Grinding wheel polishing system and polishing control method thereof

A grinding wheel and polisher technology, which is applied to grinding/polishing equipment, grinding automatic control devices, grinding machines, etc., can solve problems such as reducing work efficiency, inability to ensure the consistency of installed workpieces, and the impact on the yield rate of processed products, so as to achieve control convenient effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0033] The technical solutions and beneficial effects of the present invention will be further elaborated below according to the drawings and embodiments.

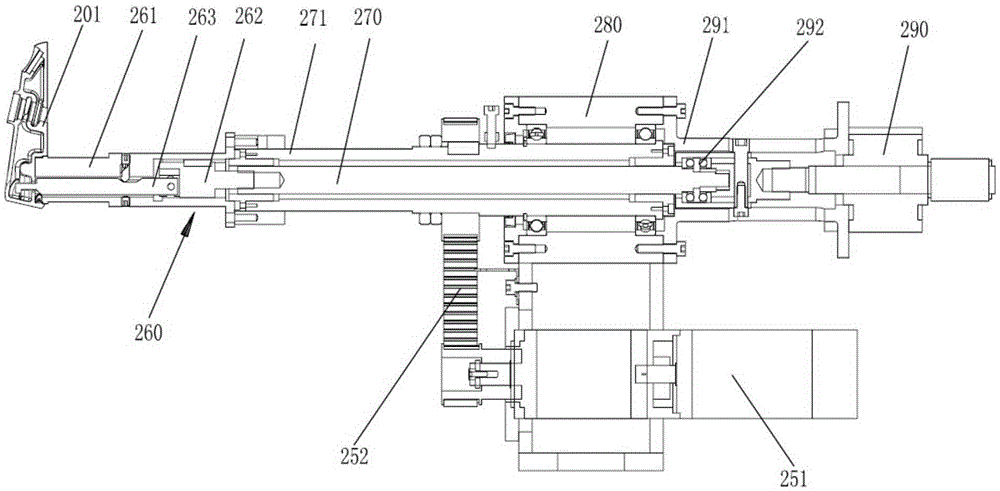

[0034] refer to Figure 1 ~ Figure 4 , the present invention provides a grinding wheel polishing system, including a grinding base 300, a polishing platform 200, a control main cabinet and a human-computer interaction terminal. The grinding base 300 and the polishing platform 200 are respectively connected to the control main cabinet through a bus cable or an optical fiber bus.

[0035] The grinding seat 300 includes a grinding wheel and a grinding wheel driving seat. The grinding seats 300 are evenly distributed on the periphery of the polishing platform 100. There are N grinding seats 300, where N≥2 and N is an integer.

[0036] The polishing platform 200 includes a base 210, and a turntable 240 and a first driving device arranged on the base 210, the first driving device drives the turntable 240 to rotate around the cen...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com