Plasma arc method for perforating key hole by current

A plasma arc and plasma arc technology, applied in plasma welding equipment, manufacturing tools, welding equipment, etc., can solve problems such as affecting welding and cutting quality, limiting plasma arc efficiency, etc., to increase thickness, improve incision quality, and improve utilization. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

specific Embodiment approach 1

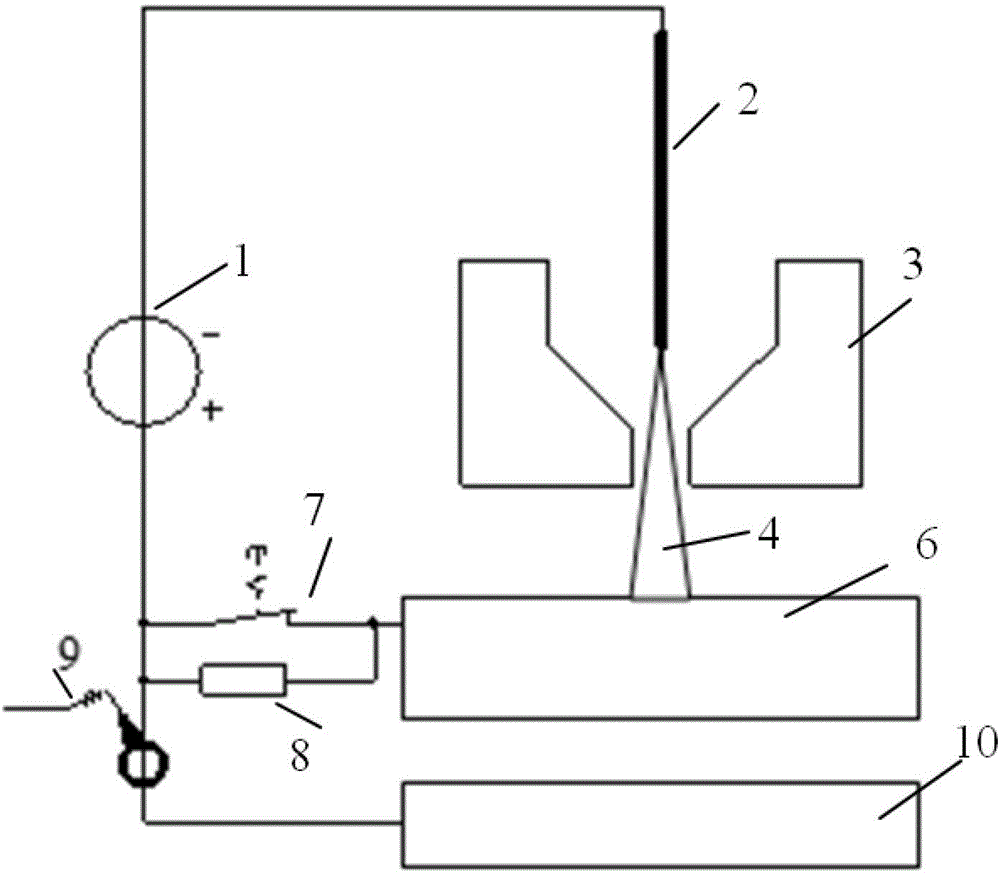

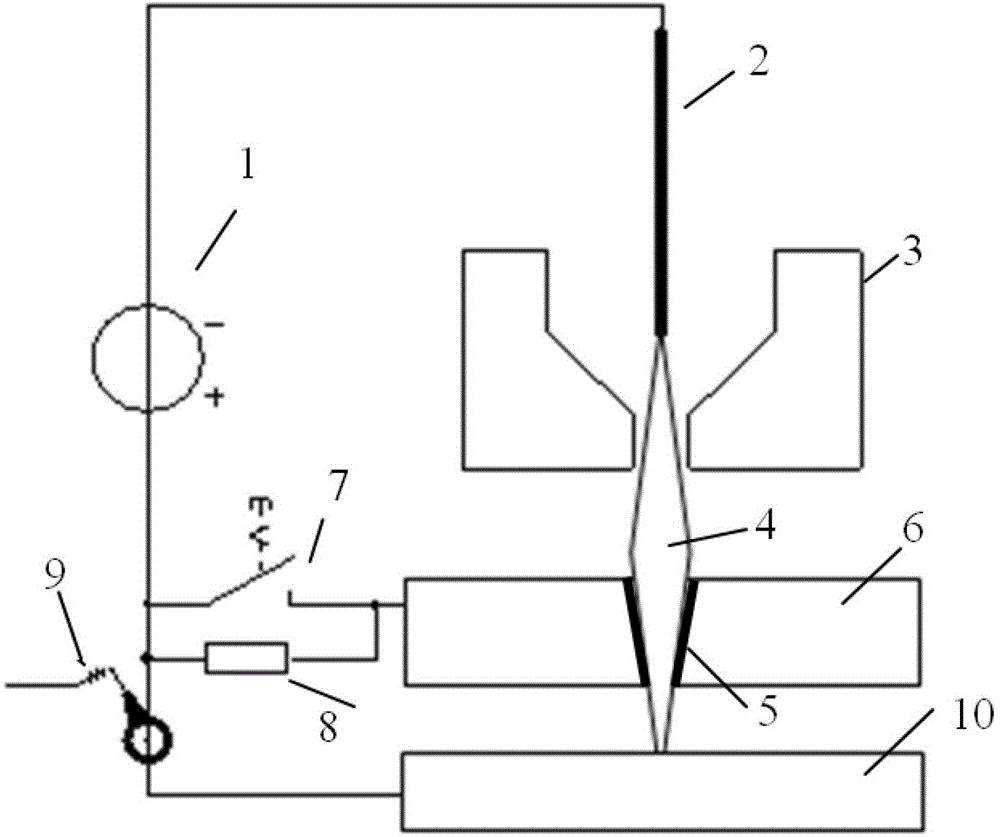

[0017] Specific implementation mode one: the following combination figure 1 and figure 2 Describe the present embodiment, the plasma arc method that the electric current of present embodiment runs through the keyhole, it connects the negative pole of plasma arc power supply 1 to the head end of plasma gun electrode 2, and the end of plasma gun electrode 2 corresponds to plasma gun compression nozzle 3, Connect the positive pole of the plasma arc power supply 1 to the workpiece 6 through the switch 7, the switch 7 is connected in parallel with the current regulator 8, the positive pole of the plasma arc power supply 1 is connected to one end of the current sensor 9 at the same time, and the other end of the current sensor 9 is connected to one end of the receiving electrode 10 , the receiving electrode 10 is placed correspondingly to the workpiece 6, and the plasma arc method is:

[0018] Put the switch 7 in the closed state, and put the outlet of the plasma gun compression ...

specific Embodiment approach 2

[0024] Specific implementation mode two: the following combination figure 1 and figure 2 This embodiment will be described. This embodiment will further describe the first embodiment. The current sensor 9 in this embodiment is a through current detector.

specific Embodiment approach 3

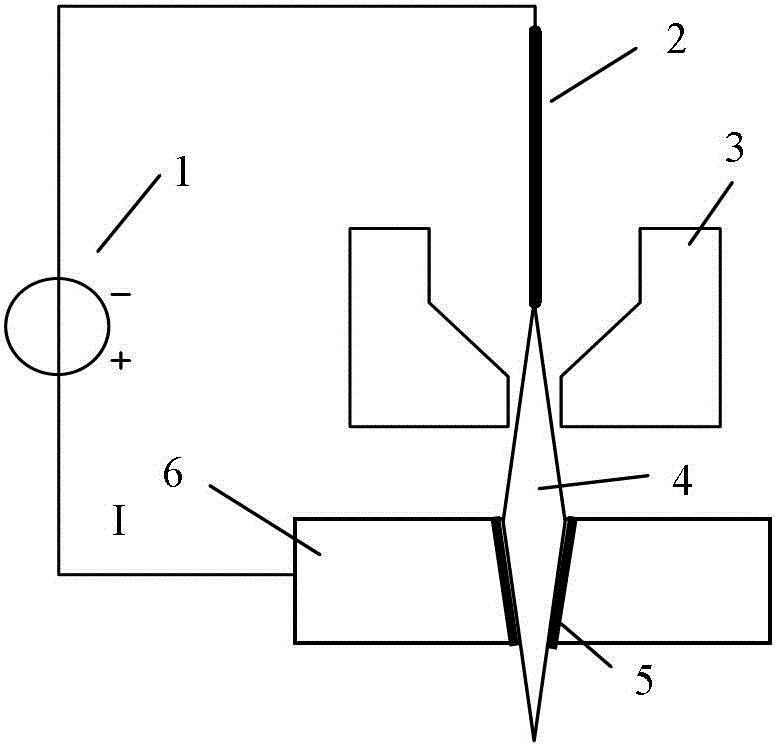

[0025] Embodiment 3: This embodiment further describes Embodiment 1 or 2. The receiving electrode 10 in this embodiment is a metal plate, a metal rod or a metal electrode.

[0026] In this embodiment, the receiving electrode 10 is a metal plate parallel to the workpiece 6 in most cases; it can also be simplified as a metal rod parallel to the workpiece 6 in some cases, such as for welding or cutting of only a single straight line; or It can also be simplified as a metal electrode perpendicular to the workpiece 6 and corresponding to the position of the plasma gun electrode 2 , for example, when the workpiece 6 can move or the receiving electrode 10 can move synchronously with the plasma gun electrode 2 . The receiving electrode 10 can be water-cooled to withstand large currents as required.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com