Gas-fired boiler for overheating foreign steam

An external steam and gas boiler technology, applied in the field of gas boilers, can solve the problems of low utilization rate and unstable steam production of low-temperature exhaust gas, and achieve the effects of reducing losses, basically stable steam supply, and increasing production.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

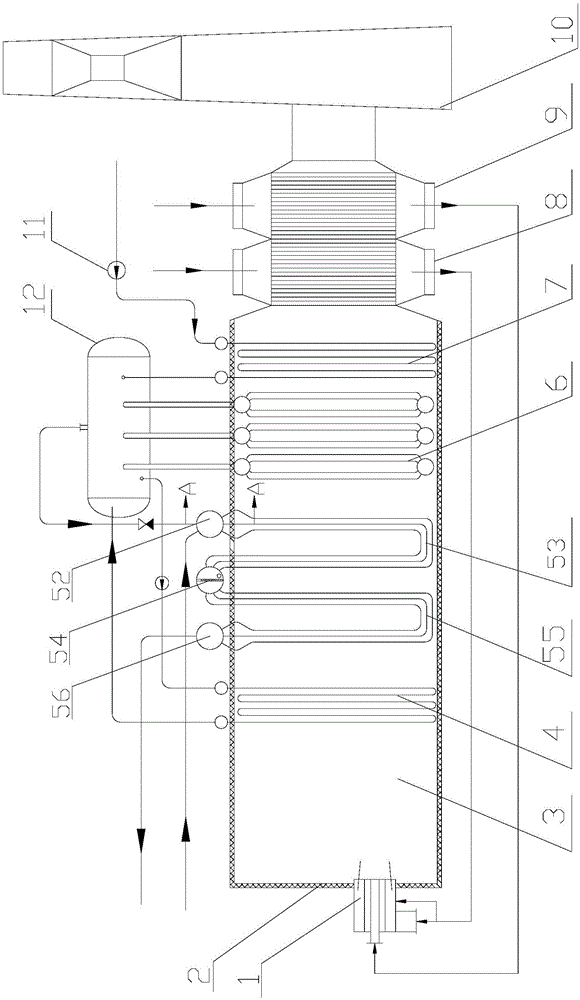

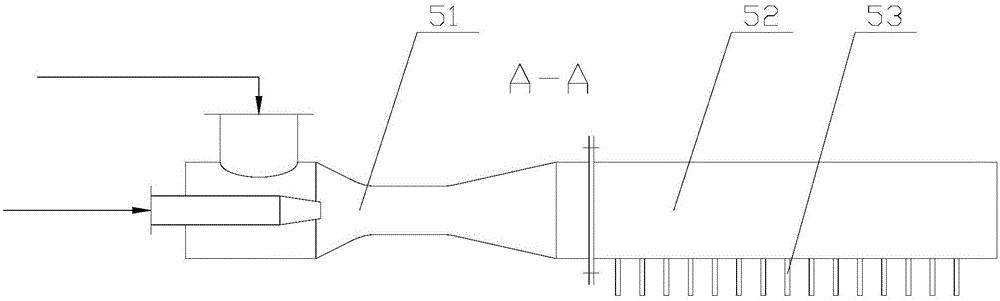

[0025] The present invention is described in further detail now in conjunction with accompanying drawing. These drawings are all simplified schematic diagrams, which only illustrate the basic structure of the present invention in a schematic manner, so they only show the configurations related to the present invention.

[0026] like figure 1 , 2 As shown, the arrow in the figure indicates the direction of gas or water flow movement, which is the best embodiment of the present invention, a gas boiler for superheating external steam, the gas boiler includes a pot part and a furnace part, and the pot part includes a steam drum 12, a front Forced circulation evaporator 4, composite superheater 5, rear natural circulation evaporator 6 and economizer 7, the furnace part includes burner 1, furnace body 2, combustion chamber 3, air preheater 8, gas preheater 9. With the chimney 10, the burner 1 is arranged at the front end of the furnace body 2, the chimney 10 is arranged at the end...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com