Manufacturing device of ultra-large type special thick plate rectangular ingotblank

A manufacturing device and a super-large and extra-large technology, which are applied in the field of manufacturing devices for super-large and extra-thick rectangular ingots, can solve the problems of uneven temperature distribution of molten steel, low yield and high opening, and avoid cracks and entrainment. , Improve the quality of ingot and the effect of uniform temperature field

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

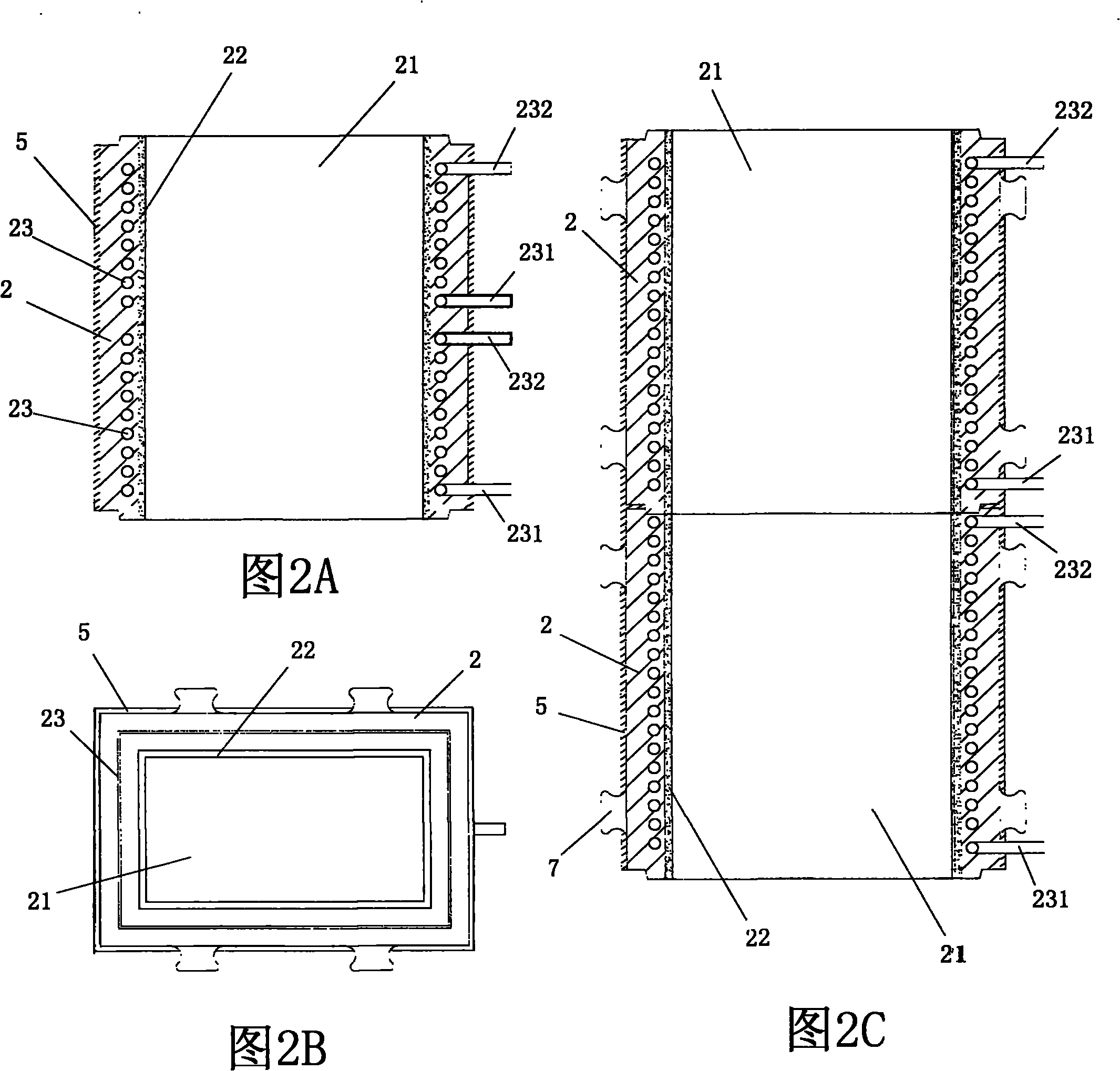

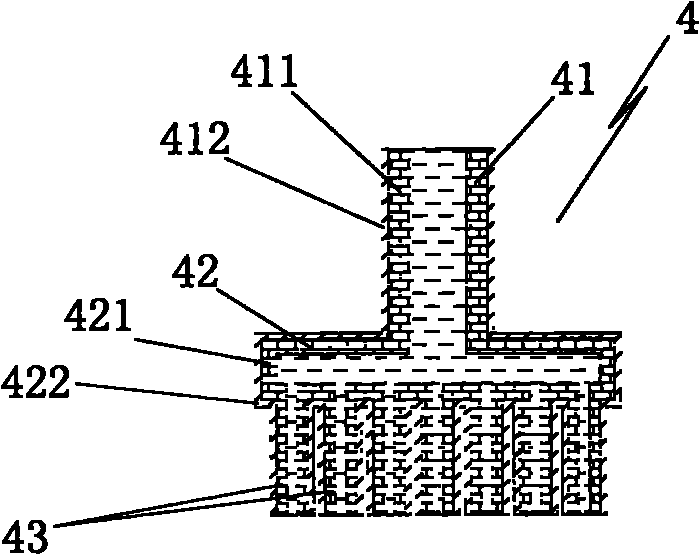

[0042] Such as Figure 1A , Figure 1B As shown, it is a top-casting manufacturing device for a super-large extra-thick plate rectangular ingot. The top-casting manufacturing device 100 is composed of a water-cooled metal mold chassis 3, a water-cooled metal mold 2, and a thermal insulation riser 1. The chassis 3 and the water-cooled Between the metal molds 2, between the water-cooled metal molds 2 and the riser 1 with heat insulation and heat preservation, the positioning seams that cooperate up and down are all placed together. The width flow distributor 4 is extended into the hollow cavity 21 of the water-cooled metal mold by adding heat insulation riser 1, such as Figure 3A , Figure 3BAs shown, the width distributor 4 includes a vertical sprue 41, and the bottom of the sprue 41 is communicated with a horizontal distribution pipe 42; the flow distribution pipe 42 is arranged along the width direction of the water-cooled metal mold 2 A plurality of spray tubes 43 vertica...

Embodiment 2

[0090] Such as Figure 9A , Figure 9B , Figure 10A , Figure 10B As shown, it is a bottom casting manufacturing device for a super-large extra-thick plate rectangular ingot. The structure and principle of the bottom casting manufacturing device 100 are basically the same as those of the top casting manufacturing device described in Embodiment 1. The difference is that the width distribution Device 4 is made of refractory brick 8 that is arranged in the groove 31 of water-cooled metal mold chassis 3. A distribution pipe 81 formed in the refractory brick 8, the distribution pipe 81 is arranged along the width direction of the water-cooled metal mold 2, and the upper side of the distribution pipe 81 is formed with a plurality of penetrating refractory bricks 8 and connected with the water-cooled metal mold The injection pipe 82 connected to the hollow cavity 21 of the hollow cavity 21; the distribution pipe 81 communicates with the straight pipe 84 arranged vertically outsid...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com