Full-automatic water-drill grinding and polishing machine

A fully automatic, grinding and polishing machine technology, applied in the direction of grinding/polishing equipment, grinding machines, machine tools suitable for grinding the edge of workpieces, etc., can solve the problems of large processing size error, low processing accuracy, and low product grade, and achieve The effects of trimming processing size errors, high precision grinding and polishing, and highlighting substantive features

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

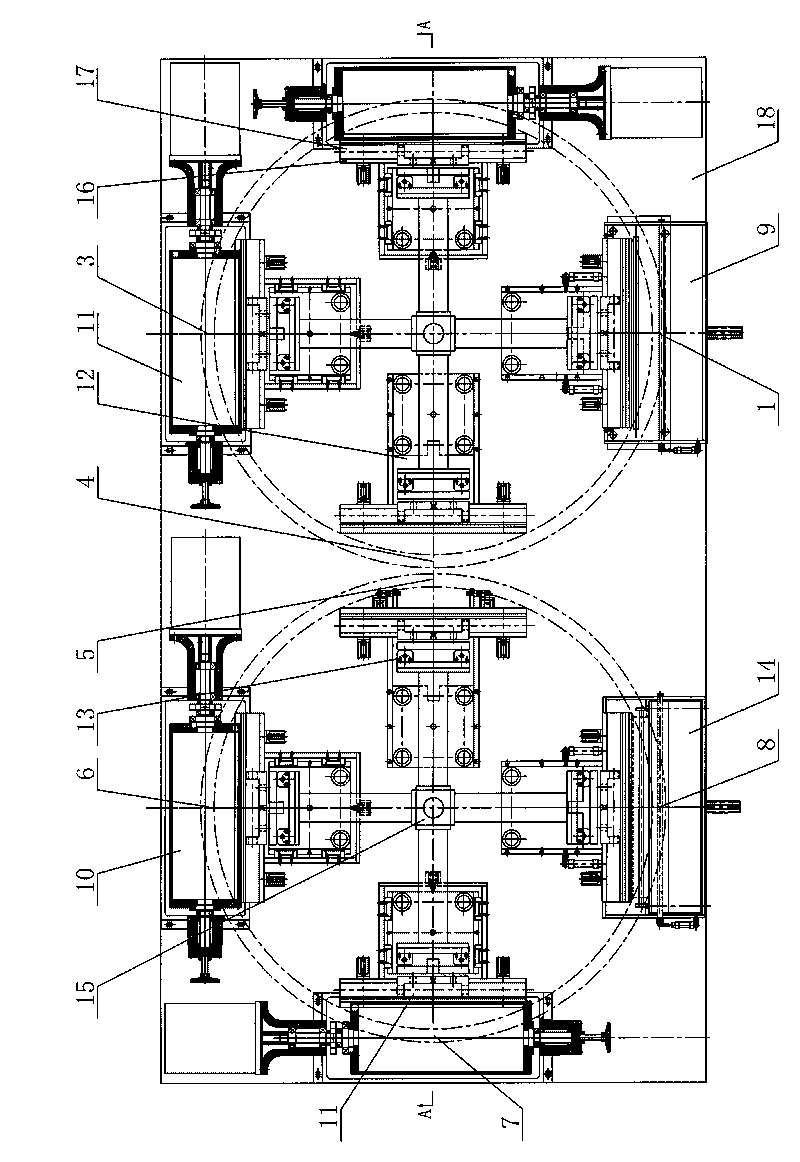

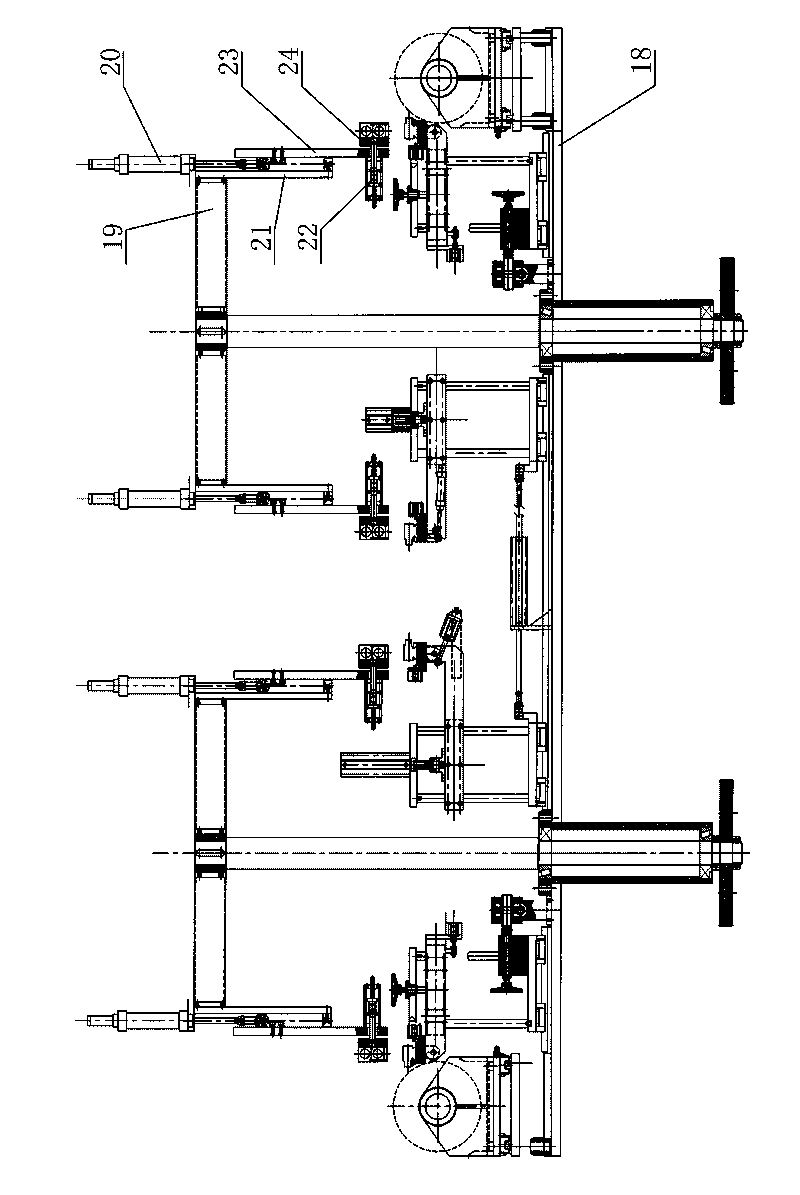

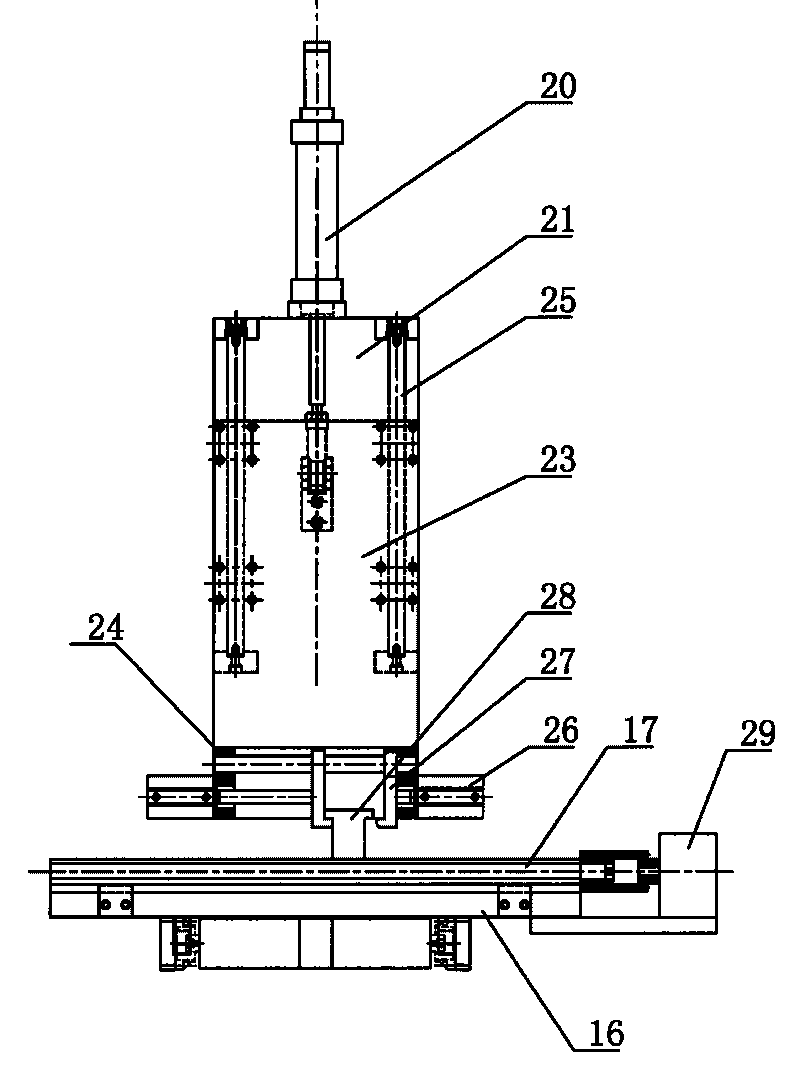

[0029] The accompanying drawings show the technical solution of the present invention and its embodiments, and the relevant details and working principles of the embodiments will be further described below in conjunction with the accompanying drawings.

[0030] Refer to attached figure 1 , 2, the full-automatic rhinestone grinding and polishing machine includes frame 18, fixture 17, fixture seat 16, manipulator 15 and two groups of grinding and polishing parts. The two groups of grinding and polishing parts are symmetrically arranged on the frame 18. It has four stations (the four stations in the right grinding and polishing part are the bead loading station 1, the right grinding station 2, the right polishing station 3 and the right docking station 4, and the four stations in the left grinding and polishing part It is the left docking station 5, the left grinding station 6, the left polishing station 7 and the beading station 8, wherein the left and right docking stations ar...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com