A kind of phosphate ore washing classification roasting flotation method

A phosphate ore and roasting technology, applied in the field of mineral processing, can solve the problems of difficult density, poor comprehensive technical and economic indicators, and low resource utilization rate, and achieve the effects of reducing energy consumption, improving flotation environment, and reducing beneficiation costs.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

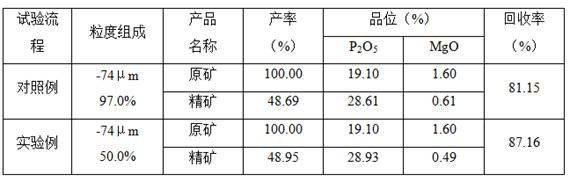

Examples

Embodiment 1

[0033] Embodiment 1, a kind of phosphate ore washing classification roasting flotation method:

[0034] The raw ore is crushed to -40mm by crushing operation and then scrubbed; through two-stage scrubbing operations, the ore slime and useful minerals are separated; through multi-stage desliming operations, the fine mud is removed;

[0035] Through multi-stage screening operations, the raw ore is divided into three grades of high, medium and low grade ores; high grade ores are roasted to remove calcite contained in them, and medium and low grade ores are processed by grinding and flotation.

[0036] The high-grade ore and low-grade ore pass through the P 2 o 5 content to distinguish; the method of distinction is as follows: high-grade ore refers to P 2 o 5 Ores with a content of not less than 28%; the low- and medium-grade ores mentioned refer to P 2 o 5Ore with a content of 16%-28%; the grade distinction is preferably obtained by detecting and analyzing the particle size ...

Embodiment 2

[0039] Embodiment 2, a kind of phosphate ore washing classification roasting flotation method:

[0040] The raw ore is crushed to -20mm by crushing operation and then scrubbed; through two-stage scrubbing operations, the ore slime and useful minerals are separated; through multi-stage desliming operations, the fine mud is removed;

[0041] Through multi-stage screening operations, the raw ore is divided into three grades of high, medium and low grade ores; high grade ores are roasted to remove calcite contained in them, and medium and low grade ores are processed by grinding and flotation.

[0042] The middle and high-grade ores and the middle and low-grade ores are distinguished by sieving; the distinction method is as follows: one stage of scrubbing followed by one stage of screening, and the particle size of the first stage of sieve sieve is controlled to 1~10mm; Carry out the second-stage screening, the sieve size of the second-stage screening is controlled to 0.3~0.7mm, t...

Embodiment 3

[0043] Embodiment 3, a kind of phosphate ore washing graded roasting flotation method is carried out according to the following steps:

[0044] (1) The raw ore is crushed to below -20mm after the crushing operation, and then sent to the ore washing operation for scrubbing. The scrubbed pulp is sent to the first section of screening operation, the material on the screen is sent to the tailings stockyard, and the material under the screen is sent to the first section For desliming operation, the sieve size of the first stage of screening operation is controlled to 2mm, and the particle size of the first stage of desliming is controlled to 63μm.

[0045] (2) The coarse-grained pulp of the first stage of desliming operation is fed into the second stage of scrubbing operation, and the pulp of the second stage of scrubbing operation is fed into the second stage of desliming operation. Slurry feeding into tailings thickening operation;

[0046] (3) The fine-grained slurry of the sec...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com