Patents

Literature

Hiro is an intelligent assistant for R&D personnel, combined with Patent DNA, to facilitate innovative research.

40results about How to "Improve flotation environment" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

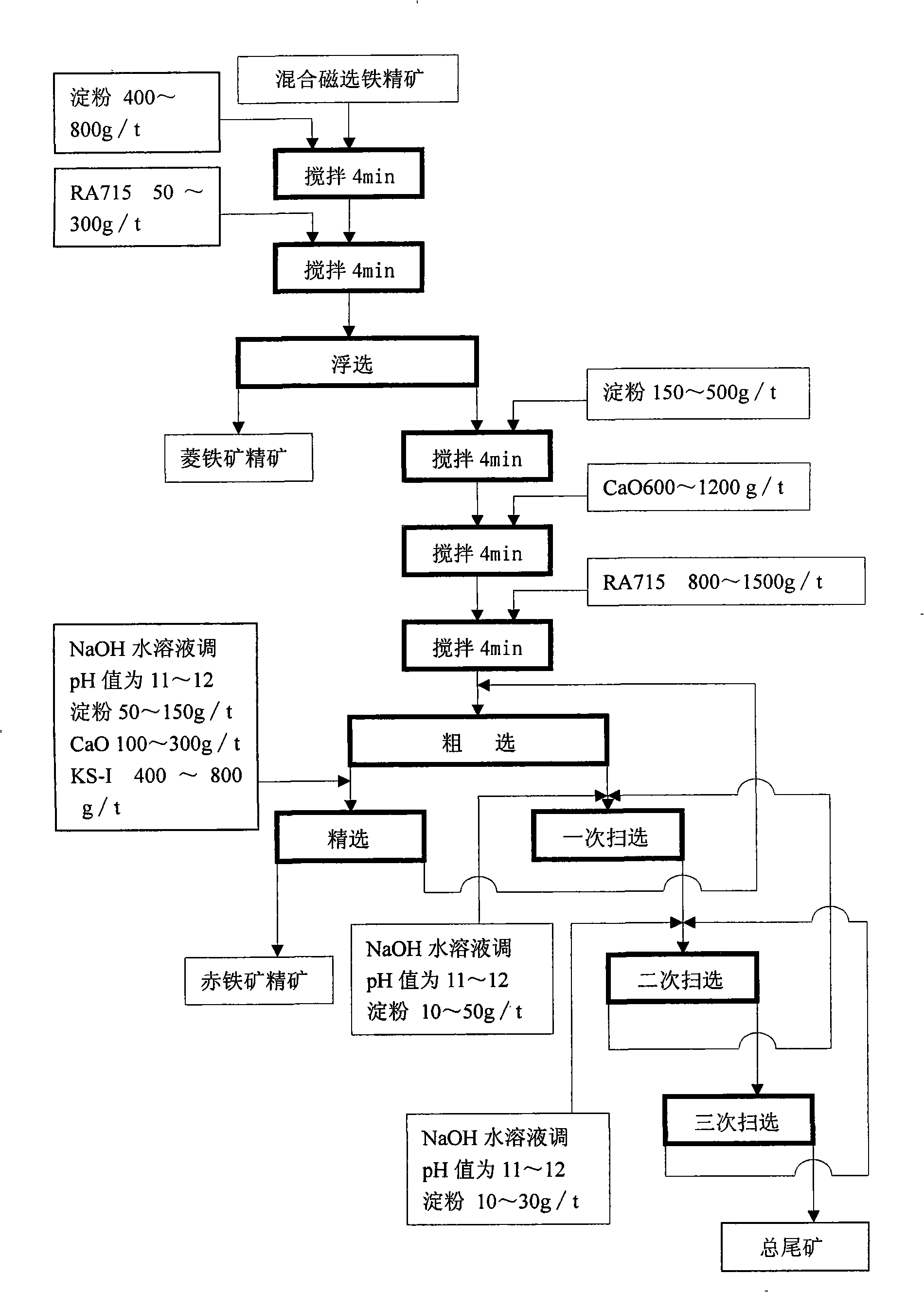

Stepped-flotation separation method for iron ore containing carbonas

InactiveCN101274302ANo difficulty returningImprove flotation environmentFlotationMagnetic separationIronstoneHigh intensity

The invention discloses a flotation and separation method of carbonate-bearing iron ore which has fractional steps and is characterized in that the carbonate-bearing iron ore is milled by a ball milling method and pre-separated by adopting low-intensity magnetic separation and high-intensity magnetic separation, and iron ore concentrate that is obtained from the mixed magnetic separation is separated by the flotation technique with fractional steps, which comprises the following steps: in the first step, siderite concentrate is selected under neutral condition by adopting the direct flotation technique; in the second step, the hematite concentrate is selected under strong basicity condition by adopting the reverse flotation technique. The flotation and separation method of the carbonate-bearing iron ore of the invention has smooth process running, the siderite selection in the first step improves flotation environment, and the hematite selection in the second step can finally obtain the hematite concentrate with the iron grade of over 66 percent and the recovery rate of over 62 percent. The flotation and separation method of the carbonate-bearing iron ore of the invention provides an exploiting method of the domestic potential iron ore resources with low iron grade and has important significance to the economical and reasonable exploiting of the carbonate-bearing iron ore.

Owner:ANSTEEL GRP MINING CO LTD +1

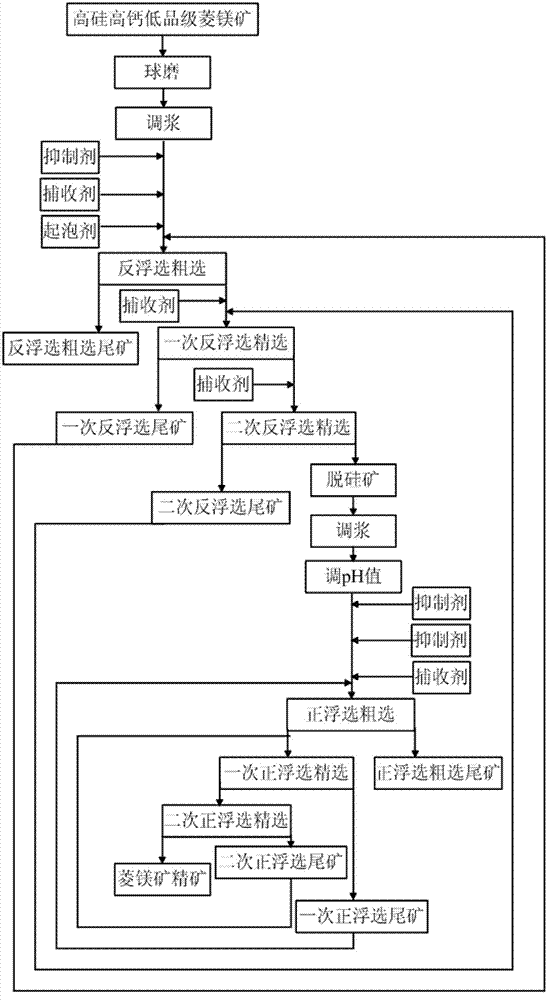

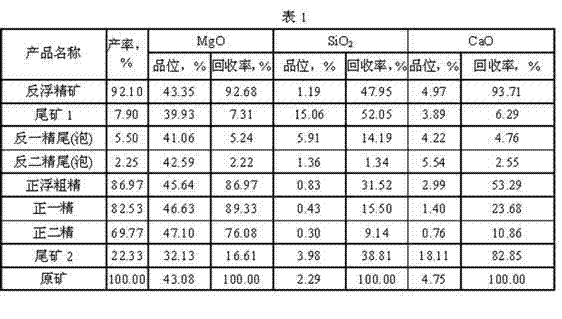

Method for carrying out flotation on high-silicon high-calcium low-grade magnesite step by step

InactiveCN102189040AImprove flotation environmentProcess runs smoothlyFlotationLow gradedLower grade

The invention relates to a method for carrying out flotation on high-silicon high-calcium low-grade magnesite step by step, belonging to the technical field of mineral processing. The method comprises the following steps of: (1) carrying out ball milling on the high-silicon high-calcium low-grade magnesite and adding water to prepare raw ore pulp; (2) placing the raw ore pulp into flotation equipment, adding inhibitor, collecting agent and foaming agent while stirring is carried out, carrying out reverse flotation roughing, and carrying out reverse flotation selection on the obtained raw ore concentrate 0-2 times to obtain desiliconized ore; and (3) adding water into the desiliconized ore to prepare ore pulp, regulating the pH value to be 10-11, adding the inhibitor water glass, the inhibitor sodium hexametaphosphate and the collector to be stirred while stirring is carried out, carrying out direct flotation roughing, and carrying out direct flotation selection on the obtained desiliconized ore concentrate 0-2 times to obtain magnesite ore concentrate. The ore processed by the method provided by the invention has low grade, the obtained magnesite ore concentrate can reach super standard in the metallurgical industry, the flotation effect is good, and the cost is low.

Owner:丹东市镁宝镁业有限公司 +1

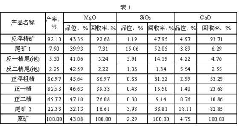

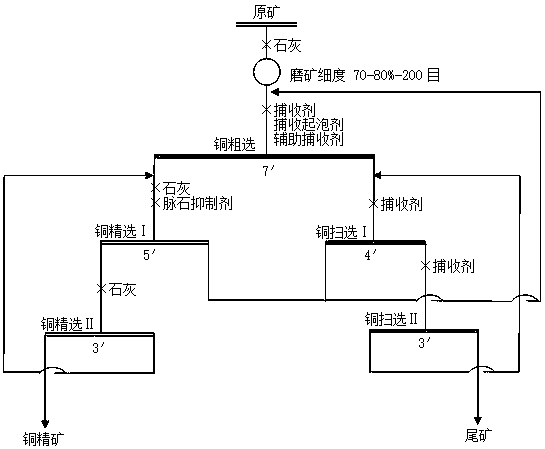

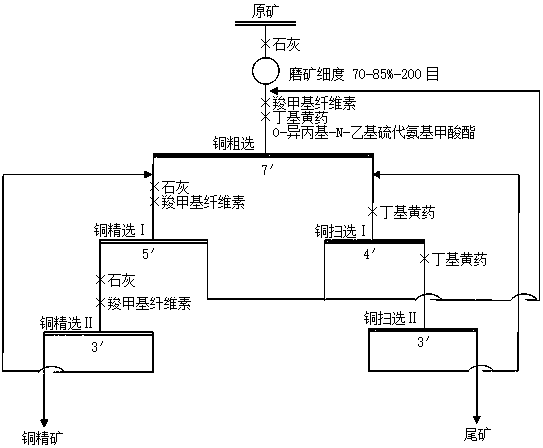

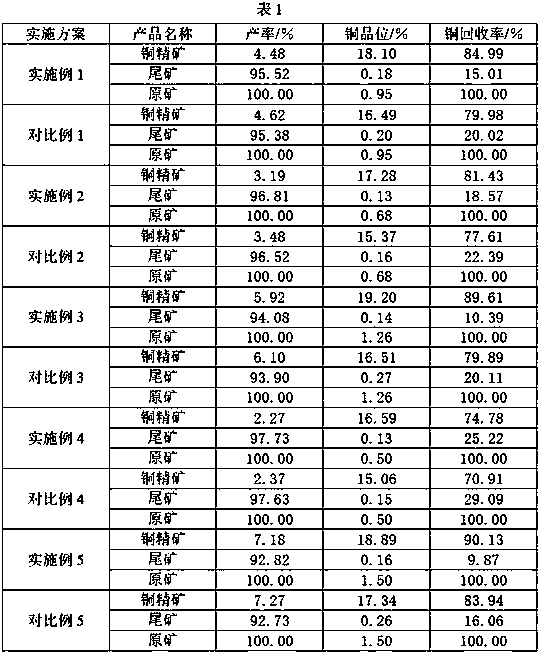

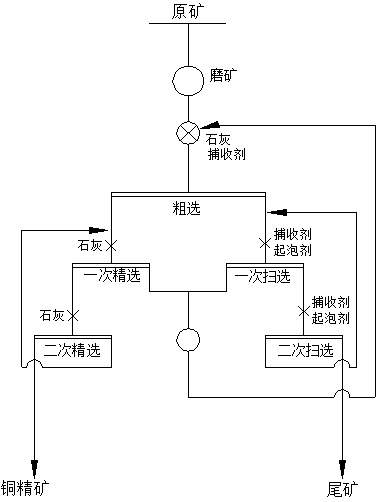

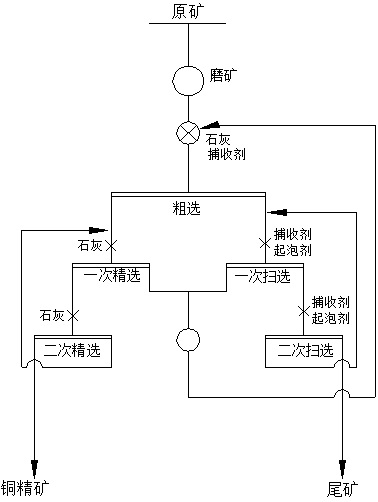

Gangue inhibitor and beneficiation method of copper sulfide ore containing easily floated gangue minerals

The invention discloses a gangue inhibitor and a beneficiation method of copper sulphide ore containing easily floated gangue minerals, belongs to the technical field of flotation, and solves the problem that gangue minerals have very adverse effects on flotation of copper sulphide ore. The gangue inhibitor comprises sodium polyacrylate, carboxymethyl cellulose, Arabic gum, sodium silicate, sodiumtripolyphosphate, anhydrous sodium sulfite, sodium lignosulfonate and anhydrous zinc sulfate. The method comprises the following steps: adding lime for ore grinding, and adding water for size mixing;sequentially adding a collecting foaming agent, an auxiliary collecting agent and a collecting agent into obtained ore pulp for roughing; adding a collecting agent into obtained roughing tailings, and scavenging for the first time; adding a collecting agent into the scavenging tailings, and carrying out secondary scavenging; sequentially adding pH regulator lime and the gangue inhibitor into an obtained roughing concentrate, and carrying out primary concentration; and adding pH regulator lime into an obtained primary concentration concentrate for secondary concentration. The gangue inhibitoris capable of reducing the floatability of gangue minerals greatly; the method is capable of improving the copper grade and the copper recovery rate of rough concentrate.

Owner:NORTHWEST RES INST OF MINING & METALLURGY INST

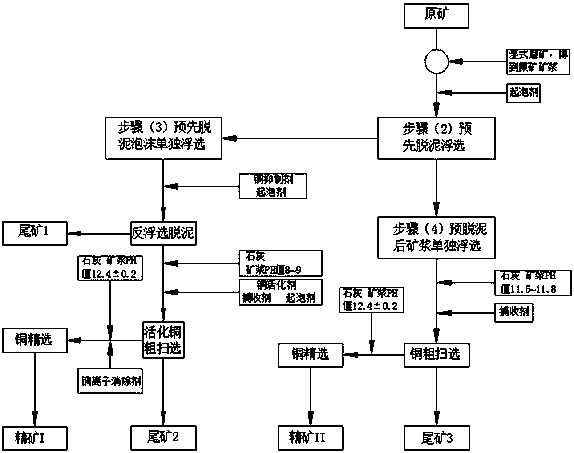

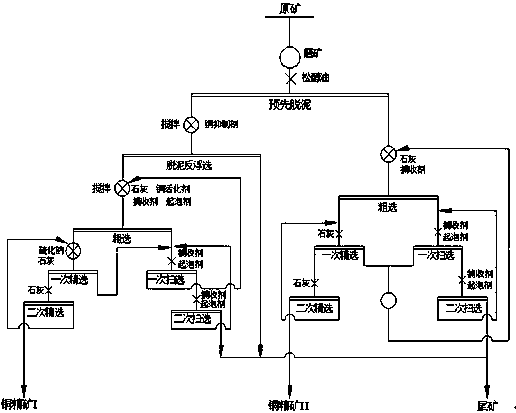

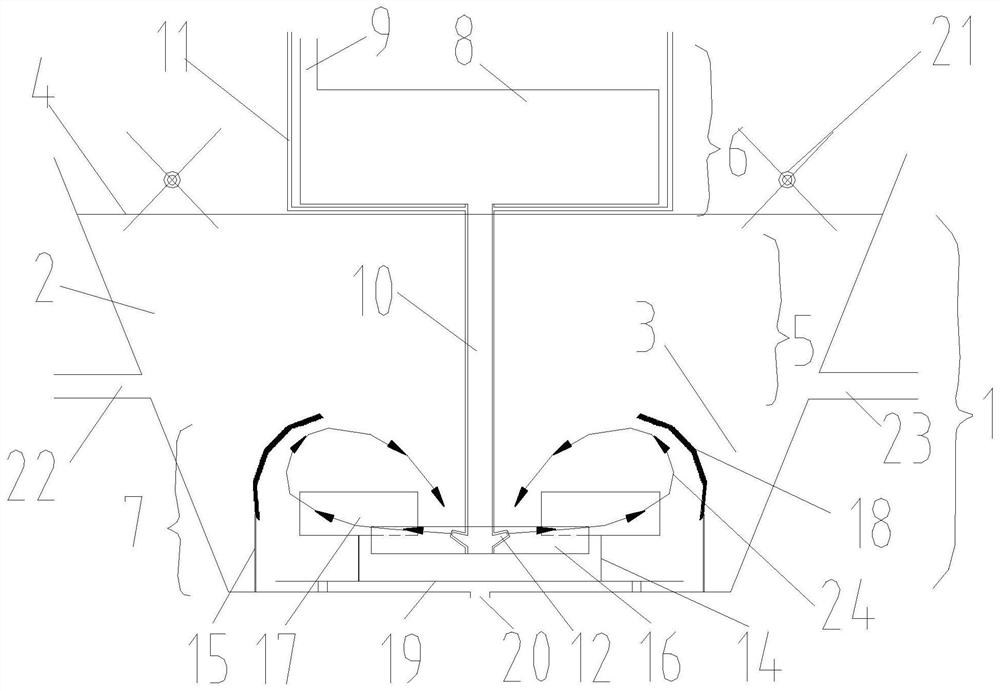

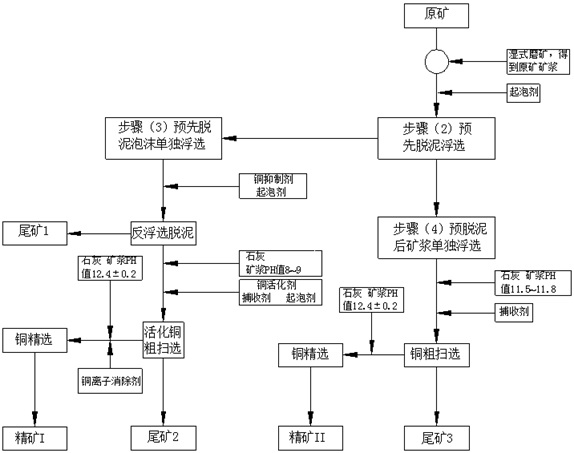

Beneficiation method of copper-containing talc-serpentinite ore easy to argillate and float

ActiveCN111451003AImprove flotation environmentEasy to recycleFlotationMechanical material recoveryFoaming agentMining engineering

The invention discloses a beneficiation method of copper-containing talc-serpentinite ore easy to argillate and float, comprising the following steps of: (1) ore grinding: grinding the copper-containing talc-serpentinite ore easy to argillate and float to obtain raw ore pulp; (2) conducting pre-desliming flotation: specifically, adding a foaming agent into the raw ore pulp, conducting pre-flotation of argillization easy-floating gangue, and therefore obtaining pre-deslimed foam and pre-deslimed ore pulp; (3) carrying out independent flotation of the pre-deslimed foam; and (4) carrying out independent flotation of the pre-deslimed ore pulp. The method has the beneficial effects that firstly, the raw ore pulp is subjected to pre-desliming, so that the flotation environment of the pre-deslimed ore pulp is optimized; the technical scheme that copper floating mud is inhibited firstly, and then the ore pulp is activated and subjected to copper flotation enrichment after reverse flotation ofdeslimed ore pulp is creatively provided, so that the influence of a large amount of mud-containing gangue on copper enrichment in pre-deslimed foam is avoided, and therefore the dosage of chemicals is greatly reduced, and a powerful guarantee is provided for improving the quality of copper concentrate.

Owner:TONGLING NON FERROUS METAL GROUP CORP

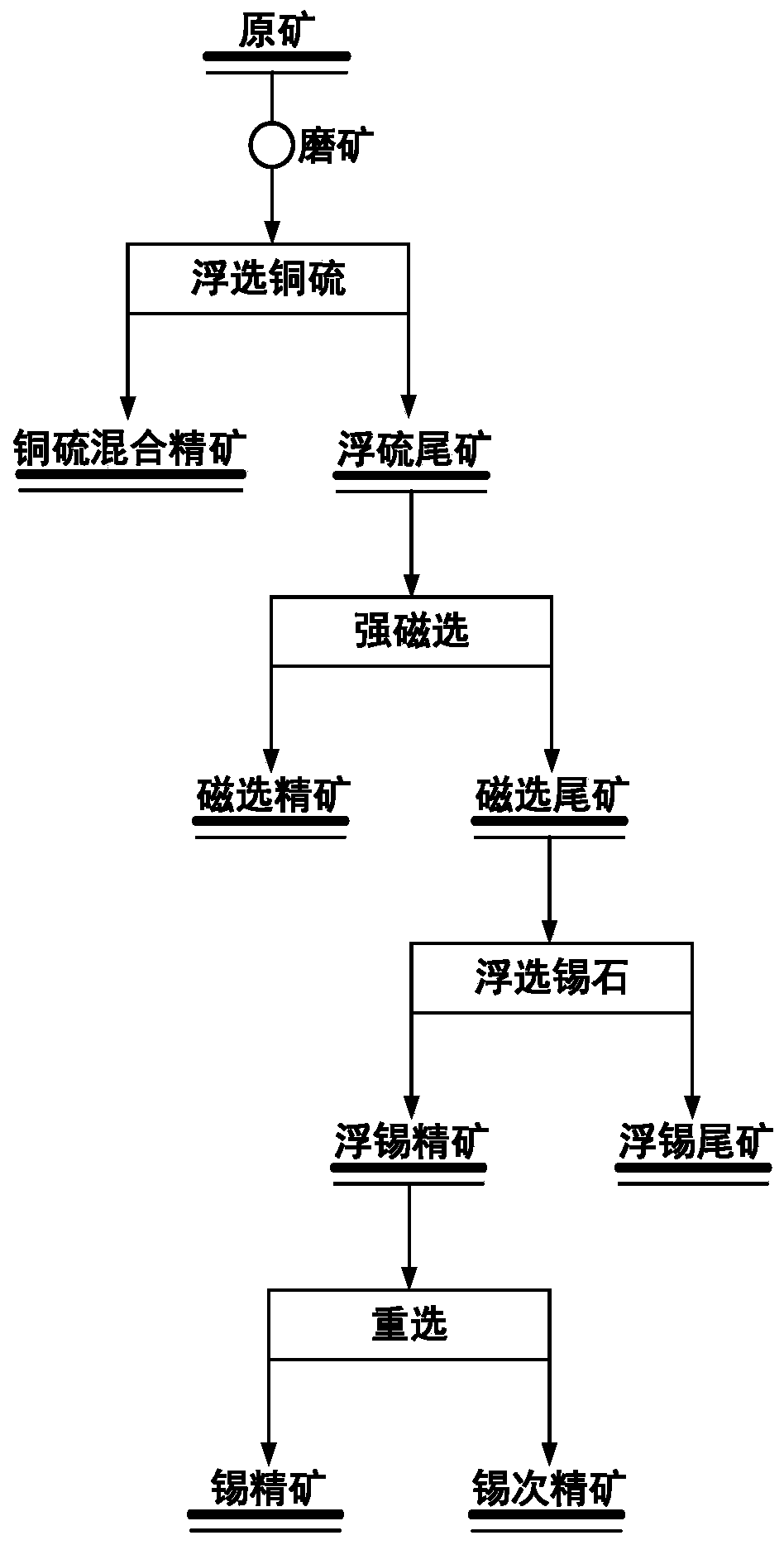

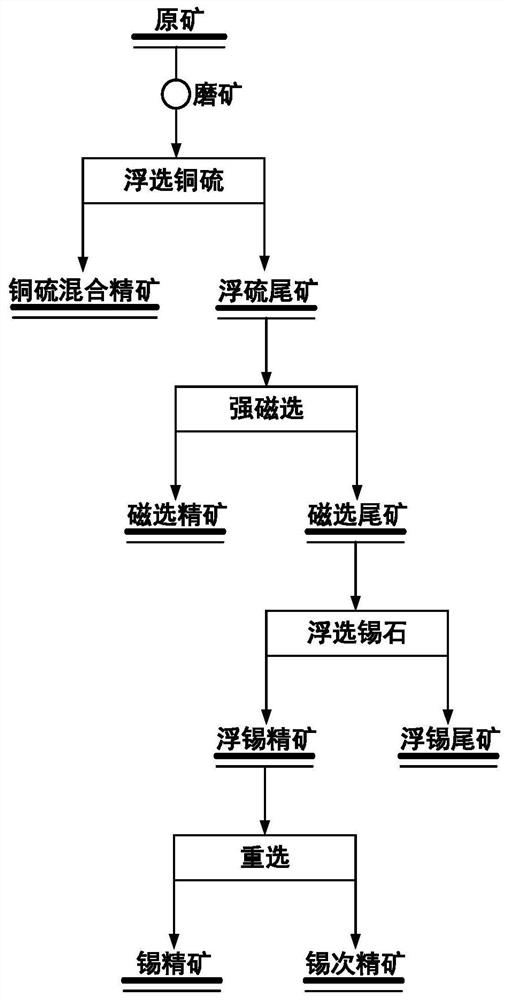

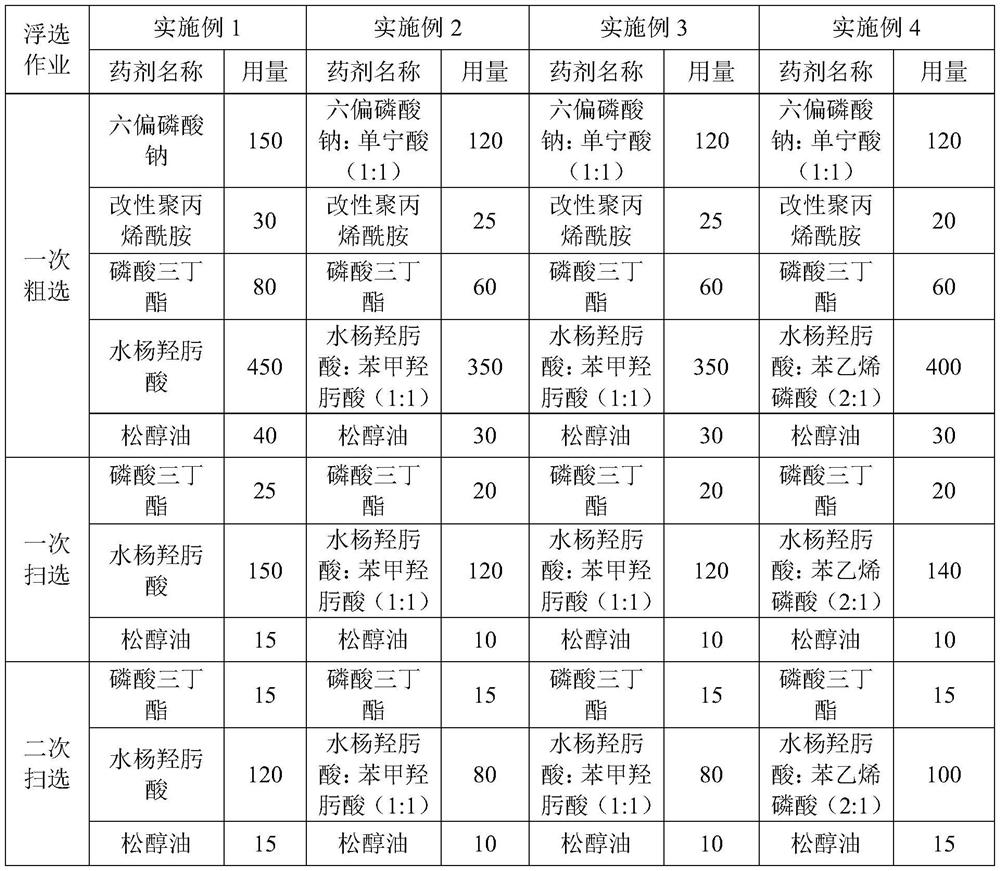

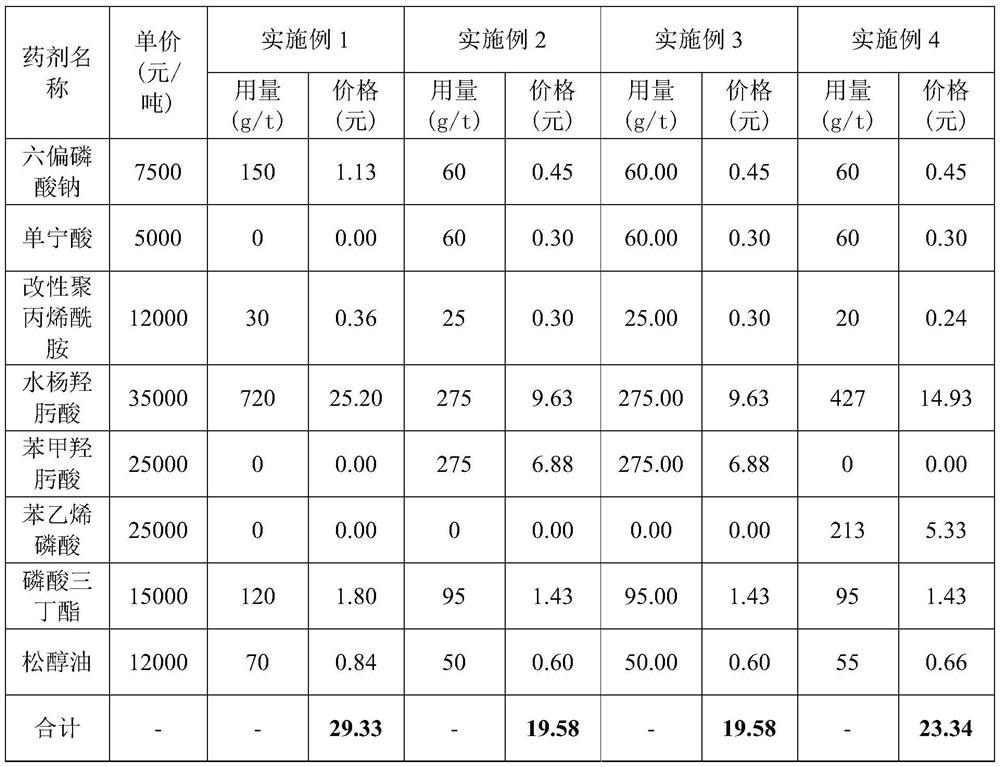

Mineral separation method for recovering cassiterite from tin-copper paragenic ore

ActiveCN110170381AReduce distractionsImprove flotation environmentDifferential sedimentationFlotationFlocculationCassiterite

The invention discloses a mineral separation method for recovering cassiterite from tin-copper paragenic ore. The method includes the steps of conducting ore grinding on raw ore, conducting flotationon copper sulfur to obtain copper-sulfur bulk concentrates and flotation sulfur tailings, conducting magnetic separation on the flotation sulfur tailings to obtain magnetic separation concentrates andmagnetic separation tailings, conducting flotation on the magnetic separation tailings through a specific agent to obtain tin flotation concentrates and tailings, and conducting centrifugal separation on the tin flotation concentrates to obtain tin concentrates and tin secondary concentrates. According to the method, in the flotation process of cassiterite, through the selective flocculation of fine cassiterite, by means of a specifically-combined inhibitor, the consumption of a collector can be reduced, the cost of the agent is reduced, and meanwhile it is ensured that the recovery grade andrecovery rate of the cassiterite are not reduced, the tin grade is higher than 40% and the total recovery rate is larger than 85%. According to the method, by means of the non-desliming bulk flotation, efficient cassiterite enrichment is realized, and the method is short in technological process, good in technical index and excellent in recycled product structure and has high application value incassiterite recovery.

Owner:广东省资源综合利用研究所

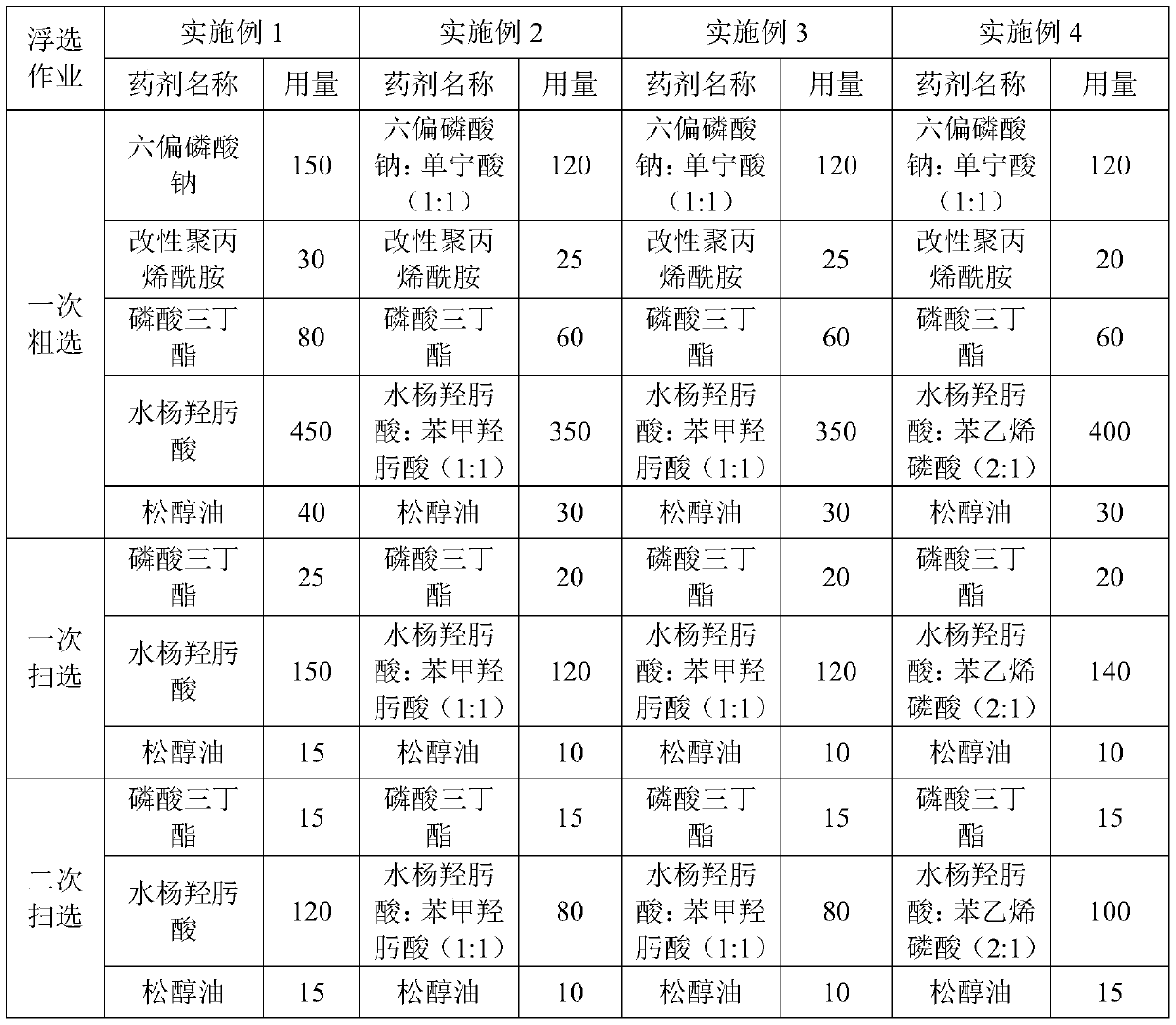

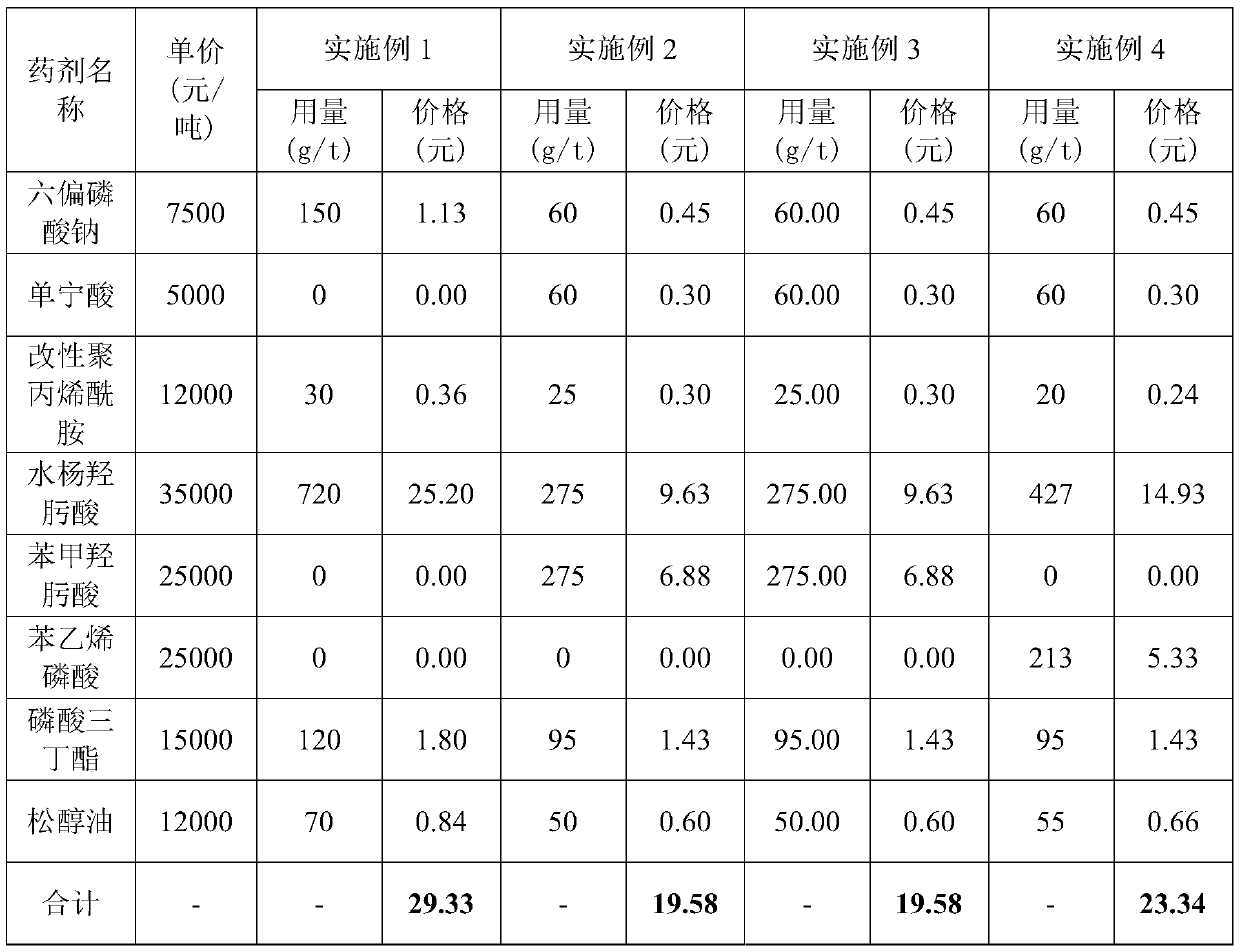

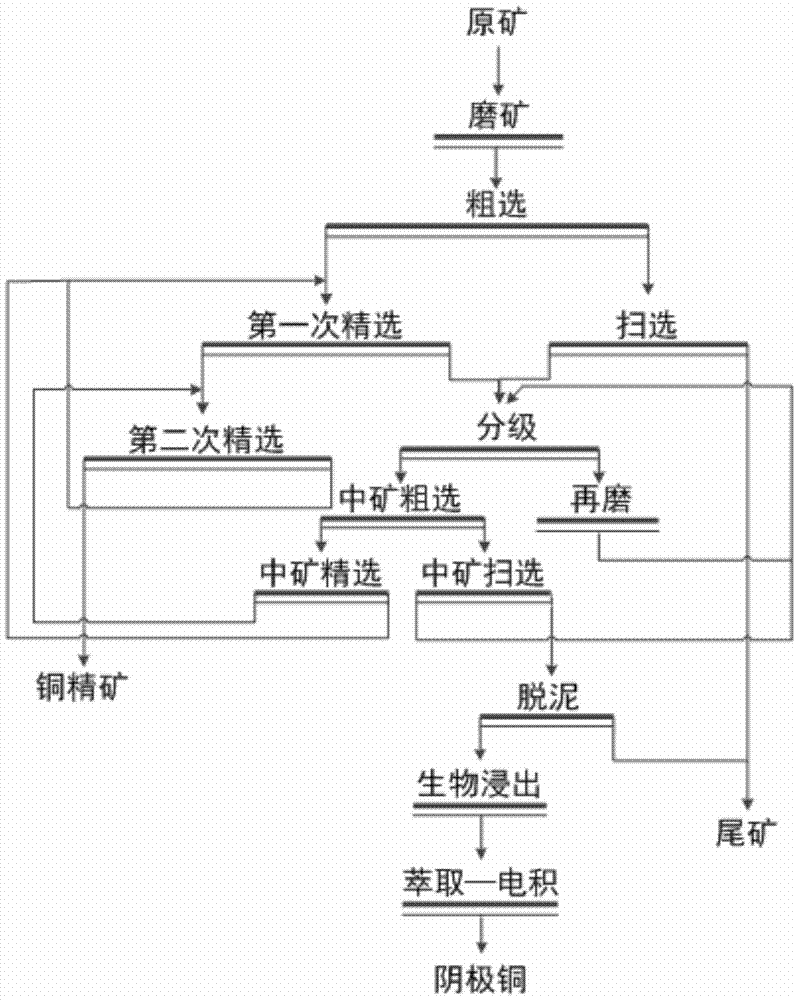

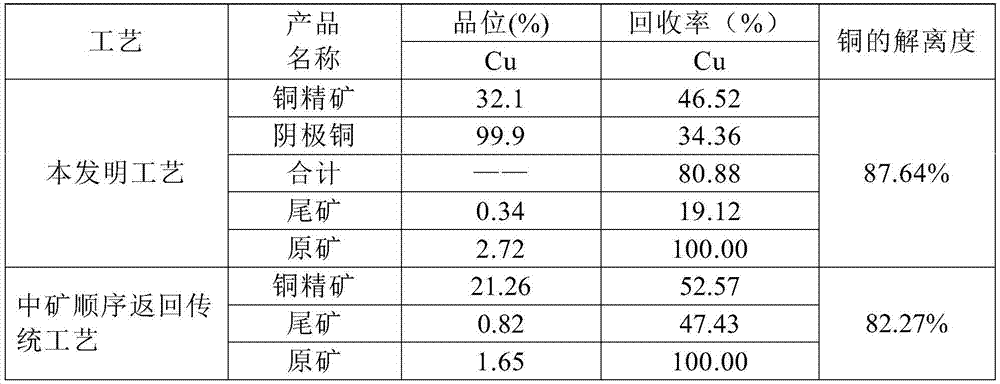

Beneficiation and metallurgy combined treatment technology for recovering copper of complex copper sulfide ore

ActiveCN106868303AHigh recovery rateLower the coverFlotationProcess efficiency improvementSulfurSlurry

The invention relates to a beneficiation and metallurgy combined treatment technology for recovering copper of complex copper sulfide ore, and aims to provide a flotation-bioleaching combined treatment technology so as to solve the problems that in the practical production process, the gluey copper sulfide ore is prone to oxidization and degradation in water, sequentially returning foam of middling ore is unstable, and the recovery indexes are low. By the adoption of the technology, the quantity of middling ore slurry can be greatly reduced, the concentration of residual agents can be reduced, the influence of water-soluble metal ions on the flotation main process can be avoided, micro-fine particle secondary copper ore which cannot be recovered from the middling ore through flotation is recovered, the grade of copper concentrate and the comprehensive recovery rate of copper are substantially improved, the grade of metal in tailings is reduced, and the comprehensive utilization rate of resources is improved.

Owner:有研资源环境技术研究院(北京)有限公司

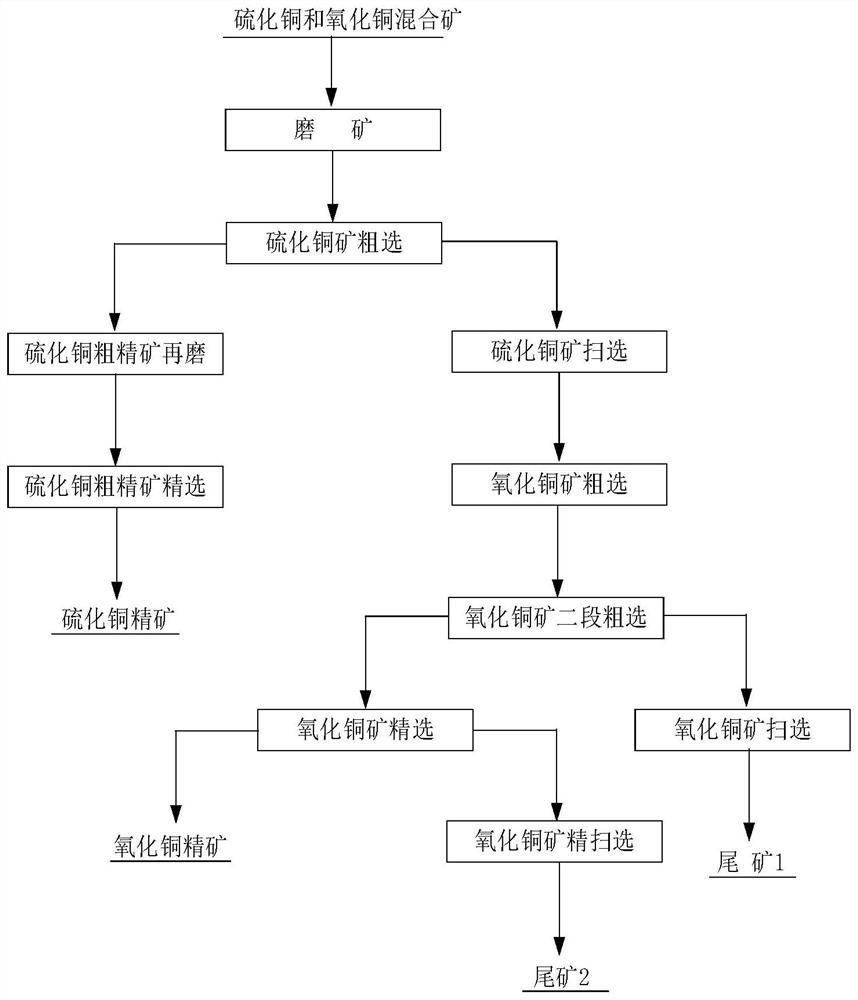

Separation method for cupric oxide and copper sulfide mixed ore

The invention discloses a separation method for cupric oxide and copper sulfide mixed ore. The separation method comprises the following steps: S1, grinding the cupric oxide and copper sulfide mixed ore to below the grade of 0.074mm accounting for 60 to 70 percent of fineness; S2, adding a regulator, a collector and a foaming agent for floating copper sulfide ore into ore pulp obtained from S1; S3, grinding copper sulfide rough concentrate obtained from S2, and carrying out aeration floatation to obtain copper sulfide concentrate; S4, adding a vulcanizing agent, the regulator, the collector and the foaming agent into copper sulfide rougher tailings obtain from S2 and carrying out floatation to obtain cupric oxide rough concentrate; and S5, adding the vulcanizing agent, the regulator, the collector and the foaming agent into the cupric oxide rough concentrate obtained from S4, carrying out floatation to obtain cupric oxide concentrate and cleaner tailings, scavenging the cleaner tailings and outputting the cleaner tailings. By use of the separation method disclosed by the invention, the copper sulfide concentrate and the cupric oxide concentrate with higher grade and higher recoveryrate can be obtained, so that the investment is saved; and the separation method can be applied to industrial production.

Owner:CHINA ENFI ENGINEERING CORPORATION

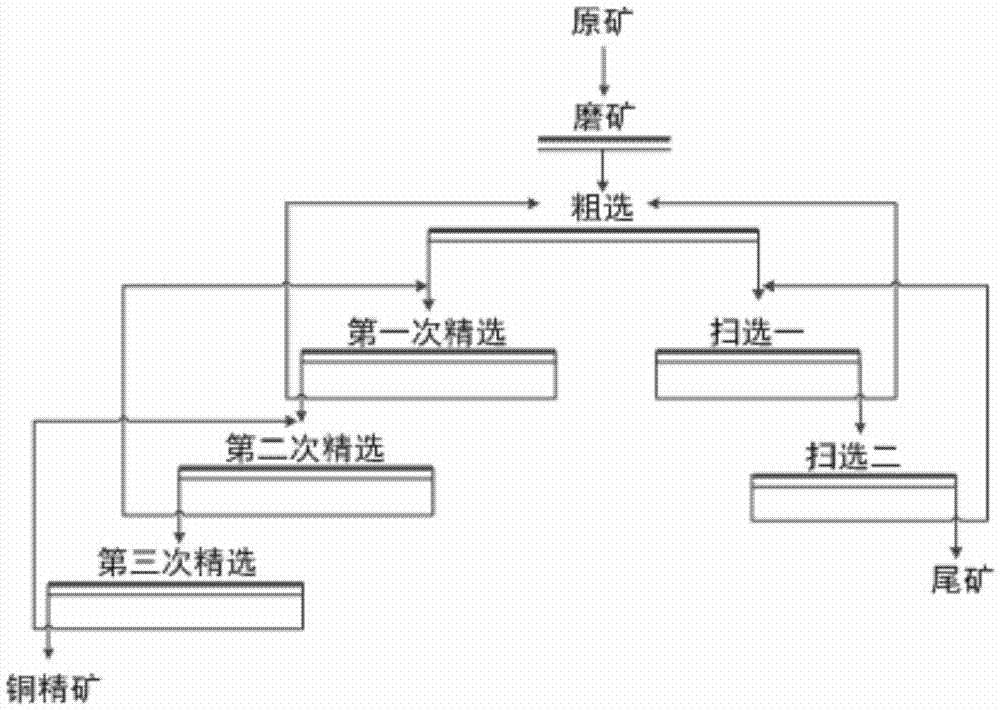

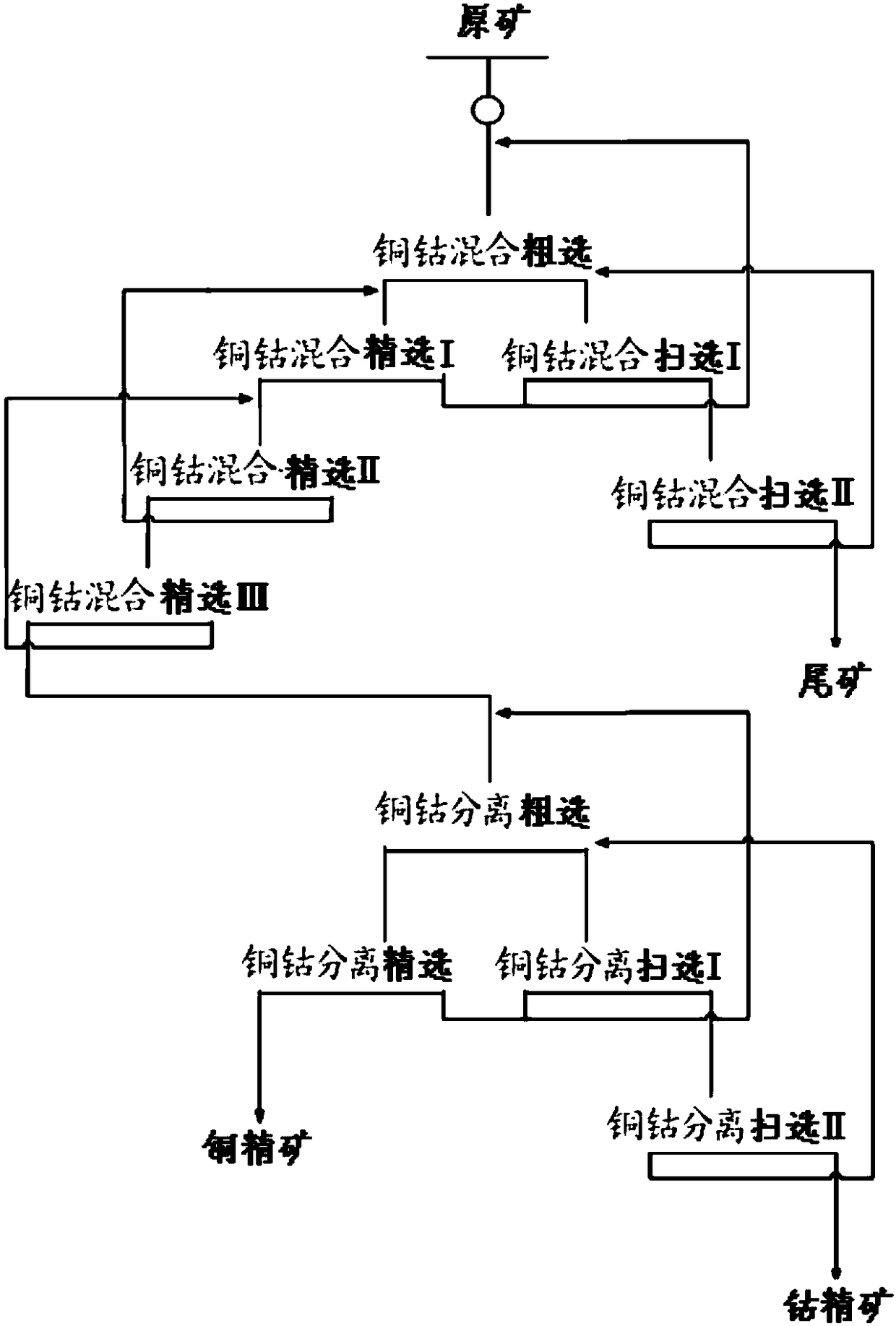

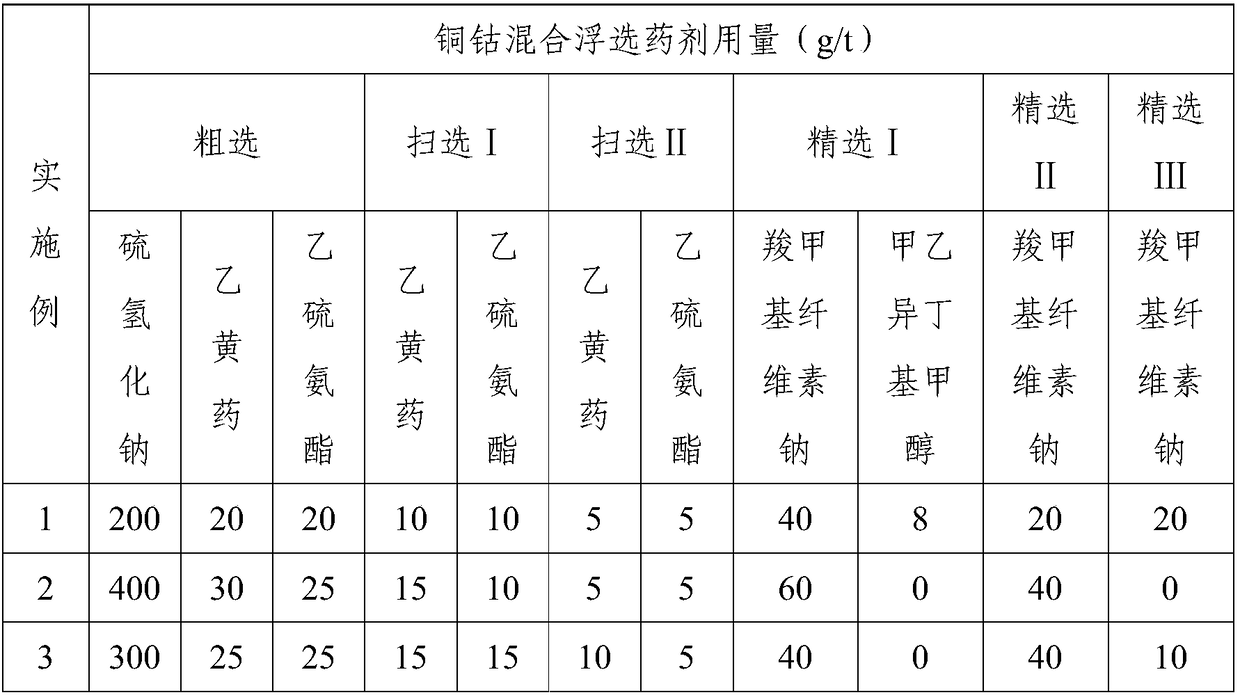

Beneficiation method for separating copper and cobalt

The invention belongs to the field of mineral processing, and particularly relates to a beneficiation method for separating copper and cobalt of pyrite copper sulphide cobalt ores including cobalt. The beneficiation method comprises the steps that comminuting, slurry preparation and copper-cobalt bulk flotation are carried out; ore pulp is subjected to one time of roughing and two times of scavenging, and copper-cobalt mixed roughing concentrate, scavenging concentrate and tailings are obtained; the copper-cobalt mixed roughing concentrate is subjected to concentration three times, and copper-cobalt mixed concentrate is obtained; then copper-cobalt separating flotation is carried out; the copper-cobalt mixed concentrate is subjected to one time of copper-cobalt separating roughing and twotimes of copper-cobalt separating scavenging, and copper-cobalt separating roughing concentrate and cobalt concentrate are obtained; and the copper-cobalt separating roughing concentrate is subjectedto one time of copper-cobalt separating concentration, and copper concentrate is obtained. According to the beneficiation method, separation of the copper concentrate and cobalt concentrate is effectively achieved, cost is reduced, and economic benefits are increased; and meanwhile proper copper sulphide concentrate and cobalt sulphide concentrate are provided for the subsequent metallurgy process.

Owner:WANBAO MINING

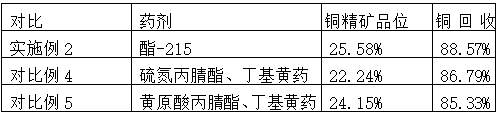

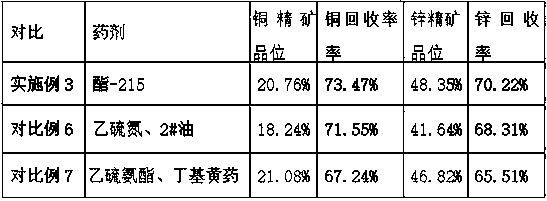

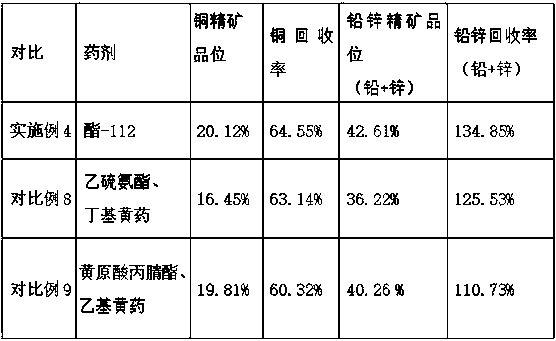

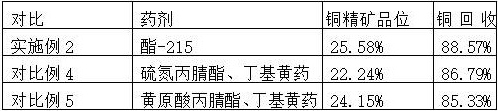

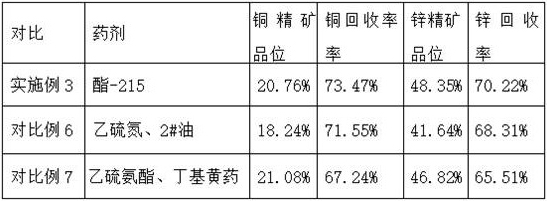

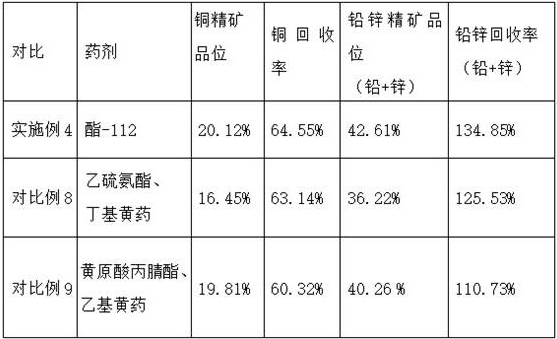

Collecting agent for recovering copper-lead-zinc minerals from iron tailings

ActiveCN110947523AGood harvesting effectEnhanced harvesting capacityFlotationAcrylonitrilePropionitrile

The invention belongs to the technical field of mineral flotation, and particularly relates to a collecting agent for comprehensive recovery of copper-lead-zinc minerals from iron tailings. The collecting agent is a composition ester-215, and the ester-215 is composed of the following raw materials: diethyl dithiocarbamate acrylonitrile ester, n-butyl xanthate propionitrile ester, ammonium dibutyldithiophosphate and terpenic oil. Compared with a conventional collecting agent, the ester-215 is high in collecting capacity and good in selectivity, particularly has a good collecting effect on secondary sulfide and fine-grained copper-lead-zinc minerals with large silt content, has foamability, effectively improves the flotation environment of the copper-lead-zinc minerals in the iron tailings, improves the floatability of the copper-lead-zinc minerals, and can achieve efficient and rapid flotation. Meanwhile, the requirement of the ester-215 for the medium range of ore pulp is wide, the collecting agent can be used within the pH range of 7-13, the effect is good, the collecting capacity for pyrite is weak, and the concentrate grade can be improved.

Owner:NORTHWEST RES INST OF MINING & METALLURGY INST

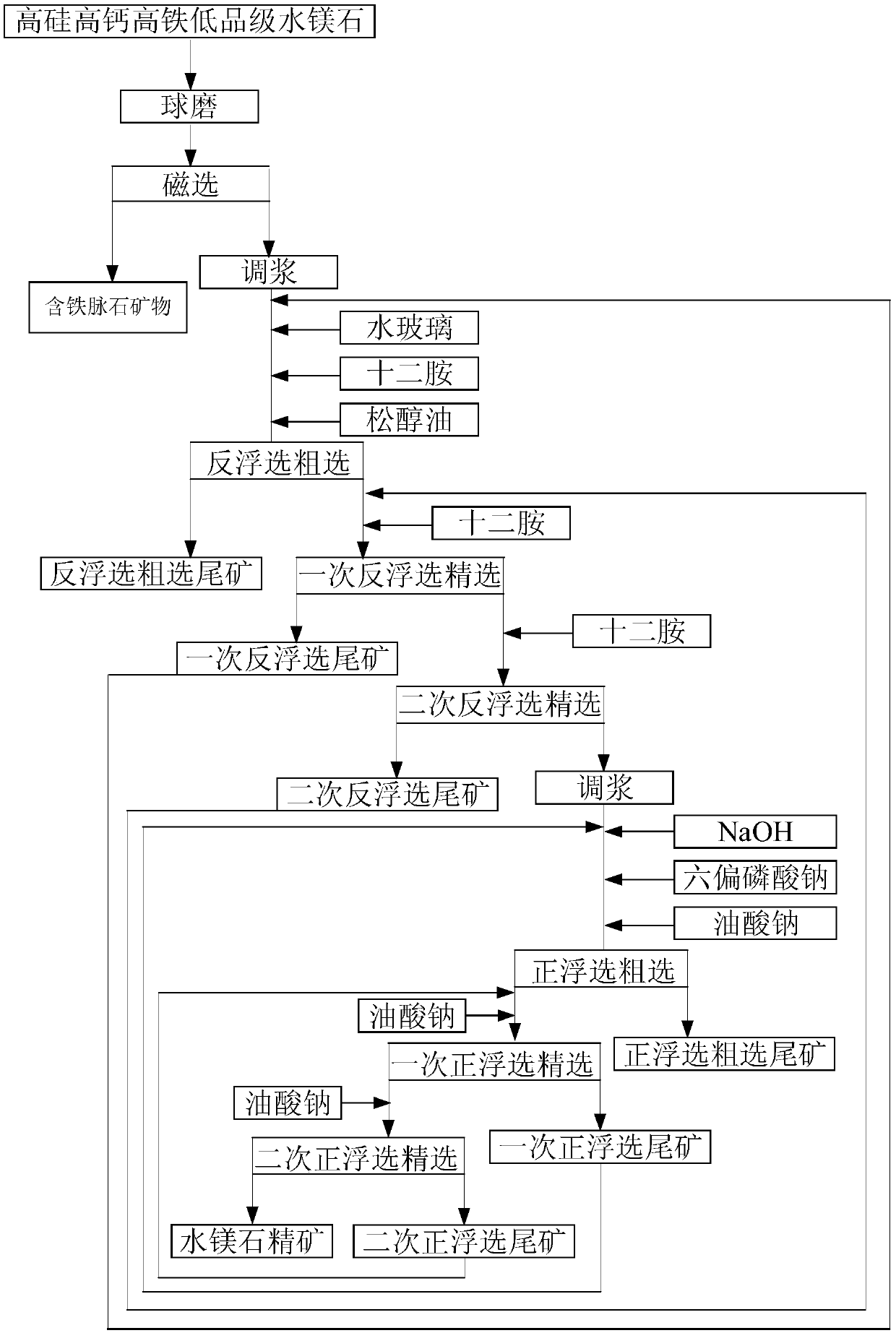

Efficient purification method for high-silicon high-calcium high-iron low-grade brucite

InactiveCN108672092ARun smoothlyHigh quality concentrate productsFlotationMagnetic separationLow gradedMagnetic separation

The invention relates to an efficient purification method for high-silicon high-calcium high-iron low-grade brucite and belongs to the technical field of mineral processing. The method comprises the steps that (1), ore grinding is carried out on the high-silicon high-calcium high-iron low-grade brucite; (2), magnetic separation is carried out on the material after ore grinding, and iron-bearing minerals are removed; (3), water is added to magnetic separation concentrate for pulp conditioning, then an inhibitor, a collector and a foaming agent are added for reverse flotation rough selection, the obtained reverse flotation coarse concentrate is subjected to 1-2 times of reverse flotation selection, and desiliconized concentrate is obtained; and (4), water is added to the desiliconized concentrate for pulp conditioning, the pH value is adjusted, the inhibitor and the collector are added and stirred, direct flotation rough flotation is carried out, the obtained decalcified concentrate is subjected to 1-2 times of positive flotation selection, and brucite concentrate is obtained. The ore processed by the method has high content of calcium, silicon, iron and other gangue minerals, the purified brucite concentrate has high purity and good mineral processing effect, and the method is of great significance in development and efficient utilization of high-silicon high-calcium high-iron low-grade brucite resources in China.

Owner:NORTHEASTERN UNIV

Method for carrying out flotation on high-silicon high-calcium low-grade magnesite step by step

The invention relates to a method for carrying out flotation on high-silicon high-calcium low-grade magnesite step by step, belonging to the technical field of mineral processing. The method comprises the following steps of: (1) carrying out ball milling on the high-silicon high-calcium low-grade magnesite and adding water to prepare raw ore pulp; (2) placing the raw ore pulp into flotation equipment, adding inhibitor, collecting agent and foaming agent while stirring is carried out, carrying out reverse flotation roughing, and carrying out reverse flotation selection on the obtained raw ore concentrate 0-2 times to obtain desiliconized ore; and (3) adding water into the desiliconized ore to prepare ore pulp, regulating the pH value to be 10-11, adding the inhibitor water glass, the inhibitor sodium hexametaphosphate and the collector to be stirred while stirring is carried out, carrying out direct flotation roughing, and carrying out direct flotation selection on the obtained desiliconized ore concentrate 0-2 times to obtain magnesite ore concentrate. The ore processed by the method provided by the invention has low grade, the obtained magnesite ore concentrate can reach super standard in the metallurgical industry, the flotation effect is good, and the cost is low.

Owner:丹东市镁宝镁业有限公司 +1

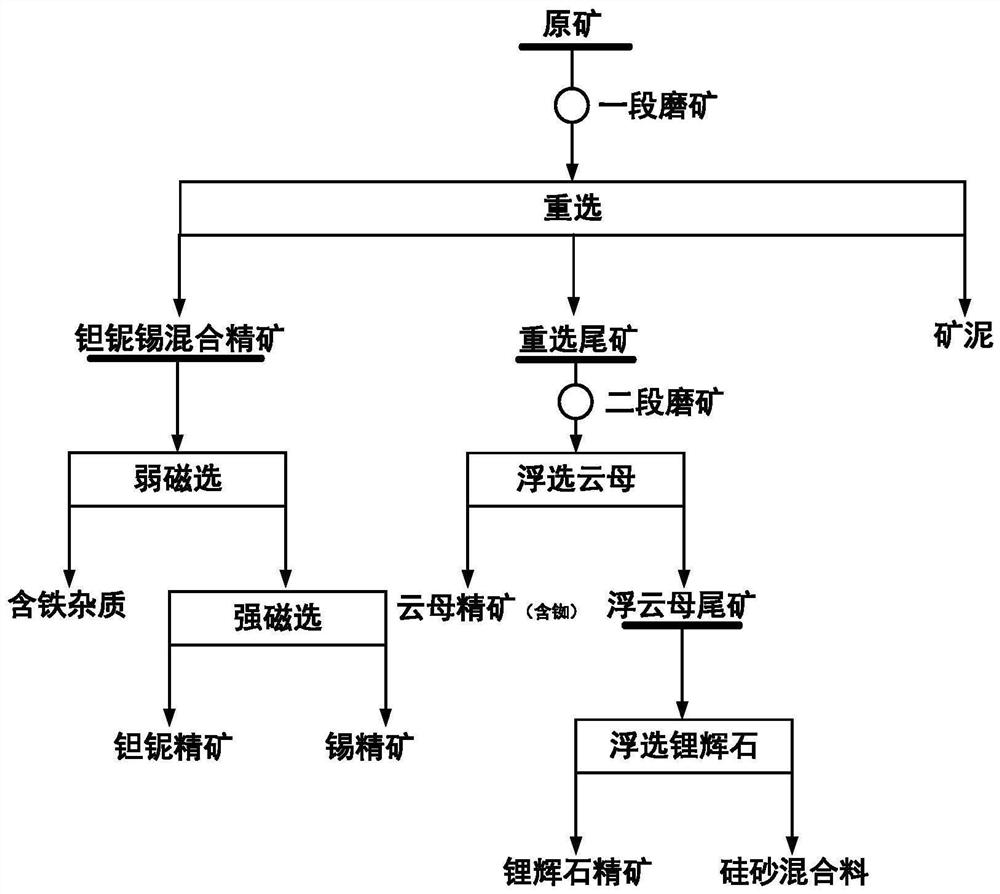

Beneficiation method for pegmatite type lithium polymetallic ore

ActiveCN112958273AAchieve high enrichmentAchieve recyclingSolid separationMechanical material recoveryNiobiumSeparation technology

The invention relates to a beneficiation method for pegmatite type lithium polymetallic ore. The beneficiation method comprises the steps of first-stage ore grinding, screening, reselection, magnetic separation, second-stage ore grinding, size mixing, flotation of rubidium-containing mica, flotation of spodumene and the like. The tantalum-niobium concentrate, the tin concentrate, the mica concentrate, the spodumene concentrate and the silica sand mixture are obtained through the gravity-magnetism-flotation combined technology, comprehensive recovery of tantalum, niobium, tin, rubidium, lithium, silicon, aluminum and other elements is sequentially achieved, and the method has the advantages of being simple and convenient in separation technology, good in separation effect, high in resource utilization rate and the like.

Owner:INST OF RESOURCES COMPREHENSIVE UTILIZATION GUANGDONG ACAD OF SCI

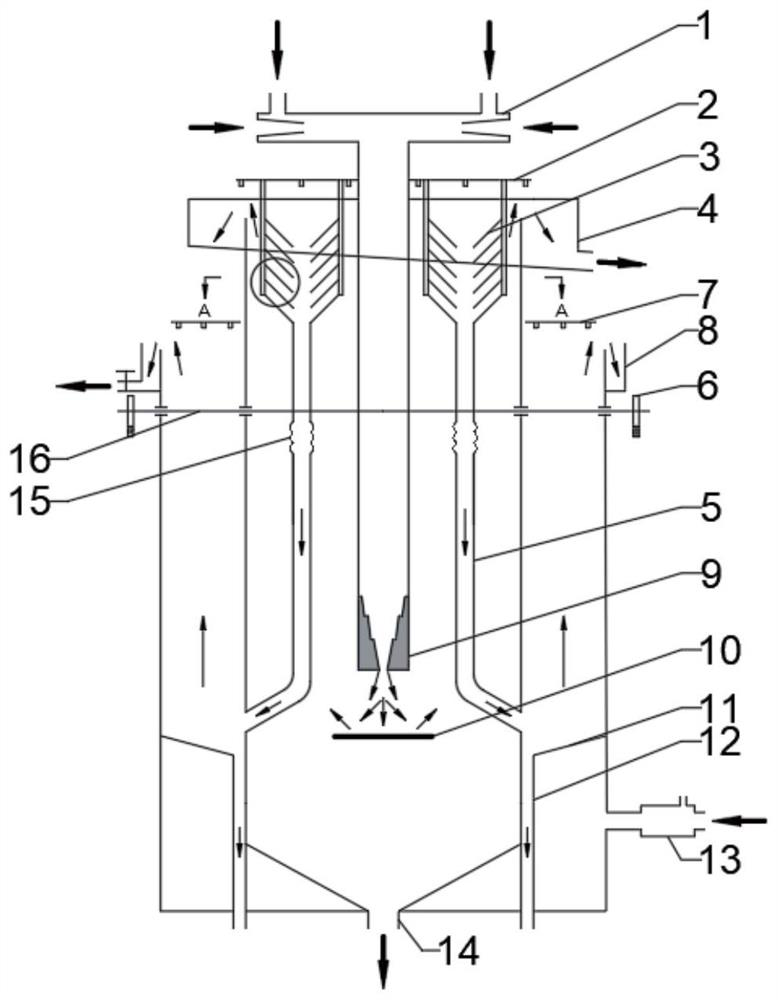

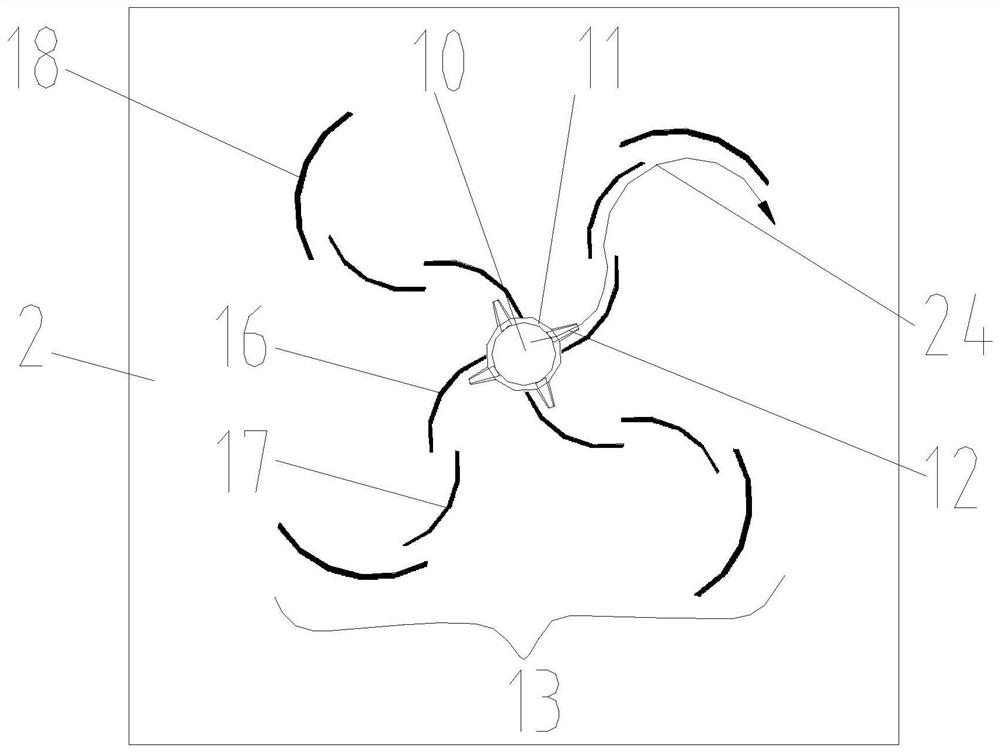

Three-product flotation column and method suitable for high-ash fine-fraction coal slime

ActiveCN112337655AImprove mineralization efficiencyImprove clean coal qualityFlotationEngineeringCoal product

The invention relates to a three-product flotation column and method suitable for high-ash fine-fraction coal slime recovery, and belongs to the technical field of coal recovery. The three-product flotation column comprises an inner-layer column body and an outer-layer column body, the top of the inner-layer column body is provided with a clean coal collecting tank a and a feeding pipe, the periphery of the top of the outer-layer column body is provided with a clean coal collecting tank b, the bottom end of a feeding pipe is provided with a stepped jet device, and a flow baffle is arranged under the stepped jet device and in the inner-layer column body; the upper opening of the inner-layer column body is provided with a plurality of upper water spraying devices around the feeding pipe, thebottom of the inner-layer column body is provided with an L-shaped coarse grain recycling channel which is communicated with the outside of the inner-layer column body, and the clean coal collectingtank b and an outer-layer top water spraying device are arranged around the opening of the outer-layer column body; and a foam layer vibrating mechanism is arranged at the position below the clean coal collecting tank b on the same horizontal plane of the inner-layer column body and the outer-layer column body, an inclined flow distribution plate of an annular structure is arranged in the outer-layer column body, and an annular middling coal product collecting tank is reserved between the inclined flow distribution plate and the inner-layer column body. The three-product flotation column is high in recovery capacity, coal quality adaptability and separation precision.

Owner:CHINA UNIV OF MINING & TECH

Flotation impurity-removing method for asbestos-containing talcose ore

Owner:NORTHEASTERN UNIV LIAONING

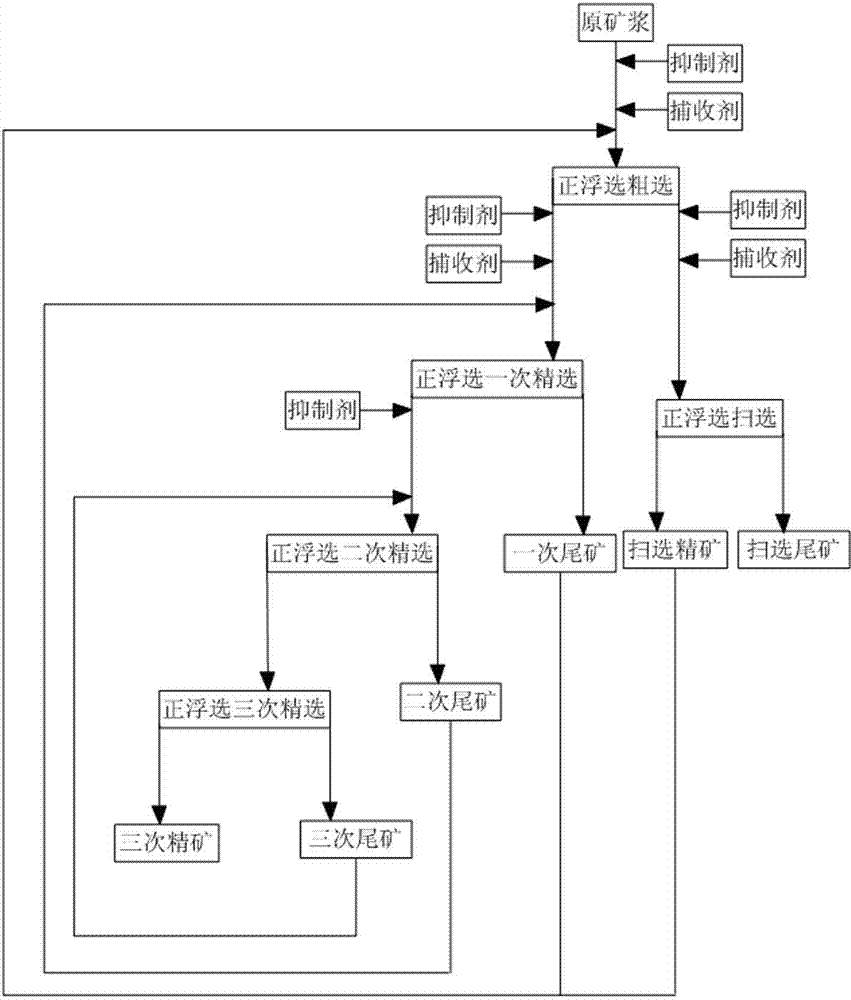

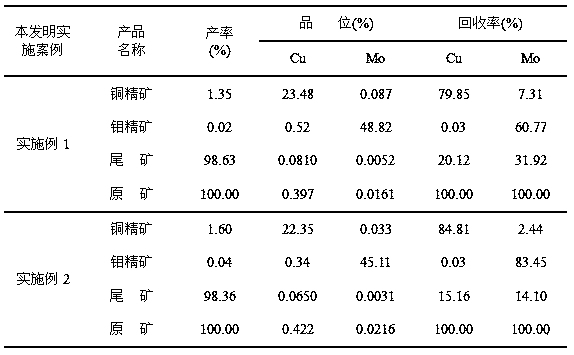

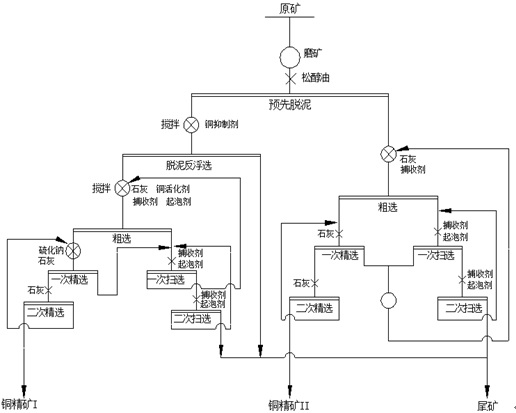

A kind of beneficiation method of molybdenum-containing low-grade mixed copper ore

ActiveCN105435953BImprove the quality of selectionIncrease ion concentrationFlotationWet separationMineral SourcesLower grade

The invention discloses a beneficiation method for low-grade mixed copper ore containing molybdenum. According to the properties and characteristics of the low-grade mixed copper ore containing molybdenum, the copper and molybdenum bulk floatation and re-separation principle technological process is adopted, and high-efficiency concentration of minerals is achieved by using a combination of butyl xanthate and a high-efficiency collector M201 during copper and molybdenum bulk floatation operation; high-efficiency reagent removal of bulk concentrates is achieved through a concentration dewatering and fine grinding method during copper and molybdenum separation operation so that the impact of a large number of reagents existing in copper-lead bulk concentrates on copper and molybdenum separation can be reduced; and moreover, copper minerals are suppressed by means of suppressant F-6, so that separation of copper and molybdenum is effectively realized, and the copper content and molybdenum content of the concentrates are effectively reduced. Meanwhile, in order to stabilize the floatation indexes, the floatation process is optimized for site production, namely, branching and streaming floatation; accordingly, the purpose of comprehensive recovery and utilization of mineral resources is achieved.

Owner:NORTHWEST RES INST OF MINING & METALLURGY INST

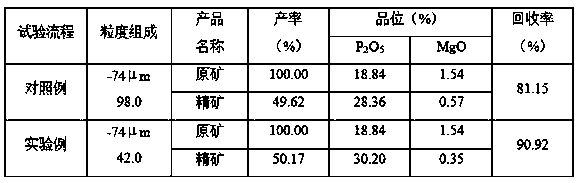

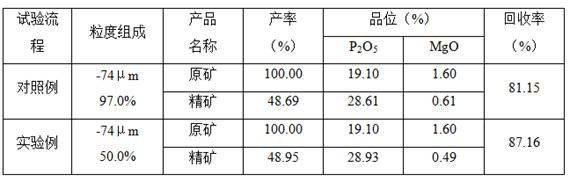

Phosphate ore washing classification and separation method

ActiveCN111375485AReduce the cost of beneficiationImprove flotation environmentSolid separationMining engineeringCalcite

The invention discloses a phosphate ore washing classification and separation method, and belongs to the technical field of mineral processing. The method comprises the steps that slurry and valuableminerals are separated through a plurality of sections of scrubbing operation; slurry is removed through a plurality of sections of desliming operation; after multi-section screening operation, raw ore is separated into minerals of three grades: the high grade, the medium-low grade and barren rock; calcite contained in the minerals of the high grade is removed through an acid leaching method, theminerals of the medium-low grade are subjected to ore grinding flotation operation. According to the method, the ore washing operation and the desliming operation are combined so that phosphorite obtained after monomer separation and slurry can be separated, the grain size of the flotation pulp is controlled within the narrow range, the mineral separation cost is greatly lowered, and the floatation environment is greatly improved. Broken materials are separated into different grain sizes through multi-section screening, some grain sizes of the high level and the grain sizes of the low level are separated independently, then, separated processing is performed, energy consumption of the ore grinding operation is greatly lowered, and the dehydration operation effect is improved.

Owner:BLUESTAR LEHIGH ENG INST CO LTD

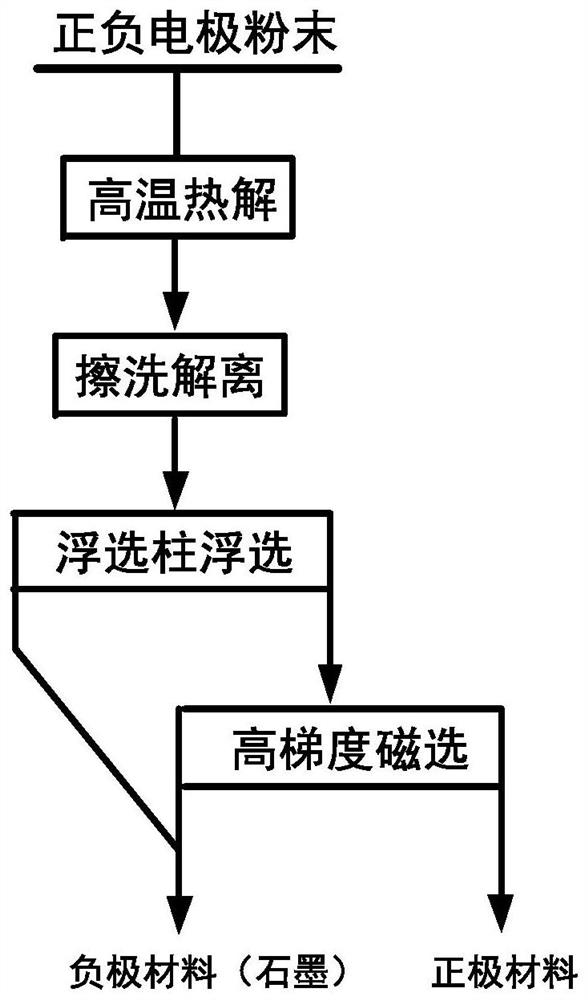

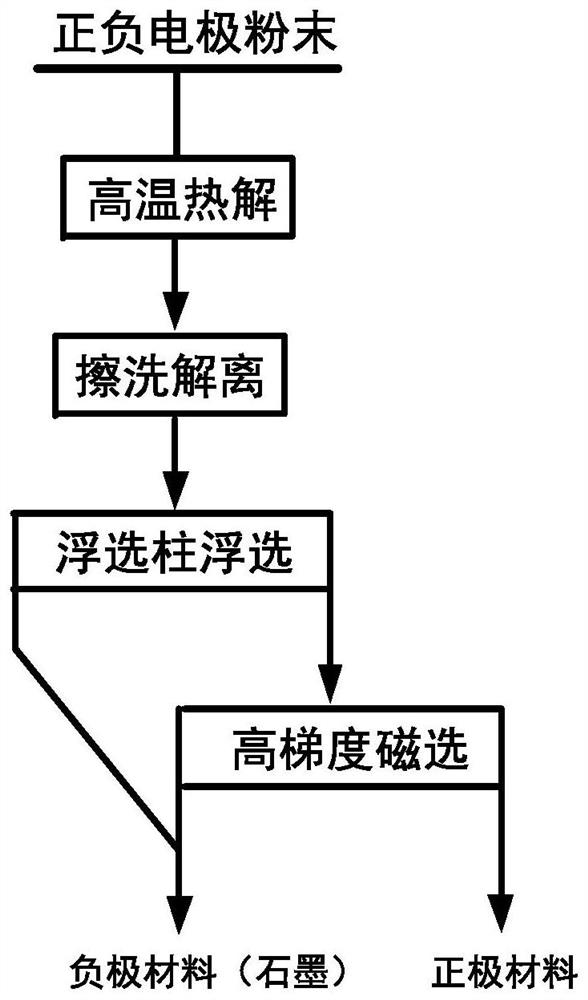

A physical separation and recovery method for positive and negative electrode materials of waste ternary lithium batteries

ActiveCN112736314BEliminate adhesionEliminate flotation environmentWaste accumulators reclaimingBattery recyclingProcess engineeringGraphite

The invention relates to the technical field of recycling waste power lithium-ion batteries, and specifically discloses a method for physically sorting and recovering positive and negative electrode materials of waste ternary lithium batteries. The invention lays the foundation for clean and environmentally friendly physical separation by pyrolyzing the positive and negative electrode materials while removing organic matter, and eliminates the adhesion between the positive electrode material and the graphite by stirring and scrubbing, providing a solid foundation for subsequent flotation and The step-by-step recovery of graphite by magnetic separation creates favorable conditions. The method has the advantages of economy and environmental protection, simple operation and high product purity, realizes efficient separation of positive and negative electrode materials, and improves resource utilization.

Owner:INST OF RESOURCES UTILIZATION & RARE EARTH DEV GUANGDONG ACAD OF SCI

Physical sorting and recycling method for positive and negative electrode materials of waste ternary lithium battery

ActiveCN112736314AEliminate adhesionEliminate flotation environmentWaste accumulators reclaimingBattery recyclingElectrical batteryGraphite

The invention relates to the technical field of recycling of waste power lithium ion batteries, and particularly discloses a physical sorting and recycling method of positive and negative electrode materials of a waste ternary lithium battery. Herein, the positive electrode material and the negative electrode material are pyrolyzed, wherein a foundation is laid for clean and environment-friendly physical separation while organic matter is removed; the adhesion effect between the positive electrode material and graphite is eliminated through stirring and scrubbing, and beneficial conditions are created for step-by-step recovery of the graphite through subsequent flotation and magnetic separation. The method has the advantages of economy, environmental protection, simple operation, high product purity and the like, realizes efficient separation of positive and negative electrode materials, and improves the utilization rate of resources.

Owner:INST OF RESOURCES UTILIZATION & RARE EARTH DEV GUANGDONG ACAD OF SCI

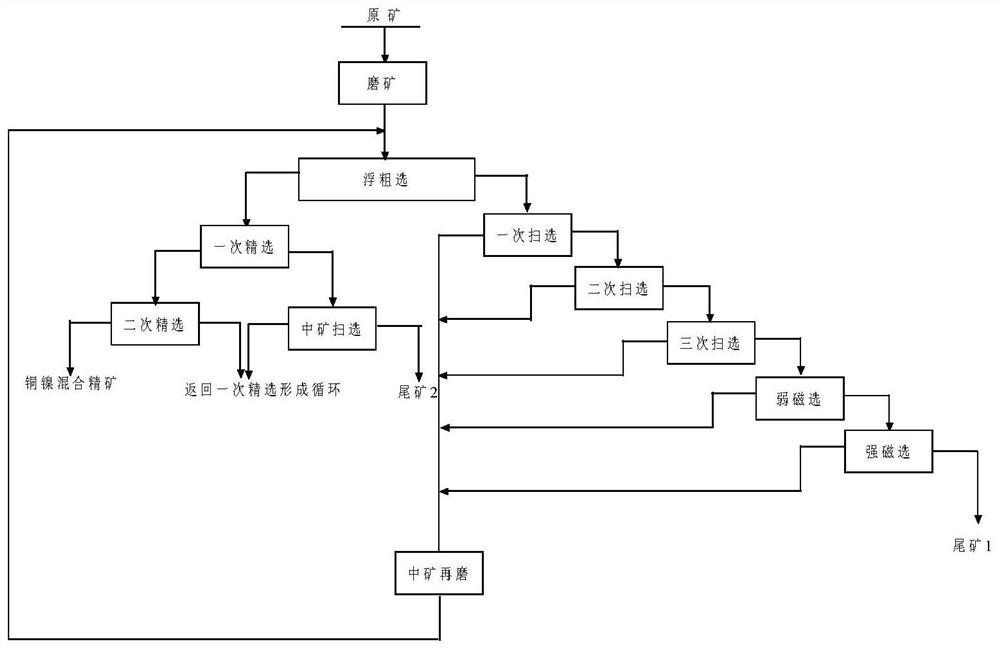

A kind of method for selecting copper and nickel from copper-nickel ore

ActiveCN112619889BHigh recovery rateReduce circulationSolid separationProcess efficiency improvementMagnetic separationGangue

The invention provides a method for beneficiation of copper and nickel from copper-nickel ore. The concentrate obtained by sweeping and the concentrate obtained by magnetic separation are selected. The invention provides a method for separating copper and nickel from copper-nickel ore. The flotation method is used to first select easily floating copper-nickel-bearing minerals, then magnetic separation to select "magnetic" copper-nickel conjoined bodies, and finally regrinding through medium ore. The dissociated conjoined cells are returned to the flotation operation for re-election, which further increases the recovery rate of copper and nickel. At the same time, part of the magnesia-containing gangue can be discarded in advance, reducing the circulation amount of the magnesia-containing gangue in the flotation system, improving the flotation environment, and thereby increasing the copper and nickel content. Nickel recovery rate, reduce MgO content in copper-nickel concentrate. The method has the advantages of simple process, easy control, high separation efficiency, excellent method index, and high quality of the obtained copper-nickel mixed concentrate.

Owner:BEIJING MINING & METALLURGICAL TECH GRP CO LTD

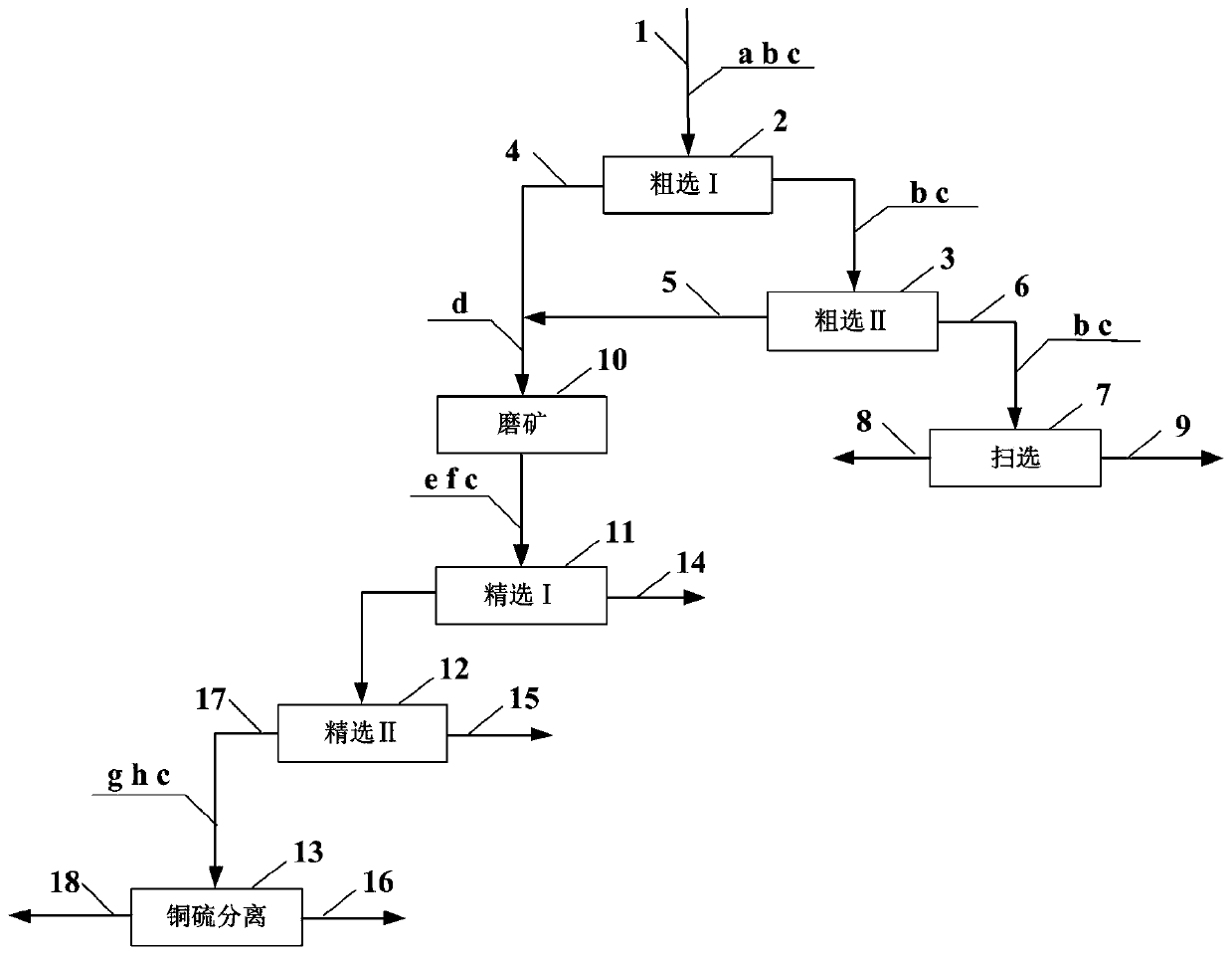

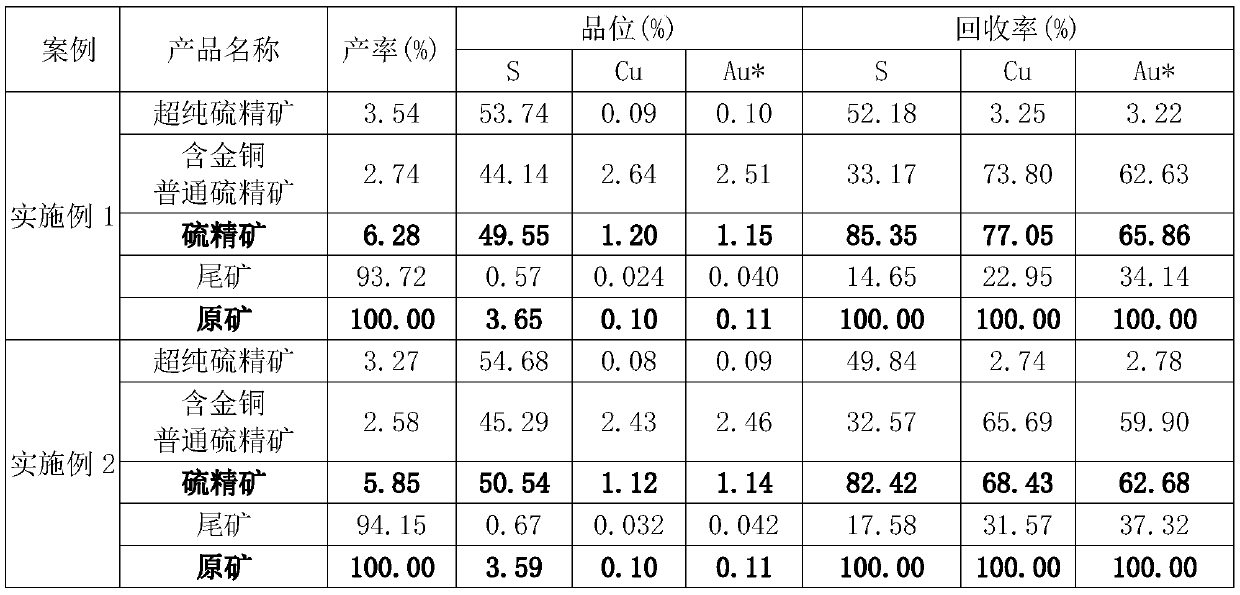

Flotation Technology for Comprehensive Recovery of Gold and Sulfur from Copper Tailings

The invention relates to a flotation process for comprehensively recovering gold and sulfur from copper tailings. According to the floatation process, cave acid waste water, a capture agent and an alcohol foaming agent are added to the tailings from copper processing, recovery of objective minerals, copper and associated gold and silver is intensified, regrinding is conducted after ammonium sulfate is added, the objective minerals are cleaned and dissociated, sulfur concentrates are obtained through two-time concentration and serial return of middling products, the sulfur concentrates are subjected to size mixing through sulfuric acid and then subjected to flotation, and super-pure sulfur concentrates (sulfuric acid residues can be directly used as raw materials for iron-making) and gold-copper containing common sulfur concentrates (the sulfuric acid residues can comprehensively recover gold-copper). The flotation process has the advantages that the concentration effect is good, recovery of subsequent operation is facilitated, the sulfur concentrates are high in grade and good in purity, and the resource additive value of the sulfur concentrates can be improved, and the flotation process is suitable for being applied to copper mineral dressing plants for obtaining the super-pure sulfur concentrates with sulfur-copper tailings as raw materials and comprehensively recovering associated gold elements.

Owner:ZIJIN MINING GROUP +1

A jet suction stirring flotation machine

The invention belongs to the technical field of mineral separation, and specifically relates to a jet-suction agitation flotation machine. The flotation machine adopts deflectors to replace the stirring impeller of the mechanical agitation flotation machine, which reduces the frictional energy between the impeller and the shaft. Loss and internal energy loss caused by impeller agitation of slurry reduces flotation energy loss. The static deflector guides the submerged jet inflow three times, accompanied by the sweeping and stirring of the pulp in the tank, so that the pulp, chemicals and air bubbles are fully mixed in a wider range in the tank. At the same time, the static deflector can realize the control of the pulp mixing circulation area by inducing the direction of the pulp flow, so as to prevent the pulp mixing circulation area from interfering with the transport area of mineralized air bubbles and the foam layer, forming a good flotation environment and the deflector Through multiple cutting and impact crushing of large air bubbles in the pulp, air bubbles with smaller particle sizes are formed, and are fully and evenly distributed in various sections of the tank along the deflector to achieve full mineralization.

Owner:ANHUI UNIV OF SCI & TECH

Flotation recovery method for high-calcium-magnesium high-argillaceous zinc carbonate

The invention relates to a high-calcium-magnesium high-argillaceous zinc carbonate flotation recovery method which comprises the following steps: (1) desliming flotation: taking lead-zinc sulfide flotation tailings as raw ores, adding a slime collecting agent, stirring and reacting for 3-6 minutes, and then desliming before zinc oxide flotation to respectively obtain slime-containing ore pulp and deslimed tailing ore pulp; (2) roughing zinc oxide: adding regulators of sodium carbonate, sodium sulfide, gangue inhibitor, lauryl amine acetate and butyl xanthate into the deslimed tailing pulp for roughing zinc to respectively obtain zinc rough concentrate pulp and roughed tailing pulp; (3) zinc oxide concentration: performing concentration operation on the zinc rough concentrate pulp twice to obtain zinc oxide concentrate; and (4) zinc oxide scavenging: performing one-time zinc oxide scavenging operation on the roughing tailing pulp to obtain zinc oxide scavenged tailings. According to the method, the floatability of the zinc oxide mineral can be remarkably enhanced, and better mineral separation technical indexes are obtained.

Owner:NORTHWEST RES INST OF MINING & METALLURGY INST

A kind of beneficiation method of easy muddy and easy floating copper-bearing talc-serpentinite ore

ActiveCN111451003BImprove flotation environmentEasy to recycleFlotationMechanical material recoveryFoaming agentMining engineering

The invention discloses a method for beneficiation of copper-containing talc-serpentinite ore that is easy to muddy and float. The ore is ground to obtain the raw ore pulp; (2) Pre-deliming flotation: adding a foaming agent to the raw ore pulp to perform pre-flotation of muddy and easy-to-float gangue to obtain pre-delimed foam and pre-delimed Ore pulp; (3) separate flotation of pre-delimed ore pulp: (4) individual flotation of ore pulp after pre-delimed; In addition, creatively put forward the technical scheme of suppressing copper floating mud first, then reactivating the pulp after reverse flotation desliming and copper flotation enrichment, so as to avoid the influence of a large amount of mud-containing gangue on the enrichment of copper in the pre-desilting foam , thereby greatly reducing the dosage of chemicals, thus providing a strong guarantee for improving the quality of copper concentrate.

Owner:铜陵有色金属集团股份有限公司

A collector for recovering copper, lead and zinc minerals from iron beneficiation tailings

ActiveCN110947523BGood harvesting effectEnhanced harvesting capacityFlotationMineral flotationAcrylonitrile

Owner:NORTHWEST RES INST OF MINING & METALLURGY INST

A kind of beneficiation method of recovering cassiterite from tin-copper symbiotic ore

ActiveCN110170381BReduce distractionsReduce adverse effects of flotationDifferential sedimentationFlotationFlocculationCassiterite

The invention discloses a beneficiation method for recovering cassiterite from tin-copper symbiotic ore. The method is as follows: first grinding the raw ore; obtaining copper-sulfur mixed concentrate and floating sulfur tailings by flotation of copper and sulfur; then magnetically separating the floating sulfur tailings to obtain magnetic separation concentrate and magnetic separation tailings; The magnetic separation tailings are flotation with specific reagents to obtain the floating tin concentrate and tailings; finally, the floating tin concentrate is centrifugally separated to obtain tin concentrate and tin sub-concentrate. In the flotation process of cassiterite, the method of the present invention uses selective flocculation of fine-grained cassiterite and uses a specific combination of inhibitors, which can reduce the use of collectors, reduce the cost of agents, and ensure the recovery of cassiterite The grade and recovery rate are not reduced, the tin grade is greater than 40%, and the total recovery rate is greater than 85%. The method adopts full flotation without desliming to realize efficient enrichment of cassiterite, with short process flow, good technical indicators, and excellent structure of recovered products. It has high application value in the recovery of cassiterite.

Owner:广东省资源综合利用研究所

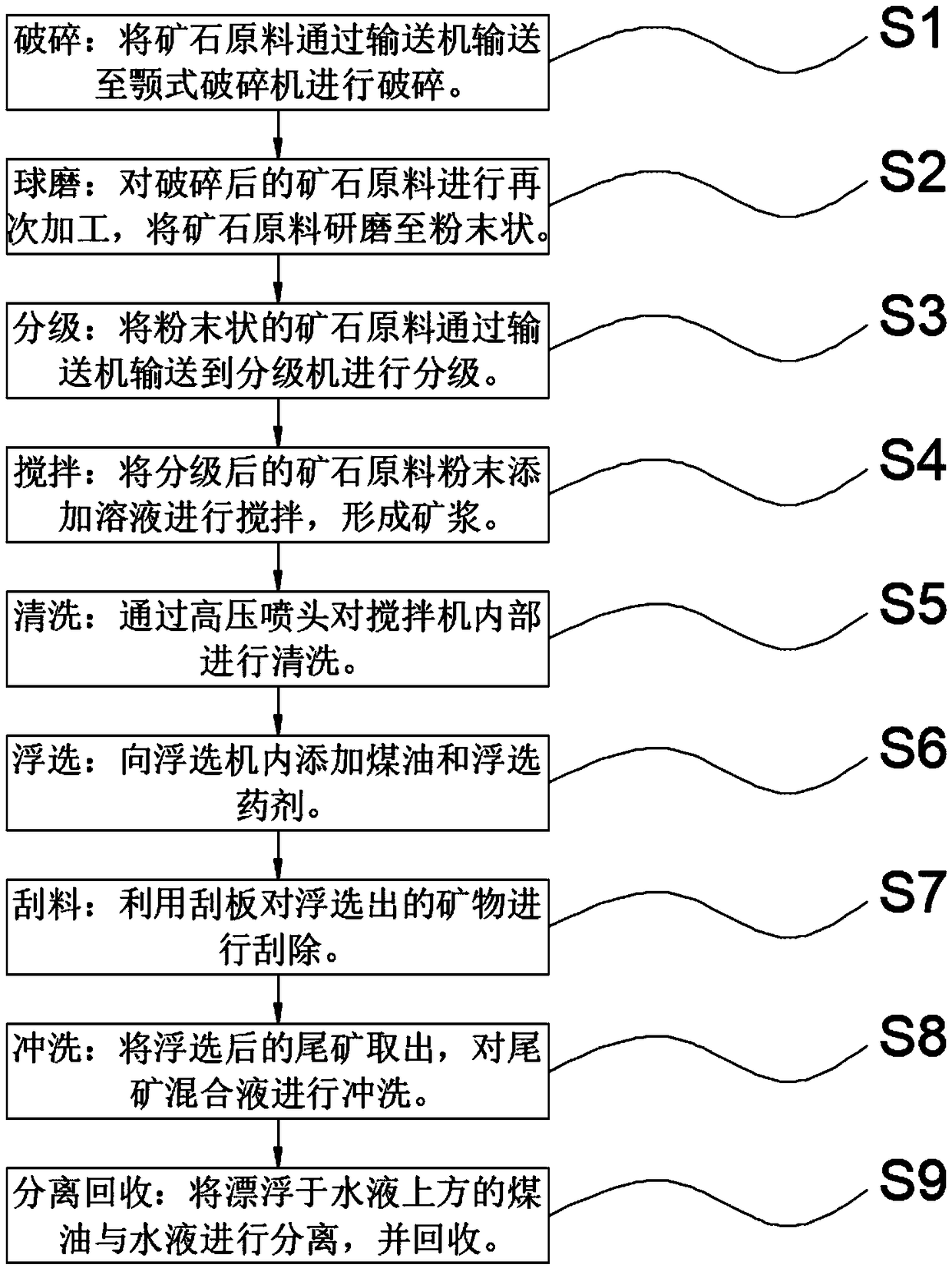

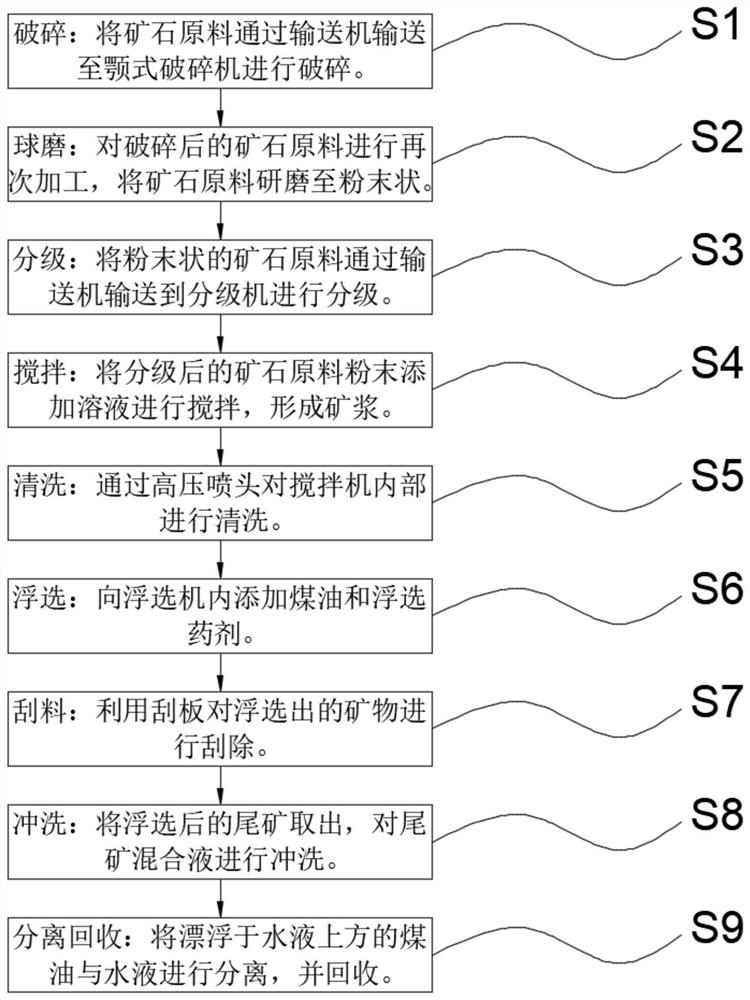

Application method of separating kerosene from sulphide ores

The invention discloses an application method of separating kerosene from sulphide ores. The application method comprises the steps of crushing, ball milling, a grading, stirring, floatation, scraping, flushing, separating and recycling. According to the application method, steps are reasonable, using is safe and convenient, and proper kerosene is added in the separating process of the sulphide ores to replace an inhibitor of certain ores, so that the flotation environment of the sulphide ores is effectively improved, the purity and effect of flotation of the sulphide ores are improved, the floatation degree of the sulphide ores is greatly improved, and the efficiency of flotataion of the sulphide ores is improved. Cleaning can be conducted after stirring, so that stirred ore pulp is effectively prevented from being adhered to the inner wall of a stirrer. On the one hand, the clean degree of the inner wall of the stirrer can be guaranteed; and on the other hand, waste of the ore pulp can be effectively avoided, and the floatation yield of the sulphide ores is improved.

Owner:HUNAN SHIZHUYUAN NON FERROUS METAL

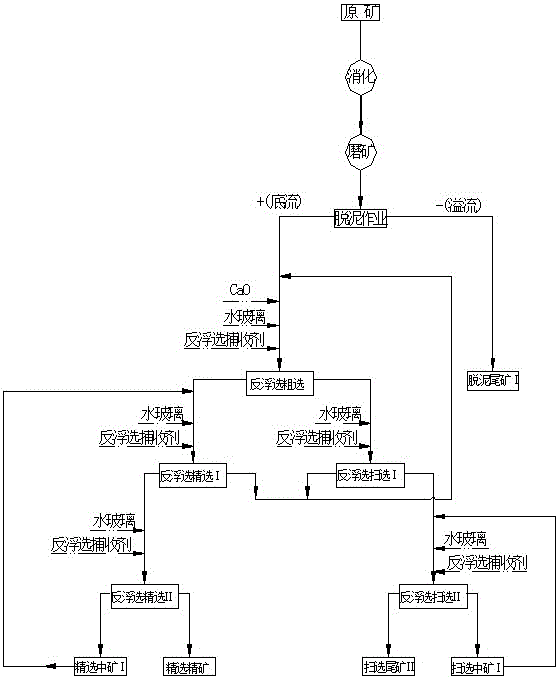

Digestion-desliming-reverse flotation method for processing low-grade high-silicon and high-calcium magnesite

ActiveCN104437883BIncrease planktonic diversityRaise the gradeFlotationGrain treatmentsSlurryPericlase

The invention discloses a digestion-desliming-reverse floatation method for treatment of low-grade magnesite high in silicon content and calcium content. The digestion-desliming-reverse floatation method for treatment of the low-grade magnesite high in silicon content and calcium content comprises the following steps that low-grade magnesite raw ore high in silicon content and calcium content is crushed and then is fed into a rotary kiln or a fluidized bed boiler to b roasted; the roasted material is ground by a ball grinder to be fine, and then water is added to the fine material, so that raw ore pump is obtained; the raw ore pulp is placed in a desliming hydrocyclone, so that slurry is removed; the deslimed raw ore pulp is placed in a floating device, the regulator such as sodium carbonate or CaO is added firstly, sodium silicate is added, then a reverse flotation collecting agent is added, stirring is conducted, reverse floatation rough concentration is conducted, rough concentrate is obtained, and tailings containing quartz and dolomite are separated. According to the digestion-desliming-reverse floatation method, through digestion, the floating difference between periclase and dolomite is increased, the effect that a qualified product is obtained at low ore dressing cost is achieved finally through the reverse flotation technology, and industrial production for purification of the low-grade magnesite high in silicon content and calcium content can be achieved easily.

Owner:BLUESTAR LEHIGH ENG INST CO LTD

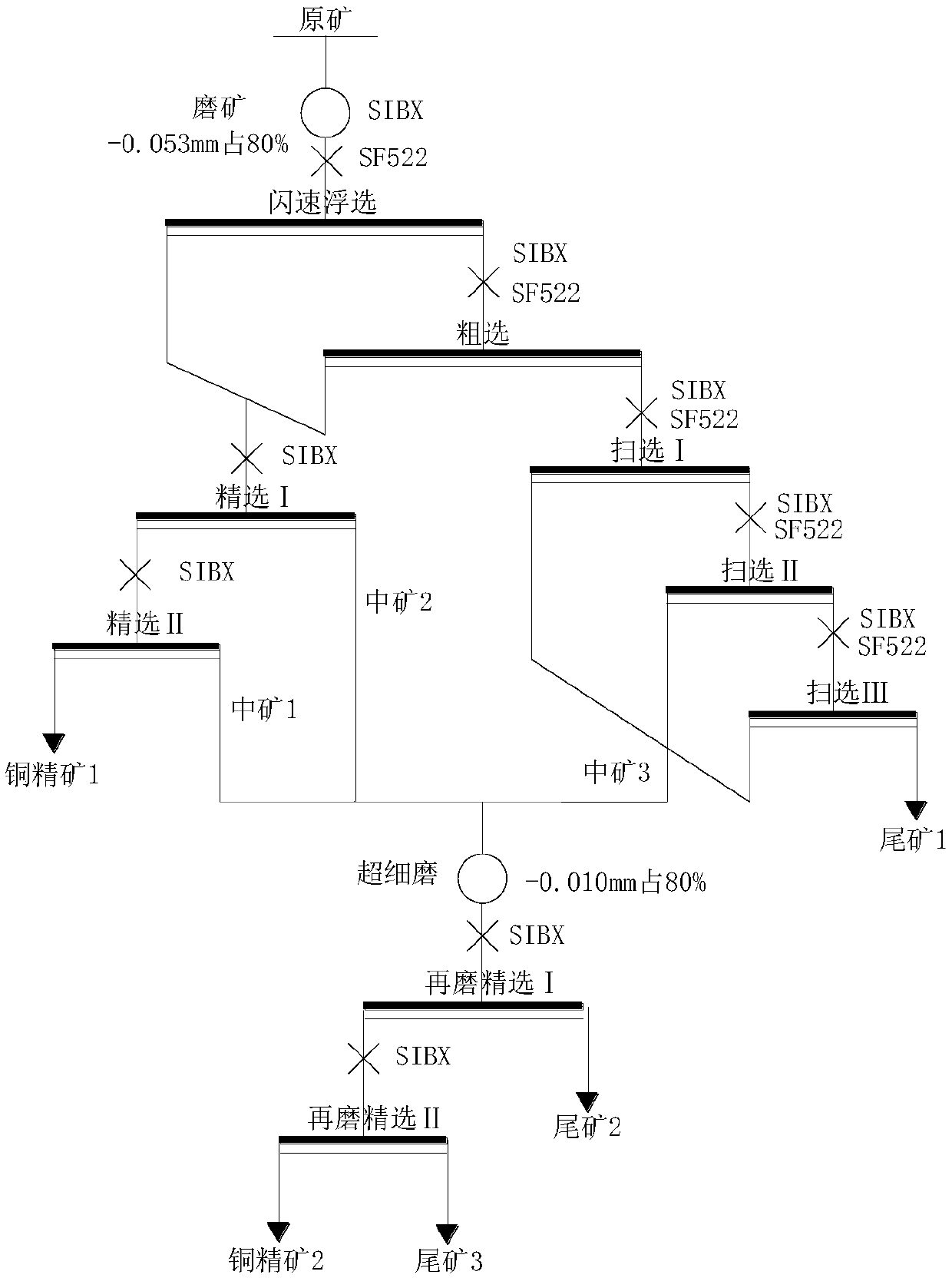

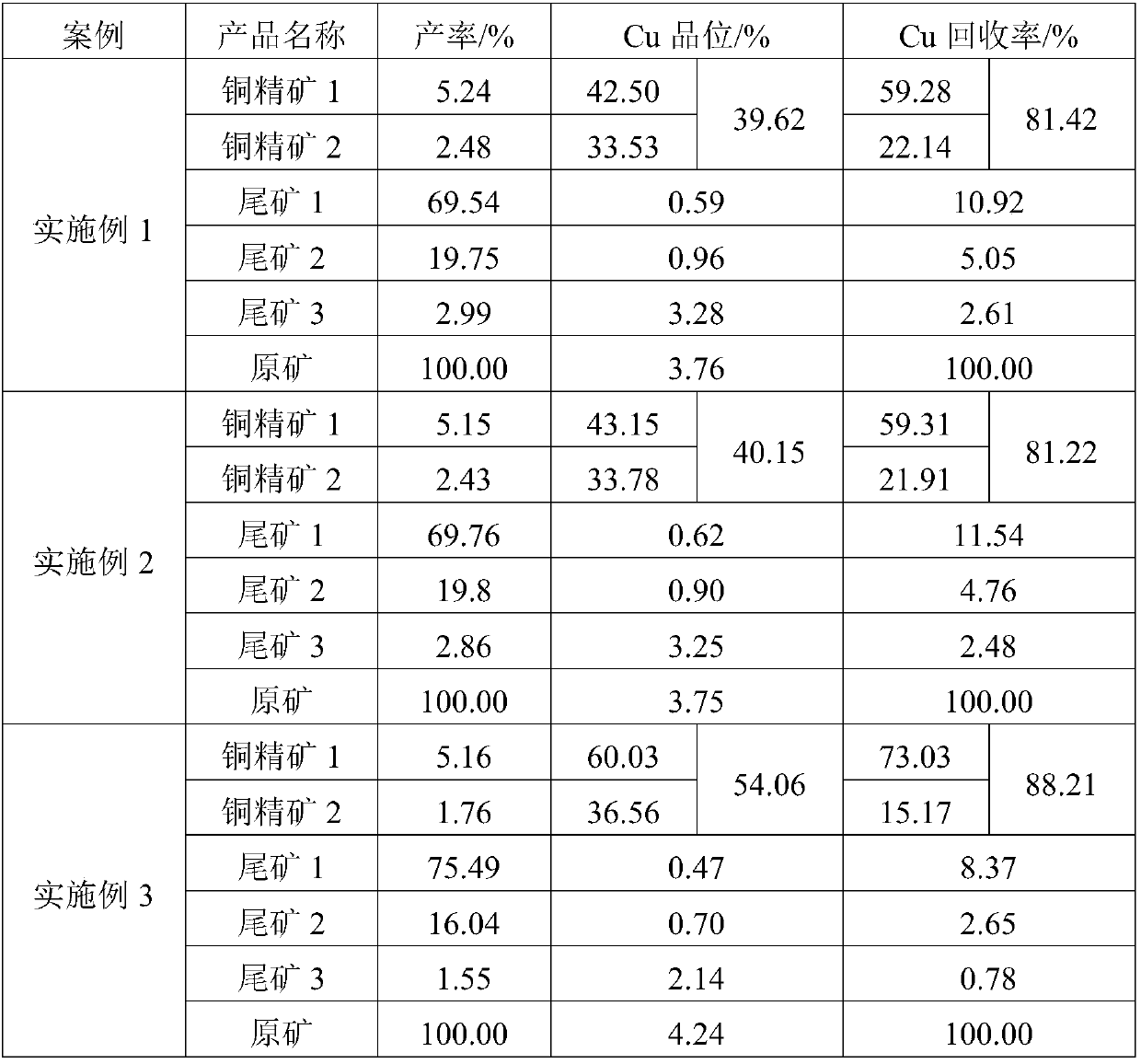

A sorting process of copper sulfide ore with fine particle size embedded

ActiveCN107282312BImproved particle size distributionIncrease monomer dissociationFlotationGrain treatmentsMaceralCopper ore

The invention discloses a separation process for copper sulphide ore with superfine disseminated grain sizes. The separation process comprises the steps that collectors are added in the coarse grinding process and give full play to the fresh surfaces of minerals, the action efficiency of the collectors on the mineral surfaces is improved, a part of copper ore which is subjected to monomer separation is obtained through quick floatation, rough concentrate is then subjected to low concentration and medium rotating speed concentration operation for two times to obtain high-grade copper concentrate 1, middlings 1 and middlings 2, roughing tailings are subjected to three-section scavenging operation to obtain middlings 3, the middlings 1, the middlings 2 and the middlings 3 are combined and enter ultrafine grinding operation, ultrafine grinding products are subjected to regrinding concentration I and regrinding concentration II operation, and copper concentrate 2 is obtained. The effect of treating the copper sulphide ore with the superfine disseminated grain sizes is good, adaptability is high, and high-grade concentrate products can be obtained.

Owner:厦门紫金矿冶技术有限公司

A kind of phosphate ore washing classification roasting flotation method

ActiveCN111375484BReduce the cost of beneficiationImprove flotation environmentSolid separationMining engineeringCalcite

Owner:BLUESTAR LEHIGH ENG INST CO LTD

A kind of application method of kerosene in the separation of sulfide ore

Owner:HUNAN SHIZHUYUAN NON FERROUS METAL

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com