Beneficiation and metallurgy combined treatment technology for recovering copper of complex copper sulfide ore

A technology for combination of beneficiation and metallurgy and processing technology, applied in the fields of beneficiation and metallurgy, can solve the problems of poor recovery index, unstable foam, easy sludge, etc., and achieve the effects of improving grade, improving selectivity and improving recovery rate.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

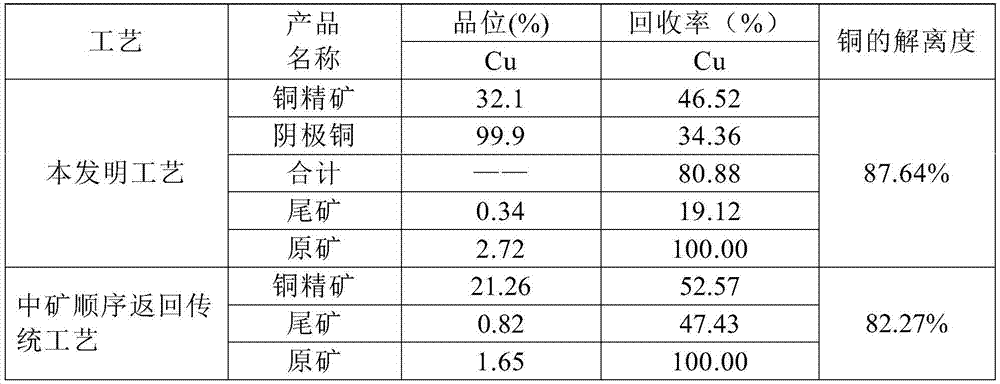

[0028] 1. The nature of the raw ore

[0029] A sulfide ore in Tongling, Anhui Province contains 1.65% copper, 28.6% sulfur, and 31.24% iron. The metal minerals mainly include chalcopyrite, colloidal chalcopyrite, copper blue, pyrite, and colloidal pyrite. There are also a small amount of chalcocite, etc.; gangue mainly include quartz, calcite and so on. Metal minerals account for 70.26% of the ore, and gangue accounts for 29.74%. Among them, secondary copper minerals account for 32.5% of the total copper, colloidal chalcopyrite in chalcopyrite accounts for 40%, and colloidal pyrite in pyrite accounts for 35%.

[0030] Two, utilize process of the present invention to handle

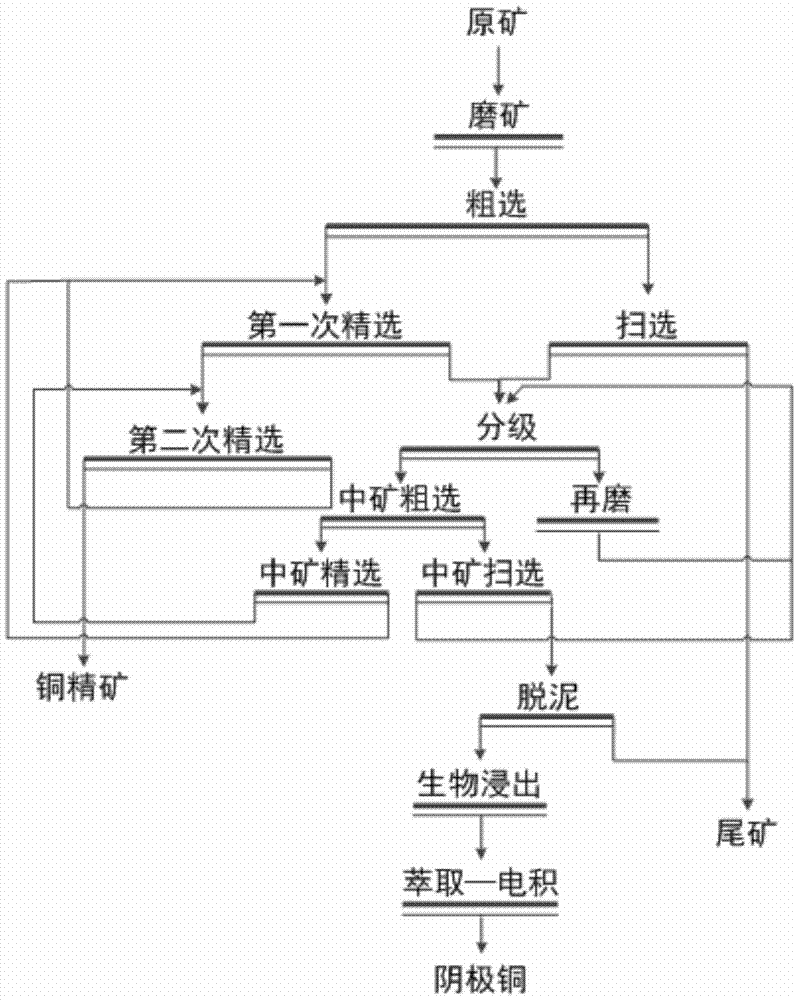

[0031] See the process flow figure 1 , the specific process is as follows:

[0032] (1) Grinding the raw ore to -0.074mm accounts for 65%.

[0033] (2) After the ore grinding, one rough, one sweep and two fine operations are carried out to obtain copper concentrate. Among them, the concentration of r...

Embodiment 2

[0044] 1. The nature of the raw ore

[0045] A colloidal copper-sulfur ore in Chifeng, Inner Mongolia, the ore contains 0.88% copper and 18.36% sulfur. The main metal minerals are pyrite, pyrrhotite and arsenopyrite, followed by chalcopyrite, chalcocite and blue chalcocite; gangue minerals are quartz, calcite and chlorite. The ore structure mainly includes dissolution metasomatism and colloid co-precipitation. Metal minerals account for 41.32% of the ore, and gangue accounts for 58.68%. Among them, secondary copper minerals accounted for 36.8% of the total copper, colloidal chalcopyrite in chalcopyrite accounted for 31.9%, and colloidal pyrite in pyrite accounted for 32.6%.

[0046] Two, utilize process of the present invention to process

[0047] See the process flow figure 1 , the specific process is as follows:

[0048] (1) Grinding the raw ore to -0.074mm accounts for 73%.

[0049] (2) After the ore grinding, one rough, one sweep and two fine operations are carried o...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com