A kind of application method of kerosene in the separation of sulfide ore

An application method and technology of sulfide ore, which is applied in the direction of solid separation and flotation, can solve the problems of mineral content and purity reduction, low flotation efficiency, ore purity reduction, etc., so as to improve the purity and effect and improve the flotation environment , the effect of increasing the degree and yield

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

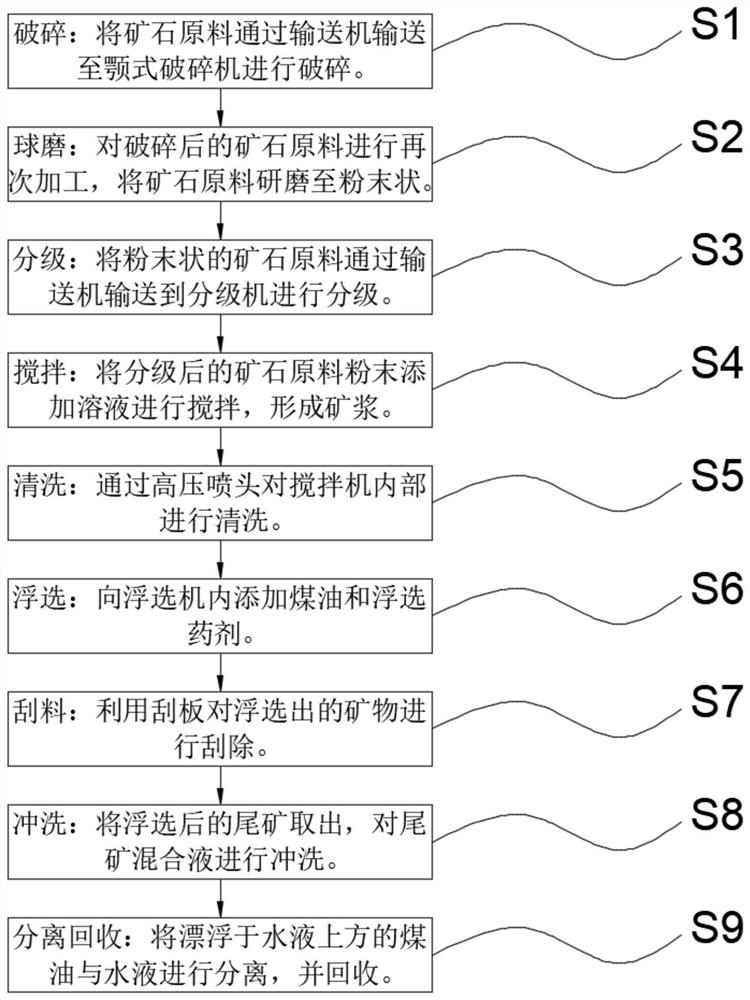

[0028] Embodiment 1: as figure 1 As shown, the present invention provides a kind of technical scheme, a kind of application method of kerosene separation in sulfide ore, comprises the following steps:

[0029] S1. Crushing: The ore raw material is transported to the jaw crusher through the conveyor for crushing.

[0030] S2. Ball milling: reprocessing the crushed ore raw materials, and grinding the ore raw materials into powder.

[0031] S3. Classification: The powdered ore raw materials are transported to the classifier through the conveyor for classification.

[0032] S4. Stirring: adding the classified ore raw material powder into the solution for stirring to form a slurry.

[0033] S5. Cleaning: Clean the inside of the mixer through a high-pressure nozzle.

[0034] S6. Flotation: add kerosene and flotation agents to the flotation machine.

[0035] S7. Scraping: Scraping the flotation minerals with a scraper.

[0036] S8. Flushing: take out the tailings after flotation...

Embodiment 2

[0047] Embodiment 2: as figure 1 Shown, a kind of application method of kerosene separation in sulfide ore, comprises the following steps:

[0048] S1. Crushing: The ore raw material is transported to the jaw crusher through the conveyor for crushing.

[0049] S2. Ball milling: reprocessing the crushed ore raw materials, and grinding the ore raw materials into powder.

[0050] S3. Classification: The powdered ore raw materials are transported to the classifier through the conveyor for classification.

[0051] S4. Stirring: adding the classified ore raw material powder into the solution for stirring to form a slurry.

[0052] S5. Cleaning: Clean the inside of the mixer through a high-pressure nozzle.

[0053] S6. Flotation: add kerosene and flotation agents to the flotation machine.

[0054] S7. Scraping: Scraping the flotation minerals with a scraper.

[0055] S8. Flushing: take out the tailings after flotation, and flush the tailings mixture.

[0056] S9. Separation and...

Embodiment 3

[0066] Embodiment 3: as figure 1 Shown, a kind of application method of kerosene separation in sulfide ore, comprises the following steps:

[0067] S1. Crushing: The ore raw material is transported to the jaw crusher through the conveyor for crushing.

[0068] S2. Ball milling: reprocessing the crushed ore raw materials, and grinding the ore raw materials into powder.

[0069] S3. Classification: The powdered ore raw materials are transported to the classifier through the conveyor for classification.

[0070] S4. Stirring: adding the classified ore raw material powder into the solution for stirring to form a slurry.

[0071] S5. Cleaning: Clean the inside of the mixer through a high-pressure nozzle.

[0072] S6. Flotation: add kerosene and flotation agents to the flotation machine.

[0073] S7. Scraping: Scraping the flotation minerals with a scraper.

[0074] S8. Flushing: take out the tailings after flotation, and flush the tailings mixture.

[0075] S9. Separation and...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com