Separation method for treating low-grade refractory zinc lead oxide ores

A technology of lead-zinc oxide and beneficiation method, which is applied in chemical instruments and methods, wet separation, solid separation, etc., can solve the problems of high cost and inapplicability, and achieve the effects of small investment, reduced beneficiation cost and large processing capacity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

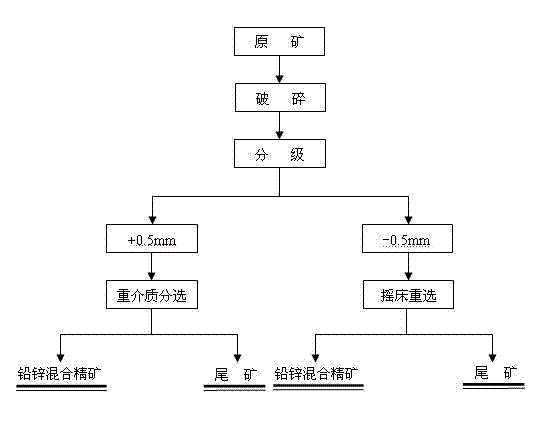

Image

Examples

Embodiment 1

[0030] The raw ore composition of the processed lead-zinc oxide ore: Zn 7.81%, Pb 1.49%, Fe 5.55%, CaO 29.13%, MgO 0.47%, SiO 2 20.04%, lead oxidation rate 89.45%, zinc oxidation rate 91.30%.

[0031] Above-mentioned raw ore is passed through following processing steps:

[0032] (1) Crushing all the raw ore to -10mm;

[0033] (2) Sieve the crushed ore into four grades: -10mm~+0.5mm, -0.5mm~+0.2mm, -0.2mm~+0.074mm, -0.074mm;

[0034] (3) Sorting the raw ore with a particle size of -10mm to +0.5mm in a dense medium cyclone with a separation specific gravity of 2.85, the resuspension liquid is prepared with ferrosilicon powder, and the lead-zinc mixed concentrate is separated;

[0035] (4) Feed the raw ore with particle size of -0.5mm~+0.2mm to the coarse sand bed for shaker gravity separation operation, the feeding concentration is 30%; feed the raw ore with particle size of -0.2mm~+0.074mm to the fine sand shaker gravity separation operation on the rocker bed, and the ore c...

Embodiment 2

[0039]The composition of the processed lead-zinc oxide ore: Zn 9.76%, Pb 2.12%, Fe 8.51%, CaO 18.23%, MgO 3.23%, SiO 2 16.52%, lead oxidation rate 87.31%, zinc oxidation rate 90.05%.

[0040] Above-mentioned raw ore is passed through following processing steps:

[0041] (1) Crushing all the raw ore to -10mm;

[0042] (2) Sieve the crushed ore into four grades: -10mm~+0.5mm, -0.5mm~+0.2mm, -0.2mm~+0.074mm, -0.074mm;

[0043] (3) Sorting the raw ore with a grain size of -10mm ~ +0.5mm in a dense medium cyclone with a dense medium separation specific gravity of 2.80, the resuspension liquid is prepared with ferrosilicon powder, and the lead-zinc mixed concentrate is separated;

[0044] (4) Feed the raw ore with particle size of -0.5mm~+0.2mm to the coarse sand bed for shaking table gravity separation operation, the feeding concentration is 30%, after shaking table rough separation, lead-zinc mixed rough concentrate, middle ore and Tailings, lead-zinc mixed coarse concentrate ...

Embodiment 3

[0048] The raw ore composition of zinc oxide ore processed: Zn 12.45%, Pb 1.95%, Fe 9.32%, CaO 22.13%, MgO 2.85%, SiO 2 14.65%, lead oxidation rate 81.85%, zinc oxidation rate 83.75%.

[0049] Above-mentioned raw ore is passed through following processing steps:

[0050] (1) Crushing all the raw ore to -16mm;

[0051] (2) Sieve the crushed ore into four grades: -16mm~+0.5mm, -0.5mm~+0.15mm, -0.15mm~+0.037mm, and -0.037mm;

[0052] (3) Sorting the raw ore with a particle size of -16mm to +0.5mm in a dense medium cyclone with a separation specific gravity of 2.75, the resuspension liquid is prepared with magnet powder, and the lead-zinc mixed concentrate is separated;

[0053] (4) Feed the raw ore with particle size of -0.5mm~+0.15mm to the coarse sand bed for shaking table gravity separation operation, the feeding concentration is 30%. Tailings and sub-concentrates are re-grinded and concentrated on a shaking table to obtain lead-zinc mixed concentrate, middle ore and taili...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com