Production method for solving strip breakage of P-containing high-strength IF (Intermediate Frequency) hot rolling strip steel while withdrawal and straightening

A production method and technology of hot-rolled strip steel, applied in the field of steel rolling, can solve problems such as difficult smelting and not very ideal, and achieve the effect of simple method, remarkable effect, and high cost efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

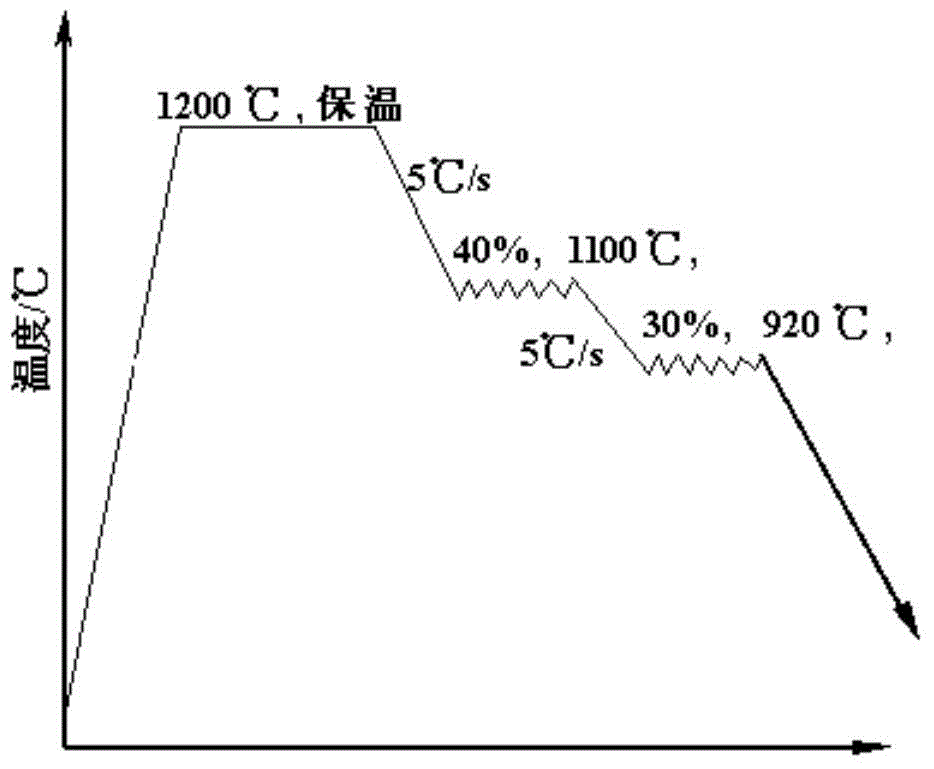

[0046] The hot-rolled high-Si, high-P, high-strength IF steel whose chemical composition meets the chemical composition shown in Example 1 in Table 3 is produced according to the following production process: continuous casting slab heating→rough rolling→finish rolling→laminar flow cooling →Coiled into hot-rolled raw material coils→Uncoiled from cold-rolled line→Stretching and straightening scale breaking→Pickling→Cold rolling→Continuous annealing→Coiled into finished steel coils. Among them, the temperature of the continuous casting slab entering the heating furnace is 700°C, the heating temperature in the heating furnace is 1280°C, the rough rolling pass is 1+5 mode, the temperature of RT2 is 1080°C, and the final rolling temperature is 920°C °C, the cooling rate of laminar cooling is 50 °C / s, and the temperature for coiling into hot-rolled raw material coils is 710 °C. The control of each process parameter of hot rolling is shown in Table 4. The chemical composition of the ...

Embodiment 2

[0048] The hot-rolled high-Si, high-P, high-strength IF steel whose chemical composition meets the chemical composition shown in Example 2 in Table 3 is produced according to the following production process: continuous casting slab heating→rough rolling→finish rolling→laminar cooling →Coiled into hot-rolled raw material coils→Uncoiled from cold-rolled line→Stretching and straightening scale breaking→Pickling→Cold rolling→Continuous annealing→Coiled into finished steel coils. Among them, the temperature of the continuous casting slab entering the heating furnace is 630°C, the heating temperature in the heating furnace is 1290°C, the rough rolling pass is 1+5 mode, the temperature of RT2 is 1090°C, and the final rolling temperature is 930°C °C, the cooling rate of laminar cooling is 45 °C / s, and the temperature for coiling into hot-rolled raw material coils is 700 °C. The control of various process parameters of hot rolling is shown in Table 4. The chemical composition of the s...

Embodiment 3

[0050] The hot-rolled high-Si, high-P, high-strength IF steel whose chemical composition meets the chemical composition shown in Example 3 in Table 3 is produced according to the following production process: continuous casting slab heating→rough rolling→finish rolling→laminar cooling →Coiled into hot-rolled raw material coils→Uncoiled from cold-rolled line→Stretching and straightening scale breaking→Pickling→Cold rolling→Continuous annealing→Coiled into finished steel coils. Among them, the temperature of the continuous casting slab entering the heating furnace is 670°C, the heating temperature in the heating furnace is 1270°C, the rough rolling pass is 1+5 mode, the temperature of RT2 is 1070°C, and the final rolling temperature is 930°C °C, the cooling rate of laminar cooling is 40 °C / s, and the temperature for coiling into hot-rolled raw material coils is 700 °C. The control of each process parameter of hot rolling is shown in Table 4. The chemical composition of the steel...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com