A kind of beneficiation method of easy muddy and easy floating copper-bearing talc-serpentinite ore

A beneficiation method and serpentine technology, applied in flotation, recycling technology, solid separation, etc., can solve the effect of flotation effect caused by easy-floating talc serpentine, the adverse effect of effective recovery of copper minerals, and the deterioration of flotation slurry. environment and other issues, to achieve the effect of maximizing the recovery of resources, improving the quality and recovery rate of copper concentrate, and improving the quality of copper concentrate

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

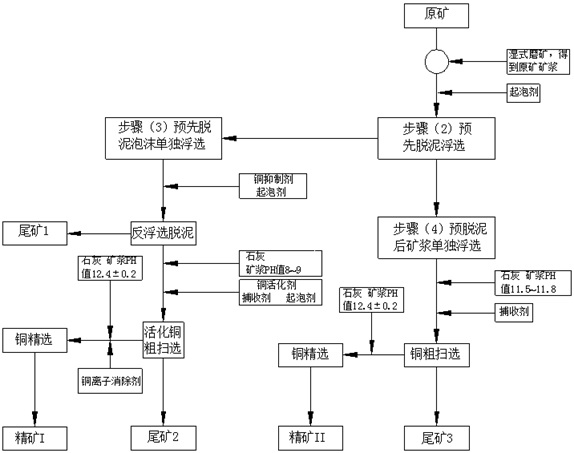

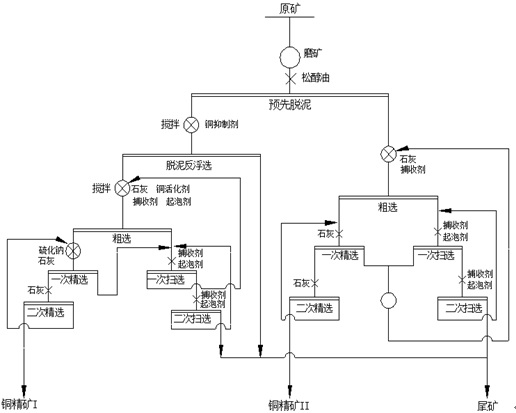

[0027] Example 1: as figure 1 and figure 2 As shown, a kind of beneficiation method of easy argillization and easy flotation of copper-containing talc-serpentine ore is carried out according to the following steps:

[0028] (1) Grinding: Grind the easy-mudification and easy-floating copper-containing talc-serpentine ore, and the grinding fineness is -0.074mm and the particle size content is 75%, thereby obtaining raw ore pulp;

[0029] (2) Pre-desliming and flotation: add the foaming agent butyl ether alcohol to the raw ore pulp, the dosage is 2g / t, and carry out the pre-flotation of sludged buoyant gangue, so as to obtain the pre-deslimed foam and the pre-deslimed pulp. ;

[0030] (3) Separate flotation of pre-deslimed foam: ①Add copper mineral inhibitor to the pre-deslimed foam obtained in step (2), stir for 5 minutes, carry out de-slimed reverse flotation, and obtain reverse-flotation sludge foam and deslimed foam After the copper-containing gangue pulp, the reverse flo...

Embodiment 2

[0038] Example 2: as figure 1 and figure 2 As shown, a kind of beneficiation method of easy argillization and easy flotation of copper-containing talc-serpentine ore is carried out according to the following steps:

[0039] (1) Grinding: Grind the easy-mudification and easy-floating copper-containing talc-serpentine ore, and the grinding fineness is -0.074mm and the particle size content is 75%, thereby obtaining raw ore pulp;

[0040] (2) Pre-desliming and flotation: add the foaming agent butyl ether alcohol to the raw ore pulp, the dosage is 2g / t, and carry out the pre-flotation of sludged buoyant gangue, so as to obtain the pre-deslimed foam and the pre-deslimed pulp. ;

[0041] (3) Separate flotation of pre-deslimed foam: ①Add copper mineral inhibitor to the pre-deslimed foam obtained in step (2), stir for 5 minutes, carry out de-slimed reverse flotation, and obtain reverse-flotation sludge foam and deslimed foam After the copper-containing gangue pulp, the reverse flo...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com