Using method of coke with different initial reaction temperatures in blast furnace

A technology of reaction temperature and coke, applied in blast furnaces, blast furnace details, furnaces, etc., can solve the problems of increasing ironmaking costs, waste of resources, and rising coal blending costs, improving gas flow distribution, ensuring stable and forward running, and reducing furnace costs. the effect of fluctuations

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

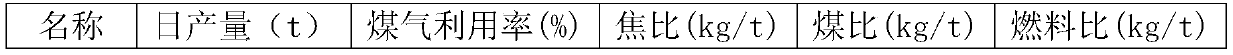

[0059] at 3200m 3 Taking the first-class blast furnace as an example (all the second-class cokes were used before), the cokes with different initial reaction temperatures are classified and used in the blast furnace according to the blast furnace conditions.

[0060] 1. Check the initial reaction temperature of the coke produced in the whole plant, and classify and use it according to the first-class coke: the initial reaction temperature is 970-1010°C; the second-class coke: the initial reaction temperature is 900-970°C.

[0061] 2. First divide the equal area of the material surface into 11 equal parts, and measure the actual cloth angle and material flow angle corresponding to each equal part respectively, from the center to the edge in order of 1 # →11 # bit, set 1 # →3 # Defined as the central part; 4 # →7 # defined as the middle part; 8 # →11 # defined as the edge.

[0062] 3. With its current coke distribution system (The superscript 876541 indicates the rin...

Embodiment 2

[0074] at 4000m 3 Taking a high-grade blast furnace as an example (all the first-class high-quality cokes were used before), the cokes with different initial reaction temperatures are classified and used in the blast furnace according to the blast furnace conditions.

[0075] 1. Check the initial reaction temperature of the coke produced in the whole plant, and classify and use it according to the first-class coke: the initial reaction temperature is 970-1010°C; the second-class coke: the initial reaction temperature is 900-970°C.

[0076] 2. First divide the equal area of the material surface into 11 equal parts, and measure the actual cloth angle and material flow angle corresponding to each equal part respectively, from the center to the edge in order of 1 # →11 # bit, set 1 # →3 # Defined as the central part; 4 # →7 # defined as the middle part; 8 # →11 # borderline

[0077] 3. With its current coke distribution system For example, according to the batch weight...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com