Method for replacing rubber belt by long-distance steel cord rubber belt conveyor

A technology of belt conveyor and steel cord core, applied in the direction of conveyor, transportation and packaging, etc., to achieve the effect of ensuring production time, huge social and economic benefits, extensive social benefits and

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

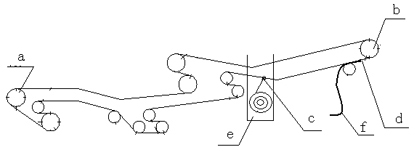

[0014] Such as figure 1 As shown, the layout and structure of a long-distance tape, the left end a is the nose, the right end b is the tail, and the middle part e is 6# Hengchuan. In order to replace the tape, we adopt the following method,

[0015] A method for replacing the belt of a long-distance steel cord belt conveyor. The steps are: stop the car, loosen and tighten the trolley (or tensioning wheel), then tighten the lower belt, punch the upper and lower belts at the tail b, and lift 6 The upper tape of #横川, remove the rack at 6# Hengchuan, install the tape reel at 6# Hengchuan, cut off the lower tape at point d of the tail and 6# Hengchuan (the distance between the two places is about 120 meters), and put the new tape f Connect with the old tape, remove the tape card under the tail of the machine, pull the old tape for 120 meters at 6# Hengchuan, then cut off the 120-meter old tape, roll the 120-meter old tape, and remove the old tape with a forklift to complete a unit ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com