Rapid wire calibration device for photoelectric sensor

A photoelectric sensor, fast technology, applied in the direction of measuring devices, instruments, measuring electricity, etc., can solve problems such as time-consuming, labor-intensive, and affecting the stability and smoothness of blast furnace production

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0011] The present invention will be further described below in conjunction with the accompanying drawings and specific embodiments.

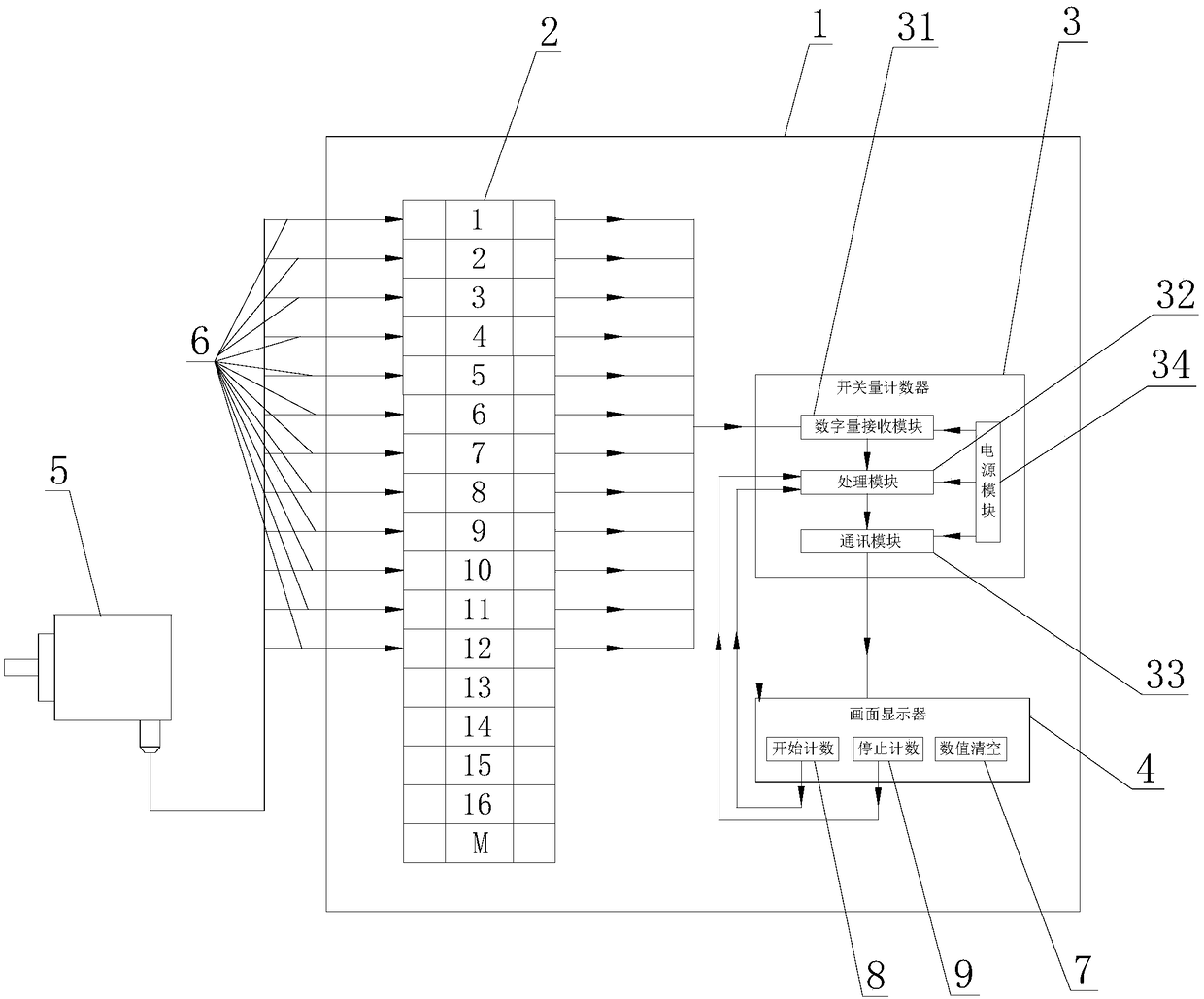

[0012] Such as figure 1 As shown, the described a kind of photoelectric sensor rapid calibration device includes a backboard 1, on which a terminal block 2, a switching value counter 3 and a screen display 4 are arranged, and the number of terminals in the terminal block 2 is greater than Or equal to the number of cables 6 in the encoder 5, to ensure that all the cables 6 of the encoder 5 can be connected to the terminal block 2 at the same time, and the output terminals of each terminal in the terminal block 2 are simultaneously connected with the input signal of the switch value counter 3 Connect, the output terminal of switch quantity counter 3 is connected with the input terminal signal of picture display 4; Said switch quantity counter 3 can rotate the switch quantity pulse that each terminal correspondingly accesses encoder cable 6 to pro...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com