Beneficiation method for separating copper and cobalt

A beneficiation method, copper-cobalt technology, applied in solid separation, flotation, etc., can solve the problems of low copper-cobalt grade in mixed concentrate, high transportation cost per ton of metal, and high cost investment in metallurgical system, so as to reduce concentrate transportation and Metallurgical cost, strong applicability and cheap price

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

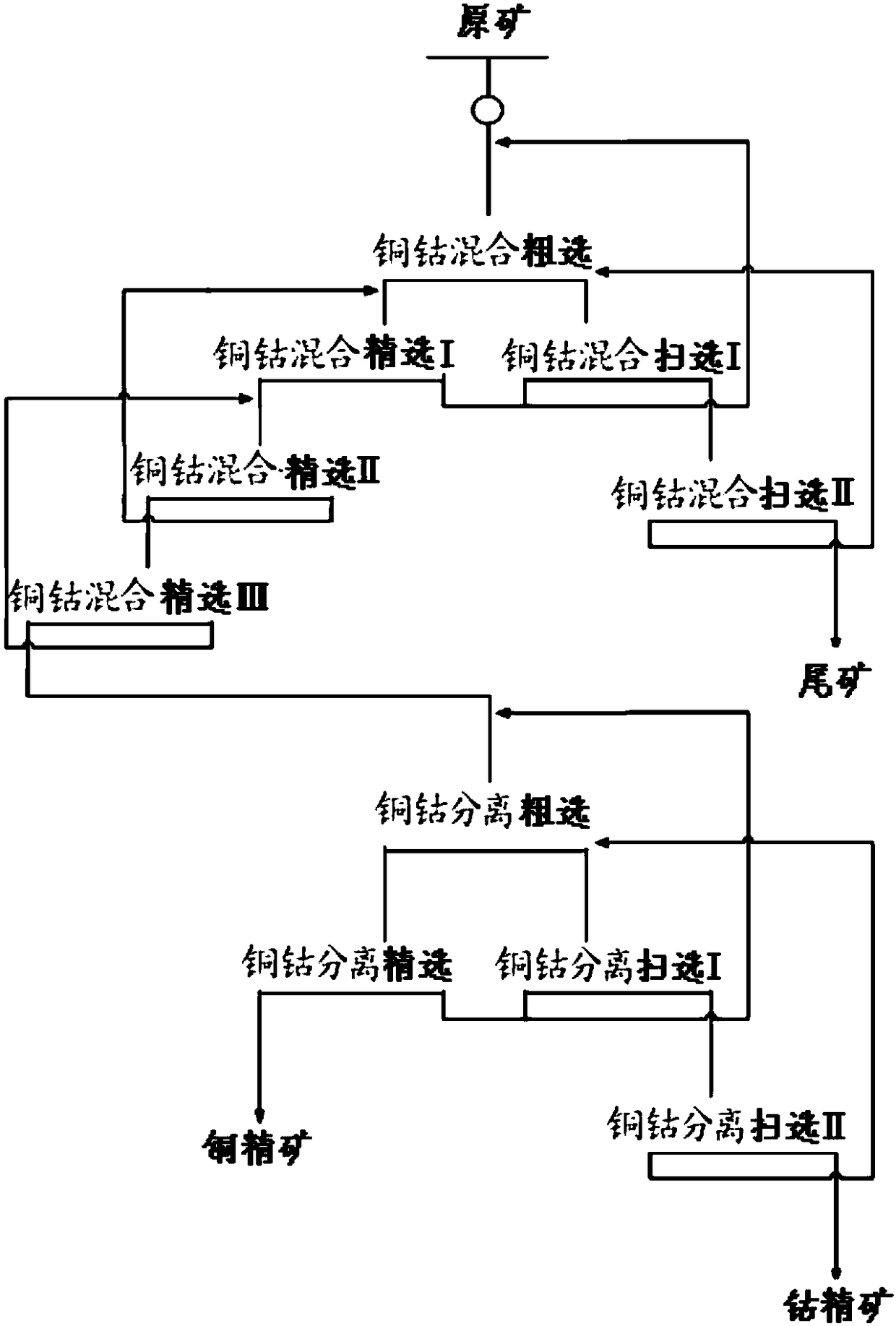

Method used

Image

Examples

Embodiment 1

[0053] In a foreign copper-cobalt sulfide mine, the original ore contains 1.13% Cu and 0.286% Co. Copper in the ore mainly exists in the form of independent minerals such as chalcopyrite, chalcocite, copper blue and natural copper; cobalt mainly exists in the form of independent minerals such as sulfur copper cobalt It exists in the form of ore, and then it is distributed in pyrite in the form of isomorphism, and the distribution law reaches 50%.

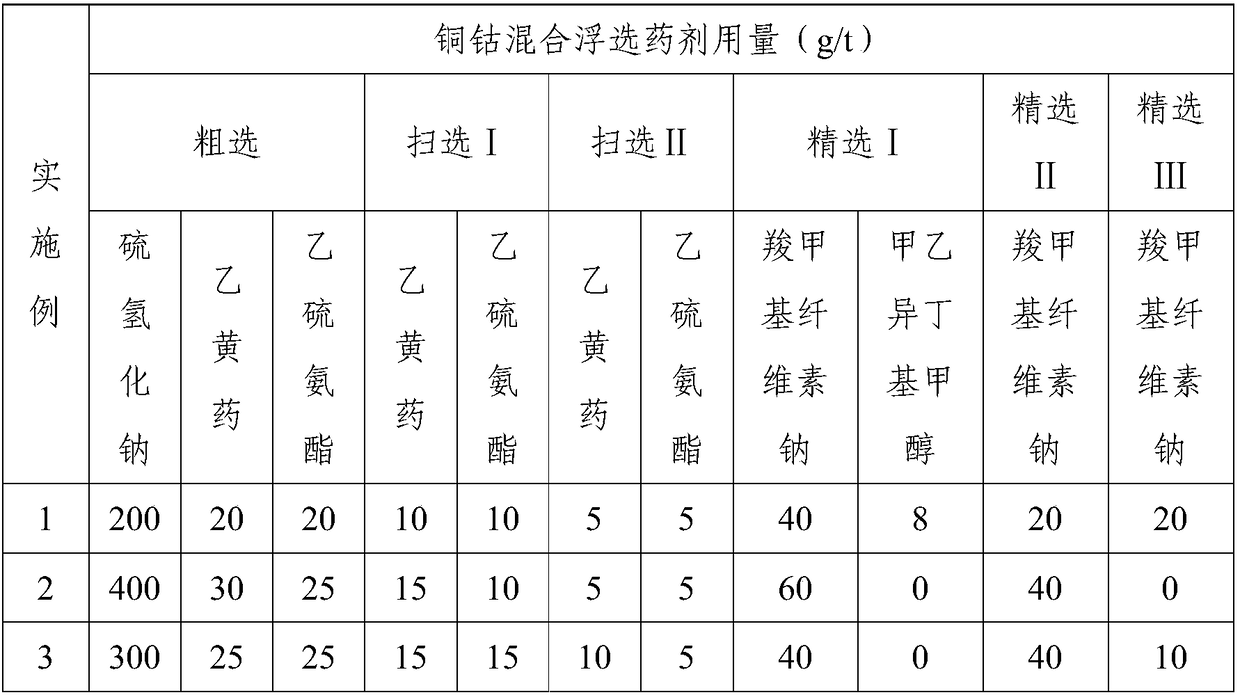

[0054] After the raw ore is crushed, ore-grinded, and slurried, -0.074mm accounts for 75%, and the ore content is 30%. The copper-cobalt mixed flotation process uses sodium hydrosulfide as an adjustment agent, and ethyl xanthate and ethyl thiocarbamate as a mixed collection agent, sodium carboxymethyl cellulose is added as a regulator in the selection process, and the specific drug system is shown in Table 1; the copper-cobalt separation and flotation process uses lime to adjust the pH to 12.15, and sodium carboxymethyl cellulose is ...

Embodiment 2

[0059] In a foreign copper-cobalt sulfide mine, the original ore contains 1.78% Cu and 0.461% Co. Copper in the ore mainly exists in the form of independent minerals such as chalcopyrite, bornite and chalcocite; cobalt mainly exists in the form of independent mineral sulfur copper ore The form exists, followed by the isomorphic form in pyrite, and the distribution law reaches 55%.

[0060] After crushing, grinding, and pulping, -0.074mm accounts for 78% of the raw ore, and the ore content is 29%. The copper-cobalt mixed flotation and copper-cobalt separation and sorting are carried out using the reagent system in Table 1 and Table 2 to obtain copper concentrate containing Cu33.49%, Co0.70%, cobalt concentrate contains Cu4.91%, Co10.58%, the total recovery rate of copper is 95.78%, and the total recovery rate of cobalt is 93.83%. The specific results are shown in Table 4.

[0061] Table 4

[0062]

[0063]

Embodiment 3

[0065] In a foreign copper-cobalt sulfide mine, the original ore contains Cu0.97% and Co0.255%. Copper in the ore mainly exists in the form of independent minerals such as chalcopyrite, chalcocite and natural copper; It exists in the form of pyrite, and then it is distributed in pyrite in the form of isomorphism, and the distribution law reaches 40%.

[0066] After the raw ore is crushed, ore-grinded, and slurried, -0.074mm accounts for 70%, and the ore content is 30%. The chemical system in Table 1 and Table 2 is used for copper-cobalt mixed flotation and copper-cobalt separation to obtain copper concentrate containing Cu37.05%, Co0.788%, cobalt concentrate contains Cu3.68%, Co7.95%, the total recovery rate of copper is 93.13%, and the total recovery rate of cobalt is 90.29%. The specific results are shown in Table 5.

[0067] table 5

[0068]

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com