Rolling mill flying scissor blade cooling method and cooling device thereof

A cooling method and a cooling device technology, which are applied in the direction of shearing devices, shearing machine accessories, metal processing machinery parts, etc., can solve problems that affect the smooth progress of production, increase equipment operating costs, and affect the yield of rolled products, etc., to achieve Improve life and shear quality, reduce spare parts cost, good shear quality effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0041] Method example:

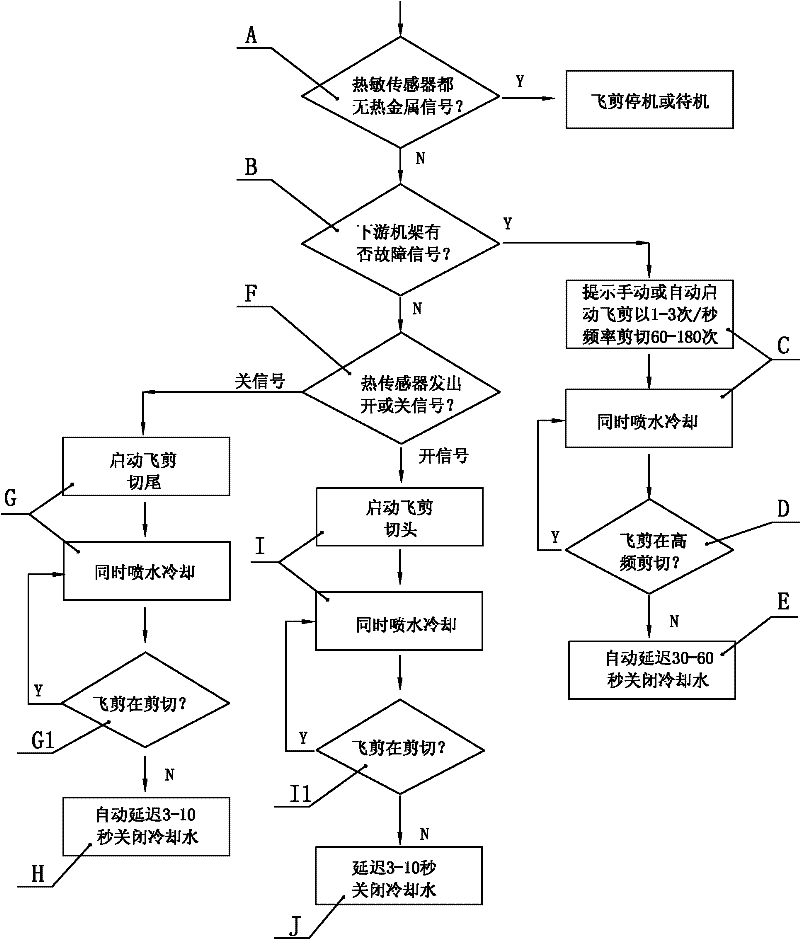

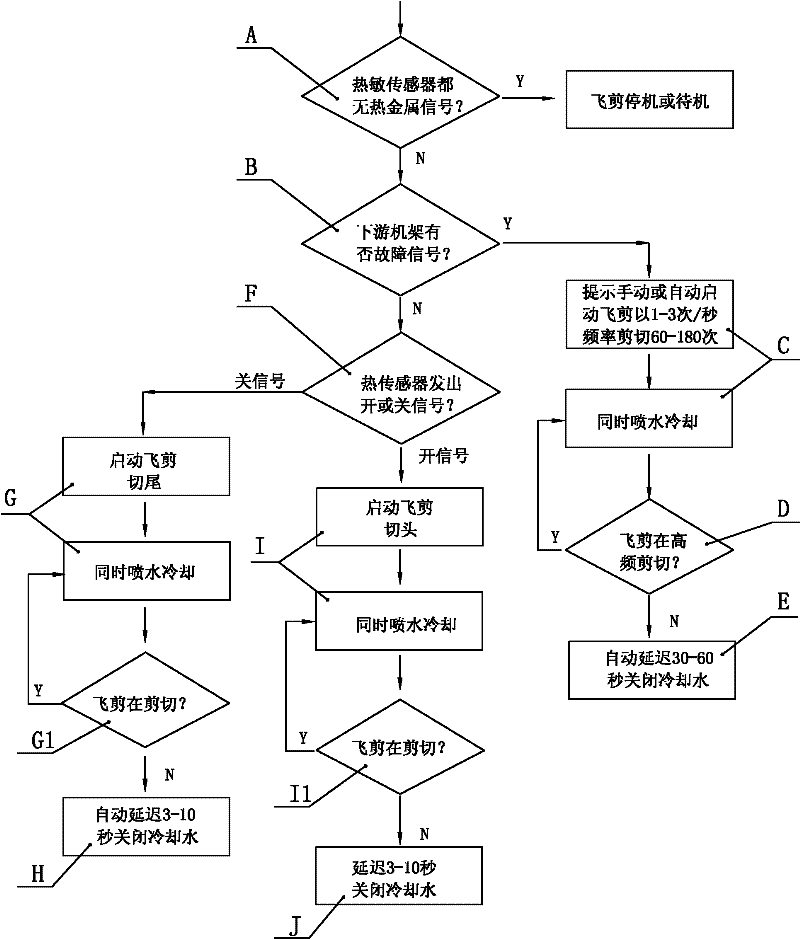

[0042] like figure 1 , which is a schematic flow diagram of an embodiment of the cooling method for rolling mill flying shear blades according to the present invention. In this embodiment of the method, a thermal sensor is set to detect the movement and position of the wire on the way to the flying shear blade, and the detection signal is transmitted to the control circuit, and includes the following steps:

[0043] A. When the thermal sensor sends out a low-level or zero-voltage detection signal without change for more than 3 minutes, and the control circuit interprets that the hot metal does not exist, the flying shears and their blades stop or stand by; when the thermal sensor sends out a signal Different from the above process, the control circuit interprets that there is hot metal and turns to step B;

[0044] B. Detect whether there is a fault signal on the frame downstream of the flying shear blade? If there is a fault signal, go to step C, i...

PUM

| Property | Measurement | Unit |

|---|---|---|

| diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com