DCS control system for material processing

A control system and material technology, applied in the direction of comprehensive factory control, comprehensive factory control, electrical program control, etc., can solve the problems of feeding, metering or measurement errors, increased labor, and unqualified products, etc., to improve accuracy, The effect of reducing operation intensity and number of people and improving safety

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

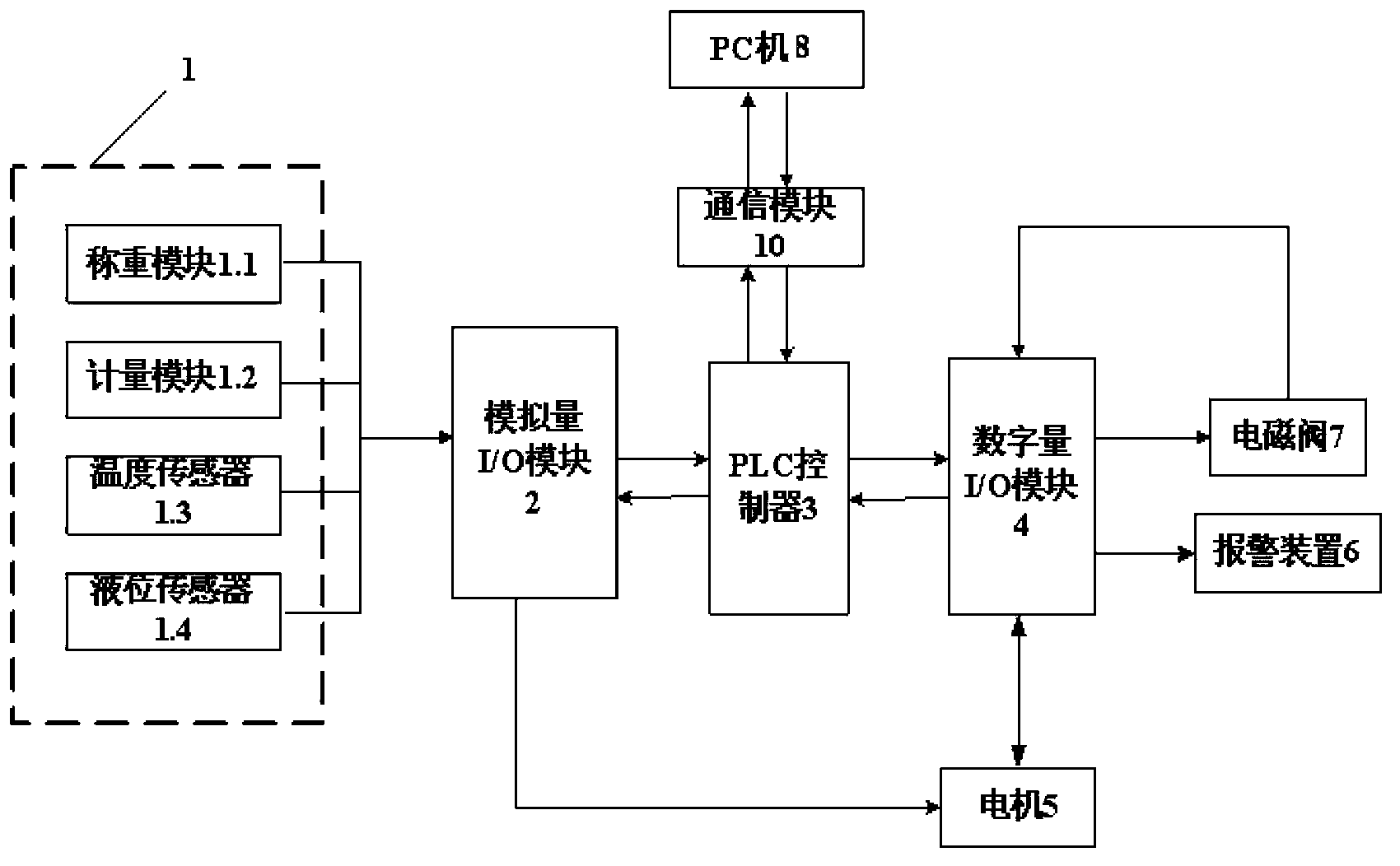

[0032] Such as figure 1 The shown DCS control system for material processing includes a diaphragm pump installed on the material storage tank and a motor 5 for starting material processing. The diaphragm pump 8 is provided with a solenoid valve 7, and a detection module 1 is provided inside the material storage tank. ; The detection module 1 is interactively connected with the PLC controller 3 through the analog I / O module 2, and the PLC controller 3 is interactively connected with the digital I / O module 4, and the digital I / O module 4 passes through Solenoid valve 7 controls described diaphragm pump to run, and the output terminal of described solenoid valve 7 is connected with the input terminal of digital quantity I / O module 4; Described analog quantity I / O module 2 and digital quantity I / O module 4 The output ends are all connected to the motor 5 ; the PLC controller 3 is also interactively connected to the touch screen 9 , and the output end of the digital I / O module 4 is...

Embodiment 2

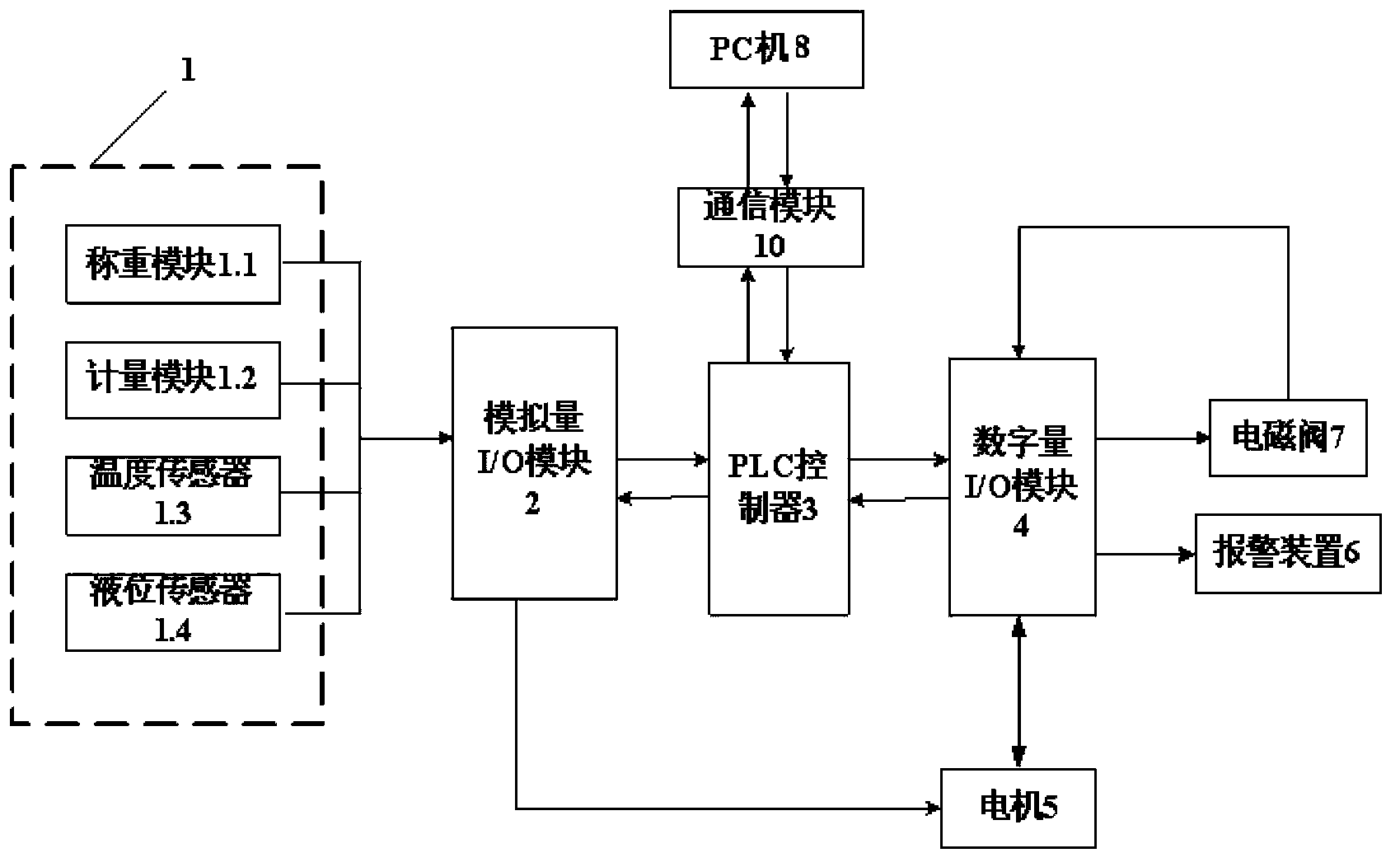

[0035] Such as figure 2 The shown DCS control system for material processing includes a diaphragm pump installed on the material storage tank and a motor 5 for starting material processing. The diaphragm pump 8 is provided with a solenoid valve 7, and a detection module 1 is provided inside the material storage tank. ; The detection module 1 is interactively connected with the PLC controller 3 through the analog I / O module 2, and the PLC controller 3 is interactively connected with the digital I / O module 4, and the digital I / O module 4 passes through Solenoid valve 7 controls described diaphragm pump to run, and the output terminal of described solenoid valve 7 is connected with the input terminal of digital quantity I / O module 4; Described analog quantity I / O module 2 and digital quantity I / O module 4 The output terminals are all connected to the motor 5 ; the PLC controller 3 is interactively connected to the PC 8 through the communication module 10 . An alarm 6 is connect...

Embodiment 3

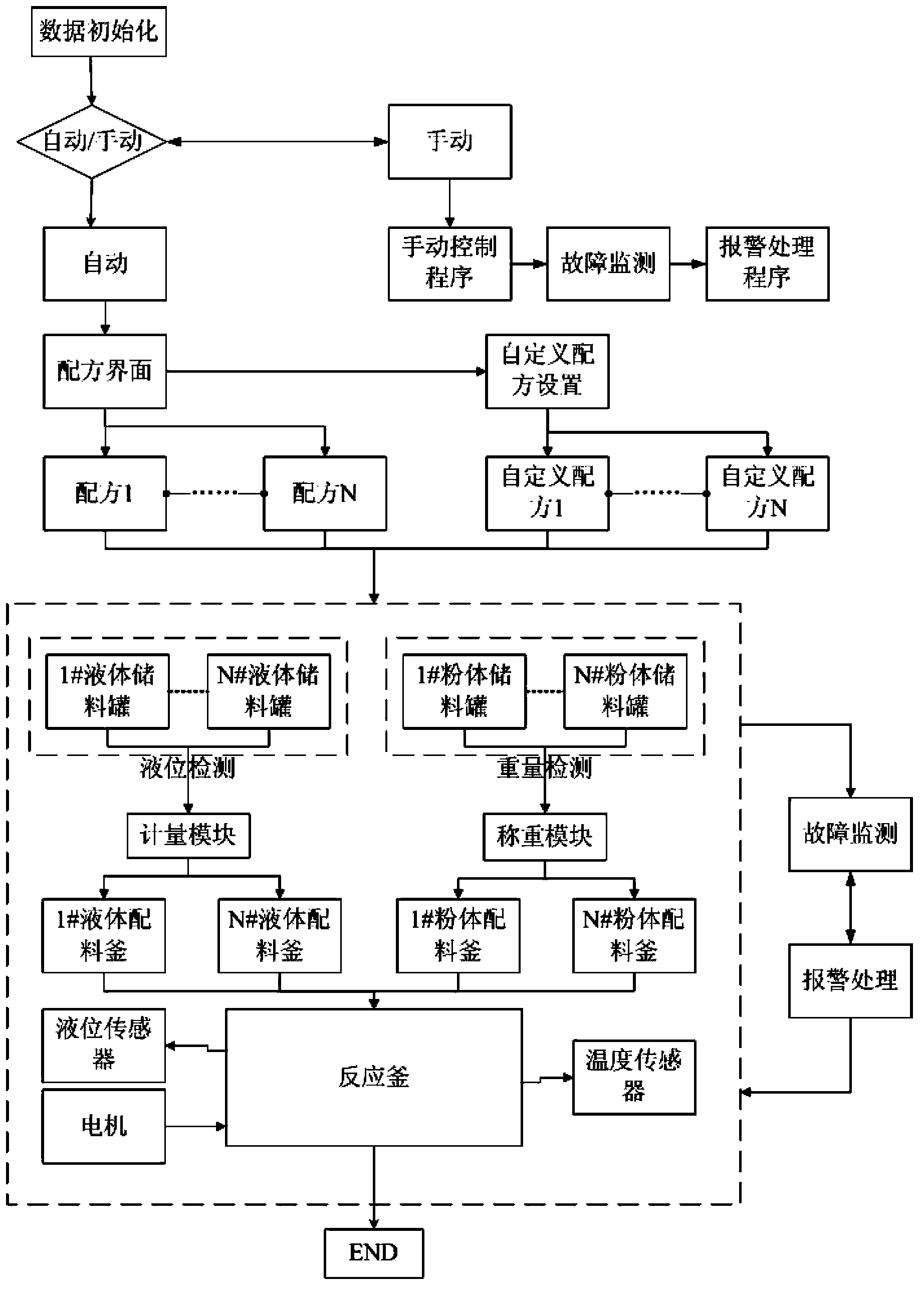

[0046] Such as image 3 Shown is the operation flow of the DCS control system, which is briefly described as follows:

[0047] 1. Turn on the power and initialize the control system;

[0048] 2. Select the automatic or manual mode, if the manual mode is selected, the manual control operation will be performed, and the system will not control;

[0049] 3. After selecting the automatic mode, enter the formula selection mode;

[0050] 4. Set the amount of each material according to the ratio of the processed substance and each raw material, and determine the output volume of each raw material storage tank according to the formula;

[0051] 5. Then open the electric valves on each raw material storage tank in turn, and make ingredients according to the formula through the weighing module and the metering module;

[0052] 6. Put each raw material into the reaction kettle in batches;

[0053] 7. The temperature sensor is used to detect the reaction kettle and control the reactio...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com