A continuous reaction device and method for amino acid surfactant

A surfactant and reaction device technology, applied in the field of amino acid surfactants, can solve the problems of cumbersome synthesis process, poor reaction uniformity, high content of by-products, etc., and achieve the effects of stable control of product process conditions, improved efficiency, and small volume

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

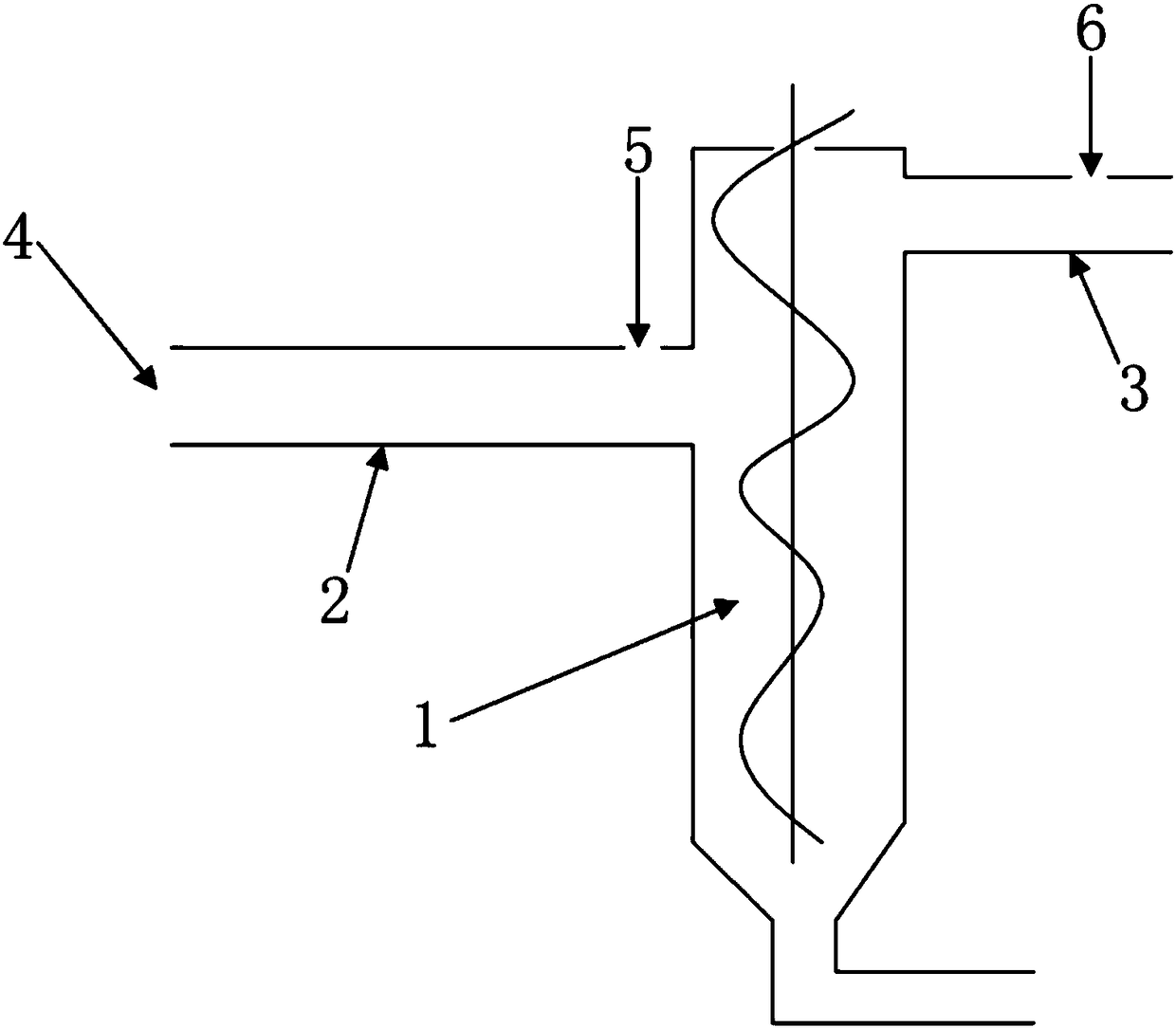

[0025] A continuous reaction device for amino acid surfactants, comprising a liquid separation tower, a pipeline synthesis reactor, and a pipeline neutralization reactor; the pipeline synthesis reactor is vertically arranged in the middle of the liquid separation tower, and is connected with the separation The liquid tower is connected; the pipe synthesis reactor is provided with a raw material inlet away from one end of the liquid separation tower, and an acid inlet is provided near the end of the liquid separation tower; the pipeline neutralization reactor is connected with the liquid separation tower The outlet at the upper end is connected, and there is an alkali inlet in the middle; the pipeline synthesis reactor and the pipeline neutralization reactor are all conventional pipeline reactors, with multi-stage static mixers inside and jackets outside to adjust the temperature.

[0026] Feed liquid caustic soda (sodium hydroxide, 10mol / L) from the storage tank and sodium sarc...

Embodiment 2

[0028] A continuous reaction device for amino acid surfactants, comprising a liquid separation tower, a pipeline synthesis reactor, and a pipeline neutralization reactor; the pipeline synthesis reactor is vertically arranged in the middle of the liquid separation tower, and is connected with the separation The liquid tower is connected; the pipe synthesis reactor is provided with a raw material inlet away from one end of the liquid separation tower, and an acid inlet is provided near the end of the liquid separation tower; the pipeline neutralization reactor is connected with the liquid separation tower The outlet at the upper end is connected, and there is an alkali inlet in the middle; the pipeline synthesis reactor and the pipeline neutralization reactor are all conventional pipeline reactors, with multi-stage static mixers inside and jackets outside to adjust the temperature.

[0029] Control the feed temperature T= 20℃~30℃, use a centrifugal pump to add to the first-stage...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com