Casting system used for twin-roll thin strip continuous casting and use method thereof

A twin-roll thin-strip continuous casting and casting system technology, applied in the thin-strip continuous casting field, can solve problems such as affecting the smooth production of product quality, unfavorable renewal of molten steel in the upper part of the molten pool, reducing the impact force of turbulent flow strands, etc. The effect of reducing the transition package, simplifying the structure and reducing the impact force of the stream

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

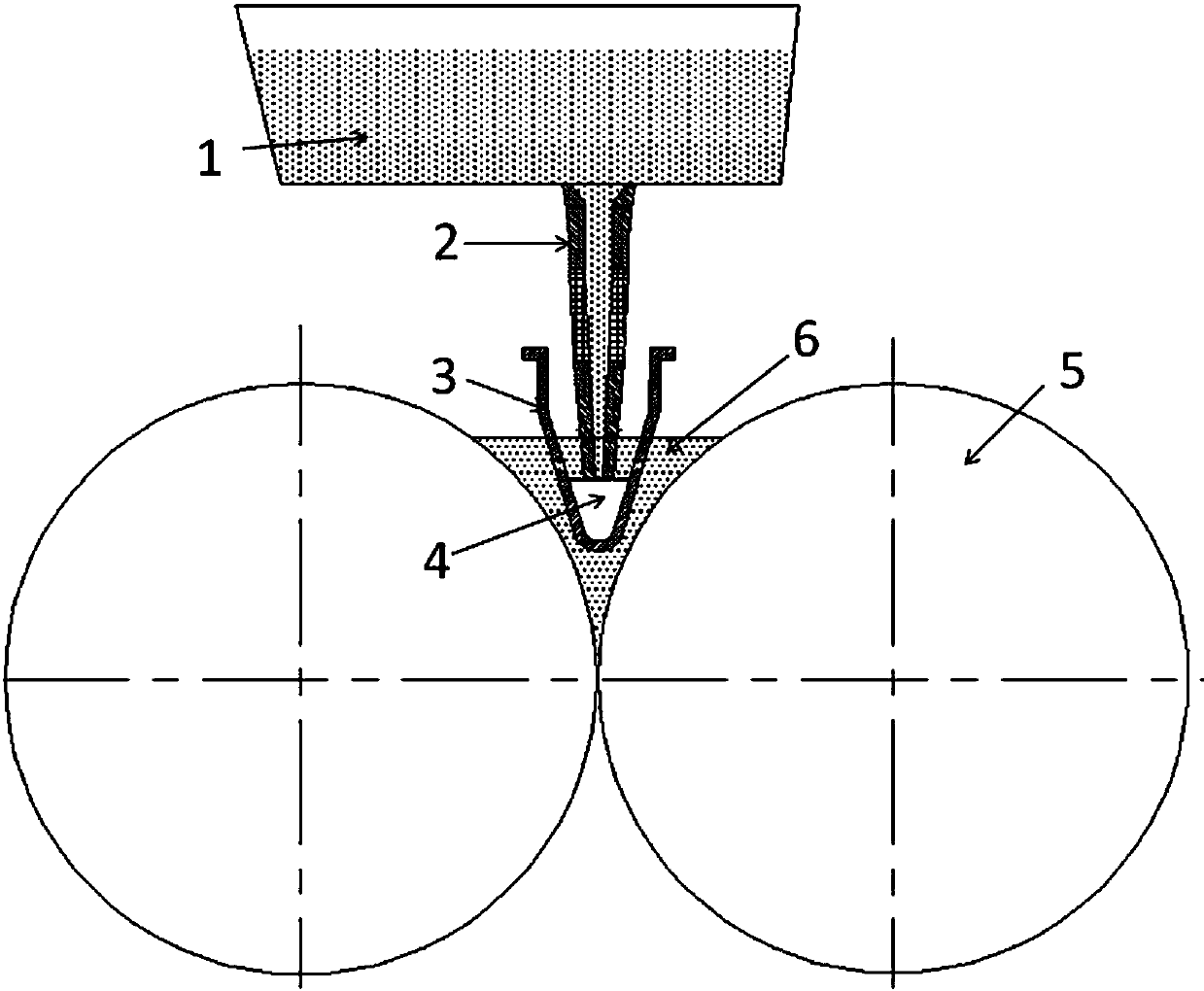

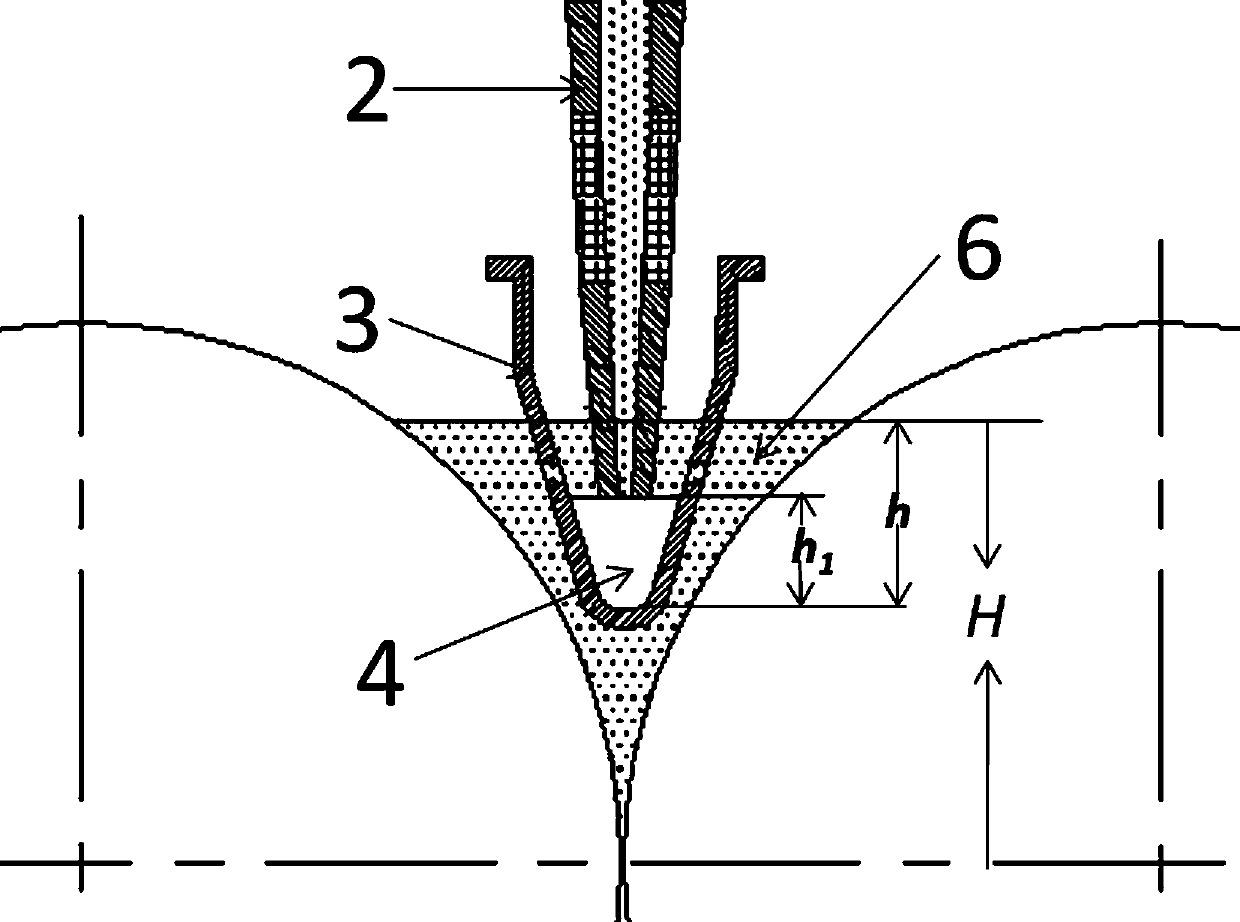

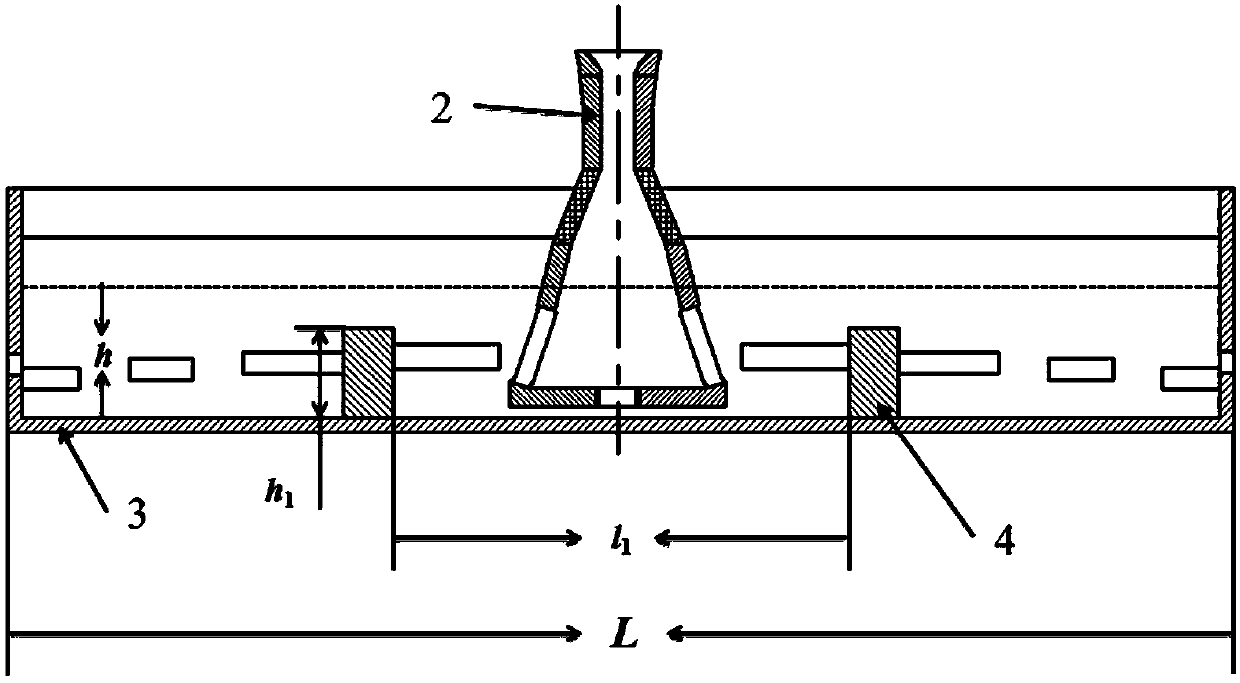

[0054] The casting system structure for twin-roll thin strip continuous casting is as follows: figure 1 As shown, the partial enlarged picture is shown in figure 2 As shown, including the submerged distribution outlet 2 and the flow distributor 3, the structure is as follows image 3 Shown; the structure of the submerged cloth outlet 3 is as follows Figure 4 As shown, the A-A section diagram is shown in Figure 5 As shown, it is composed of an inflow section 7, a transition section 8 and a flat outflow section; the outflow section is divided into two parts: a constriction section 9 and an expansion section 10 from top to bottom;

[0055] The shrinkage rate of the cross-sectional area of the shrinkage section 9 is 30%, that is, the bottom cross-sectional area of the shrinkage section 9 S 3 than the cross-sectional area of the top of the contraction section 9 S 2 30% smaller, the expansion angle between the width direction of the contraction section 9 and the vert...

Embodiment 2

[0071] The structure of the casting system for twin-roll thin strip continuous casting is the same as in Embodiment 1, the difference is that:

[0072] (1) The expansion section is provided with a narrow surface tapping hole 11 on the two side walls of the narrow surface, and a wide surface tapping hole 12 on the two side walls of the wide surface; the structure is as follows Figure 6 shown; the upper edge of the wide face tap hole 12 is equal to or lower than the upper edge of the narrow face tap hole 11; the cross-sectional area of each narrow face tap hole S 1 is the cross-sectional area of the bottom end of the constriction S 3 75% of the horizontal diversion angle α Between 175°; the cross-sectional area of each wide face tap hole is the cross-sectional area of each narrow face tap hole S 1 15% of

[0073] (2) The structure of flow distributor 3 is as follows: Figure 9 As shown, each wide surface distribution hole 14 is distributed in a step shape from th...

Embodiment 3

[0076] The structure of the casting system for twin-roll thin strip continuous casting is the same as in Embodiment 1, the difference is that:

[0077] (1) The shrinkage rate of the cross-sectional area of the shrinkage section is 15%, the expansion angle between the width direction of the shrinkage section and the vertical plane is 25°, and the convergence angle between the length direction of the shrinkage section and the vertical plane is 2°;

[0078] (2) The expansion angle between the width direction of the expansion section and the vertical plane is 10°, and the convergence angle between the length direction and the vertical plane is 5°;

[0079](3) The cross-sectional area of each narrow taphole in the expansion section is 50% of the cross-sectional area at the bottom of the contraction section, and the horizontal diversion angle is 175°; the cross-sectional area of the bottom taphole is that of the narrow taphole 5% of the cross-sectional area;

[0080] (4) The ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| height | aaaaa | aaaaa |

| height | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com