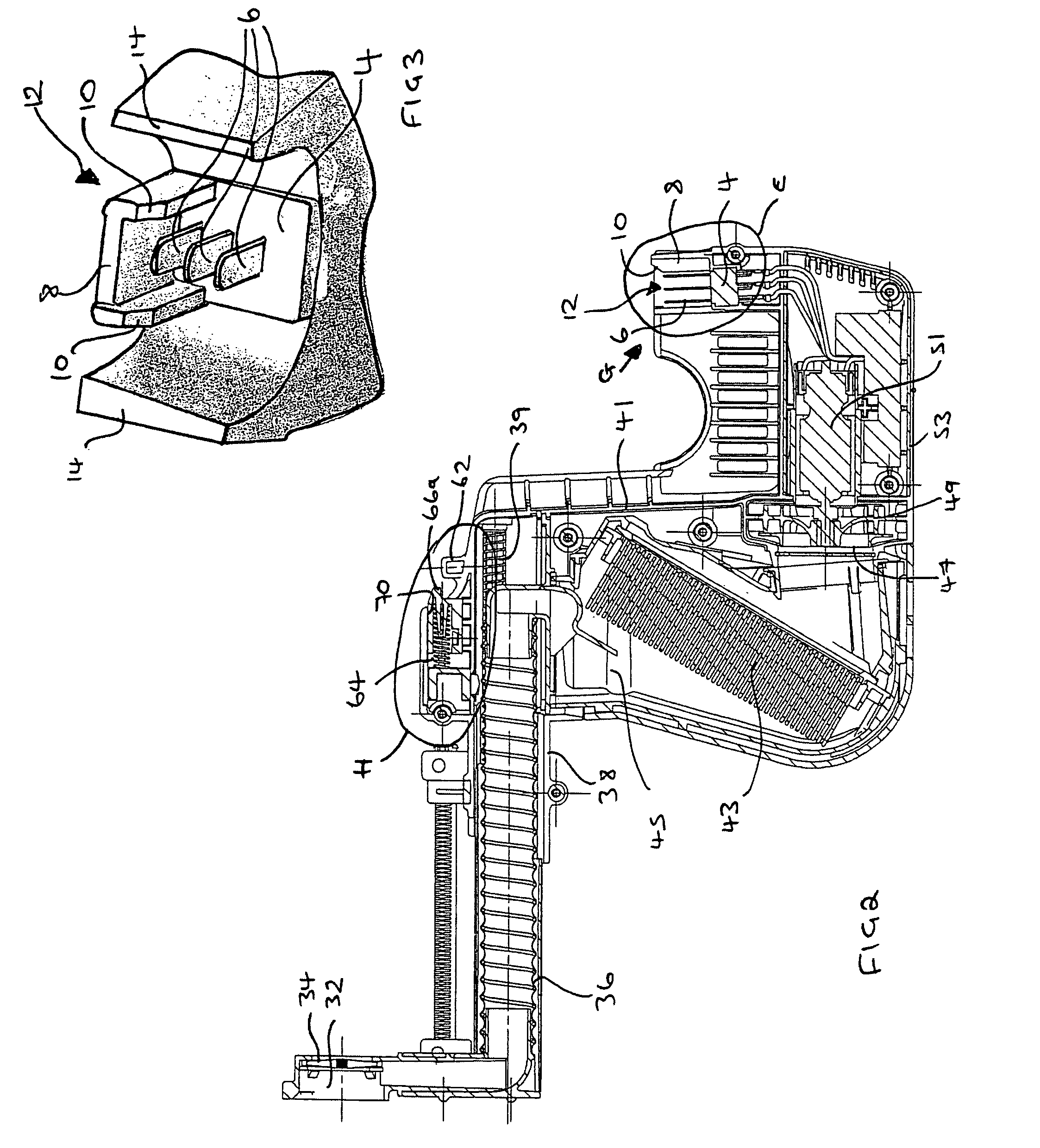

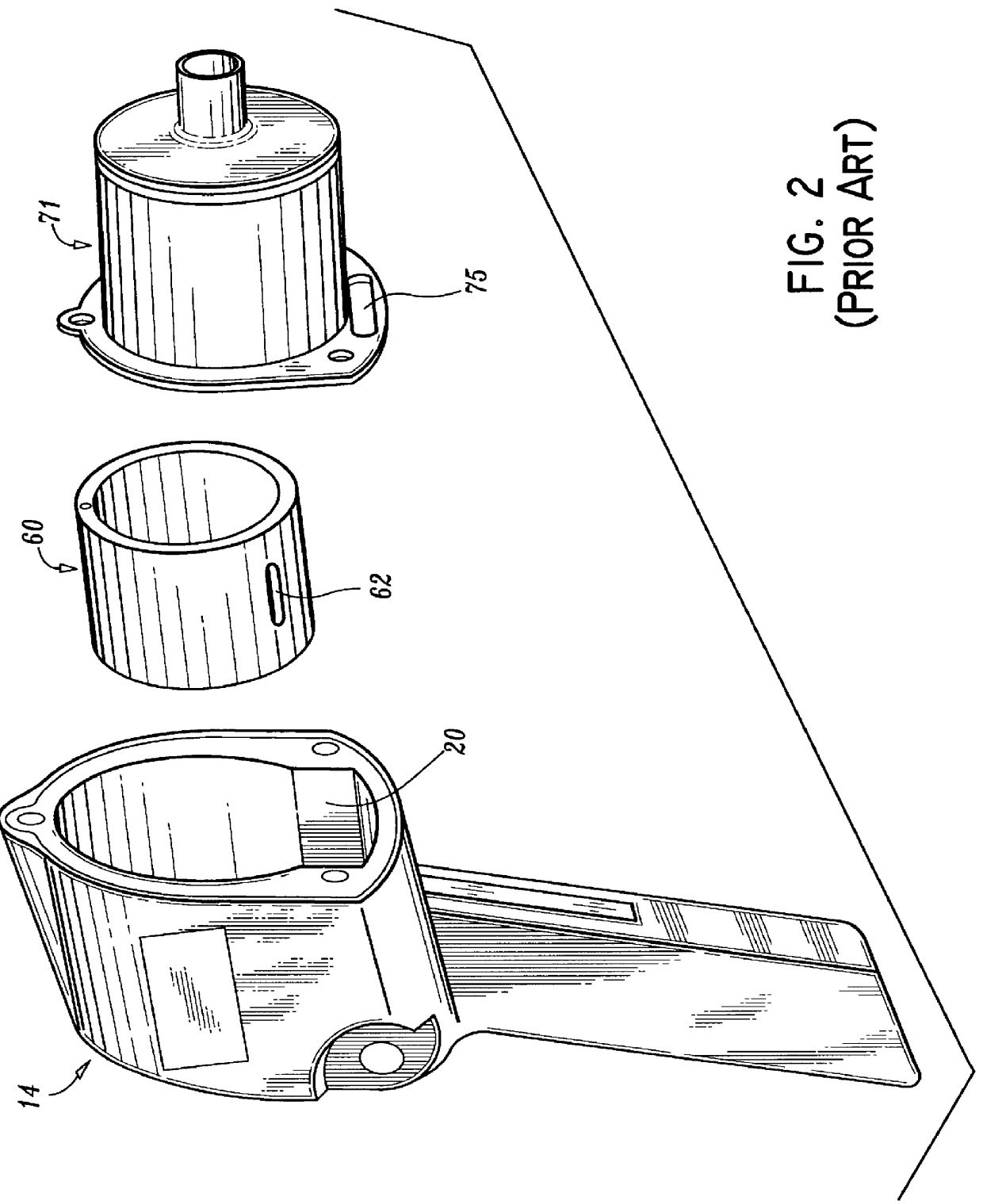

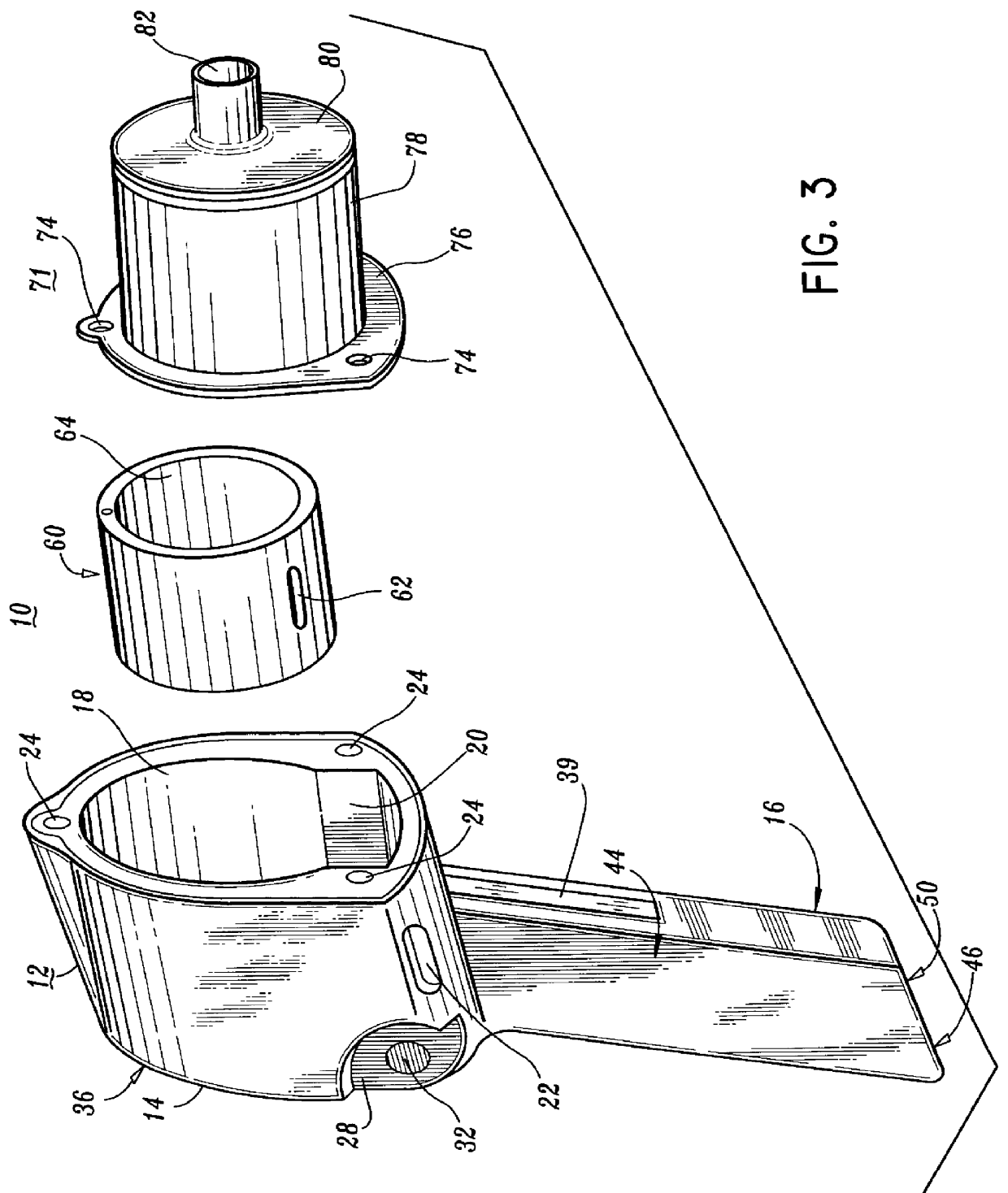

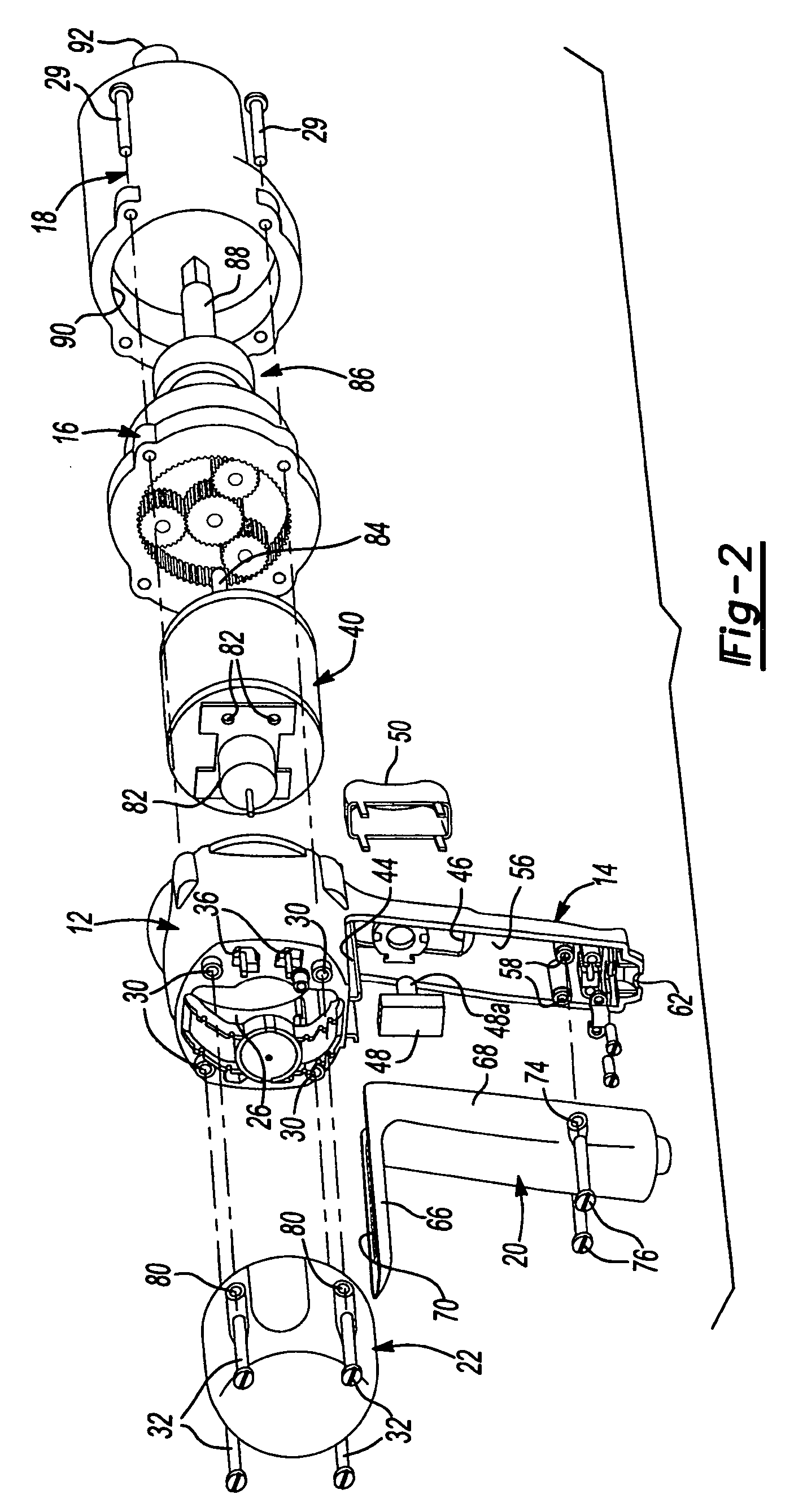

Power tool having interchangeable tool head

A power tool comprises a body (14) having a motor (22) with an output. A detachable tool head (50) is engageable with the motor output wherein the motor output has a first engagement member (32) for complimentary engagement with a second engagement member (62) on the tool head drive. The first engagement member (32) is recessed within the body (14) and accessible through an aperture (44) therein. And the second engagement member (62) is recessed within the tool head (52) and accessible through a second aperture therewithin.

Owner:BLACK & DECKER INC

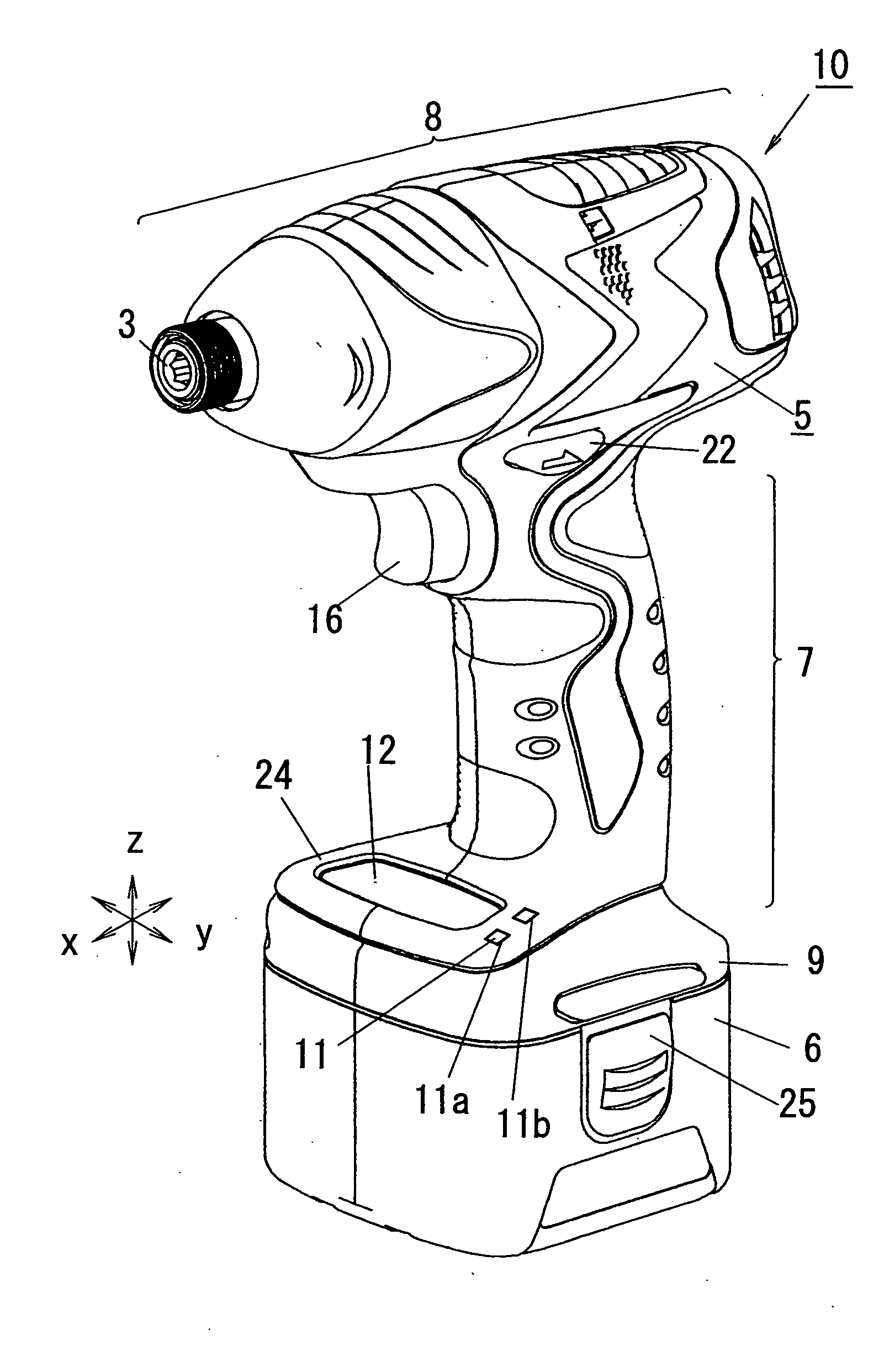

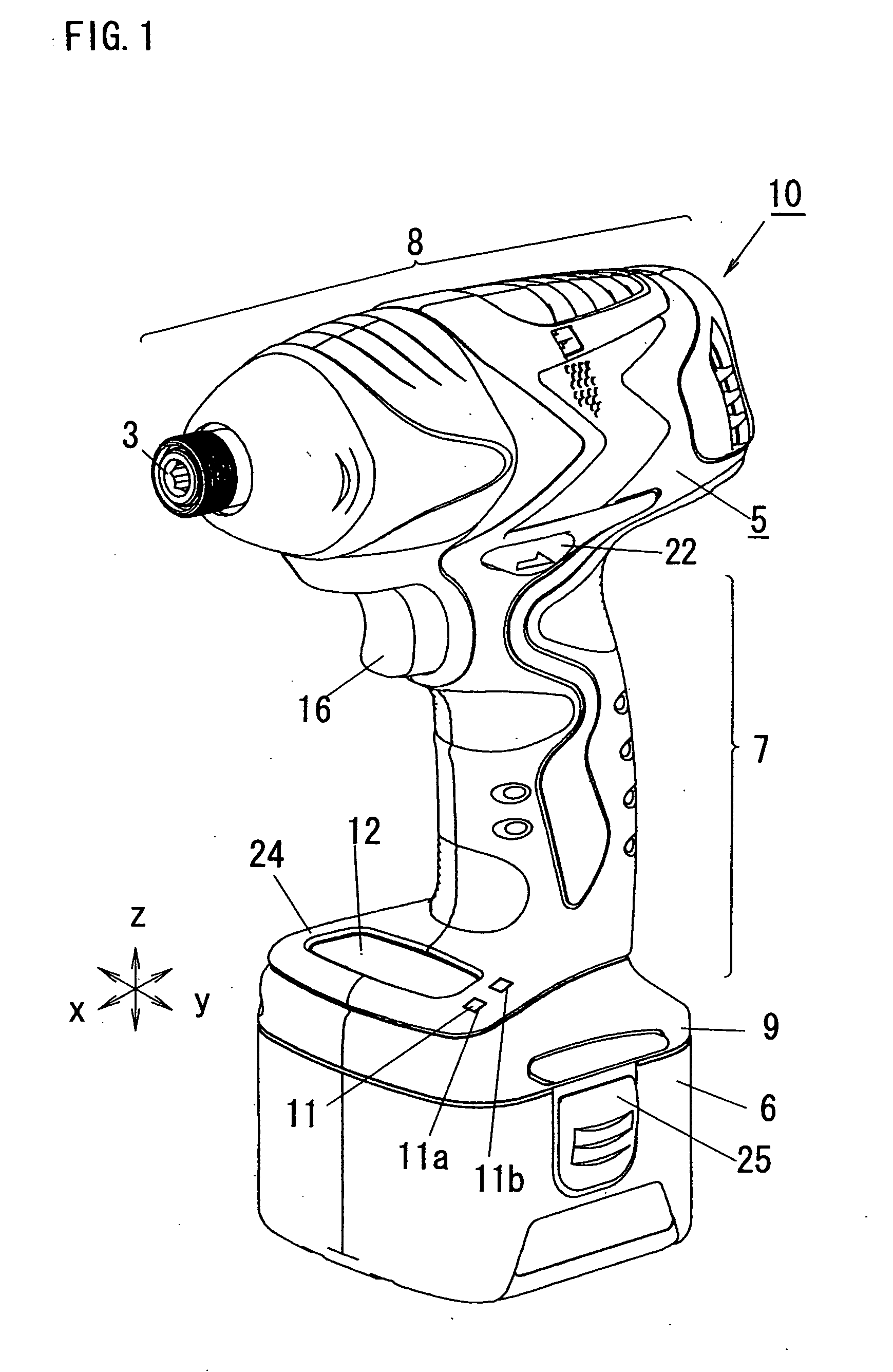

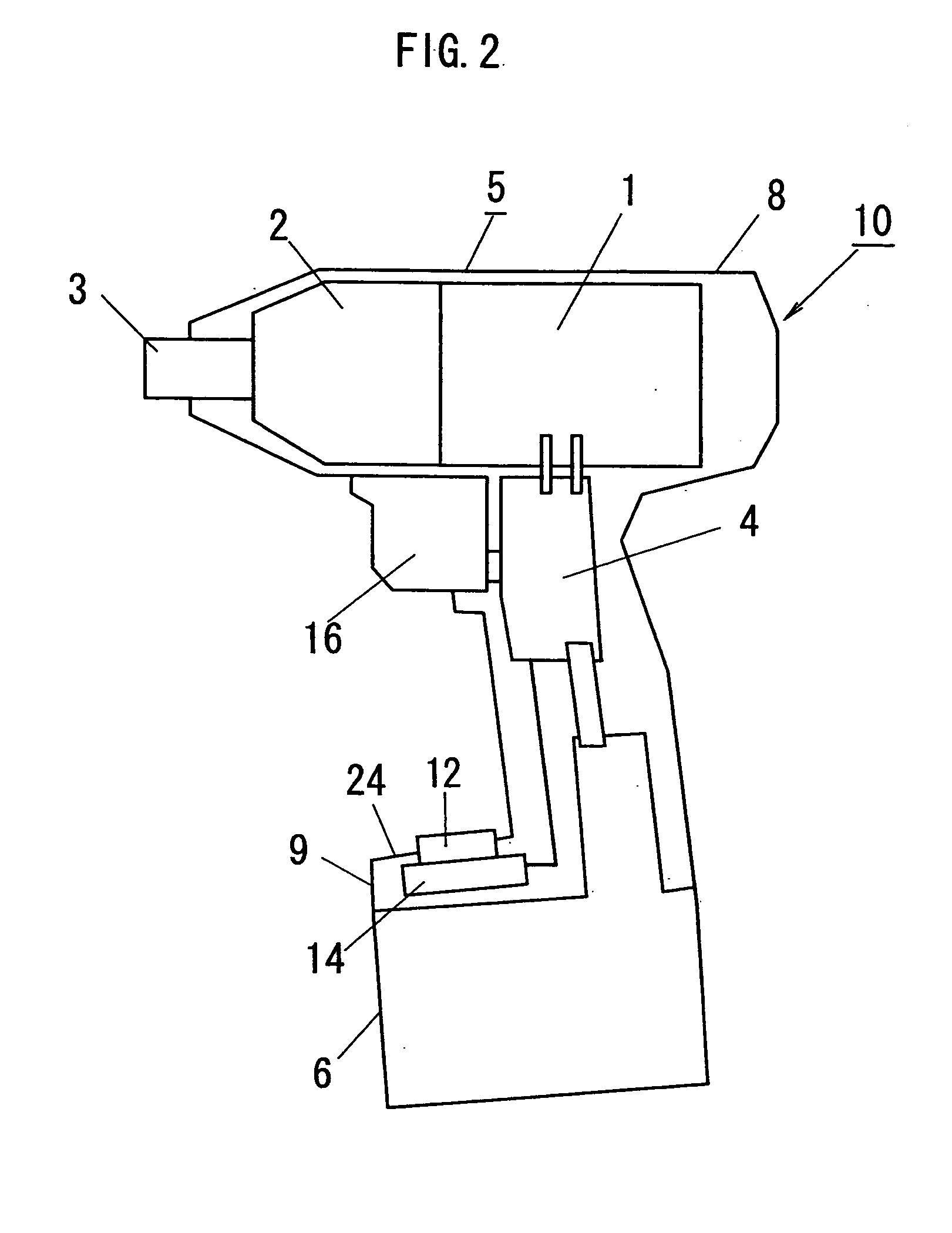

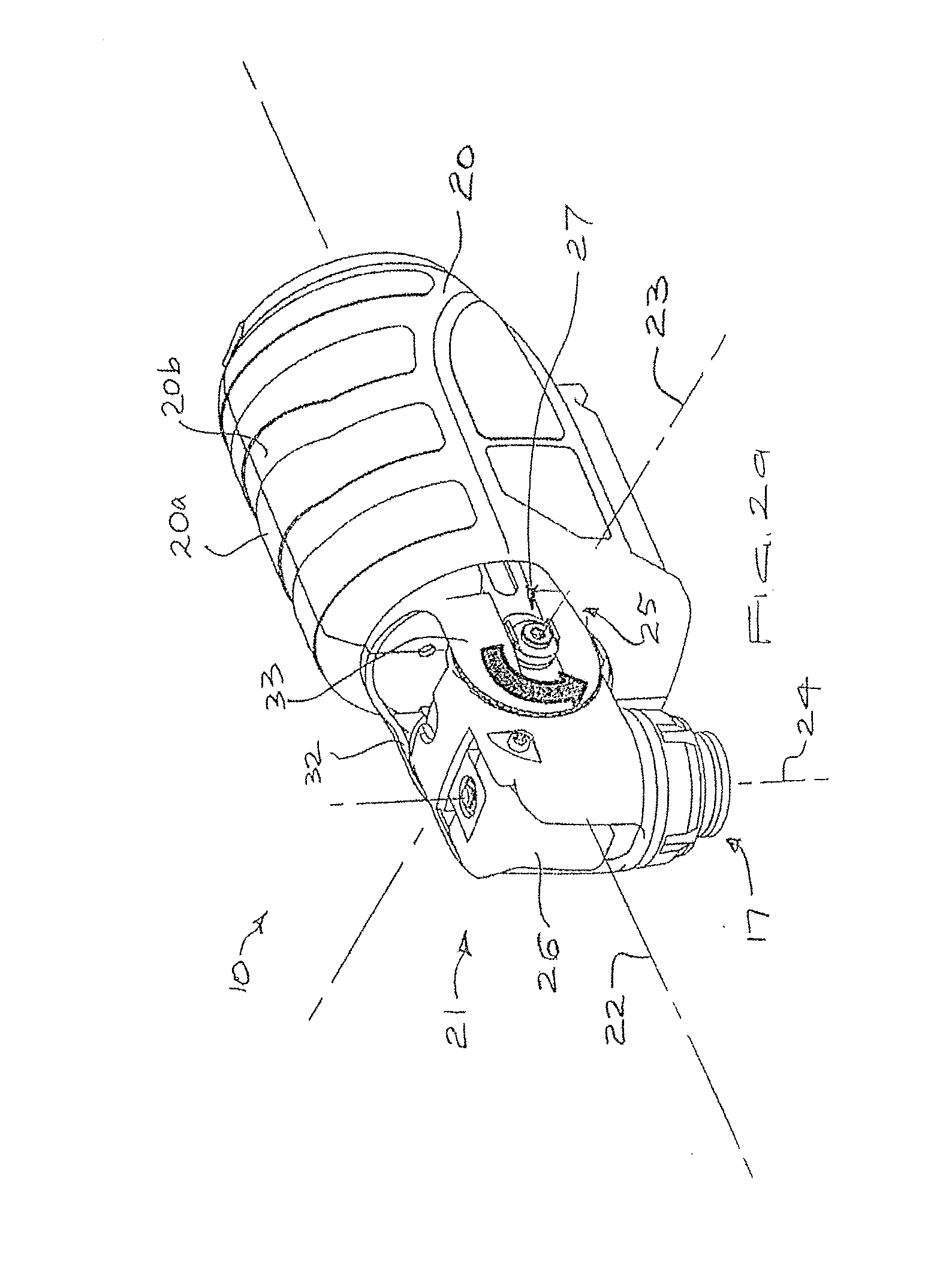

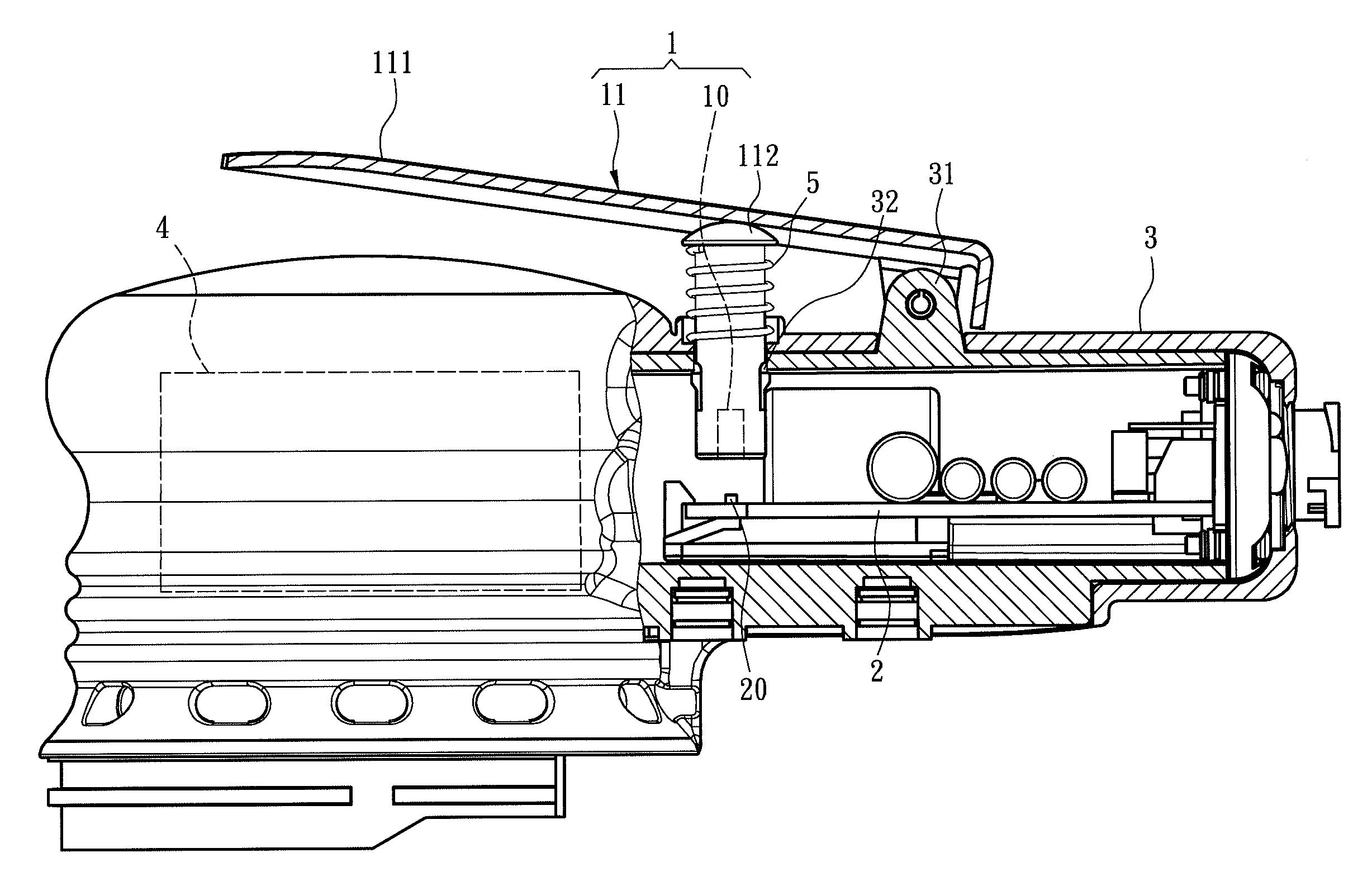

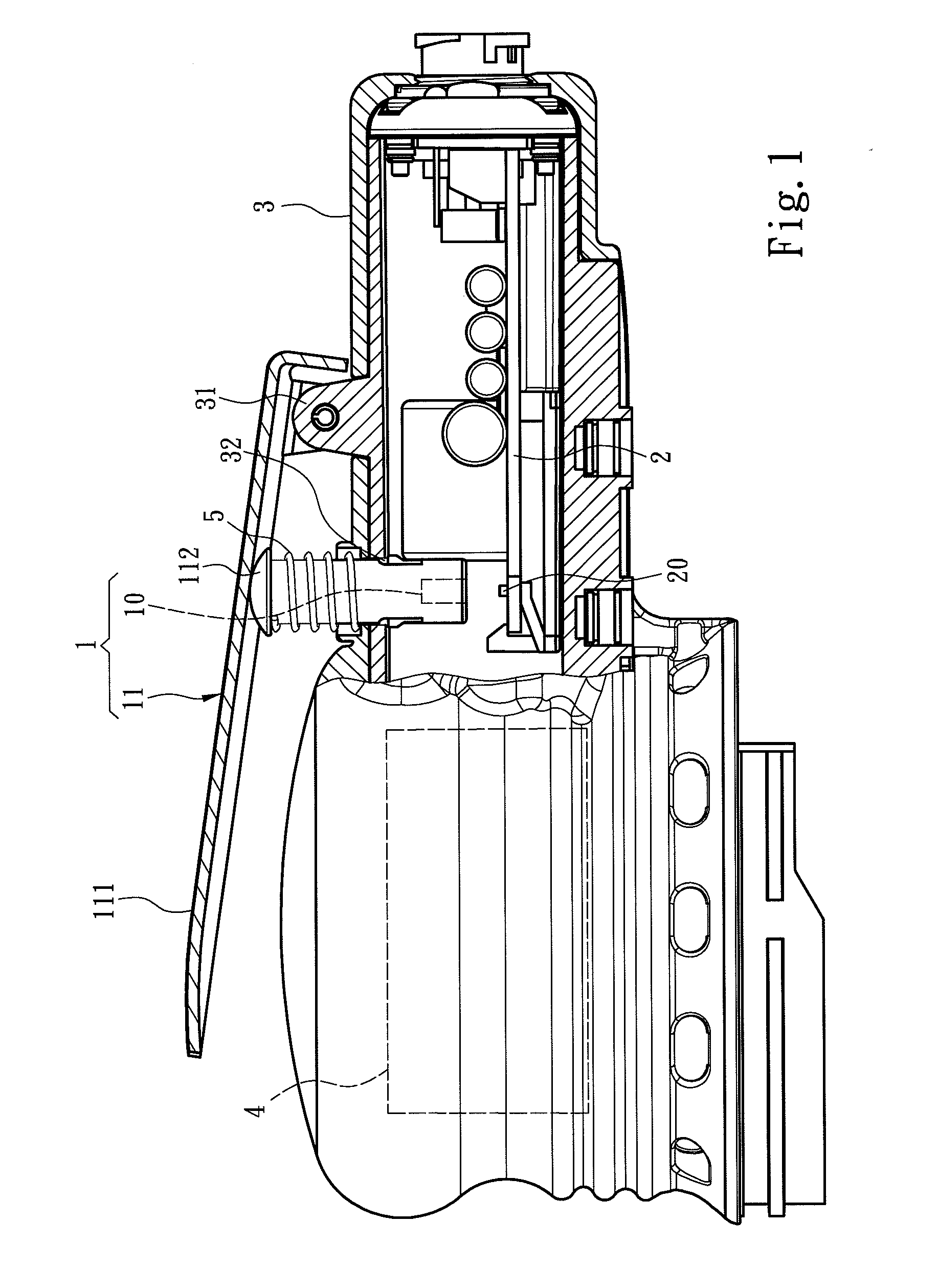

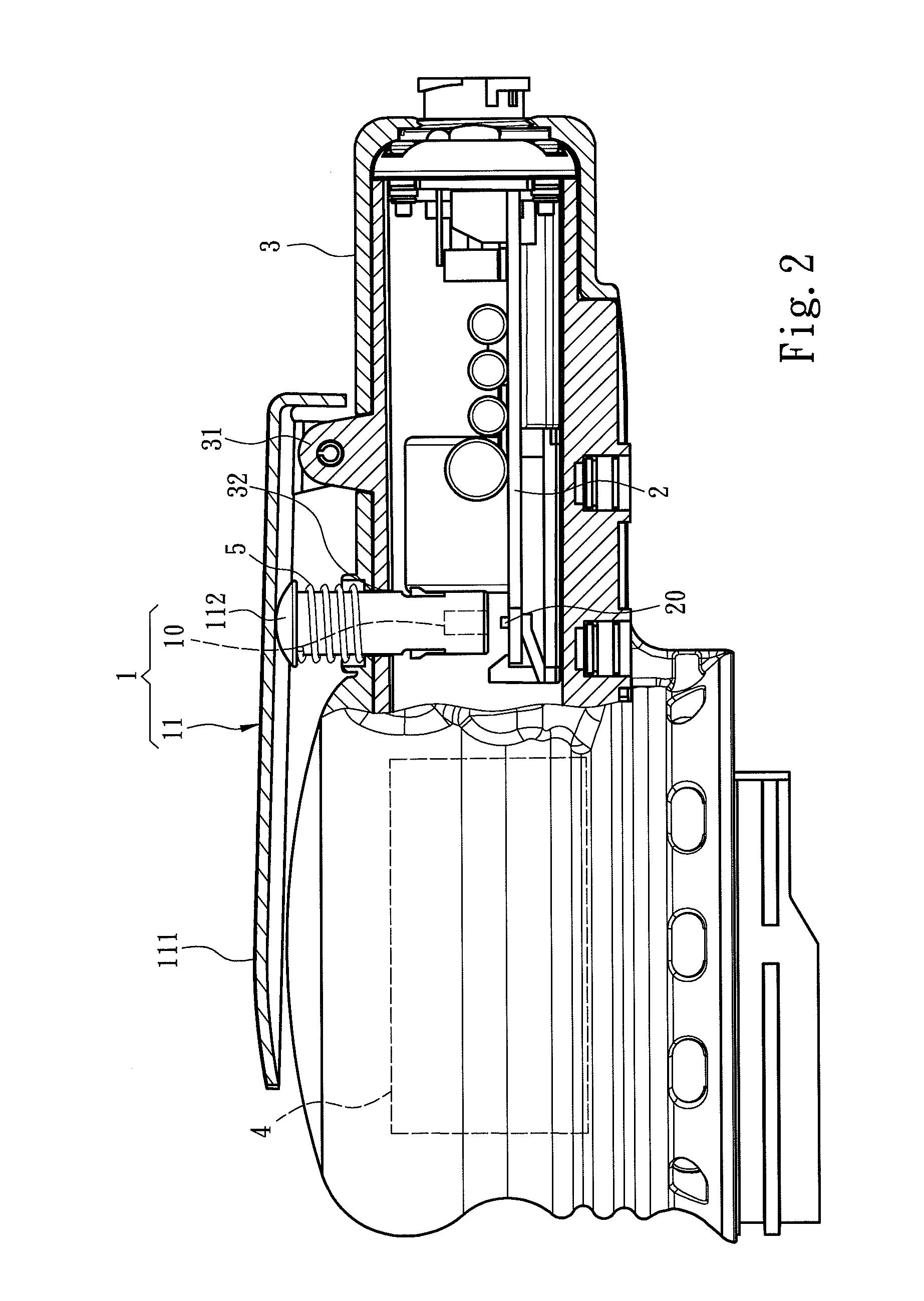

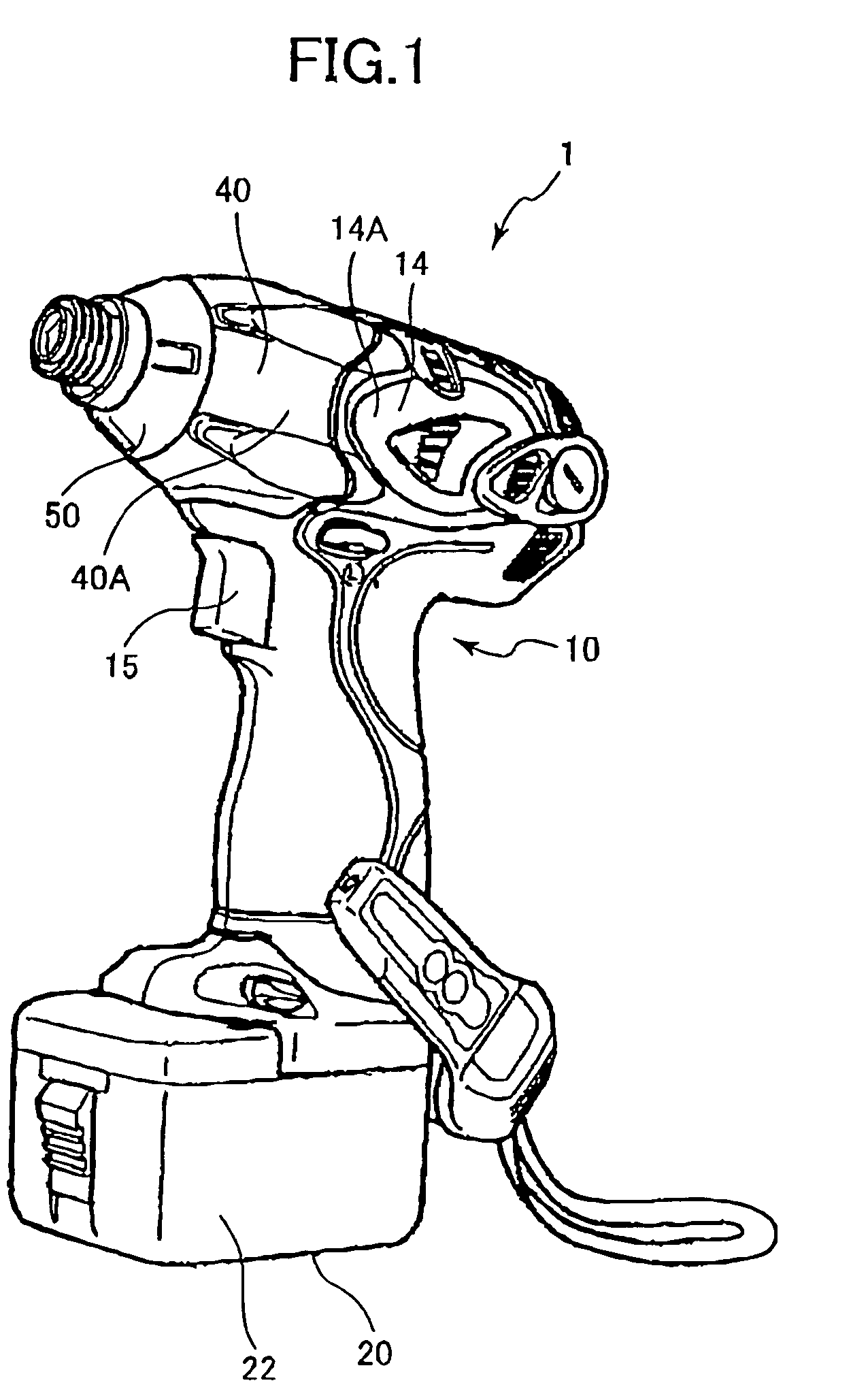

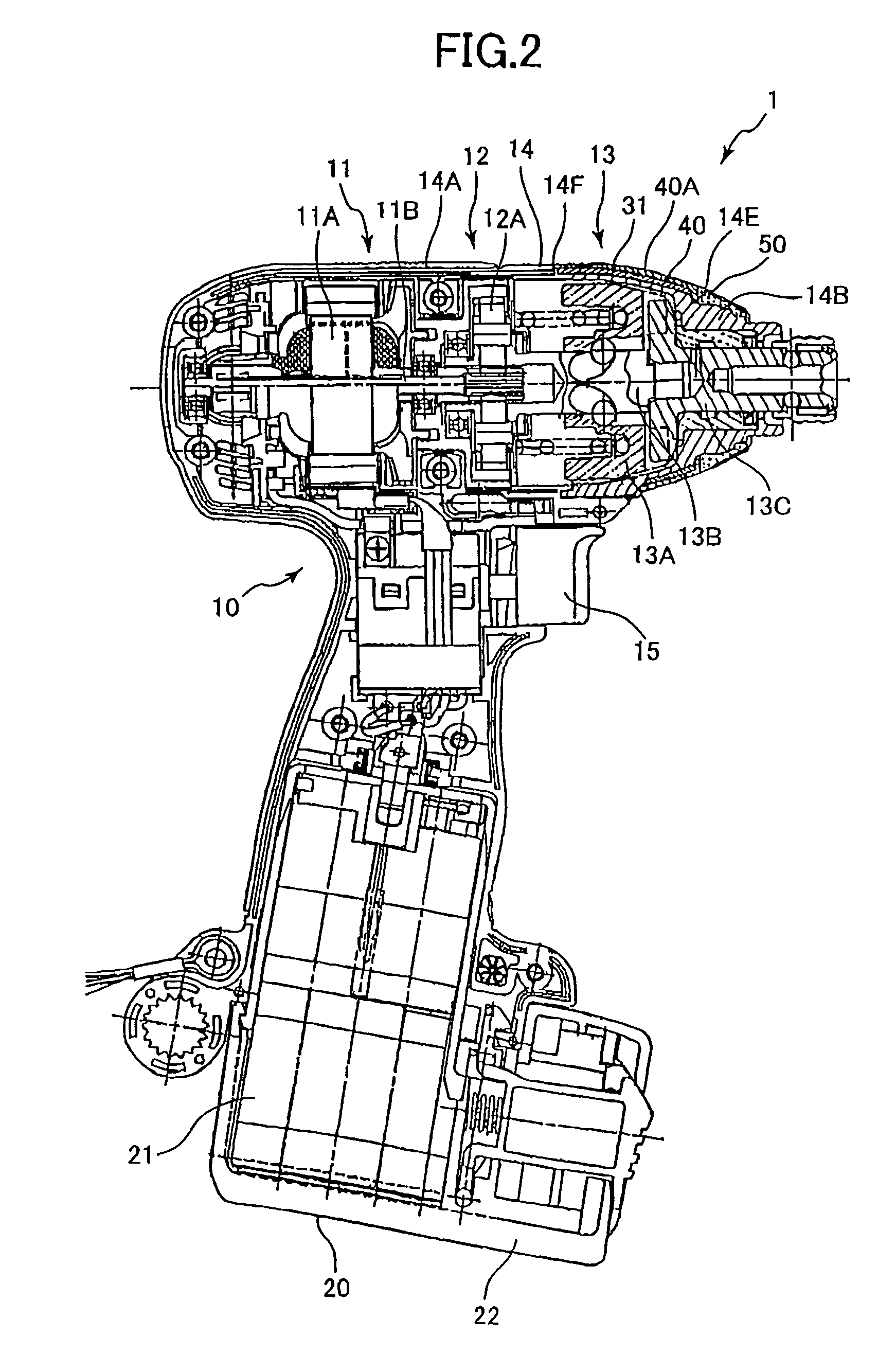

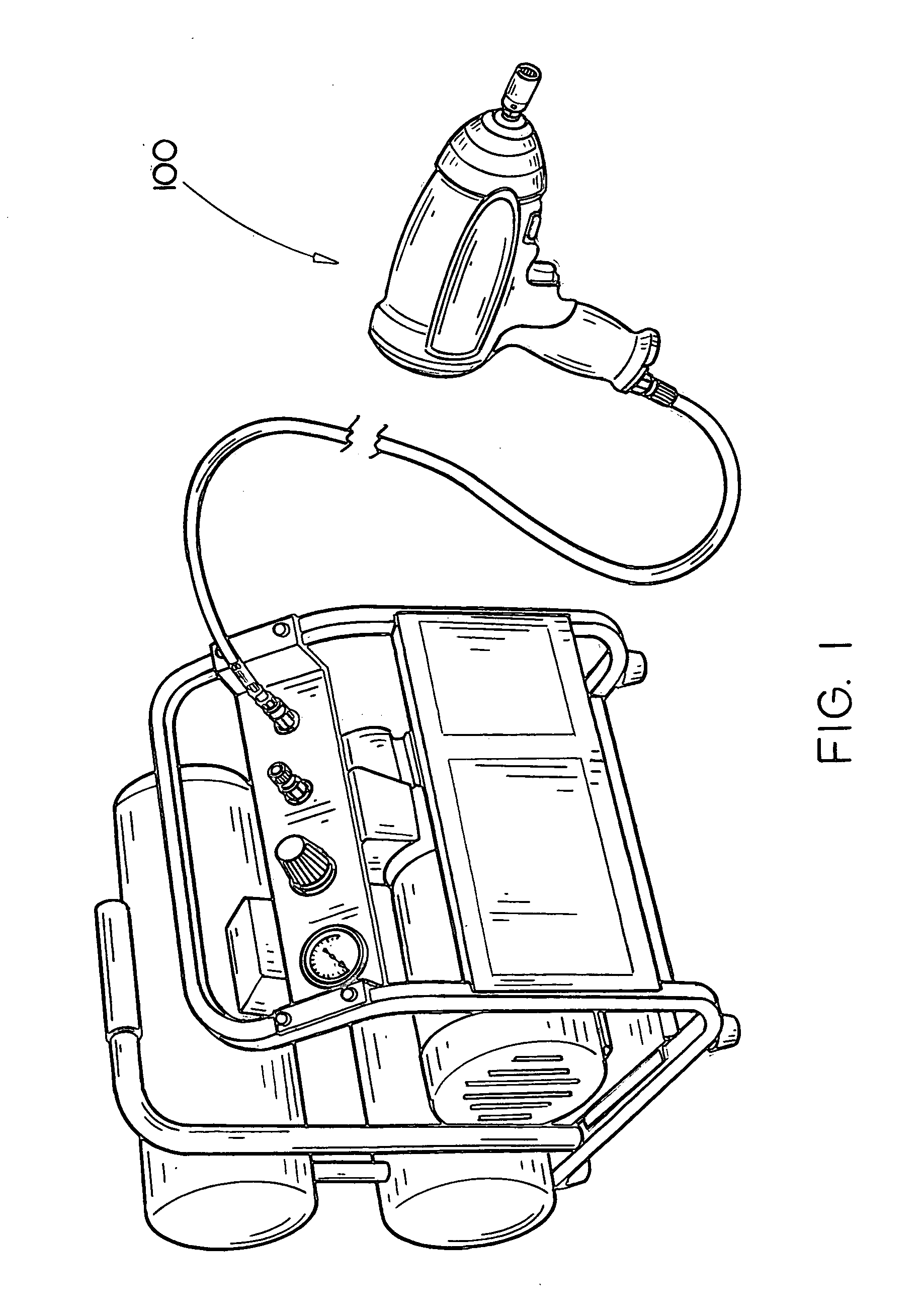

Transportable power tool

InactiveUS20050121209A1Low costEasy to useDrilling rodsConstructionsMaximum dimensionReduction drive

A transportable power tool such as an impact driver has a power unit in which a motor and a reducer-transmitter are contained, a grip and a coupler unit with which a battery pack is coupled. Maximum dimensions of the power unit and maximum dimensions of the battery pack in a direction perpendicular to both of center axes of the power unit and the grip and in a direction parallel to the center axis of the power unit are larger than those of the grip in the same directions. Operation members used for selecting an operation mode of the motor and a display device are provided at positions near to the grip from a line binding contacting portions of the power unit and the battery pack when the power unit and the battery pack are simultaneously contacted with the same plane in each state.

Owner:MATSUSHITA ELECTRIC WORKS LTD

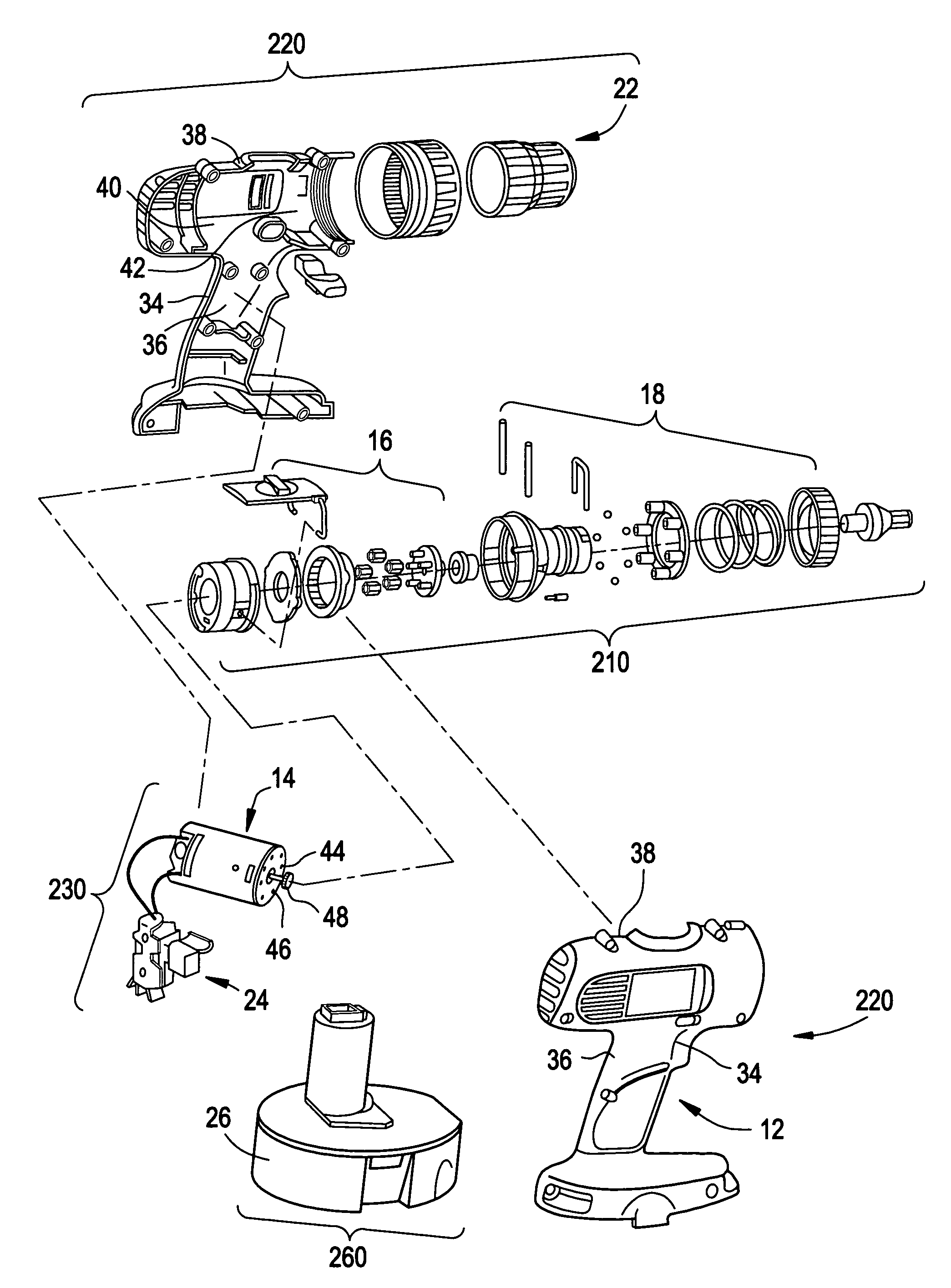

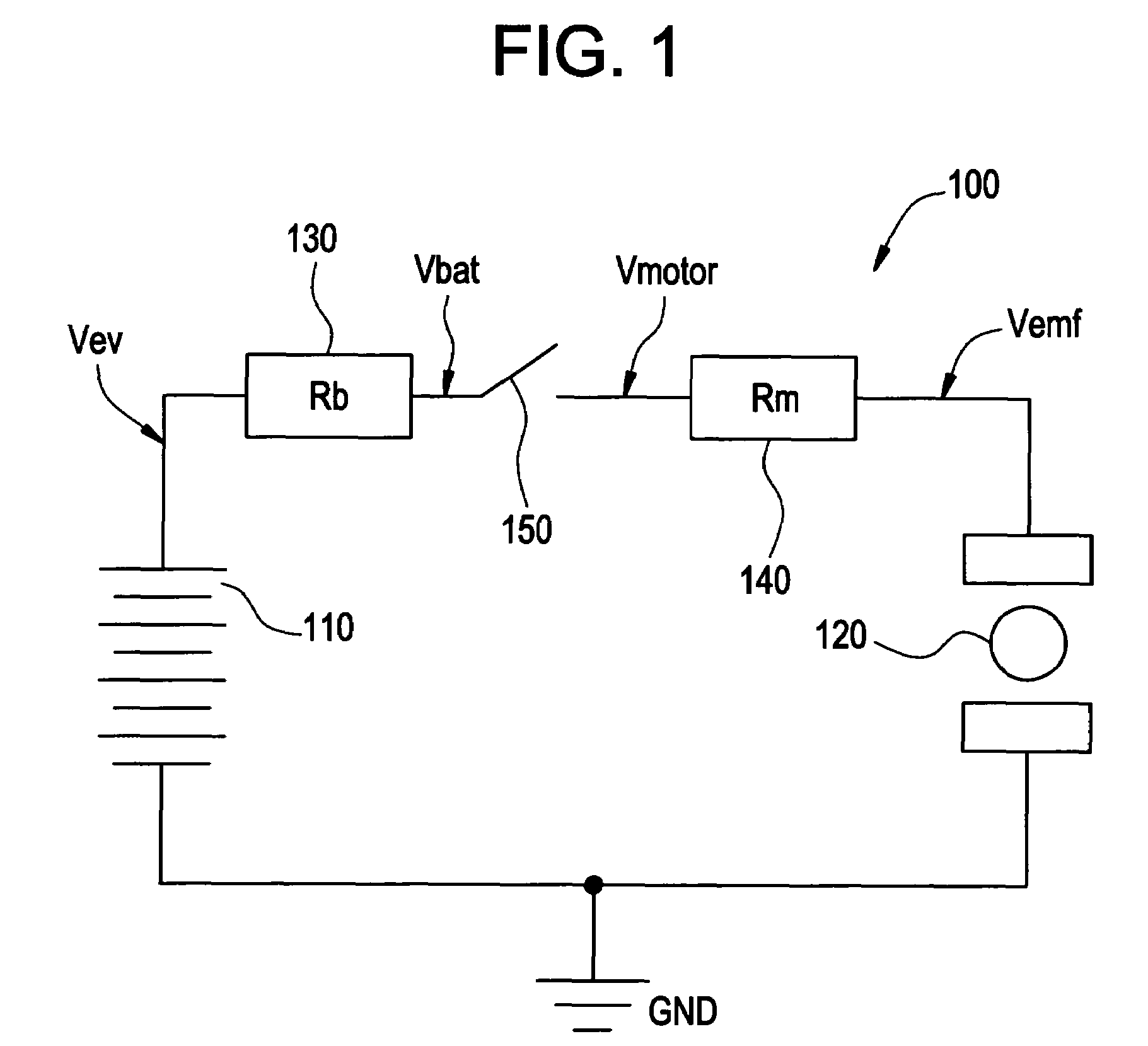

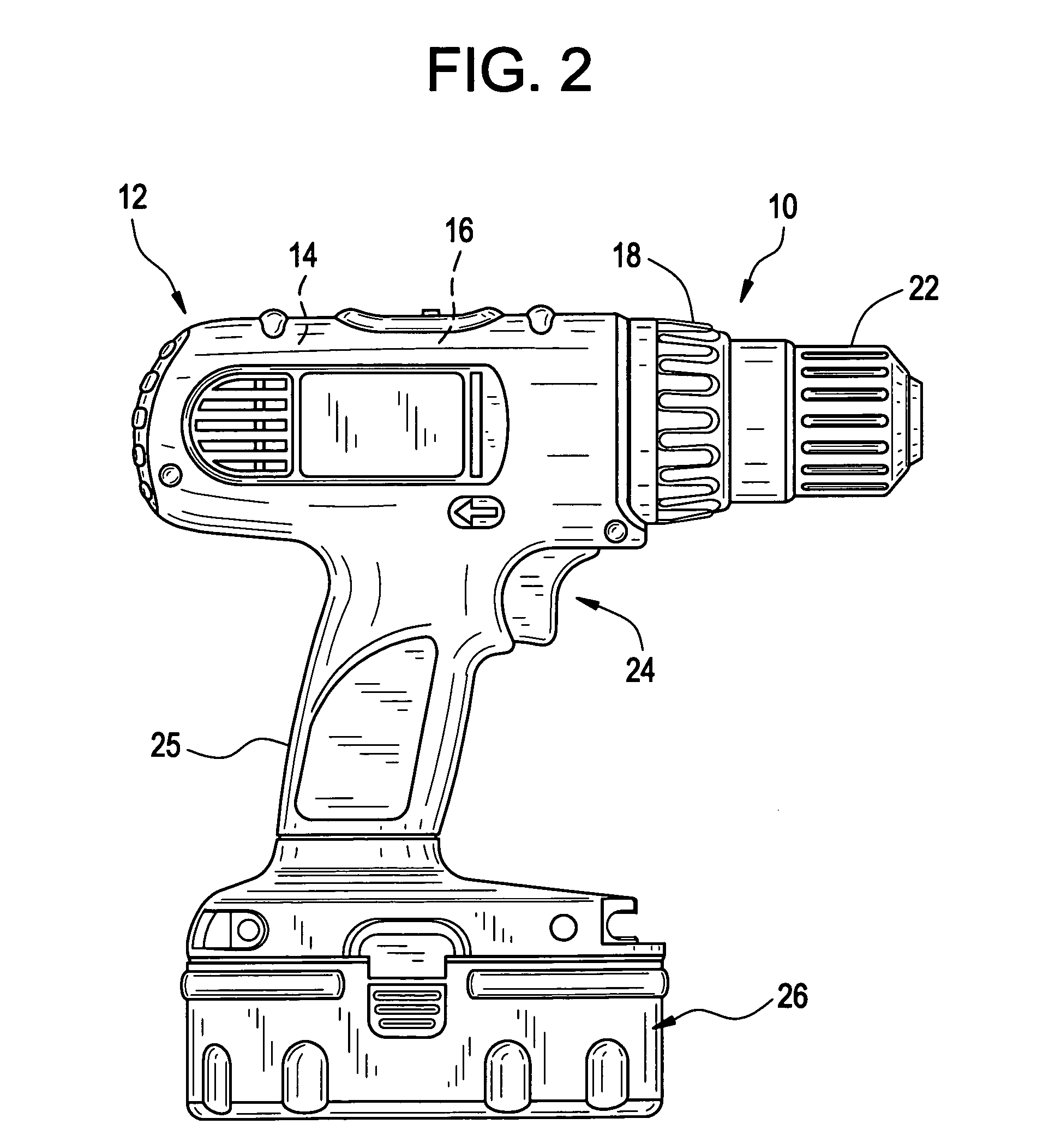

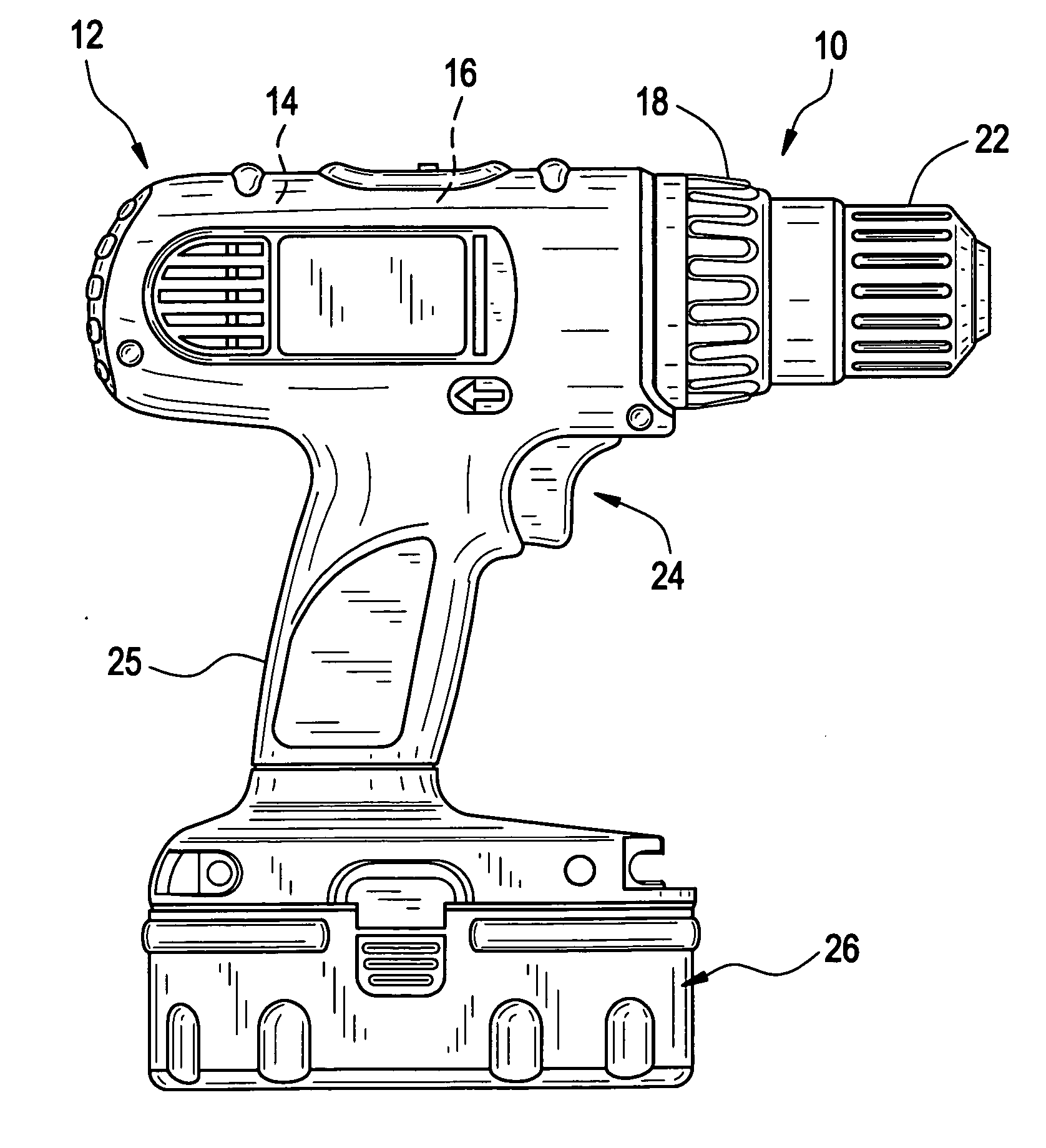

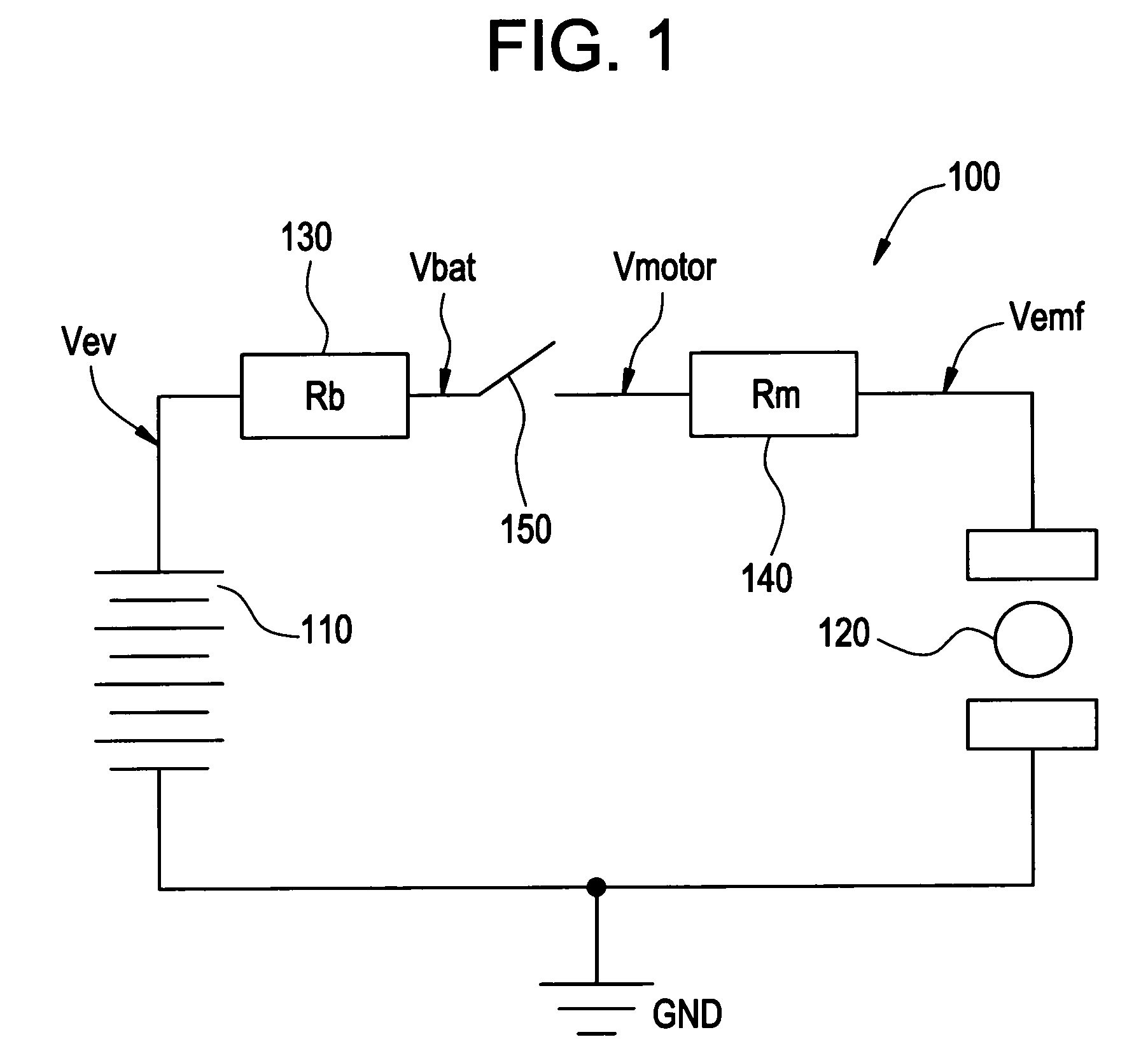

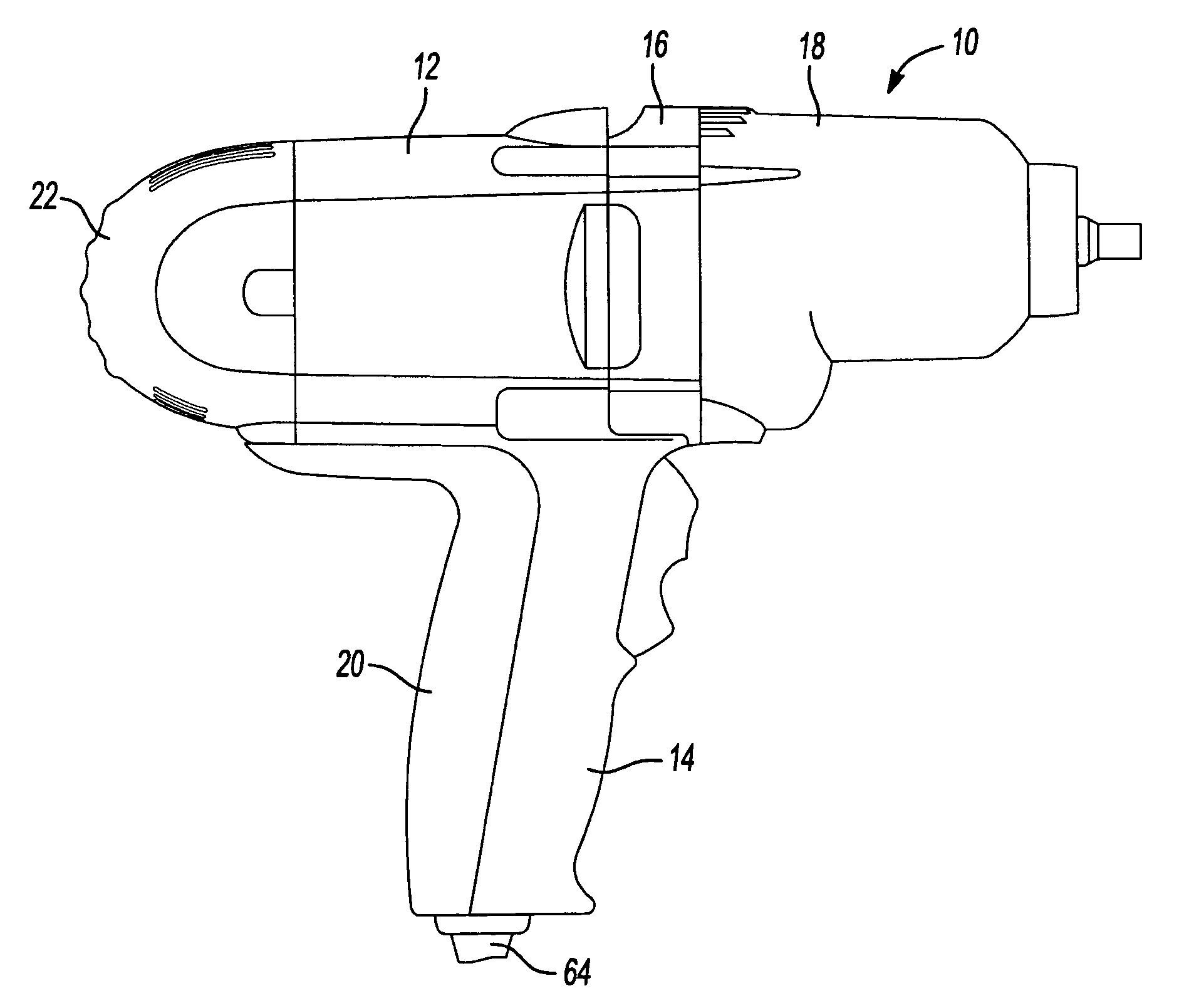

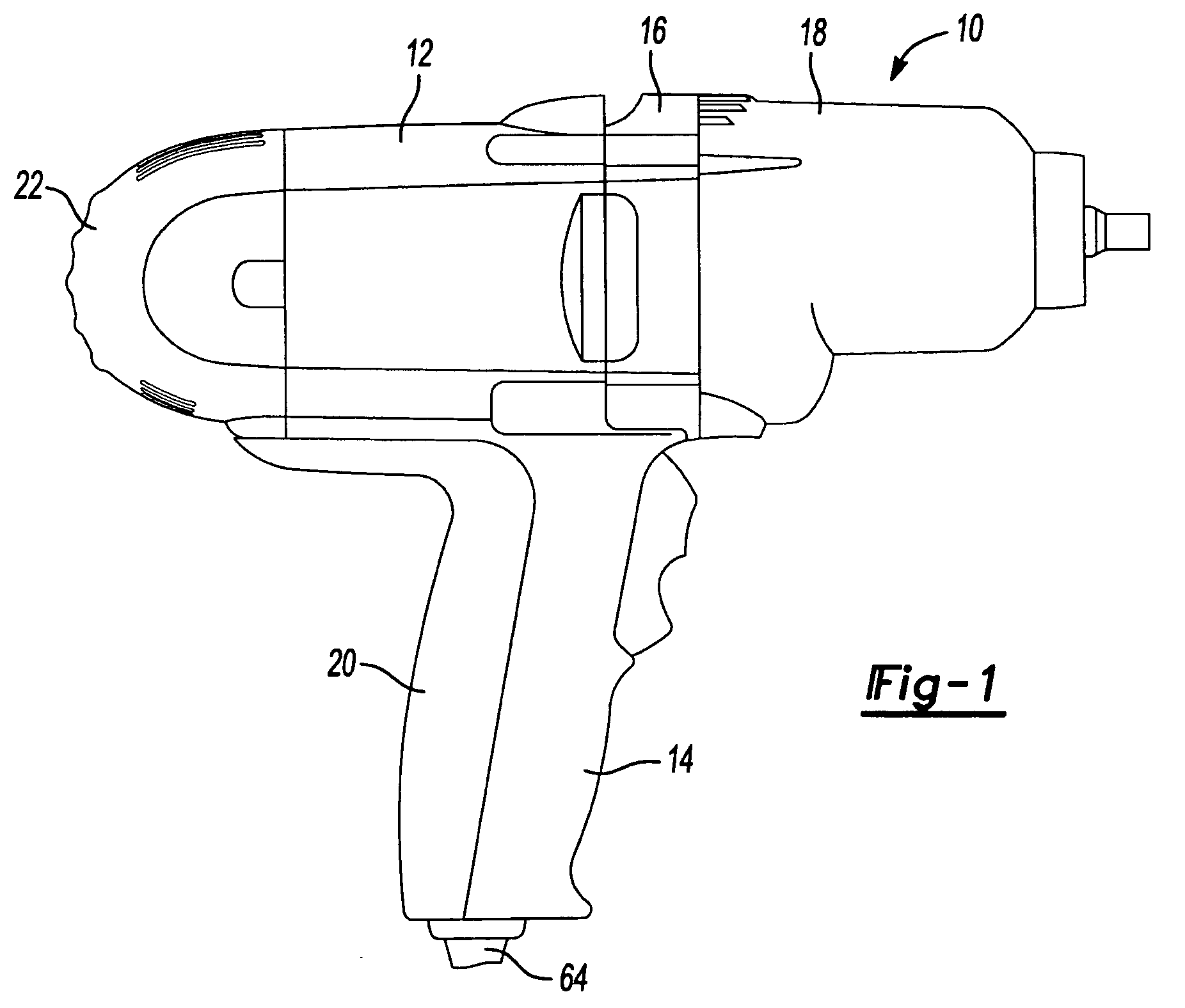

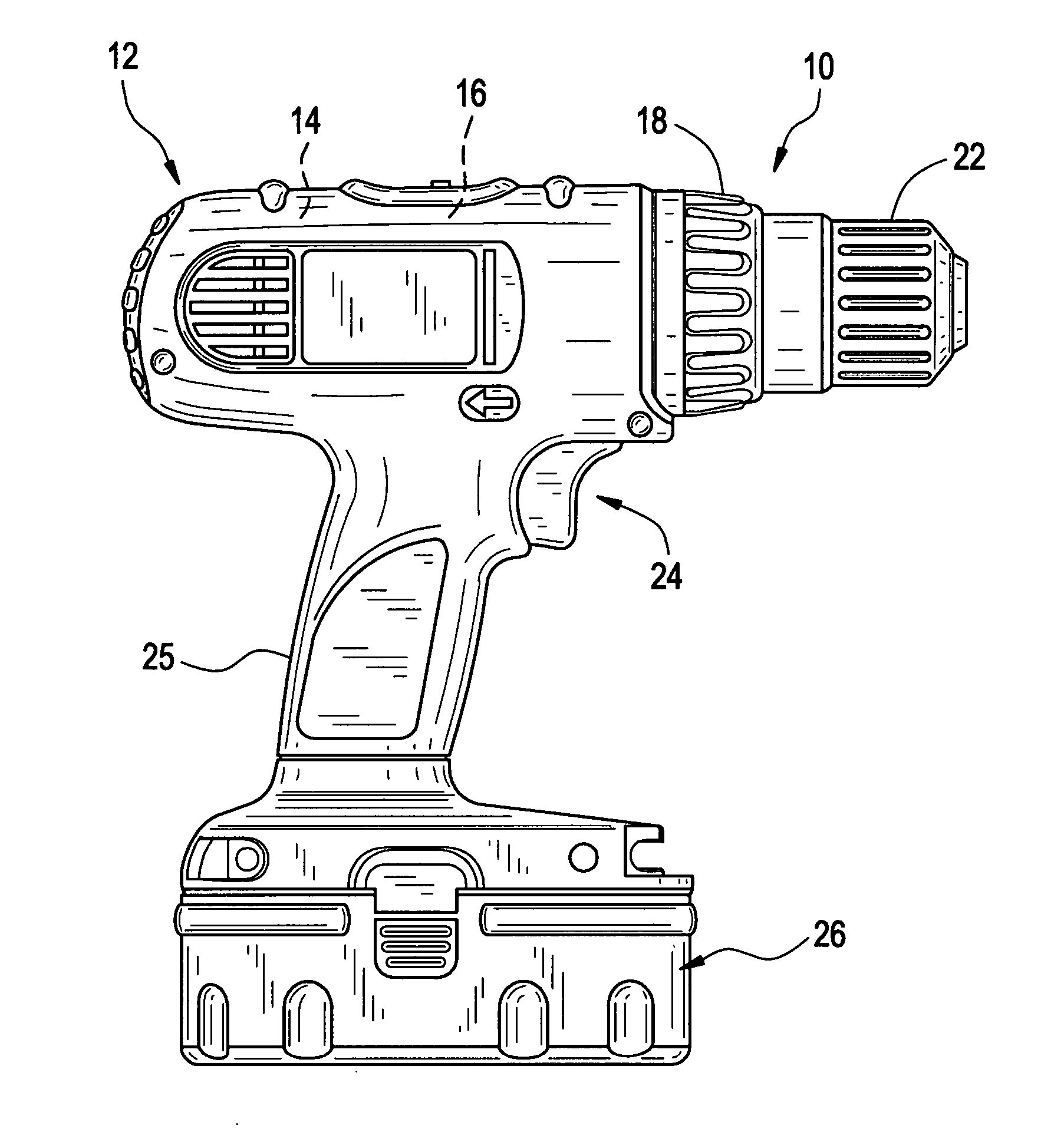

Cordless power tool system with improved power output

An ergonomically efficient cordless power tool system having desired power-to-weight ratios may be configured by reducing weight in one or more constituent weight groups of a given cordless power tool system, while maintaining or improving the total power output of the tool system. An example cordless power tool system may be configured to output a maximum power of at least 475 watts, and have a maximum power output to weight ratio of at least 70 watts per pound (W / lb).

Owner:BLACK & DECKER INC

Ergonomically efficient cordless power tool

An ergonomically efficient cordless power tool system having desired power-to-weight ratios may be configured by reducing weight in one or more constituent weight groups of a given cordless power tool system, while maintaining or improving the total power output of the tool system. An example cordless power tool system may be configured to output a maximum power of at least 475 watts, and have a maximum power output to weight ratio of at least 70 watts per pound (W / lb).

Owner:BLACK & DECKER INC

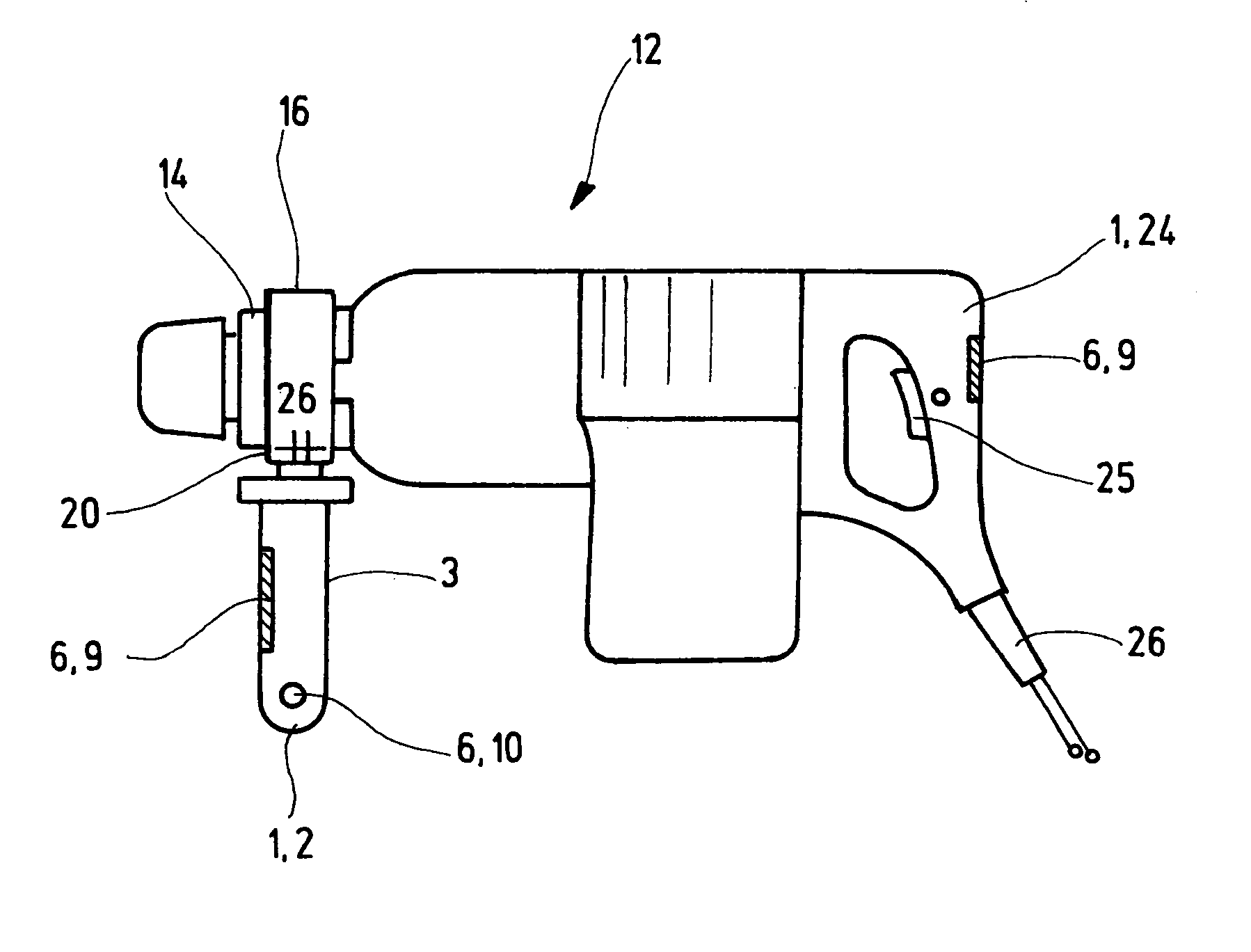

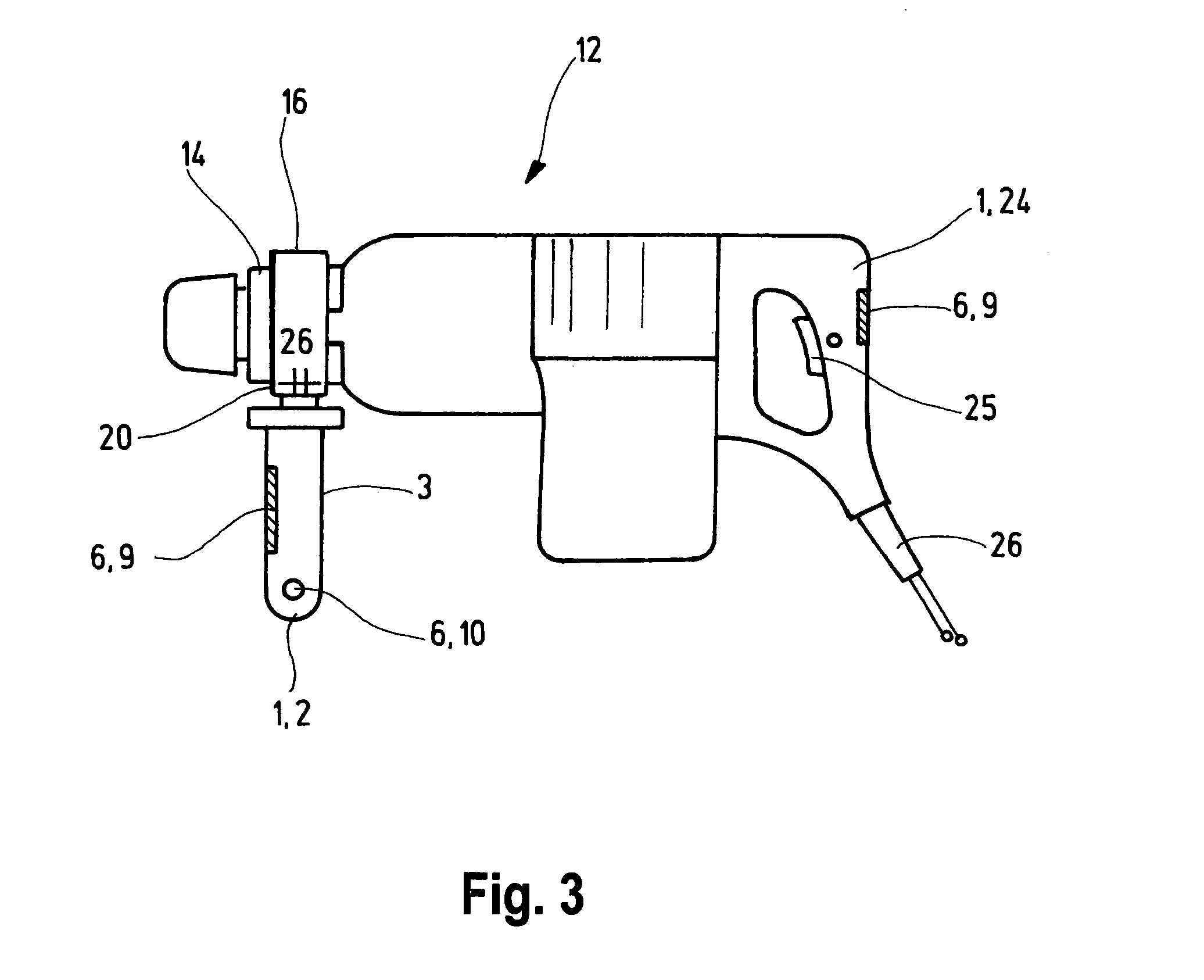

Handle with detecting unit

ActiveUS20050161241A1Fast powerQuick stopDerricks/mastsAuxillary equipmentSoftware engineeringPower tool

Owner:ROBERT BOSCH GMBH

Cordless hand held power tool with powered accessory

Owner:BLACK & DECKER INC

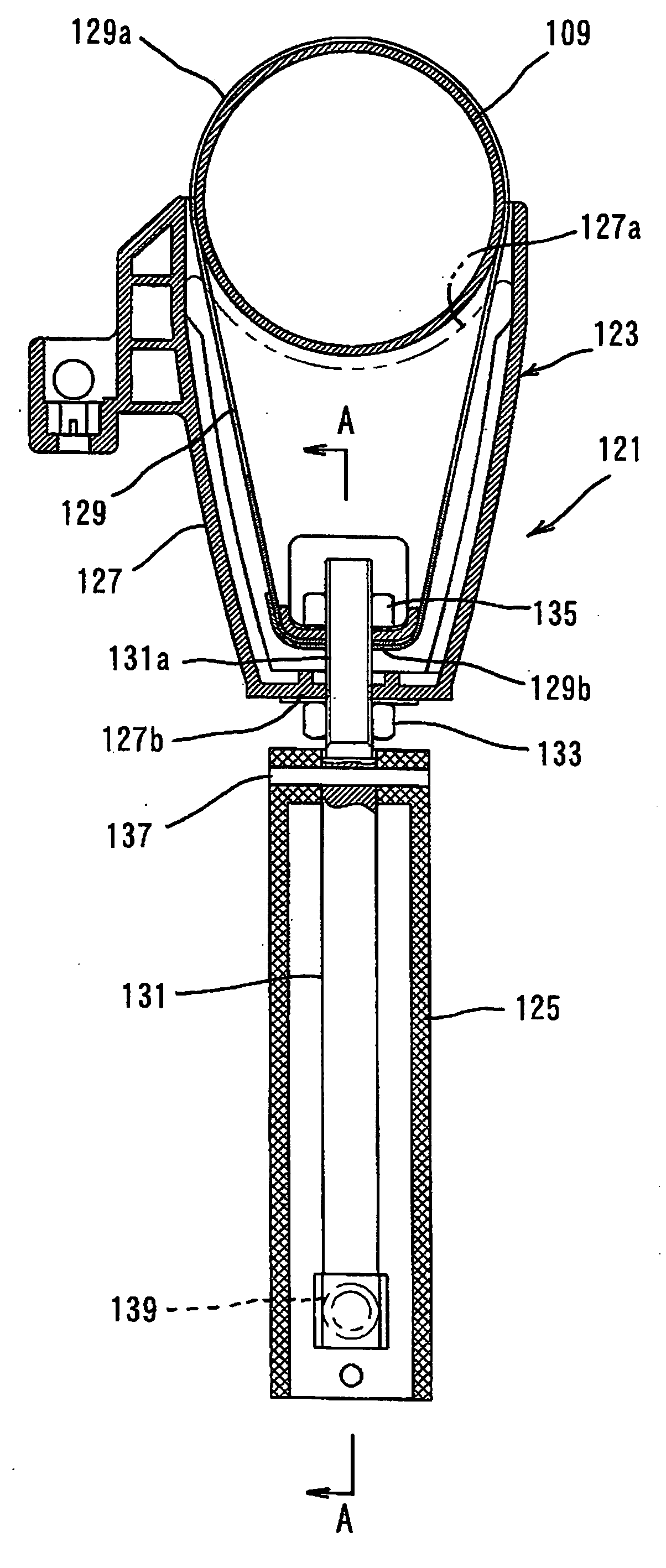

Vibration isolating handle

ActiveUS20050087353A1Reduced effectivenessReduce partOperator-supported drilling machinesPortable percussive toolsEngineeringPower tool

It is an object of the invention to provide a vibration reducing technique which is effective in obtaining stable vibration reducing effectiveness. A representative vibration isolating handle may include a body, a grip part and an elastic member. The handle body is provided to be attachable to the power tool. The grip part is connected to the handle body such that the grip part can move relatively with respect to the handle body substantially in the same direction at least as vibration of the power tool. The elastic member is provided between the handle body and the grip part. The elastic member applies a biasing force to the grip part when the grip part moves. According to the invention, vibration of the grip part can be reduced by the vibration absorbing function of the elastic member with stability regardless of whether the force of the user gripping the grip part is large or small.

Owner:MAKITA CORP

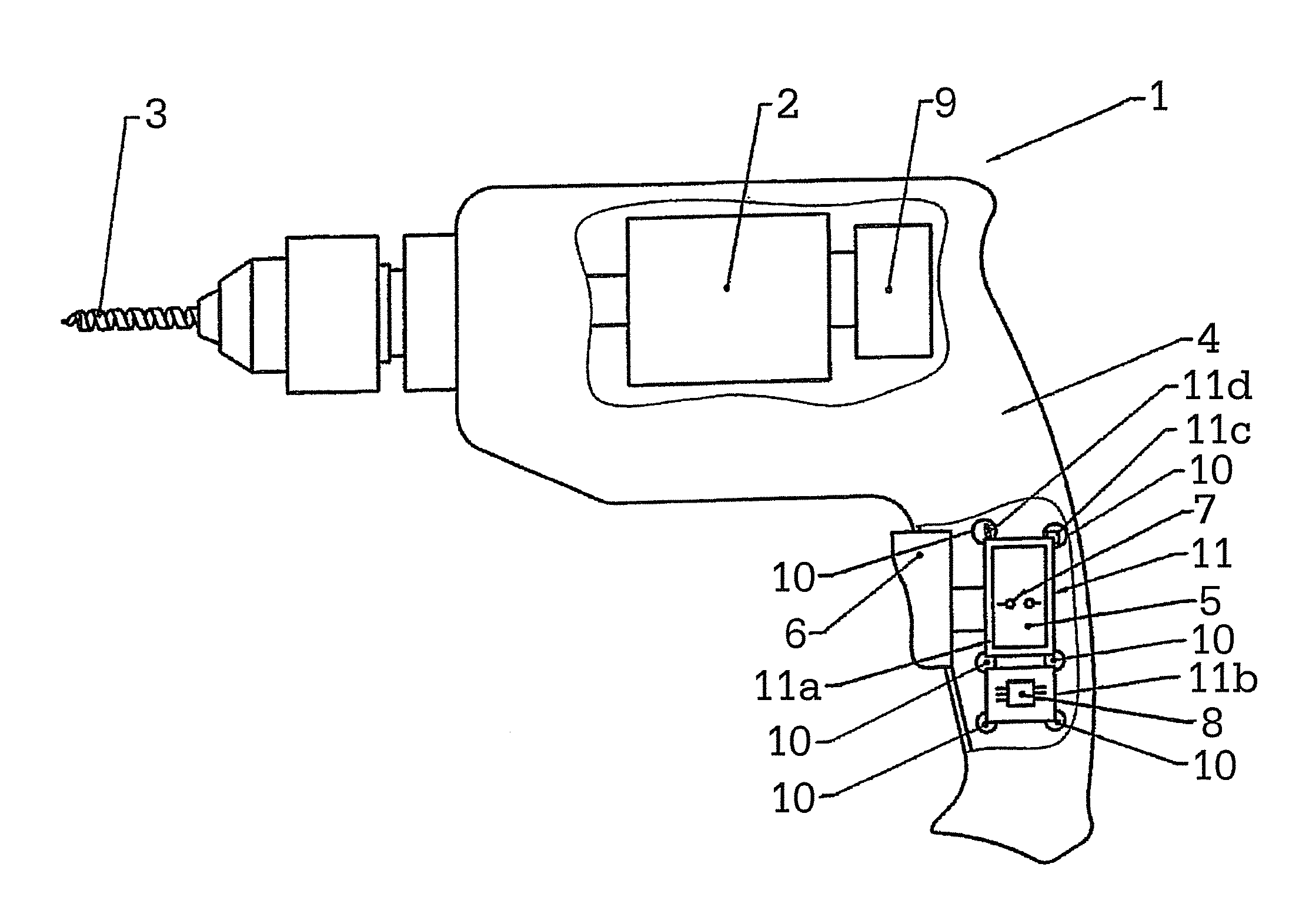

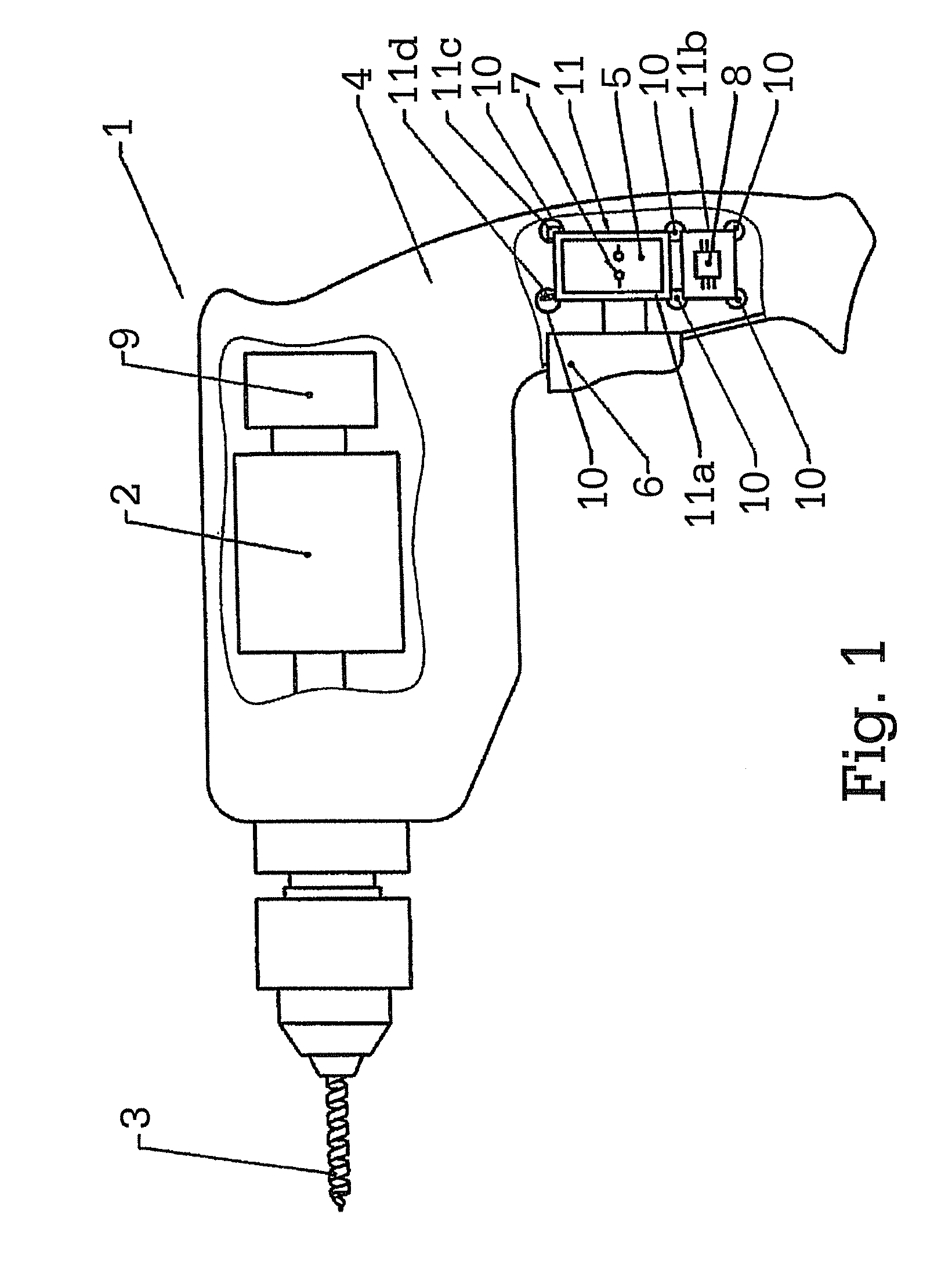

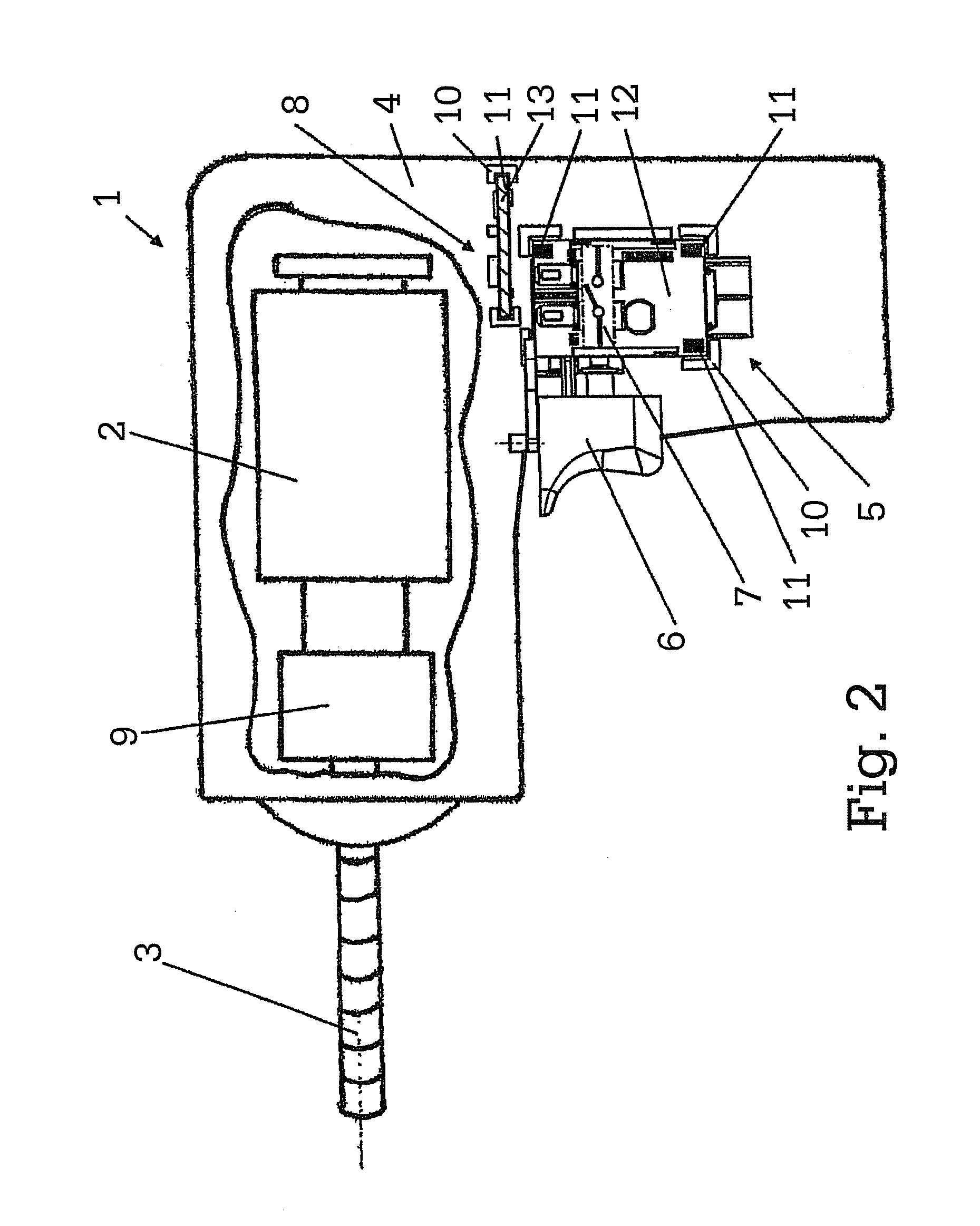

Electric rotational tool driving switch system

InactiveUS6923268B2Easy to operateImprove securityDerricks/mastsOperator-supported drilling machinesOperational systemPower circuits

An electric or power rotational tool including a driving switch of a push operating system that switches the electric motor ON when the rotational tool contacts a work object such as a screw, etc. and is displaced by being pressed, and a driving switch of a lever operating system that switches the electric motor ON when a switch lever installed in the grip portion of the electric rotational tool is displaced by being pressed. Each of the driving switches is constructed by a combination of a magnet and a magnetic sensor, and the magnetic sensor is connected to the power circuit of the electric motor, so that either one of operating systems is selected; and the driving of the electric motor is initiated by switching the power circuit ON through a magnetism sensing action of the magnetic sensor of the selected operating system.

Owner:TOTSU KATSUYUKI

Hand held drilling and/or hammering tool with dust collection unit

InactiveUS7017680B2Efficient processEasy to installThread cutting feeding devicesDrilling rodsHand heldElectrical connection

Owner:BLACK & DECKER INC

Power tools

InactiveUS20060037766A1Batteries circuit arrangementsDrilling/boring measurement devicesPower toolElectric motor

Owner:GASS STEPHEN F +1

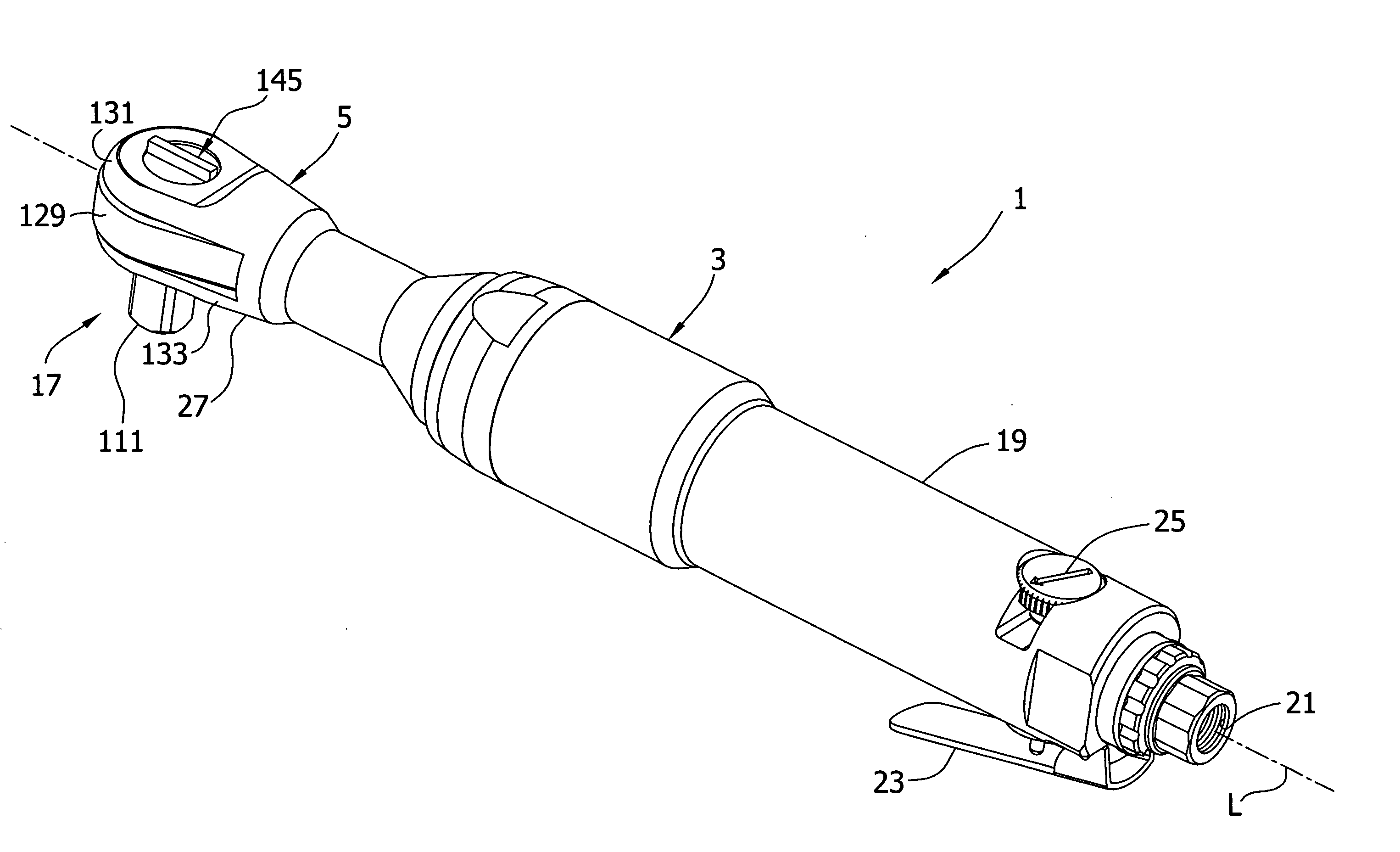

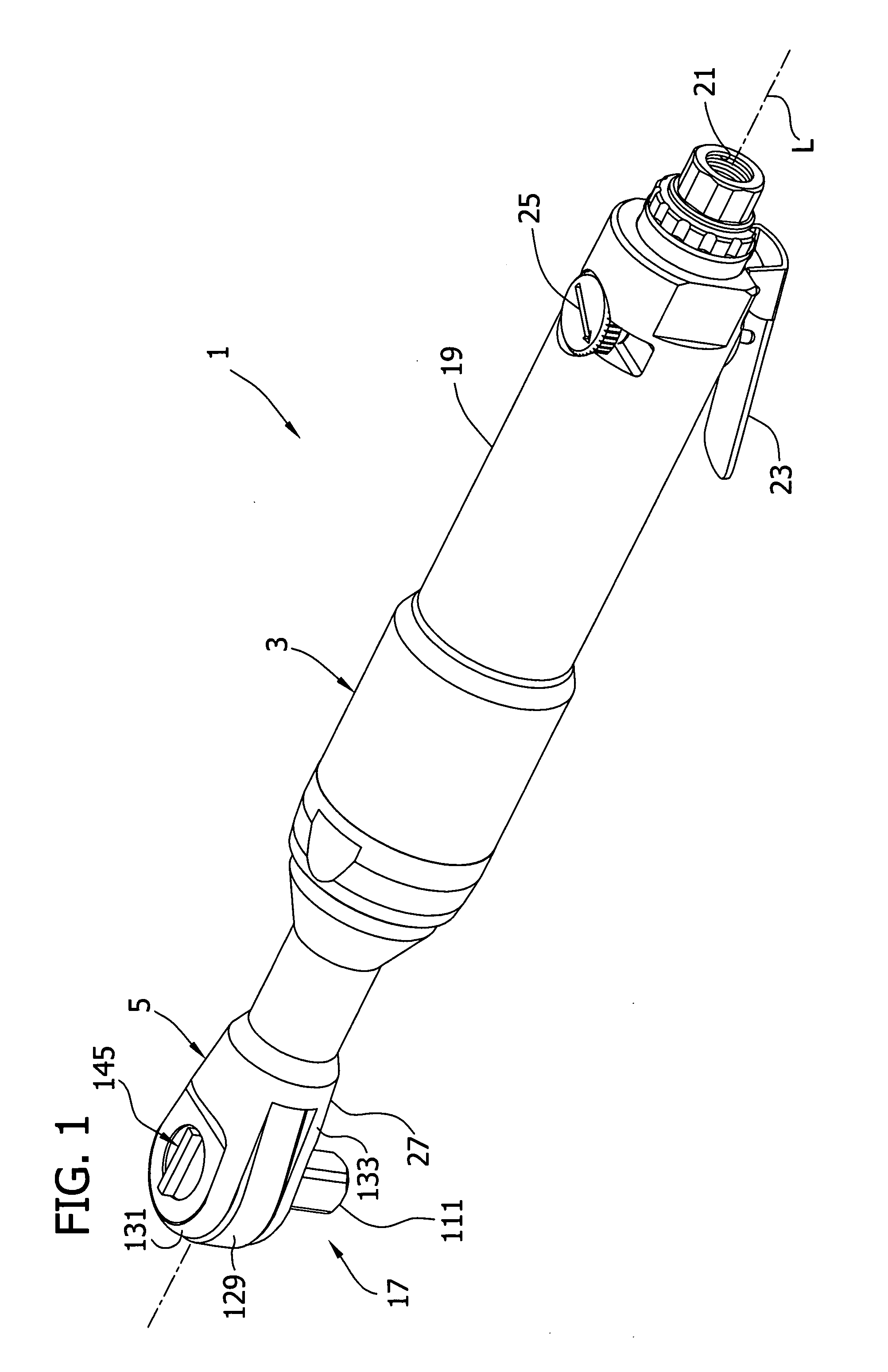

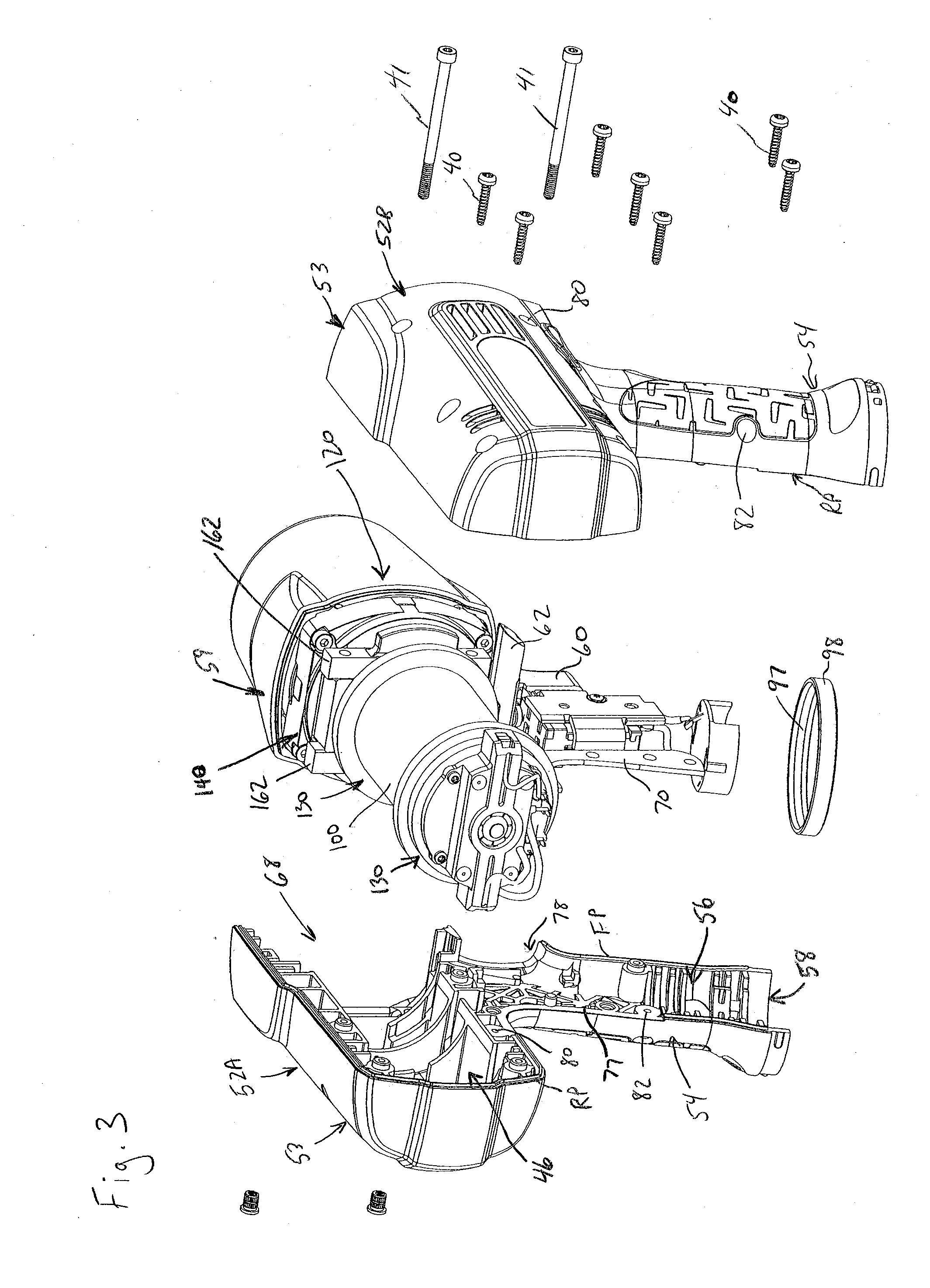

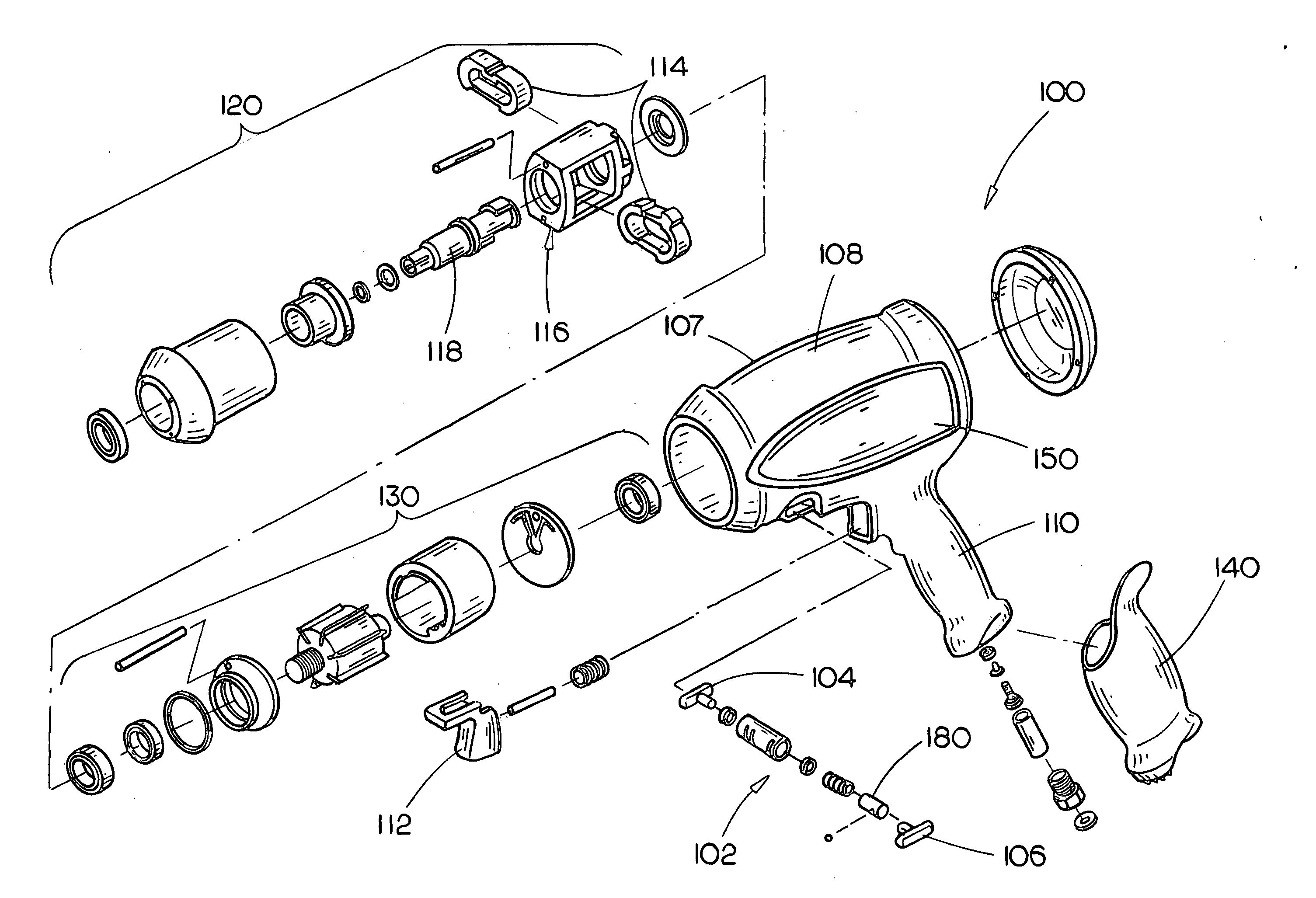

Hand-held oscillatory power tool with two-axis tool mounting

InactiveUS20110209888A1Efficient and effective useEasy to produceDrilling rodsConstructionsUniversal jointLocking mechanism

A hand-held power tool includes a motor mounted in a housing, with a two-axis universal joint mounted to the housing and supporting a rotary chuck. The universal joint includes a yoke mounted to the housing and a hub mounted to the yoke, the hub supporting the chuck. First and second clutches are provided for locking the yoke and the hub. A locking mechanism operatively connects the first and second clutches, and releases both of the first and second clutches simultaneously. A quick release chuck includes a spindle having a longitudinal bore for accepting a shank. A ball or like engaging device is disposed in a radial bore, extending into the longitudinal bore, and radially movable so that at least a portion of the ball extends radially into the longitudinal bore to engage a recess in the shank. A spring biased outer collar disposed about the spindle is movable longitudinally relative to the spindle and has a tapered face for forcing the ball into an aperture. A spring biases the collar into a locking position.

Owner:C ENTERPRISE HK

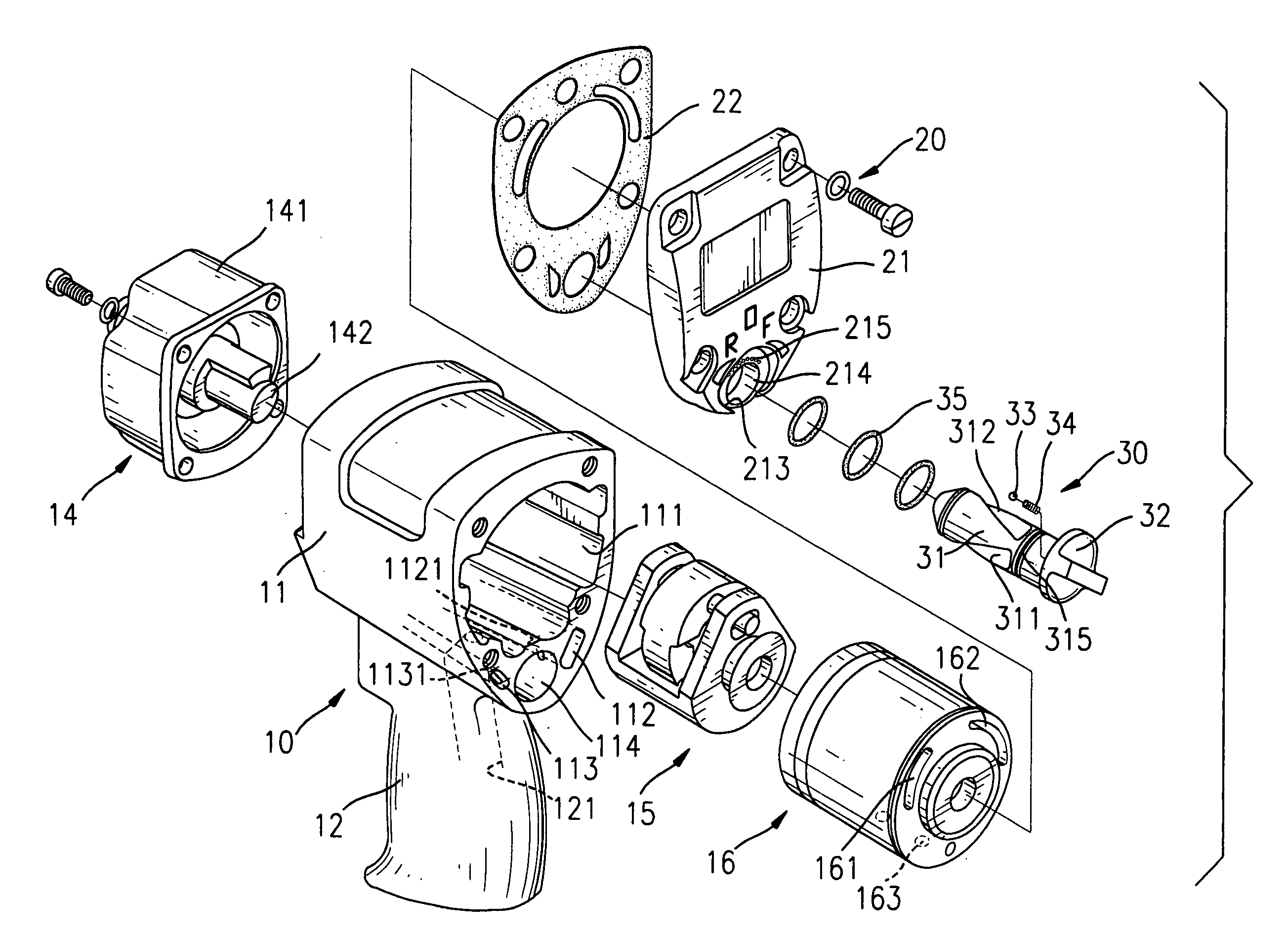

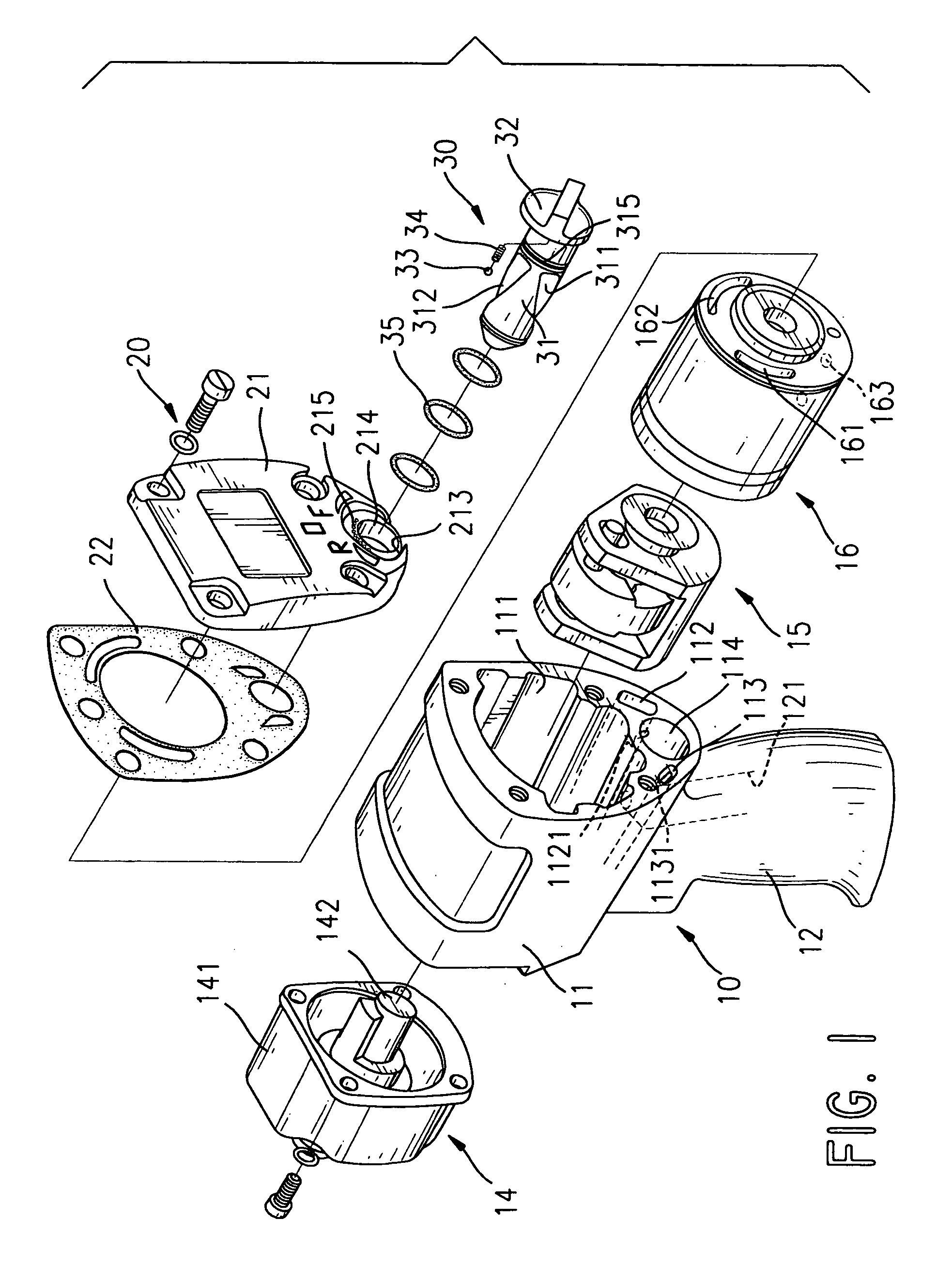

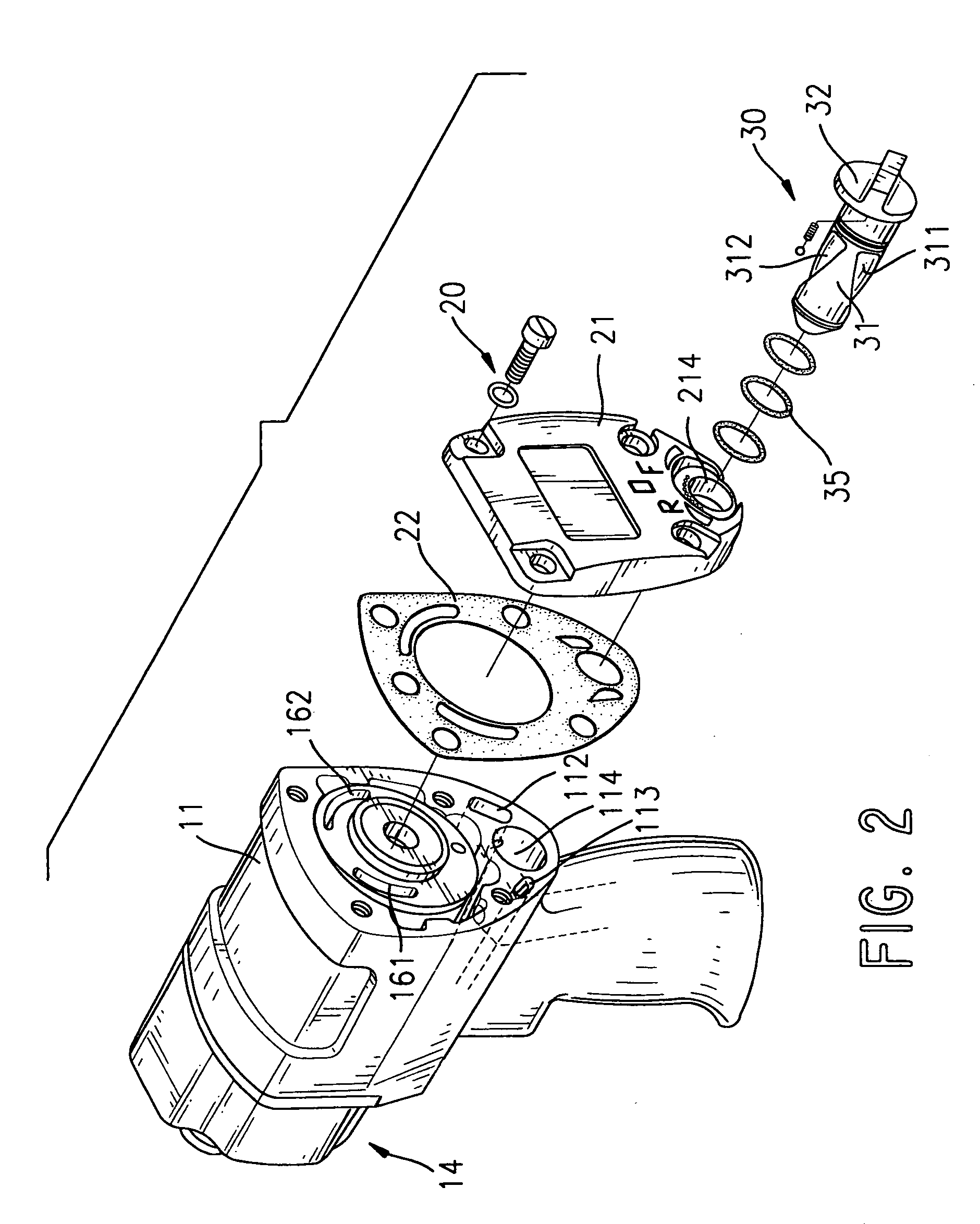

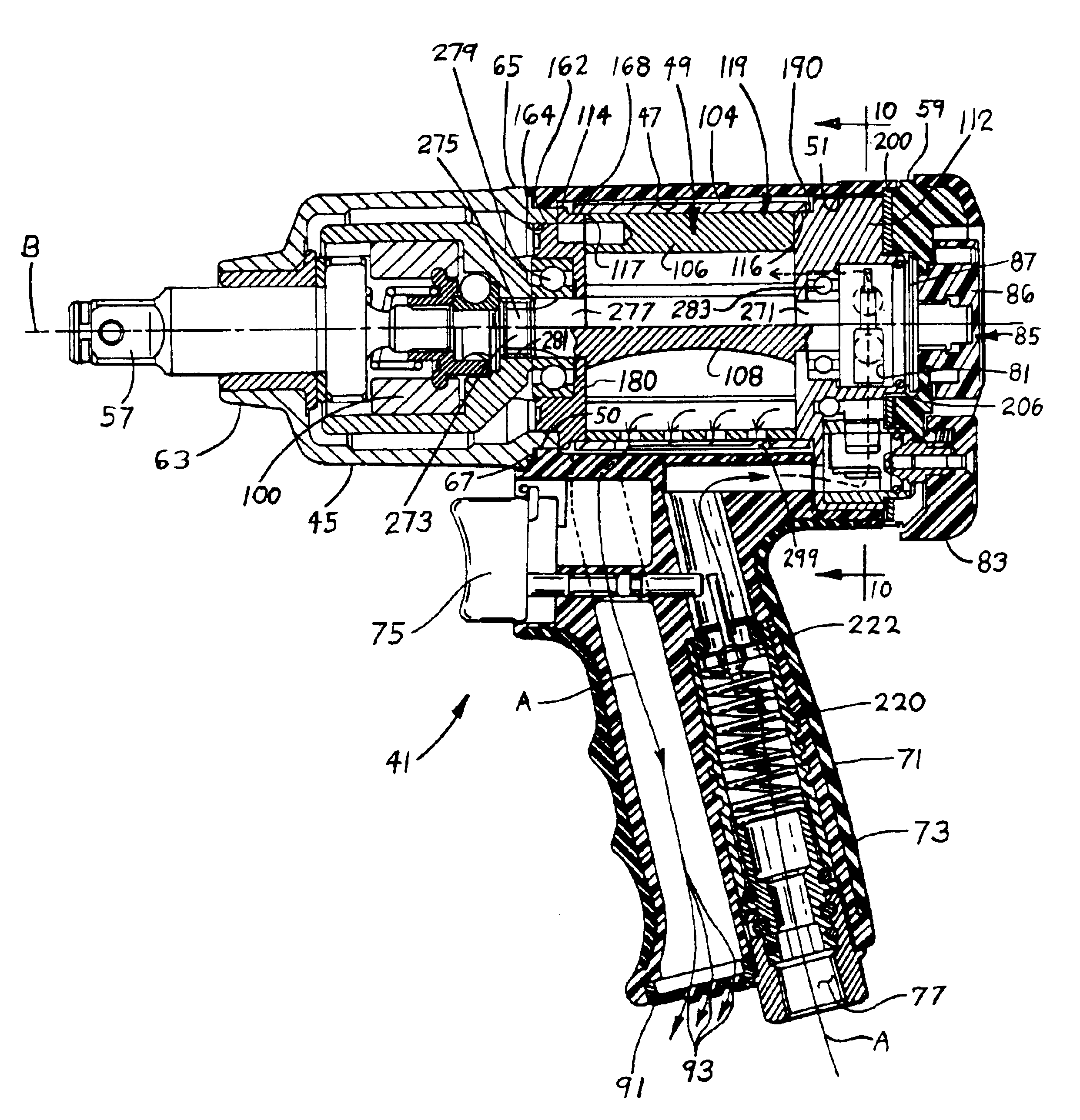

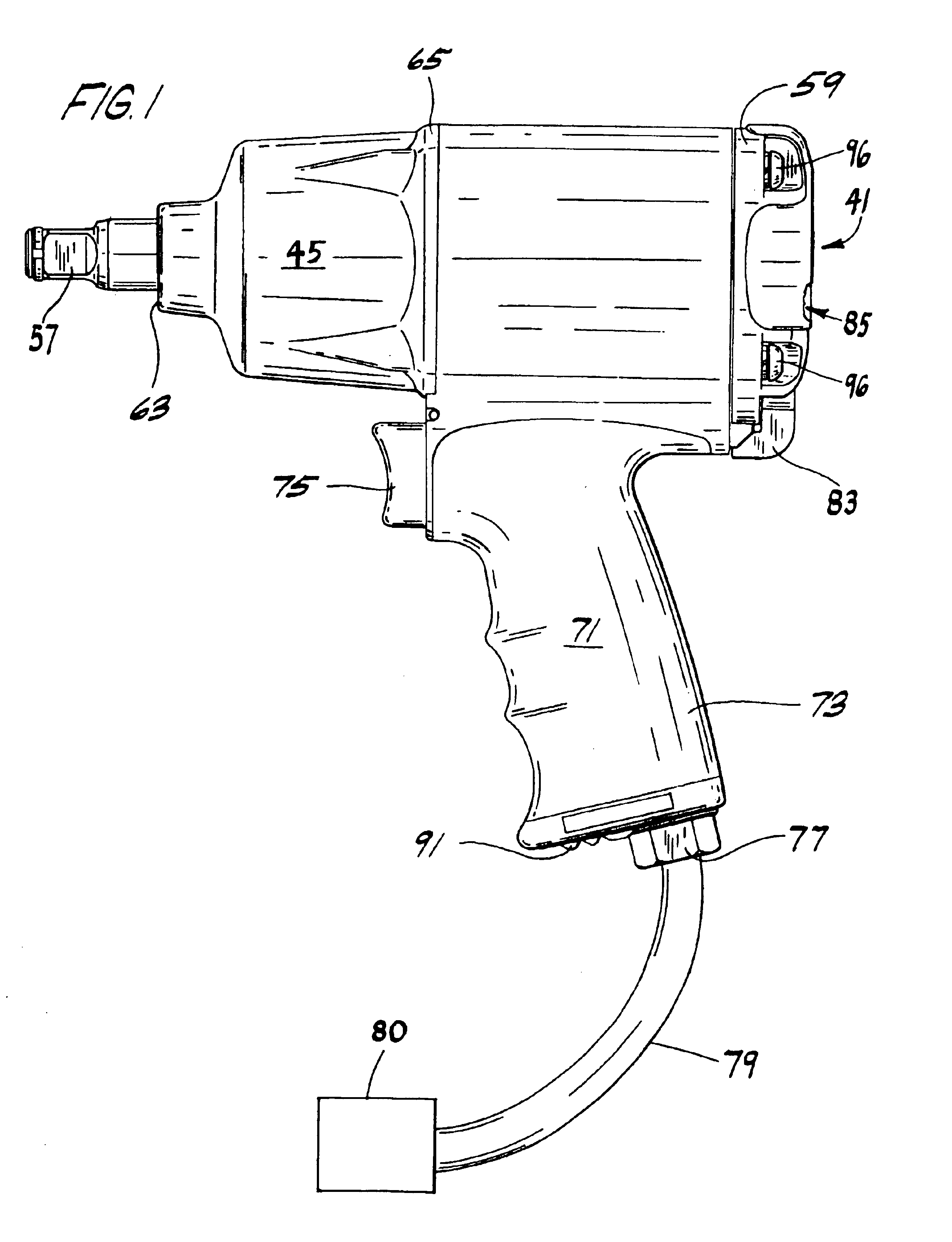

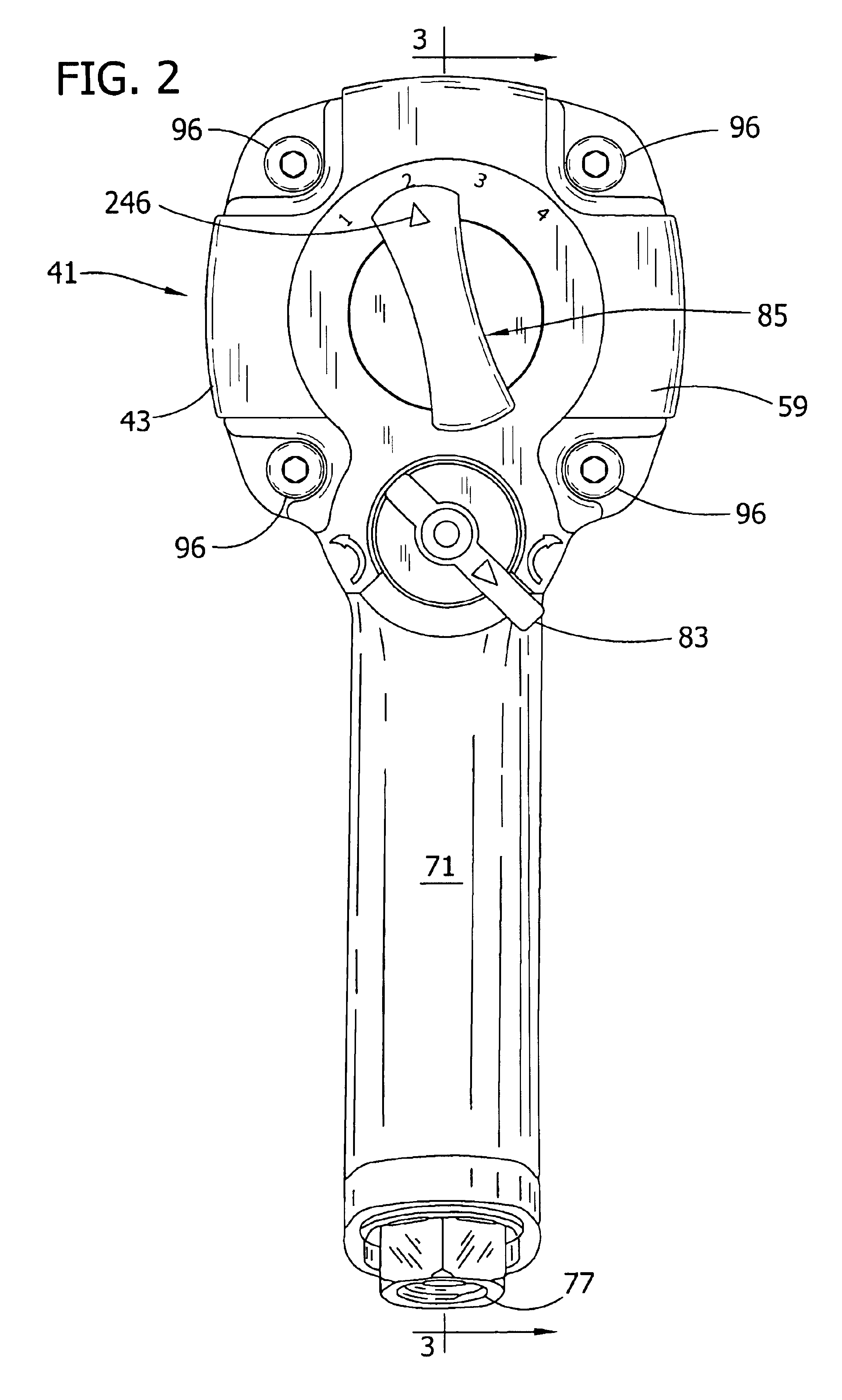

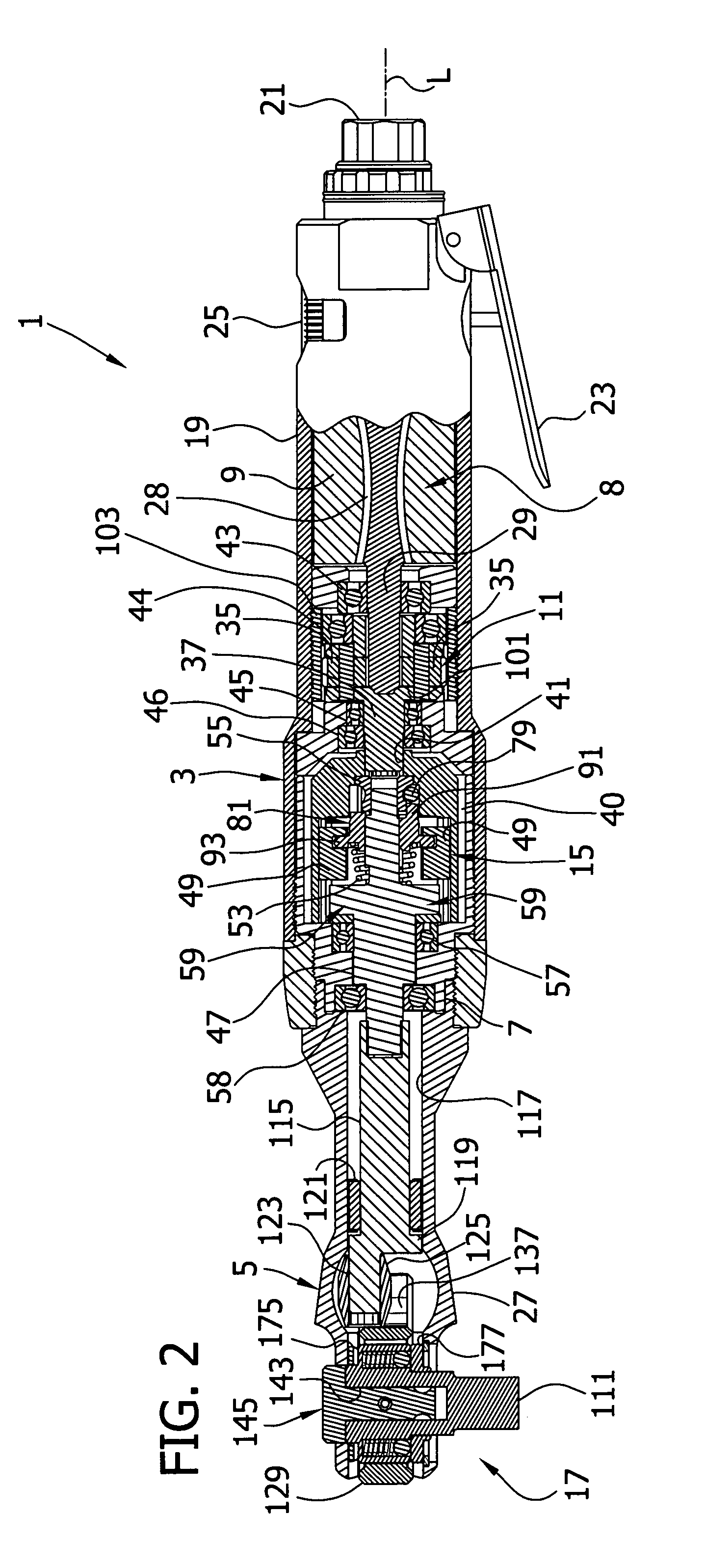

Bidirectional pneumatic impact wrench

InactiveUS6883619B1Simple structureEfficiently directsOperator-supported drilling machinesPower driven toolsControl valvesImpact wrench

A bidirectional pneumatic impact wrench has a pneumatic motor and an air control valve. The pneumatic motor has a forward air inlet and a reverse air inlet. The air control valve directs compressed air selectively into either the forward air inlet or the reverse air inlet to change the direction of rotation of the pneumatic motor and includes a rotatable shaft. The shaft has an exterior surface and a spiral forward air groove and reverse air groove that are symmetrically defined in the exterior surface to direct the compressed air efficiently. The air control valve is simple to fabricate and directs the compressed air efficiently into the pneumatic motor to improve power and efficiency of the pneumatic motor.

Owner:HUANG YUNG CHAO

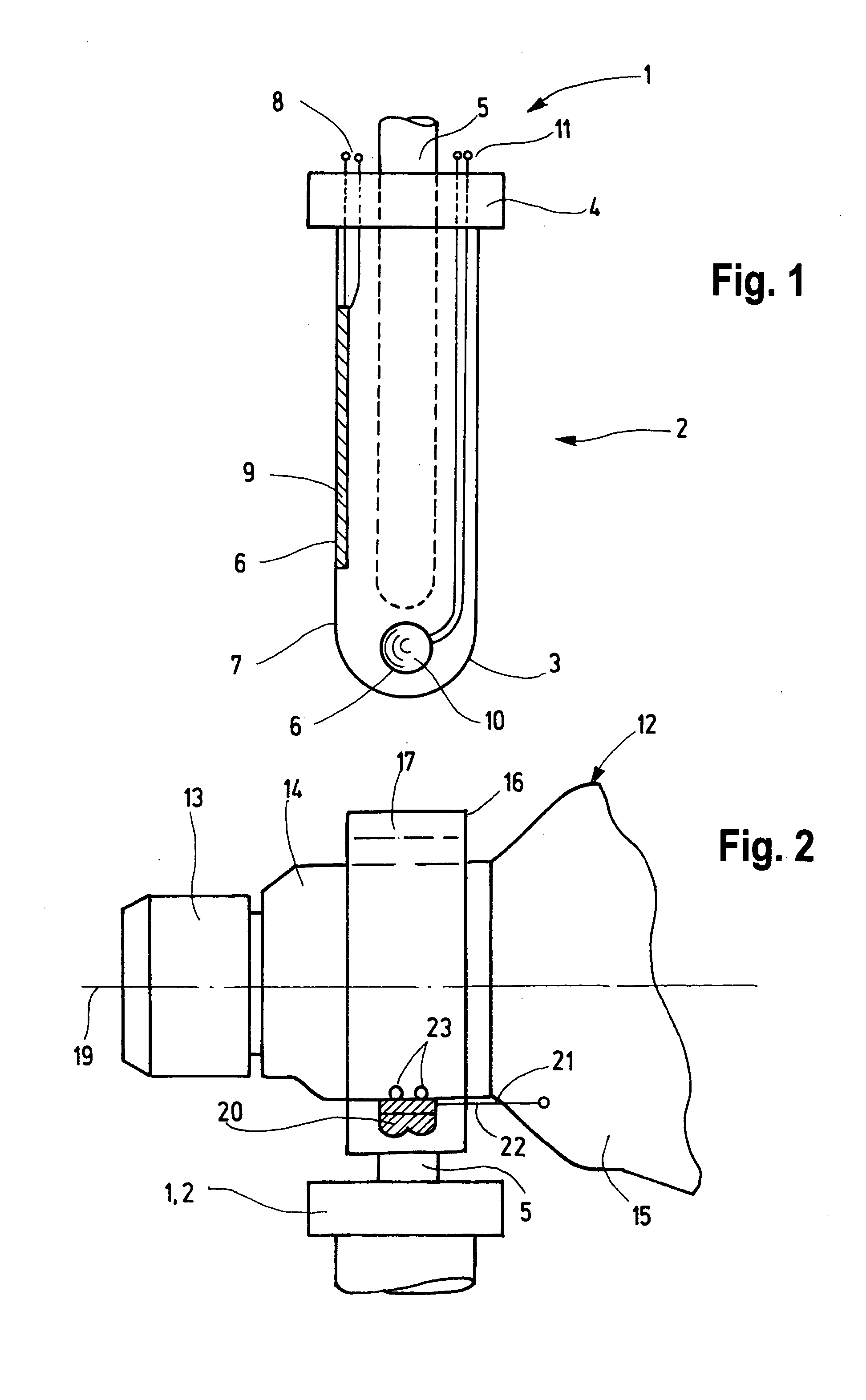

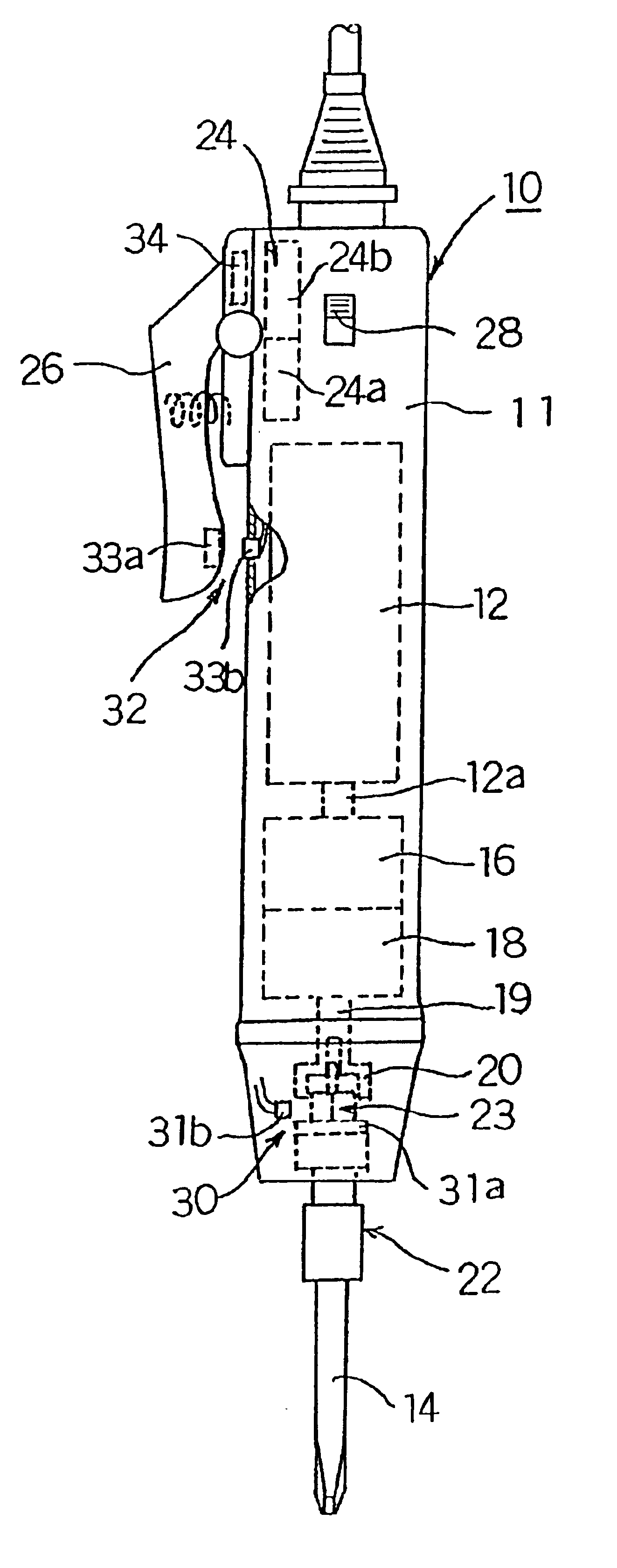

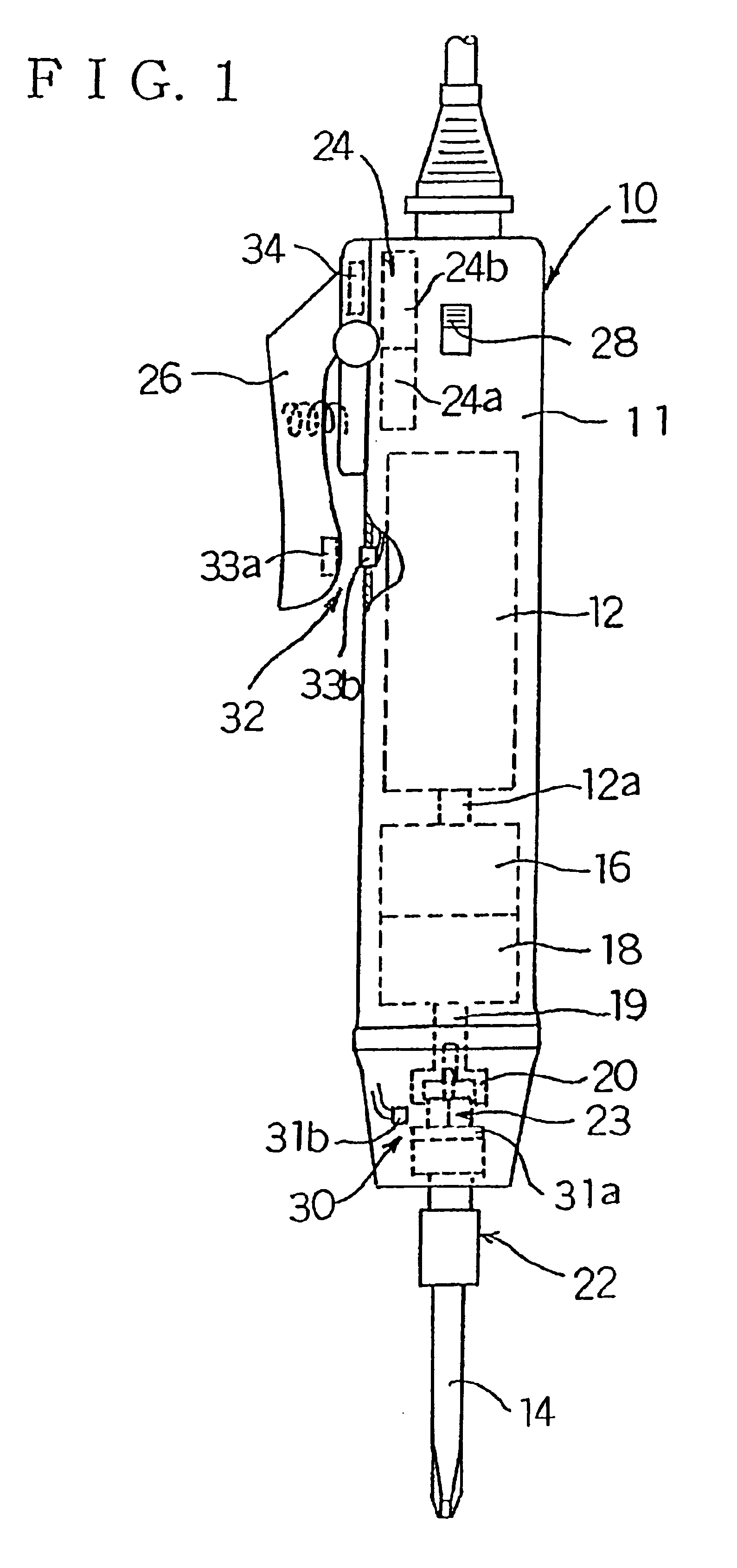

Electric screwdriver and a controller thereof

An object of the present invention is to provide an electric screwdriver device having a function for determining that a correct tightening operation has been carried out when the tightening operation has taken a time longer than a reference time predetermined for the tightening operation, characterized in comprising a novel feature for determining the reference time. The electric screwdriver device of the present invention comprises a torque monitor (40, S4) for monitoring whether or not a load torque in carrying out the tightening by using the electric screwdriver 12 has reached the tightening completion torque, a timer (40, S1, S5) for measuring the time consumed from the starting of the tightening operation until the tightening torque has reached the tightening completion torque, as the tightening operation time, and a reference time setter (40, S6-S10) for determining the reference time for a subsequent tightening operation based on a plurality of tightening operation time obtained from the timer in the tightening operations carried out for the predetermined number of screws.

Owner:NITTO KOHKI CO LTD

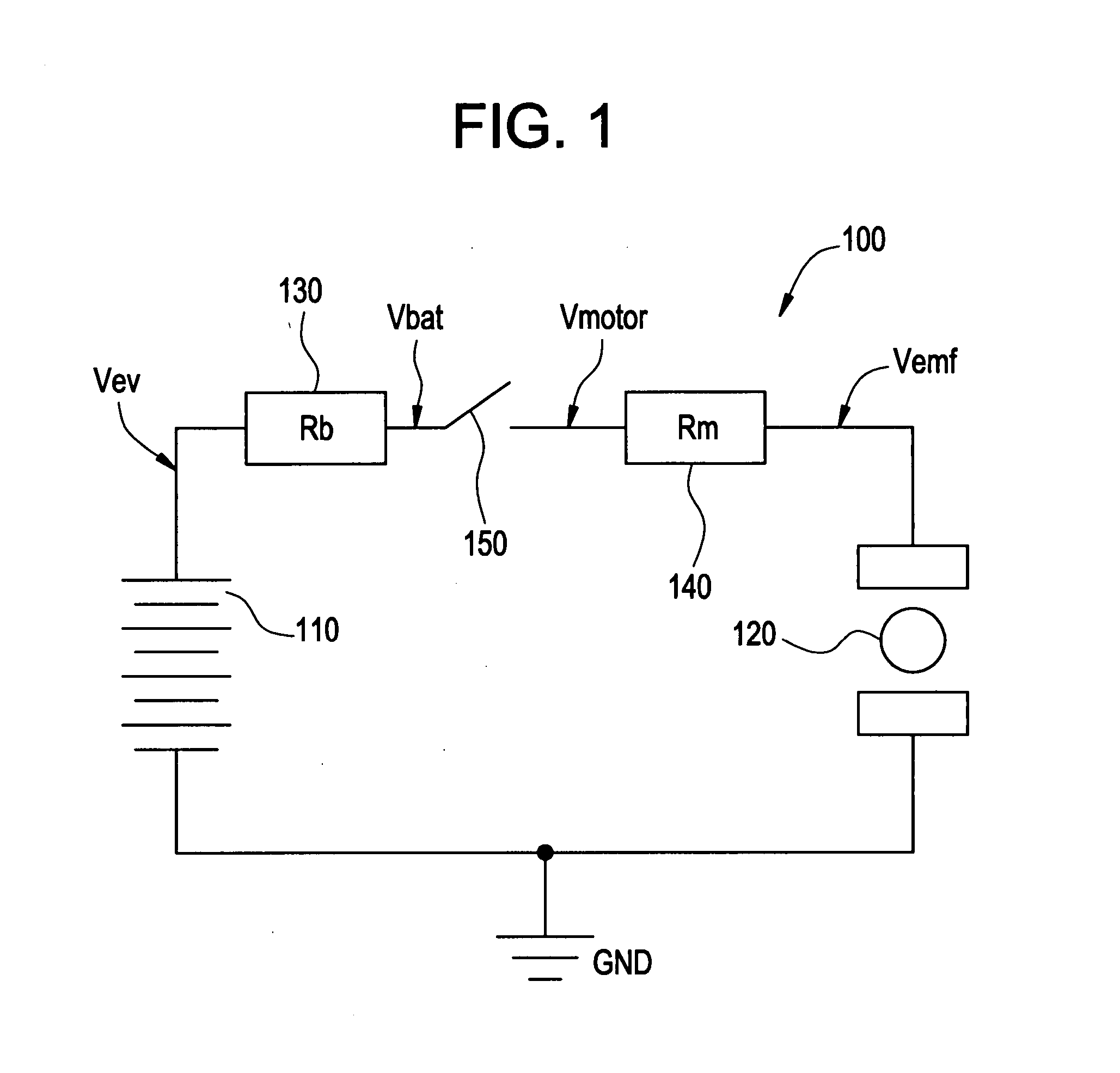

Power tools

InactiveUS20050103510A1Batteries circuit arrangementsDrilling/boring measurement devicesPower toolElectric motor

An electrically powered hand tool is disclosed. The tool includes a motor, a power source, a work element and a controller. Various alternative features, embodiments and operative configurations are disclosed.

Owner:GASS STEPHEN F +1

Power control structure for electric power tools

ActiveUS20110278035A1Optimal Control StructureAdjusting operationOperator-supported drilling machinesAC motor accelaration/decelaration controlPower modulationElectric power system

A power control structure aims for an electric power tool which gets an input power from an electric power source and converts the input power to a driving power to drive an electric motor. The electric power tool further includes a manual control means, a magnetic control element and a power modulation circuit. The manual control means includes a trigger portion movable by depressing of a user and a magnetic element movable with the trigger portion. The magnetic control element outputs an output control signal in proportion to alterations of a magnetic field caused by movements of the magnetic element. The power modulation circuit gets the input power and modulates to the driving power controlled by the output control signal to drive the electric motor. Thus by depressing the trigger portion, output power of the electric motor can be controlled to provide precise control of rotational speed and torque alterations.

Owner:XPOLE PRECISION TOOLS

Pneumatic tool

InactiveUS6161628AConstructionsReciprocating drilling machinesOperational effectivenessPneumatic tool

A pneumatic tool is disclosed. The pneumatic tool has a hollow housing with a handle extending therefrom, the handle having a chamber defined therein and an air passage communicating with the housing, an actuating mechanism mounted in the housing to actuate a tool shank and a cap securely attached to said handle to cover the chamber so as to form an oil reservoir in the handle. The pneumatic tool further has a control member mounted in the actuating mechanism to control the opening and closing of a discharge passage formed in the actuating mechanism. The disclosed pneumatic tool can limit the size of the pneumatic tool and let the air completely flow out so as to improve the convenience and operational effectiveness of the pneumatic tool.

Owner:Q C WITNESS INT

Pneumatic rotary tool

InactiveUS6880645B2Low costEasy to useConstructionsReciprocating drilling machinesPlastic materialsPneumatic tool

Owner:S P AIR

Hand tool with impact drive and speed reducing mechanism

ActiveUS7080578B2Reduce speedEasy to driveOperator-supported drilling machinesSpannersGear wheelHand tool

Owner:VESSEL FUKUCHIYAMA

Power tool

ActiveUS20100314147A1Reduce and in power toolEffective dampingOperator-supported drilling machinesPortable percussive toolsElectricityEngineering

The invention relates to a power tool, such as an impact drilling machine, impact screwdriver, saber saws, grinders, or the like, comprising a housing. In the housing, an electric motor and an electric or electronic module that is attached to holders in the housing, for example, an electric switch or electronics, are provided. Between the holders in the housing and the electrical or electronic modules, a vibration decoupling element is disposed.

Owner:MARQUARDT GMBH SCHLOSSTRASSE 16 7201 RIETHEIM-WEILHEIM 1 WEST GERMANY

Pneumatic tool with side exhaust

The present invention relates to a pneumatic tool having a housing including a motor housing portion which is pneumatically and securely connected to a handle housing portion. The motor housing portion has a motor housing exhaust opening with a motor housing exhaust opening port therethrough. The motor housing exhaust opening port functions to direct pressurized air from a forward direction to a sideways direction.

Owner:BRUNNHOELZL RACING

Portable tool having cover and label to be stuck on the portable tool for identification

InactiveUS7140451B2Low costThread cutting toolsStampsMotive powerElectrical and Electronics engineering

A portable tool includes a motive power section, a mechanical section driven by the motive power section, and an outer frame covering the motive power section and the mechanical section. A label or a sticker is affixed to an outer peripheral surface of the outer frame. The label contains specific pattern or specific color or specific character representing a specific user of the portable tool. The cover is made from a transparent resin and is removably disposed to the outer frame for protectingly covering the label. A sheet containing a plurality of labels having colors or pattern different from each other is provided. A user can select one of the labels.

Owner:KOKI HLDG CO LTD

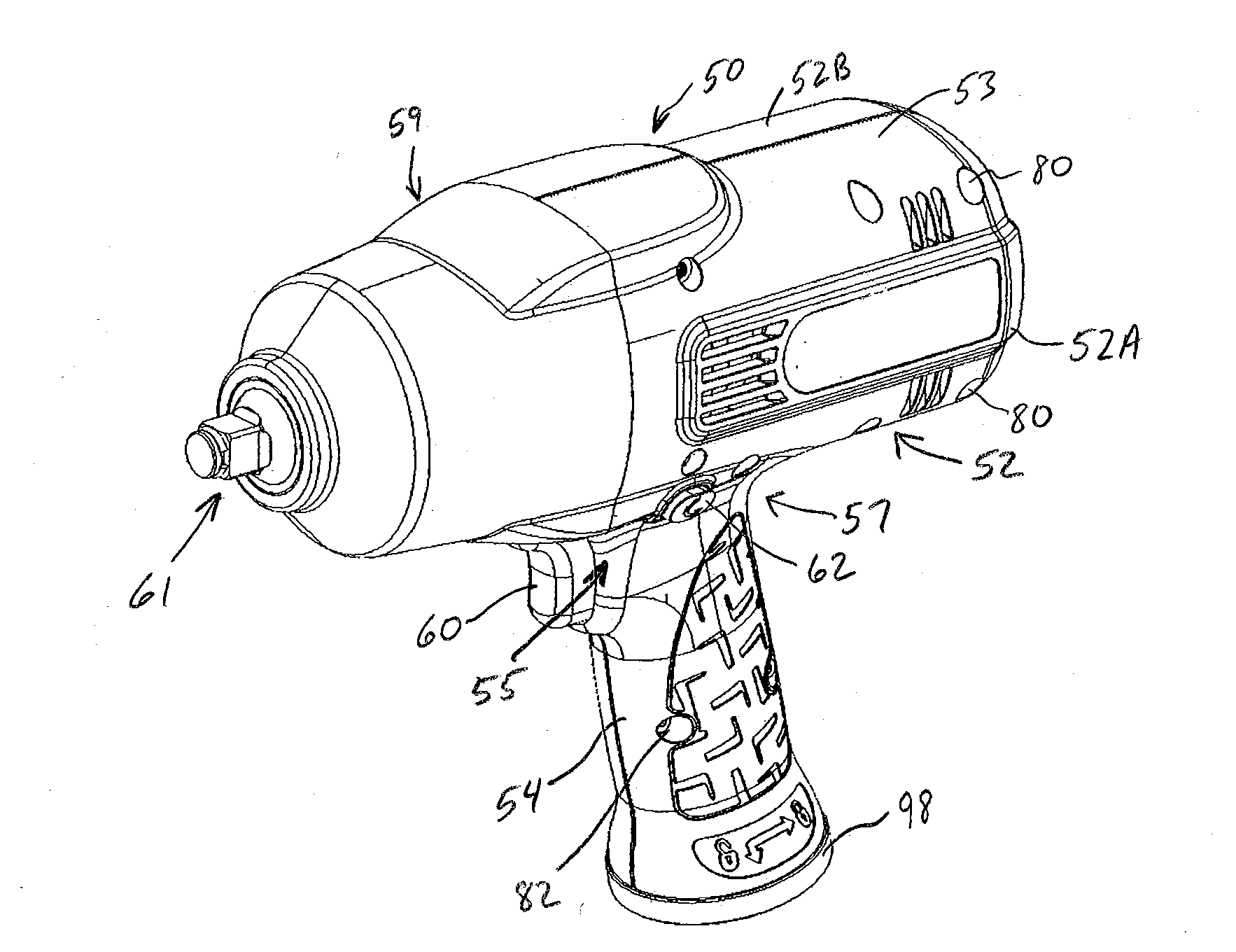

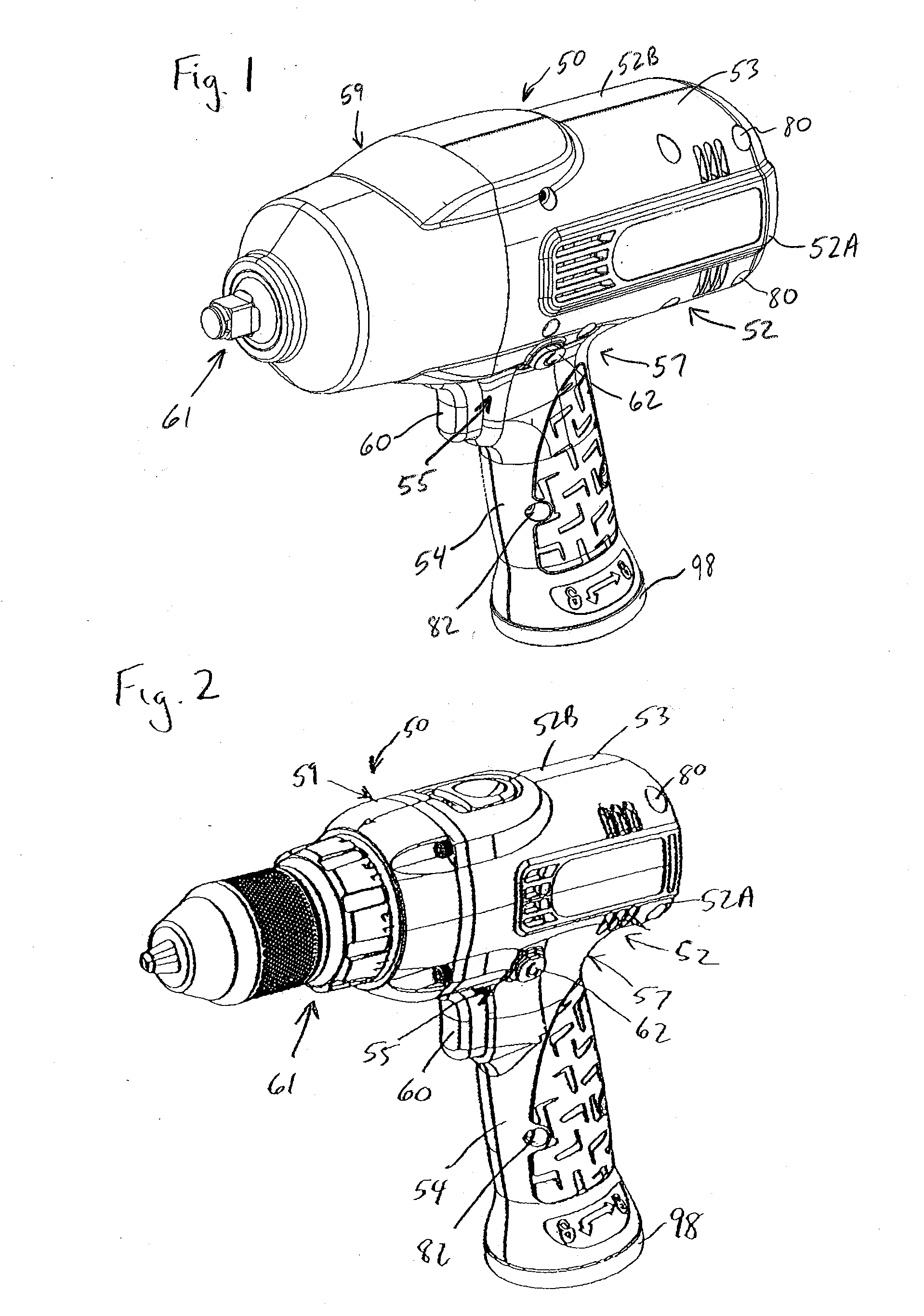

Power tool housing support structures

A tool housing which in one aspect includes a body defining a head portion with a handle portion depending therefrom to define a forward and / or a rear junction. A metal reinforcing member is configured to span along an inside surface of the body from the head portion to the handle portion such that the reinforcing member bridges either the forward or rear junction. In another aspect, the tool assembly comprises a tool housing body, a motor positioned within the tool body housing, a drive mechanism connected with the motor to define a unitary motor / drive mechanism assembly, and at least one elastic isolating member extending about a portion of the motor / drive mechanism assembly such that the motor / drive mechanism assembly is elastically isolated relative to the housing body.

Owner:INGERSOLL RAND IND U S INC

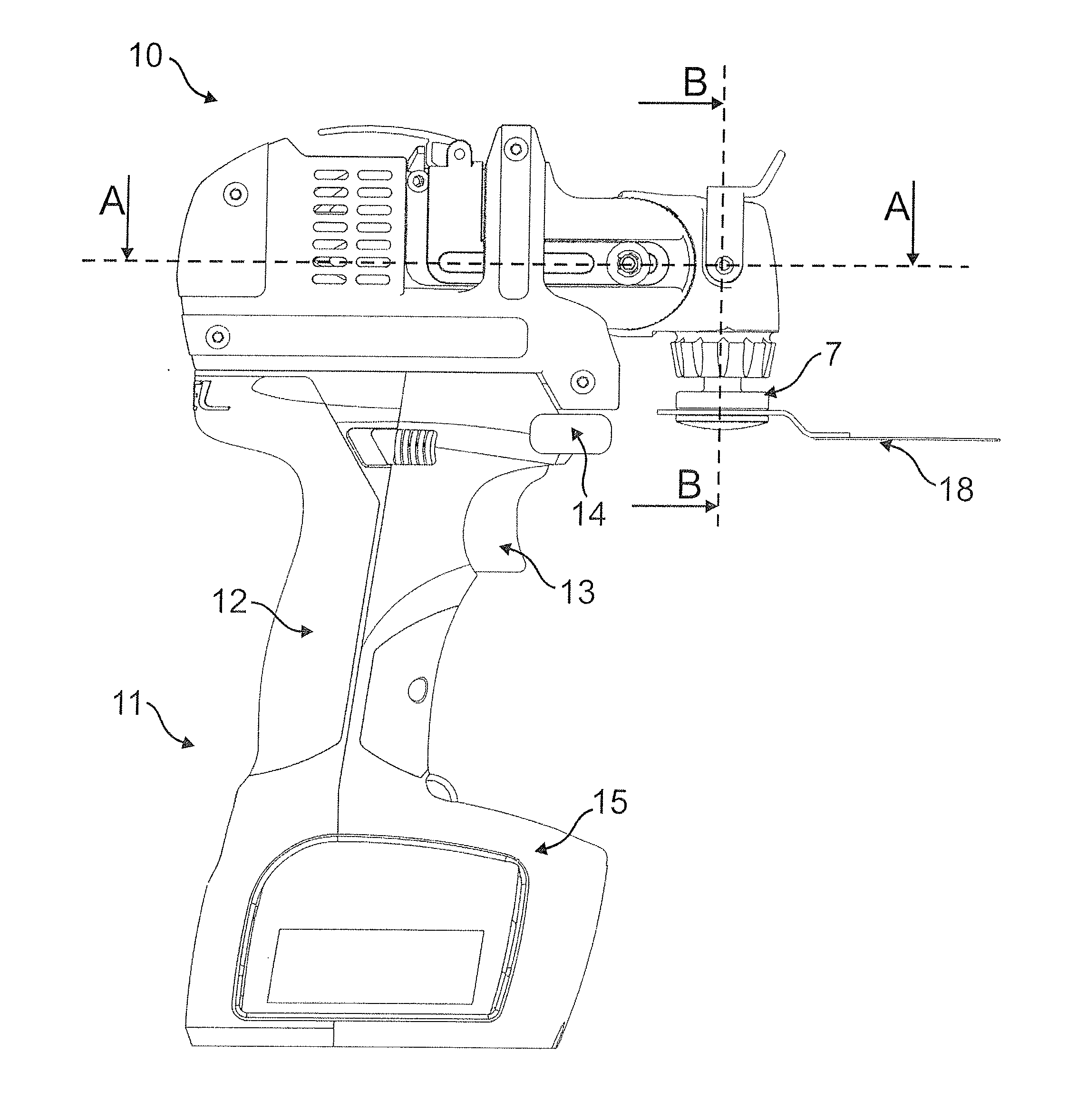

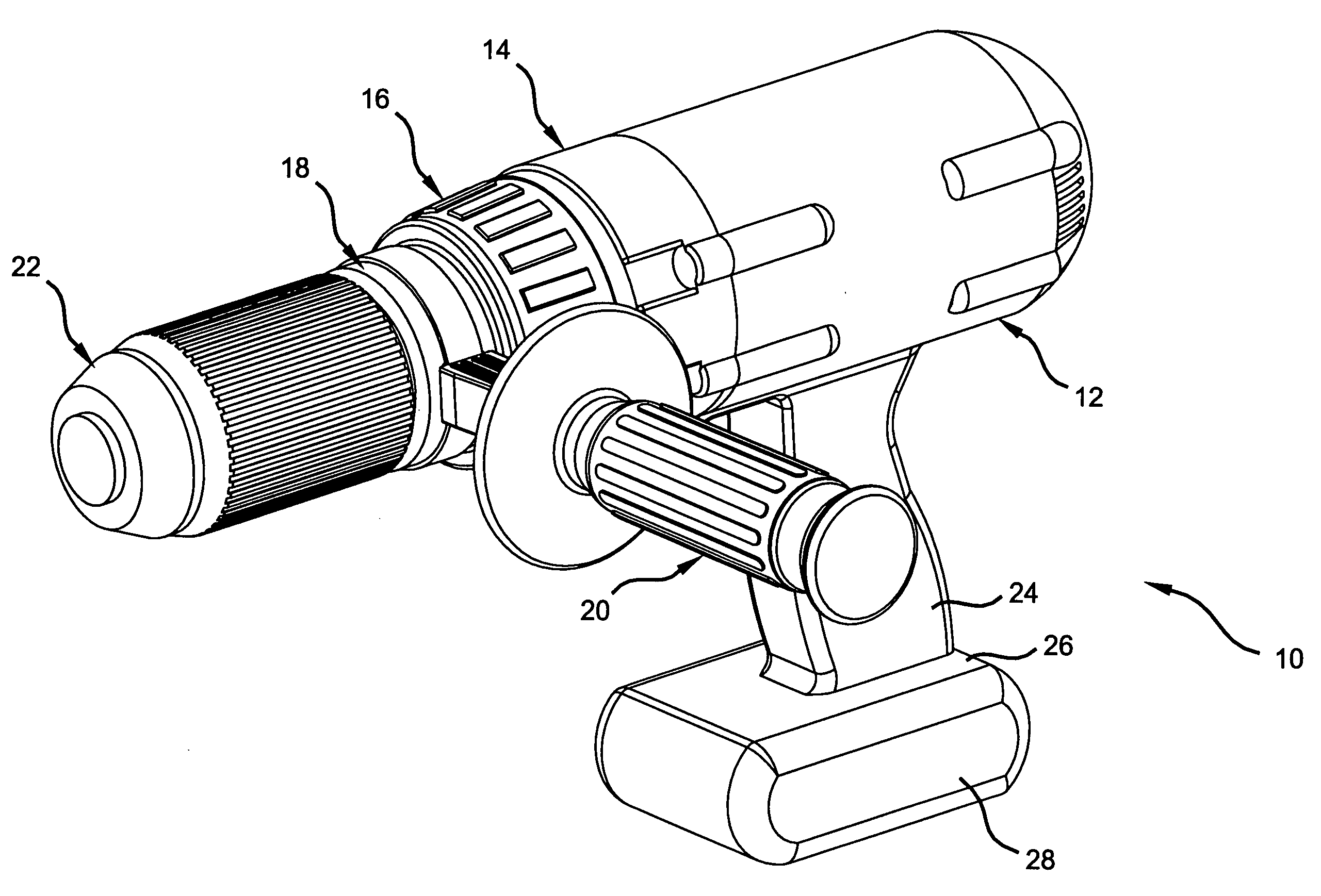

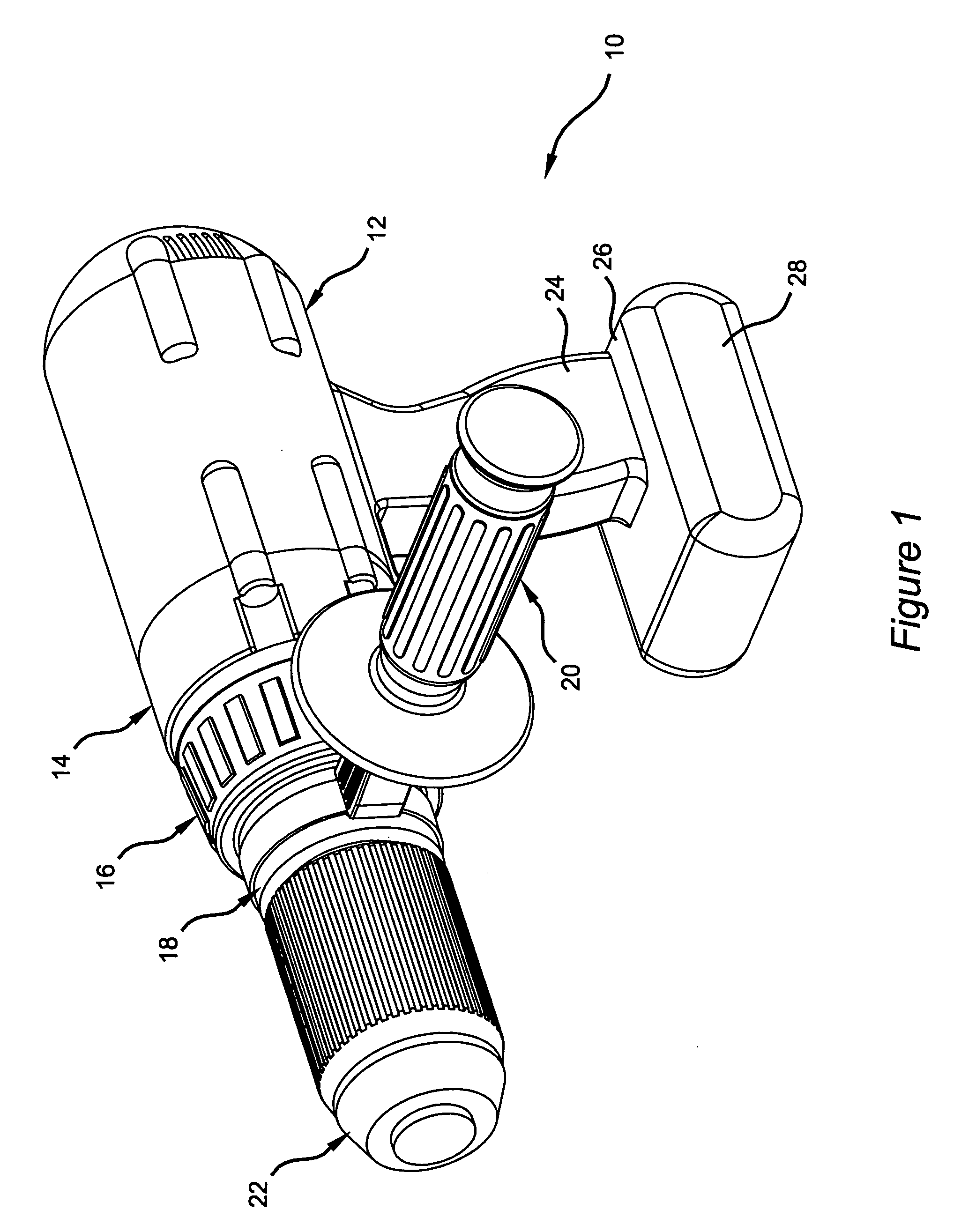

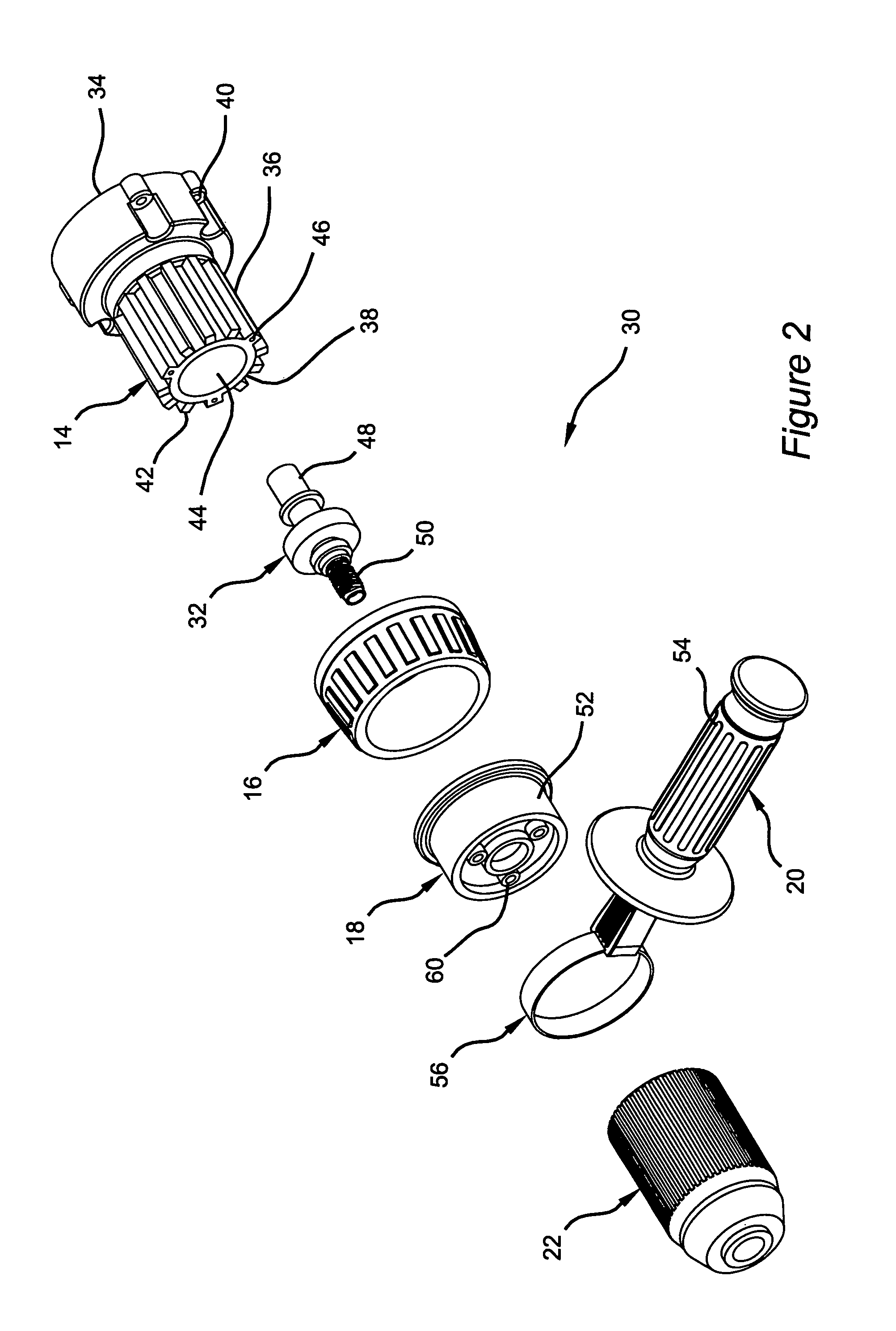

Side handles on drill/drivers

InactiveUS7000709B2Easy to adjustEasy to readTravelling carriersThread cutting machinesEngineeringShaft collar

A drill / driver is provided that includes a housing, a collar mounted at a front portion of the housing, a side handle mounting area provided forward of the collar, a handle mounted to the side handle mounting area, and a chuck mounted forward of the side handle mounting area. With the side handle mounted in front of the collar, easier access to the adjusting collar and easier reading of the collar settings is achieved.

Owner:BLACK & DECKER INC

Electric power tool

ActiveUS6971456B2Excessive overall dimensionLow costDrilling rodsConstructionsElectric power systemEngineering

An electric power tool incorporating a single fan that provides efficient cooling of the motor and transmission while reducing the cost and size of the power tool. The power tool includes a speed reduction transmission provided within a housing between the motor and a chuck which is located at the front end of the power tool. The rotation of the fan cools the motor and the transmission by drawing in external air from intake ports formed in the housing, and collectively exhausts the warmed cooling air through exhaust ports formed in the housing. The power tool includes a fan, located between the motor and the transmission, that is constructed to draw in two separate streams of cooling air from air intake ports located adjacent to the motor and the transmission, and to exhaust used cooling air through exhaust ports located adjacent to the fan.

Owner:MATSUSHITA ELECTRIC WORKS LTD

Pneumatically powered rotary tool having linear forward and reverse switch

A pneumatically powered rotary tool includes a linear forward and reverse switch assembly for alternatively setting the air motor of the tool to rotate the drive assembly of the tool in either of the clockwise direction or the counterclockwise direction. The switch assembly slides linearly along an axis generally perpendicular to the drive assembly between a first position for setting the air motor to rotate the drive assembly in the clockwise direction and a second position for setting the air motor to rotate the drive assembly in the counterclockwise direction. The switch assembly is positioned adjacent to the trigger so that the switch assembly can be slid between the first position and the second position by the index finger and thumb of the hand of the user gripping the handle portion without releasing the handle portion.

Owner:BLACK & DECKER INC

Motor housing and assembly process for impact wrench

ActiveUS20050257945A1Simplifies wire-up of power toolEasy to assembleDrilling rodsConstructionsEngineeringPower tool

A handle for a power tool is provided including a field case and front handle portion formed as a single piece. The front handle portion has an opening in a rear side thereof for receiving the wiring for the power tool. The wiring is connected to a motor that is mounted in the field case. A rear handle portion is attached to the front handle portion for covering the opening in the rear of the front handle portion. An end cap is connected to a rear of the field case for covering the remaining exposed wires connected to the motor. With the front handle design, the wire-up of the power tool can be completed from one side of the tool without having to turn the tool over during the wire-up process.

Owner:BLACK & DECKER INC

Cordless power tool system with improved power output

A cordless power tool system for improved power output includes a plurality of hand-held cordless power tools, where each power tool includes a tool housing, motor assembly, transmission / gear assembly and removable battery pack. The battery pack provides a nominal output voltage of approximately 25 volts or greater to a DC motor of the motor assembly. Each of the hand-held cordless power tools of the system has a power output to weight ratio of 70 watts per pound (W / lb) or greater.

Owner:BLACK & DECKER INC

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com