Gangue inhibitor and beneficiation method of copper sulfide ore containing easily floated gangue minerals

A beneficiation method and gangue mineral technology, applied in flotation, solid separation, etc., can solve the problems of low copper recovery rate, low copper grade of copper concentrate, adverse effects of copper sulfide minerals, etc., to improve surface characteristics, eliminate Harmful ions, beneficial to the effect of floating

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

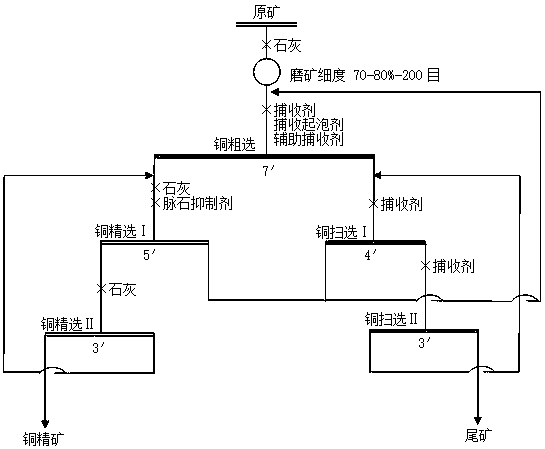

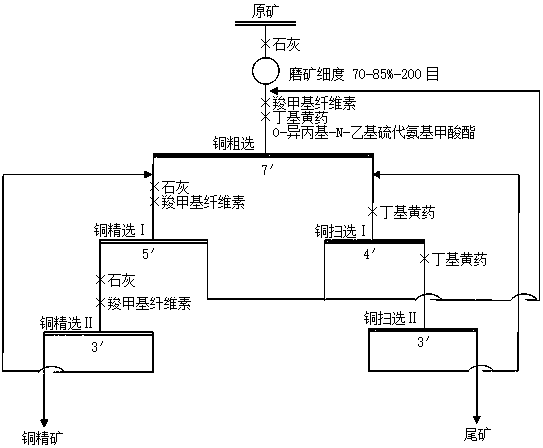

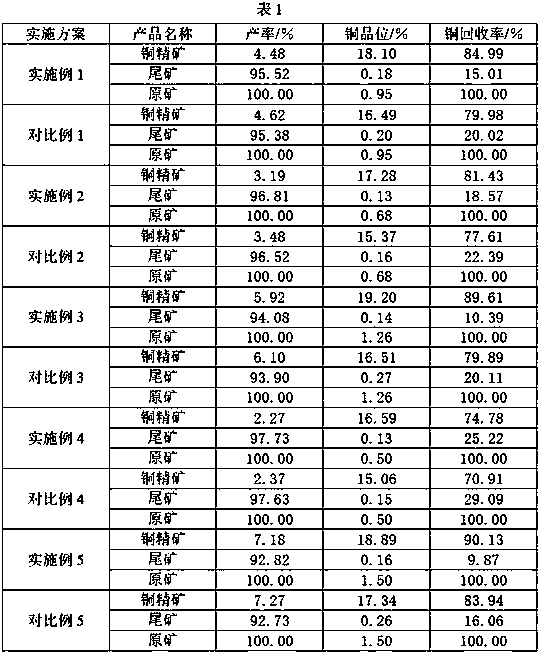

[0029] Embodiment 1, a kind of beneficiation method that contains easy pumice gangue mineral copper sulfide ore, adopts figure 1 The technological process in the process selects a certain copper sulfide ore. The copper grade of the ore is 0.95%, the sulfur content is 22.39%, the ore contains talc and serpentine, and the magnesium oxide content accounts for 25.32% of the total ore quality. The specific implementation steps are as follows:

[0030] A. Crush the raw ore, and grind the ore until the ore particle size is less than 0.074mm, accounting for 70%, so that the copper sulfide minerals are fully dissociated, add lime, add lime 5500g / t, add water to adjust the pulp until the weight concentration of the pulp is 35%, the pH value of the slurry is 10;

[0031] B. Add 20g / t of collecting foaming agent, 40g / t of auxiliary collector, and 10g / t of collecting agent to the pulp prepared in step A in sequence, stir evenly, and then carry out roughing and flotation operations. 7min,...

Embodiment 2

[0045] Embodiment 2, a kind of beneficiation method that contains easy pumice gangue mineral copper sulfide ore, adopts figure 1 The technological process in the process selects a certain copper sulfide ore. The copper grade of the ore is 0.68%, the sulfur content is 24.87%, the ore contains talc and serpentine, and the magnesium oxide content accounts for 34.30% of the total ore quality. The specific implementation steps are as follows:

[0046] A. Crush the raw ore, grind the ore until the ore particle size is less than 0.074mm, accounting for 75%, so that the copper sulfide minerals are fully dissociated, and add lime when grinding. The amount of lime added is 5000g / t, and water is added to adjust the slurry to the slurry The weight concentration is 29%, and the pH value of the slurry is 9.5;

[0047] B. Add 15g / t collecting foaming agent, 30g / t auxiliary collecting agent, and 18g / t collecting agent to the pulp prepared in step A, and stir evenly, then carry out roughing a...

Embodiment 3

[0061] Embodiment 3, a kind of beneficiation method that contains easy pumice gangue mineral copper sulfide ore, adopts figure 1 The technological process in the process selects a certain copper sulfide ore. The copper grade of the ore is 1.26%, the sulfur content is 21.55%, the ore contains talc and serpentine, and the magnesium oxide content accounts for 41.67% of the total ore quality. The specific implementation steps are as follows:

[0062] A. Crush the raw ore, grind the ore until the ore particle size is less than 0.074mm, accounting for 82%, so that the copper sulfide minerals are fully dissociated, and add lime when grinding. The amount of lime added is 5800g / t, and water is added to the slurry The weight concentration is 33%, and the pH value of the slurry is 10.5;

[0063] B. Add 25g / t collecting foaming agent, 60g / t auxiliary collecting agent, and 14g / t collecting agent to the slurry prepared in step A, stir evenly, and then carry out roughing and flotation opera...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com