Phosphate ore washing classification and separation method

A technology for phosphate ore and phosphate rock, applied in the field of mineral processing, can solve the problems of difficult defoaming, poor comprehensive technical and economic indicators, and uneven steps of useful minerals.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

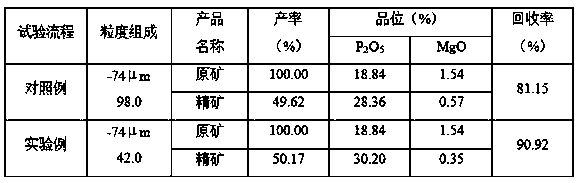

Examples

Embodiment 1

[0037] Embodiment 1, a kind of phosphate ore washing classification separation method:

[0038] Through the two-stage scrubbing operation, the slime and useful minerals are separated; through the multi-stage desliming operation, the slime is removed;

[0039] The raw ore is divided into three grades of high, medium and low grade ores through multi-stage screening operations. The high grade ores are removed by acid leaching to remove the calcite contained in them, and the middle and low grade ores are used for grinding and flotation operations.

[0040] The high-grade ore and low-grade ore pass through the P 2 o 5content to distinguish; the method of distinction is as follows: high-grade ore refers to P 2 o 5 Ores with a content of not less than 28%; the low- and medium-grade ores mentioned refer to P 2 o 5 Ore with a content of 16%-28%; the grade distinction is obtained by detecting and analyzing the particle size composition and the distribution of each particle size gra...

Embodiment 2

[0042] Embodiment 2, a kind of phosphate ore washing classification separation method:

[0043] Through the two-stage scrubbing operation, the slime and useful minerals are separated; through the multi-stage desliming operation, the slime is removed;

[0044] The raw ore is divided into three grades of high, medium and low grade ores through multi-stage screening operations. The high grade ores are removed by acid leaching to remove the calcite contained in them, and the middle and low grade ores are used for grinding and flotation operations.

[0045] The middle and high grade phosphate rocks and the middle and low grade phosphate rocks are distinguished by sieving; the distinguishing method is as follows: one stage of scrubbing followed by one stage of sieving, and the particle size of the first stage of sieve sieve is controlled to 1~10mm; the second stage of desliming The coarse-grained materials in the operation are screened in the second stage. The sieve size of the seco...

Embodiment 3

[0047] Embodiment 3, a kind of phosphate ore washing classification separation method, carries out according to the following steps:

[0048] (1) The raw ore is crushed to below -20mm after the crushing operation, and then sent to the ore washing operation for scrubbing. The scrubbed pulp is sent to the first section of screening operation, the material on the screen is sent to the tailings stockyard, and the material under the screen is sent to the first section For desliming operation, the sieve size of the first stage of screening operation is controlled to 2mm, and the particle size of the first stage of desliming is controlled to 63μm.

[0049] (2) The coarse-grained pulp of the first stage of desliming operation is fed into the second stage of scrubbing operation, and the pulp of the second stage of scrubbing operation is fed into the second stage of desliming operation. Grain-sized pulp is fed into the tailings thickening operation;

[0050] (3) The fine-grained slurry...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com