Method for controlling fluctuation of liquid level of continuous casting crystallizer

A continuous casting mold and liquid level fluctuation technology, applied in the field of steelmaking, can solve problems such as unsatisfactory control effect of continuous casting mold

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

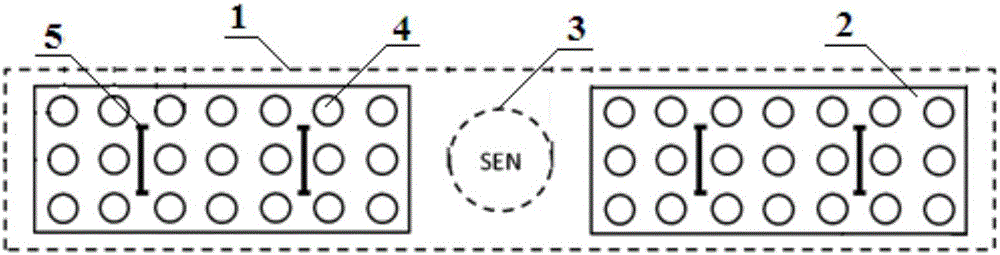

[0025] The embodiment of the present application provides a method for controlling the liquid level fluctuation of the continuous casting mold to solve the technical problem of unsatisfactory control effect of the liquid level fluctuation in the continuous casting mold in the prior art; to improve the ripple suppression efficiency and simplify the operation process technical effect.

[0026] In order to solve the above technical problems, the general idea of the technical solution provided by the embodiment of the present application is as follows:

[0027] A method for controlling liquid level fluctuations in a continuous casting mold, comprising:

[0028] Putting mold slag on the liquid surface of the crystallizer to form a mold slag layer;

[0029] resting a leveling board on the mold powder layer;

[0030] Wherein, the contact surface between the leveling plate and the mold slag layer is plane, and is kept on the mold slag layer.

[0031] From the above content, it ca...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Thickness | aaaaa | aaaaa |

| Thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com