Coating machine of prepainted steel sheet

A technology of coating machine and color-coated plate, which is applied in the direction of coating, the device for coating liquid on the surface, etc., can solve the problem that the installation accuracy of the coating roller cannot be guaranteed, the left and right positions of the coating roller cannot be guaranteed, and the influence The problems of contact between the coating roller and the steel belt, etc., can achieve the effect of superior product quality, reliable fixation, convenient and accurate adjustment

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0013] The present invention will be further described below in conjunction with the accompanying drawings and specific embodiments, but the present invention should not be limited to the embodiments.

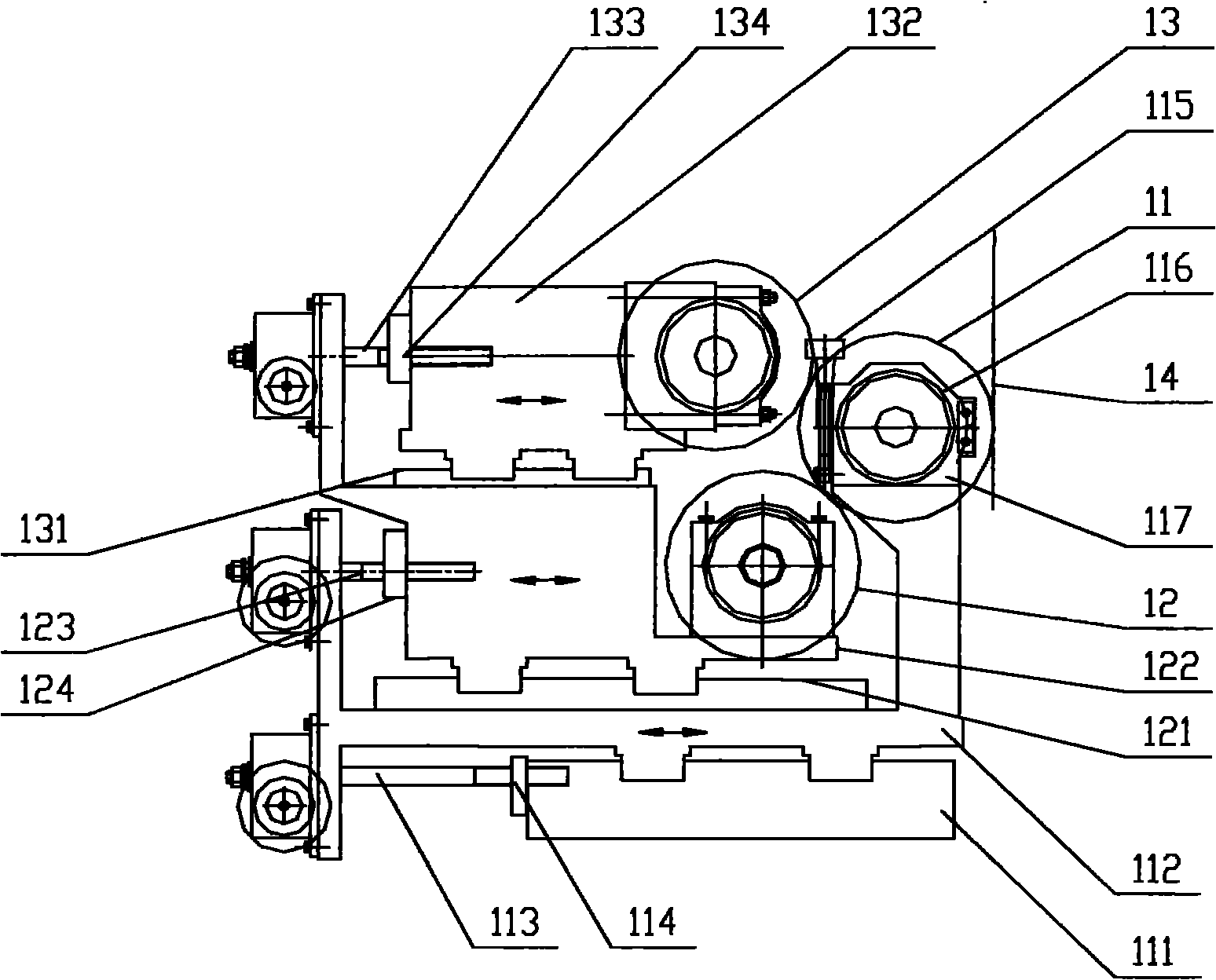

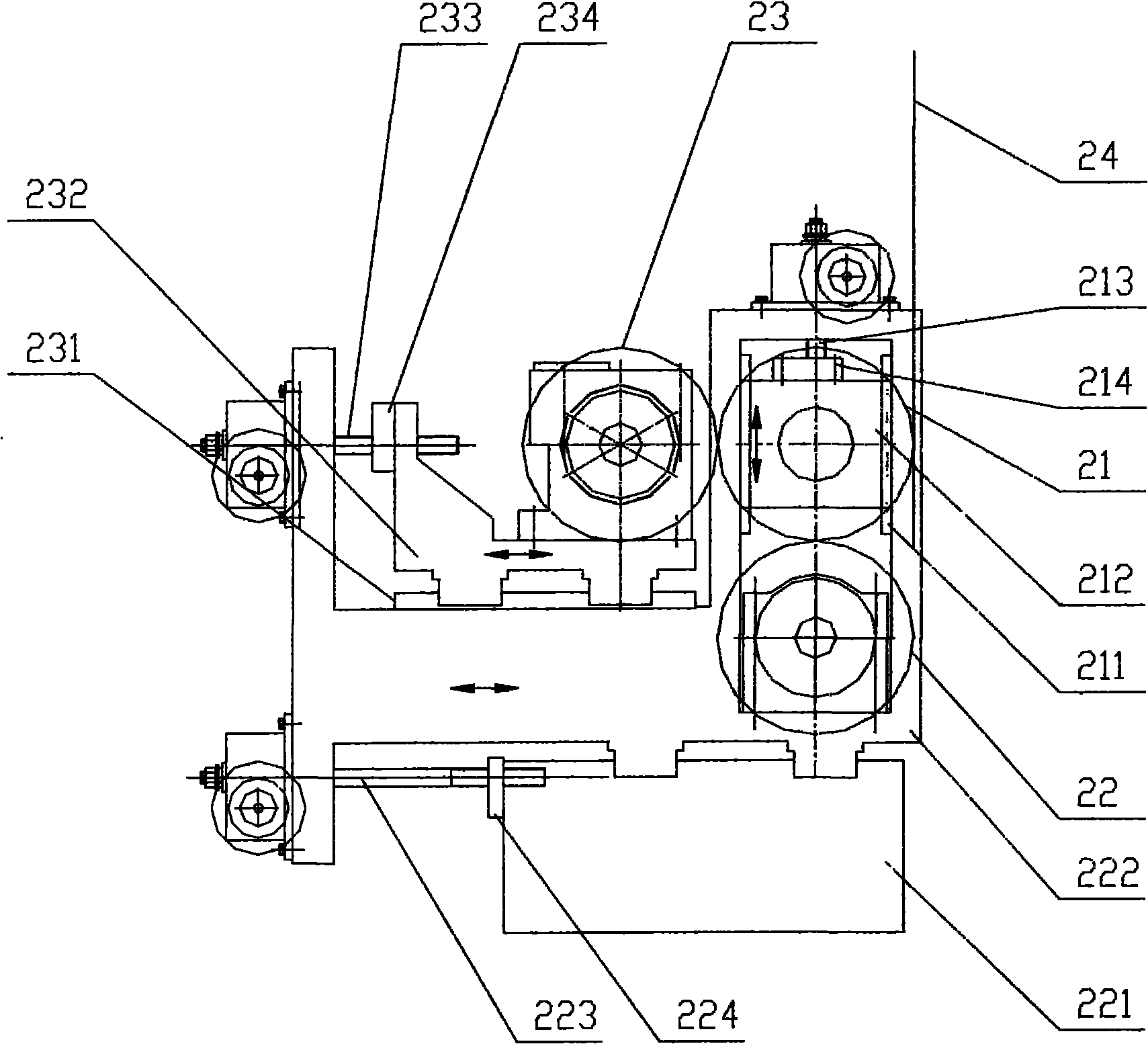

[0014] See figure 1 , The present invention is mainly made up of coating roller 11 and its adjustment device, dipping material roller 12 and its adjustment device, metering roller 13 and its adjustment device. The adjustment device of the coating roller 11 is composed of a track 111, a bracket 112, a screw 113, and a nut 114. Through the system of the screw 113 and the nut 114, the entire coating roller group can be moved left and right, and the coating roller 11 is close to the substrate 14. The coating on the surface of the applicator roller 11 can be smoothly and evenly applied to the substrate 14; The nut 124 system can move the dipping roller 12, metering roller 13 and its adjustment device left and right, thereby simultaneously adjusting the gap between the dipping roll...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com