Efficient purification method for high-silicon high-calcium high-iron low-grade brucite

A purification method and low-grade technology, applied in chemical instruments and methods, magnetic separation, solid separation, etc., to achieve the effect of high gangue mineral content, good sorting effect and high quality concentrate product

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

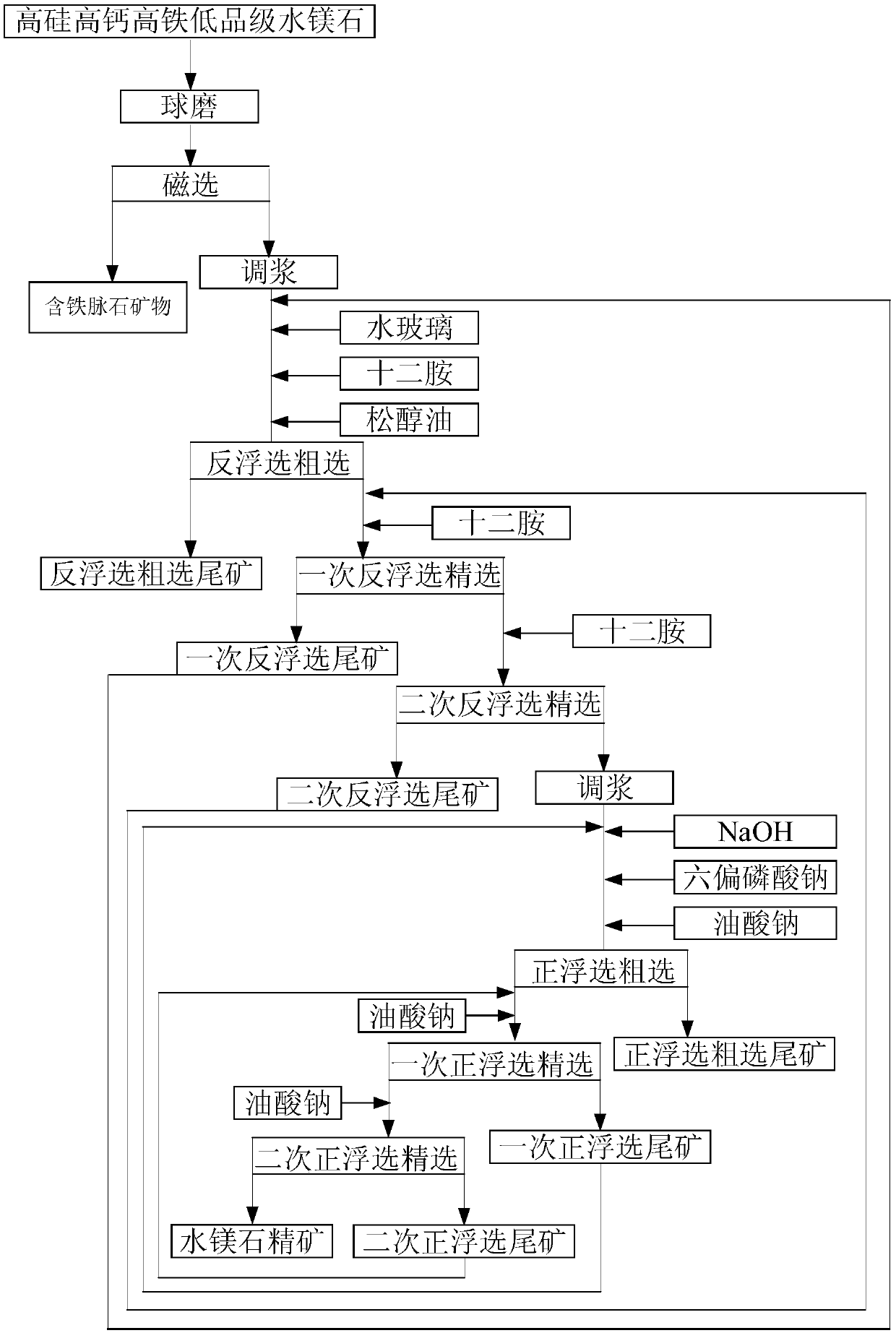

Method used

Image

Examples

Embodiment 1

[0050] The high-silicon, high-calcium, high-iron low-grade brucite used in this embodiment, the main components in the ore contain 51.28% MgO by weight percentage, SiO 2 is 7.35%, CaO is 3.59%, TFe is 2.07%, LOI is 22.12%, and the balance is impurities;

[0051] A high-efficiency purification method for high-silicon, high-calcium, high-iron low-grade brucite, specifically comprising the following steps:

[0052] Step 1: Ball Milling

[0053] The high-silicon, high-calcium, high-iron low-grade brucite is ground by a ball mill until the monomer is dissociated, and the high-silicon, high-calcium, high-iron low-grade brucite powder is obtained. Magnesite powder accounts for 70% of the weight of total high-silicon, high-calcium, high-iron low-grade brucite powder;

[0054] Step 2: Strong Magnetic Separation

[0055] The high-silicon, high-calcium, high-iron low-grade brucite powder is subjected to magnetic separation by a strong magnetic separator with a magnetic field strength ...

Embodiment 2

[0070] In the high-silicon, high-calcium, and high-iron type low-grade brucite raw materials used in this embodiment, the main components contain 58.28% by weight of MgO, SiO 2 is 2.13%, CaO is 1.36%, TFe is 7.52%, LOI is 27.63%, and the balance is impurities;

[0071] A high-efficiency purification method for high-silicon, high-calcium, high-iron low-grade brucite, comprising the following steps:

[0072] Step 1: Ball Milling

[0073] Grinding high-silicon, high-calcium, high-iron low-grade brucite until the monomer is dissociated to obtain high-silicon, high-calcium, high-iron low-grade brucite powder, among which, high-silicon, high-calcium, high-iron low-grade brucite powder with a fineness of ≤0.074mm The weight accounts for 85% of the weight of the total high-silicon, high-calcium, and high-iron low-grade brucite powder;

[0074] Step 2: Strong Magnetic Separation

[0075] The high-silicon, high-calcium, high-iron and low-grade brucite powder is subjected to magnetic ...

Embodiment 3

[0090]In the high-silicon, high-calcium, and high-iron type low-grade brucite raw materials used in this embodiment, the main components contain 54.57% of MgO by weight percentage, SiO 2 is 5.14%, CaO is 6.78%, TFe is 4.81%, LOI is 25.53%, and the balance is impurities;

[0091] A high-efficiency purification method for high-silicon, high-calcium, high-iron low-grade brucite, comprising the following steps:

[0092] Step 1: Ball Milling

[0093] Dissociate high-silicon, high-calcium, high-iron and low-grade brucite powder through a ball mill to obtain high-silicon, high-calcium, high-iron and low-grade brucite powder. Among them, the weight of high-silicon, high-calcium, high-iron and low-grade brucite powder with fineness ≤ 0.074mm It accounts for 80% of the weight of the total high-silicon, high-calcium, and high-iron low-grade brucite powder;

[0094] Step 2: Strong Magnetic Separation

[0095] The high-silicon, high-calcium, high-iron low-grade brucite powder is subject...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Fineness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com