Method to avoid steel breakout caused by continuous casting crystallizer heat-adjusted width billet shell being extruded

A technology for continuous casting mold and thermal width adjustment, which is applied in the field of avoiding steel breakout caused by extrusion of the thermally adjusted shell of the continuous casting mold, can solve the problems of easy cracking and no technical means and solutions have been published publicly. Achieve high applicability, optimized moving speed, and stable production.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

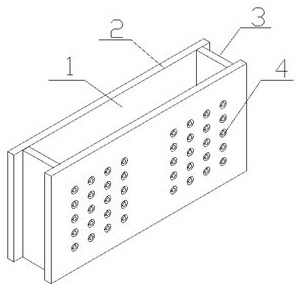

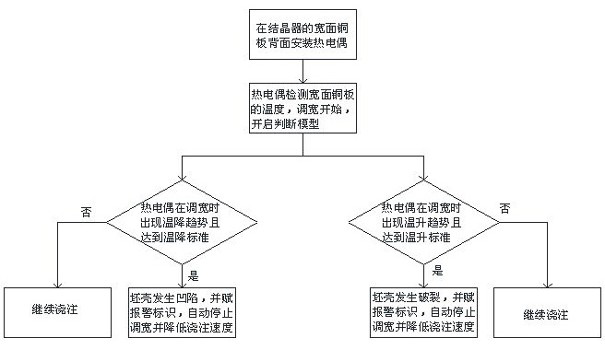

[0039] 1. For the 1# continuous casting machine of an enterprise, the wide copper plate of the crystallizer is equipped with 6 rows and 3 rows of thermocouples 4;

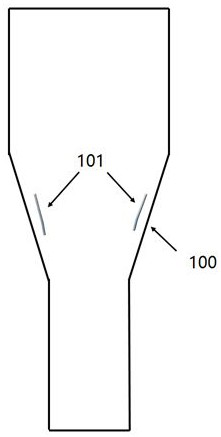

[0040] 2. For a high-carbon and high-alloy steel grade, it is planned to conduct thermal width adjustment during pouring, and the width of crystallizer 1 is reduced from 1500mm to 1400mm;

[0041] 3. When the pouring speed is 1.3m / min, start to adjust the width;

[0042] 4. At the beginning of widening, the temperature of a row of three thermocouples 4 on the inner arc width surface of crystallizer 1 is 250, 225, and 190°C respectively;

[0043] 5. The temperature of thermocouple 4 remains unchanged at the beginning of width adjustment, and the temperature of the above three thermocouples 4 drops to 215, 192, and 155°C respectively during the width adjustment process;

[0044] 6. The system sends out an abnormal alarm and automatically reduces the speed to 0.6m / min;

[0045] 7. The operator stops the width adjust...

Embodiment 2

[0048] 1. For the 1# continuous casting machine of an enterprise, the wide copper plate of the crystallizer is equipped with 6 rows and 3 rows of thermocouples 4;

[0049] 2. For a certain type of high-strength steel, the No. 1 machine is planned to carry out thermal width adjustment during pouring, and the width of crystallizer 1 is reduced from 1600mm to 1450mm;

[0050] 3. When the pouring speed is 1.1m / min, start to adjust the width;

[0051] 4. Before the width adjustment starts, the temperatures of a row of three thermocouples 4 on the west side of the inner arc width of the crystallizer 1 are 223, 199, and 170°C respectively;

[0052] 5. After the width adjustment starts, the temperatures of the above three thermocouples 4 rise to 260, 235, and 201°C respectively;

[0053] 6. The system sends out an abnormal alarm and automatically reduces the speed to 0.2m / min;

[0054] 7. The operator stopped the width adjustment operation. After the billet came out of the casting m...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com