Three-product flotation column and method suitable for high-ash fine-fraction coal slime

A fine-grained, three-product technology, used in flotation, solid separation, etc., to avoid losses, prevent short circuits, and improve the quality of clean coal products

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

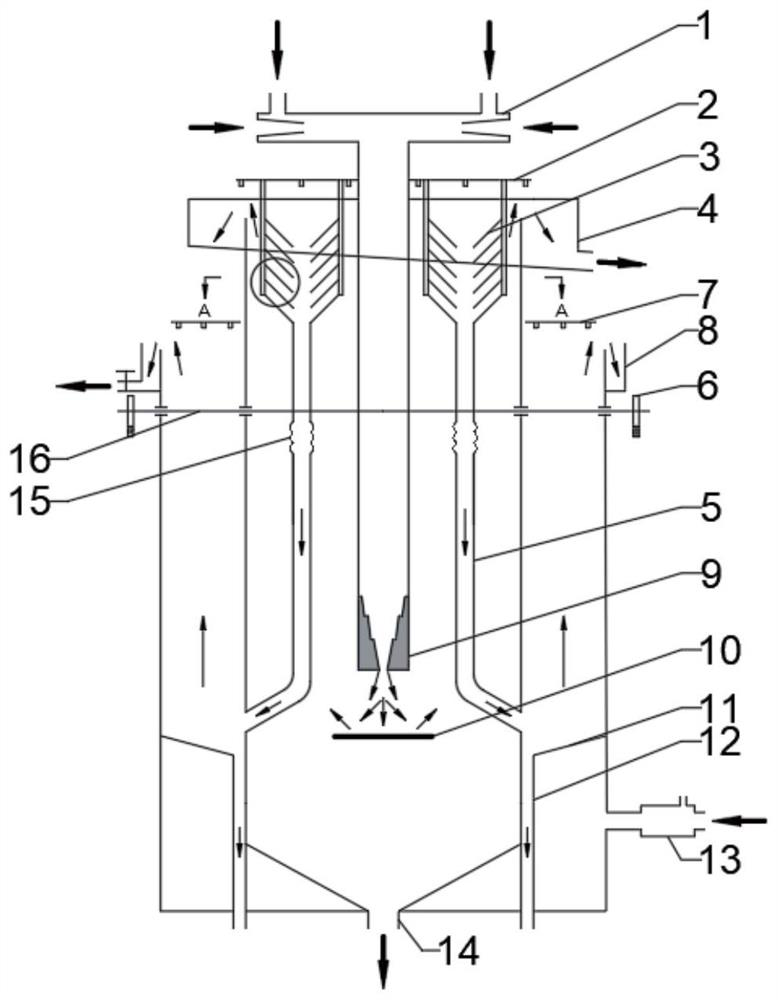

[0039] A three-product flotation column slime flotation procedure suitable for high-ash fine-grained coal slime recovery is as follows:

[0040] Before feeding the slurry to start the slime flotation, close the underflow pipe 14, fill the inner column with slurry, and fill the outer column with clear water, so that the slurry in the flotation column flows as shown by the arrow in the figure.

[0041] 1. The coal slime entering the foam layer is washed by the spray water 2, the vibration of the sieve plate 16 driven by the electromagnetic vibrator 6, and the coupling of the multi-layer annular inclined plate 3 effectively strengthen the desorption of the fine slime in the foam layer. The clean coal foam layer after desorbing the fine mud enters the clean coal collection tank 4 under the overflow action, and finally becomes the clean coal product a.

[0042] 2. The fine mud and some coarse particles falling on the inclined plate 3 slide quickly along the inclined plate 3 into th...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Tilt angle | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com